Preparation is the key to success in any interview. In this post, we’ll explore crucial Freehub servicing interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Freehub servicing Interview

Q 1. Explain the function of a freehub.

The freehub is the mechanism on your bicycle’s rear wheel that allows the wheel to spin freely when you’re not pedaling, yet engages instantly when you do. Think of it as a sophisticated one-way clutch. When you pedal, the freehub’s pawls (small, spring-loaded components) engage with the ratchet ring, transferring power to the wheel. When you stop pedaling, the pawls disengage, allowing the wheel to coast freely.

This seamless transition between freewheeling and power transmission is crucial for efficient cycling. Without a functioning freehub, you wouldn’t be able to coast, and your rear wheel would lock up when you stop pedaling.

Q 2. Describe the different types of freehubs (e.g., Shimano, SRAM, Campagnolo).

Freehubs are manufactured by different component companies, each with its own design and specifications. The most common types include:

- Shimano: Known for their reliability and wide range of compatibility. Shimano freehubs often utilize a splined connection to the hub body and are categorized by their body type (e.g., HG, FH-M8100). These designations are crucial for selecting the correct freehub body for your specific hub.

- SRAM: SRAM freehubs, like Shimano’s, come in various versions, many of which are XD-driver compatible (for wider-range cassettes). They also use a splined connection and have their own specific body designations.

- Campagnolo: Campagnolo freehubs are generally recognized for their distinctive design and high quality. Their freehub bodies use a specific interface, incompatible with Shimano or SRAM hubs.

The differences between these freehubs are often subtle but significant regarding compatibility and maintenance procedures. Always check your hub and cassette specifications before purchasing a replacement freehub body.

Q 3. What tools are essential for freehub servicing?

Servicing a freehub requires specialized tools. The specific tools will vary depending on the freehub type, but generally, you’ll need:

- Freehub body removal tool: This tool is specific to the freehub manufacturer and model. It’s designed to safely remove the freehub body from the rear hub.

- Freehub cone wrenches: These are used to adjust the end caps and bearings within the freehub.

- Pawl and spring removal tools: Often specialized to the freehub type, these tools help access and remove the pawls and springs for cleaning and inspection.

- Torque wrench: Essential for tightening components to the manufacturer’s specified torque to avoid damage.

- Degreaser: To thoroughly clean the parts of the freehub.

- Lubricant: A high-quality bicycle-specific grease designed for freehubs.

- Small parts tray: Keep all small components organized to prevent loss.

- Precision screwdrivers: May be needed for some freehub body designs.

Q 4. How do you diagnose a faulty freehub?

Diagnosing a faulty freehub involves careful observation and testing. Common symptoms include:

- Clicking or grinding noises: These usually indicate worn pawls, a damaged ratchet ring, or insufficient lubrication.

- Engagement issues: The freehub might not engage smoothly, or may skip or slip under load.

- Freewheeling issues: The wheel may not freewheel smoothly, indicating a binding or sticking freehub.

- Play in the freehub body: Excessive side-to-side movement of the freehub body indicates wear or damage to the bearings.

To test, try spinning the wheel and listening for unusual sounds. Then, apply pressure while pedaling and check for smooth engagement. Note any resistance or play in the freehub body itself.

Q 5. What are the common causes of freehub failure?

Freehub failure often stems from neglect or overuse. The most common causes are:

- Wear and tear: The pawls and ratchet ring wear down over time due to constant engagement and disengagement.

- Lack of lubrication: Insufficient lubrication leads to increased friction, wear, and potential seizing.

- Contamination: Dirt, grit, and water can get into the freehub, accelerating wear and causing damage.

- Over-tightening: Excessive tightening of components can lead to premature wear and damage.

- Impact damage: A hard impact to the wheel can damage the internal components of the freehub.

Regular cleaning and lubrication, along with proper maintenance, can significantly extend the life of your freehub.

Q 6. Explain the process of disassembling a freehub body.

Disassembling a freehub body requires caution and the correct tools. The precise steps vary depending on the manufacturer and model, but here’s a general overview:

- Secure the wheel: Use a wheel stand or clamp to securely hold the wheel.

- Remove the cassette: Use a chain whip and cassette lockring tool to remove the cassette from the freehub body.

- Remove the freehub body: Use the correct freehub body removal tool (specific to the manufacturer and model) to carefully remove the freehub body from the hub.

- Disassemble the freehub: Once removed, carefully disassemble the freehub body, paying attention to the order and position of all parts. Use appropriate tools to remove pawls, springs, and the ratchet ring.

- Clean and inspect: Thoroughly clean all parts with a degreaser, inspect them for wear or damage.

It’s crucial to carefully note the order of disassembly and take pictures as you go. This will make reassembly much easier and prevent mistakes.

Q 7. How do you clean and lubricate a freehub?

Cleaning and lubricating the freehub is vital for its longevity. After disassembling the freehub body:

- Clean thoroughly: Use a degreaser to remove all grease, dirt, and grime from all components. Pay close attention to the pawls, ratchet ring, and bearing races.

- Inspect for wear: Carefully inspect all components for wear or damage. Replace worn or damaged parts.

- Lubricate: Apply a small amount of high-quality bicycle-specific grease to the pawls, ratchet ring, and bearing races. Avoid over-lubrication.

- Reassemble: Carefully reassemble the freehub body in the reverse order of disassembly. Ensure all components are correctly aligned and seated.

- Reinstall: Install the freehub body back onto the hub and re-install the cassette.

Always use the appropriate lubricant for your freehub. Using the wrong grease can attract dirt and impair performance. Regular cleaning and lubrication—at least annually, or more frequently if ridden in wet or muddy conditions—will keep your freehub running smoothly and extend its lifespan.

Q 8. Describe the procedure for replacing freehub pawls.

Replacing freehub pawls is a crucial maintenance task that ensures smooth and reliable engagement of your rear wheel. Pawls are the small components that click into place, driving the cassette and thus your bike forward. This procedure varies slightly depending on the freehub design, but the general steps remain similar.

- Disassemble the freehub: First, you’ll need to remove the freehub body from the rear wheel. This usually involves removing the cassette lockring and then the cassette itself. Then, depending on the freehub design, you may need to remove retaining rings, screws, or even press the freehub body off the axle.

- Access the pawls: Once the freehub is disassembled, you will usually find the pawls held in place by a spring or a retaining mechanism. Carefully remove these to access the individual pawls.

- Inspect the pawls: Before installing new pawls, carefully inspect the existing ones. Look for wear, damage, or any signs of bending. You’ll want to replace any pawls showing significant wear and tear, as even slight imperfections can impact shifting performance.

- Install the new pawls: Install the new pawls, ensuring they are correctly oriented and seated. Pay close attention to the spring mechanism; it’s crucial for proper pawl engagement.

- Reassemble the freehub: Carefully reassemble the freehub, paying attention to the order of components and the proper torque specifications for any bolts or screws. A torque wrench is highly recommended to prevent damage.

- Test the freehub: Once reassembled, spin the wheel and test the engagement. You should hear a distinct and consistent click as the pawls engage. If not, carefully disassemble and recheck your work.

Remember to always consult your freehub’s specific manual for detailed instructions. Improper assembly can lead to damage or failure.

Q 9. How do you check the engagement of a freehub?

Checking freehub engagement is a straightforward process that allows you to quickly assess its health. It reveals whether the pawls are engaging properly, indicating the freehub’s ability to transfer power effectively.

The most basic method involves spinning the rear wheel by hand and then lightly pushing backward on the cassette. You should feel and hear distinct clicks as the pawls engage, preventing backward rotation. The number of clicks, and their consistency, can help assess the health of your freehub. A weak or inconsistent click may indicate worn or damaged pawls. A lack of clicks entirely means the pawls aren’t engaging, necessitating repair. A more precise method is using a dedicated freehub engagement tester, which accurately measures the engagement angle.

For example, if you notice a gritty or hesitant engagement, it might indicate that the pawls are worn, or that the springs are weakened, requiring service. If there’s absolutely no engagement, the pawls are likely damaged or incorrectly installed.

Q 10. What are the signs of worn freehub bearings?

Worn freehub bearings exhibit several telltale signs, often impacting the smooth operation of your rear wheel and potentially leading to premature failure.

- Rough rotation: The wheel feels noticeably gritty or stiff when rotated, indicating friction and increased resistance.

- Noise: You might hear a grinding, clicking, or buzzing sound while spinning the wheel or riding, indicating damage or wear within the bearings.

- Play: Excessive play or looseness in the freehub body, indicating the bearings’ inability to maintain proper support.

- Increased resistance: Noticeably more effort is required to pedal, indicative of friction and resistance due to worn-out bearings.

Imagine the bearings as tiny ball bearings inside a raceway; if these ball bearings are worn or damaged, you’ll experience a noticeable drop in performance, leading to the symptoms above. Early identification and replacement prevent more significant damage to your wheel or freehub.

Q 11. How do you replace freehub bearings?

Replacing freehub bearings is a more involved task than replacing pawls, often requiring specialized tools and some mechanical aptitude. The process is generally similar across different freehub designs, although the specific steps may vary slightly depending on the manufacturer.

- Disassemble the freehub: This step involves removing the freehub body from the wheel, often requiring special tools like cassette lockring tools and sometimes a freehub body removal tool.

- Remove the bearings: Once the freehub is disassembled, you’ll need to remove the old bearings. This might involve using a bearing press or other specialized tool to remove them without damage. Note the orientation of the bearings and any spacers.

- Install new bearings: Using the bearing press or other appropriate tools, carefully install the new bearings, ensuring they are correctly seated and oriented. Again, maintaining the original orientation of spacers is crucial.

- Reassemble the freehub: Carefully reassemble the freehub body, ensuring all components are correctly positioned and tightened to the manufacturer’s specifications. A torque wrench is essential here.

- Test and lubricate: After reassembly, grease the bearings and test the freehub’s operation, ensuring smooth, quiet rotation and consistent engagement.

Remember that using the correct tools and following the manufacturer’s instructions carefully is crucial for success. Forcing components can cause irreversible damage.

Q 12. Explain the process of adjusting freehub preload.

Adjusting freehub preload is critical for optimal performance and longevity. Preload refers to the slight tension applied to the bearings, ensuring they rotate smoothly without play but preventing them from being overly tight, causing unnecessary friction.

The process usually involves using a special adjustment tool or a small wrench to tighten or loosen an adjustment ring or nut on the freehub body. Turning the adjustment ring alters the axial preload on the bearings. Too little preload results in play or looseness, while too much can lead to increased friction and premature bearing wear. The correct preload is usually specified by the manufacturer, sometimes marked on the freehub body itself.

The ideal adjustment point is usually found by achieving a balance: the bearings spin smoothly with a slight amount of resistance, with no discernible play.

Incorrect preload can lead to premature bearing wear and poor engagement, highlighting the importance of precise adjustment. Practice and attention to detail are essential for this task.

Q 13. How do you identify different freehub body styles and compatibilities?

Identifying different freehub body styles and compatibilities is crucial for proper wheel and drivetrain integration. Freehub bodies come in various styles, primarily determined by the cassette spline pattern and mounting system.

Key factors to consider include:

- Cassette compatibility: Different freehub bodies are designed to work with specific cassette spline patterns (e.g., Shimano HG, SRAM XD, Microspline). Using an incompatible cassette can lead to damage.

- Mounting system: Freehub bodies can have different mounting systems, like standard quick-release or thru-axle. The body must be compatible with the rear hub’s system.

- Manufacturer and model: Specific freehub bodies are designed for particular wheel hubs, so compatibility is often dependent on the manufacturer and model number.

Visual inspection and referring to the manufacturer’s specifications are the primary ways to verify compatibility. Using a mismatch can result in significant problems, from poor shifting performance to complete failure.

Q 14. What are the safety precautions when servicing a freehub?

Servicing a freehub involves working with small, precise components and requires careful attention to safety. Here are crucial safety precautions:

- Use appropriate tools: Using the wrong tools can damage components or cause injury. Only use tools specifically designed for the job. Invest in high-quality tools to ensure precision and durability.

- Wear safety glasses: Small parts and debris can fly during disassembly and assembly, posing a risk to your eyes.

- Work in a clean environment: Dirt and grit can contaminate bearings, leading to premature wear and poor performance. A clean workspace is essential for preventing contamination.

- Properly dispose of old components: Old bearings and pawls should be disposed of responsibly, considering their potential environmental impact.

- Consult a professional if uncertain: If you are uncomfortable or unsure about any aspect of the process, consult a professional bicycle mechanic for assistance. Improper service can cause more damage and potentially lead to costly repairs.

By adhering to these safety precautions, you can minimize risks and ensure a smooth and successful freehub service.

Q 15. How do you inspect the freehub for damage after disassembly?

Inspecting a disassembled freehub for damage is crucial for ensuring smooth operation and preventing future issues. Think of it like a thorough car inspection after an accident – you need to check every part carefully.

- Pawls: Examine the pawls for wear, cracks, or bent tips. Bent pawls won’t engage properly, leading to skipping or freewheeling. Look for scoring or significant wear on the pawl contact surfaces.

- Springs: Check the springs for fatigue or breakage. Weak springs won’t provide enough force for reliable engagement. A simple visual inspection is sufficient here, but you may want to check for consistency in spring tension.

- Pawl Springs: Check for wear, corrosion or damage to the springs. These often get overlooked but are crucial to freehub function.

- Freehub Body: Inspect the freehub body for dents, scratches, or excessive wear on the ratchet ring engagement points. Deep scratches could compromise the integrity of the mechanism and lead to premature failure.

- Bearings: Check the bearings for play, roughness, or damage. Rotate them individually to check for smoothness. Excessive play indicates wear and needs replacing. Listen for any unusual noises that could indicate bearing damage.

- Seals: Examine the seals for wear or damage that might allow contaminants to enter. Damaged seals lead to premature bearing wear and failure.

Remember to clean all parts thoroughly before inspection to ensure you don’t miss anything crucial.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the correct type of grease for a freehub?

Choosing the right grease for your freehub is critical for optimal performance and longevity. The wrong grease can attract dirt, harden, or become too thin, leading to premature wear and failure. Imagine trying to lubricate a clock with motor oil – it’s a disaster waiting to happen!

You generally need a high-quality, waterproof grease specifically designed for bicycle hubs. Look for greases with good extreme pressure (EP) additives and a high viscosity suitable for the operating temperature range. The grease should be compatible with the materials used in your freehub (typically steel and aluminum).

Many reputable manufacturers offer greases specifically for bicycle hubs. Reading the grease’s specifications is crucial to ensure compatibility and performance. Some good options include Phil Wood Tenacious Grease, Park Tool Polylube 1000, and other similar premium bicycle hub greases.

Avoid using general-purpose greases, as these often lack the necessary properties for bicycle components and might harm seals or bearings.

Q 17. How to remove a seized freehub?

Removing a seized freehub can be challenging, but with the right tools and techniques, it’s manageable. Imagine trying to unscrew a rusty bolt – you need the right approach to avoid damage.

- Penetrating Oil: Apply a generous amount of penetrating oil (like PB Blaster or similar) to the freehub body threads. Let it soak for several hours or even overnight to help break down corrosion.

- Heat: Carefully apply heat to the freehub body using a heat gun or propane torch. This helps expand the metal and break the bond between the seized components. Be cautious not to overheat the components, which could damage them.

- Proper Tools: Use the correct freehub removal tool for your specific hub model. Improper tools can easily damage the hub or freehub body.

- Torque Wrench: Apply even pressure when attempting to remove the freehub. A torque wrench is preferable to avoid stripping the threads.

- Impact Driver: As a last resort, a high-quality impact driver might be employed. But proceed with extreme caution to avoid damaging threads or the freehub body.

If you’re unable to remove the freehub yourself, consult a professional bicycle mechanic.

Q 18. Describe how to handle a freehub with a damaged body.

A damaged freehub body typically requires replacement. Think of it like a cracked engine block – you can’t simply patch it up and expect it to work reliably.

Attempting to repair a damaged freehub body is usually not worthwhile. The forces exerted on a freehub body during use are substantial, and a compromised body can lead to catastrophic failure.

The best course of action is to replace the freehub body with a new one. Ensure you purchase a compatible replacement for your specific hub model. Attempting to use an incompatible part can lead to further damage or even injury.

Q 19. What are the consequences of improper freehub servicing?

Improper freehub servicing can have several negative consequences, leading to anything from minor annoyances to catastrophic failure. Think of it like neglecting regular car maintenance – eventually, something will break down.

- Premature Wear: Inadequate lubrication or the use of improper grease can significantly accelerate the wear of pawls, springs, and bearings, leading to premature replacement costs.

- Freewheeling: Incorrect adjustment or damage during servicing can cause the freehub to skip or not engage properly, resulting in a loss of power while pedaling.

- Noise: Worn or damaged components can create excessive noise, from a subtle ticking to a loud clunking sound.

- Failure: In severe cases, an improperly serviced freehub might completely fail, leading to a sudden loss of drive and potentially causing an accident.

Q 20. How to prevent premature freehub wear?

Preventing premature freehub wear involves a combination of regular maintenance, proper cleaning, and mindful riding habits. Think of it like taking good care of your teeth – regular brushing and flossing prevent problems down the road.

- Regular Cleaning: Regularly clean your drivetrain, paying particular attention to the freehub area, to remove dirt and grit. A simple degreaser and brush will help remove mud, dust, and grime.

- Proper Lubrication: Use the correct type and amount of grease during servicing, ensuring proper lubrication of all components.

- Avoid Harsh Conditions: Minimize exposure to extreme conditions, like mud, water, and sand, as these can accelerate wear and damage. Regularly wash and lubricate your bike after exposure to these conditions.

- Regular Servicing: Schedule regular professional servicing of your freehub to catch potential issues early and prevent catastrophic failures.

Q 21. What’s the difference between a freehub and a cassette?

The freehub and cassette are distinct but related components in a bicycle’s drivetrain. Think of them as two pieces of a larger puzzle, both essential for function but distinctly different parts.

The cassette is the cluster of gears attached to the freehub. It’s the part you shift to change gears.

The freehub is the mechanism inside the rear hub that allows the wheel to spin freely when you’re not pedaling and engages to drive the wheel when you are. It’s the mechanism that directly interacts with the cassette. The cassette is mounted onto the freehub body.

In short, the cassette provides the gearing, while the freehub allows for freewheeling and power transmission.

Q 22. How to choose the correct replacement parts for a freehub?

Choosing the correct replacement parts for a freehub is crucial for its proper function and longevity. It’s like choosing the right parts for a car engine – using incorrect parts can lead to damage or failure.

- Identify your freehub type: First, you need to determine the exact model and manufacturer of your freehub. This information is usually found etched onto the freehub body itself. Different manufacturers (Shimano, SRAM, DT Swiss, etc.) use different designs, even within the same hub type (e.g., Shimano HG, Shimano Microspline).

- Match specifications: The replacement parts must match the original specifications precisely. This includes the number of pawls, the type of pawls, the spring configuration, the spline count, and the overall dimensions. A simple misalignment can lead to catastrophic failure.

- Source reputable suppliers: Purchase parts from reputable bicycle part suppliers or authorized dealers to ensure authenticity and quality. Counterfeit parts may seem cheaper upfront, but often compromise durability and performance.

- Consider wear and tear: When ordering parts, think about the overall condition of your freehub. Replacing just one worn part without checking the others might only solve a problem temporarily. If you’re replacing the pawls, it’s often a good idea to replace the springs as well, since they tend to wear down together.

For example, replacing a Shimano HG freehub body with a SRAM XD freehub body wouldn’t work – the cassette splines are incompatible.

Q 23. Explain the importance of torque specifications when servicing a freehub.

Torque specifications are paramount when servicing a freehub. Over-tightening can strip threads, damage components, or even cause the freehub body to crack. Under-tightening, conversely, can lead to loose parts and eventual failure, possibly even causing a crash. It’s like assembling a delicate clock – every component must be in the right place and tightened with precision.

Always consult the manufacturer’s instructions or a reputable workshop manual for the correct torque specifications for each component. This information is usually expressed in Newton-meters (Nm). Using a calibrated torque wrench is essential to avoid both over-tightening and under-tightening. Many freehub bodies are made of lightweight materials that are easily damaged.

For instance, the torque required to tighten a freehub body onto the hub shell will differ significantly from the torque required to tighten the pawls to the freehub body. Using the wrong torque can cause problems ranging from annoying clicking to catastrophic failure.

Q 24. How do you ensure proper alignment after freehub servicing?

Ensuring proper alignment after freehub servicing is crucial for smooth operation and longevity. Misalignment can cause premature wear, noise, and potential failure. It’s like aligning the wheels of a car – if they’re out of alignment, you’ll experience uneven tire wear and poor handling.

- Clean the interfaces: Carefully clean all mating surfaces of the freehub body and hub shell before reassembly. Any debris can prevent proper alignment.

- Visual Inspection: Carefully examine the freehub body and hub shell for any damage or deformation. These can prevent proper seating and cause misalignment.

- Careful installation: Install the freehub body carefully and evenly, avoiding any forcing or undue pressure.

- Check for play: Once installed, check for any radial or axial play in the freehub body. Excessive play indicates misalignment. If play is present, loosen the freehub body and carefully re-install.

- Final Torque Check: Once you have confirmed the freehub is properly seated and without play, perform a final torque check using your calibrated torque wrench to ensure the specified torque has been applied.

Q 25. What are the common problems associated with different freehub types?

Different freehub types have their own set of common problems. Understanding these is key to effective troubleshooting. It’s similar to understanding the specific issues that might plague different car engines – a diesel engine has different issues than a gasoline engine.

- Pawl and Spring Wear: This is a common problem in all freehub types. Pawls can wear down, becoming rounded, leading to engagement issues and clicking noises. Springs can lose tension, resulting in poor engagement and slipping.

- Bearing Failure: Bearings in freehubs are subjected to significant stress, and failure can manifest as roughness, noise, and increased resistance when pedaling.

- Spline Damage: This is more prevalent in certain types like Shimano HG or SRAM XD. Damaged splines can lead to cassette slippage or inability to install the cassette correctly.

- Seal Degradation: In cartridge bearing freehubs, seal failure can lead to water and dirt ingress, contaminating the bearings and ultimately causing premature wear. This is especially crucial for freehubs exposed to wet conditions.

For example, Shimano HG freehubs are known for potential issues with their pawl springs losing tension over time, while SRAM XD freehubs are sometimes prone to spline damage due to the high clamping forces required for wider cassette bodies.

Q 26. How do you troubleshoot a freehub that’s making noise?

Troubleshooting a noisy freehub requires a systematic approach. It’s like diagnosing a car engine issue – you need to methodically check various components.

- Identify the type of noise: Is it a clicking sound, a grinding noise, or a whirring sound? Different noises indicate different problems.

- Check pawl engagement: Inspect the pawls and springs for wear. If the pawls are worn or the springs are weak, they won’t engage properly, leading to noise.

- Inspect bearings: Check for roughness, play, or noise in the bearings. If the bearings are damaged, they’ll likely cause whirring, grinding, or clicking noises.

- Examine freehub body for damage: Check for cracks or damage to the freehub body itself, as this could contribute to noise generation.

- Check for proper cassette installation: Incorrect cassette installation can also result in noise.

- Clean the freehub body: Dirt and debris can also cause clicking sounds. Cleaning the freehub body thoroughly can sometimes resolve the issue.

For example, a clicking noise usually indicates pawl or spring issues, while a grinding noise suggests bearing problems.

Q 27. Describe the process for reassembling a freehub body.

Reassembling a freehub body requires careful attention to detail and the correct procedure. It’s a bit like assembling a complex puzzle, where each piece has a specific place and orientation.

- Clean all components: Thoroughly clean all parts using a degreaser and a suitable brush. Ensure everything is completely dry before reassembly.

- Inspect for damage: Inspect all parts for damage, wear, and tear. Replace worn or damaged parts.

- Grease bearings (if applicable): Apply a suitable grease to the bearings, ensuring even distribution.

- Install pawls and springs: Install the pawls and springs carefully, making sure they’re correctly seated and oriented.

- Install seals (if applicable): Install the seals correctly, ensuring they’re properly seated.

- Install the freehub body: Carefully install the freehub body onto the hub shell, ensuring it’s properly aligned.

- Tighten to correct torque specifications: Tighten the freehub body to the manufacturer’s specified torque using a calibrated torque wrench.

Q 28. What are some advanced techniques used in freehub servicing?

Advanced freehub servicing techniques often involve specialized tools and knowledge. These techniques are not for the beginner mechanic. Think of it as the difference between basic car maintenance and engine rebuilding – both are related but require different skill sets.

- Ultrasonic Cleaning: This technique removes microscopic contaminants from the freehub components, ensuring optimal performance and longevity.

- Bearing Inspection and Replacement Using Specialized Tools: Advanced tools allow for precise inspection of bearings, enabling the mechanic to identify micro-pitting and other subtle signs of wear that might go unnoticed during standard inspection.

- Precision Measurement of Component Dimensions: Using precision measuring tools to ensure components are within tolerance can make all the difference in performance and longevity.

- Advanced Lubrication Techniques: Selecting and applying specialized lubricants optimized for the bearing material and operating conditions can dramatically improve performance and durability.

- Pawl Modification (for high-end applications): In specific cases, experienced mechanics may modify pawls (e.g., polishing) to optimize engagement and performance but this is highly specialized and should be done with extreme care.

Key Topics to Learn for Freehub Servicing Interview

- Freehub Body Disassembly and Reassembly: Understanding the intricacies of different freehub body designs (e.g., Shimano, SRAM, DT Swiss), proper tool usage, and torque specifications for optimal performance and longevity.

- Bearing Inspection and Replacement: Identifying bearing wear and damage, selecting appropriate replacement bearings, and mastering the techniques for efficient and precise bearing installation and adjustment.

- Pawl and Spring Inspection and Replacement: Recognizing worn or damaged pawls and springs, understanding their function in engagement, and performing accurate replacements to ensure smooth and reliable engagement.

- Cleaning and Lubrication: Mastering proper cleaning techniques to remove debris and contaminants, and selecting appropriate lubricants for optimal performance and reduced friction.

- Troubleshooting Common Freehub Issues: Diagnosing problems such as noisy engagement, skipping, or lack of engagement, and effectively implementing solutions.

- Understanding Different Freehub Mechanisms: Gaining a thorough understanding of various freehub systems (e.g., ratchet, pawl, and clutch mechanisms) and their operational principles.

- Tool Selection and Usage: Demonstrating proficiency in selecting and using specialized tools required for efficient and precise freehub servicing.

- Safety Procedures: Understanding and adhering to all safety protocols while handling tools and components.

Next Steps

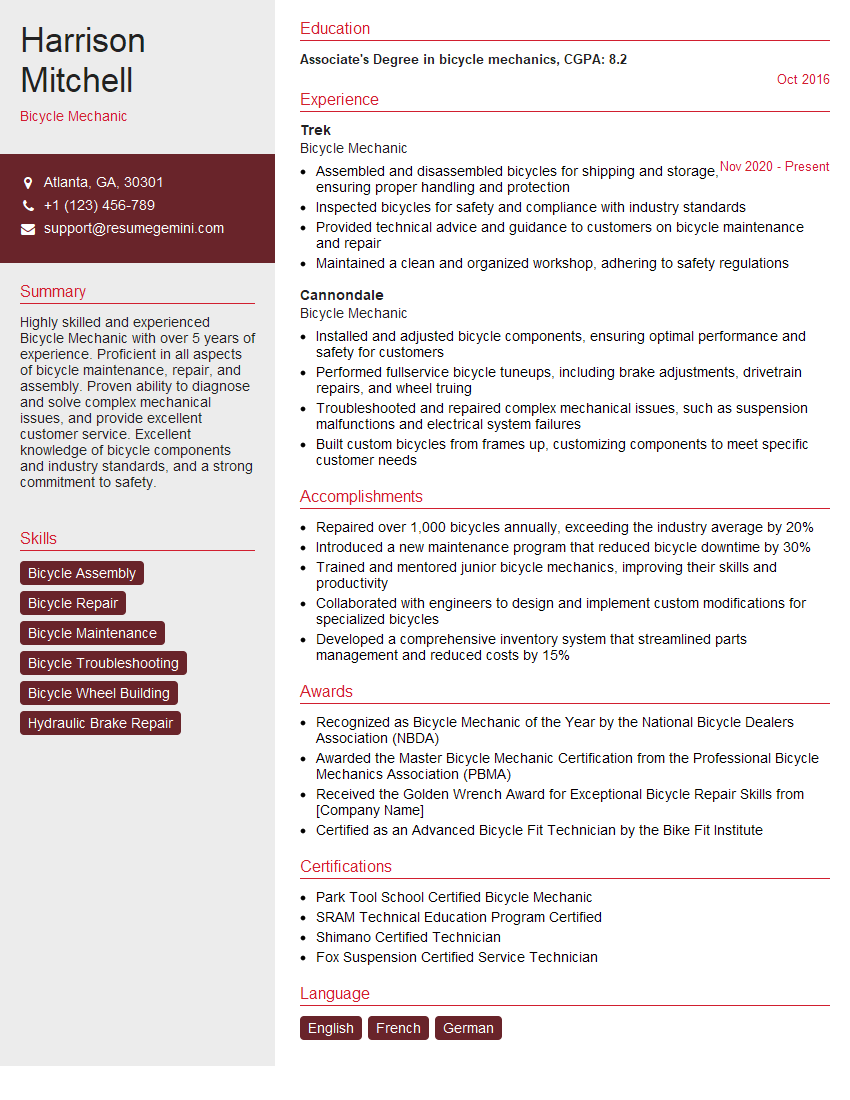

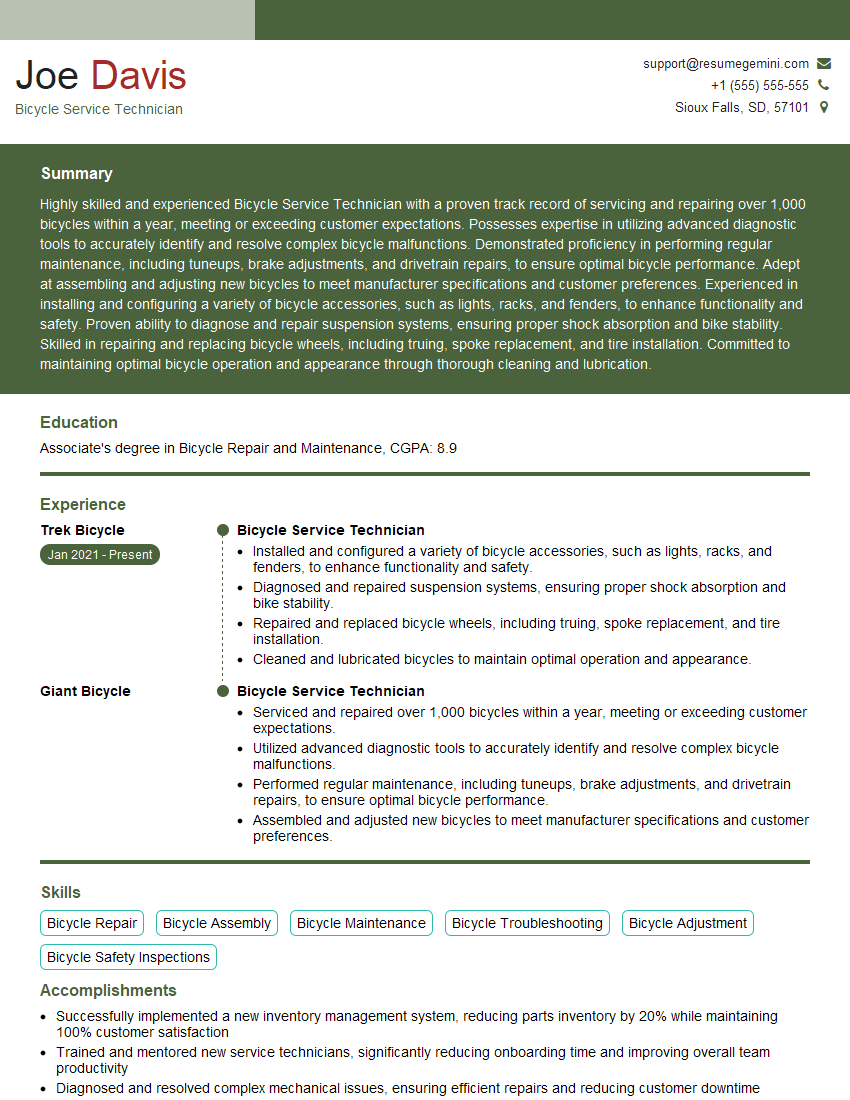

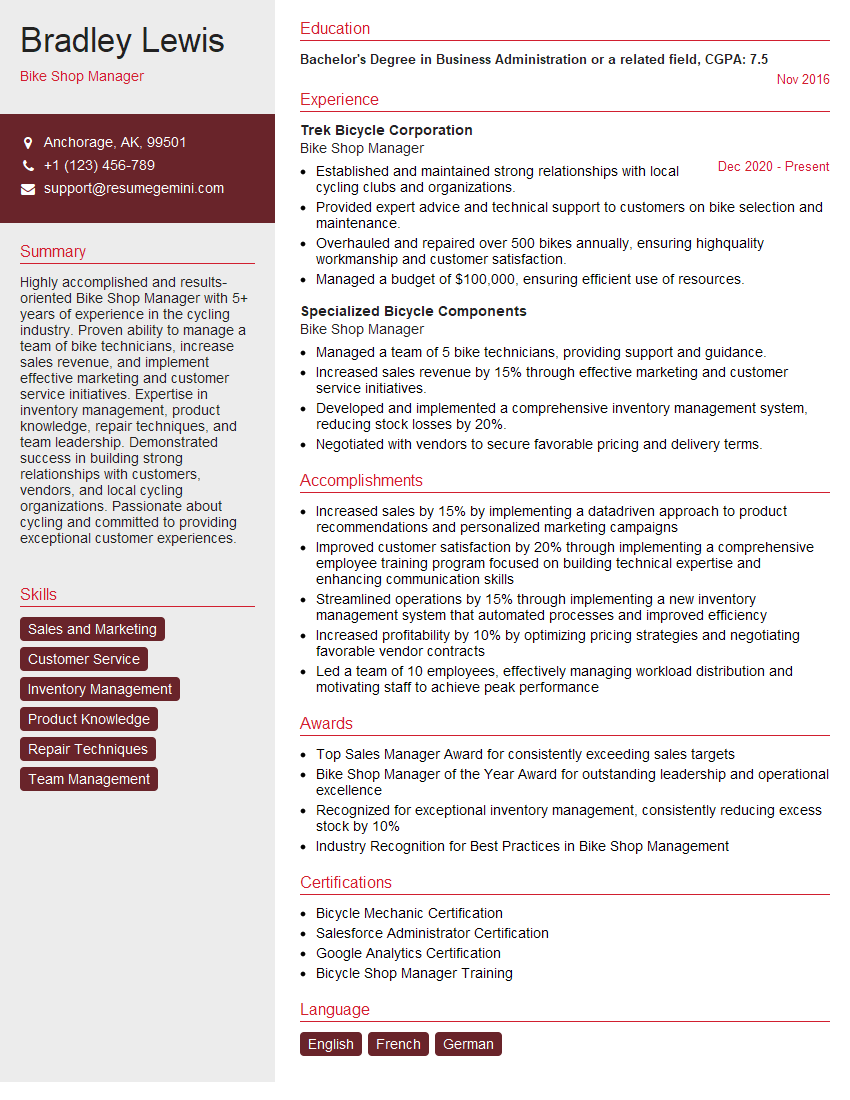

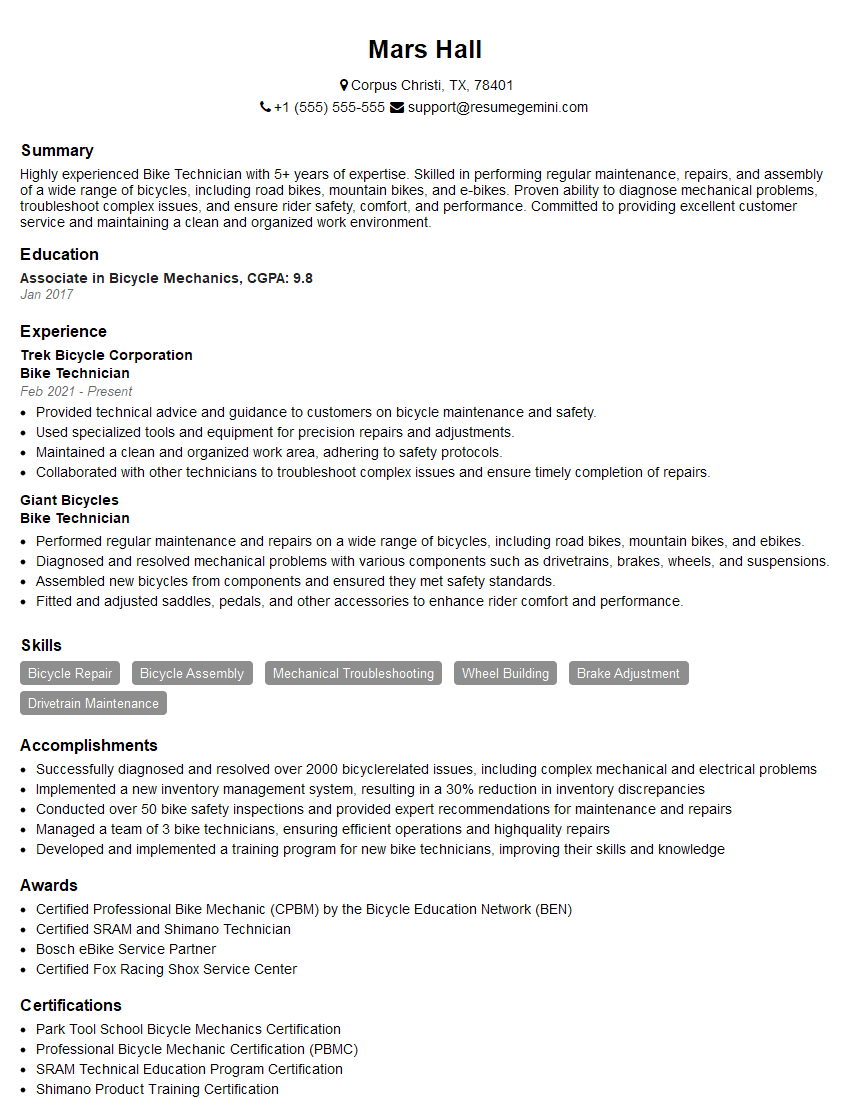

Mastering freehub servicing opens doors to specialized roles within the bicycle industry, enhancing your skillset and making you a highly valuable asset to any team. To increase your chances of landing your dream job, crafting an ATS-friendly resume is crucial. ResumeGemini can help you build a professional and impactful resume that highlights your expertise. ResumeGemini offers a streamlined approach to resume creation, helping you showcase your skills effectively. Examples of resumes tailored to Freehub servicing are available within the ResumeGemini platform to further assist your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO