Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Fueling Vehicles interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Fueling Vehicles Interview

Q 1. Explain the different types of fuel injectors used in modern vehicles.

Modern vehicles utilize various fuel injector types, primarily categorized by their design and operation. The most common are:

- Port Fuel Injection (PFI): These injectors are located in the intake manifold, spraying fuel into the intake ports just before the intake valves. This is a relatively simple and cost-effective system, widely used in many gasoline engines. Think of it like sprinkling water onto a plant – the fuel is distributed before entering the combustion chamber.

- Direct Fuel Injection (GDI/DI): These injectors are positioned directly within the combustion chamber, spraying fuel directly onto the pistons or into the cylinder. This offers better fuel atomization and control, leading to increased efficiency and power, but often requires more sophisticated engine management systems. Imagine it like precisely targeting a water jet at a specific point – the fuel is injected directly where needed.

- Multi-Point Fuel Injection (MPFI): This is a variation of PFI with multiple injectors per cylinder, offering more precise fuel delivery for improved performance and emissions control. Think of it as having multiple sprinklers for a plant, ensuring even coverage.

- Common Rail Injection: Often found in diesel engines, a high-pressure fuel rail supplies fuel to multiple injectors. This allows for more precise control over injection timing and quantity, leading to cleaner and more efficient combustion. This is similar to a central water reservoir providing precise watering to multiple areas.

The choice of injector type depends on factors such as engine design, desired performance, and emissions regulations. For example, GDI is common in high-performance gasoline engines aiming for better fuel economy, while common rail is standard in modern diesel vehicles for their power and efficiency.

Q 2. Describe the process of safely refueling a vehicle with alternative fuels (e.g., propane, CNG).

Refueling vehicles with alternative fuels like propane (LPG) and compressed natural gas (CNG) requires extra caution due to their unique properties. Safety procedures vary slightly depending on the fuel but generally include:

- Proper tank connection: Ensure the dispensing nozzle is securely connected to the vehicle’s tank. A loose connection can cause leaks.

- No smoking or open flames: These fuels are flammable and any ignition source must be kept far away.

- Ventilation: Adequate ventilation is crucial, especially during refueling, as these fuels can accumulate in poorly ventilated areas and cause asphyxiation.

- Slow fill rate: Avoid rapid filling, which can create pressure buildup and potential leaks.

- Check for leaks: After filling, visually inspect the connection points for any signs of leaks (smell or sound of escaping gas) .

- Grounding: For CNG fueling, ensure proper grounding to prevent static electricity buildup, which can spark an ignition.

- Emergency shut-off: Know the location of the emergency shut-off valve on both the vehicle and the dispensing equipment.

Always consult the vehicle’s owner’s manual for specific refueling instructions for alternative fuels. Improper handling can lead to serious accidents like explosions or fires.

Q 3. What are the common safety regulations and procedures for fueling vehicles?

Fueling vehicle safety regulations and procedures are crucial for preventing accidents. These typically include:

- No smoking: Flammable vapors are present near fueling points; even a small spark can ignite them.

- Engine off: Always turn off the vehicle’s engine before refueling to minimize the risk of sparks.

- Static electricity grounding: Static discharge can ignite fuel vapors, particularly in dry conditions. Some dispensing systems incorporate grounding mechanisms.

- Spill prevention: Proper handling of the nozzle and avoiding overfilling helps prevent fuel spills.

- Emergency response plan: Fueling stations are often required to have emergency plans in place, including fire extinguishers and spill containment measures.

- Proper personal protective equipment (PPE): Depending on the situation, appropriate PPE, such as gloves, eye protection, and potentially respirators, might be necessary.

- Adherence to local and national regulations: Fueling stations must comply with specific safety standards related to storage, handling, and dispensing of fuels.

These regulations are designed to minimize the risks of fire, explosions, and environmental damage associated with fueling operations.

Q 4. How do you identify and troubleshoot fuel leaks?

Identifying and troubleshooting fuel leaks requires a systematic approach. The process typically involves:

- Visual inspection: Carefully examine all fuel lines, connections, and the fuel tank for any signs of leakage. Look for wet spots, fuel stains, or puddles.

- Smell test: Fuel has a distinctive odor. A strong fuel smell can indicate a leak, even if it’s not visually apparent.

- Pressure testing: In some cases, pressure testing the fuel system can help identify leaks that are not easily visible. This usually requires specialized tools and equipment.

- Listening for leaks: Sometimes, you can hear a hissing sound from a small leak, especially under pressure.

- Using leak detection fluid: Specialized leak detection fluids can help pinpoint leaks by reacting with escaping fuel.

Once the leak is located, the repair will depend on the nature and location of the leak. It might involve tightening loose connections, replacing damaged fuel lines or components, or even repairing or replacing the fuel tank. Safety is paramount; always disconnect the fuel supply before performing any repairs.

Q 5. What are the potential hazards associated with improper fueling procedures?

Improper fueling procedures can lead to a variety of hazards, including:

- Fires and explosions: Flammable fuel vapors can ignite, leading to serious fires or explosions, especially in the presence of an ignition source.

- Injuries: Burns, cuts, and other injuries can result from fuel spills or fires.

- Environmental damage: Fuel spills can contaminate soil and water sources, causing significant environmental harm.

- Health hazards: Inhalation of fuel vapors can lead to headaches, nausea, and other health problems. Prolonged exposure can have more serious consequences.

- Vehicle damage: Fuel leaks can damage vehicle components, potentially affecting the engine and other systems.

Following proper safety procedures is essential to mitigating these risks and ensuring a safe fueling experience.

Q 6. Describe your experience with fuel dispensing equipment maintenance and repair.

My experience with fuel dispensing equipment maintenance and repair encompasses both preventative maintenance and troubleshooting. I’m proficient in performing routine checks on pumps, hoses, nozzles, and meters. This includes checking for leaks, wear and tear, and proper calibration. I’ve also handled repairs ranging from replacing worn seals and gaskets to more complex tasks such as troubleshooting electrical issues or replacing faulty pump motors. I’m familiar with various types of dispensing equipment, from conventional gasoline pumps to those designed for alternative fuels such as LPG and CNG. I always prioritize safety when working on this equipment, following all relevant safety protocols and lockout/tagout procedures to prevent accidents.

For example, in one instance, I diagnosed a problem with a fuel pump that was intermittently dispensing fuel at incorrect flow rates. Through systematic troubleshooting, I identified a faulty flow meter, which was replaced, restoring accurate dispensing.

Q 7. How do you ensure accurate fuel measurement and prevent fuel theft?

Ensuring accurate fuel measurement and preventing fuel theft requires a multi-pronged approach. Accurate measurement relies on:

- Regular calibration of dispensing equipment: Meters must be regularly calibrated to ensure accurate readings. This is typically done using certified testing equipment.

- Proper maintenance: Maintaining dispensing equipment in good working order is crucial for accuracy. Regular inspections and repairs help prevent mechanical errors that can impact metering.

- Use of automatic tank gauging (ATG): ATG systems provide real-time monitoring of fuel tank levels, helping track inventory and detect discrepancies.

Fuel theft prevention measures include:

- Security cameras: Installing surveillance cameras around the fueling area can deter theft and help identify perpetrators.

- Access control: Restricting access to the fueling area can help prevent unauthorized fuel access.

- Tamper-evident seals: Using tamper-evident seals on fuel dispensing equipment can help detect any unauthorized tampering.

- Regular inventory checks: Regularly reconciling fuel sales with inventory levels can help identify discrepancies that may indicate theft.

A combination of these measures ensures both accurate fuel measurement and effective theft prevention, protecting the business’s assets and maintaining customer trust.

Q 8. Explain the importance of fuel quality control and testing procedures.

Fuel quality is paramount in ensuring optimal engine performance, minimizing emissions, and preventing costly repairs. Control and testing procedures are crucial for maintaining this quality throughout the entire supply chain, from refinery to vehicle tank.

Testing involves analyzing various parameters including:

- Cetane number (for diesel): Measures ignition quality; a higher number indicates faster and smoother ignition.

- Octane number (for gasoline): Measures resistance to knocking or pinging during combustion. A higher number signifies greater resistance.

- Sulfur content: Excessive sulfur contributes to air pollution and engine wear. Strict limits are imposed by environmental regulations.

- Water content: Water in fuel can lead to corrosion, microbial growth, and fuel system blockages.

- Sediment and particulate matter: These impurities can clog fuel filters and injectors.

Regular quality control involves sampling fuel at various stages, performing laboratory analysis, and implementing corrective actions if deviations from specifications are found. For instance, a refinery might adjust its production process based on test results to ensure consistent fuel quality. Similarly, a gas station may be required to remove contaminated fuel from its tanks.

Q 9. What are the different types of fuel storage tanks and their safety considerations?

Fuel storage tanks come in various types, each with its own set of safety considerations. The choice depends on the fuel type, storage capacity, and environmental conditions.

- Aboveground Storage Tanks (ASTs): These are commonly used for smaller volumes and are easier to inspect and maintain. Safety measures include double-walled tanks, leak detection systems, spill containment berms, and proper ventilation to prevent the buildup of flammable vapors.

- Underground Storage Tanks (USTs): These are often preferred for larger storage capacities and to minimize environmental impact. However, they require rigorous monitoring for leaks using techniques like cathodic protection and regular integrity testing. Strict regulations govern their installation and operation.

- Double-Walled Tanks: These tanks provide an added layer of protection against leaks by containing any spills within the outer shell. They offer enhanced safety compared to single-walled tanks.

Regardless of the tank type, crucial safety measures include: proper grounding and bonding to prevent static electricity buildup, emergency shut-off valves, fire suppression systems, and operator training on safe handling procedures. A detailed risk assessment should always be conducted before installing or operating any fuel storage tank.

Q 10. How do you handle fuel spills and contamination incidents?

Fuel spills and contamination are serious incidents that require immediate and effective action to minimize environmental damage and safety risks. The response follows a structured approach:

- Containment: The primary objective is to prevent the spread of the spill. This involves using absorbent materials like booms, pads, and spill kits to contain the fuel.

- Recovery: Once contained, the spilled fuel should be recovered using vacuum trucks or other suitable equipment.

- Clean-up: The affected area should be thoroughly cleaned and decontaminated, ensuring the removal of all traces of fuel. This may involve soil remediation in case of ground contamination.

- Reporting: All spills must be reported to the relevant authorities, such as the Environmental Protection Agency (EPA) in the US or equivalent agencies in other countries.

- Investigation: A thorough investigation is conducted to determine the cause of the spill to prevent recurrence. This may involve reviewing operating procedures, maintenance records, and equipment integrity.

Contamination incidents may involve water ingress into fuel tanks or mixing of different fuel types. The response involves similar containment, recovery, and cleanup procedures, with an emphasis on proper disposal of contaminated materials. In all cases, meticulous documentation of actions taken is necessary for compliance and future reference.

Q 11. What are the environmental regulations related to fuel handling and storage?

Environmental regulations concerning fuel handling and storage are stringent and designed to protect air, water, and soil quality. These regulations vary by location but typically encompass:

- Spill Prevention, Control, and Countermeasure (SPCC) plans (US): Facilities that store certain volumes of fuel are required to develop and implement SPCC plans to prevent spills and respond effectively in case of an incident.

- Underground Storage Tank (UST) regulations (US): These regulations dictate the design, installation, operation, and monitoring of USTs to prevent leaks and contamination of groundwater.

- Air quality regulations: These regulations limit emissions of volatile organic compounds (VOCs) from fuel storage and handling operations. This often involves using vapor recovery systems during refueling.

- Wastewater discharge permits: Permits are required to discharge wastewater containing fuel or fuel-related contaminants into waterways. Treatment of wastewater is typically mandated before discharge.

- Fuel quality standards: Regulations often dictate the permissible levels of contaminants in fuel, such as sulfur and benzene. This ensures that fuels meet specific quality standards to minimize pollution.

Non-compliance with these regulations can lead to significant penalties, including fines and legal actions. It’s crucial for all fuel handling facilities to stay abreast of and adhere to current environmental regulations.

Q 12. Describe your experience with different fuel types and their properties.

My experience encompasses a wide range of fuel types, including gasoline, diesel, jet fuel, and biofuels. Each fuel type has unique properties affecting its handling, storage, and combustion characteristics.

- Gasoline: Highly volatile and flammable, requiring careful handling to prevent vapor explosions. It’s characterized by its octane rating, influencing its combustion behavior in engines.

- Diesel: Less volatile than gasoline but still flammable. Its cetane number is a key property affecting ignition quality and engine performance. It’s also susceptible to microbial growth if moisture is present.

- Jet fuel: Similar to diesel fuel but with stricter purity requirements and specific freezing-point specifications to ensure reliable operation at high altitudes.

- Biofuels: These fuels are derived from renewable sources, such as vegetable oils and algae. Their properties vary depending on the source material, and may require adjustments in engine design or fuel systems.

Understanding these properties is critical for ensuring proper fuel handling, storage, and efficient engine operation. For example, the volatility of gasoline requires specialized storage tanks with vapor recovery systems to minimize emissions. The susceptibility of diesel to microbial growth necessitates the use of biocides to prevent fuel degradation.

Q 13. How do you maintain fuel system cleanliness and prevent contamination?

Maintaining fuel system cleanliness is crucial for preventing contamination and ensuring optimal performance. This involves a multi-faceted approach:

- Regular filter changes: Fuel filters trap contaminants, preventing them from reaching the engine. Regular filter replacement is crucial, following the manufacturer’s recommended schedule.

- Proper fuel handling practices: Preventing water ingress during refueling, using clean transfer pumps and hoses, and avoiding cross-contamination between different fuel types are vital.

- Tank cleaning and maintenance: Periodic cleaning of storage tanks and fuel lines is necessary to remove sediment and other contaminants. This may involve specialized cleaning techniques, depending on the level of contamination.

- Use of fuel additives: Some additives can help to improve fuel stability, prevent microbial growth, and reduce the formation of deposits.

- Regular inspection of fuel system components: Visual inspection of fuel lines, filters, and other components can help to identify potential leaks or contamination early on.

By adhering to these practices, fuel system cleanliness can be maintained, minimizing the risk of equipment failure and ensuring efficient engine operation. Neglecting these steps can lead to costly repairs and engine damage.

Q 14. What are the common causes of fuel system failure and how are they addressed?

Fuel system failures can stem from various causes, each requiring a specific approach for resolution:

- Contaminated fuel: Water, sediment, or microbial growth in fuel can clog fuel filters, damage injectors, and lead to poor engine performance. Addressing this involves replacing contaminated fuel, cleaning or replacing fuel filters, and possibly cleaning or replacing injectors.

- Faulty fuel pumps: A malfunctioning fuel pump will fail to deliver fuel to the engine, leading to engine stalling or failure to start. This necessitates replacing the faulty pump.

- Clogged fuel injectors: Clogged injectors reduce fuel delivery efficiency, leading to poor engine performance and potentially increased emissions. Cleaning or replacing injectors may be necessary.

- Leaks in the fuel system: Leaks can occur in fuel lines, tanks, or other components, leading to fuel loss and potential fire hazards. Repairing or replacing the leaking component is essential.

- Fuel pressure problems: Insufficient fuel pressure can prevent the engine from receiving sufficient fuel. Diagnosing the cause, which could include a faulty fuel pump or regulator, is vital for resolving the issue.

Troubleshooting fuel system failures requires systematic diagnosis. This may involve using diagnostic tools to check fuel pressure, inspecting components for leaks or damage, and conducting tests to assess fuel quality. Addressing the root cause is crucial to ensure long-term reliability.

Q 15. Describe your experience with fuel system diagnostics and troubleshooting.

Fuel system diagnostics and troubleshooting require a systematic approach. My experience spans over 10 years, encompassing various vehicle makes and models, from diagnosing simple fuel pressure issues to complex problems involving fuel injectors, pumps, and control modules. I begin by gathering information: checking engine warning lights, reviewing diagnostic trouble codes (DTCs), listening for unusual noises (e.g., a whining fuel pump), and visually inspecting the fuel system for leaks or damage. This initial assessment helps me narrow down the potential causes. Then, I employ a combination of diagnostic tools, including scan tools capable of reading live data from the engine control unit (ECU), pressure gauges to measure fuel pressure, and specialized testers for individual components. For example, I once diagnosed a vehicle’s poor performance as a faulty fuel pump by utilizing a pressure gauge to identify low fuel pressure at the fuel rail, even though the pump itself was producing minimal noise; the issue was a failing pump motor unable to generate sufficient pressure. I use a combination of hands-on testing, data analysis, and manufacturer-provided diagnostic information to isolate and resolve the problem efficiently and effectively.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of fuel filters and their functions?

Fuel filters are critical for removing contaminants from fuel, protecting delicate engine components. There are several types:

- In-tank filters: These are located inside the fuel tank and are the first line of defense against larger particles such as rust and debris. Think of them as a coarse pre-filter.

- In-line filters: Placed within the fuel line, usually before the fuel pump or fuel rail. They provide finer filtration, removing smaller particles that could clog injectors.

- Fuel filter/water separator: This type combines filtration with water separation. It’s crucial in areas with humid climates or questionable fuel quality. The separated water is collected in a reservoir that can be drained periodically. A good analogy is a coffee filter that also separates coffee grounds from the liquid.

Each filter’s function is to ensure clean fuel reaches the engine, preventing damage to injectors, fuel pump, and other sensitive components. Neglecting fuel filter maintenance can lead to poor fuel economy, engine misfires, or even engine failure.

Q 17. How do you inspect and maintain fuel lines and connections?

Inspecting and maintaining fuel lines and connections are crucial for preventing leaks and ensuring system integrity. Inspection involves carefully examining all fuel lines, fittings, and connections for signs of damage like cracks, kinks, corrosion, or leaks. I use visual inspection with good lighting to check for any signs of fuel weeping, paying close attention to the areas where the lines connect to the tank, the pump, and the engine. I also check the condition of the clamps securing the fuel lines and hoses ensuring they are tight and properly secured. For maintenance, I begin with checking and tightening all the clamps, making sure all connections are secure. If there are any signs of wear or damage to fuel lines, they must be replaced. Any damaged or corroded components need to be replaced promptly to avoid fuel leaks which can be both costly and dangerous. I often use a leak detection spray to verify the integrity of connections that may not be visibly leaking. Following manufacturer’s guidelines and using the correct tools are vital for safe and effective maintenance.

Q 18. Explain the process of performing a fuel system pressure test.

A fuel system pressure test measures the pressure within the fuel system, verifying the fuel pump’s output and the integrity of the system’s components. The procedure typically involves using a fuel pressure gauge specifically designed for this task. This gauge is connected to the fuel system, usually at the fuel rail, using an adapter. The engine is then started and allowed to run. The gauge will display the fuel pressure reading, which should fall within the manufacturer’s specified range. A low pressure reading indicates a possible problem with the fuel pump, fuel filter, pressure regulator, or a leak in the system. For example, if the pressure is significantly below the specifications during the test, this pinpoints that there might be an issue with fuel delivery, such as a clogged filter or a failing fuel pump. Comparing the actual reading with the manufacturer’s specification allows accurate diagnosis. It’s important to follow all safety precautions, as working with a pressurized fuel system can be hazardous. After the test is complete, the fuel pressure gauge must be properly disconnected, and all safety measures should be observed before disassembling any other components.

Q 19. What are the safety procedures for working with high-pressure fuel systems?

Working with high-pressure fuel systems demands strict adherence to safety procedures. Fuel is flammable and under pressure, making it potentially hazardous. First, I always ensure proper ventilation to prevent the buildup of flammable vapors. Eye protection, gloves, and clothing that protects skin are essential. Before beginning any work, I disconnect the negative battery terminal to prevent accidental ignition. When working with a pressure gauge, I carefully follow the manufacturer’s instructions for connection and handling. Never allow a fuel line to become fully pressurized without a pressure relief valve in place and always use the correct tools to avoid damaging components. I never use open flames or sparks near the fuel system. If a leak occurs during diagnostics or repair, I immediately stop the work and address the leak before proceeding. Proper training and understanding of the system’s operation are crucial for safe work practices.

Q 20. How do you interpret fuel system diagnostic trouble codes (DTCs)?

Fuel system diagnostic trouble codes (DTCs) are alphanumeric codes stored by the vehicle’s ECU indicating specific problems within the fuel system. Interpreting these codes requires using a scan tool to retrieve them. Once retrieved, I cross-reference the codes with the vehicle’s repair manual or a reputable online database to determine their meaning. For instance, a code such as P0171 (System Too Lean Bank 1) suggests a problem with fuel delivery to one side of the engine. This could result from a variety of issues: a faulty fuel injector, a vacuum leak in the intake manifold, or a malfunctioning oxygen sensor. A systematic approach, beginning with the most probable causes based on the DTCs and my diagnostic testing experience, helps me to efficiently isolate the problem. Some codes can be quite specific to the problem, whereas others point to a broader issue requiring further investigation.

Q 21. Describe your experience with fuel injection system calibration and adjustment.

Fuel injection system calibration and adjustment are advanced procedures typically performed using specialized equipment and software. My experience with this involves using scan tools with calibration capabilities. This allows precise adjustment of fuel injector pulse width, fuel pressure, and air/fuel ratios to optimize engine performance and emissions. Calibration typically involves accessing the ECU’s parameters and adjusting them based on data acquired during various tests, such as a dynamometer run or emission testing. This is a precision-oriented process that requires a deep understanding of engine management systems and precise measurement tools. I ensure that every step follows manufacturer recommendations, maintaining precise and safe calibration to achieve optimized performance and adhere to emission standards. Incorrect adjustment could have severe consequences, including increased fuel consumption, poor engine performance, and emission levels exceeding regulations.

Q 22. What are the common signs of a faulty fuel pump?

A faulty fuel pump can manifest in several ways, often impacting the vehicle’s ability to start or run smoothly. Think of the fuel pump as the heart of your fuel delivery system – if it’s weak or failing, the entire system suffers.

Difficulty Starting: The engine cranks but struggles to start, especially when hot. This is because the pump might not be delivering enough fuel under pressure.

Engine Hesitation or Stuttering: The engine may sputter or hesitate during acceleration, indicating an inconsistent fuel supply. Imagine a dripping faucet – the inconsistent flow mirrors the inconsistent fuel delivery.

Reduced Power: A weaker fuel pump can’t supply enough fuel to maintain optimal engine power, leading to sluggish acceleration and reduced performance. This is like trying to run a race while carrying a heavy weight.

Whining Noise from the Fuel Tank: A failing fuel pump often emits a whining or buzzing sound, especially when the ignition is turned on. This sound is the pump struggling to operate.

Fuel Pressure Issues (Requires Gauge): Using a fuel pressure gauge, you can directly measure the fuel pressure. Low or fluctuating pressure is a definitive sign of a failing pump.

Q 23. How do you identify and replace a fuel filter?

Identifying and replacing a fuel filter is a relatively straightforward procedure, but safety is paramount. Always work in a well-ventilated area, away from open flames. The fuel filter cleans contaminants from the fuel before it reaches the engine. A clogged filter starves the engine of fuel.

Locate the Filter: Consult your vehicle’s repair manual to pinpoint the fuel filter’s location. It’s typically found near the fuel tank or engine.

Safety First: Disconnect the battery’s negative terminal to prevent accidental sparks. Release any pressure in the fuel line by carefully loosening the fuel cap to allow air to enter.

Drain Fuel: Place a container below the filter to catch any remaining fuel. Carefully loosen the fuel lines connected to the filter, allowing the fuel to drain.

Remove the Filter: Unscrew or unclamp the old fuel filter and remove it carefully. Note the orientation of the filter to ensure correct installation of the new one.

Install New Filter: Install the new fuel filter, ensuring it’s properly seated and tightened. Reconnect the fuel lines, making sure they are secure.

Reconnect Battery: Reconnect the battery’s negative terminal.

Check for Leaks: Inspect all connections for leaks. Start the engine and check for leaks again. If leaks persist, re-tighten connections and recheck.

Q 24. Explain the process of bleeding air from a fuel line.

Bleeding air from a fuel line is necessary after fuel system repairs or replacements, such as filter changes or pump work. Air in the lines prevents the fuel pump from priming and delivering fuel to the engine. Think of it like trying to drink from a straw with air bubbles in it – the liquid won’t flow properly.

Prime the Pump (if applicable): Some fuel systems have a manual priming mechanism. Consult your vehicle’s manual. This helps to get the initial fuel flowing.

Check for Leaks: Before starting, thoroughly check all fuel lines and connections for leaks. A leak will reintroduce air into the system.

Cranking the Engine: Repeatedly turn the ignition key to the ‘on’ position, for a few seconds each time, without actually starting the engine. This allows the fuel pump to cycle and push out air.

Monitor Fuel Pressure (if equipped): If you have a fuel pressure gauge, monitor the pressure while cranking. The pressure should build steadily, indicating air is being removed.

Start the Engine: Once you’ve cranked the engine several times, try starting it. It may take a few attempts. If it starts but runs roughly, continue cranking it in short bursts.

Observe Engine Performance: If the engine starts and runs smoothly, the air has been bled. If it continues to run roughly, further troubleshooting might be necessary.

Q 25. What are the different types of fuel delivery systems?

Fuel delivery systems have evolved over time, with several variations depending on the vehicle’s age and design. Here are some common types:

Mechanical Fuel Pump: This older system uses a mechanical pump directly driven by the engine’s camshaft. Simpler in design, it’s prone to wear and tear.

Electric Fuel Pump: The more modern system uses an electric pump submerged in the fuel tank, powered by the vehicle’s electrical system. These are more reliable and can deliver higher fuel pressure.

Return-Style System: Excess fuel is returned to the tank. This is common in many modern vehicles and helps regulate fuel pressure.

Returnless System: Excess fuel isn’t returned to the tank. Precise fuel pressure regulation is handled by a fuel pressure regulator at the fuel rail. This system is designed for increased fuel efficiency.

Common Rail Injection: Used in diesel and increasingly in gasoline engines, a high-pressure common rail supplies fuel to injectors, improving fuel atomization and combustion efficiency.

Q 26. Describe your experience with fuel tank removal and installation.

I’ve extensive experience with fuel tank removal and installation on various vehicles. This procedure requires careful attention to safety and precision. The process generally involves several steps:

Safety Precautions: Always disconnect the battery’s negative terminal and relieve fuel system pressure. Work in a well-ventilated area away from ignition sources.

Fuel Line Disconnection: Carefully disconnect the fuel lines, using appropriate tools and capturing any spilled fuel. Note the routing and connections for easy reassembly.

Electrical Connections: Disconnect any electrical connections to the fuel sending unit or pump.

Tank Support Removal: Securely support the fuel tank to prevent damage during removal. Release any straps or bolts holding the tank in place.

Tank Removal: Carefully lower the fuel tank, paying attention to its weight and any potential obstacles. A helper is often beneficial for this step.

Installation: Reverse the removal process for installation. Ensure all connections are secure and no leaks are present before testing.

In one instance, I encountered a fuel tank with a corroded sending unit, causing an inaccurate fuel gauge reading. This highlighted the importance of thoroughly inspecting components during removal and replacement.

Q 27. What are the OSHA regulations related to fuel handling?

OSHA (Occupational Safety and Health Administration) regulations related to fuel handling are stringent and crucial for worker safety. Key regulations focus on:

Ventilation: Adequate ventilation is essential in areas where fuel is handled or stored to prevent the buildup of flammable vapors. This often involves using explosion-proof equipment and ensuring proper air circulation.

Personal Protective Equipment (PPE): Workers must use appropriate PPE, including safety glasses, gloves, and flame-resistant clothing. Respiratory protection may be required in certain situations.

Fire Prevention: No smoking or open flames are allowed near fuel. Fire extinguishers must be readily available and employees must be trained in their use.

Spill Prevention and Control: Procedures for preventing and responding to fuel spills are critical. This includes using spill containment materials and proper cleanup methods.

Hazardous Communication: Employees must be trained on the hazards of fuel handling, including the risks of fire, explosion, and health effects from exposure.

Storage and Handling: Fuel storage areas must be properly designed and maintained to prevent leaks and spills.

Q 28. Describe your experience with emergency response procedures related to fuel incidents.

My experience with emergency response procedures related to fuel incidents involves a comprehensive approach focusing on safety and containment. I’ve been involved in training sessions on:

Spill Response: Containing and cleaning up fuel spills using absorbent materials and appropriate equipment.

Fire Suppression: Using fire extinguishers and other fire suppression methods to control and extinguish fuel fires.

Emergency Evacuation: Ensuring safe evacuation of personnel from the affected area.

Notification Procedures: Reporting the incident to appropriate authorities, such as emergency services and environmental protection agencies.

Post-Incident Procedures: Documenting the incident, conducting a root-cause analysis to prevent future occurrences.

In one incident, a minor fuel leak occurred during a tank swap. Our swift response, following established procedures, prevented a major incident. We used spill kits to control the leak, ensuring the environment was protected, and completed a thorough investigation.

Key Topics to Learn for Fueling Vehicles Interview

- Fuel Dispensing Systems: Understanding the mechanics of fuel pumps, nozzles, and meters; troubleshooting common malfunctions; knowledge of safety protocols and regulations.

- Fuel Storage and Handling: Safe storage practices, including tank maintenance, leak detection, and environmental regulations; understanding of fuel quality control and testing procedures.

- Fuel Types and Properties: Differences between gasoline, diesel, and alternative fuels; understanding the impact of fuel properties on engine performance and emissions; knowledge of fuel additives and their functions.

- Automation and Control Systems: Familiarity with automated fueling systems, including remote monitoring and control; understanding of data acquisition and analysis from fueling operations.

- Safety and Compliance: Thorough understanding of relevant safety regulations and industry best practices for fueling operations; knowledge of emergency procedures and response protocols.

- Environmental Considerations: Awareness of environmental impacts of fuel handling and dispensing; knowledge of spill prevention and response techniques; familiarity with relevant environmental regulations.

- Maintenance and Troubleshooting: Proactive maintenance strategies for fuel dispensing equipment; effective troubleshooting techniques for common problems; understanding of preventative maintenance schedules.

- Financial Aspects: Understanding of fuel pricing, inventory management, and cost control strategies within a fueling operation; basic accounting principles related to fuel sales and expenses.

Next Steps

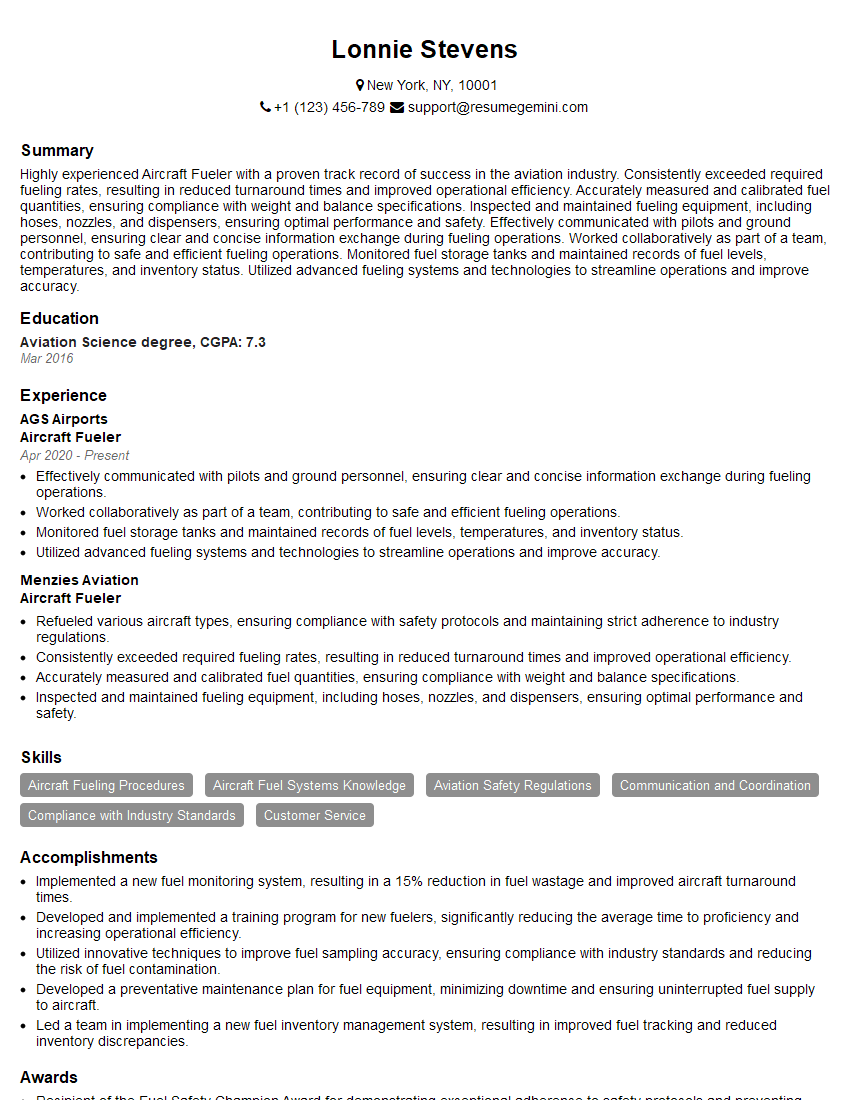

Mastering the intricacies of fueling vehicles opens doors to rewarding careers in a vital industry. A strong understanding of the technical aspects, safety protocols, and operational efficiency will significantly boost your job prospects. To maximize your chances of landing your dream role, it’s crucial to present yourself effectively. Create an ATS-friendly resume that highlights your skills and experience in a clear and concise manner. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the Fueling Vehicles industry. Examples of resumes specifically designed for this field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO