Are you ready to stand out in your next interview? Understanding and preparing for Glass Replacement interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Glass Replacement Interview

Q 1. What types of glass are you experienced in installing and repairing?

My expertise spans a wide range of glass types commonly used in residential and commercial applications. This includes annealed glass (standard window glass), tempered glass (safety glass, much stronger than annealed), laminated glass (two or more layers bonded together for safety and sound insulation), insulated glass units (IGUs, double or triple-paned windows), and various specialty glasses like patterned, textured, or energy-efficient low-E glass. I’ve worked with these in diverse settings, from replacing a simple window pane in a home to intricate projects involving large storefront windows or skylights. For example, I recently replaced a series of large, laminated storefront windows in a downtown shop, requiring careful handling and precise measurements to ensure a perfect fit and maintain the building’s aesthetic.

Q 2. Describe your experience with different glass cutting techniques.

Glass cutting necessitates precision and safety. I’m proficient in several techniques. The most common is using a glass cutter, scoring the glass with a carbide wheel and then snapping it along the score line using a pair of pliers or a breaking bar. This requires a steady hand and the right amount of pressure to avoid chipping. For curved or intricate cuts, I utilize a wet saw, which uses a diamond blade and water coolant to prevent overheating and cracking. This is particularly helpful for custom-shaped glass replacements. Finally, for very delicate or complex designs, I’ve used specialized tools like nibblers or a CNC glass cutter for precise and efficient results. The choice of technique depends on the glass type, its thickness, and the desired shape.

Q 3. Explain the process of measuring and ordering glass for a replacement project.

Accurate measurements are paramount. I begin by carefully measuring the existing glass opening, accounting for any framing irregularities or existing sealant buildup. This involves using a measuring tape, a level, and often a square to ensure precise dimensions. I then account for any necessary tolerances – a small amount of extra space – to allow for proper installation and to avoid binding. These measurements are carefully documented, including the type of glass required, thickness, and any specific features like coatings or patterns. I then prepare a detailed order, including the exact dimensions and specifications, to ensure the new glass perfectly fits the opening. This eliminates the risk of costly errors and ensures a clean, professional installation. I often take photos to aid in the process and for documentation purposes.

Q 4. How do you handle damaged glass during removal and disposal?

Safety is my top priority. Damaged glass is always handled with extreme caution. I use gloves and safety glasses, and if necessary, cover the glass with heavy-duty tape to prevent further shattering. I then carefully remove the broken pieces, using specialized tools to avoid injury. Broken glass is disposed of responsibly, usually in heavy-duty containers labeled for hazardous waste, in accordance with local regulations. In some cases, larger pieces of damaged glass can be carefully salvaged and repurposed after cleaning, for example for mosaic projects or artistic installations.

Q 5. What safety precautions do you take when working with glass?

Working with glass inherently carries risks, so safety is always paramount. I always wear safety glasses, gloves, and closed-toe shoes. I use appropriate tools for the task, ensuring they’re in good working order. When removing old glass, I take extra precautions to avoid cuts and punctures, such as using a putty knife or other specialized tools to minimize the risk of shattering. If working at heights, I use appropriate fall protection equipment. I also ensure the work area is clear and well-lit to prevent accidents. A clean workspace allows for a safer and more efficient job.

Q 6. What are the different types of sealants used in glass installation?

The choice of sealant is crucial for a durable and weather-tight installation. Common sealants include silicone, polyurethane, and butyl. Silicone is flexible, weather-resistant, and adheres well to various substrates; it’s ideal for many glass applications. Polyurethane provides excellent adhesion and durability, though it can be less flexible than silicone. Butyl is a more traditional sealant, known for its ability to create a strong, lasting bond, particularly in IGUs. The best sealant selection depends on factors such as the type of glass, the application, and environmental conditions. For instance, I’d use silicone for general window installations, but perhaps polyurethane for exterior applications requiring superior weather resistance.

Q 7. Describe your experience with installing insulated glass units (IGUs).

IGUs, or Insulated Glass Units, require specialized handling. My experience includes the precise installation and replacement of these units, paying close attention to the integrity of the spacer frame and the sealant. Improper installation can lead to moisture or air leakage, affecting energy efficiency and potentially causing damage. I’m experienced in using spacers and sealants specifically designed for IGUs, ensuring a proper seal. For example, during a recent project replacing several IGUs in a historic home, I was careful to maintain the original style and ensure a flawless seal to preserve the home’s character and energy efficiency. This required meticulous attention to detail and the use of specialized tools and materials.

Q 8. How do you ensure a proper fit and seal during glass installation?

Ensuring a proper fit and seal during glass installation is crucial for preventing drafts, leaks, and energy loss. It’s like building a perfectly airtight window frame. It involves several key steps. First, precise measurements are paramount. We use high-precision tools to ensure the new glass pane is the exact size needed. Any deviation can lead to gaps or pressure points. Second, the use of appropriate sealant is critical. Different sealants are better suited to different materials. For example, silicone caulk is excellent for most applications, offering great adhesion and flexibility to accommodate movement in the frame. We apply the sealant evenly, ensuring complete contact between the glass and the frame. Third, proper glazing methods are used. This might involve using glazing tape or specialized glazing compounds to create a strong, weather-resistant seal. Finally, we always perform a final inspection to ensure there are no gaps or inconsistencies. Imagine testing the seal by trying to blow air around the edges of the glass – there shouldn’t be any passage.

Q 9. What tools and equipment are essential for glass replacement?

Glass replacement requires specialized tools and equipment for safety and precision. Essential tools include:

- Measuring tools: Accurate tape measures, steel squares, and digital calipers are necessary to obtain precise measurements.

- Cutting tools: Glass cutters (for cutting custom sizes), and possibly a wet saw for thicker glass.

- Safety equipment: Safety glasses, gloves, dust masks are mandatory. Depending on the location, harnesses and fall protection may be necessary.

- Installation tools: Glazing points, sealant guns, putty knives, and suction cups are essential for handling and securing the glass.

- Other tools: Utility knives, scrapers, and cleaning supplies are helpful for preparation and cleanup.

Specialized equipment, like glass lifters for larger panes, can significantly improve efficiency and safety, especially on high-rise buildings.

Q 10. How do you troubleshoot common glass installation problems?

Troubleshooting glass installation problems requires a systematic approach. Common issues include poor sealing, cracking, and improper fit. A cracked pane after installation often points back to improper handling or pre-existing damage. We’ll examine the glass carefully and check for stress fractures before installation. Poor sealing is frequently caused by improper sealant application or using an unsuitable sealant for the materials. If we detect air leakage, we may need to remove the existing sealant, clean the surfaces thoroughly and reapply using the correct product. If the glass doesn’t fit properly, we’ll double-check our measurements and potentially make minor adjustments to the frame, but only after carefully assessing structural soundness. Accurate diagnosis is key, and sometimes, re-measuring or replacing the glass pane is the best solution.

Q 11. What is your experience with different types of window frames?

My experience encompasses a wide range of window frame types, including:

- Aluminum frames: These are common due to durability and low maintenance but require careful attention to sealant application to prevent leaks.

- Vinyl frames: These are popular for energy efficiency but can be more challenging to work with due to their flexibility.

- Wood frames: These offer a classic aesthetic but require regular maintenance and careful handling to prevent damage.

- Fiberglass frames: These are strong and durable, similar to aluminum, but often more expensive.

Each frame type presents unique challenges and requires specific techniques for glass installation. For example, wood frames may need additional preparation to ensure a good seal, while aluminum frames need a sealant that can withstand expansion and contraction.

Q 12. How do you handle difficult or unusual glass replacement projects?

Difficult projects require a higher level of planning and problem-solving. This might involve working with unusually shaped glass, dealing with historical buildings with unique window designs, or replacing very large panes. For example, working with curved or textured glass necessitates extra caution and precision during handling and installation to avoid breakage. Historical restorations may require careful sourcing of period-appropriate materials and working within conservation guidelines. Large panes require specialized equipment like glass suckers and cranes to ensure safe handling and installation. Thorough preparation is paramount for successful outcomes, especially when dealing with unpredictable variables.

Q 13. Describe your experience with working at heights.

Safety is always my priority when working at heights. I’m fully certified in fall protection techniques and use appropriate safety equipment including harnesses, lanyards, and fall arrest systems. I meticulously inspect all equipment before commencing work and am adept at using scaffolding and other elevated work platforms securely. I always adhere to strict safety protocols, including double-checking all anchor points and ensuring that all team members are properly trained and equipped. My experience includes working on high-rise buildings and multi-story structures, and my safety record is impeccable. I understand the regulations and potential dangers associated with height work.

Q 14. What is your understanding of building codes related to glass installation?

I have a thorough understanding of building codes related to glass installation, including those concerning safety glass requirements (like laminated or tempered glass in specific applications), energy efficiency standards (related to glazing and insulation), and structural integrity. I’m familiar with local and national codes and regulations. I ensure all work complies with these standards. For example, knowing when safety glass is mandatory in areas prone to impact is critical to ensuring project safety and compliance. I always obtain necessary permits and documentation before commencing any project, and I remain updated on any changes or amendments to the applicable building codes.

Q 15. How do you maintain the quality of your work?

Maintaining quality in glass replacement is paramount. It’s a multi-faceted approach encompassing meticulous preparation, precise execution, and a commitment to using high-quality materials. I start by thoroughly inspecting the existing frame for damage, ensuring a stable base for the new glass. This includes checking for rot, warping, or any inconsistencies that could compromise the final installation. During installation, I utilize only the most appropriate tools and techniques for the specific glass type, employing careful measurement and precision cutting where necessary. Finally, a thorough cleaning of the completed installation is crucial, ensuring a professional finish free from any debris or imperfections.

For instance, with a large window, I might use suction cups to carefully manipulate the glass pane into place, ensuring a perfectly flush fit against the glazing bead. This avoids any stress points that could lead to future cracks or breakage. My commitment to quality is a matter of pride, and I always aim for perfection.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with using specialized glass installation equipment (e.g., suction cups, glazing tools)?

My experience with specialized glass installation equipment is extensive. I’m proficient in using a wide array of tools, including various sizes of suction cups for safe and efficient handling of large glass sheets, different types of glazing tools for precise application of sealant and bedding, and specialized knives and cutters for accurate trimming and cutting of glass. I’m also familiar with equipment used for measuring and leveling, ensuring a perfect fit and preventing future problems.

For example, when working with insulated glass units (IGUs), which are often quite heavy, I rely on a combination of suction cups and specialized lifting straps to maneuver them safely and efficiently. These tools minimize the risk of damage to the glass or injury to myself. Regular maintenance and calibration of these tools are also crucial for ensuring accurate and safe work.

Q 17. Describe your experience with different types of glass (e.g., tempered, laminated, annealed).

I have extensive experience working with a variety of glass types, each with its unique properties and applications.

- Annealed glass is the standard, common type, relatively inexpensive, but prone to shattering into sharp pieces when broken.

- Tempered glass (or toughened glass) is significantly stronger and safer than annealed glass because when it breaks, it shatters into small, relatively harmless, granular pieces. This makes it ideal for applications like shower doors and automotive windows.

- Laminated glass consists of two or more layers of glass bonded together with a layer of polyvinyl butyral (PVB) interlayer. This creates a safety feature; the PVB holds the glass fragments together even when broken, preventing them from scattering. Laminated glass is commonly used in car windshields and security applications.

Understanding these differences is critical for selecting the right type of glass for a given job, ensuring both safety and longevity.

Q 18. How do you determine the appropriate type of glass for a specific application?

Determining the appropriate glass type requires careful consideration of several factors. First, I assess the specific application; is it a storefront window, a residential window, a shower enclosure, or a skylight? Each application presents unique challenges and safety considerations. Then I consider the structural requirements; what are the load-bearing needs? Lastly, the aesthetic considerations and budget are taken into account. For example, a storefront window might require laminated glass for security, while a residential window could utilize tempered glass for safety and impact resistance, and a budget-friendly option might use annealed glass in a less critical area. I always discuss the options with the client to ensure we choose the best solution that meets their specific needs.

Q 19. Explain your understanding of glass properties and their relevance to installation.

Understanding glass properties is fundamental to successful installation. Factors such as thickness, strength, thermal properties (expansion and contraction), and light transmission all influence the installation process and the long-term performance of the glass. For example, the thickness dictates the necessary support structure and the type of sealant required. Thermal properties are crucial to prevent stress cracking due to temperature fluctuations. Light transmission affects the amount of natural light entering a space. Ignoring these properties can lead to installation failures, such as cracking or leakage.

For instance, installing a thick piece of glass in a frame designed for thinner glass might cause stress and cracking. Similarly, failing to account for thermal expansion and contraction during hot and cold weather can lead to similar problems. Understanding these properties helps prevent such issues.

Q 20. What is your experience with repairing chipped or cracked glass?

Repairing chipped or cracked glass depends heavily on the extent and location of the damage. Minor chips or cracks in some glass types can sometimes be repaired using specialized resins that fill and bond the damaged areas, restoring some structural integrity and improving appearance. However, this is only feasible for small imperfections and not always effective for all glass types. Often, significant cracks or chips require complete glass replacement. The safety of the occupants is always the primary concern, and if the damage compromises the structural integrity or safety of the glass, replacement is the only responsible course of action.

I assess the damage carefully, considering the glass type, size and location of the crack, and overall structural integrity. If a repair is deemed feasible, I meticulously prepare the area before applying the resin to ensure a long-lasting result.

Q 21. How do you handle customer complaints or concerns?

Handling customer complaints and concerns is a crucial aspect of providing excellent service. I always approach such situations with empathy and professionalism. I start by actively listening to the customer’s concerns without interrupting, ensuring I fully understand their perspective. Then, I objectively assess the situation, determining whether the issue is a result of faulty workmanship, material defect, or other factors. I clearly explain my findings to the customer, offering solutions to address the problem, whether it’s a repair, replacement, or other appropriate action. My goal is to resolve the issue quickly, fairly, and in a way that leaves the customer feeling satisfied and valued. Open and honest communication is key throughout this process.

For example, if a customer reports a leak around a newly installed window, I would carefully examine the area, looking for any gaps in the sealant or other installation issues. I would then explain my findings to the customer and outline the steps I’ll take to rectify the problem, including any necessary repairs. Maintaining a positive relationship with the client is essential, even during challenging situations.

Q 22. Describe your experience working independently and as part of a team.

Throughout my career in glass replacement, I’ve thrived in both independent and team-based environments. Working independently, I’m adept at managing projects from initial assessment to final installation, requiring strong organizational and problem-solving skills. For instance, I once handled a complex storefront glass replacement project requiring precise measurements, specialized tools, and meticulous attention to detail, all while working solo and meeting a tight deadline. As part of a team, I excel at collaboration and communication, contributing my expertise while effectively supporting my colleagues. A recent example involves working with a team on a large-scale residential window replacement project where efficient communication and teamwork were crucial to staying on schedule and within budget.

My experience has taught me the importance of adapting my approach based on the situation. I can confidently lead a team or work independently based on the demands of the job, always focusing on delivering high-quality results.

Q 23. How do you prioritize tasks and manage your time effectively?

Effective time management and task prioritization are essential in glass replacement, where projects often involve multiple deadlines and various complexities. I use a combination of methods to stay organized and efficient. I begin by creating a detailed schedule, breaking down large projects into smaller, manageable tasks. I prioritize tasks based on urgency and importance, focusing on those with the most immediate deadlines and greatest impact. This often involves using a Kanban board or similar system to visualize workflow and track progress.

For example, when faced with multiple urgent requests for emergency glass repairs, I prioritize based on factors like safety concerns and the potential for further damage. I also proactively communicate with clients and colleagues to manage expectations and ensure smooth workflow. Regular review and adjustment of my schedule ensures that I’m always adapting to changing priorities and unforeseen circumstances.

Q 24. What are your salary expectations?

My salary expectations are in line with my experience and the industry standard for a skilled glass replacement specialist with my qualifications. I am open to discussing a competitive compensation package that reflects my contributions and aligns with the position’s responsibilities and the company’s compensation structure.

Q 25. What are your long-term career goals?

My long-term career goals involve becoming a recognized expert in the field of glass replacement, specializing in complex architectural projects and advanced techniques. I aim to expand my knowledge and skills through continuous professional development, potentially pursuing certifications in specialized glass types or construction techniques. I also envision myself mentoring and training the next generation of glass specialists, sharing my expertise and contributing to the overall advancement of the industry.

Q 26. Why are you interested in this position?

I am interested in this position because of [Company Name]’s reputation for excellence and its commitment to providing high-quality services. The opportunity to contribute my skills and experience to a company with such a strong track record is very appealing. I’m particularly excited about the prospect of working on [mention specific projects or aspects of the job that interest you] and collaborating with a team of skilled professionals.

Q 27. What are your strengths and weaknesses?

One of my greatest strengths is my meticulous attention to detail. In glass replacement, accuracy is paramount, and I take pride in ensuring every installation is perfect. This precision has consistently led to positive client feedback and minimized issues down the line. A weakness I’m actively working on is delegating tasks. While I enjoy hands-on involvement, I recognize the value of efficiently utilizing team resources. I’ve implemented strategies to improve my delegation skills by breaking down complex tasks and clearly communicating expectations to my team members. This has improved overall team efficiency and allowed me to focus on more complex aspects of projects.

Q 28. Do you have any questions for me?

Yes, I do have a few questions. First, can you tell me more about the company’s training and development opportunities for employees? Secondly, what are the typical project timelines and types of projects that I would be working on? Finally, what are the company’s safety protocols and procedures, particularly concerning handling of specialized glass and equipment?

Key Topics to Learn for Glass Replacement Interview

- Types of Glass: Understanding different glass types (e.g., annealed, tempered, laminated) and their properties, including strengths, weaknesses, and appropriate applications.

- Glass Measurement and Cutting Techniques: Accurate measurement skills and proficiency in using various glass cutting tools to minimize waste and ensure a precise fit.

- Installation Methods: Familiarity with different installation methods for various glass types and applications, including glazing techniques, sealants, and adhesives.

- Safety Procedures and Regulations: Knowledge of relevant safety protocols, including personal protective equipment (PPE) usage and adherence to industry regulations for handling glass.

- Troubleshooting and Repair: Ability to identify and resolve common issues during glass replacement, such as cracks, leaks, and improper sealing.

- Tools and Equipment: Familiarity with the operation and maintenance of various tools and equipment used in glass replacement, including glass cutters, suction cups, and glazing tools.

- Estimating and Costing: Ability to accurately estimate materials and labor costs for glass replacement projects.

- Customer Service and Communication: Understanding the importance of clear communication with customers, addressing their concerns, and maintaining professional conduct.

- Project Management: Basic project management skills, including scheduling, resource allocation, and meeting deadlines for glass replacement projects.

Next Steps

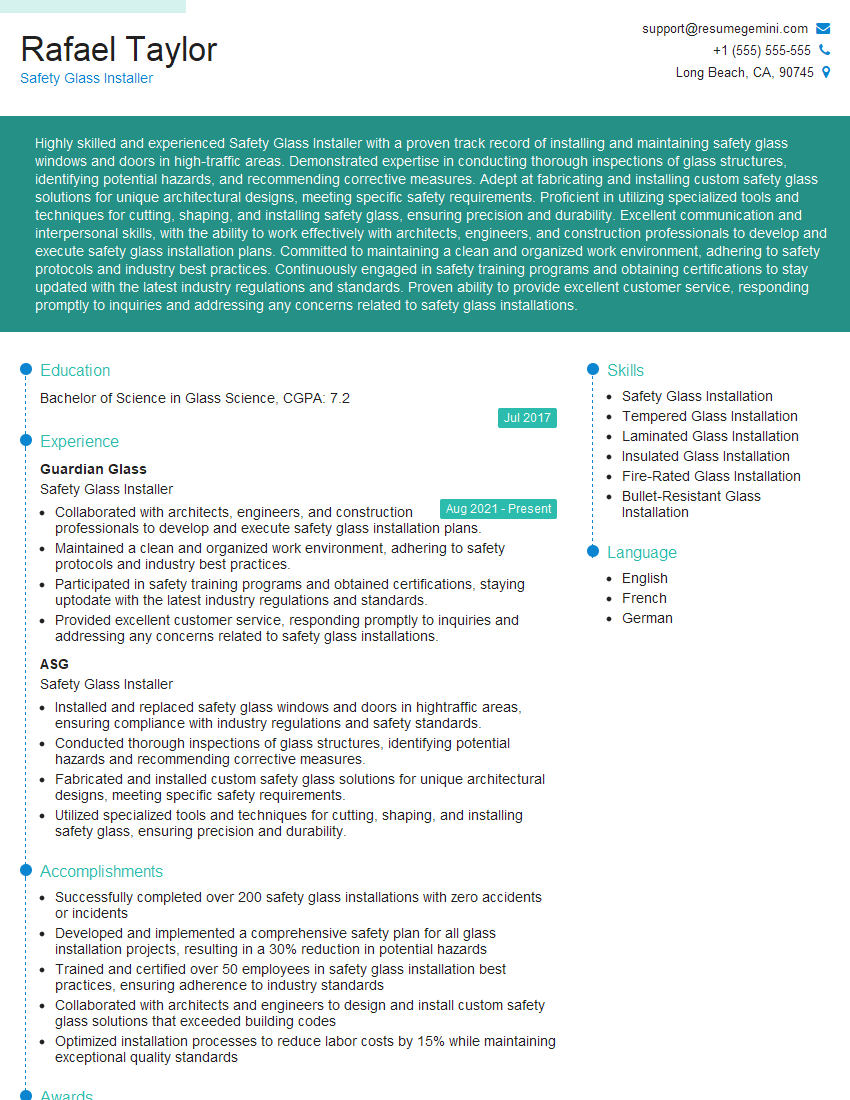

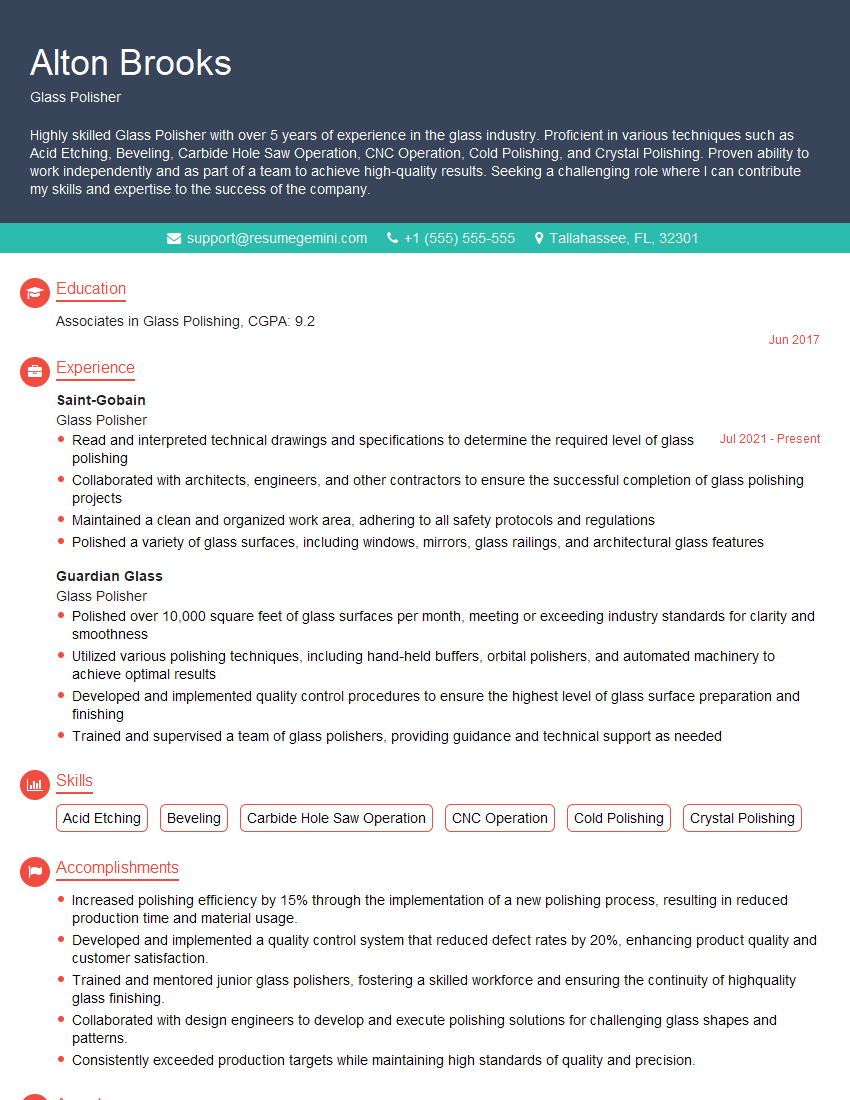

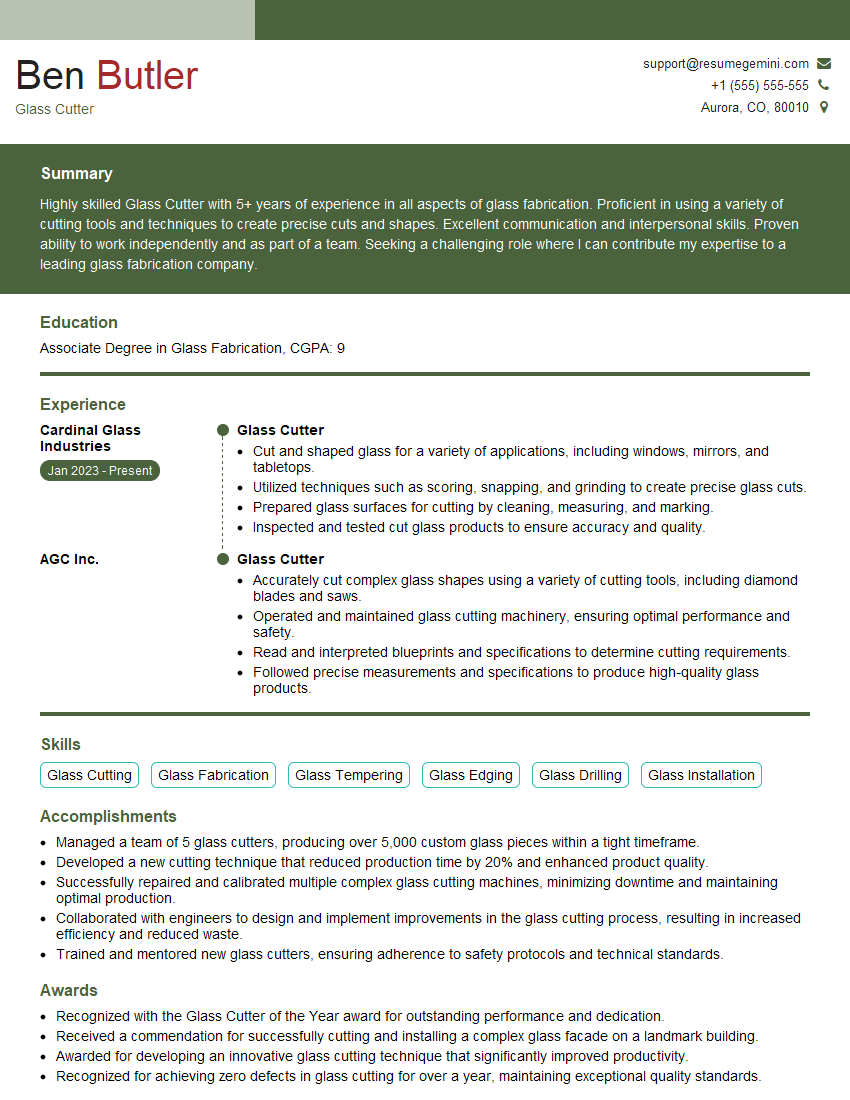

Mastering glass replacement opens doors to a rewarding career with excellent growth potential in the construction, automotive, and home improvement industries. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your expertise. Examples of resumes tailored to the Glass Replacement field are available to help guide your creation. Invest the time to craft a compelling resume—it’s your first impression and a vital step in securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO