The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Fuel System Maintenance and Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Fuel System Maintenance and Repair Interview

Q 1. Explain the function of a fuel pump.

The fuel pump’s primary function is to draw fuel from the tank and deliver it under sufficient pressure to the engine. Think of it as the heart of your fuel system, constantly pumping lifeblood (fuel) to the engine. It works by using an electric motor (in most modern vehicles) to create suction and pressure, moving the fuel through the lines. The pressure ensures that the fuel is delivered efficiently and consistently to the injectors, regardless of engine speed or demand. A faulty fuel pump can lead to poor engine performance, sputtering, or even complete engine failure.

Q 2. Describe the different types of fuel injectors.

Fuel injectors come in a few main types, primarily categorized by their operation: Single-point injection systems use a single injector to spray fuel into the intake manifold. This is a simpler, older system. Multi-point injection, much more common in modern vehicles, utilizes a separate injector for each cylinder, allowing for more precise fuel delivery and better engine control. Within multi-point, we have various designs based on how the fuel is sprayed: Speed-density systems rely on engine speed and air pressure sensors to calculate fuel needs. Mass airflow sensor (MAF) systems use a sensor to measure the exact amount of air entering the engine, allowing for even more precise fuel metering. Finally, there are direct injection systems where fuel is injected directly into the combustion chamber, rather than the intake manifold, offering improved efficiency and power.

Q 3. How do you diagnose a fuel pressure problem?

Diagnosing a fuel pressure problem starts with understanding the expected fuel pressure for your specific vehicle (consult your repair manual). We use a fuel pressure gauge, connected to the fuel rail (the line supplying fuel to the injectors), to measure the actual pressure. If the pressure is too low, several checks need to be performed. First, inspect the fuel pump for proper operation. You might hear a humming sound when the ignition is turned on, indicating the pump is working. Next, check the fuel filter for blockages – a clogged filter restricts fuel flow. Inspect the fuel lines and pressure regulator for leaks. A faulty pressure regulator can cause low pressure. If all these components check out, a faulty fuel pump or other internal engine issues might be to blame. Always remember to follow safety precautions when working with fuel systems, as gasoline is highly flammable.

Q 4. What are the common causes of a fuel leak?

Fuel leaks can stem from several sources. Worn or damaged fuel lines are a common culprit, particularly in older vehicles. Cracks, holes, or loose connections can all lead to leaks. Loose or damaged fuel injectors can leak fuel, often resulting in a noticeable smell. Faulty fuel pump seals can allow fuel to escape internally, potentially leading to a leak at the pump or along the fuel lines. A failing fuel pressure regulator can leak fuel, either externally or internally. Finally, damage to the fuel tank itself, from rust or impact, is another cause for concern. Regular visual inspection of fuel lines and components is key to preventing major leaks.

Q 5. Explain the process of replacing a fuel filter.

Replacing a fuel filter is a fairly straightforward procedure, but safety is paramount. First, locate the fuel filter; its position varies by vehicle. Next, relieve fuel system pressure. This usually involves disconnecting the fuel pump relay or fuse, then starting the car and letting it run until it stalls – this exhausts the fuel in the lines. Disconnect the fuel lines, carefully collecting any spilled fuel. Remove the fuel filter and install the new one, ensuring the arrows indicating fuel flow direction match the lines. Reconnect the fuel lines, ensuring they are tight and free of leaks. Reconnect the fuel pump relay or fuse and check for any leaks before starting the engine.

Q 6. How do you troubleshoot a fuel injection system?

Troubleshooting a fuel injection system requires a systematic approach. Start with a visual inspection for leaks or loose connections. Then, check fuel pressure as described earlier. Next, analyze the fuel injector operation. This often requires a specialized scan tool to monitor injector pulse width and duration. If the injectors aren’t firing correctly, the problem could be with the engine control module (ECM), wiring, or the injectors themselves. Low fuel pressure or a faulty fuel pump will also prevent the injectors from working properly. Finally, a leak detection pump can pinpoint leaks in the fuel delivery system. Each step involves specific tests and tools to precisely pinpoint the faulty component.

Q 7. Describe the function of a fuel pressure regulator.

The fuel pressure regulator maintains a consistent fuel pressure in the fuel rail. It does this by diverting excess fuel back to the fuel tank, preventing overly high pressure that could damage the system. Think of it as a pressure relief valve. If the fuel pressure is too high, the regulator opens to relieve some pressure. Conversely, if pressure drops too low, it closes to maintain the necessary pressure for optimal engine operation. A faulty pressure regulator can lead to inconsistent fuel delivery, poor engine performance, and potentially damage to fuel injectors.

Q 8. What are the symptoms of a clogged fuel injector?

A clogged fuel injector can significantly impact engine performance. Imagine a water pipe with a partial blockage – water flow is restricted. Similarly, a clogged injector restricts the flow of fuel to the engine’s cylinders. Symptoms include rough idling, hesitation during acceleration, decreased fuel efficiency, and a misfire (the engine may ‘sputter’ or run unevenly).

More specifically, you might observe:

- Rough idling: The engine shakes or vibrates excessively when at idle speed.

- Poor acceleration: The vehicle is sluggish to respond when you press the accelerator.

- Reduced fuel economy: Your vehicle gets fewer miles per gallon than usual.

- Black smoke from the exhaust: This indicates incomplete combustion of fuel due to insufficient fuel delivery by the clogged injector.

- Check engine light: Your vehicle’s diagnostic system will often illuminate a check engine light, storing a diagnostic trouble code (DTC) related to a misfire or fuel system problem.

These symptoms don’t always definitively point to a clogged injector; other issues could mimic these problems. A thorough diagnosis, often involving a fuel pressure test and injector flow test, is necessary for accurate identification.

Q 9. How do you test a fuel pump?

Testing a fuel pump involves a multi-step process to ensure both pressure and flow are within specifications. You can’t simply ‘listen’ for the pump; modern fuel pumps are often quite quiet. A faulty fuel pump can lead to similar symptoms as a clogged injector, but diagnosing the root cause requires careful investigation.

Here’s how you’d typically test it:

- Visual Inspection: Check the fuel pump relay and fuse for any signs of damage. A faulty relay or blown fuse can prevent the pump from operating.

- Fuel Pressure Test: This is the most critical step. A fuel pressure gauge is connected to the fuel rail (the metal pipe that distributes fuel to the injectors). The engine is then started, and the pressure reading is compared to the manufacturer’s specifications for that specific vehicle. Low pressure indicates a potential fuel pump problem.

- Fuel Flow Test: If the pressure is acceptable, you can test the volume of fuel delivered over a period. This requires measuring the amount of fuel delivered into a container over a specific time, comparing it to expected flow rates.

- Listen for the pump (with caution): After turning the ignition key to the ‘on’ position (but not starting the engine), you should hear a brief humming sound from the fuel pump. If you don’t, it’s a strong indicator of failure. Always be mindful of safety (see question 4).

Remember, safety is paramount when working with fuel systems. Always consult a repair manual specific to your vehicle before performing any tests.

Q 10. Explain the operation of a carburetor.

A carburetor is a mechanical device that mixes air and fuel in the correct ratio for combustion in an internal combustion engine. Think of it as a precise air-fuel metering system, pre-dating the more modern electronic fuel injection systems. It uses a series of valves, jets, and passages to achieve this mixing. The key is the venturi effect.

Here’s a breakdown of its operation:

- Venturi Effect: As air flows through a constricted passage (the venturi), its speed increases, and its pressure decreases. This lower pressure draws fuel from a reservoir (fuel bowl) via a small jet.

- Float Level: A float mechanism in the fuel bowl maintains a consistent fuel level.

- Throttle Valve: This valve controls the amount of air flowing through the carburetor, thereby regulating the engine speed. Opening the throttle increases airflow, drawing more fuel and increasing engine power.

- Fuel Jets and Air Bleeds: Different sized jets and air bleeds control the air-fuel mixture at different engine speeds and loads.

- Choke: The choke restricts airflow during cold starts, enriching the fuel mixture to help the engine start easier.

The precise air-fuel ratio is critical. Too rich (too much fuel) leads to inefficient combustion and potential fouling of spark plugs. Too lean (too much air) can cause overheating and engine damage. Carburetors are intricate and require careful adjustment for optimal performance.

Q 11. What are the safety precautions when working with fuel systems?

Working with fuel systems presents significant safety hazards due to the flammability of gasoline and its vapors. Improper handling can result in fires, explosions, and serious injury. Always prioritize safety!

- Proper Ventilation: Work in a well-ventilated area, ideally outdoors. Gasoline vapors are heavier than air and can accumulate in low-lying areas.

- No Smoking or Sparks: Absolutely no smoking, open flames, or sparks near fuel. Static electricity discharge can ignite fuel vapors.

- Eye Protection: Wear safety glasses to protect your eyes from splashes.

- Gloves: Wear gloves to protect your hands from gasoline, which can cause skin irritation.

- Fire Extinguisher: Have a readily available fire extinguisher rated for Class B fires (flammable liquids).

- Disconnect Battery: Disconnect the negative battery terminal before working on fuel system components to prevent accidental sparking.

- Proper Disposal: Dispose of fuel and fuel-soaked rags responsibly according to local regulations. Never throw them in the trash.

- Use appropriate tools: Do not attempt to bend or cut fuel lines with tools that could create sparks

Remember, a little precaution goes a long way in ensuring a safe working environment.

Q 12. How do you diagnose a fuel system problem using diagnostic tools?

Modern vehicles are equipped with sophisticated diagnostic tools that greatly aid in diagnosing fuel system problems. The most common tool is an OBD-II (On-Board Diagnostics) scanner.

Here’s how you’d use these tools:

- OBD-II Scanner: This device plugs into the vehicle’s diagnostic port (usually located under the dashboard). It reads trouble codes stored by the vehicle’s computer (ECU – Engine Control Unit). These codes provide clues about potential fuel system problems, such as fuel pressure sensor failures, oxygen sensor malfunctions, or injector issues.

- Fuel Pressure Gauge: As discussed earlier, this is essential for measuring fuel pressure. Low pressure points to problems with the fuel pump, pressure regulator, or fuel filter.

- Injector Flow Tester: This specialized tool allows you to test the flow rate of each individual fuel injector, identifying clogged or malfunctioning injectors.

- Fuel System Scanner: More advanced scanners allow for real-time monitoring of various fuel system parameters, such as fuel pressure, injector pulse width, and oxygen sensor readings. This allows for dynamic observation of the fuel system while the engine is running.

The data from these tools, in combination with a methodical approach to troubleshooting, significantly improves the efficiency and accuracy of fuel system diagnosis.

Q 13. Describe the different types of fuel tanks.

Fuel tanks vary in design and materials depending on the vehicle and application. The material itself must be resistant to fuel, while the design prioritizes safety and durability.

- Steel Tanks: Common in older vehicles, these are robust but susceptible to rust and corrosion. They often have a coating to enhance their resistance to corrosion.

- Aluminum Tanks: Lighter and more corrosion-resistant than steel, aluminum tanks are increasingly popular. However, they can be more expensive.

- Plastic Tanks (Polyethylene): These tanks are lightweight, corrosion-resistant, and often more complex in shape. They can withstand impacts better in some cases, but are more prone to cracking under stress than steel or aluminum.

- Integrated Tanks: Some vehicles have the fuel tank integrated into the body structure for better weight distribution and protection.

- Fuel Cell Tanks: These are specialized tanks used in high-performance applications, offering exceptional strength and durability, often made from composite materials.

The design of a tank also includes considerations for the fuel pump placement, venting system, and safety mechanisms to prevent leakage or explosions. Each type of tank has its own set of strengths and weaknesses.

Q 14. How do you repair a fuel tank leak?

Repairing a fuel tank leak depends on the location, size, and cause of the leak. Small leaks in plastic tanks might be repairable with specialized fuel tank repair kits; however, larger leaks or leaks in metal tanks often require replacement. Improper repair can result in catastrophic fuel spills and fires.

For small leaks in plastic tanks:

- Thoroughly clean the area: Remove any dirt, debris, or rust from around the leak.

- Apply a fuel tank repair kit: These kits often contain an epoxy or sealant designed to withstand fuel exposure. Follow the manufacturer’s instructions carefully.

- Allow sufficient curing time: Ensure the repair has fully cured before refilling the tank and operating the vehicle.

For leaks in metal tanks or large leaks in plastic tanks:

Replacement is generally the safest and most effective solution. This involves draining the fuel tank, disconnecting the fuel lines, and installing a new tank. Improperly repairing a fuel tank leak is extremely dangerous.

Always prioritize safety when working with fuel systems. If you are unsure about how to repair a fuel tank leak, consult a qualified professional.

Q 15. Explain the function of a fuel rail.

The fuel rail is a crucial component in a fuel-injected engine. Think of it as a small, pressurized pipeline that distributes fuel evenly to each fuel injector. Each injector is responsible for delivering a precisely metered amount of fuel into the engine’s combustion chamber. The fuel rail itself is typically mounted on top of the engine and is connected to the fuel pump through fuel lines. It’s a robust, sealed assembly that maintains consistent fuel pressure, ensuring reliable and efficient engine operation. Without a properly functioning fuel rail, your engine wouldn’t receive the necessary fuel for combustion, leading to misfires or even a complete engine stall.

For example, imagine a watering system for a garden. The fuel rail is like the main pipe distributing water (fuel) to individual sprinklers (fuel injectors) across your garden (engine). Each sprinkler needs equal pressure to operate efficiently – that’s the job of the fuel rail.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common problems associated with fuel lines?

Common problems with fuel lines often stem from age, wear, and exposure to the elements. Cracks, leaks, and corrosion are prevalent issues. These can lead to fuel leaks, which are not only dangerous due to fire hazards but also cause performance issues like poor engine running or stalling. Another common problem is clogging from debris or contamination, restricting fuel flow and impacting engine performance. Incorrect routing or clamping of fuel lines can also lead to vibrations or kinks, causing further complications.

For instance, a tiny crack in a fuel line might go unnoticed for a while, but over time it can progressively worsen, resulting in a significant fuel leak. Similarly, using the wrong type of fuel line clamp could lead to the line coming loose and causing fuel starvation.

Q 17. How do you replace a fuel line?

Replacing a fuel line requires careful preparation and adherence to safety procedures. Always disconnect the battery’s negative terminal first to prevent electrical hazards. Next, you’ll need to identify the damaged section and carefully disconnect it from the fuel system. This will likely involve loosening clamps and disconnecting fittings. It’s crucial to relieve system pressure before disconnecting any fuel line. Measure the length of the replacement line carefully and ensure it’s compatible with the fuel system’s specifications. Install the new line, ensuring secure connections and proper clamping. Reconnect the battery and test the system for leaks. Never rush this process; precision is key to avoiding fuel leaks and fire hazards.

An example is replacing a section of the high-pressure fuel line. You would need specialized fuel line tools and ensure a precise fit to maintain pressure and avoid leaks. Specialized clamps may be required to ensure the connection can withstand the pressure and vibration of the engine.

Q 18. Explain the function of a fuel sender unit.

The fuel sender unit is the unsung hero of your fuel gauge. Located inside the fuel tank, it’s a float mechanism that measures the level of fuel. A float is attached to a potentiometer, which changes resistance as the fuel level changes. This change in resistance is converted into an electrical signal, transmitted to the fuel gauge on your dashboard, providing an accurate reading of how much fuel remains in your tank. It’s a simple yet critical part; without it, your fuel gauge would be useless.

Think of it like a dipstick for your gas tank, but instead of manually checking the level, it sends an electrical signal to the dashboard.

Q 19. How do you diagnose a problem with a fuel gauge?

Diagnosing a fuel gauge problem starts with simple checks. First, ensure the gauge is accurate by comparing it to the actual amount of fuel in the tank (if you can safely access it). Then, inspect the wiring and connections for any damage, corrosion, or loose connections. Test the fuel sender unit using a multimeter to check the resistance changes as the float moves. If the gauge still doesn’t work, the issue might lie within the gauge itself, requiring replacement. A faulty fuel sender unit is a common cause, and its resistance readings should correlate with the fuel level.

For example, if your fuel gauge shows empty even when the tank is full, it could be a faulty fuel sender unit, a broken wire, or a problem with the gauge itself. Systematic testing, starting with the simplest checks, is key to efficient diagnosis.

Q 20. What is the purpose of a fuel filter?

A fuel filter’s primary purpose is to remove contaminants from the fuel before it reaches the engine’s injectors or carburetor. These contaminants – dirt, rust, water, etc. – can severely damage engine components. By filtering out these impurities, the fuel filter protects sensitive engine parts and ensures consistent fuel flow and engine performance. Regular fuel filter replacement is crucial for engine longevity.

Imagine trying to run a water pump with dirty water; the pump will eventually clog up and fail. The fuel filter serves the same role in preventing this kind of damage within the fuel system.

Q 21. What are the different types of fuel filters?

Fuel filters come in various types, primarily categorized by their construction and filtering material. Common types include:

- Paper filters: These are the most common type, using a pleated paper element to trap contaminants. They are relatively inexpensive but have a limited lifespan.

- Mesh filters: These filters utilize a metal mesh screen to filter larger particles. They are more durable than paper filters but may not trap finer particles as effectively.

- Spin-on filters: These are screw-on filters that are readily replaced, offering convenience and are commonly found in modern vehicles.

- In-tank filters: These are located within the fuel tank and often incorporate a filter screen as part of the fuel pump module.

The choice of fuel filter depends on the vehicle’s make, model, and fuel system design. Always consult the vehicle’s owner’s manual for the correct type and replacement intervals.

Q 22. Explain the difference between gasoline and diesel fuel systems.

Gasoline and diesel fuel systems differ fundamentally in their fuel type, combustion process, and injection system design. Gasoline engines utilize a spark plug to ignite a pre-mixed air-fuel charge, requiring a relatively simpler fuel delivery system. Diesel engines, on the other hand, rely on the heat generated by compressing air to ignite the fuel, necessitating a higher-pressure fuel injection system to atomize the fuel effectively.

- Fuel Type: Gasoline is a volatile, easily vaporized fuel, while diesel is a denser, less volatile fuel requiring higher pressure for atomization.

- Combustion: Gasoline engines use spark ignition, while diesel engines use compression ignition.

- Injection System: Gasoline systems historically used carburetors or simpler fuel injectors, while diesel systems always required high-pressure injection systems, evolving from simple pump-line-nozzle systems to sophisticated common rail systems.

- Fuel Delivery: Gasoline systems often rely on lower pressures to deliver fuel, while diesel systems operate at significantly higher pressures to ensure proper atomization.

Think of it like this: a gasoline engine is like a gas stove – you need a spark to ignite the gas. A diesel engine is more like a charcoal grill – you get ignition from the heat generated by compressing the air.

Q 23. Describe the operation of a common rail fuel injection system.

A common rail fuel injection system is a sophisticated technology used predominantly in modern diesel engines. It works by using a high-pressure pump to pressurize fuel into a common rail. This rail then distributes the fuel to individual injectors, each controlled by its own solenoid valve. This precise control allows for highly accurate fuel metering and injection timing, optimizing combustion efficiency and reducing emissions.

- High-Pressure Pump: This pump builds up and maintains pressure in the common rail, typically in the range of 15,000 to 25,000 psi.

- Common Rail: A pipe that stores the pressurized fuel, allowing injectors to draw fuel on demand.

- Solenoid Injectors: Each cylinder has its own injector, electronically controlled to open and close precisely, injecting the correct amount of fuel at the optimal time.

- Electronic Control Unit (ECU): The ECU monitors various engine parameters (like speed, load, and temperature) to control the injection timing and quantity for each cylinder individually.

The advantage is that the injectors only need to overcome the pressure difference between the common rail and the cylinder, significantly reducing mechanical wear and tear compared to older pump-line-nozzle systems. Imagine it like a water sprinkler system: the pump provides the pressure, the rail distributes the water, and each sprinkler (injector) is independently controlled to water the specific areas (cylinders).

Q 24. What are the environmental concerns related to fuel system leaks?

Fuel system leaks pose significant environmental hazards. Leaked fuel, whether gasoline or diesel, can contaminate soil and groundwater, harming plant and animal life. Gasoline, being volatile, also contributes to air pollution through evaporation. The aromatic hydrocarbons and other components in both gasoline and diesel are toxic and carcinogenic, posing serious threats to human health and the environment.

- Soil Contamination: Fuel spills contaminate soil, affecting soil microbial activity and plant growth. This contamination can persist for years, impacting the entire ecosystem.

- Groundwater Contamination: Fuel can leach into groundwater, contaminating drinking water sources and harming aquatic life.

- Air Pollution: Volatile organic compounds (VOCs) from gasoline evaporate into the atmosphere, contributing to smog formation and respiratory problems.

- Waterway Pollution: Fuel spills can contaminate rivers, lakes, and oceans, harming aquatic life and potentially affecting human health through consumption of contaminated seafood.

The consequences can be far-reaching, requiring costly cleanup efforts and potentially leading to legal ramifications for those responsible. Therefore, regular inspection and prompt repair of fuel system leaks are crucial.

Q 25. How do you properly dispose of fuel system components?

Proper disposal of fuel system components is crucial for environmental protection. Spent fuel, filters, and other components should never be disposed of in regular trash. Instead, they must be handled according to local and national regulations. Typically, this involves contacting a licensed hazardous waste disposal facility. These facilities are equipped to handle the hazardous materials and dispose of them safely and responsibly.

- Contact a licensed hazardous waste disposal facility: This is the most critical step. They will provide guidance on proper packaging and transportation.

- Proper packaging: Fuel and filters must be sealed in appropriate containers to prevent leaks and spills.

- Labeling: Containers should be clearly labeled with the contents to ensure safety during transportation and handling.

- Documentation: Maintain records of disposal, including the date, quantity, and the facility used for disposal.

Improper disposal can lead to severe environmental contamination and legal penalties. Always prioritize responsible disposal practices.

Q 26. Explain the role of emission control systems in relation to the fuel system.

Emission control systems are directly integrated with the fuel system to reduce harmful emissions from vehicle exhaust. The fuel system’s precise delivery of fuel directly impacts the combustion process, which in turn, affects the amount of pollutants produced. Components like catalytic converters and particulate filters rely on the efficient and controlled combustion achieved through the fuel system to perform their functions effectively.

- Precise fuel metering: Accurate fuel delivery ensures optimal air-fuel ratio, minimizing unburnt hydrocarbons and carbon monoxide.

- Injection timing: Precise injection timing optimizes combustion, reducing emissions of NOx (nitrogen oxides).

- Exhaust Gas Recirculation (EGR): EGR systems, often linked to fuel system control, recirculate exhaust gases back into the intake manifold, lowering combustion temperatures and reducing NOx formation.

- Catalytic converter: This device relies on the complete combustion of fuel to convert harmful pollutants like CO and NOx into less harmful substances.

- Diesel Particulate Filter (DPF): In diesel engines, the DPF traps soot particles, significantly reducing particulate matter emissions.

Modern emission control systems are sophisticated and rely heavily on precise fuel management for effective operation. A malfunctioning fuel system can directly impact emissions and potentially trigger fault codes related to emission control.

Q 27. Describe your experience with different fuel injection systems (e.g., MPI, GDI).

Throughout my career, I’ve extensively worked with various fuel injection systems, including Multi-Point Injection (MPI), Gasoline Direct Injection (GDI), and common rail diesel systems. MPI systems, common in gasoline engines, inject fuel into the intake manifold, creating a relatively homogenous air-fuel mixture. GDI systems, on the other hand, inject fuel directly into the combustion chamber, offering benefits in terms of fuel efficiency and power. I’ve also had significant experience diagnosing and repairing issues in both systems, ranging from fuel pressure leaks to injector malfunctions and sensor failures.

- MPI (Multi-Point Injection): I’ve worked on numerous MPI systems, diagnosing problems like fuel pressure regulators, fuel injectors, and intake manifold leaks. I understand the intricacies of fuel rail pressure regulation and its impact on engine performance.

- GDI (Gasoline Direct Injection): GDI systems are more complex, demanding a thorough understanding of high-pressure fuel pumps, injectors, and their electronic control systems. I’m proficient in diagnosing carbon buildup issues, injector cleaning, and high-pressure fuel pump replacement.

- Common Rail Diesel: As previously discussed, I have extensive experience with common rail systems, encompassing diagnosis of high-pressure pump failures, injector malfunctions, and sensor issues.

My experience spans various vehicle makes and models, giving me a comprehensive understanding of the differences and challenges associated with each type of fuel injection system.

Q 28. What are the latest advancements in fuel system technology?

The fuel system technology landscape is constantly evolving, driven by the need for improved fuel efficiency, reduced emissions, and alternative fuel compatibility. Some of the latest advancements include:

- Higher injection pressures: This allows for finer fuel atomization, leading to improved combustion efficiency and reduced emissions.

- Advanced fuel injection strategies: Techniques like multiple injections per cycle allow for optimized combustion and reduced emissions of NOx and particulate matter.

- Flexible fuel systems: Systems designed to operate with multiple fuel types (e.g., gasoline and ethanol blends), enabling greater fuel choice flexibility.

- Improved sensor technology: More precise sensors provide real-time feedback to the ECU, allowing for more precise fuel control and optimization.

- Integration with alternative fuel technologies: Fuel systems are being adapted to work with alternative fuels like hydrogen, biodiesel, and synthetic fuels.

These advancements are aimed at creating more efficient, cleaner, and adaptable fuel systems for the future of transportation. The field is constantly pushing boundaries, resulting in continuous innovation.

Key Topics to Learn for Fuel System Maintenance and Repair Interview

- Fuel System Components: Understanding the function and operation of fuel pumps, injectors, filters, sensors, and pressure regulators. Be prepared to discuss their interdependencies.

- Diagnostic Techniques: Mastering diagnostic tools and procedures for identifying fuel system malfunctions. This includes interpreting diagnostic trouble codes (DTCs) and using scan tools effectively.

- Fuel System Repair Procedures: Demonstrate knowledge of safe and efficient repair techniques, including component replacement, leak detection, and system pressure testing.

- Fuel Injection Systems: Detailed understanding of various fuel injection types (e.g., port injection, direct injection) and their maintenance requirements. Discuss troubleshooting common injection-related issues.

- Emission Control Systems: Knowledge of how fuel systems interact with emission control components (e.g., evaporative emission control systems, catalytic converters). Understanding relevant regulations and emission testing procedures.

- Safety Procedures: Highlight your understanding of safety protocols when handling fuel, working with high-pressure systems, and using specialized tools. Emphasize safe work practices and hazard awareness.

- Preventive Maintenance: Explain the importance of regular maintenance schedules, including filter replacements, inspections, and fluid changes, to prevent major failures and extend system lifespan.

- Troubleshooting and Problem-Solving: Showcase your ability to systematically diagnose complex fuel system problems, using logical reasoning and your technical knowledge to isolate and solve issues efficiently.

Next Steps

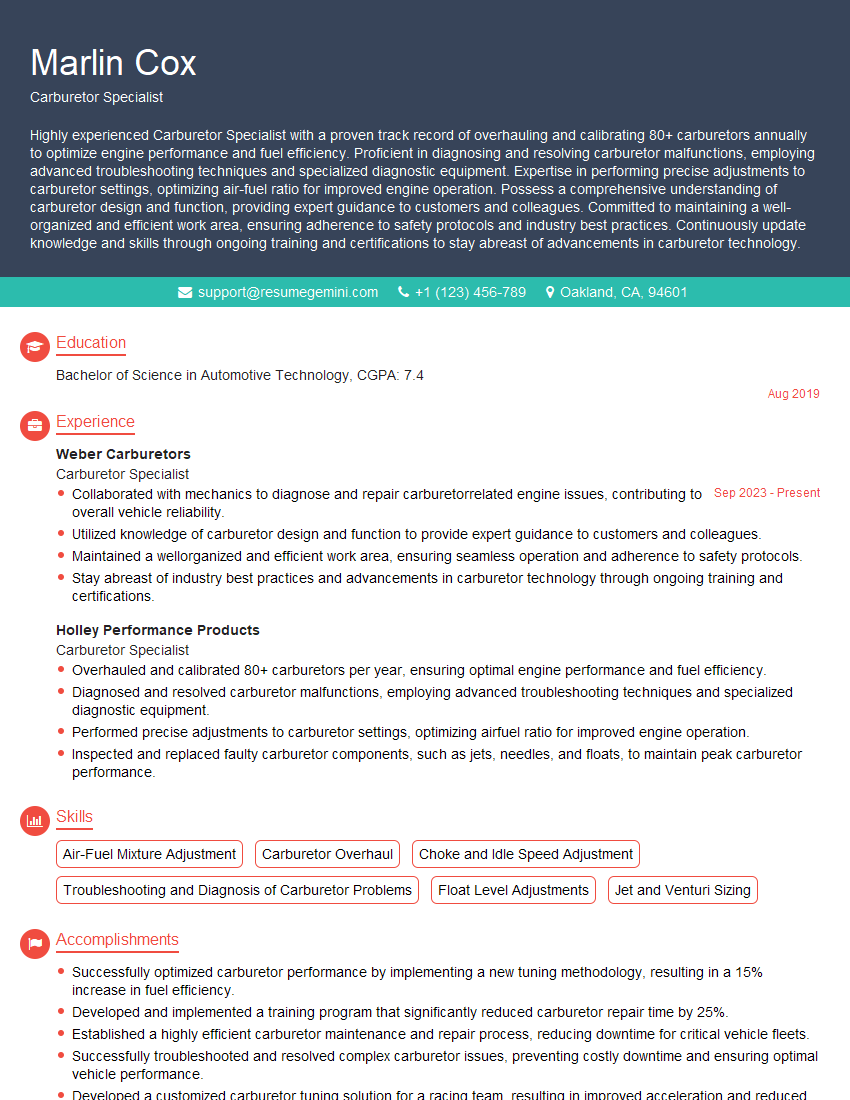

Mastering Fuel System Maintenance and Repair opens doors to exciting career opportunities with excellent growth potential. A strong understanding of these crucial systems is highly valued across various industries. To maximize your chances of landing your dream job, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specifics of your field. Examples of resumes tailored to Fuel System Maintenance and Repair are available, providing a great template for building your own compelling application.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO