Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Follow safety procedures and regulations interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Follow safety procedures and regulations Interview

Q 1. Describe your experience implementing safety protocols in a high-risk environment.

In my previous role at a petrochemical plant, a high-risk environment demanding stringent safety protocols, I was responsible for implementing and overseeing a comprehensive safety management system. This involved developing and delivering site-specific training programs on topics ranging from lockout/tagout procedures to confined space entry, incorporating interactive simulations and real-world case studies to ensure comprehension and retention. We also implemented a robust permit-to-work system, meticulously tracking every high-risk activity and ensuring all necessary precautions were in place before commencement. For instance, before any hot work could begin, a detailed risk assessment was conducted, fire watch personnel assigned, and appropriate fire suppression equipment deployed. This rigorous approach drastically reduced near misses and incidents.

Furthermore, I led the initiative to upgrade our personal protective equipment (PPE) inventory, ensuring employees had access to the highest quality and best-fitting equipment tailored to their specific tasks. Regular inspections and fit testing were implemented to maintain effectiveness. This proactive approach to PPE management contributed significantly to injury prevention.

Q 2. Explain your understanding of OSHA regulations (or relevant regional regulations).

My understanding of OSHA regulations, and similar regional safety standards, is extensive. I am familiar with the General Duty Clause, which places a broad responsibility on employers to provide a safe and healthful workplace, free from recognized hazards. I’m also proficient in specific OSHA standards, such as those related to hazard communication (HazCom), personal protective equipment (PPE), lockout/tagout (LOTO), fall protection, and confined space entry. I understand the importance of record-keeping, incident reporting, and employee training mandated by these regulations.

For example, I know that under HazCom, employers must provide safety data sheets (SDS) for all hazardous chemicals and train employees on their safe handling and use. Similarly, the LOTO standard aims to prevent the unexpected energization or startup of machinery during maintenance or repair work, protecting workers from serious injury or death. My knowledge allows me to identify potential non-compliance and create appropriate corrective actions. This includes understanding the nuances of different regulations depending on the type of industry, location and employee roles.

Q 3. How would you conduct a safety audit?

Conducting a safety audit involves a systematic evaluation of an organization’s safety performance. It’s a multi-faceted process that starts with planning – defining the scope, identifying key areas to be audited, and assembling a competent audit team. The audit itself would involve a combination of methods: reviewing documents (safety policies, training records, incident reports), conducting interviews with employees at all levels, and carrying out physical inspections of the worksite, looking for compliance with safety regulations and identifying potential hazards.

For example, during a physical inspection, I would observe working conditions, check the condition of equipment and PPE, and assess the implementation of safety procedures. I’d look for things like proper use of guardrails, adequate lighting, emergency exits, and the presence of potential trip hazards. After the audit, a detailed report is prepared, outlining findings, highlighting deficiencies, and recommending corrective actions. Follow-up is crucial to ensure these actions are implemented effectively and to measure the impact of the audit.

Q 4. What are the key elements of a comprehensive safety program?

A comprehensive safety program isn’t just about complying with regulations; it’s about fostering a safety-conscious culture. Key elements include a strong safety policy statement from leadership, clearly defined roles and responsibilities, comprehensive hazard identification and risk assessment processes, regular safety training programs that are tailored to specific job roles and risks, a system for reporting, investigating and analyzing accidents and near misses, and procedures for corrective actions. Effective communication channels are vital, allowing employees to voice concerns and contribute to safety improvement initiatives.

For example, a robust program includes regular safety meetings, toolbox talks, and employee involvement in safety committees. It also includes a system for continuous improvement—regularly reviewing procedures, updating training materials, and adapting to evolving risks. The aim is to create a proactive environment where safety is everyone’s responsibility.

Q 5. How do you identify and mitigate workplace hazards?

Identifying and mitigating workplace hazards involves a systematic approach. It starts with a thorough hazard identification process, which can involve various methods like job hazard analyses (JHAs), workplace inspections, incident investigations, and employee feedback. Once hazards are identified, a risk assessment is conducted to determine the likelihood and severity of potential harm. This helps prioritize hazards and determine appropriate control measures.

Control measures can range from elimination (removing the hazard entirely), substitution (replacing a hazardous substance with a less hazardous one), engineering controls (modifying the workplace to reduce exposure), administrative controls (changing work practices or procedures), and personal protective equipment (PPE) as the last line of defense. For example, if a hazard is identified as excessive noise, engineering controls like installing noise-reducing barriers might be implemented, followed by administrative controls such as limiting exposure time, and finally PPE such as hearing protection.

Q 6. Describe your experience with incident investigation and reporting.

I have extensive experience in incident investigation and reporting. My approach follows a structured methodology, starting with securing the scene (if applicable) and ensuring the safety of all involved. Then, I gather information from multiple sources: interviewing witnesses, reviewing documents (e.g., incident reports, maintenance logs), and examining the physical evidence. The goal is to determine the root cause of the incident, not just the immediate cause. I use tools like fault tree analysis or the “5 Whys” technique to delve deeper into the contributing factors.

Once the root cause is identified, I develop corrective actions to prevent similar incidents from occurring in the future. This often involves implementing new safety procedures, providing additional training, or modifying equipment. The findings are documented in a comprehensive report, which is shared with relevant parties. This report then informs updates to safety procedures and training programs, contributing to a continuous improvement cycle.

Q 7. How would you handle a safety violation by a colleague?

Handling a safety violation by a colleague requires a tactful and professional approach. I would first address the situation privately, ensuring a respectful and non-confrontational dialogue. I would clearly explain the safety regulation that was violated, outlining the potential consequences and emphasizing the importance of adherence to safety protocols. Depending on the severity of the violation, I might offer additional training or coaching. For minor infractions, a verbal warning might suffice; however, serious violations would necessitate reporting the incident to the appropriate supervisor, following company procedures.

Throughout the process, the focus would be on education and prevention, not punishment. My goal would be to correct the behavior and ensure the safety of all employees. The approach would always be guided by company policy and the seriousness of the violation. Maintaining open communication and demonstrating support while addressing the violation is key.

Q 8. Explain your knowledge of emergency response procedures.

Emergency response procedures are a crucial aspect of any safety-conscious organization. My knowledge encompasses a wide range of situations, from minor incidents to major disasters. This includes understanding the organization’s specific emergency action plan (EAP), which outlines roles, responsibilities, and evacuation procedures.

For instance, I’m familiar with procedures for fire emergencies, including identifying assembly points, using fire extinguishers (depending on training and certification), and assisting with evacuations. In medical emergencies, I know the steps involved in providing first aid, calling emergency services, and securing the scene. My understanding extends to other emergencies like hazardous material spills, where containment and evacuation procedures are prioritized, and active shooter situations, focusing on Run, Hide, Fight principles.

Beyond knowing the procedures, I believe in regular drills and training to reinforce familiarity and address potential weaknesses. I’ve participated in many fire drills, medical emergency simulations, and other exercises designed to ensure efficient and safe response in real-world situations. The goal isn’t just to follow a plan, but to effectively execute it under pressure.

Q 9. What are your strategies for promoting a safety-conscious culture?

Promoting a safety-conscious culture is not a one-time effort but a continuous process that involves leadership, communication, and ongoing reinforcement. My strategies center around three key pillars: leadership commitment, employee engagement, and ongoing improvement.

- Leadership Commitment: Safety starts at the top. Leaders need to actively demonstrate a commitment to safety by prioritizing it in decisions, allocating resources, and holding themselves and others accountable. This includes visibly participating in safety initiatives and celebrating successes.

- Employee Engagement: Safety is everyone’s responsibility. I focus on empowering employees to identify and report hazards. This is achieved through open communication channels, regular safety meetings, and providing training on hazard recognition and reporting procedures. Rewarding safe behaviors and recognizing contributions further strengthens this engagement.

- Ongoing Improvement: Safety is not static. Regular safety audits, incident investigations, and near-miss reporting help identify areas for improvement. This data is used to refine procedures, improve training, and address systemic issues. The process of continual improvement is vital in maintaining a proactive safety culture.

For example, in a previous role, we implemented a peer-to-peer safety observation program, empowering employees to identify and address unsafe behaviors amongst their colleagues. This fostered a sense of shared responsibility and significantly reduced near-miss incidents.

Q 10. How do you ensure compliance with safety regulations?

Ensuring compliance with safety regulations involves a multi-faceted approach. It begins with a thorough understanding of all applicable regulations, standards, and industry best practices. This knowledge informs all safety procedures and training programs.

Regular audits and inspections are critical for identifying non-compliance issues. These audits should cover all aspects of the work environment, from equipment maintenance to employee practices. I utilize checklists and standardized procedures to ensure consistency and thoroughness. Documentation is paramount; all inspections, training, and corrective actions should be meticulously recorded.

Proactive measures, such as hazard identification and risk assessments, are key to preventing non-compliance. By identifying potential hazards early and implementing appropriate controls, the risk of non-compliance is significantly reduced. Training employees on the regulations and their responsibilities is essential; it ensures that everyone understands their role in maintaining compliance. Any non-compliance identified is addressed promptly with corrective actions and preventative measures to avoid recurrence.

Q 11. Describe your experience with safety training and education.

My experience with safety training and education spans several years and diverse settings. I’ve developed and delivered training programs on various topics, including hazard recognition, lockout/tagout procedures, emergency response, and specific equipment operation. My approach emphasizes practical application and interactive learning.

I believe in tailoring training to the specific needs and skill levels of the audience. For example, I’ve designed basic safety orientations for new hires and advanced training for experienced workers on specialized equipment. I utilize a mix of methods, including presentations, hands-on demonstrations, simulations, and case studies, to keep the training engaging and effective. Post-training assessments and follow-up sessions ensure understanding and retention.

I have experience using various training materials and technologies, including online modules, videos, and interactive software. I also actively seek opportunities to update my knowledge and skills through continuing education courses and professional development programs to ensure that my training reflects the latest best practices and regulatory changes.

Q 12. How do you prioritize safety risks?

Prioritizing safety risks involves a systematic process that combines qualitative and quantitative analysis. I typically use a risk assessment matrix that considers both the likelihood and severity of potential hazards. The matrix assigns a risk score based on the combination of these factors.

Likelihood: This refers to the probability of the hazard occurring. Factors considered include frequency of exposure, presence of controls, and historical data.

Severity: This assesses the potential consequences if the hazard occurs, ranging from minor injuries to fatalities.

Hazards with high risk scores (high likelihood and high severity) are prioritized first. This ensures that resources are allocated to address the most critical risks. The process is documented, allowing for tracking progress and demonstrating proactive risk management.

For example, in a manufacturing setting, the risk of a machine malfunction causing serious injury would likely rank higher than the risk of a minor slip and fall. This prioritization informs the implementation of controls, such as machine guarding and regular maintenance for the high-risk hazard.

Q 13. Explain your understanding of lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energization of equipment during maintenance or repair. My understanding of LOTO encompasses all aspects of the process, from the initial planning and preparation to the final verification and release of the equipment.

The process typically involves the following steps:

- Preparation: Identify the energy sources, select appropriate lockout/tagout devices, and gather necessary tools.

- Notification: Inform all personnel who may be affected by the lockout/tagout.

- Lockout/Tagout: Turn off the energy source, apply lockout devices, and then tag the device with information about the work being performed and the person responsible.

- Verification: Verify that the energy source is completely de-energized before beginning work.

- Energy Isolation: Ensure that the energy source cannot be accidentally re-energized.

- Release: Once the work is complete, remove the lockout/tagout devices, and verify that the equipment is safe to operate.

I am familiar with the OSHA regulations for LOTO and ensure that all procedures comply with these standards. Regular training and drills are crucial to ensure that everyone involved understands and follows these procedures properly.

Q 14. How do you handle workplace emergencies?

Handling workplace emergencies effectively requires a calm and organized approach. My response is guided by the organization’s EAP and my specific training. The initial steps are focused on ensuring the safety of myself and others.

Immediate Actions:

- Assess the situation: Determine the nature and extent of the emergency.

- Activate the EAP: Follow established procedures, which may involve calling emergency services, evacuating the area, or providing first aid.

- Secure the scene: Take steps to prevent further harm or injury.

Post-Emergency Actions:

- Provide assistance: Administer first aid if trained and appropriate, and provide comfort and support to those affected.

- Cooperate with emergency personnel: Provide them with necessary information and assistance.

- Document the incident: Record details of the emergency, actions taken, and injuries sustained.

- Conduct a post-incident review: Analyze the event to identify contributing factors and implement corrective actions to prevent future occurrences.

For instance, I’ve helped manage a workplace fire by efficiently evacuating the building, guiding colleagues to the assembly point and then assisting emergency responders.

Q 15. What are your methods for documenting safety procedures?

Documenting safety procedures requires a systematic approach ensuring clarity, accessibility, and ongoing relevance. I utilize a multi-faceted strategy combining written documentation, visual aids, and training records.

Standard Operating Procedures (SOPs): I create detailed, step-by-step SOPs for every task, outlining potential hazards, recommended PPE, and emergency procedures. These are written in clear, concise language, avoiding jargon, and often include diagrams or flowcharts for complex processes. For example, an SOP for operating a forklift would detail pre-operation checks, safe operating techniques, and emergency shutdown procedures.

Checklists: Checklists are invaluable for routine tasks and pre-operation inspections, ensuring consistent adherence to safety protocols. A pre-shift checklist for a machine operator might include verifying safety guards are in place, lubrication levels, and emergency stop functionality.

Training Records: I maintain meticulous records of all safety training sessions, including attendance sheets, test results, and certificates of completion. This ensures accountability and demonstrates compliance with regulations. These records are crucial for audits and investigations.

Incident Reports: Thorough incident reports are vital for identifying trends, implementing corrective actions, and preventing future incidents. These reports document the details of the incident, contributing factors, injuries, and corrective actions taken. They also serve as valuable learning tools.

Digital Platforms: Leveraging digital platforms allows for easy access, updates, and version control of safety documents. These could range from shared drives to dedicated safety management systems.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with personal protective equipment (PPE).

My experience with PPE encompasses selection, training, and enforcement of its proper use. I understand the importance of choosing the right PPE for specific hazards and ensuring it’s properly fitted and maintained.

Hazard Assessment: Before selecting PPE, I conduct a thorough hazard assessment to identify the risks involved. This informs the type and level of protection required. For instance, working with chemicals might necessitate respirators and chemical-resistant gloves, while working at heights requires harnesses and helmets.

Fit Testing: I ensure proper fit testing for respiratory protection to guarantee an effective seal and prevent exposure to airborne hazards. I also ensure that all PPE is sized correctly and comfortable for the wearer.

Training and Education: I provide comprehensive training on the proper use, limitations, and maintenance of PPE. This includes practical demonstrations and hands-on exercises. Employees are trained to inspect their PPE before each use and report any damage or defects.

Enforcement: I enforce the consistent and correct use of PPE through regular observations and reminders. Non-compliance is addressed promptly and appropriately, with retraining or disciplinary measures as necessary. For example, consistent failure to wear safety glasses could lead to temporary suspension until retraining is completed.

Q 17. How do you ensure that safety equipment is properly maintained?

Proper maintenance of safety equipment is crucial for its effectiveness and the safety of personnel. My approach involves regular inspections, scheduled maintenance, and prompt repairs.

Inspection Schedules: I establish regular inspection schedules for all safety equipment, tailored to the specific equipment and its usage. This could include daily checks for certain items and more infrequent checks for others. For example, fire extinguishers require annual inspections, while hand tools might only need a weekly visual check.

Maintenance Logs: I maintain detailed maintenance logs recording all inspections, repairs, and calibrations. This creates a transparent record of the equipment’s history and ensures compliance with regulations.

Calibration and Testing: I ensure that equipment requiring calibration (like gas detectors or pressure gauges) undergoes regular calibration by qualified technicians to guarantee accuracy and reliability. Similarly, regular testing of emergency equipment, like fire alarms and sprinklers, is essential.

Prompt Repairs: Any damaged or malfunctioning safety equipment is repaired or replaced immediately. Out-of-service equipment is clearly marked to prevent accidental use.

Training on Maintenance: Employees are sometimes trained in basic maintenance tasks, like cleaning and minor adjustments for their assigned equipment. This promotes ownership and helps identify potential problems early.

Q 18. How do you conduct a job safety analysis?

A Job Safety Analysis (JSA) is a systematic process to identify hazards and control measures associated with a specific task. My approach involves a structured methodology.

Select the Task: The first step is selecting the specific job task to be analyzed. This could range from operating a machine to handling chemicals.

Break Down the Task: The task is broken down into its individual steps, ensuring that no detail is overlooked.

Identify Hazards: For each step, potential hazards are identified, considering both immediate and potential longer-term risks.

Identify Control Measures: For each identified hazard, appropriate control measures are determined using the hierarchy of controls (elimination, substitution, engineering controls, administrative controls, PPE). For example, if a hazard involves heavy lifting, engineering controls might involve using a hoist, and administrative controls might involve limiting the weight of the lifts and providing adequate rest periods.

Document the Findings: The entire process is documented in a JSA form, outlining each step, its associated hazards, and the control measures implemented.

Review and Update: The JSA is regularly reviewed and updated to reflect changes in the task, equipment, or regulations.

For example, a JSA for changing a lightbulb might identify hazards such as falls from a ladder and electrical shock. Control measures would include using a stable ladder, wearing appropriate footwear, and de-energizing the circuit before starting work.

Q 19. Explain your understanding of hazard communication standards.

Hazard communication standards, such as OSHA’s Hazard Communication Standard (HCS), aim to ensure that employees are informed of the hazards associated with the chemicals they handle. My understanding involves the proper labeling, safety data sheets (SDS), and employee training.

Labels and SDS: All containers of hazardous chemicals must be properly labeled with clear warnings, hazard pictograms, signal words, and precautionary statements. The SDS provides detailed information about the chemical’s hazards, safe handling procedures, and emergency response measures. I ensure that both labels and SDS are readily available and updated as per the latest requirements.

Training Programs: I develop and conduct comprehensive training programs to educate employees on how to interpret hazard labels and SDSs. Training includes information on handling, storage, and emergency procedures for each hazardous chemical used in the workplace.

Communication Channels: Beyond formal training, I utilize various communication channels such as safety meetings, posters, and email updates to keep employees informed about hazardous chemicals and any changes in safety procedures.

Record Keeping: Meticulous records are kept of all safety data sheets, training records, and any incidents related to hazardous materials. These are essential for compliance audits and investigations.

Q 20. How do you manage safety concerns raised by employees?

Addressing safety concerns raised by employees is paramount. My approach prioritizes open communication, prompt investigation, and effective resolution.

Open Communication Channels: I foster a culture of open communication where employees feel comfortable reporting safety concerns without fear of reprisal. This might involve suggestion boxes, regular safety meetings, or a dedicated reporting system.

Prompt Investigation: All reported concerns are promptly investigated, documenting the details of the issue, potential hazards, and any witnesses.

Corrective Actions: Based on the investigation, appropriate corrective actions are implemented. This could involve immediate hazard abatement, modification of procedures, additional training, or equipment upgrades.

Follow-up: After implementing corrective actions, a follow-up is conducted to ensure the effectiveness of the measures taken and to address any remaining concerns. This demonstrates that employee input is valued and their safety is prioritized.

Documentation: All safety concerns, investigations, and corrective actions are meticulously documented to maintain a comprehensive record of safety management practices.

Q 21. What are your experience with safety inspections and monitoring?

Safety inspections and monitoring are essential for proactive hazard identification and prevention. My experience involves both planned and unplanned inspections, using a systematic approach and detailed reporting.

Scheduled Inspections: I develop and implement a schedule for regular safety inspections, covering all areas of the workplace. The frequency of inspections depends on the risk level of each area. For example, areas with high-risk machinery might require daily inspections.

Inspection Checklists: I utilize checklists to ensure consistent and thorough inspections, covering all key safety aspects. This ensures that no critical safety issues are overlooked.

Unplanned Inspections: In addition to scheduled inspections, I conduct unplanned inspections, responding to employee reports, incidents, or observed hazards. These are crucial for identifying immediate threats.

Corrective Actions: Any identified hazards are addressed promptly, with corrective actions documented and communicated. This might involve immediate repairs, procedural changes, or employee retraining.

Reporting and Analysis: Detailed reports are generated from each inspection, summarizing findings, corrective actions, and any trends observed. This data is used to refine safety procedures and prioritize resources.

Monitoring Systems: I utilize monitoring systems, such as environmental monitoring equipment for hazardous substances, to continuously track safety parameters and provide real-time data for early detection of potential problems.

Q 22. How do you stay up-to-date with changes in safety regulations?

Staying current with evolving safety regulations requires a multi-faceted approach. It’s not a one-time task but an ongoing commitment.

- Subscription to Regulatory Updates: I subscribe to newsletters and alerts from relevant organizations like OSHA (Occupational Safety and Health Administration) and other industry-specific regulatory bodies. This ensures I receive timely notifications of changes and updates.

- Professional Development: I actively participate in workshops, conferences, and training sessions focused on safety regulations. This allows me to learn about best practices and interact with other professionals in the field, expanding my knowledge base.

- Industry Publications and Journals: I regularly read industry publications and peer-reviewed journals that focus on safety. This keeps me abreast of emerging research, new technologies, and evolving safety standards.

- Internal Communication: I maintain open communication with my colleagues and management to ensure that we are all on the same page regarding updated safety procedures and regulations.

For example, recently I learned about a significant update to lockout/tagout procedures through an OSHA newsletter, which immediately prompted a company-wide refresher training session.

Q 23. Describe a situation where you had to make a difficult decision regarding safety.

During a construction project, we discovered a significant crack in a supporting beam that was not initially identified in the structural assessment. This presented a serious risk of collapse. The decision was whether to halt the entire project, incurring substantial financial penalties, or to attempt a risky, expedited repair while minimizing disruption.

After careful consideration of several factors, including the severity of the risk, the feasibility of the repair, and consultation with structural engineers and safety officers, we chose to halt operations in the affected area. We prioritized the safety of our workers, as the potential for injury or fatality outweighed the financial implications. While this decision was costly, it prevented a potentially catastrophic accident and upheld the company’s unwavering commitment to safety.

Q 24. Explain how you’ve used data to improve safety performance.

Data analysis is crucial for proactive safety management. We use data to identify trends, pinpoint weaknesses, and implement targeted improvements.

- Near Miss Reporting: We meticulously track near-miss incidents. Analyzing these events, even though they didn’t result in injuries, helps us understand potential hazards and prevent future accidents. For instance, a pattern of near misses involving a specific piece of equipment might indicate a need for enhanced training or equipment upgrades.

- Incident Investigation: After every incident, a thorough investigation is conducted, documenting the cause, contributing factors, and corrective actions. This data is compiled and analyzed to identify root causes and patterns, leading to more effective preventative measures.

- Safety KPIs: Key performance indicators like Lost Time Injury Rate (LTIR) and Total Recordable Incident Rate (TRIR) are regularly monitored. Trends in these metrics help us measure the effectiveness of safety initiatives and guide resource allocation. For example, a rising LTIR might signal a need for additional training or improved safety equipment.

By leveraging data, we can move beyond reactive safety measures and develop a proactive, data-driven approach to minimizing risks and fostering a safer work environment.

Q 25. What are your strengths and weaknesses related to safety management?

My strengths in safety management lie in my analytical skills, proactive approach, and ability to communicate effectively with diverse teams. I excel at identifying potential hazards, developing preventative measures, and engaging others in a shared commitment to safety. I’m also highly organized and detail-oriented, ensuring compliance with regulations and best practices.

My area for improvement is delegation. While I’m thorough, I sometimes take on too much myself. I am actively working on this through structured delegation, clear communication of expectations, and providing appropriate training and support to my team members.

Q 26. How do you handle conflicting safety requirements from different stakeholders?

Conflicting safety requirements are a common challenge. Handling them effectively involves clear communication, collaboration, and a structured approach.

- Identify and Document: I begin by clearly documenting all conflicting requirements, identifying the stakeholders involved and the rationale behind each requirement.

- Collaboration and Communication: I facilitate open communication among stakeholders to understand the underlying concerns and priorities. This often involves meetings and discussions to find common ground.

- Risk Assessment and Prioritization: A comprehensive risk assessment is crucial. I help stakeholders prioritize requirements based on the severity and likelihood of risks. This helps to find mutually acceptable solutions.

- Documentation and Agreement: Once a solution is reached, it is documented and communicated to all stakeholders to ensure clarity and accountability. This document serves as a record of the decision-making process.

Sometimes, compromise is necessary. The goal is to find the safest solution that meets the needs of all stakeholders to the greatest extent possible.

Q 27. Explain your experience with safety performance indicators (KPIs).

Safety performance indicators (KPIs) are essential for measuring the effectiveness of safety programs. My experience involves using a variety of KPIs, both leading and lagging indicators.

- Lagging Indicators: These reflect past performance, such as the number of accidents, lost-time incidents, and near misses. These are crucial for identifying areas of concern.

- Leading Indicators: These predict future performance. Examples include the number of safety training hours completed, the number of safety inspections conducted, and the number of hazard reports submitted. These help to anticipate potential problems and identify areas for improvement before incidents occur.

- Data Analysis and Reporting: I have experience collecting, analyzing, and presenting KPI data to stakeholders. This often involves creating reports and presentations that highlight trends, identify areas for improvement, and demonstrate the impact of safety initiatives.

By regularly monitoring and analyzing KPIs, we can track progress, identify areas needing attention, and demonstrate the value of our safety programs to the organization.

Q 28. Describe your understanding of risk assessment methodologies.

Risk assessment methodologies are crucial for identifying and mitigating hazards. I’m familiar with several methodologies, including HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis).

- HAZOP: This systematic approach involves reviewing a process step-by-step to identify potential deviations from the intended operation and their consequences. It is particularly useful for complex processes.

- FMEA: This method identifies potential failure modes in a system or process, evaluates their effects, and assesses the severity and likelihood of each failure. This allows for prioritization of risk mitigation efforts.

- Qualitative and Quantitative Analysis: Risk assessment can be both qualitative (describing the likelihood and severity of a risk using descriptive terms) and quantitative (assigning numerical values to likelihood and severity to calculate a risk score). I’m proficient in both approaches.

The choice of methodology depends on the complexity of the process and the available data. Regardless of the method used, a thorough risk assessment requires a multidisciplinary team approach, involving individuals with diverse expertise and perspectives.

Key Topics to Learn for Follow Safety Procedures and Regulations Interview

- Understanding Safety Regulations: Learn the legal framework and industry-specific regulations governing safety in your field. This includes understanding the rationale behind these regulations.

- Identifying Hazards and Risks: Develop skills in proactively identifying potential hazards and assessing associated risks in various work environments. Practice conducting thorough risk assessments.

- Implementing Safety Procedures: Understand how to correctly implement established safety procedures, including the use of Personal Protective Equipment (PPE) and emergency response protocols. Be prepared to discuss practical examples.

- Reporting and Documentation: Learn the importance of accurate and timely reporting of safety incidents and near misses. Understand the proper documentation procedures and their significance.

- Emergency Response and Procedures: Familiarize yourself with emergency response plans, evacuation procedures, and first aid protocols relevant to your industry. Be ready to discuss your role in an emergency scenario.

- Continuous Improvement and Training: Demonstrate an understanding of the importance of continuous safety training, improvement initiatives, and staying updated on new regulations and best practices.

- Communication and Teamwork: Highlight the crucial role of effective communication and teamwork in maintaining a safe work environment. Be prepared to discuss situations requiring collaboration to ensure safety.

Next Steps

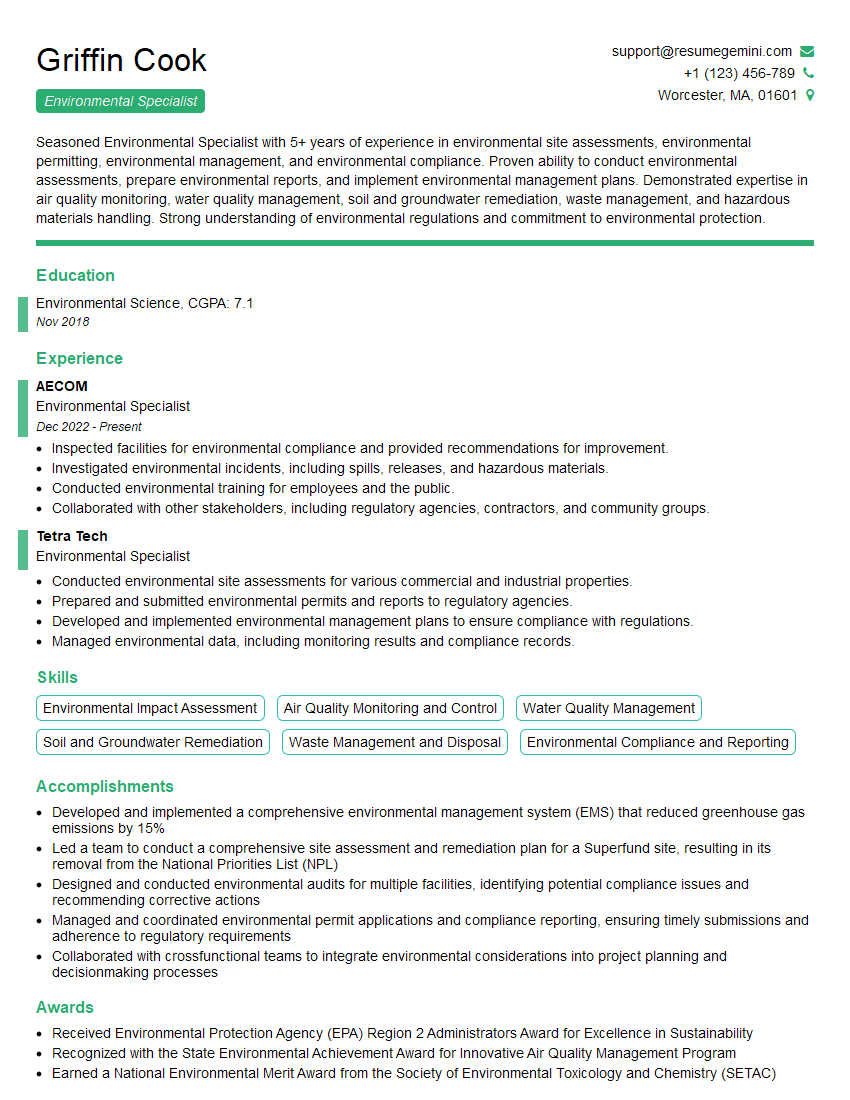

Mastering safety procedures and regulations is crucial for career advancement. It demonstrates your commitment to a safe and productive workplace, increasing your value to any employer. To enhance your job prospects, build an ATS-friendly resume that clearly highlights your safety expertise and experience. We recommend using ResumeGemini, a trusted resource for creating professional and effective resumes. ResumeGemini provides examples of resumes tailored to roles emphasizing “Follow safety procedures and regulations,” helping you craft a compelling application that stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO