Preparation is the key to success in any interview. In this post, we’ll explore crucial Fuel Handling Equipment Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Fuel Handling Equipment Operation Interview

Q 1. Describe your experience with different types of fuel handling equipment.

My experience encompasses a wide range of fuel handling equipment, from basic hand pumps and drum fillers to sophisticated automated systems. I’ve worked extensively with:

- Tank trucks: I’m proficient in operating and maintaining various types, including those with bottom loading, top loading, and vacuum systems. I understand the importance of pre-trip inspections, ensuring proper grounding and bonding to prevent static electricity buildup, and adhering to strict loading and unloading procedures.

- Fuel dispensers: I have experience with both manual and automated dispensers, including those used in industrial settings and retail fuel stations. This includes calibrating equipment, troubleshooting malfunctions, and implementing preventative maintenance to ensure accurate dispensing and prevent leaks.

- Pumps and transfer systems: I’m familiar with centrifugal pumps, positive displacement pumps, and various piping systems used for fuel transfer. This includes understanding the implications of different pump types on fuel flow rate, pressure, and the potential for cavitation.

- Fuel storage tanks: I understand the safety procedures and regulations surrounding the operation and maintenance of above-ground and underground fuel storage tanks, including tank gauging, leak detection, and overfill prevention.

This diverse experience allows me to adapt quickly to different fuel handling environments and equipment.

Q 2. Explain the safety procedures you follow when handling fuel.

Safety is paramount in fuel handling. My safety procedures are meticulous and follow established industry best practices. They include:

- Pre-operation checks: Before starting any task, I perform thorough inspections of equipment to identify and address potential hazards. This includes checking for leaks, ensuring proper grounding, and verifying the integrity of hoses and connections.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including flame-resistant clothing, safety glasses, gloves, and hearing protection. The specific PPE used depends on the task and the type of fuel being handled.

- Spill prevention and response: I’m trained in spill response procedures, including the use of spill containment materials and proper cleanup techniques. I understand the importance of quickly containing any spill to minimize environmental impact and prevent fire hazards.

- Emergency procedures: I’m familiar with emergency shutdown procedures for equipment and know how to react to emergencies like fires or injuries. This includes knowing the location of fire extinguishers, emergency shut-off valves, and communication protocols.

- Lockout/Tagout (LOTO): When performing maintenance or repairs, I strictly adhere to LOTO procedures to prevent accidental start-ups and injuries.

Safety is not just a set of procedures; it’s a mindset. I approach every task with a proactive, safety-first attitude.

Q 3. How do you ensure the accurate measurement of fuel during transfer?

Accurate fuel measurement is crucial for inventory management and cost control. I employ several methods to ensure accuracy:

- Calibrated meters: I regularly check and calibrate fuel dispensers and meters to ensure they are within acceptable tolerances. This involves using standardized testing procedures and maintaining detailed calibration records.

- Tank gauging: For larger storage tanks, I use level gauges and automated tank gauging systems to accurately determine the fuel level. I understand the limitations of different gauging methods and choose the most appropriate technique for the situation.

- Manual measurement: For smaller quantities, I use calibrated measuring containers or hand-held flow meters to ensure accurate dispensing. I double-check measurements to eliminate human error.

- Data recording: All fuel transfers are meticulously documented, recording the starting and ending readings, the volume transferred, the date, time, and the equipment used. This provides a complete audit trail.

Through these methods, I maintain a high degree of accuracy in fuel measurement, minimizing discrepancies and improving operational efficiency.

Q 4. What are the common causes of fuel spills and how do you prevent them?

Fuel spills are a significant safety and environmental concern. Common causes include:

- Equipment malfunction: Faulty pumps, leaks in hoses or fittings, and damaged tank seals can all contribute to spills.

- Human error: Overfilling tanks, improper handling of hoses, and neglecting pre-operation checks are common human errors leading to spills.

- External factors: Acts of vandalism, natural disasters, and vehicle accidents can also cause fuel spills.

To prevent spills, I focus on:

- Regular maintenance: Routine inspections and maintenance of equipment are crucial to identify and rectify potential leaks before they become problems.

- Proper training: All personnel involved in fuel handling are adequately trained on safe operating procedures and emergency response.

- Spill prevention measures: Using secondary containment systems, overfill prevention devices, and proper grounding and bonding helps mitigate spill risks.

- Emergency response plan: A well-defined emergency response plan outlines procedures for containing and cleaning up spills, minimizing environmental impact and preventing further incidents.

A proactive approach to spill prevention, combined with proper training and equipment maintenance, dramatically reduces the likelihood of spills.

Q 5. Describe your experience with fuel quality control and testing procedures.

Fuel quality control is essential for engine performance and equipment longevity. My experience includes:

- Visual inspection: I regularly inspect fuel for clarity, presence of water or sediment, and unusual coloration. Changes in appearance can indicate contamination or degradation.

- Testing: I’m trained in using various testing equipment to analyze fuel properties, such as specific gravity, flashpoint, and water content. I understand the significance of these parameters and how they relate to fuel quality and engine performance.

- Sampling techniques: I’m proficient in using appropriate sampling methods to obtain representative fuel samples for testing. This is critical to ensure that the test results accurately reflect the quality of the fuel in the tank.

- Documentation: All fuel quality testing results are meticulously documented, including the date, time, location, and the results of each test. This information helps track fuel quality over time and identify potential problems.

Maintaining fuel quality not only protects equipment but also ensures smooth and efficient operations.

Q 6. How do you handle emergencies, such as fuel leaks or equipment malfunctions?

In case of emergencies, my response is swift and follows a structured protocol:

- Assess the situation: I quickly assess the nature and extent of the emergency, identifying immediate threats and potential hazards.

- Activate emergency procedures: Depending on the nature of the emergency (fuel leak, equipment malfunction, fire), I follow established emergency procedures. This might involve shutting down equipment, contacting emergency services, or initiating spill containment measures.

- Secure the area: I evacuate personnel from the immediate vicinity and ensure the area is secured to prevent further incidents or injuries.

- Follow safety protocols: Throughout the emergency, I strictly adhere to safety protocols, prioritizing the safety of myself and others.

- Post-incident analysis: After the emergency has been resolved, I participate in a post-incident analysis to identify the root cause, learn from the experience, and implement corrective actions to prevent future occurrences.

Effective emergency response requires training, preparation, and a clear understanding of safety protocols. My experience in handling various emergency situations has equipped me with the skills to effectively manage such events.

Q 7. Explain your understanding of fuel storage and handling regulations.

My understanding of fuel storage and handling regulations is comprehensive and encompasses local, state, and federal guidelines. I’m familiar with regulations related to:

- Storage tank design and construction: I know the standards for above-ground and underground storage tanks, including requirements for leak detection, overfill prevention, and corrosion protection.

- Spill prevention and control: I’m versed in regulations related to spill prevention, containment, and cleanup, including the use of secondary containment and emergency response plans.

- Environmental protection: I understand the environmental regulations governing the handling and disposal of fuel, including the requirements for preventing groundwater contamination and air emissions.

- Worker safety: I’m familiar with regulations related to worker safety and training, including requirements for personal protective equipment (PPE), hazard communication, and lockout/tagout (LOTO) procedures.

- Record keeping: I know the importance of maintaining accurate records of fuel transactions, testing results, maintenance activities, and emergency responses, as required by regulatory agencies.

Compliance with these regulations is critical not only to avoid penalties but also to ensure the safety of personnel and the protection of the environment. I prioritize adherence to all applicable regulations.

Q 8. What is your experience with different types of fuel dispensing nozzles?

My experience encompasses a wide range of fuel dispensing nozzles, from the common automatic nozzles used in everyday refueling to specialized nozzles for aviation fuel or specific fuel types with additives. I’m familiar with the variations in nozzle designs, including those with vapor recovery systems to minimize emissions, and those designed for different flow rates and pressure requirements. For instance, I’ve worked extensively with nozzles designed for high-volume dispensing at truck stops, which have different safety features and flow control mechanisms compared to nozzles for smaller vehicles. I also have experience troubleshooting malfunctioning nozzles, identifying issues like leaks or faulty shut-off mechanisms, and performing necessary repairs or replacements.

- Automatic Nozzles: These are the most common type, featuring a spring-loaded mechanism that automatically shuts off when the tank is full.

- Breakaway Nozzles: Designed to detach from the vehicle in case of accidental pulling or vehicle movement, preventing damage and spills.

- Specialty Nozzles: These are engineered for specific fuels (like aviation fuels) and have features addressing unique handling requirements (e.g., anti-static properties).

Q 9. How do you ensure the compatibility of fuel with different equipment?

Ensuring fuel compatibility is paramount to preventing damage to equipment and ensuring operational safety. This involves a multi-step process. First, I always verify the type of fuel required by the equipment through its specifications or manuals. Then, I meticulously check the fuel being dispensed to ensure it matches these specifications. This often involves checking labels on fuel storage tanks and delivery trucks. Incompatible fuels can cause significant damage, from engine failure to corrosion of fuel lines and storage tanks. For example, mixing gasoline and diesel fuel can lead to engine damage due to incompatible combustion properties. Incorrect fuel usage may require extensive cleaning or component replacement, leading to costly downtime. Therefore, careful cross-checking and adherence to manufacturer’s guidelines are always my top priority.

Q 10. Describe your experience with maintaining fuel handling equipment.

My maintenance experience includes regular inspections of all fuel handling equipment, which encompasses visual checks for leaks, corrosion, and damage, as well as functional tests to ensure proper operation of pumps, meters, and nozzles. I’m proficient in performing routine maintenance tasks such as filter changes, lubrication, and cleaning. I’m also well-versed in troubleshooting common malfunctions, like identifying and repairing leaks in hose assemblies or replacing faulty pressure sensors. I utilize preventative maintenance schedules to reduce the risk of equipment failure, and always document all maintenance activities and findings. For example, regular cleaning of fuel filters prevents blockages and ensures efficient fuel flow, while proper lubrication of pumps minimizes friction and wear.

Q 11. What are the signs of contaminated fuel and how do you address them?

Contaminated fuel can have serious consequences. Signs of contamination include discoloration (e.g., cloudy or off-color fuel), the presence of water (often visible as a separate layer), sediment at the bottom of tanks, or an unusual odor. Addressing contamination requires immediate action. First, I isolate the contaminated fuel supply to prevent further contamination. Depending on the type and extent of contamination, I might need to filter the fuel, treat it with additives to remove water, or replace the entire fuel supply. In severe cases of contamination, a complete system flush may be necessary. Documentation of the contamination event, including the source, extent of contamination, and remediation steps, is crucial for future preventative measures.

Q 12. How do you manage fuel inventory and track fuel usage?

Fuel inventory management and usage tracking are handled using a combination of methods. We utilize tank gauging systems, which provide real-time readings of fuel levels in storage tanks. Delivery receipts and purchase orders meticulously track fuel acquisitions. Fuel dispensing systems often incorporate digital meters that record the amount of fuel dispensed for each transaction. This data is then compiled and analyzed to create accurate reports on fuel usage, identifying trends and helping predict future fuel needs. We also perform regular reconciliation checks to ensure the accuracy of inventory records and to detect any discrepancies. This data is vital for cost control, forecasting, and ensuring smooth operational continuity. Discrepancies are investigated thoroughly to uncover potential loss or theft.

Q 13. What are the different types of fuel storage tanks and their safety features?

Fuel storage tanks come in various types, including aboveground storage tanks (ASTs) and underground storage tanks (USTs). ASTs are typically made of steel or fiberglass and are situated above ground. USTs, as the name suggests, are buried underground and are usually made of steel with corrosion-resistant coatings. Safety features are critical and vary depending on the type and location. These include: overfill prevention devices, spill containment systems, leak detection systems, venting systems to prevent pressure buildup, and emergency shut-off valves. Regular inspections and maintenance are crucial to ensure that these safety features remain functional and prevent accidents like spills or leaks. USTs, in particular, are subject to stringent regulations due to their potential for groundwater contamination.

Q 14. Explain the process of connecting and disconnecting fuel hoses.

Connecting and disconnecting fuel hoses requires careful attention to safety. Before connecting, I always ensure the nozzle and hose are compatible with the fuel type and the receiving tank. I visually inspect the hose and nozzle for any signs of damage or leaks. The connection process involves aligning the nozzle and coupling, then firmly securing the connection. To disconnect, I always release the pressure in the hose and then carefully separate the nozzle from the coupling. I then inspect the connection points for any leaks and address any issues immediately. Proper handling is essential to prevent spills and to protect both personnel and equipment from potential hazards. Safety measures such as using gloves and eye protection are always followed. In addition to standard procedures, I’m familiar with emergency procedures for dealing with hose failures or spills.

Q 15. How do you prevent static electricity buildup during fuel handling?

Preventing static electricity buildup during fuel handling is crucial for safety. Static electricity discharge can ignite flammable fuel vapors, leading to fires or explosions. We mitigate this risk through several key methods:

- Bonding and Grounding: This is the most effective technique. We use conductive straps or chains to connect all fuel handling equipment and containers to a common ground point. This equalizes the electrical potential, preventing a spark from forming. Think of it like a lightning rod for your fuel system – it provides a safe path for any stray electricity to dissipate.

- Using Static-Dissipative Hoses and Equipment: Many hoses and equipment are now manufactured with special materials that help dissipate static charges gradually, minimizing the risk of sudden discharge. These materials are often identified by specific markings or certifications.

- Controlling the Environment: Maintaining a humid environment can reduce static buildup. Dry air is a major contributor to static electricity. In some cases, we might use humidifiers in fuel storage or handling areas.

- Proper Training: All personnel involved in fuel handling receive rigorous training on static electricity prevention measures. This includes understanding the risks, identifying potential sources of static, and following established procedures. For instance, we’re trained to avoid using nylon clothing near fuel due to its high static-generating potential.

A real-world example: During a bulk fuel transfer, I once noticed a hose wasn’t properly grounded. I immediately stopped the operation and ensured proper grounding before resuming, preventing a potential hazard. Safety is paramount.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using personal protective equipment (PPE) while handling fuel.

Personal Protective Equipment (PPE) is non-negotiable in fuel handling. My experience includes consistent use of:

- Flame-Resistant Clothing: This includes coveralls, jackets, and gloves designed to withstand high temperatures and flames, preventing burns in case of a fire or spill.

- Safety Glasses or Goggles: Protecting my eyes from splashes of fuel, debris, or chemicals is crucial.

- Hearing Protection: Some fuel handling equipment can be quite noisy, so earplugs or muffs are essential for hearing protection.

- Respirators: Depending on the specific task and the type of fuel, respirators may be required to prevent inhalation of harmful fumes or vapors. For example, when working with solvents or additives, an appropriate respirator is always worn.

- Safety Shoes: Steel-toed boots protect my feet from potential falling objects or punctures.

Regular inspections and proper maintenance of my PPE are also part of my routine. I always ensure everything is in good working condition before starting any task, and report any damage immediately.

Q 17. How do you identify and report fuel-related hazards?

Identifying and reporting fuel-related hazards is a continuous process. It starts with understanding the potential risks associated with the specific fuel being handled and the environment.

- Visual Inspections: Regularly checking for leaks, spills, damaged equipment, corrosion, or signs of deterioration is critical. I’m trained to recognize even subtle signs of a problem.

- Monitoring Equipment: I monitor the performance of fuel pumps, gauges, and other equipment for any irregularities or malfunctions.

- Following Safety Procedures: Adherence to established safety protocols is crucial. Deviation from these procedures could lead to potential hazards.

- Reporting: Any identified hazard, no matter how minor, is immediately reported to my supervisor using the established reporting system. This could be through a written report, verbal notification, or utilizing a dedicated safety management software.

For example, I once discovered a small leak in a fuel storage tank during a routine inspection. I immediately reported it, which enabled prompt action to prevent a larger, more dangerous incident.

Q 18. What is your experience with fuel system troubleshooting and repair?

My experience with fuel system troubleshooting and repair is extensive. I’ve been involved in diagnosing and resolving issues ranging from simple leaks to complex system malfunctions.

- Diagnostic Techniques: I employ various diagnostic techniques, including visual inspections, pressure testing, flow rate measurements, and component testing to pinpoint the source of a problem.

- Repair Procedures: I’m proficient in performing repairs, including replacing hoses, filters, pumps, and other components. I always follow manufacturer specifications and safety guidelines during repairs.

- Preventive Maintenance: I regularly perform preventive maintenance tasks, such as filter changes, lubrication, and inspections, to prevent breakdowns and extend the lifespan of the equipment.

A challenging case involved a fuel pump malfunction that was initially difficult to diagnose. Using systematic troubleshooting, I narrowed down the issue to a faulty pressure regulator, which I successfully replaced. I emphasize a meticulous, systematic approach to ensure accuracy and safety in every repair.

Q 19. Describe your understanding of fuel transportation regulations.

Fuel transportation regulations are complex and vary by jurisdiction. My understanding encompasses several key areas:

- Hazardous Materials Regulations: I am familiar with regulations concerning the transportation of flammable liquids, including proper labeling, packaging, and placarding requirements. These regulations dictate the type of transport vehicles permissible, the driver qualifications, and emergency response protocols.

- Safety Data Sheets (SDS): I understand the importance of consulting SDSs for each fuel type to determine the appropriate handling, storage, and transportation procedures.

- DOT Regulations (or equivalent): I am aware of the specific requirements and guidelines of the Department of Transportation (DOT) or the equivalent regulatory bodies in other countries, depending on the location of transport. These regulations usually cover aspects like driver’s licenses, vehicle inspections, and routes.

- Emergency Response Plans: I’m knowledgeable about emergency response procedures in case of accidents or spills during transportation, including containment measures, spill cleanup, and communication with emergency services.

Non-compliance with these regulations can lead to severe penalties, environmental damage, and safety hazards. I prioritize strict adherence to all applicable regulations.

Q 20. How do you ensure the proper grounding of fuel handling equipment?

Proper grounding of fuel handling equipment is essential to prevent static electricity buildup and the risk of fire or explosions. The process involves connecting the equipment to a known ground point using conductive materials.

- Grounding Clamps and Cables: We use heavy-duty grounding clamps and cables made of copper or other conductive materials to create a reliable connection between the equipment and the ground. These cables are designed to safely conduct electrical current.

- Grounding Points: We ensure the existence of suitable grounding points. These can be provided through dedicated ground rods or metal structures already grounded in the earth.

- Visual Inspection: Before any operation, we visually inspect the grounding connection to ensure it is securely attached and free from any damage or corrosion. This verification is a crucial step in the safety checklist before any operation is initiated.

- Testing (Where Applicable): In certain operations, we may use grounding testers to verify the continuity and effectiveness of the grounding circuit.

Failure to properly ground equipment can have devastating consequences. I’ve witnessed situations where improper grounding led to static discharges that ignited fuel vapors, highlighting the critical importance of following proper grounding procedures.

Q 21. What is your experience with different types of fuel filters?

My experience encompasses various types of fuel filters, each designed for specific purposes and fuel types:

- Paper Filters: These are commonly used for removing larger particulate matter from fuel. They are relatively inexpensive but have a limited lifespan.

- Wire Mesh Filters: These filters are primarily used for removing larger contaminants and debris, offering a coarser filtration level compared to paper filters.

- Spin-on Filters: These are readily replaceable cartridges housed in a cylindrical casing. They are convenient to replace and widely used in many fuel systems.

- Water Separators: These filters not only remove particulate matter but also separate water from the fuel, protecting the engine from water damage. These are particularly important in environments with high humidity or potential for water contamination.

- High-Efficiency Filters: These filters are designed to remove extremely fine particles and contaminants, crucial for protecting sensitive fuel injection systems in modern engines.

Selecting the correct filter is crucial. The wrong filter could lead to inadequate filtration, resulting in engine damage or malfunction. For example, using a filter with insufficient micron rating could allow damaging particles to pass through, leading to costly repairs.

Q 22. Explain the process of cleaning and maintaining fuel storage tanks.

Cleaning and maintaining fuel storage tanks is crucial for safety, environmental protection, and ensuring fuel quality. The process involves several key steps, beginning with a thorough inspection for any signs of damage, leaks, or corrosion. This often includes visual checks, pressure testing, and sometimes even ultrasonic testing for hidden flaws.

Next, the tank needs to be emptied completely. This often requires specialized equipment and procedures to prevent spills or accidents. Then, the tank undergoes a rigorous cleaning process. This could involve high-pressure washing with specialized detergents designed to remove contaminants without damaging the tank’s integrity. For particularly stubborn residues, specialized cleaning agents may be required.

Following the cleaning, the tank is thoroughly rinsed with clean water, and the water is then tested to ensure that it meets purity standards. Finally, the tank is inspected again, and if everything checks out, it is dried completely and prepared for refilling. Regular maintenance also includes checking and maintaining the tank’s ventilation system, cathodic protection (to prevent corrosion), and ensuring all seals and connections are intact.

For instance, during my time at PetroTech, we followed a strict protocol for tank cleaning, documented every step meticulously, and conducted regular audits to ensure compliance. We used specialized equipment like vacuum trucks and vapor recovery systems to minimize environmental impact and worker exposure to hazardous fumes.

Q 23. How do you handle different types of fuel, such as gasoline, diesel, and jet fuel?

Handling different fuel types requires specialized knowledge and equipment due to their varying properties and hazards. Gasoline, for example, is highly volatile and flammable, requiring careful handling and storage in appropriately rated tanks. Diesel fuel is less volatile but can still present fire hazards and requires specific dispensing equipment. Jet fuel (Jet A or Jet A-1) has its own set of specifications, requiring careful adherence to quality standards and often necessitating specialized filtering and handling procedures.

The key is to understand the specific hazards associated with each fuel type. This includes understanding their flash points (the temperature at which they ignite), their vapor pressures (how readily they evaporate), and their potential for environmental contamination. We always use the right type of equipment – for example, using bonded and grounded hoses to prevent static electricity buildup, which could cause sparks and ignition.

In my previous role, we managed a facility that handled all three fuel types, and we maintained strict segregation protocols. Dedicated storage tanks, pipelines, and dispensing equipment were used for each type to avoid cross-contamination and accidental mixing, which could result in dangerous reactions or equipment damage. Detailed procedures and training programs were in place to make sure all personnel were fully aware of the risks and proper handling techniques.

Q 24. Describe your experience with automated fuel dispensing systems.

My experience with automated fuel dispensing systems spans several years and includes both installation and operation. I’m proficient in using and maintaining a variety of systems, from simple, self-service pumps to complex, automated systems found at large fueling depots. These systems typically include features like automated tank gauging, flow meters, and inventory management software. They often incorporate safety features such as overfill prevention and vapor recovery systems.

I’ve worked on systems using different communication protocols, such as MODBUS and Profibus, to integrate with central monitoring systems. Understanding these communication protocols is crucial for troubleshooting and making sure the systems operate flawlessly. I’m also skilled in performing preventative maintenance, diagnosing malfunctions, and making necessary repairs.

For example, at one facility, we implemented a new automated system that significantly improved efficiency and reduced the risk of human error during dispensing. It also provided real-time data on fuel inventory, which helped optimize our logistical planning.

Q 25. What are the environmental considerations related to fuel handling?

Environmental considerations are paramount in fuel handling. Spills, leaks, and vapor emissions can all have severe consequences, contaminating soil and water, and harming both human and environmental health. We need to adhere to strict regulations concerning air and water quality, soil remediation, and waste management.

Prevention is key. This includes regular inspections of equipment for leaks, implementing robust spill response plans, and employing secondary containment systems to prevent spills from spreading. Vapor recovery systems are also essential to minimize volatile organic compound (VOC) emissions during dispensing and storage. Proper disposal of contaminated materials according to local and national regulations is also important.

For instance, at my previous company, we had a detailed environmental management system that included regular environmental audits, employee training on spill response procedures, and a comprehensive program to reduce our carbon footprint.

Q 26. How do you ensure compliance with all relevant safety regulations and standards?

Compliance with safety regulations and standards is non-negotiable in fuel handling. This involves understanding and adhering to regulations set by local, national, and often international bodies. These regulations cover many aspects, including worker safety, fire prevention, environmental protection, and equipment standards.

This includes ensuring that all equipment is properly inspected, maintained, and certified; that employees receive appropriate training and safety gear; and that procedures are in place for handling emergencies. Regular audits and safety inspections are vital to ensure that we are maintaining the highest level of compliance. Thorough record keeping and documentation are also crucial for demonstrating compliance to regulatory agencies.

I’ve always been meticulous in following safety protocols, and I’ve participated in numerous safety training courses, including HAZWOPER (Hazardous Waste Operations and Emergency Response) training. At previous facilities, I’ve actively participated in safety inspections and have contributed to the development and implementation of updated safety procedures.

Q 27. Describe your experience with working in a team environment during fuel handling operations.

Fuel handling is inherently a team effort. Effective teamwork is essential for smooth and safe operations. My experience highlights the importance of clear communication, collaboration, and mutual respect within a team. Everyone needs to understand their roles and responsibilities, and we must have effective communication channels to ensure coordination and problem-solving during operations.

I’ve worked in teams where we’ve successfully navigated challenging situations, like handling unexpected equipment malfunctions or responding to emergency situations. Effective teamwork allows us to efficiently solve problems, make informed decisions quickly, and maintain a safe working environment. Regular team meetings, open communication, and a culture of mutual respect are all essential elements of successful teamwork in this high-risk environment.

I recall one instance where a sudden equipment failure threatened to disrupt operations. However, due to the excellent teamwork and quick thinking of my team, we managed to quickly resolve the issue and prevent any significant disruption or safety hazards. This incident solidified the importance of a strong and collaborative team in the fuel handling industry.

Q 28. How do you adapt to changing fuel handling procedures and technologies?

The fuel handling industry is constantly evolving, with new technologies and procedures being introduced regularly. Adaptability is key to remaining proficient in this field. I consistently stay updated with the latest industry best practices, safety regulations, and technological advancements through professional development courses, industry publications, and participation in relevant conferences.

I’m a quick learner, and I’m comfortable using new equipment and software, from advanced fuel management systems to new types of dispensing equipment. I embrace the challenges of learning new techniques and adapting to changes in procedures, which is essential in a field that’s constantly innovating for efficiency, safety, and environmental responsibility.

For example, recently I completed a training course on the use of a new automated fuel-management system that significantly improved operational efficiency and reduced potential risks. I have also actively sought opportunities to learn new skills and adapt to changing technologies throughout my career.

Key Topics to Learn for Fuel Handling Equipment Operation Interview

- Safety Procedures and Regulations: Understanding and adhering to all relevant safety protocols, including lockout/tagout procedures, personal protective equipment (PPE) requirements, and emergency response plans. This is crucial for ensuring a safe working environment for yourself and others.

- Equipment Operation and Maintenance: Gain a thorough understanding of the specific equipment you’ll be operating (e.g., fuel tankers, pumps, storage tanks). This includes pre-operational checks, routine maintenance tasks, troubleshooting common malfunctions, and knowing the limitations of the equipment.

- Fuel Transfer Procedures: Mastering the safe and efficient transfer of fuel, including understanding different fuel types, flow rates, pressure management, and the prevention of spills or contamination. Practical experience here is highly valuable.

- Quality Control and Inventory Management: Learn about procedures for maintaining fuel quality, tracking inventory levels, and ensuring accurate documentation. Understanding inventory management systems is a valuable skill.

- Environmental Regulations and Compliance: Familiarity with environmental regulations related to fuel handling and storage, including spill prevention and response, waste management, and air quality standards. Demonstrating awareness of environmental impact is increasingly important.

- Troubleshooting and Problem-Solving: Develop your ability to identify and address equipment malfunctions, analyze problems systematically, and implement effective solutions. Being able to explain your problem-solving approach is vital.

- Communication and Teamwork: Effective communication with colleagues and supervisors is essential in a fuel handling environment. Highlight your ability to work collaboratively and safely as part of a team.

Next Steps

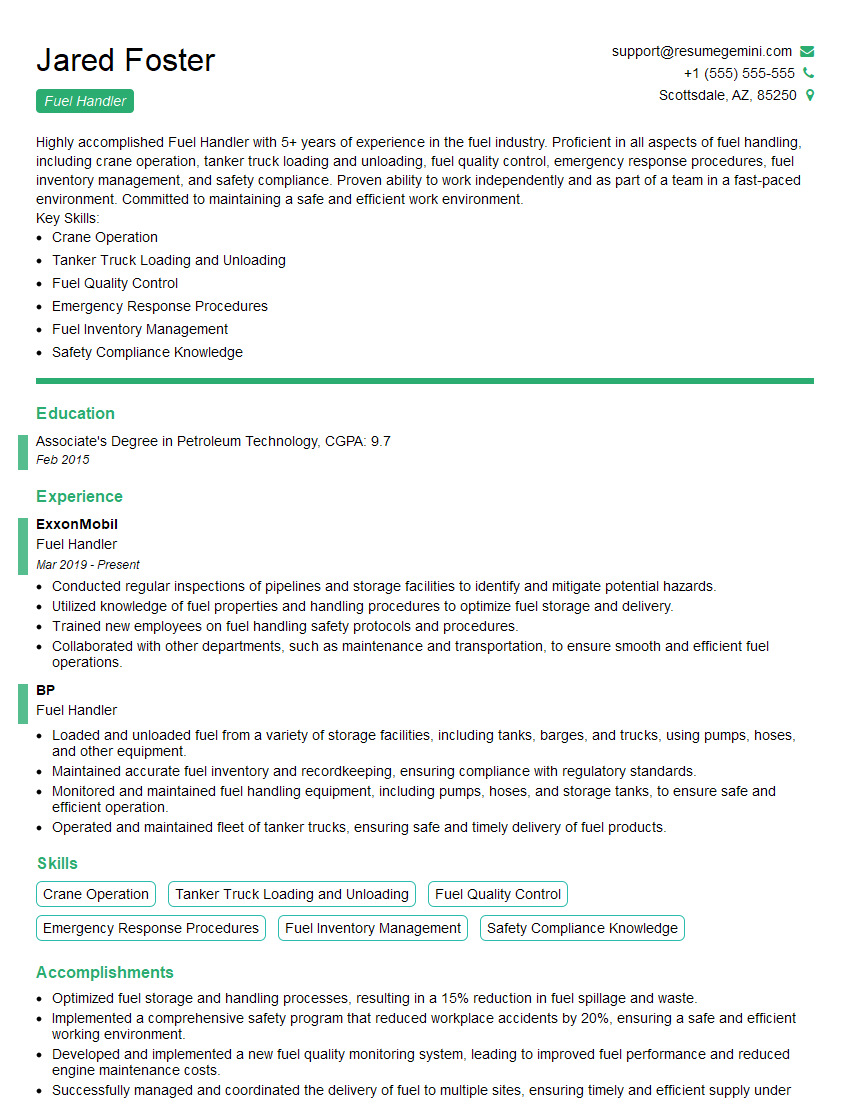

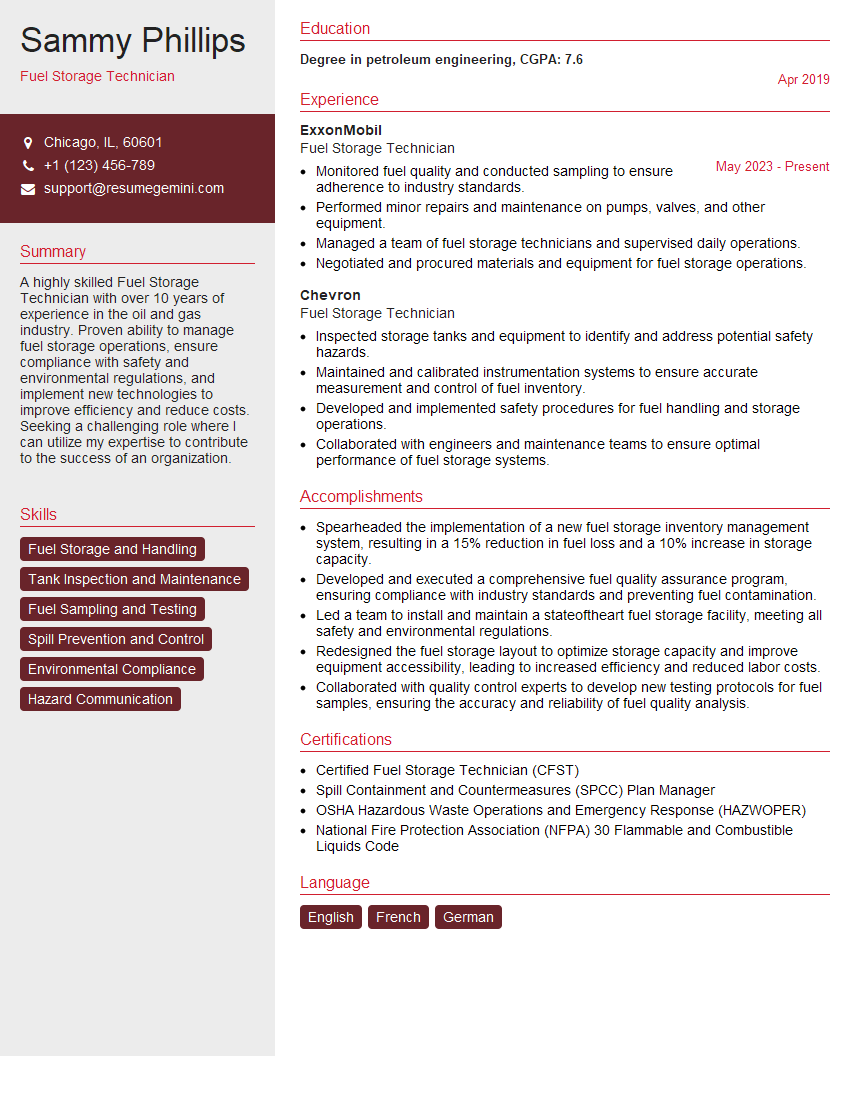

Mastering Fuel Handling Equipment Operation opens doors to rewarding and stable career opportunities within the energy sector. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is essential for getting your application noticed by potential employers. ResumeGemini can help you build a professional and impactful resume that highlights your qualifications for these in-demand positions. Examples of resumes tailored to Fuel Handling Equipment Operation are available to help guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO