Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Gantry Crane Operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Gantry Crane Operation Interview

Q 1. Describe your experience operating gantry cranes.

I have over eight years of experience operating various gantry cranes in diverse industrial settings, including shipbuilding, construction, and manufacturing. My experience encompasses handling a wide range of loads, from delicate machinery components weighing a few hundred kilograms to massive steel structures exceeding 100 tons. I’m proficient in operating both conventional and modern gantry cranes equipped with advanced control systems. For example, I’ve successfully managed the intricate lifting and placement of prefabricated sections during the construction of a large offshore platform, requiring precise control and coordination with other operators.

Q 2. What are the different types of gantry cranes you are familiar with?

My familiarity extends to several gantry crane types, including:

- Overhead Gantry Cranes: These are commonly used in workshops and factories for lifting and moving heavy materials. They travel on fixed rails.

- Portable Gantry Cranes: More mobile and often utilized for temporary lifting needs on construction sites. They can be disassembled and moved to different locations.

- Jib Gantry Cranes: Combine gantry crane features with a jib, offering a wider reach than a standard overhead crane.

- Container Gantry Cranes: Specifically designed for handling shipping containers at ports, and are extremely large and powerful.

- Rubber-Tyred Gantry Cranes (RTGs): These are self-propelled and use rubber tyres, offering greater flexibility in movement within a yard.

The choice of crane type depends heavily on the specific application and load requirements.

Q 3. Explain the load chart and its significance in safe crane operation.

A load chart is a crucial document that specifies the safe working load (SWL) of a crane for different configurations and radii. It’s essentially a graphical representation of the crane’s capacity under varying conditions. The SWL is the maximum weight a crane can safely lift without compromising its structural integrity or operational safety. The load chart considers factors like boom angle (if applicable), radius of the lift, and the crane’s configuration (e.g., outriggers extended or retracted). Ignoring the load chart is a serious safety violation, potentially leading to catastrophic equipment failure and injuries. For example, attempting to lift a load exceeding the SWL at a given radius could cause the crane to tip over or structural components to fail. I always ensure the load chart is readily available and I strictly adhere to its specifications before undertaking any lifting operation.

Q 4. How do you ensure the stability of a load during lifting and movement?

Maintaining load stability during lifting and movement involves a multi-faceted approach:

- Proper Load Securing: Using appropriate slings, chains, or other lifting devices that are rated for the load’s weight and evenly distribute the load’s weight. I always perform a thorough inspection before attaching lifting gear.

- Smooth Crane Operation: Avoiding sudden movements or jerky starts and stops. This minimizes sway and reduces the risk of load instability.

- Careful Consideration of Wind Conditions: High winds can significantly impact load stability, so operations might need to be halted in severe weather. If winds are moderate, I might need to adjust my lifting speed and technique to compensate.

- Load Monitoring: Keeping a close eye on the load throughout the lifting and movement process, using visual checks and potentially additional sensors for very large or sensitive loads.

- Proper Load Centering: Ensuring that the load’s center of gravity is properly aligned with the lifting hook to prevent tilting or rotation.

Think of it like carrying a heavy box – you would keep it close to your body and move slowly to maintain balance. It’s the same principle with gantry cranes but on a larger scale.

Q 5. What safety procedures do you follow before operating a gantry crane?

Before operating any gantry crane, I adhere to the following stringent safety procedures:

- Pre-Operational Inspection: A thorough visual inspection of the crane, including structural components, cables, hooks, and control systems. This ensures everything is in sound working order and meets safety standards.

- Documentation Review: Checking the crane’s logbook for any recent maintenance, repairs, or reported issues.

- Permit to Work System: Ensuring I have the necessary permits, authorizations, and approvals before commencing work.

- Risk Assessment: Identifying potential hazards associated with the specific lifting operation, including environmental factors and personnel safety.

- Communication Plan: Establishing clear communication protocols with ground personnel to coordinate movements and ensure a safe working environment. I always use hand signals as a backup in the event that radio communication fails.

These steps are crucial in mitigating risks and ensuring a safe working environment.

Q 6. Describe your experience with pre-operational checks and inspections.

My experience with pre-operational checks and inspections is extensive. I meticulously document all findings in the crane’s logbook, including date, time, operator name, and details of any issues identified. I’m trained to recognize signs of wear and tear, such as frayed cables, loose bolts, or hydraulic leaks, and I know the appropriate procedures to follow if such problems are detected (reporting to supervisors and halting operations until repairs are completed). I’ve developed a systematic approach to these inspections, working methodically through a checklist to ensure nothing is overlooked. Regular maintenance and proactive inspections are key to preventing catastrophic failures.

Q 7. How do you handle unexpected situations or emergencies during crane operation?

Handling unexpected situations requires quick thinking, decisive action, and adherence to emergency procedures. For instance, if a load starts to sway excessively, I’d immediately lower it to a safe position and stop the operation. If a mechanical failure occurs (e.g., a cable snapping), my training dictates that I immediately shut down the crane, clear the area, and report the incident to the appropriate personnel. In the case of a power outage, I’d follow established procedures to safely lower the load using emergency lowering mechanisms. I’ve been trained in emergency response protocols including fire safety and evacuation procedures relevant to the site. Effective communication is critical during emergencies, and I’d ensure clear and concise communication with everyone involved.

Q 8. What are the limitations of a gantry crane?

Gantry cranes, while incredibly useful for lifting heavy loads, have several limitations. Their primary limitation is their mobility; they are typically fixed to a specific location, unlike mobile cranes. This restricts their operational area and necessitates careful planning of load movement paths. Another key limitation is their structural limitations. They have a maximum lifting capacity and a defined reach, both crucial parameters that must never be exceeded. Exceeding these limits could lead to catastrophic structural failure. Finally, gantry cranes are often susceptible to weather conditions, especially high winds. Strong winds can make it dangerous or impossible to operate the crane safely. Consider a gantry crane in a shipyard: it might be highly efficient for moving containers within a designated area, but moving it to a different location is costly and time-consuming.

Q 9. Explain the concept of swing radius and its importance in safe operation.

The swing radius is the horizontal distance from the crane’s center of rotation to the furthest point the hook can reach. It’s absolutely critical for safe operation. Imagine it as a circle drawn around the crane’s base, defining the area within which the load can swing. Understanding the swing radius helps prevent collisions with surrounding objects, personnel, or other equipment. For example, before lifting a load near a wall or other structure, I meticulously calculate the swing radius and ensure that the load’s path will clear obstacles during all lifting phases, from initial lift to final placement. Failing to do this can lead to significant damage or even serious injury.

Q 10. How do you communicate with ground personnel during crane operation?

Communication with ground personnel is paramount for safe crane operation. We use a combination of methods: Hand signals are a primary method, standardized and universally understood. These signals direct the crane operator for lifting, lowering, and maneuvering the load. Two-way radios ensure clear verbal communication, especially for complex lifts or situations where hand signals might be obscured. Additionally, a designated spotter is often positioned on the ground, observing the lift and relaying vital information to the operator, alerting them to potential hazards that the operator might not see from the crane cab. We also maintain detailed pre-lift check lists that detail the communication protocols specific to the job.

Q 11. Describe your experience with different types of crane hooks and attachments.

My experience encompasses a variety of crane hooks and attachments, including standard hooks for general lifting, specialized hooks for handling specific materials (like coil hooks for steel coils), and various attachments like slings (wire rope, chain, synthetic fiber), magnets for ferrous materials, and vacuum lifters for delicate or non-ferrous materials. Selecting the appropriate hook and attachment is crucial and depends entirely on the load characteristics, including its weight, shape, and fragility. For instance, using a standard hook to lift a delicate glass panel would likely result in damage, whereas a vacuum lifter provides a much safer solution. Each hook type has a specific weight limit and needs regular inspection to maintain safety.

Q 12. How do you calculate the weight of a load before lifting?

Calculating the load weight before lifting is a crucial safety procedure. It’s rarely a matter of simply eyeballing the load. We use several methods: if the load has a known weight, it is typically marked, and we verify this information with documentation. If not marked, we can estimate based on dimensions and material density if that information is available. However, the most reliable way is using scales to directly weigh the load before lifting. In the event none of these are possible, using a detailed material list and factoring densities provides the most accurate estimation. This information must always be compared with the crane’s lifting capacity to ensure it remains within safe operational parameters. A common mistake is neglecting to consider the weight of the lifting gear, such as slings and hooks, which adds to the total load weight.

Q 13. What are the common causes of crane accidents and how can they be prevented?

Crane accidents frequently stem from several preventable factors. Overloading, lifting beyond the crane’s rated capacity, is a significant cause. Improper rigging, using unsuitable slings or incorrectly attaching them, can lead to load slippage or failure. Lack of communication between the operator and ground crew results in miscommunication which is highly dangerous. Inadequate inspections and maintenance allow for mechanical failures and structural compromises to occur. Lastly, environmental factors like high winds can cause loss of control of the load. Prevention relies on strict adherence to safety regulations, thorough pre-lift inspections, employing proper lifting techniques, regular crane maintenance, and effective communication protocols, which often include a formalized risk assessment protocol.

Q 14. Explain your understanding of load charts and their significance in safe operation.

Load charts are essentially graphs or tables that show the crane’s safe lifting capacity at various radii and heights. They are instrumental in ensuring safe operation. They visually represent the maximum load the crane can lift at different boom lengths, or in the case of a gantry crane, at various distances from the center of rotation. Before initiating a lift, we always consult the load chart to verify that the load weight, plus the weight of rigging and attachments, falls within the safe working limits specified for the intended lifting configuration. Disregarding the load chart is a recipe for disaster, potentially leading to structural failure and injuries. I treat load charts as an essential part of a pre-lift planning session, ensuring everyone is aware of and understands the limitations of the equipment.

Q 15. Describe your experience with different types of crane signals.

Crane signals are crucial for safe and efficient gantry crane operation. They ensure clear communication between the crane operator and the signal person, who directs the crane’s movements. I’m experienced with a range of signaling methods, including:

- Hand signals: These are standardized gestures using arms and hands to indicate hoisting, lowering, swinging, and traveling directions. For instance, a hand raised above the head signals hoisting, while a hand moving in a circle indicates swinging the load.

- Radio communication: This offers more flexibility and is especially useful in noisy environments or when working over large distances. Clear, concise communication is paramount – using standardized terminology and confirming instructions prevents misunderstandings. We often use pre-determined phrases to ensure clarity.

- Visual signals: Lights or other visual cues can be utilized to supplement hand signals or radio communication. For example, a light system might show the direction the crane is moving to increase visibility.

My experience includes working with both experienced and inexperienced signal persons, adjusting my communication style to suit their skills and ensuring everyone is on the same page. I always verify the signal before executing the command, especially when dealing with critical lifts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address potential hazards in the work environment?

Hazard identification is a critical aspect of safe crane operation. My approach involves a proactive and multi-faceted strategy:

- Pre-operational checks: Before any lift, I thoroughly inspect the crane, including the structure, hoisting mechanisms, load-handling devices, and surrounding area. This checks for any visible damage or potential hazards.

- Environmental assessment: I consider the weather conditions (wind speed, visibility), ground conditions (stability of the ground for the crane and load), and proximity to obstructions (power lines, buildings).

- Load assessment: The weight, dimensions, and center of gravity of the load are crucial. Incorrect weight estimation can lead to catastrophic accidents. I ensure I have accurate information and appropriate lifting gear.

- Personnel awareness: I actively look out for anyone working in the crane’s operating radius and ensure clear communication to maintain safe distances. Establishing exclusion zones is vital for high-risk operations.

If a hazard is identified, I immediately address it. This could involve halting operations, reporting the issue to the supervisor, or implementing control measures (e.g., erecting barriers, increasing the number of spotters).

For instance, I once noticed a crack in the gantry leg during a pre-operational check. I immediately stopped work and reported this to my supervisor, preventing a potential catastrophic failure.

Q 17. What are your experience with different types of crane controls?

I have experience with various crane control systems, including:

- Pendant controls: These are handheld devices with buttons and levers to control the crane movements. They are common in many gantry cranes and provide direct, localized control.

- Cabin controls: Larger gantry cranes often have operator cabins offering better visibility and environmental protection. These controls are typically more complex, but offer greater precision.

- Remote controls: Radio-controlled systems allow operation from a distance, especially advantageous in hazardous environments. This needs extremely careful planning to make sure signal clarity is never compromised.

Regardless of the control system, I prioritize understanding the specific controls and safety features before operating any crane. This includes understanding emergency stop mechanisms and procedures. Regular training and certification are essential to maintain proficiency.

Q 18. Describe your experience working with various load handling devices.

My experience encompasses a wide range of load-handling devices, including:

- Hooks: These are the most common and are essential for lifting a wide range of loads.

- Clamps: Designed for handling specific materials like steel plates or pipes, ensuring secure and safe lifting.

- Spreader beams: Used to distribute the load across multiple attachment points, suitable for larger and more oddly-shaped objects.

- Magnetic lifters: Ideal for lifting ferrous materials efficiently.

- Vacuum lifters: Employed for lifting materials with a smooth surface like glass, and are extremely reliable if applied properly.

The selection of the appropriate load-handling device is critical. Incorrect selection can lead to damage to the load, the crane, or both. I always verify that the chosen device is rated for the load’s weight and characteristics. Moreover, regular inspections of all load handling devices are essential to ensure optimal safety.

Q 19. How do you handle situations with poor visibility?

Poor visibility presents significant challenges in gantry crane operation. My approach involves:

- Increased caution: Operations are significantly slowed down and performed with extra care, prioritizing safety over speed.

- Additional personnel: Employing extra spotters to improve visual awareness of the surroundings, and the load’s path and position. Their input is crucial in compensating for limited visibility.

- Utilizing lighting: Employing additional lighting, such as portable lights or work lamps, to enhance visibility.

- Suspending operations if necessary: If visibility is dangerously low (e.g., during heavy fog or severe storms), operations are halted completely until conditions improve.

I’ve experienced situations where dense fog reduced visibility to only a few meters. In these cases, we employed a team of spotters, used powerful lamps, and considerably reduced lifting speed until visibility improved.

Q 20. How do you ensure compliance with relevant safety regulations?

Compliance with safety regulations is paramount. My approach includes:

- Understanding relevant legislation and standards: I’m familiar with OSHA regulations (or equivalent regulations in other regions) governing gantry crane operation. This includes knowing requirements for operator certification, pre-operational checks, load limits, and safety procedures.

- Regular training and certification: Staying current with training and certifications ensures I am up-to-date with safety procedures and best practices.

- Following company safety procedures: Adhering strictly to all company-specific safety policies and procedures.

- Reporting incidents and near misses: Proactive reporting ensures that potential hazards are identified and addressed before they lead to accidents.

I treat every operation as if it were my own life and safety at stake, exceeding minimum requirements for a safety-conscious operation.

Q 21. What is your experience with maintenance and troubleshooting of gantry cranes?

Maintenance and troubleshooting are integral parts of ensuring safe and reliable crane operation. My experience includes:

- Preventative maintenance: This involves regular inspections, lubrication, and adjustments to minimize the risk of breakdowns. I’m familiar with scheduled maintenance procedures and checklists.

- Troubleshooting: I can diagnose common problems like hoist malfunctions, brake issues, or electrical faults. This is achieved by systematically identifying the source of the problem through observations, checks, and testing.

- Working with maintenance personnel: I effectively communicate with certified crane maintenance personnel to ensure repairs are conducted correctly and safely.

- Record keeping: Maintaining detailed records of inspections, repairs, and maintenance is a cornerstone of preventive maintenance to allow for accurate tracking of repairs.

For example, I once identified a failing brake mechanism by listening to the unusual noise. I immediately reported it and halted operations to prevent potential accidents. Preventative maintenance is far more cost-effective than dealing with the costs and disruptions of major repairs caused by lack of maintenance.

Q 22. Describe your experience with different types of crane lifting techniques.

My experience encompasses a wide range of crane lifting techniques, tailored to the specific load, environment, and crane capabilities. Think of it like choosing the right tool for the job – a delicate antique requires a different approach than a heavy steel beam.

- Lifting with multiple slings: This technique distributes the load across multiple points, reducing stress on any single point and improving stability. For example, lifting a large, irregularly shaped object would require strategically placed slings to ensure even weight distribution. Incorrect placement can lead to uneven stress and potential damage to the load or the crane.

- Lifting with a spreader beam: Used for loads too wide for a single sling, a spreader beam distributes the weight evenly across multiple slings. I’ve used this extensively when handling long steel sections or large machinery, ensuring safe and efficient movement.

- Tandem lifting: This involves using two or more cranes to lift a single, extremely heavy load. The coordination required is crucial; I’ve participated in tandem lifts for massive industrial components, where precise synchronization between cranes was paramount to avoid accidents.

- Critical lifts: These involve detailed planning, risk assessments, and often specialized equipment. One memorable project involved a critical lift of a transformer; thorough pre-lift checks, including load calculations and rigging inspections, were essential to the lift’s success and prevented potential hazards.

My approach always prioritizes safety and efficiency. Careful load calculations, proper rigging techniques, and thorough pre-lift inspections are integral parts of every lifting operation I undertake.

Q 23. How do you maintain accurate records of crane operations?

Maintaining accurate records is crucial for safety, regulatory compliance, and efficient operation. Imagine trying to solve a crime without proper documentation – you wouldn’t get far! Similarly, crane operations need meticulously documented records.

My record-keeping process typically includes:

- Pre-operation checklists: These document inspections of the crane, rigging equipment, and the load itself, ensuring everything is safe and functional.

- Lift plans: Detailed plans outlining the lift procedure, including load weight, lifting points, crane configurations, and safety precautions. These are crucial for complex or high-risk lifts.

- Daily logs: These record each lift performed, including date, time, load details, operator’s name, and any unusual incidents or observations. This forms a crucial safety audit trail.

- Maintenance records: I diligently record all routine and preventative maintenance performed on the crane, which is crucial for its longevity and safety.

- Incident reports: Any accidents, near misses, or mechanical issues are documented in detail, including root cause analysis and corrective actions. This feedback helps to continuously improve safety and procedures.

Digital logbooks and specialized crane management software greatly simplify this process. We often use software that automatically records lift data and integrates with maintenance scheduling.

Q 24. How do you react to mechanical failures during operation?

Mechanical failure during operation is a serious event demanding immediate and decisive action. My first priority is always safety – of myself, my crew, and the surroundings. Think of it as a fire drill; your response needs to be trained and effective.

My response protocol involves:

- Immediate shutdown: The first step is to safely shut down the crane using the emergency stop procedures. This prevents further damage and reduces potential harm.

- Assess the situation: Once the crane is stopped, I carefully evaluate the nature and extent of the failure, determining the immediate hazards.

- Alert relevant personnel: I notify the supervisor, maintenance crew, and anyone else who needs to know about the incident, ensuring clear communication.

- Secure the load: If the load is suspended, I carefully secure it to prevent it from falling or shifting. Depending on the situation, I might use secondary rigging equipment or blocks and tackles.

- Prevent unauthorized access: I ensure that the area around the faulty crane is secured to prevent access until it has been inspected and repaired by qualified personnel.

- Complete incident report: A detailed report is generated documenting the incident, including the type of failure, the actions taken, and any contributing factors.

Regular preventative maintenance is crucial in minimizing the risk of mechanical failures. Consistent inspections and adherence to the manufacturer’s recommendations are essential in maintaining a safe operating environment.

Q 25. Describe your experience with emergency shutdown procedures.

Emergency shutdown procedures are practiced regularly and are ingrained in my operating methodology. Knowing these procedures is as important as knowing how to operate the crane itself. It’s about muscle memory and clear thinking under pressure.

My experience involves:

- Familiarization with emergency stop buttons and switches: These are clearly marked and easily accessible, ensuring rapid shutdown in critical situations.

- Understanding power disconnects: I know the location and method for disconnecting power to the crane, vital in severe emergency scenarios.

- Emergency lowering procedures: I’m proficient in safely lowering a suspended load in case of power failure, utilizing auxiliary systems or mechanical brakes.

- Evacuation procedures: I’m familiar with escape routes and assembly points in case of a major emergency affecting the entire worksite.

- Communication protocols: I understand the communication channels used in emergencies and how to effectively communicate with fellow workers and supervisors.

Regular drills and simulations help refine these procedures, ensuring we react quickly and effectively to unforeseen circumstances. These drills aren’t just theoretical exercises; they’re vital for real-world preparedness and safety.

Q 26. What are your skills in using crane operating software/systems?

Modern crane operating systems enhance safety and efficiency. My skills involve using various software for load monitoring, operational logging, and preventative maintenance scheduling. It’s like having a sophisticated co-pilot.

My experience includes:

- Crane management software: I can use software that tracks crane usage, maintenance schedules, and lift records, improving operational efficiency and safety management. These systems often include features that alert operators to potential hazards or maintenance needs.

- Load moment indicators (LMIs): I’m proficient in using LMIs, which display the crane’s load moment, helping to prevent overloading and ensuring safe operation. They’re crucial for calculating the stability of the lift.

- Remote monitoring systems: Some systems allow for remote monitoring of the crane’s status, aiding in preventative maintenance and reducing downtime. This allows for early detection of potential problems.

- Data analysis: I’m capable of analyzing the data from these systems to identify trends, improve operational efficiency, and optimize maintenance schedules. This data-driven approach ensures continuous improvement.

Staying updated with the latest technology and software is essential for staying efficient and safe in this industry.

Q 27. How do you ensure the proper use of personal protective equipment (PPE)?

The proper use of PPE is non-negotiable. It’s the first line of defense against potential hazards. Imagine a surgeon performing surgery without gloves; it’s unthinkable! PPE should be treated with the same level of importance.

My approach to PPE includes:

- Daily inspection: Before each shift, I inspect all my PPE – hard hats, safety glasses, gloves, high-visibility clothing, and safety harnesses – ensuring they’re in good condition and properly fitted.

- Correct usage: I understand and adhere to the correct methods for wearing and using each piece of PPE, ensuring maximum protection. This includes understanding the limitations of each item.

- Proper storage and maintenance: I store PPE correctly to prevent damage and ensure its longevity. Damaged or worn-out PPE is immediately replaced.

- Training and awareness: I am actively involved in training and awareness programs relating to PPE, ensuring that I and others understand the importance and correct usage of safety gear.

- Reporting damaged equipment: I report any damaged or faulty PPE to my supervisor to ensure that it is replaced promptly.

A safe working environment starts with a commitment to wearing and maintaining appropriate PPE.

Q 28. Explain your understanding of the different types of crane brakes and their functions.

Different crane brakes play vital roles in ensuring safe and controlled operations. Think of them as the multiple safety nets that keep everything under control.

Common types include:

- Mechanical brakes: These are typically friction brakes that engage when power is lost or the operator releases the control. They are a crucial safety feature providing fail-safe control. I’ve witnessed their reliable action during power outages.

- Regenerative brakes: These convert kinetic energy into electrical energy during deceleration, reducing wear on the mechanical brakes and improving energy efficiency. It’s like a more environmentally friendly and efficient braking system.

- Eddy current brakes: These use electromagnetic forces to slow down the crane’s movement, offering smooth and precise control. They are often used for more precise movements in sensitive operations.

- Hydraulic brakes: These use hydraulic pressure to engage the braking mechanism, offering powerful and reliable braking force. They are prevalent in larger cranes and heavy-duty applications.

Understanding how each brake functions and its limitations is crucial for safe operation. Regular inspections and maintenance are necessary to ensure their effectiveness. The failure of any braking system could have catastrophic consequences.

Key Topics to Learn for Gantry Crane Operation Interview

- Crane Mechanics and Hydraulics: Understanding the fundamental principles of how gantry cranes function, including load bearing, lifting mechanisms, and hydraulic systems. Consider exploring different types of gantry cranes and their specific operational characteristics.

- Safety Procedures and Regulations: Deeply understanding OSHA (or relevant regional) safety regulations and best practices for gantry crane operation. This includes pre-operation checks, load securing, and emergency procedures.

- Load Handling and Stability: Mastering techniques for safely handling various loads, including calculating weight distribution, center of gravity, and understanding the implications of wind and environmental factors on stability. Practical experience in load calculations and planning will be highly beneficial.

- Communication and Teamwork: Demonstrating an understanding of effective communication protocols with ground crew and other operators, emphasizing safety and coordination during lifting operations. Discuss examples of successful teamwork in high-pressure situations.

- Troubleshooting and Maintenance: Familiarize yourself with common gantry crane malfunctions and the basic troubleshooting steps involved. Understanding preventative maintenance schedules and procedures is also crucial.

- Advanced Operational Techniques: Explore specialized techniques such as precise load placement, working in confined spaces, and understanding the limitations of the crane’s capabilities.

Next Steps

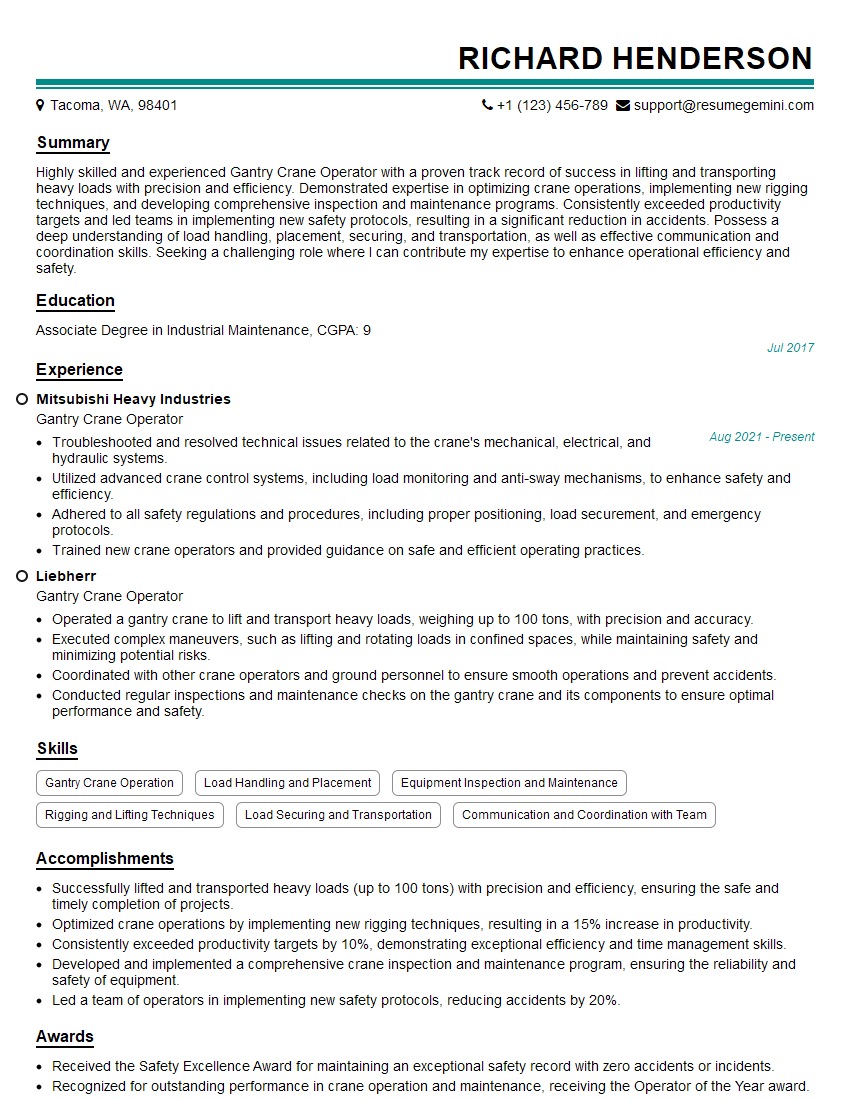

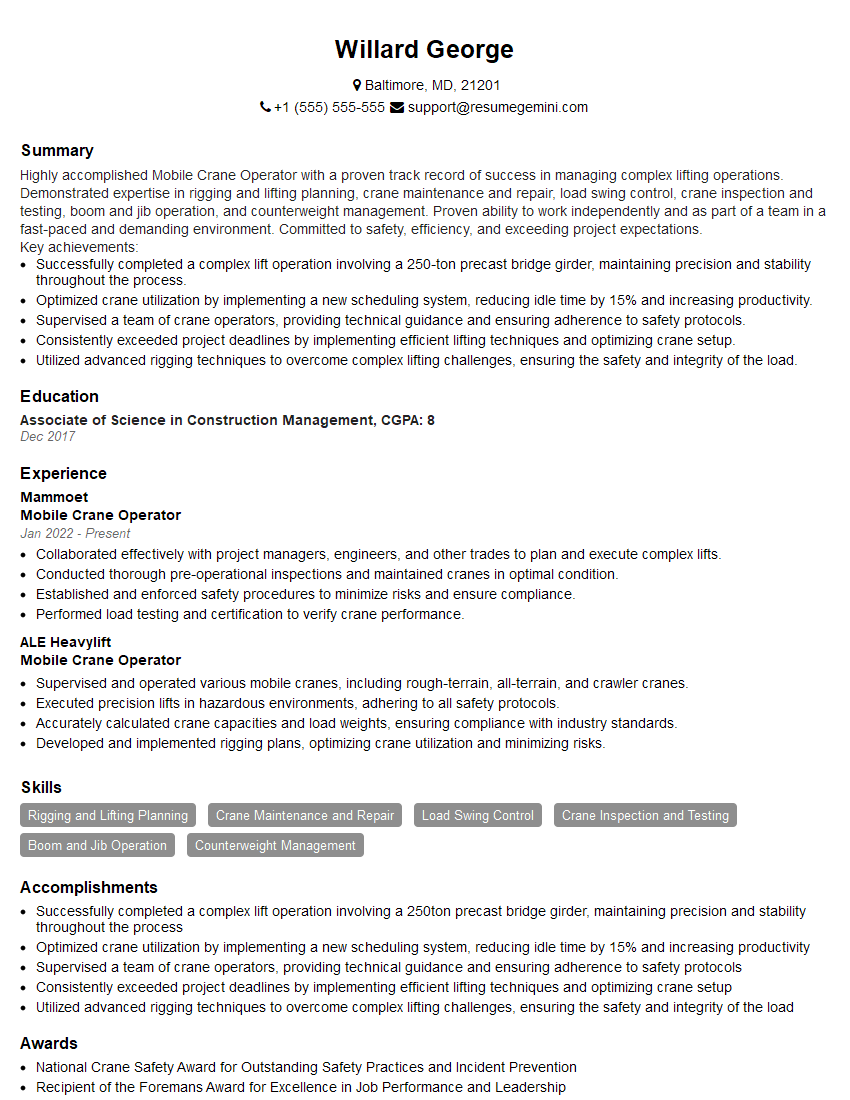

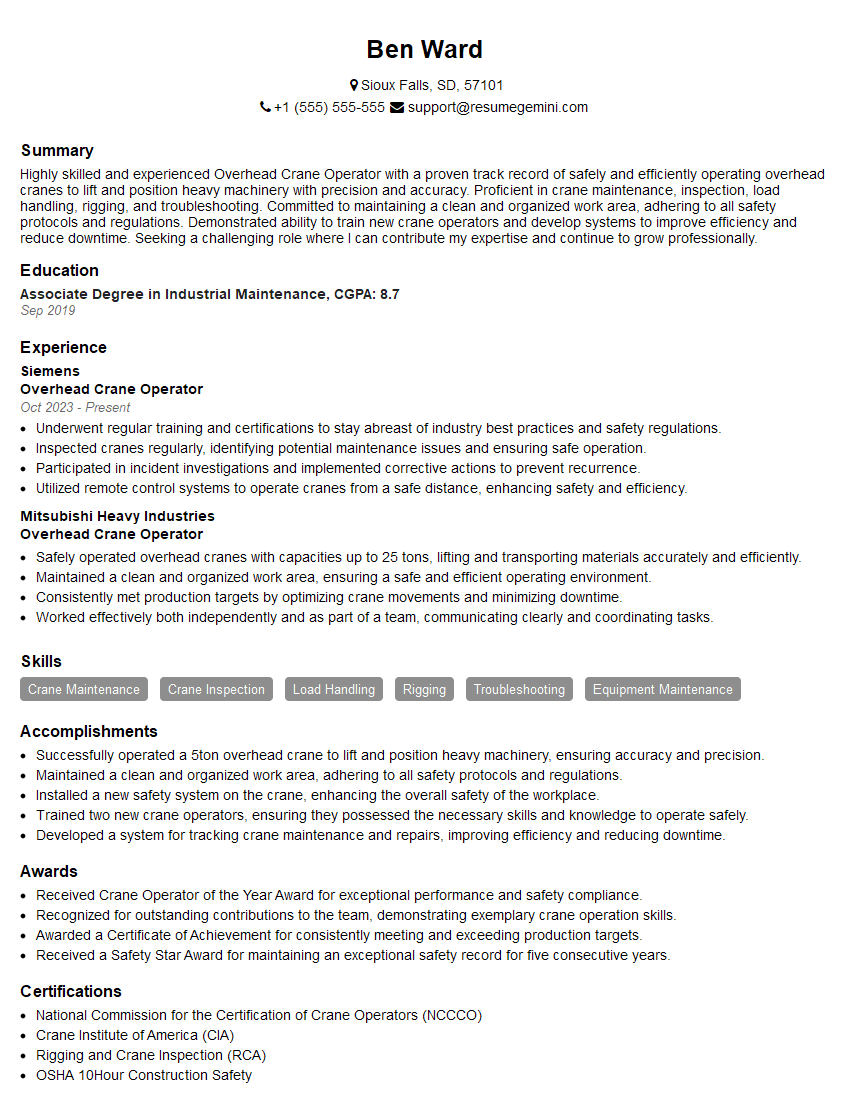

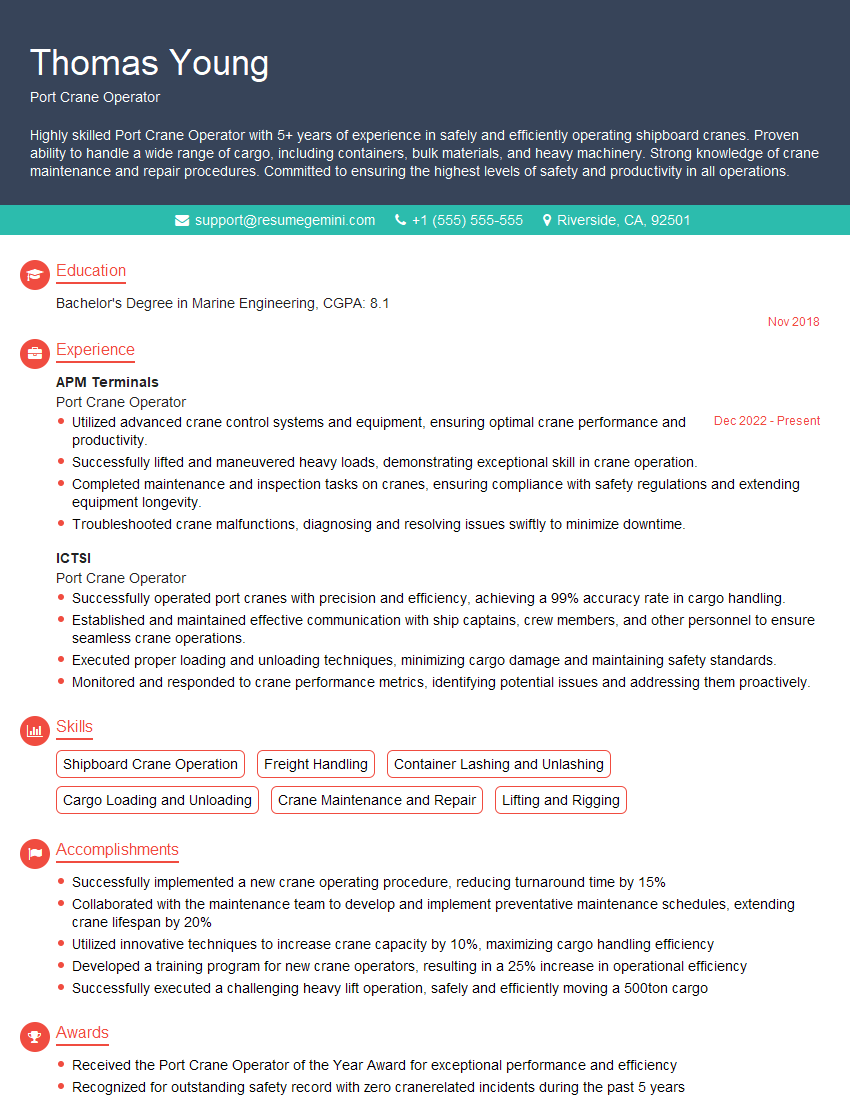

Mastering Gantry Crane Operation opens doors to rewarding and highly skilled careers within various industries. This specialized skillset is in high demand, offering excellent job security and potential for career advancement. To maximize your job prospects, focus on creating a compelling and ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of Gantry Crane Operation roles. Examples of resumes tailored to this field are available to guide you through the process. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO