Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Food Processing and Handling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Food Processing and Handling Interview

Q 1. Explain the principles of HACCP.

HACCP, or Hazard Analysis and Critical Control Points, is a preventative food safety system. Instead of simply reacting to contamination, HACCP identifies potential biological, chemical, and physical hazards throughout the food production process and implements controls to minimize or eliminate those risks.

- Hazard Analysis: This involves identifying all possible hazards at each step of the process, from raw material sourcing to final product distribution. For example, in a canned tuna production facility, a hazard analysis would identify potential hazards like Listeria contamination during processing or the presence of heavy metals in the tuna itself.

- Critical Control Points (CCPs): These are points in the process where control can prevent, eliminate, or reduce a hazard to an acceptable level. For canned tuna, CCPs might include cooking temperature (killing bacteria) and the hermetic seal of the can (preventing recontamination).

- Critical Limits: For each CCP, a critical limit is established – a measurable value that must be met to ensure safety. This could be a minimum cooking temperature (e.g., 121°C for 3 minutes) or a maximum level of heavy metals.

- Monitoring: Regular monitoring of CCPs is essential to ensure critical limits are met. This might involve checking temperature with thermometers and recording the data.

- Corrective Actions: If a critical limit is not met, corrective actions must be taken to rectify the situation and prevent unsafe product from reaching the consumer. For instance, if the cooking temperature is too low, the entire batch might be discarded.

- Verification: This involves confirming that the HACCP plan is working effectively. This could include regular audits, microbiological testing, and employee training reviews.

- Record Keeping: Detailed records are essential to demonstrate compliance and traceability. This includes all monitoring data, corrective actions, and verification results.

Implementing HACCP requires a thorough understanding of the entire food production process and a commitment to continuous improvement. It’s not just a checklist; it’s a proactive system that emphasizes risk prevention.

Q 2. Describe your experience with GMPs (Good Manufacturing Practices).

My experience with GMPs spans over 15 years, encompassing various roles in food manufacturing. I’ve been directly involved in developing, implementing, and auditing GMP programs for diverse food products, from ready-to-eat meals to dairy products. This includes ensuring adherence to standards related to personnel hygiene, facility sanitation, equipment maintenance, and raw material handling.

In one instance, I spearheaded a GMP improvement project in a bakery facing consistent issues with pest infestations. By implementing a comprehensive pest control program, improving sanitation practices, and training employees on proper hygiene protocols, we significantly reduced contamination risks and improved our overall GMP compliance. This involved everything from regular inspections and pest control treatments to thorough cleaning schedules and employee training on best practices. We even utilized improved packaging to reduce pest attraction. The result was a noticeable decrease in pest activity and improved product safety and quality.

GMPs aren’t just regulations; they’re fundamental practices that build a culture of quality and safety. They create a framework for consistent production of safe, high-quality food.

Q 3. How do you ensure food safety throughout the processing chain?

Ensuring food safety throughout the processing chain requires a multi-faceted approach, incorporating several key strategies:

- Supplier Management: Selecting reputable suppliers who adhere to stringent food safety standards is critical. This includes regular audits of supplier facilities and documentation review.

- Effective Sanitation Programs: Rigorous cleaning and sanitization procedures must be implemented throughout the facility, including equipment, surfaces, and utensils. We regularly utilize ATP testing to verify effectiveness.

- Temperature Control: Maintaining appropriate temperatures during storage, processing, and transportation is crucial to prevent bacterial growth. Utilizing temperature monitoring systems and recording is key.

- Allergen Control: Implementing strategies to prevent cross-contamination of allergens is vital for those with allergies. This might involve dedicated equipment, thorough cleaning, and clear labeling.

- Pest Control: Preventative measures are needed to keep pests out of the facility and away from food products. Regular inspections and preventative measures should be in place.

- Employee Training: Thorough training on food safety practices is essential for all employees, from production workers to management.

- Traceability: A robust traceability system allows for rapid identification and removal of contaminated products in case of a recall. This involves detailed record-keeping at every stage of the production process.

Essentially, it’s about building a culture of food safety, where everyone understands their role in preventing contamination and protecting consumers. A proactive approach—not a reactive one—is vital.

Q 4. What are common foodborne illnesses and how are they prevented?

Common foodborne illnesses are caused by pathogenic bacteria, viruses, or parasites present in food. Some of the most prevalent include:

- Salmonella: Often linked to poultry, eggs, and unpasteurized dairy products. Symptoms include diarrhea, fever, and abdominal cramps.

- E. coli: Found in undercooked beef, contaminated water, and unpasteurized juices. Can cause bloody diarrhea, vomiting, and kidney failure in severe cases.

- Listeria monocytogenes: Found in ready-to-eat foods and can survive refrigeration temperatures. Particularly dangerous for pregnant women, newborns, and immunocompromised individuals.

- Campylobacter: Common in poultry, unpasteurized milk, and contaminated water. Symptoms include diarrhea, fever, and abdominal pain.

- Norovirus: Highly contagious virus often spread through contaminated food or surfaces. Causes vomiting and diarrhea.

Prevention strategies include:

- Proper Cooking Temperatures: Cooking food to the appropriate internal temperature kills most pathogenic bacteria.

- Safe Food Handling Practices: Washing hands thoroughly, avoiding cross-contamination, and refrigerating perishable foods promptly.

- Source Control: Sourcing ingredients from reputable suppliers who practice good food safety standards.

- Effective Sanitation: Thorough cleaning and sanitization of food contact surfaces and equipment.

- Pasteurization: Heating food products to a temperature that kills harmful microorganisms.

Thorough employee training and adherence to proper food safety protocols are paramount in preventing foodborne illnesses.

Q 5. Describe your experience with different food preservation methods.

My experience encompasses a broad range of food preservation methods, each with its own advantages and limitations:

- Thermal Processing: This includes canning, pasteurization, and sterilization. I’ve worked extensively with retort systems for canning low-acid foods, ensuring proper lethality to eliminate pathogens. Pasteurization, a milder heat treatment, is vital for many dairy and juice products.

- Refrigeration and Freezing: These methods slow down microbial growth but do not eliminate all microorganisms. Understanding appropriate temperatures and storage times is critical. I’ve been involved in optimizing cold chain management for various products to maintain quality and safety.

- Dehydration: Removing water reduces microbial activity. I’ve worked with various drying techniques, from air drying to freeze-drying, focusing on maintaining nutritional value and preventing spoilage.

- High-Pressure Processing (HPP): This non-thermal method uses high pressure to inactivate microorganisms. I have experience in evaluating HPP’s suitability for different food matrices and ensuring product quality.

- Fermentation: Microorganisms are used to preserve food and enhance flavor. I’ve worked with various fermentation processes, understanding the control of fermentation parameters to ensure safety and quality. This includes the fermentation of yogurts, cheeses, and fermented vegetables.

- Irradiation: This method uses ionizing radiation to kill microorganisms and extend shelf life. While controversial, it’s an effective method, and understanding consumer perception is crucial.

The choice of preservation method depends on the specific food product, its characteristics, and the desired shelf life. Each method requires careful control of processing parameters to ensure both safety and quality are maintained.

Q 6. Explain the importance of proper sanitation in food processing.

Proper sanitation is paramount in food processing. It’s the cornerstone of preventing contamination and ensuring the safety of the final product. Neglecting sanitation can lead to serious health risks, product recalls, and significant financial losses.

A comprehensive sanitation program includes:

- Cleaning: Removing visible dirt, debris, and food residues from surfaces and equipment.

- Sanitization: Reducing the number of microorganisms to a safe level using chemical sanitizers or heat. The choice between chemical and heat sanitization will vary depending on the food processing environment and food being handled.

- Preventive Maintenance: Regularly inspecting and maintaining equipment to prevent contamination and ensure proper functionality. This includes checking for leaks, cracks, or other damage that could harbor microorganisms.

- Pest Control: Implementing preventative measures to exclude pests from the facility and prevent their access to food products. This might include routine inspections for pest activity and the use of pest control treatments.

- Employee Training: Educating employees on proper sanitation procedures and emphasizing their role in maintaining a clean and sanitary environment is essential.

Regular audits, microbiological testing, and record-keeping are crucial to ensure the effectiveness of the sanitation program. A well-structured sanitation program minimizes the risk of contamination, protects consumer health, and upholds the reputation of the food processing facility. Think of it as creating a clean and controlled environment where microorganisms cannot easily survive or spread.

Q 7. How do you identify and resolve food safety issues?

Identifying and resolving food safety issues requires a systematic approach:

- Monitoring: Regularly monitoring CCPs and other critical points in the production process is essential for early detection. This includes temperature monitoring, microbiological testing, and visual inspections.

- Root Cause Analysis: If a food safety issue is identified, a thorough investigation must be conducted to determine the root cause. This often involves interviewing personnel, reviewing records, and conducting environmental sampling.

- Corrective Actions: Once the root cause is identified, appropriate corrective actions must be implemented to prevent the issue from recurring. This could involve modifying processing parameters, improving sanitation procedures, or retraining employees.

- Preventive Measures: Implementing preventative measures to prevent future incidents is crucial. This could include upgrading equipment, improving facility design, or strengthening supplier relationships.

- Documentation: Maintaining thorough documentation of all incidents, investigations, and corrective actions is essential for traceability and accountability. This facilitates continuous improvement and allows for better response in future instances.

Addressing food safety issues proactively, with a focus on prevention, is essential. My approach involves using a combination of data-driven analysis and practical problem-solving skills, always prioritizing consumer safety and minimizing any negative impact.

Q 8. What is your experience with food labeling regulations?

Food labeling regulations are crucial for ensuring consumer safety and transparency. My experience encompasses a deep understanding of regulations like the FDA’s Food and Drug Act and the USDA’s labeling requirements, including understanding the nuances of nutrition facts panels, allergen declarations, and claims substantiation. I’ve been involved in numerous projects ensuring compliance with these regulations, from developing compliant labels for new products to conducting audits of existing labels to identify and rectify non-compliances. For example, I once identified a potential labeling issue concerning a specific allergen that wasn’t clearly stated on our product’s packaging, which could have led to serious health consequences for consumers. This required a thorough review of the ingredient list, reformulation in some cases and a complete label redesign to ensure full compliance.

I’m familiar with variations in labeling regulations across different regions and countries, including the EU’s labeling requirements and those of other global markets. This knowledge is crucial for successfully navigating the complexities of international trade and distribution.

Q 9. Describe your experience with different types of food packaging.

My experience with food packaging spans a wide range of materials and technologies, each suited to different product types and preservation needs. I’ve worked extensively with flexible packaging (like pouches and films), rigid packaging (like cans and bottles), and modified atmosphere packaging (MAP). Flexible packaging offers cost-effectiveness and versatility, but its barrier properties need careful consideration to prevent spoilage. Rigid packaging provides excellent protection and shelf-life extension, especially for products that require high-pressure sterilization. MAP, on the other hand, extends shelf life by modifying the gaseous environment inside the packaging to inhibit microbial growth. For example, I helped a client choose the optimal packaging for their new line of ready-to-eat salads, opting for a modified atmosphere pouch to maintain freshness and quality.

I’m also familiar with sustainable packaging options such as biodegradable and compostable materials, and actively contribute to the efforts to minimize environmental impact throughout the supply chain. Choosing the right packaging involves a thorough analysis of product characteristics, shelf life requirements, distribution logistics, and consumer preferences.

Q 10. How do you manage inventory in a food processing environment?

Managing inventory in a food processing environment requires a sophisticated approach combining effective forecasting, real-time tracking, and robust inventory management systems. We utilize FIFO (First-In, First-Out) methodology to ensure that older products are processed and shipped before newer ones, minimizing waste and preventing spoilage. This system often involves barcoding or RFID tagging for accurate tracking of materials from receiving to finished goods. I’ve implemented and overseen inventory management systems using ERP (Enterprise Resource Planning) software which provides real-time visibility of stock levels across all locations, allowing for proactive adjustments to purchasing and production schedules.

Effective inventory management also necessitates a well-defined process for managing expiration dates and preventing stockouts. Regular cycle counts help validate inventory accuracy and address discrepancies promptly. We use data analytics to forecast demand, optimizing stock levels to meet customer needs while minimizing storage costs and waste. In one instance, implementing advanced forecasting reduced our waste by 15% by optimizing production runs based on accurate demand predictions.

Q 11. What is your experience with production scheduling and optimization?

Production scheduling and optimization are critical for efficiency and profitability in food processing. My experience includes developing and implementing production schedules using techniques such as lean manufacturing principles and capacity planning. I’m proficient in using scheduling software to optimize production runs, minimizing downtime and maximizing output. This often involves considering factors such as equipment availability, raw material availability, labor constraints, and order deadlines. For instance, I optimized a production line by implementing a Kanban system, which significantly reduced lead times and improved overall efficiency.

Production optimization also involves continuous improvement initiatives aimed at identifying bottlenecks and inefficiencies in the production process. I often employ techniques like value stream mapping to analyze the entire production flow, identify areas for improvement, and develop solutions to enhance efficiency and reduce waste. This might involve streamlining processes, automating tasks, or improving equipment utilization.

Q 12. How do you handle equipment malfunctions or production line stoppages?

Handling equipment malfunctions or production line stoppages requires a swift and organized response to minimize production losses and ensure food safety. Our procedures involve a clearly defined escalation process, with immediate attention to the safety of personnel. We maintain a well-stocked inventory of spare parts to facilitate rapid repairs. Root cause analysis is conducted after each stoppage to identify the underlying problem and prevent recurrence. Preventive maintenance is integral to our approach; regular equipment inspections help us identify potential issues before they cause significant disruptions.

For example, during a recent production line stoppage due to a faulty sensor, our team followed established protocols, promptly addressed the safety concerns, and identified the faulty part, resulting in minimal downtime thanks to our well-maintained spare parts inventory and a thorough root cause analysis that prevented future incidents related to that sensor.

Q 13. Describe your experience with quality control testing and analysis.

Quality control testing and analysis are paramount in food processing, ensuring product safety and consistency. My experience encompasses a wide range of testing methods, including microbiological analysis (e.g., testing for pathogens like E. coli and Salmonella), physical testing (e.g., measuring texture, viscosity, and color), and chemical analysis (e.g., determining moisture content and pH levels). I’m proficient in interpreting test results, identifying deviations from specifications, and implementing corrective actions. We utilize statistical process control (SPC) techniques to monitor process variability and identify trends that could signal quality issues.

We also maintain comprehensive documentation of all testing procedures and results, ensuring traceability throughout the production process. A robust quality management system (QMS) including ISO 22000 and HACCP principles guides our quality control efforts, fostering a culture of continuous improvement and emphasizing prevention over reaction.

Q 14. Explain your understanding of different food processing technologies.

My understanding of food processing technologies is extensive, encompassing a wide range of techniques used to transform raw materials into finished food products. I’m familiar with thermal processing methods like pasteurization and sterilization, which are crucial for ensuring food safety and extending shelf life. I understand the principles of high-pressure processing (HPP), a non-thermal method that preserves the quality and nutritional value of products while inactivating microorganisms. I also have experience with drying and freezing technologies, which are essential for preserving food for extended periods.

Beyond these core technologies, I’m knowledgeable about more specialized techniques such as fermentation, which is widely used in the production of various food products, including yogurt, cheese, and sauerkraut. I understand the impact of different processing technologies on product quality, nutritional value, and shelf life. My experience allows me to select and implement optimal processing techniques depending on the specific product and its requirements.

Q 15. How do you ensure the efficient use of resources (energy, water) in food processing?

Efficient resource utilization in food processing is paramount for both economic viability and environmental responsibility. It involves a multi-pronged approach focusing on energy and water conservation.

Energy Efficiency: This includes optimizing equipment performance through regular maintenance, using energy-efficient motors and drives (e.g., Variable Frequency Drives or VFDs), implementing heat recovery systems to capture waste heat from processes like sterilization and utilize it for preheating, and optimizing process parameters to reduce energy consumption. For instance, in a canning line, optimizing the sterilization cycle duration without compromising safety can significantly reduce energy usage.

Water Conservation: Strategies here focus on reducing water consumption in cleaning and processing steps. This can be achieved through implementing closed-loop water systems where wastewater is recycled after appropriate treatment, using water-efficient cleaning technologies (e.g., high-pressure cleaning systems with precise chemical dosage), and investing in water-saving fixtures throughout the facility. For example, in a vegetable washing line, a multi-stage counter-current washing system can dramatically reduce the overall water needed compared to a single-stage system.

Integrated Approach: The most effective strategies integrate energy and water conservation. For instance, using heat pumps to heat process water reduces both energy and water consumption as less water is needed for heating. A comprehensive energy audit and water usage analysis provides a baseline to identify areas for improvement and track progress.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with process improvement initiatives.

I have extensive experience leading process improvement initiatives, focusing on Lean Manufacturing and Six Sigma methodologies. In my previous role at a large-scale dairy processing plant, we implemented a Lean project to streamline the milk pasteurization process. This involved mapping the value stream to identify bottlenecks and areas of waste, such as unnecessary transport or excessive inventory. We eliminated non-value-added steps, improved workflow, and reduced processing time by 15%. This resulted in a significant reduction in production costs and improved product quality. Another project utilized DMAIC (Define, Measure, Analyze, Improve, Control) principles of Six Sigma to reduce the defect rate in cheese production. Through detailed data analysis, we pinpointed the root cause of defects (a faulty mixing tank) and implemented corrective actions, leading to a 30% reduction in defects.

Quantifiable results and data-driven decision-making are central to my approach. I’m proficient in using various tools, including process mapping, value stream mapping, statistical process control (SPC), and root cause analysis.

Q 17. How do you maintain a safe and productive work environment?

Maintaining a safe and productive work environment is paramount. My approach involves a multi-layered strategy incorporating:

Strict Adherence to Safety Regulations: This includes ensuring compliance with all relevant food safety regulations (e.g., HACCP, GMP), regular safety training for all employees, and implementing robust safety protocols for handling equipment and chemicals.

Preventive Maintenance: Regular inspections and maintenance of equipment significantly reduce the risk of accidents and breakdowns. This is crucial in a food processing environment where malfunctioning equipment can cause injuries or contamination.

Ergonomic Design: Designing workstations and workflows to minimize physical strain on employees reduces the risk of musculoskeletal disorders. This involves investing in ergonomic equipment and providing training on proper lifting techniques and posture.

Open Communication: Creating a culture where employees feel comfortable reporting safety concerns or near misses is crucial for proactively identifying and addressing hazards. Regular safety meetings and feedback mechanisms are essential.

Personal Protective Equipment (PPE): Providing and ensuring the proper use of appropriate PPE (e.g., gloves, safety glasses, earplugs) is non-negotiable.

Q 18. What is your experience with managing a team in a food processing setting?

My experience in managing teams in food processing spans several years and various roles. I’ve successfully led teams ranging from 5 to 30 individuals, fostering collaboration and achieving production goals while maintaining high safety standards. My leadership style is participative, encouraging open communication and empowering team members. I believe in providing clear expectations, regular feedback, and opportunities for skill development. For instance, I implemented a mentorship program within a team to foster knowledge sharing and develop junior staff. I use performance management tools, both formal and informal, to track progress, identify areas for improvement and reward high performance. I also focus on building a positive work environment based on mutual respect and teamwork.

Q 19. How do you handle pressure and meet tight deadlines in a fast-paced environment?

The food processing industry often operates under pressure with tight deadlines. My ability to manage pressure stems from experience, planning, and effective prioritization. I use project management techniques, such as creating detailed schedules, assigning tasks efficiently, and regularly monitoring progress to ensure we stay on track. I also excel at identifying potential bottlenecks or issues early on and proactively develop contingency plans. Effective communication is key – maintaining transparency with the team helps to mitigate stress and ensures everyone is aware of priorities. Moreover, I delegate tasks effectively based on individual team member strengths, thereby ensuring efficient workload distribution. I firmly believe in the importance of maintaining a calm and focused approach, even under pressure.

Q 20. Explain your experience with different types of food processing equipment.

My experience encompasses a wide range of food processing equipment, including:

Thermal Processing Equipment: Retorts (for canning), pasteurizers (for milk and juices), ovens (for baking), and freezers (for frozen products).

Size Reduction Equipment: Grinders, cutters, and homogenizers used in various stages of food processing.

Mixing and Blending Equipment: Mixers, blenders, and agitators for creating uniform food products.

Separation Equipment: Centrifuges, filters, and separators for removing solids, liquids, or unwanted materials.

Packaging Equipment: Fillers, sealers, and labeling machines for packaging final products.

I understand the operational principles, maintenance requirements, and safety protocols associated with each type of equipment. My experience includes both manual and automated systems.

Q 21. How do you troubleshoot problems with food processing equipment?

Troubleshooting food processing equipment requires a systematic approach. My process usually involves:

Identify the Problem: Accurately define the nature and scope of the problem, observing the equipment’s behavior and gathering data.

Gather Information: Check relevant operational logs, maintenance records, and consult with operators to understand the context of the failure. For instance, if a pasteurizer isn’t reaching the required temperature, review temperature logs and check for potential issues like faulty sensors or heating elements.

Analyze the Problem: Systematically investigate potential causes. This might involve checking for mechanical issues (e.g., worn-out belts, broken parts), electrical problems (e.g., faulty wiring, blown fuses), or process-related problems (e.g., incorrect settings, clogged pipes).

Develop Solutions: Based on the analysis, propose solutions, ranging from simple repairs to more complex overhauls or replacements. I will always prioritize safety and food safety compliance.

Implement and Test: Implement the chosen solution and thoroughly test the equipment to ensure the problem is resolved.

Document Findings: Maintain thorough documentation of the problem, the troubleshooting process, and the solution implemented for future reference.

I’m proficient in using diagnostic tools and techniques to pinpoint the root cause of equipment malfunctions. Preventative maintenance is a crucial component of my strategy to minimize the occurrence of equipment failures.

Q 22. Describe your experience with food waste reduction strategies.

Food waste reduction is crucial for both economic and environmental sustainability. My experience encompasses a multi-pronged approach, focusing on minimizing waste at each stage of the food processing chain. This includes implementing robust inventory management systems to prevent overstocking and spoilage, optimizing production processes to minimize by-products, and creatively repurposing waste streams.

- Improved Forecasting: We use predictive analytics to forecast demand more accurately, reducing the risk of producing excess inventory. For example, analyzing historical sales data and seasonal trends helped us reduce surplus production of seasonal items by 15%.

- Process Optimization: By streamlining our production line and implementing lean manufacturing principles, we’ve minimized waste during processing. This involved identifying bottlenecks and optimizing equipment usage, leading to a 10% reduction in trim losses.

- Waste Valorization: We’ve implemented innovative solutions to repurpose food waste. For instance, fruit peels are now used to produce fruit-infused water, reducing waste while creating a new revenue stream.

- Employee Training: Regular training sessions educate employees about proper handling techniques and inventory management, emphasizing the importance of reducing waste at every step.

These combined strategies have significantly reduced our overall food waste, resulting in cost savings and improved environmental performance.

Q 23. How do you ensure traceability throughout the food processing chain?

Traceability in food processing ensures the ability to track a product’s journey from origin to consumer. This is essential for identifying the source of contamination or quality issues, and for managing recalls efficiently. We utilize a comprehensive system involving batch coding, detailed record-keeping, and advanced technologies.

- Batch Tracking: Each batch of raw materials and finished products is assigned a unique identification number, meticulously recorded at every stage of processing. This allows for complete tracking of each batch’s history.

- RFID and Barcode Technology: We leverage RFID tags and barcodes for accurate and automated tracking of raw materials and finished goods throughout the supply chain. Real-time data is accessible via our central system, providing complete transparency.

- Secure Databases: All information is stored in secure, auditable databases, ensuring data integrity and compliance with regulations. Access is controlled and monitored to prevent unauthorized alterations.

- Supplier Collaboration: We work closely with our suppliers to ensure their traceability systems align with ours, creating a transparent and accountable supply chain from farm to table.

This robust traceability system allows us to respond swiftly and effectively to any issues that may arise, protecting both consumers and our brand reputation.

Q 24. What is your experience with food allergen management?

Food allergen management is paramount for ensuring consumer safety and compliance with regulations. My experience involves implementing rigorous control measures throughout the entire food processing process. We prioritize allergen prevention, strict segregation, and clear labeling.

- Allergen Control Plan: We have a detailed allergen control plan that identifies all potential allergens, outlines control measures at each processing step, and designates responsible personnel.

- Dedicated Equipment: We use dedicated equipment and processing lines for allergen-containing products to prevent cross-contamination. For example, we have separate lines for processing nuts and dairy products.

- Cleaning and Sanitation: Our cleaning and sanitation protocols are stringent, using validated procedures to eliminate allergen residues from equipment and work surfaces. We conduct thorough allergen residue testing on a regular basis.

- Labeling Accuracy: All products are clearly labeled with accurate allergen information, complying with all relevant regulations. This includes clear statements on potential cross-contamination.

- Supplier Audits: We perform regular audits of our suppliers to verify their allergen management practices and ensure that our supply chain is free of contamination risks.

Our rigorous approach to allergen management ensures that our products are safe for consumption by individuals with food allergies and mitigates the risk of costly recalls.

Q 25. How do you handle customer complaints related to food quality or safety?

Handling customer complaints related to food quality or safety is a critical aspect of our operations. We have a robust system in place to address these concerns promptly and effectively.

- Immediate Response: All complaints are acknowledged promptly and investigated thoroughly. We aim to contact the customer within 24 hours of receiving a complaint.

- Detailed Investigation: We gather all relevant information, including the product details, batch number, and the nature of the complaint. We may also request samples for analysis.

- Root Cause Analysis: We conduct a root cause analysis to identify the underlying cause of the problem. This may involve reviewing production records, sanitation logs, and other relevant documents.

- Corrective Actions: Based on our investigation, we implement appropriate corrective and preventative actions to prevent similar incidents from happening again. This could include improvements to our processes or enhanced employee training.

- Customer Communication: We keep the customer informed throughout the investigation and resolution process, maintaining open and transparent communication.

- Documentation: All complaints, investigations, and corrective actions are meticulously documented to ensure compliance and continuous improvement.

Our aim is to resolve customer complaints fairly and efficiently, while learning from each incident to improve our products and processes.

Q 26. Describe your experience with data analysis and reporting in food processing.

Data analysis and reporting play a critical role in optimizing food processing operations and improving decision-making. My experience involves utilizing various data analysis techniques to gain insights into production efficiency, quality control, and cost optimization.

- Production Monitoring: We utilize real-time data from our processing equipment and sensors to monitor production parameters such as temperature, pressure, and flow rate. This data allows us to detect anomalies and identify areas for improvement.

- Quality Control: We analyze quality control data to identify trends and patterns in product defects. This helps us to pinpoint the source of quality issues and implement corrective measures.

- Predictive Maintenance: We use data analysis to predict potential equipment failures, allowing for preventative maintenance to minimize downtime and production losses.

- Inventory Management: Data analysis enables us to optimize inventory levels, reducing waste and improving supply chain efficiency.

- Reporting and Visualization: We use dashboards and reports to visualize key performance indicators (KPIs) and communicate our findings to management and other stakeholders.

By leveraging data analytics, we can make data-driven decisions to enhance operational efficiency, improve product quality, and reduce costs.

Q 27. Explain your understanding of food regulations and compliance.

A thorough understanding of food regulations and compliance is essential for operating a safe and successful food processing business. My expertise encompasses various regulations, including those related to food safety, labeling, and traceability.

- Food Safety Modernization Act (FSMA): I have extensive knowledge of the FSMA regulations and their implementation in our operations, including preventive controls, hazard analysis, and supply chain management.

- Good Manufacturing Practices (GMPs): I am well-versed in GMP guidelines and their application in ensuring the safety and quality of our products. This involves maintaining sanitary facilities, implementing proper hygiene practices, and conducting regular inspections.

- Labeling Regulations: I understand the requirements for accurate and truthful food labeling, including nutritional information, allergen statements, and ingredient declarations.

- HACCP (Hazard Analysis and Critical Control Points): I have extensive experience in developing and implementing HACCP plans to identify and control potential hazards throughout the food processing process.

- Regulatory Compliance: I ensure that our operations are consistently compliant with all applicable federal, state, and local regulations. We conduct regular internal audits and engage third-party auditors for external validation.

Maintaining compliance is not just about avoiding penalties, it’s about protecting public health and building consumer trust. We prioritize compliance as a core value of our business.

Q 28. How do you stay updated with the latest trends and technologies in food processing?

Staying updated with the latest trends and technologies in food processing is crucial for maintaining a competitive edge. I employ several strategies to ensure I remain informed.

- Industry Publications: I regularly read industry journals, magazines, and online publications to stay abreast of new developments in food processing technology and regulatory changes.

- Trade Shows and Conferences: Attending trade shows and conferences provides opportunities to network with industry professionals, learn about new technologies, and gain insights into emerging trends.

- Professional Organizations: Membership in professional organizations like the Institute of Food Technologists (IFT) provides access to valuable resources, networking opportunities, and continuing education programs.

- Online Courses and Webinars: I regularly participate in online courses and webinars to enhance my knowledge and skills in specific areas of food processing.

- Research and Development: I actively participate in research and development activities within our company to explore new technologies and innovative solutions.

Continuous learning is essential in this dynamic industry. By actively seeking new information and participating in professional development activities, I can ensure that our food processing operations remain efficient, safe, and innovative.

Key Topics to Learn for Your Food Processing and Handling Interview

Ace your interview by mastering these essential areas of Food Processing and Handling. Remember, practical application and problem-solving skills are key!

- Food Safety and Hygiene: Understanding HACCP principles, GMPs (Good Manufacturing Practices), and allergen control. Consider how you’d handle a contamination incident or implement a new safety protocol.

- Processing Technologies: Familiarize yourself with various processing methods (e.g., thermal processing, refrigeration, freezing, drying, fermentation) and their applications for different food products. Think about the advantages and disadvantages of each method and how to select the appropriate one for a given product.

- Quality Control and Assurance: Learn about quality control measures, including testing methods, statistical process control, and quality assurance systems (e.g., ISO 22000). Prepare examples demonstrating your ability to identify and solve quality issues.

- Packaging and Storage: Understand different packaging materials and their impact on food preservation. Discuss effective storage practices to maintain product quality and safety. Think about the environmental impact of packaging choices.

- Supply Chain Management: Explore the complexities of food supply chains, including sourcing, transportation, and distribution. Consider how to ensure efficient and safe movement of food products throughout the supply chain.

- Legislation and Regulations: Be aware of relevant food safety regulations and industry standards. Demonstrate your understanding of compliance requirements.

- Waste Management and Sustainability: Discuss environmentally responsible practices within food processing and handling, including waste reduction and recycling strategies.

Next Steps: Unlock Your Career Potential

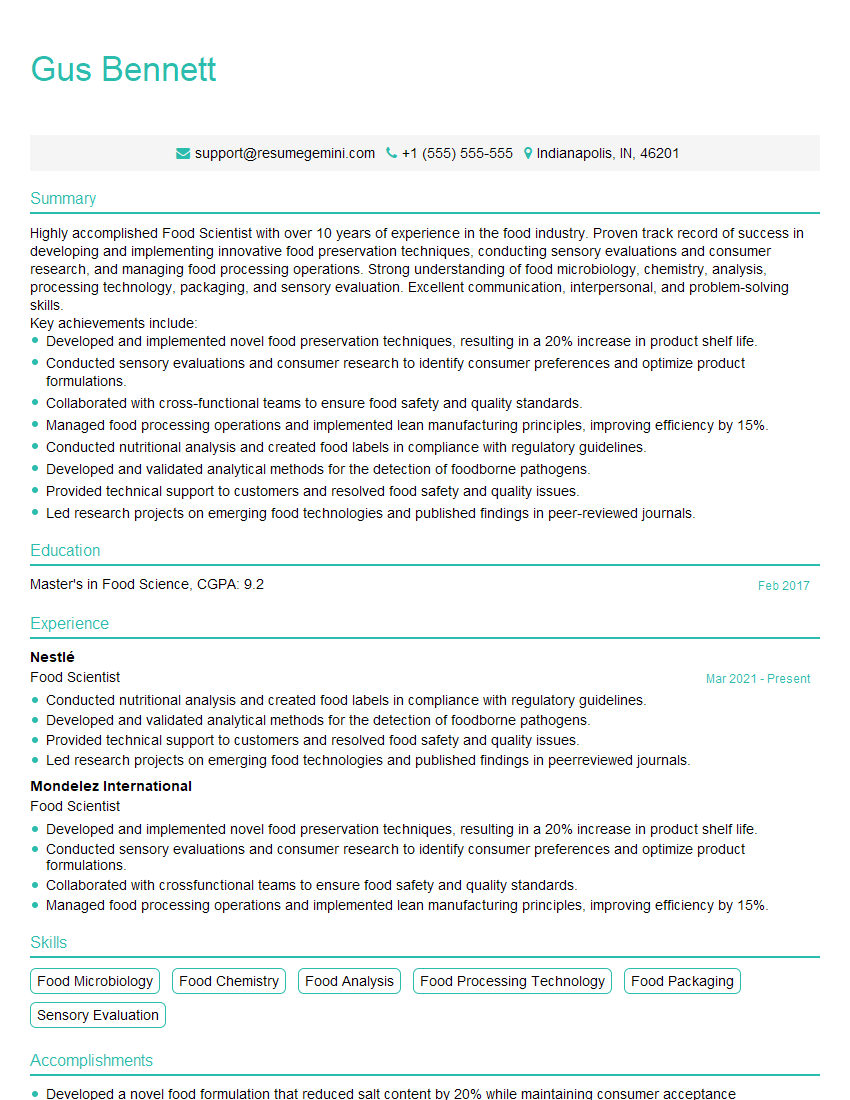

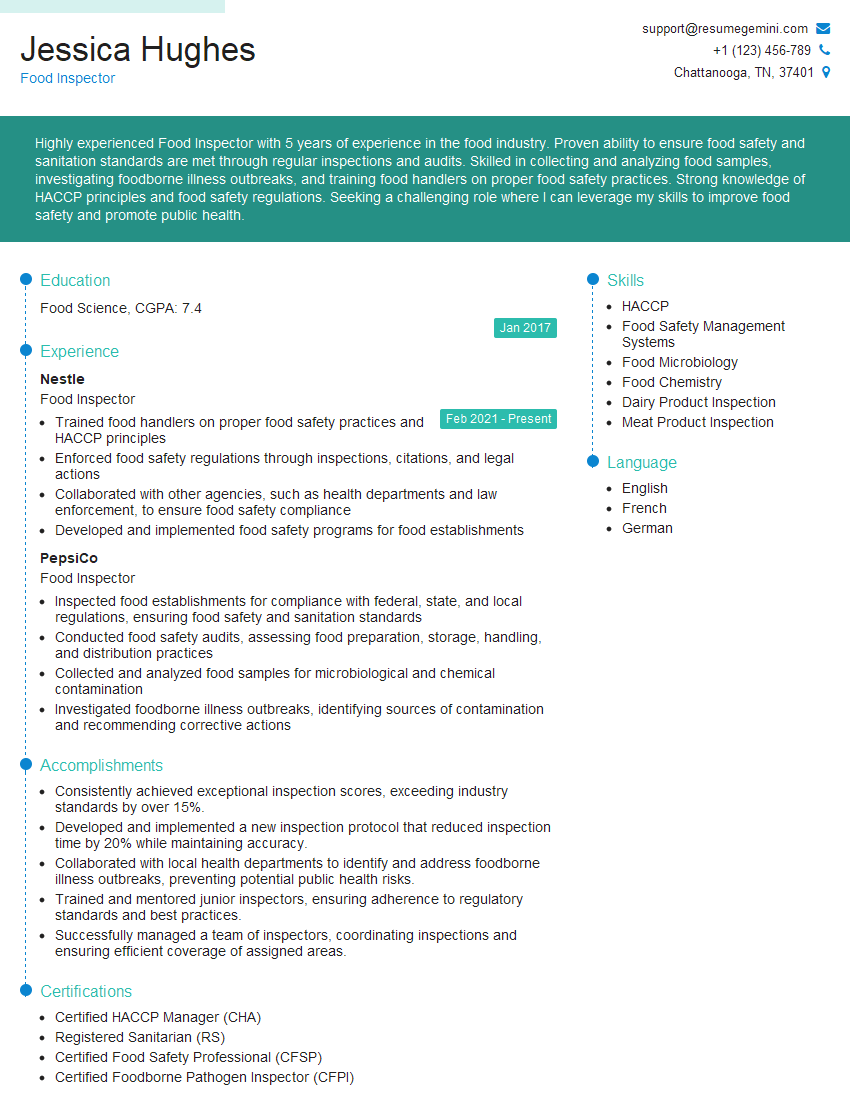

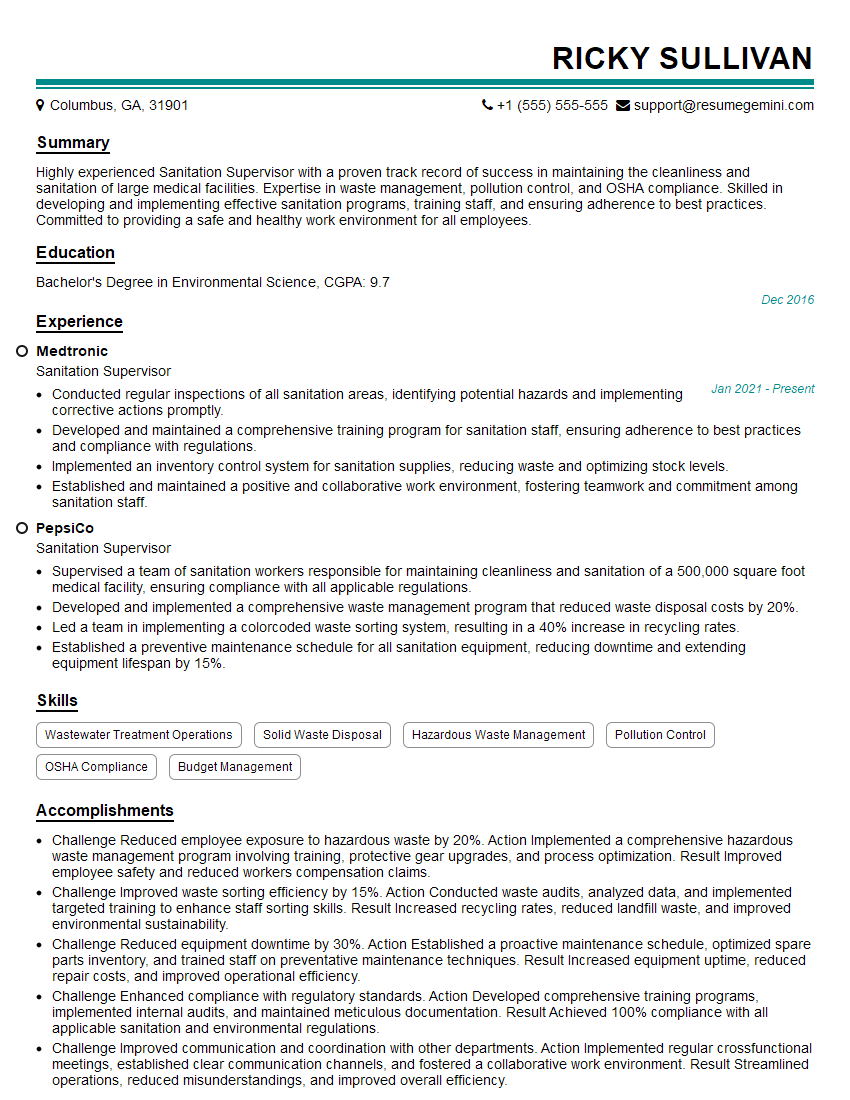

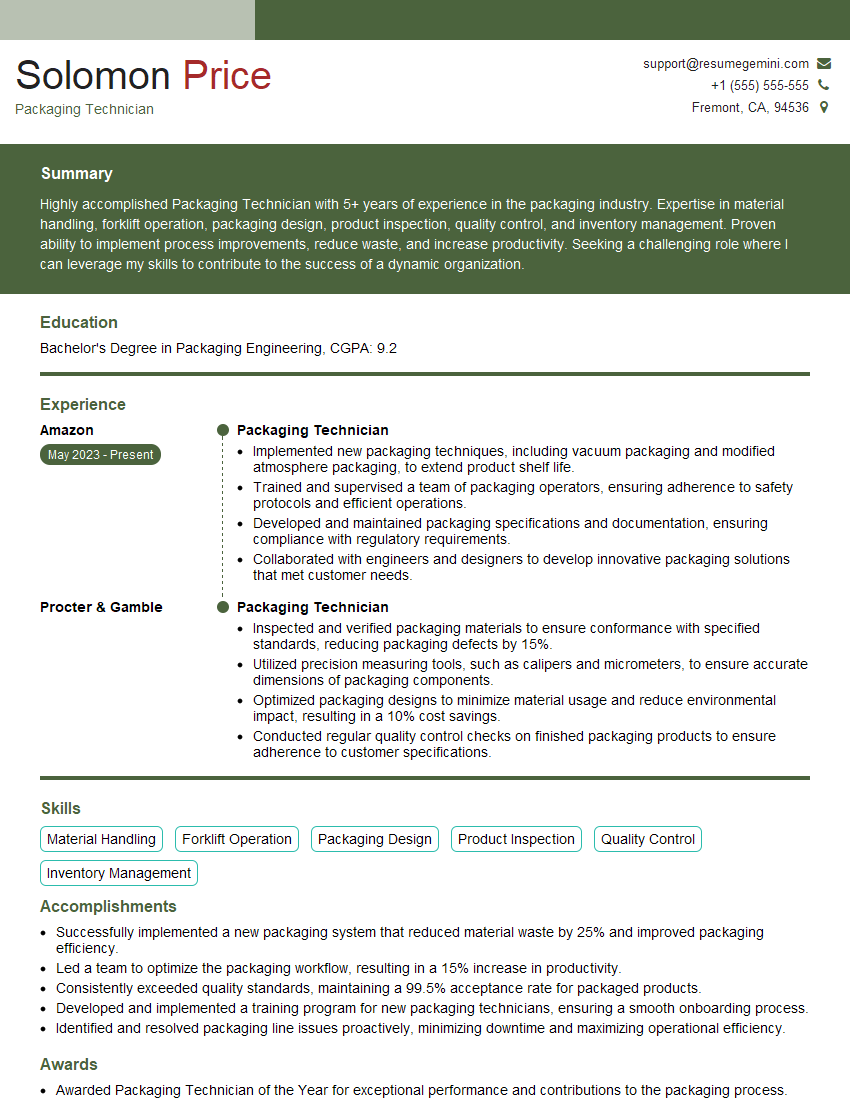

Mastering Food Processing and Handling opens doors to exciting career opportunities. A strong resume is your key to unlocking these possibilities. Creating an ATS-friendly resume is crucial for getting your application noticed by recruiters. To enhance your resume-building experience and increase your chances of landing your dream job, leverage the power of ResumeGemini. ResumeGemini offers a streamlined process for creating professional and effective resumes. Examples of resumes tailored to the Food Processing and Handling industry are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.