Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Fit-Up and Alignment interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Fit-Up and Alignment Interview

Q 1. Explain the difference between static and dynamic alignment.

Static alignment refers to the alignment of machines while they are stationary. It focuses on the geometric relationship between the shafts of connected machines, checking for offset, angularity, and parallel misalignment. Think of it like carefully aligning two pencils – you’re checking their positions relative to each other without them spinning. Dynamic alignment, on the other hand, considers alignment while the machines are running. It assesses how the shafts behave under operational loads and speeds. This is more sophisticated because it accounts for factors that affect alignment during operation, such as thermal growth and vibration. Imagine those same pencils spinning rapidly; their alignment might change due to centrifugal forces or slight imperfections. Dynamic alignment is crucial for high-speed machinery where subtle misalignments can lead to significant vibration and premature wear.

Q 2. Describe the process of laser alignment for a rotating machine.

Laser alignment for a rotating machine typically involves these steps: First, highly accurate laser sensors are mounted on the rotating shafts. These sensors project laser beams onto detectors placed on the adjacent machine. The initial readings are taken to establish a baseline of misalignment. Then, the machine is carefully adjusted using shims, coupling bolts, or base adjustments to minimize the detected misalignment. Readings are continually taken and adjustments made iteratively until the target alignment tolerances are met. Sophisticated software often manages the process, calculating necessary adjustments and providing visual representations of the alignment status. Some systems even use rotating laser heads to measure alignment during operation, offering real-time feedback and dynamic correction capabilities. This whole process requires a skilled technician who understands the specific machine’s characteristics and tolerances.

For instance, imagine aligning two large pumps in a refinery. Laser alignment ensures they are perfectly coupled, minimizing vibration and maximizing efficiency. Imperfect alignment could lead to catastrophic failure and production downtime.

Q 3. What are the common causes of misalignment in machinery?

Misalignment in machinery is a common problem arising from various factors. These can be broadly categorized as:

- Foundation Issues: Uneven or settling foundations are a frequent culprit, causing shifts in machine position and introducing misalignment.

- Thermal Growth: Different components of the machine expand and contract at different rates due to temperature variations during operation, inducing misalignment.

- Wear and Tear: Over time, bearings and other machine components wear out, leading to changes in shaft position and increased misalignment.

- Improper Installation: Incorrect initial installation, including inaccurate bolting or improper shimming, can introduce significant misalignment.

- External Forces: External forces, such as vibrations from nearby equipment or impacts, can subtly shift machine position.

- Manufacturing Defects: Faulty machine parts or manufacturing defects can contribute to inherent misalignment.

Consider a scenario where a large motor drives a pump. If the foundation shifts slightly due to ground settling, it can throw the alignment off, causing excessive vibration and bearing wear.

Q 4. How do you measure shaft misalignment?

Shaft misalignment is measured using various methods, with laser alignment being the most precise. Other methods include:

- Dial Indicators: These tools measure radial and axial movement of shafts using mechanical indicators. They are less precise than laser alignment but simpler and often used for initial checks.

- Magnetic Bases and Straight Edges: Used in conjunction with dial indicators, these provide stable mounting points and straight references for accurate measurements.

- Laser Alignment Systems: These systems offer the highest precision by using laser beams to precisely measure shaft positions and angularity. They provide detailed data on all types of misalignment (parallel, angular, and offset).

The chosen method depends on the precision required and the size of the machinery. For critical applications, laser alignment is the preferred choice because it detects even very small misalignments.

Q 5. What are the different types of shaft couplings and their applications?

Several types of shaft couplings connect rotating shafts, each with specific applications:

- Rigid Couplings: Transmit torque directly without allowing any misalignment. They are simple, cost-effective, and used for applications with precise alignment and low vibration.

- Flexible Couplings: Accommodate minor misalignments (parallel, angular, and axial). Types include jaw couplings, elastomeric couplings, and gear couplings. They are used where slight misalignments are expected or where vibration damping is needed.

- Fluid Couplings: Transmit torque using a fluid medium, allowing for smooth starting and shock absorption. Used in high-torque applications needing smooth operation.

- Universal Joints: Allow for angular misalignment and are commonly used in applications with significant shaft angles, such as vehicles.

Choosing the right coupling depends on the application’s specific requirements. A rigid coupling might be suitable for a small fan motor, while a flexible coupling is better suited for a high-speed pump in a processing plant to compensate for thermal growth and minor installation imperfections.

Q 6. Explain the concept of soft foot in machine alignment.

Soft foot is a condition where a machine’s foot (or mounting surface) doesn’t sit completely flat on its foundation. This creates an uneven load distribution, leading to stress concentrations, vibration, and misalignment. Imagine trying to balance a chair on an uneven floor; it wobbles and is unstable. Similarly, soft foot makes the machine unstable, creating unwanted stress.

It’s typically identified by measuring the amount of force required to lift each foot of the machine. A foot requiring significantly less force to lift indicates soft foot. This is often detected during laser alignment or during initial machine installation.

Q 7. How do you correct soft foot in a machine?

Correcting soft foot involves ensuring even contact between the machine’s feet and its foundation. This usually involves shimming under the feet to lift them to the same plane. The process typically involves these steps:

- Identify the Soft Foot: Using a feeler gauge or other measurement tools, determine which foot(s) are not contacting the foundation evenly.

- Measure the Gap: Measure the gap between the soft foot and the foundation.

- Apply Shims: Insert shims (thin metal plates) under the soft foot to lift it, ensuring the machine is level and the feet make uniform contact.

- Re-check Alignment: Once shims are added, re-measure the alignment to verify that the soft foot has been corrected.

- Bolt Tightening: Ensure that all foundation bolts are tightened correctly after shimming.

A properly corrected soft foot eliminates stress concentration and improves the machine’s overall stability and alignment. This is crucial for preventing premature wear and tear and ensuring optimal operational performance.

Q 8. What are the safety precautions to follow during machine alignment?

Safety is paramount during machine alignment. Think of it like this: you’re working with heavy machinery, often under power, and any mistake can lead to serious injury or damage. Before starting any alignment, we must always:

- Lockout/Tagout (LOTO): This is the most crucial step. Ensure all power sources (electrical, hydraulic, pneumatic) to the machine are completely isolated and locked out. Never trust a coworker’s word – always perform your own LOTO procedures.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, steel-toed boots, and hearing protection. If working at heights, a harness and fall protection system are essential.

- Clear the Area: Ensure the work area is free from obstructions and that nobody is in the vicinity of the moving parts. Use appropriate barriers or signage to prevent unauthorized access.

- Use Proper Tools and Techniques: Always use properly calibrated tools and follow established procedures. Never force anything; if something doesn’t fit or align correctly, investigate the cause before proceeding.

- Be Aware of Hot Surfaces: Some machinery components can become extremely hot during operation. Allow sufficient cooling time before starting alignment.

- Regular Checks: Continuously monitor the machine and its surroundings for any potential hazards during the alignment process.

Ignoring even one of these precautions can have devastating consequences. Safety isn’t just a rule; it’s a mindset.

Q 9. What tools and equipment are used in Fit-Up and Alignment?

Fit-up and alignment require a variety of tools and equipment, depending on the specific application and machine type. However, some common tools include:

- Dial Indicators: These are used for precise measurement of shaft misalignment, using both horizontal and vertical indicators. They provide a direct and visual reading of misalignment.

- Laser Alignment Systems: These sophisticated systems offer highly accurate and efficient alignment. Laser beams project onto the target shafts, allowing for quick detection of angular and parallel misalignment. Software often accompanies these systems to analyze data and suggest corrections.

- Shims: Thin metal plates used to adjust the alignment between machine components.

- Wedges: Similar to shims but offer a greater range of adjustment.

- Levels: Essential for ensuring that the machine’s base is level. Both electronic and bubble levels can be used.

- Measuring Tapes and Rules: Used for taking initial measurements and verifying alignment changes.

- Torque Wrenches: Used to ensure bolts and fasteners are tightened to the correct specifications to prevent damage or loosening.

- Jacks and other lifting equipment: for adjusting machine positions during the alignment process. This equipment needs to have adequate capacity for the weight of the machines involved.

- Alignment Software: many laser systems use software to analyse the data and assist in corrections and report generation.

The choice of tools depends on the complexity of the alignment, the required accuracy, and the budget. However, the safety and proper calibration of every tool are of utmost importance.

Q 10. Describe your experience with different alignment techniques (e.g., dial indicator, laser alignment).

I have extensive experience with both dial indicator and laser alignment techniques. Dial indicator methods, while more labor-intensive, offer valuable hands-on experience and a deeper understanding of the alignment process. I’ve used them extensively for aligning pumps, motors, and gearboxes in older equipment where laser technology may not be suitable or economical. The process involves carefully positioning the dial indicators, taking readings at multiple points, and calculating the misalignment based on those readings. It requires careful attention to detail and a good understanding of geometry.

Laser alignment systems, on the other hand, offer significant advantages in terms of speed, accuracy, and ease of use. I’ve used them extensively on large and complex machinery like turbines and paper machines. The non-contact measurement capabilities also make them much safer and easier for alignment of high speed machinery. The system rapidly calculates the misalignment, often providing a graphical representation that makes it easy to interpret and correct. One specific instance involved aligning two large pumps in a petrochemical plant using a laser system. The speed and accuracy of the system allowed us to complete the alignment in a fraction of the time compared to using dial indicators, minimizing production downtime.

Q 11. How do you interpret alignment data?

Interpreting alignment data involves understanding the different types of misalignment and their effects on machinery. Both dial indicators and laser systems provide data that indicates three primary types of misalignment: parallel misalignment (offset), angular misalignment (skew or angularity), and combined misalignment (a combination of both). The interpretation is done based on the numerical readings for parallel and angular misalignment, provided by the instrument.

For dial indicators, we analyze the readings at multiple points around the shaft circumference. Significant differences in readings indicate misalignment. For laser systems, the software typically provides a clear visual representation of the misalignment along with numerical data, simplifying the interpretation.

It’s crucial to look beyond just the numerical values. We also consider factors such as the machine’s operating conditions, the type of coupling used, and the manufacturer’s specifications to make informed decisions about acceptable tolerance levels. Understanding this context helps differentiate between normal variations and unacceptable misalignment.

Q 12. What are the tolerance limits for acceptable misalignment?

Tolerance limits for acceptable misalignment vary significantly depending on several factors, including the type of machine, its operating speed, coupling type, and the manufacturer’s recommendations. There isn’t a single universally applicable value. Generally, the tighter the tolerances, the smoother and more efficient the operation of the machinery. However, excessively tight tolerances can lead to unnecessary costs in machining and alignment time.

For instance, a high-speed turbine will demand significantly tighter tolerances than a low-speed conveyor belt. While some general guidelines exist in industry standards and handbooks, it’s best practice to always refer to the equipment manufacturer’s alignment specifications to determine the acceptable limits. A common metric used is mils (thousandths of an inch) or microns for shaft offset, and arc-minutes or degrees for angular misalignment. Failing to adhere to these tolerances can lead to increased vibration, premature wear, and potentially catastrophic failure.

Q 13. Explain the relationship between alignment and vibration analysis.

Alignment and vibration analysis are intrinsically linked. Misalignment is a primary source of vibration in rotating machinery. Improper alignment causes unbalanced forces that result in increased vibration. This vibration can lead to increased wear and tear of bearings, seals, and other components, resulting in reduced machine efficiency and ultimately failure.

Vibration analysis acts as a diagnostic tool that can highlight potential alignment problems. By analyzing the frequency and amplitude of vibrations, we can identify patterns indicative of specific types of misalignment. For example, high levels of vibration at 1X rotational frequency often suggest misalignment. Therefore, alignment is a crucial preventative maintenance step and vibration analysis is a great tool to determine if alignment has drifted out of spec. We use vibration data to either confirm alignment quality or detect subtle misalignments that might otherwise be missed during a visual inspection.

Q 14. How do you troubleshoot alignment problems?

Troubleshooting alignment problems involves a systematic approach. It begins with a thorough visual inspection to look for any obvious issues like damaged components, loose bolts, or physical obstructions.

Then, we move to precise measurements using dial indicators or laser alignment systems. The data gathered allows us to identify the type and magnitude of the misalignment. Once the problem is identified, we need to determine the root cause. This might involve checking the foundation, ensuring proper coupling selection, inspecting shaft run-out, or even reviewing the installation procedure. After the root cause is diagnosed, we implement the necessary corrective actions, which may involve adjusting shims, wedges, or even machining components. Finally, we verify the corrections by performing another alignment check and vibration analysis to ensure the problem has been solved and the machine is operating within acceptable limits.

It’s essential to document every step of the process, including measurements, adjustments, and the final results. This documentation is crucial for future maintenance and troubleshooting.

Q 15. What are the effects of misalignment on machinery?

Misalignment in machinery leads to a cascade of negative effects, significantly impacting efficiency, lifespan, and safety. Think of it like trying to ride a bicycle with a crooked wheel – it’s bumpy, unstable, and prone to failure. Specifically, misalignment causes increased vibration, leading to premature wear and tear on bearings, shafts, and couplings. This vibration translates to increased noise levels, reduced operational efficiency (loss of power transmission), and potential catastrophic failure of components. In extreme cases, misalignment can cause significant damage, resulting in costly repairs or even complete equipment replacement. For instance, a misaligned pump can lead to cavitation, reducing its efficiency and damaging internal parts. Similarly, misaligned gears can experience excessive wear, resulting in noise, vibration, and eventually, failure.

- Increased Vibration: Leading to premature wear and tear.

- Reduced Efficiency: Loss of power transmission and reduced output.

- Premature Component Failure: Bearings, shafts, couplings, and other components wear out faster.

- Increased Noise Levels: A clear indication of a problem.

- Safety Hazards: Vibration can cause loose components or even catastrophic failure, posing safety risks.

Career Expert Tips:

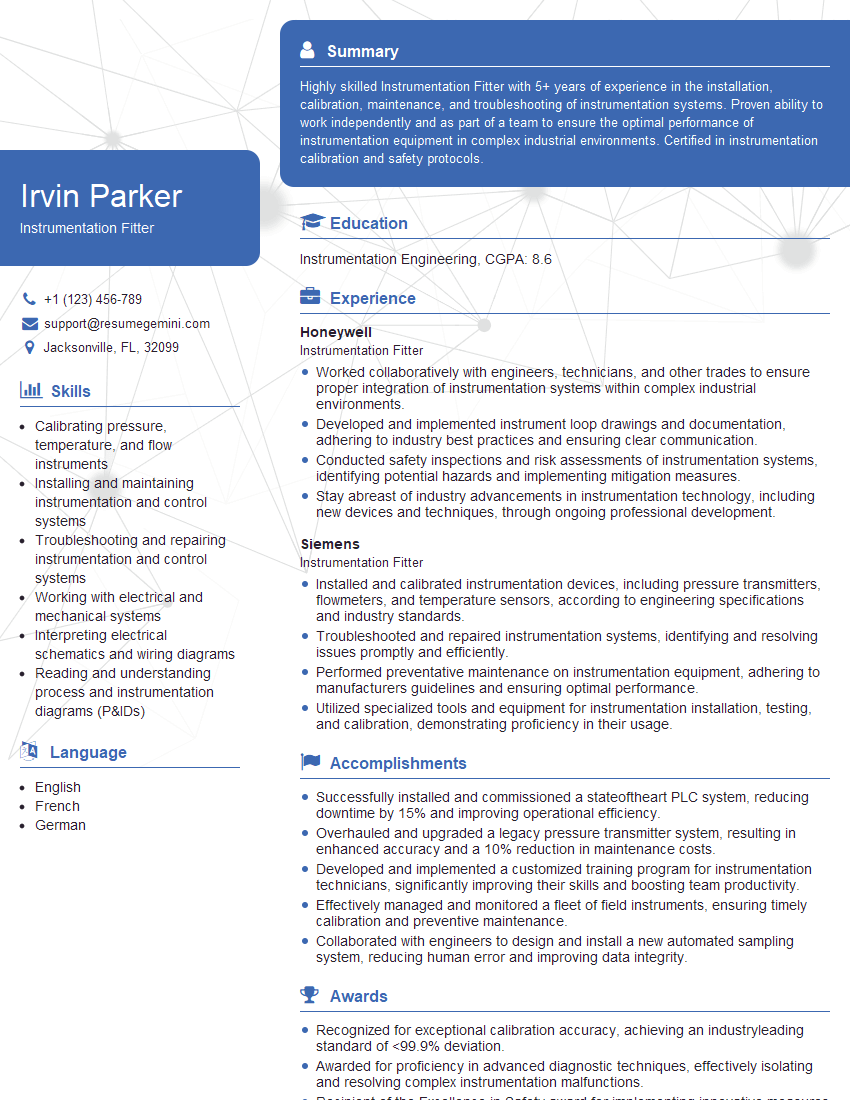

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of piping systems and their alignment challenges.

My experience encompasses a wide range of piping systems, from small-diameter process lines to large-diameter pipelines. Each system presents unique alignment challenges. For example, working with flexible piping, such as those used in chemical plants, requires attention to sag and expansion loops to prevent stress on the system. Rigid piping systems, commonly found in power plants, necessitate precise alignment to prevent undue stress on welds and flanges. The challenges also vary depending on the material. Stainless steel piping might require extra care due to its susceptibility to stress corrosion cracking if not properly aligned. I’ve worked extensively with both above-ground and underground piping, each presenting unique accessibility and support challenges. Underground piping requires careful consideration of ground settlement and thermal expansion. Above-ground systems, on the other hand, require careful consideration of wind loading and thermal expansion, particularly in large-diameter systems.

In one project involving a high-pressure steam line, I had to use laser alignment tools to ensure the perfect alignment of multiple expansion loops to prevent undue stress during operation. In another project with a complex network of process piping in a refinery, careful planning and utilization of 3D modeling software was crucial for successful alignment.

Q 17. How do you ensure proper alignment of large equipment?

Aligning large equipment requires a methodical approach and often involves specialized tools. We typically use a combination of techniques, starting with a thorough pre-alignment inspection to identify any potential obstacles. This includes checking the foundation’s levelness and the equipment’s condition. For precision, we employ laser alignment systems, which provide accurate measurements and allow for adjustments to be made in real-time. This technology is particularly helpful in ensuring concentricity and parallelism, which are crucial for proper operation. Depending on the equipment’s size and weight, we might use shims, wedges, or even hydraulic jacks to make fine adjustments. Throughout the process, we frequently check our work using measuring tapes, levels, and dial indicators to ensure the alignment is within acceptable tolerances. Furthermore, for extremely large and heavy equipment, we may need to utilize alignment software for calculating adjustments and analyzing the results to ensure the alignment is optimal.

For example, while aligning a large turbine, we would use laser alignment to ensure the shaft is perfectly aligned with the generator, minimizing vibration and maximizing efficiency. This process would involve multiple measurements taken at different points along the shaft, with adjustments made as needed to ensure the alignment falls within the specified tolerances.

Q 18. What is your experience with using alignment software?

I have extensive experience using various alignment software packages, including [Mention specific software, e.g., AlignAlyzer, Laser-Based Alignment software]. These software packages significantly enhance the alignment process by providing automated calculations, data logging, and reporting capabilities. They allow us to analyze alignment data from various measurement devices (laser trackers, dial indicators, etc.) and provide precise adjustments needed. The software also helps in generating comprehensive reports for documentation and future reference. I’m proficient in using these tools to perform both static and dynamic alignment, analyze vibration data, and create detailed reports that highlight any alignment issues. The software significantly improves efficiency and accuracy compared to traditional manual methods.

For example, using alignment software during the alignment of a large compressor train allows for precise calculation of shim values for each individual bearing foot, optimizing the alignment to minimize vibrations and improve efficiency.

Q 19. Describe a time you had to solve a complex alignment problem.

During the installation of a large centrifugal pump in a chemical plant, we encountered a significant challenge. The pump’s baseplate was slightly warped, causing significant misalignment despite initial attempts at correction. This resulted in excessive vibration during testing. To resolve this, we first utilized advanced laser alignment technology for precise measurement and analysis of the misalignment. We then employed a combination of shimming and machining to correct the warped baseplate. The machining involved carefully removing material from specific points on the baseplate to restore its flatness. After these corrections, we performed a final alignment check using both laser and dial indicator measurements. This multi-faceted approach was successful in resolving the complex alignment issue and ensuring the pump operated smoothly without excessive vibration. The successful resolution required collaboration with the machining team and a thorough understanding of the pump’s operational requirements.

Q 20. How do you manage multiple alignment projects simultaneously?

Managing multiple alignment projects simultaneously requires meticulous planning and effective resource allocation. I typically start by prioritizing projects based on their criticality and deadlines. This involves clear communication with clients and stakeholders, understanding their expectations and potential challenges. I then create a detailed schedule for each project, outlining tasks, responsibilities, and required resources. To maintain efficiency, I leverage project management software and regularly monitor progress, making adjustments as needed. This includes allocating skilled technicians to specific projects, ensuring that appropriate equipment is available, and proactively addressing any potential delays. Regular team meetings and progress reports help keep everyone informed and aligned, enhancing collaboration and problem-solving. Clear communication is key to success in managing simultaneous projects to avoid overlaps and conflicts.

Q 21. Explain your experience with preventative maintenance related to alignment.

Preventative maintenance concerning alignment focuses on minimizing the risk of misalignment issues before they lead to costly repairs or downtime. This includes regular inspections and measurements of critical equipment using laser alignment tools or other suitable methods. Based on the inspection data, we can identify potential problems early on and plan for corrective action. This preventative approach avoids major breakdowns and enhances the lifespan of the equipment. We also implement a vibration monitoring system, which provides early warnings of impending alignment problems. Furthermore, training is a crucial aspect, ensuring that the operating personnel understand the importance of proper alignment and can recognize signs of misalignment. Regular lubrication and proper operating procedures also prevent the premature degradation of equipment, contributing to better alignment and longer operational life. A well-structured preventative maintenance plan, customized to the specific operational context, is a key element of ensuring optimal equipment performance and a reduction in downtime.

Q 22. What are the common standards and specifications related to Fit-Up and Alignment?

Common standards and specifications in Fit-Up and Alignment are crucial for ensuring consistent quality and interchangeability. They vary depending on the industry and application, but some overarching principles and standards apply. For instance, ISO standards often dictate tolerances and methodologies. Specific industries, like aerospace or automotive manufacturing, will have their own detailed specifications that must be meticulously followed.

Industry-Specific Standards: Automotive manufacturers, for example, may have their own internal standards specifying acceptable deviations in alignment for engine blocks or chassis components. These specifications are usually far more stringent than general engineering tolerances.

Dimensional Tolerances: Standards define acceptable variations in dimensions, like length, width, and angles. These are often expressed using Geometric Dimensioning and Tolerancing (GD&T) symbols, which we’ll discuss later. For example, a shaft might need to be aligned within a specific angular tolerance of ±0.005 degrees to ensure proper operation within a bearing.

Material Specifications: The material properties of the components being aligned also influence the applicable standards. For example, aligning a high-precision optical component requires much tighter tolerances and different alignment procedures compared to aligning components made of less precise materials.

Alignment Methods: Standards may also dictate the acceptable methods for alignment, including laser alignment, optical alignment, or traditional methods using dial indicators and straight edges.

Q 23. How do you ensure accuracy and precision during alignment procedures?

Ensuring accuracy and precision during alignment is paramount. It involves a combination of meticulous planning, precise measurement techniques, and the use of appropriate tools. Imagine trying to assemble a highly complex engine – if the components aren’t aligned properly, the entire system could fail.

Calibration and Verification: All measuring instruments, like laser trackers or dial indicators, must be regularly calibrated and their accuracy verified against known standards. This ensures that measurements are reliable and traceable.

Environmental Control: Temperature and humidity fluctuations can affect measurements. Controlling these variables, as much as possible, is essential for precision. This can involve temperature-controlled work environments or compensating for temperature changes through calculations.

Multiple Measurements and Averaging: Taking multiple measurements and averaging the results reduces the impact of random errors. This is especially important with less precise measurement tools.

Proper Tool Selection: Choosing the right tools for the job is critical. Laser trackers provide high precision for long distances, while dial indicators are better suited for smaller, more localized alignments. Selecting the right tool depends on the precision required and the geometry of the parts being aligned.

Statistical Process Control (SPC): Employing SPC methodologies allows for real-time monitoring of the alignment process, helping to identify potential problems and deviations early on.

Q 24. Explain your experience with different types of shims and their application.

Shims are essential in Fit-Up and Alignment for precisely adjusting the spacing and alignment of components. Different types of shims offer varying levels of precision and suitability for different applications. Think of shims as tiny, precisely machined spacers.

Metal Shims: These are the most common type, usually made of steel, brass, or aluminum. They come in various thicknesses and can be stacked to achieve the desired alignment. The precision of metal shims varies; some are manufactured to very tight tolerances.

Plastic Shims: These are often used in less demanding applications where high precision isn’t critical. They are less expensive than metal shims but can be less durable.

Tapered Shims: These shims are thicker on one edge than the other. They are useful for adjusting alignment in multiple directions simultaneously. They allow for fine adjustments by simply adjusting the location of the shim.

Hydraulic Shims: For highly precise alignments, hydraulic shims allow for fine adjustments without the need to repeatedly remove and replace shims. They offer controlled adjustments through a hydraulic fluid system.

Application: Shims are used extensively in various applications. In machinery installation, shims level machinery on uneven floors. In automotive applications, shims precisely adjust components to ensure proper clearance and alignment. In aerospace, they are used for critical alignments of extremely sensitive equipment.

Q 25. What is your understanding of geometric dimensioning and tolerancing (GD&T) in relation to alignment?

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to precisely define the size, shape, orientation, and location of features on a part. In alignment, GD&T ensures that all components fit together within specified tolerances. Imagine building a skyscraper – each component must be perfectly aligned with others according to strict specifications. GD&T makes those specifications precise and unambiguous.

Importance in Alignment: GD&T provides clear tolerances for alignment parameters like parallelism, perpendicularity, and concentricity. This avoids ambiguity and ensures all parties involved understand the acceptable variations.

Example: A drawing might specify that two surfaces must be parallel within 0.01 mm. This is crucial for ensuring proper alignment and functionality. Without GD&T, the acceptable deviation might be ambiguous and open to interpretation.

Practical Application: When aligning components, GD&T ensures that the actual alignment conforms to the design specifications. This is crucial for preventing costly rework, and ensuring the final product meets the required performance.

Q 26. How do you handle situations with conflicting priorities during alignment work?

Conflicting priorities during alignment work are common. For example, you might need to prioritize speed of completion but also ensure extremely high precision. This calls for a systematic approach.

Prioritization Matrix: I often use a prioritization matrix where I list all the alignment requirements along with their importance and the potential consequences of not meeting them. This helps to objectively rank the priorities.

Negotiation and Communication: Open communication with stakeholders is essential. Clearly outlining the trade-offs between different priorities ensures everyone is informed and agrees on the approach.

Risk Assessment: A risk assessment helps determine the potential consequences of compromises on specific alignment criteria. This informs the decision-making process.

Iterative Approach: Sometimes, it’s beneficial to start with a quick alignment to ensure functionality and then iteratively refine it to achieve higher precision. This approach balances speed and precision.

Q 27. What is your experience with documenting alignment procedures and results?

Meticulous documentation of alignment procedures and results is critical for traceability, quality control, and future troubleshooting. Imagine trying to fix an alignment problem months after the initial installation – without detailed records, the process would be significantly more difficult.

Step-by-Step Procedure: The documentation should include a detailed step-by-step procedure, including the tools used, measurement techniques, and acceptance criteria.

Measurement Data: All measurements taken during the alignment process should be recorded, along with any deviations from the specified tolerances.

Photographs and Sketches: Visual documentation, such as photographs and sketches, can significantly enhance understanding and facilitate troubleshooting.

Software and Databases: Specialized software and databases can be used to manage and analyze alignment data. This allows for efficient data storage and retrieval, and also for creating reports that summarize the alignment process and results.

As-Built Drawings: The final alignment should be documented on as-built drawings, reflecting the actual dimensions and positions achieved during the process.

Q 28. How do you stay updated with the latest advancements in Fit-Up and Alignment technologies?

The field of Fit-Up and Alignment is constantly evolving. Staying updated is crucial to remain competitive and provide the best possible service. This involves a multi-faceted approach.

Professional Organizations: Actively participating in professional organizations related to mechanical engineering or precision manufacturing provides opportunities to network with peers and learn about the latest advancements.

Trade Publications and Journals: Reading relevant trade publications and journals keeps me abreast of new techniques, technologies, and standards.

Conferences and Workshops: Attending conferences and workshops provides opportunities for hands-on experience and direct interaction with industry experts.

Online Resources: Utilizing reputable online resources like manufacturers’ websites and educational platforms allows me to access the latest information on tools and techniques.

Vendor Training: Many manufacturers offer training programs on their products and technologies. These programs can be invaluable for expanding skills and knowledge.

Key Topics to Learn for Fit-Up and Alignment Interview

- Geometric Dimensioning and Tolerancing (GD&T): Understanding GD&T principles and their application in ensuring proper fit-up and alignment during assembly.

- Tolerance Stack Analysis: Analyzing the accumulation of tolerances throughout an assembly to predict potential fit-up issues and ensure functionality.

- Fixture Design and Usage: Knowledge of different types of fixtures and their role in maintaining accurate alignment during manufacturing and assembly processes.

- Measurement Techniques and Tools: Proficiency with various measurement tools (e.g., calipers, micrometers, CMMs) and techniques for verifying fit-up and alignment.

- Troubleshooting Fit-Up and Alignment Problems: Developing problem-solving skills to identify and resolve issues related to improper fit, misalignment, and interference.

- Material Properties and their Influence: Understanding how material characteristics (e.g., thermal expansion, elasticity) affect fit-up and alignment.

- Manufacturing Processes and their Impact: Recognizing how different manufacturing processes (e.g., machining, casting, welding) can influence component tolerances and assembly fit.

- Design for Manufacturing and Assembly (DFMA): Applying DFMA principles to improve the manufacturability and ease of assembly, reducing fit-up challenges.

- Automation and Robotics in Fit-Up and Alignment: Familiarity with automated systems used for precise alignment and assembly in industrial settings.

- Quality Control and Inspection Procedures: Understanding quality control methods to ensure accurate fit-up and alignment throughout the production process.

Next Steps

Mastering Fit-Up and Alignment is crucial for career advancement in engineering and manufacturing, opening doors to specialized roles and increased earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is vital for getting your application noticed by recruiters. We highly recommend using ResumeGemini to build a professional and effective resume that highlights your skills and experience in Fit-Up and Alignment. ResumeGemini provides tools and resources to craft a compelling narrative, and examples of resumes tailored to Fit-Up and Alignment are available to help you get started. Invest the time to create a resume that truly showcases your capabilities – your future self will thank you!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO