Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Grinding Machine Troubleshooting interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Grinding Machine Troubleshooting Interview

Q 1. Explain the different types of grinding machines and their applications.

Grinding machines are categorized based on their function and the type of grinding operation they perform. Think of it like choosing the right tool for a specific job in carpentry – you wouldn’t use a hammer to screw in a screw, right? Similarly, different grinding machines are suited for different tasks.

- Cylindrical Grinding Machines: These are workhorses for creating cylindrical parts with high precision. Imagine machining the outside of a shaft or the inside of a hollow cylinder. They’re used extensively in automotive and aerospace industries.

- Surface Grinding Machines: These are ideal for achieving flat, smooth surfaces on a workpiece. Think of the perfectly flat surface of a table top or a precise plane on a machine component. These are common in manufacturing processes where flatness is critical.

- Internal Grinding Machines: As the name suggests, these are used for grinding the inside diameter of holes or bores. Imagine machining the inside of a bearing or a precise hole in a complex engine part. High precision is key here.

- Centerless Grinding Machines: These machines grind workpieces without the need for a center. This makes them incredibly efficient for mass production of cylindrical parts like pins and shafts. Think of the production lines creating thousands of identical parts.

- Tool and Cutter Grinders: Specialized machines for sharpening and re-profiling cutting tools. Keeping your cutting tools sharp is crucial for efficiency and safety, and these machines ensure accuracy in the sharpening process.

The choice of grinding machine depends heavily on the workpiece’s geometry, material, required precision, and production volume. For example, a cylindrical grinder is ideal for high-volume production of shafts while a surface grinder is needed for creating precision flat surfaces on larger parts.

Q 2. Describe the process of diagnosing a grinding machine malfunction.

Diagnosing a grinding machine malfunction requires a systematic approach. Think of it like a detective solving a crime – you need to gather clues and systematically eliminate possibilities.

- Observe the Problem: Start by carefully observing the machine’s operation. What are the symptoms? Is it producing poor surface finish, unusual noises, vibrations, or is it completely stalled?

- Check the Obvious: Examine the grinding wheel for damage, cracks, or glazing. Make sure the workpiece is properly secured and the coolant system is functioning correctly. Often, simple issues like a loose clamp or depleted coolant are the culprit.

- Review the Machine Settings: Verify the grinding parameters like wheel speed, workpiece speed, feed rate, and depth of cut. Incorrect settings can lead to poor performance or damage.

- Inspect the Mechanical Components: Check the machine’s bearings, belts, motors, and hydraulic systems for any wear, tear, or damage. Listen carefully for unusual noises that can indicate problems with these components.

- Test the Electrical System: Check for proper voltage and current readings in the motor and control circuits using appropriate measuring instruments. Electrical faults can manifest in various ways, affecting the machine’s operation.

- Systematic Elimination: After examining all the above components, start eliminating possibilities based on your findings. Sometimes, it’s a combination of factors contributing to the malfunction.

Remember to always consult the machine’s manual and follow all safety procedures throughout the diagnosis process. Keeping detailed records of your findings will be invaluable for future troubleshooting.

Q 3. How do you identify and resolve common grinding wheel issues (e.g., glazing, loading, dressing)?

Grinding wheel issues significantly impact the quality of the grinding process. Let’s address these common problems:

- Glazing: This occurs when the grinding wheel becomes too smooth, reducing its cutting ability. Imagine trying to cut a piece of wood with a dull knife. The solution often involves dressing the wheel with a diamond dressing tool to expose fresh, sharp abrasive grains.

- Loading: This happens when the workpiece material builds up on the grinding wheel, hindering its cutting action. It’s like trying to cut with a knife coated in sticky substance. This can be resolved by using a suitable coolant, adjusting the grinding parameters, or cleaning the wheel with a suitable cleaning tool. Sometimes, a wheel change might be required.

- Dressing: This is a proactive measure to maintain wheel sharpness and performance. Think of it as sharpening a kitchen knife. Regular dressing removes glazed material and re-profiles the wheel surface for optimal cutting performance. There are various dressing methods, including diamond tools and crush dressing.

Identifying the issue requires careful observation. Glazing will result in a poor surface finish, while loading causes reduced material removal rate and potential for wheel damage. Dressing is a preventive measure and should be performed at regular intervals.

Q 4. What are the safety precautions you should take when working with grinding machines?

Safety is paramount when working with grinding machines. These machines are powerful and can cause serious injury if not handled correctly. Think of it like handling a powerful tool; you must respect its capabilities and take appropriate precautions.

- Eye Protection: Always wear safety glasses or a face shield to protect your eyes from flying debris. Grinding operations produce small particles that can easily damage your eyes.

- Hearing Protection: Grinding machines can be noisy. Using earplugs or earmuffs protects your hearing from long-term damage.

- Proper Clothing: Wear close-fitting clothing to prevent it from getting caught in the machine. Avoid loose sleeves or jewelry.

- Machine Guards: Ensure all safety guards are in place and functioning correctly. Guards prevent accidental contact with the rotating grinding wheel.

- Workpiece Securement: Properly secure the workpiece to prevent it from moving during the grinding operation. Loose workpieces are a major safety hazard.

- Coolant Usage: Use coolant appropriately to prevent overheating and potential fires or burns. Make sure you are following all safety guidelines in the coolant’s usage.

- Emergency Shutdown: Familiarize yourself with the location and operation of the emergency stop button. Knowing where it is and how to use it can save precious seconds in case of an accident.

Regular safety training and adherence to safety protocols are essential to prevent accidents and injuries.

Q 5. Explain the importance of coolant selection and usage in grinding.

Coolant selection and usage are crucial for successful grinding. Think of it like lubrication for a moving part – it prevents damage and ensures smooth operation.

- Cooling: Coolant effectively removes the heat generated during the grinding process, preventing workpiece and wheel damage from overheating. This is especially crucial when working with high-speed grinding or hard materials.

- Lubrication: Coolant reduces friction between the wheel and workpiece, improving the grinding process and extending wheel life. It creates a lubricating layer, akin to engine oil in your car.

- Chip Removal: Coolant helps flush away the metal chips or debris produced during grinding, preventing clogging of the wheel and maintaining consistent cutting action.

- Corrosion Prevention: Certain coolants help prevent corrosion on the workpiece and machine surfaces, maintaining quality and prolonging lifespan.

The choice of coolant depends on the material being ground and the specific application. Water-based coolants are common and cost-effective, while oil-based coolants offer better lubrication for certain materials. Proper coolant filtration and maintenance are also necessary to ensure efficiency and prevent contamination.

Q 6. How do you maintain grinding machine accuracy and precision?

Maintaining grinding machine accuracy and precision requires regular maintenance and calibration. Think of it as keeping your car well-maintained to optimize performance.

- Regular Inspection: Conduct regular inspections of all machine components, looking for wear, damage, or misalignment. This includes checking the grinding wheel, spindles, bearings, ways, and coolant system.

- Calibration: Periodically calibrate the machine using precision measuring instruments. This ensures that the machine is accurately producing parts to the required tolerances.

- Wheel Dressing: Regular wheel dressing maintains the wheel’s sharpness and profile, crucial for maintaining precision. Think of it as sharpening a chef’s knife to ensure clean and accurate cuts.

- Lubrication: Proper lubrication of moving parts reduces wear and tear and maintains the machine’s precision. This is like oiling the hinges of a door to ensure smooth operation.

- Cleanliness: Keep the machine clean and free from debris. This prevents clogging of the coolant system and other components, ensuring efficient and accurate operation.

- Operator Training: Well-trained operators can significantly contribute to maintaining machine accuracy and prolonging its lifespan. Skilled operators avoid mishaps and maximize efficiency.

A well-maintained grinding machine produces high-quality parts with consistent accuracy, which is essential for many manufacturing processes.

Q 7. Describe your experience with different grinding wheel materials and their properties.

My experience encompasses a wide range of grinding wheel materials, each possessing unique properties suited for different applications. Choosing the right wheel is crucial for optimal performance and part quality.

- Aluminum Oxide (Al2O3): A very common and versatile abrasive, excellent for grinding ferrous metals. Its strength and durability make it suitable for a broad range of applications, from roughing to finishing.

- Silicon Carbide (SiC): Known for its sharpness and ability to grind non-ferrous materials like cast iron, aluminum, and ceramics effectively. It’s often the preferred choice when a finer finish is needed.

- CBN (Cubic Boron Nitride): A superabrasive ideal for grinding very hard materials like hardened steel, superalloys, and ceramics. Think of it as the high-end choice for the most challenging materials. It offers exceptional wear resistance and a superior surface finish.

- Diamond: The hardest known material, diamond wheels are used for grinding the hardest materials or for extremely precise finishing operations. They’re often used for grinding non-metallic materials like glass or stone.

The selection of a grinding wheel material depends on factors such as the workpiece material, desired surface finish, required material removal rate, and the grinding machine itself. I’ve had extensive experience matching wheel materials to specific applications to optimize grinding performance and efficiency. Selecting the wrong wheel can lead to inefficient grinding, wheel damage, and poor surface finish.

Q 8. How do you troubleshoot problems related to workpiece clamping and fixturing?

Workpiece clamping and fixturing are crucial for accurate and safe grinding. Improper clamping can lead to workpiece movement, resulting in inaccurate grinding, surface damage, or even accidents. Troubleshooting begins with a visual inspection. Check for any loose bolts, worn clamping pads, or misalignment. Then, systematically investigate the clamping force. Insufficient force can cause vibration and inaccurate dimensions, while excessive force may deform the workpiece. Here’s a step-by-step approach:

- Visual Inspection: Carefully examine the clamping mechanism, workpiece, and fixture for any signs of damage, wear, or misalignment.

- Clamping Force Check: Use a torque wrench to verify that the clamping bolts are tightened to the manufacturer’s specifications. If using hydraulic or pneumatic clamps, check the pressure gauges.

- Workpiece Alignment: Ensure the workpiece is properly aligned within the fixture using precision measuring tools like dial indicators or height gauges. Correct any misalignment.

- Fixture Condition: Assess the condition of the fixture itself. Worn or damaged fixtures can lead to inconsistent clamping and should be repaired or replaced.

- Material Compatibility: Confirm that the clamping material is compatible with the workpiece material to prevent damage or reactions.

For instance, I once encountered a situation where inconsistent surface finish was traced back to a worn clamping pad on a complex aerospace component. Replacing the pad immediately solved the issue. Always remember, proper fixturing is as important as the grinding process itself.

Q 9. What are the common causes of chatter during grinding and how do you address them?

Chatter, those annoying vibrations during grinding, are usually caused by unstable cutting conditions. This can lead to poor surface finish, dimensional inaccuracy, and even machine damage. The primary causes are often:

- Excessive cutting depth or feed rate: Pushing the machine too hard creates unstable vibrations.

- Poor workpiece rigidity: A flexible workpiece will amplify vibrations.

- Worn or damaged grinding wheel: An unbalanced or damaged wheel will cause chatter.

- System Resonance: The grinding process may resonate with the natural frequencies of the machine structure.

- Improper wheel dressing or truing: A poorly dressed wheel can introduce surface irregularities that cause chatter.

Addressing chatter involves a systematic approach. Start by reducing the depth of cut and feed rate. If chatter persists, check the workpiece for rigidity issues – perhaps additional support is needed. Inspect the grinding wheel for any damage and replace if necessary. Wheel truing/dressing is critical. Ensure the machine is properly aligned and free from excess vibration. In more complex cases, a vibration analysis might be required to identify the resonant frequencies of the system and adjust the cutting parameters accordingly. Think of it like tuning a musical instrument – finding the right combination eliminates unwanted noise.

Q 10. Explain the importance of proper machine setup and alignment in achieving desired results.

Proper machine setup and alignment are fundamental to achieving accurate and consistent grinding results. Misalignment can lead to uneven wear of the grinding wheel, premature wheel failure, inaccurate dimensions of the workpiece, and potentially damage the machine itself. A precisely aligned machine ensures the grinding wheel contacts the workpiece at the correct angle and speed, resulting in a high-quality surface finish. Imagine trying to sharpen a pencil with a blade that’s not perfectly aligned – you’d get a jagged and uneven result. The same principle applies to grinding.

The setup includes checking the wheel alignment (parallelism and perpendicularity), table alignment, and the overall machine structure. Laser alignment tools and dial indicators are frequently used. Regular preventative maintenance to check for and correct machine alignment is essential for reliable and long-lasting grinding performance.

Q 11. How do you interpret grinding machine parameters and adjust them for optimal performance?

Grinding machine parameters, such as wheel speed, work speed, feed rate, and depth of cut, are crucial for achieving optimal performance. They interact in complex ways, affecting the surface finish, dimensional accuracy, and material removal rate. Understanding these parameters requires both theoretical knowledge and practical experience.

For example, increasing the wheel speed generally increases the material removal rate but may also decrease the surface finish. The feed rate controls the amount of material removed per pass, influencing both speed and finish. Depth of cut affects the amount of material removed in a single pass and influences the quality of the surface finish and tool life. Optimal settings are often determined through experimentation and fine-tuning, using empirical data and real-time monitoring. Software and process optimization tools can assist in this process, and keeping meticulous records of parameter settings and their effects is crucial for future improvements.

Q 12. Describe your experience with CNC grinding machine programming and operation.

My experience with CNC grinding machine programming and operation spans several years and various machine types. I’m proficient in developing and optimizing CNC grinding programs using CAM software such as Mastercam, FeatureCAM, and Siemens NX. I can create programs for various grinding processes, including cylindrical, surface, and internal grinding. My expertise includes creating complex toolpaths for intricate geometries, optimizing cutting parameters for maximum efficiency and surface finish, and incorporating in-process measurement techniques to ensure dimensional accuracy. I’m also skilled in troubleshooting CNC programs and resolving errors related to toolpath generation, machine parameters, and sensor data. A recent project involved programming a complex profile grinding operation on a five-axis CNC machine, and my program resulted in a 20% reduction in cycle time and a significant improvement in surface finish.

Q 13. How do you troubleshoot problems related to grinding machine control systems (e.g., PLC, CNC)?

Troubleshooting grinding machine control systems requires a systematic approach combining knowledge of PLC (Programmable Logic Controller) and CNC systems. The first step is to identify the nature of the problem: is it a hardware issue, a software issue, or a combination of both?

Hardware Troubleshooting: This involves checking power supplies, motor drives, limit switches, sensors, and other components. The use of multimeters, oscilloscopes, and other diagnostic tools is crucial. I have extensive experience with troubleshooting issues such as faulty sensors, drive problems, and mechanical issues within the control system.

Software Troubleshooting: This might involve analyzing alarm codes, examining the PLC program and CNC code, and checking for software bugs. Troubleshooting might involve using debugging tools and simulating the program’s logic to identify errors. For example, I once resolved an issue causing repeated machine stops by carefully tracing a logic error in the PLC program that resulted from a poorly written conditional statement.

My approach always begins with a thorough investigation of the fault codes and logs followed by systematic elimination of the possible causes. Often, the solution involves a combination of hardware and software diagnostics and repair.

Q 14. Explain the different types of grinding processes (e.g., surface, cylindrical, internal).

Grinding processes are broadly categorized based on the shape and type of the workpiece and the type of grinding wheel used. Here are a few key types:

- Surface Grinding: This process removes material from a flat or planar surface using a rotating wheel. It’s used for creating precise flat surfaces on a wide range of materials. Think of making a perfectly flat surface on a metal block.

- Cylindrical Grinding: This involves grinding cylindrical surfaces, such as shafts and rolls. It achieves high precision and surface finish on round components.

- Internal Grinding: This technique is used to grind the inner surfaces of holes and bores. Specialized tools and machines are needed for this.

- Centerless Grinding: This unique method grinds cylindrical parts without using a center. It uses two wheels – one grinding and one regulating.

- Creep Feed Grinding: This process uses very slow feed rates and high depth of cuts for material removal. It is highly effective in grinding hard materials.

The choice of grinding process depends on several factors, including the workpiece geometry, material properties, desired surface finish, and dimensional tolerances. Each process has its own set of parameters that must be carefully controlled to achieve desired results.

Q 15. Describe your experience with different grinding wheel dressing and truing methods.

Grinding wheel dressing and truing are crucial for maintaining wheel sharpness and accuracy. Dressing removes unwanted material from the wheel’s surface, restoring its profile, while truing ensures the wheel runs true and concentrically. I’ve extensive experience with various methods:

Diamond Dressing Tools: These are highly effective for fast material removal and producing sharp, precise cutting edges. I’ve used single-point and multi-point diamond tools, choosing the appropriate type based on the wheel material, desired surface finish, and the amount of stock removal needed. For example, a single-point diamond dresser is ideal for fine truing and dressing of precision grinding wheels, while multi-point dressers are better suited for heavy-duty applications needing faster stock removal.

Crush Dressing: This method employs a specially shaped crushing roll to form the wheel profile. It’s particularly well-suited for large wheels or complex profiles where diamond dressing might be less efficient or precise. I’ve used this method successfully in applications requiring high production rates and consistent wheel shape.

Automatic Dressing: Many modern grinding machines offer automated dressing systems, where the dressing process is controlled and monitored via a computer program. This ensures consistency and reduces operator intervention. My experience includes programming and optimizing these systems for various applications, minimizing downtime and maximizing part quality.

Hand Dressing: While less precise than automated methods, hand dressing with a suitable dressing tool allows for quick adjustments and localized corrections. I’ve employed this technique for minor adjustments when dealing with slight wheel imperfections.

The choice of method depends on factors like wheel type, material being ground, required surface finish, and production volume. I always select the method that best balances efficiency and quality for the task at hand.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform regular maintenance checks on a grinding machine?

Regular maintenance is vital for preventing costly downtime and ensuring consistent performance. My typical check involves:

Visual Inspection: Checking for any signs of wear, damage, or loose components on the machine structure, coolant system, and electrical components.

Coolant System Check: Checking coolant level, cleanliness, and proper functioning of the pump and filtration system. I regularly check for signs of contamination or bacterial growth which can impact grinding efficiency and wheel life.

Wheel Inspection: Assessing the grinding wheel for wear, cracks, or glazing. Proper wheel storage and handling are also key for wheel longevity.

Spindle Check: Verifying spindle runout and vibration levels within acceptable limits. Excessive runout will directly impact the final workpiece quality.

Lubrication: Lubricating moving parts as per manufacturer’s recommendations. This includes way lubrication and guideways. Neglecting this can lead to premature wear and costly repairs.

Safety Checks: Ensuring that all safety guards are in place and functioning correctly. Grinding machines present inherent risks, so safety is paramount.

I maintain meticulous records of all maintenance activities, including dates, observations, and corrective actions taken. This allows for preventative maintenance scheduling and trend analysis, helping to predict potential issues before they lead to significant problems.

Q 17. How do you calculate grinding wheel speed and feed rates?

Calculating grinding wheel speed and feed rates is critical for achieving the desired surface finish and minimizing workpiece damage. The formulas are:

Grinding Wheel Surface Speed (SFM):

SFM = (π × D × N) / 12, where D is the wheel diameter in inches, and N is the wheel speed in RPM.Feed Rate: This depends on many factors, including the material being ground, the grinding wheel type, the desired surface finish, and the depth of cut. Feed rate is typically expressed as inches per minute (IPM) or millimeters per minute (mm/min) and is often determined through experimentation and optimization for each specific application. Many CNC grinding machines allow for the creation of controlled feed rate profiles based on these variables and can be optimized for throughput while maintaining tolerances.

Example: Let’s say we have a 10-inch diameter grinding wheel rotating at 3000 RPM. The surface speed would be: SFM = (π × 10 × 3000) / 12 ≈ 7854 SFM. The optimal feed rate for this setup would then need to be determined based on the specifics of the workpiece material and the desired finish.

It’s important to note that exceeding recommended speeds or feed rates can lead to wheel damage, workpiece burn, or dimensional inaccuracies.

Q 18. What are the common causes of surface finish defects in grinding and how to avoid them?

Surface finish defects in grinding can stem from various issues:

Chatter: This produces a wavy surface finish due to vibrations in the machine or workpiece. It’s often caused by worn bearings, insufficient clamping, or improper coolant application. Avoiding chatter requires careful machine setup, proper clamping of the workpiece, and appropriate coolant selection and application.

Burn: This results in a discolored or heat-affected zone on the workpiece surface. It’s typically caused by excessive grinding pressure, insufficient coolant, or incorrect wheel speed. Proper selection of grinding parameters, along with sufficient coolant flow and efficient coolant application methods are key to avoiding burn.

Wheel Loading: The accumulation of material on the wheel’s surface leading to poor surface finish and reduced cutting efficiency. This can be resolved through appropriate dressing and truing of the wheel.

Insufficient Stock Removal: Leaving too little material between passes can also cause unwanted surface irregularities and dimensional inaccuracies.

Wheel Wear: A dull grinding wheel will lead to rougher surface finishes. Regular inspection and replacement or dressing is crucial.

Addressing these defects often involves adjusting machine parameters, such as speed, feed rate, and depth of cut, and optimizing the cooling system. Regular maintenance, proper wheel selection, and consistent operation procedures are crucial to maintaining high quality surface finishes.

Q 19. How do you handle emergency situations involving grinding machines?

Emergency situations involving grinding machines require immediate and decisive action. My approach is based on:

Safety First: Immediately shut down the machine and secure the area to prevent further accidents. My priority is always to ensure the safety of myself and others nearby.

Assess the Situation: Determine the nature of the emergency (e.g., wheel fracture, coolant leak, electrical fault). This will dictate the next steps.

Emergency Procedures: Follow established emergency procedures, which include contacting maintenance personnel and potentially first aid if required.

Problem Isolation: If possible, isolate the problem to prevent further damage. For instance, if a coolant leak occurs, close the appropriate valves to prevent further spillage.

Reporting and Documentation: Thoroughly document the incident, including details about the cause, the actions taken, and any damage incurred.

Regular safety training and drills are critical for effectively handling unexpected events. In my experience, a proactive approach to safety, including adherence to safety guidelines and regular machine inspections, significantly minimizes the likelihood of emergencies.

Q 20. Explain your experience with different types of grinding fluids and their applications.

Grinding fluids play a vital role in cooling the workpiece and wheel, flushing away debris, and improving surface finish. I have experience with various types:

Water-Based Fluids (Emulsions): These are cost-effective and widely used. I’ve worked with different formulations, adjusting the concentration based on the material being ground and the desired cooling and lubrication effects. They are easier to manage and dispose of than oil-based fluids.

Oil-Based Fluids (Soluble Oils): These offer superior lubrication for difficult-to-grind materials, but require more careful handling and disposal due to environmental concerns. I’ve used this type for grinding harder metals where better lubrication was crucial.

Synthetic Fluids: These provide excellent performance in various applications and usually have better environmental characteristics than traditional oil-based fluids. They are generally more expensive than traditional fluids.

The choice of grinding fluid depends on factors like material being ground, surface finish requirements, machine type, and environmental regulations. Regular monitoring of fluid condition and timely replacement or treatment are crucial for maintaining its effectiveness and preventing issues like bacterial growth and poor lubrication. I always carefully consider the fluid’s impact on both the process and the environment when making my selection.

Q 21. Describe your experience with measuring and inspecting ground workpieces.

Precise measurement and inspection are crucial for ensuring the quality of ground workpieces. My experience includes:

Dimensional Measurement: Using various instruments, including micrometers, calipers, dial indicators, and coordinate measuring machines (CMMs), to check dimensions, tolerances, and surface flatness.

Surface Roughness Measurement: Employing surface roughness testers to quantify the surface finish using parameters like Ra (average roughness) and Rz (maximum peak-to-valley height). This ensures the workpiece meets the required surface quality specifications.

Optical Inspection: Using microscopes and optical comparators to assess surface quality, detect imperfections like scratches and cracks, and verify complex profiles.

Data Acquisition and Analysis: Collecting and analyzing measurement data to identify trends, deviations from specifications, and opportunities for process improvement. I use statistical process control (SPC) methods to help maintain quality and identify trends.

I understand the importance of traceability, so I always meticulously document all measurement results along with associated workpiece identification. I am proficient in interpreting measurement data and recommending appropriate corrective actions to address any discrepancies.

Q 22. How do you troubleshoot problems related to vibration and noise in grinding machines?

Excessive vibration and noise in a grinding machine are serious issues that can lead to premature wear, inaccurate machining, and even catastrophic failure. Troubleshooting starts with a systematic approach, focusing on identifying the source of the problem.

- Wheel imbalance: An unbalanced grinding wheel is a common culprit. Imagine a spinning wheel with uneven weight distribution – it’ll wobble and vibrate. We check for this by carefully inspecting the wheel for cracks, chips, or inconsistencies in its structure. Dynamic balancing equipment can provide precise measurements and indicate necessary corrections.

- Spindle bearing wear: Worn spindle bearings are another frequent cause. Think of them as the wheel’s supports; worn bearings allow excessive play, leading to vibrations. We assess bearing condition through vibration analysis and, if necessary, replace the bearings.

- Machine foundation issues: A poorly supported machine can amplify vibrations from the grinding process. A solid, level foundation is crucial. We inspect the foundation for cracks, settling, or instability, and make appropriate corrections.

- Loose parts: Loose components anywhere in the machine – from mounting bolts to the chuck – can lead to increased vibration and noise. A thorough inspection to tighten all connections is essential.

- Workpiece imbalance: Similar to the wheel, an unbalanced workpiece can induce vibrations. We ensure workpieces are properly secured and balanced before grinding.

Addressing these issues often involves visual inspection, vibration analysis using specialized equipment, and sometimes precision balancing. Remember, safety is paramount; always power off the machine before any inspection or repair.

Q 23. What are the common causes of grinding wheel breakage and how to prevent them?

Grinding wheel breakage is a significant safety hazard and a costly problem. Several factors contribute to this:

- Excessive centrifugal force: Spinning a wheel too fast beyond its rated speed generates excessive force, potentially causing it to shatter. This is why adhering to the manufacturer’s speed recommendations is critical.

- Improper wheel selection: Using a wheel with an inappropriate grain size, bond, or structure for the material being ground creates excessive stress and increases breakage risk. Matching the wheel to the application is fundamental.

- Wheel damage: Cracks, chips, or other damage to the wheel weakens its structure, making it prone to failure under stress. Regular inspections are a must.

- Improper mounting: Incorrect mounting, such as excessive force or improper seating, puts strain on the wheel and contributes to breakage. Following the manufacturer’s instructions precisely is vital.

- Thermal shock: Rapid temperature changes during grinding can cause cracking. Proper coolant application helps manage temperature variations.

- Excessive grinding pressure: Applying too much force during grinding overloads the wheel and can lead to failure.

Prevention involves diligent wheel inspection before each use, careful adherence to operating instructions, using the appropriate wheel for the application, maintaining proper machine settings and avoiding excessive pressure or thermal shock. A well-maintained machine and operator training are crucial safety aspects.

Q 24. How do you determine the appropriate grinding parameters for different materials?

Selecting the right grinding parameters depends heavily on the material being machined. It’s a balancing act between achieving a desired surface finish and preventing damage to the workpiece or the wheel. Consider these key parameters:

- Wheel speed: This is directly related to the material’s hardness and the desired finish. Harder materials generally require slower speeds.

- Work speed (feed rate): This controls the material removal rate. Slower feed rates yield finer finishes but may increase grinding time.

- Depth of cut: This determines how much material is removed in each pass. Heavier cuts are faster but increase the risk of burning or damaging the workpiece.

- Coolant type and flow rate: Appropriate coolants lubricate the cutting zone, prevent heat buildup, and extend wheel and workpiece life. The flow rate needs adjustments based on the material and grinding conditions.

- Grinding wheel selection: Grain size, bond type, and wheel structure influence the finish and efficiency of grinding.

Experience and consulting engineering data sheets are vital in determining appropriate parameters. Starting with conservative settings and gradually adjusting them based on observations is a safe and effective approach. Monitoring the workpiece temperature and surface finish provides valuable feedback for optimization.

Q 25. Explain your experience with different types of grinding machine accessories and attachments.

My experience spans a wide range of grinding machine accessories and attachments. This includes various types of grinding wheels (e.g., vitrified, resinoid, metal-bonded), dressing tools (for maintaining wheel sharpness), various coolant delivery systems (from simple drip systems to sophisticated high-pressure pumps), workholding fixtures (for securely holding and positioning the workpiece), and automated loading and unloading systems. I have worked with different types of wheel balancing equipment and vibration monitoring systems. I am familiar with various types of safety guards and enclosures to ensure operator safety.

For example, I’ve worked extensively with automated systems used in high-volume production, where the focus is on efficiency and repeatability. In contrast, I have also worked with manual setups requiring intricate adjustments and precise control for intricate parts. The selection of attachments always depends on the specific application, workpiece material, desired finish, and production requirements.

Q 26. How do you troubleshoot problems related to coolant system malfunctions?

Coolant system malfunctions are a common source of grinding machine problems. These issues can lead to overheating, poor surface finish, reduced wheel life, and safety hazards.

- Clogged lines or filters: Debris from the grinding process can clog coolant lines and filters, restricting coolant flow. Regular cleaning and filter replacement are essential.

- Pump failure: Coolant pumps can fail due to wear, overheating, or other mechanical issues. We check pump pressure and flow rate; replacement might be necessary.

- Leakage: Leaks in the coolant system waste coolant and can create a messy and unsafe working environment. Inspect all hoses, fittings, and seals.

- Improper coolant concentration: Using an incorrect coolant concentration can lead to poor cooling, corrosion, or other problems. Adhering to the manufacturer’s recommendations is important.

- Coolant tank issues: A dirty or improperly maintained coolant tank can harbor bacteria and lead to contamination. Regular cleaning and tank maintenance are important.

Troubleshooting coolant system problems requires a systematic approach, starting with visual inspection, checking for leaks, and verifying pump operation. Testing coolant concentration and evaluating the cleanliness of the system are also crucial steps. Safety precautions should always be followed when dealing with coolant systems.

Q 27. Describe your approach to problem-solving in a grinding machine troubleshooting scenario.

My approach to grinding machine troubleshooting is methodical and systematic. It’s like solving a detective mystery – we need to gather clues and systematically eliminate possibilities.

- Gather information: Start by documenting the problem: When did it start? What are the symptoms (e.g., noise, vibration, poor surface finish)? What were the operating parameters at the time? Talking to the operators provides valuable insights.

- Visual inspection: A careful visual inspection of the machine, the grinding wheel, the workpiece, and the coolant system is the first step. Look for obvious problems such as loose parts, damage to the wheel, or coolant leaks.

- Systematic elimination: Based on the information gathered and the visual inspection, systematically eliminate potential causes. For example, if there’s excessive vibration, we’d check for wheel imbalance, spindle bearing wear, foundation issues, etc.

- Data analysis (if applicable): If the machine is equipped with sensors, analyze the data for patterns or anomalies that could provide clues to the problem.

- Testing and verification: Once a potential cause has been identified, test it to verify whether it is the root cause. This might involve measuring wheel balance, checking bearing play, or testing coolant flow.

- Repair or replacement: If a problem is confirmed, implement the appropriate repair or replacement. Document the fix and make sure that the machine is returned to its proper operating condition.

- Preventive maintenance: Implement preventive maintenance strategies to minimize the likelihood of future problems. This includes regular inspections, lubrication, and cleaning.

This systematic approach, combined with a good understanding of grinding machine mechanics and a strong focus on safety, ensures efficient and effective troubleshooting.

Key Topics to Learn for Grinding Machine Troubleshooting Interview

- Understanding Grinding Wheel Characteristics: Learn about different wheel types (e.g., bonded abrasives, vitrified, resinoid), their specifications (grain size, grade, structure), and how these affect grinding performance and troubleshooting.

- Grinding Machine Mechanisms: Gain a solid grasp of the mechanical components (spindles, workheads, coolant systems, etc.) and their functions within various grinding machine types (e.g., cylindrical, surface, centerless).

- Troubleshooting Common Grinding Issues: Develop a systematic approach to diagnosing and resolving problems like poor surface finish, dimensional inaccuracies, excessive wear, chatter, and wheel dressing issues. Practice analyzing symptoms and identifying root causes.

- Precision Measurement and Inspection Techniques: Master the use of precision measuring tools (micrometers, calipers, dial indicators) and understand various inspection methods to verify part quality and identify defects.

- Safety Procedures and Regulations: Demonstrate a thorough understanding of safety protocols specific to grinding machines, including proper machine operation, personal protective equipment (PPE) use, and emergency procedures.

- Preventive Maintenance and Machine Care: Learn about routine maintenance tasks, lubrication schedules, and the importance of regular inspections to prevent breakdowns and extend machine lifespan.

- Coolant Systems and their Importance: Understand the function of coolant systems, different coolant types, and troubleshooting issues related to coolant flow, temperature, and contamination.

- Advanced Grinding Techniques (Optional): Explore advanced topics like CNC grinding, adaptive control systems, and advanced grinding processes depending on your experience level.

Next Steps

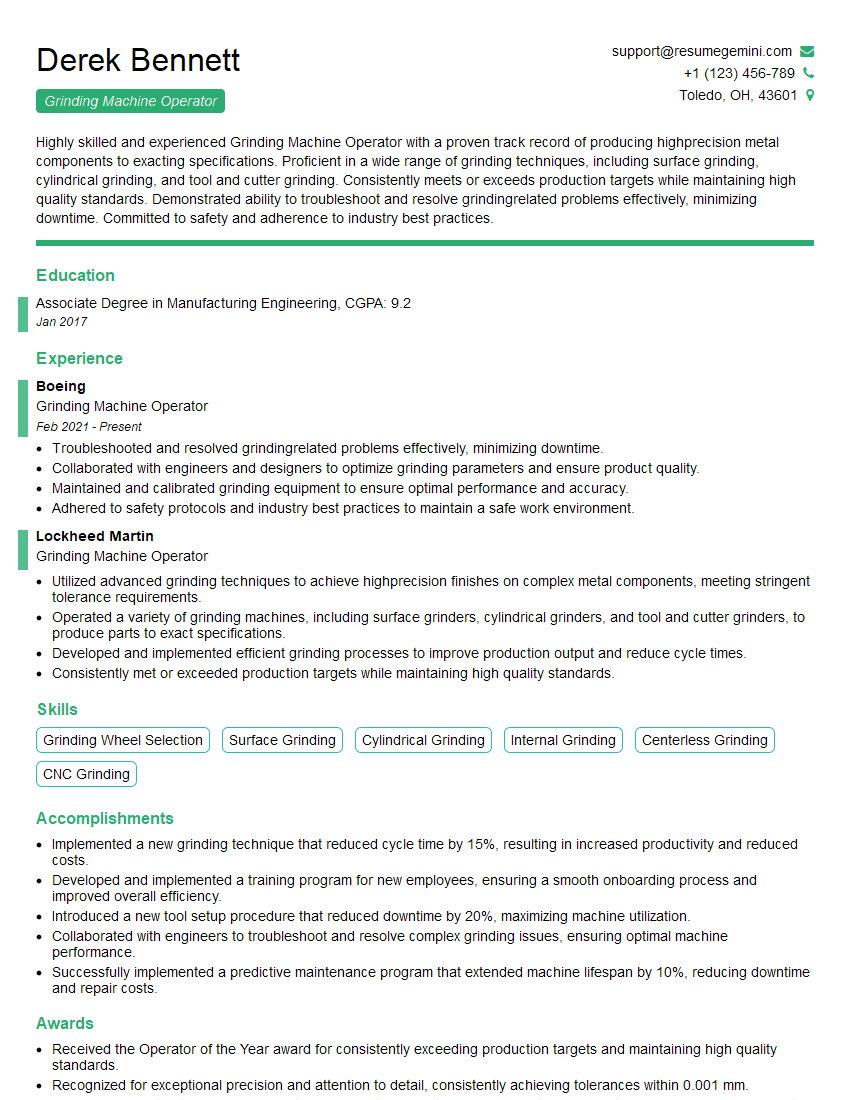

Mastering Grinding Machine Troubleshooting is crucial for career advancement in manufacturing and machining. It demonstrates valuable problem-solving skills and a deep understanding of precision engineering. To increase your chances of landing your dream job, focus on creating a compelling and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional resume that makes a lasting impression on potential employers. Examples of resumes tailored to Grinding Machine Troubleshooting are available to guide you in this process. Take control of your career journey – invest in your resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO