Cracking a skill-specific interview, like one for Ground Refueling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Ground Refueling Interview

Q 1. Describe the different types of ground refueling systems.

Ground refueling systems can be broadly categorized into two main types: hydrants and fuel trucks. Hydrant systems are fixed installations at airports, consisting of an underground network of pipelines connected to storage tanks. Aircraft are refueled through a connection point on the apron, offering a faster and more efficient method, especially for larger aircraft. Fuel trucks, on the other hand, are mobile units that transport fuel from storage to the aircraft. They offer greater flexibility but are slower and may require more personnel.

- Hydrant Systems: These systems offer higher throughput and reduced risk of spills compared to fuel truck systems, making them ideal for high-traffic airports. Think of them like a sophisticated water supply system for aircraft.

- Fuel Trucks: These are more versatile, particularly useful in smaller airports or situations where a hydrant system is unavailable. They provide fuel delivery flexibility, but require careful handling and pose a higher spill risk.

Beyond these two primary types, different dispenser systems exist within each. For example, some hydrant systems employ automated dispensing and monitoring, while others might require manual operation. Similarly, fuel trucks can vary in size, capacity, and the types of dispensing equipment they use.

Q 2. Explain the safety procedures for connecting and disconnecting fuel hoses.

Connecting and disconnecting fuel hoses requires strict adherence to safety protocols to prevent accidents. This process always begins with a thorough pre-connection inspection of both the aircraft and the refueling equipment. The process involves several crucial steps:

- Grounding: Both the aircraft and the fuel truck must be properly grounded to prevent static electricity build-up, which could ignite flammable fuel vapors.

- Visual Inspection: Inspect the hose for any damage, kinks, or leaks before connecting it. Check the nozzle and aircraft receptacle for debris.

- Secure Connection: Connect the hose securely to both the aircraft and the fuel truck, ensuring a tight, leak-free seal. Never force a connection.

- Pre-fueling Check: Before dispensing fuel, always double-check that the correct fuel type is being dispensed and that the correct aircraft is being refueled. This verification must include a visual check of the fuel markings on the aircraft and the fuel truck.

- Disconnection: Once fueling is complete, release the pressure from the hose, slowly and carefully disconnect it, keeping the nozzle away from the aircraft. Ensure there are no spills during disconnection.

- Post-Disconnection Inspection: Inspect the connection points for leaks after disconnection.

Remember, a moment of carelessness during these procedures can lead to a significant accident. Every step must be performed meticulously.

Q 3. What are the potential hazards associated with ground refueling?

Ground refueling carries several inherent hazards. The most significant is the risk of fire or explosion due to the flammability of aviation fuel. Other hazards include:

- Fuel spills: Spills can contaminate the environment and create a fire hazard.

- Fumes: Fuel vapors are toxic and can cause respiratory problems. Proper ventilation is crucial.

- Static electricity: As mentioned earlier, static discharge can ignite fuel vapors.

- Personal injury: Mishandling of equipment or hoses can result in injuries.

- Equipment malfunction: Failures in the refueling equipment can lead to spills or other hazards.

The potential for serious consequences necessitates rigorous adherence to safety procedures and the use of appropriate personal protective equipment (PPE) such as fire-retardant clothing and safety glasses. Regular training and awareness are essential to mitigate these risks.

Q 4. How do you ensure the correct fuel type is dispensed?

Ensuring the correct fuel type is dispensed is paramount. This is typically achieved through a combination of visual checks and cross-referencing information on the aircraft and fuel truck documentation.

- Visual Verification: The fuel type is clearly marked on both the aircraft and the fuel truck. Refuelers should visually confirm that the fuel markings match before commencing the fueling operation.

- Aircraft Documentation: The aircraft’s flight plan or maintenance log should specify the required fuel type. This should be cross-checked with the fuel truck’s documentation.

- Fuel Truck Documentation: The fuel truck’s manifest or delivery note should clearly indicate the type of fuel contained within.

- Pre-Flight Briefing: The ground crew and pilots should discuss the refueling plan, confirming the fuel type and quantity. This coordination is critical to safety.

Failure to verify fuel type can lead to catastrophic engine damage and even crashes. Multiple layers of verification are essential for error prevention. If there is any doubt whatsoever, fueling should cease immediately, and the discrepancy resolved before proceeding.

Q 5. What are the procedures for dealing with a fuel spill?

Dealing with a fuel spill requires immediate and decisive action. The primary goal is to contain the spill to prevent further spread and mitigate the risk of fire or environmental damage.

- Emergency Response: Alert airport emergency services immediately.

- Containment: Use absorbent materials such as spill pads or sand to absorb the spilled fuel and prevent its spread. Establish a perimeter to keep personnel away from the spill area.

- Recovery: Carefully collect the absorbed fuel and contaminated materials and dispose of them according to regulations.

- Clean-up: Thoroughly clean the affected area to remove any remaining traces of fuel. This may involve using specialized cleaning agents.

- Documentation: Complete a detailed report of the incident, including the cause, quantity spilled, and actions taken. The report should be submitted to the relevant authorities.

The seriousness of a fuel spill depends on its size and location. Even small spills require prompt attention due to the potential environmental impact and fire risk. A structured emergency response plan is essential to ensuring safety and minimizing negative repercussions.

Q 6. Explain the importance of pre-flight inspections of fuel trucks and equipment.

Pre-flight inspections of fuel trucks and equipment are crucial for ensuring safe and efficient operation. These inspections identify potential hazards before they result in accidents.

- Hose Inspection: Check for kinks, cracks, damage, and leaks in all fuel hoses. Ensure all hose clamps are secure.

- Nozzle Inspection: Inspect nozzles for damage or obstructions that could cause leaks or spills.

- Metering System Check: Verify the accuracy of the fuel metering system. Ensure it is properly calibrated.

- Grounding System: Confirm that the grounding system is functional and properly connected to prevent static electricity buildup.

- Emergency Shut-off: Check that the emergency shut-off valves are easily accessible and in good working order.

- Leaks: Thoroughly inspect all connections and components for any signs of leaks. Any leaks must be immediately repaired before operation.

- Fluid Levels: Check the level of hydraulic fluid and other essential fluids used in the vehicle’s operation.

A pre-flight checklist should be used to systematically review all these components. Skipping this vital step is a serious lapse in safety protocol, which could result in serious consequences.

Q 7. How do you identify and report fuel quality issues?

Identifying and reporting fuel quality issues is vital for maintaining aircraft safety and operational integrity. Issues can range from contamination to incorrect fuel type.

- Visual Inspection: Inspect the fuel for any unusual color, clarity, or presence of sediment or water.

- Testing: Samples of fuel should be regularly taken and tested to verify its properties, such as density and flashpoint.

- Documentation: Any issues identified should be meticulously documented, including the date, time, location, and description of the problem.

- Reporting: Report any fuel quality issues immediately to the appropriate authorities, such as the airport management and fuel supplier. This ensures prompt action to prevent further problems.

The consequences of using contaminated or substandard fuel can be catastrophic, ranging from minor engine performance issues to complete engine failure. A robust fuel quality control program involving visual inspection and laboratory testing is crucial.

Q 8. What is your experience with different types of fuel dispensing equipment?

My experience encompasses a wide range of fuel dispensing equipment, from simple gravity-fed systems to sophisticated hydrant refueling systems and advanced dispenser units with integrated fuel management systems. I’ve worked with various manufacturers and models, including those with different flow rates, pressure capabilities, and safety features. For instance, I’m proficient in operating both conventional piston-type meters and turbine meters, understanding their strengths and limitations in terms of accuracy and reliability. I’ve also worked with different nozzle types, including those with pressure-limiting devices to prevent spills and overfills.

- Gravity-fed systems: Simplest, best for smaller aircraft and remote locations. Limited flow rate, relies on fuel tank height for pressure.

- Hydrant systems: High-capacity systems found in major airports. Fuel is piped from underground storage tanks directly to the aircraft.

- Dispenser units: Self-contained units with pumps, meters, and safety features. Versatile and commonly used in various settings.

Q 9. Describe your understanding of fuel system pressure and flow rates.

Fuel system pressure and flow rates are critical for safe and efficient refueling. Pressure ensures that fuel flows consistently and quickly to the aircraft tanks, while flow rate determines how much fuel is dispensed per unit of time. Understanding these factors is crucial for preventing spills and ensuring timely completion of the refueling operation. Pressure is typically measured in pounds per square inch (psi) and flow rate in gallons per minute (GPM). Different aircraft have different pressure and flow rate limits that must be strictly adhered to. For example, exceeding the maximum allowable pressure can damage the aircraft’s fuel system, while a too low flow rate can significantly prolong the refueling process.

Imagine refueling a large airliner: it needs a high flow rate to minimize turnaround time. However, the flow rate must be precisely controlled to avoid exceeding the aircraft’s system pressure limits. Monitoring both parameters simultaneously is essential for a successful operation.

Q 10. How do you handle a fuel tank overfill situation?

An overfill situation during fuel tanking is a serious safety hazard. My immediate response involves activating the emergency shut-off valve on the dispenser, halting fuel flow instantly. Next, I’d assess the extent of the spill using visual inspection and any available spill detection technology. I would then immediately implement the necessary spill response plan, which includes containing the spill, preventing its spread, and notifying the appropriate authorities. Depending on the nature and quantity of the spill, this might involve using absorbent materials, deploying spill booms, and contacting specialized cleanup crews. Thorough documentation of the event is essential, including the amount of overfill, causes, and all actions taken. A post-incident investigation is crucial to identify contributing factors and prevent similar occurrences in the future.

Post-incident analysis could uncover issues such as faulty fuel level indicators, metering system malfunction, or operator error. Addressing these root causes is vital for ensuring future operational safety.

Q 11. What are the regulations and guidelines you follow during ground refueling?

Ground refueling adheres to strict regulations and guidelines for safety and environmental protection. I strictly follow all local, national, and international aviation regulations related to fuel handling. These guidelines cover aspects such as fuel quality control, personnel training and certification, equipment maintenance and inspection, emergency procedures, and environmental protection against spills and emissions. Specific regulations address pre-fueling checklists, bonding and grounding procedures, the use of personal protective equipment (PPE), and emergency response plans. Adherence to these guidelines is not only essential for safety but also legally mandated.

Examples of key regulations often include those from the FAA (Federal Aviation Administration) in the US or equivalent agencies in other countries. These regulations often specify the required training and certification for fuel handlers, regular inspection procedures for fuel dispensing equipment, and the procedures to follow in case of fuel spills.

Q 12. How do you maintain accurate fuel records and documentation?

Maintaining accurate fuel records and documentation is a critical aspect of ground refueling. This involves meticulously recording all fuel transactions, including the aircraft registration, date and time, fuel type, quantity dispensed, and the signatures of the involved personnel. I typically utilize both electronic and manual systems for recording fuel data. Electronic systems provide automated data logging, enhancing accuracy and efficiency, while manual records provide a secondary backup and are essential for compliance audits. This documentation is then reconciled against the fuel inventory to ensure accurate accounting and prevent discrepancies. These records are crucial for auditing, inventory management, and billing purposes.

For example, a detailed log might include the aircraft’s tail number, the fuel grade, the quantity delivered, the time the refueling began and ended, and the signatures of the fueler and aircraft crew. This information is often stored in a centralized database for easy access and analysis.

Q 13. Describe your experience with different types of aircraft fueling.

My experience encompasses a diverse range of aircraft fueling operations, including fueling various types of aircraft from small general aviation aircraft to large commercial airliners and military jets. Each aircraft type presents unique challenges and procedures. Smaller aircraft may require simpler gravity-fed systems, while larger aircraft necessitate high-capacity hydrant systems or sophisticated dispenser units with precise flow control mechanisms. The fuel types themselves vary – Jet A, Jet A-1, Avgas, and others – and the procedures for handling each fuel type differ based on their specific properties and safety requirements. I’ve adapted my techniques to meet the unique requirements of each aircraft type, from understanding their fueling points and procedures to handling potentially different pressure and flow rate limitations.

For example, fueling a large passenger jet requires a significantly higher flow rate compared to a smaller corporate jet, necessitating the use of different equipment and safety protocols to ensure both efficiency and safety.

Q 14. Explain the process of static grounding during refueling.

Static grounding is a crucial safety procedure during aircraft refueling to prevent electrostatic discharge (ESD) that could lead to a fire or explosion. ESD is a build-up of static electricity that can occur due to the friction between the aircraft and the atmosphere during flight. This static charge needs to be safely dissipated before refueling. The process involves connecting a conductive cable or grounding strap between the aircraft’s airframe and the refueling equipment, creating a path to ground for any accumulated static charge. This connection effectively equalizes the electrical potential between the aircraft and the ground, eliminating the risk of a spark that could ignite fuel vapors. The grounding strap is typically attached to a designated grounding point on the aircraft, while the other end is connected to the dispenser or the fueling vehicle itself, ensuring a continuous path to ground.

Think of it like a lightning rod: the grounding strap provides a safe path for the electrical charge to dissipate, preventing any dangerous discharge during refueling.

Q 15. What are the signs of fuel contamination and how would you respond?

Fuel contamination is a serious threat in ground refueling, potentially leading to engine damage or even catastrophic failure. Signs can be subtle or obvious. Obvious signs include discoloration (e.g., water appearing milky or sediment at the bottom of a sample container), unusual odors (sour or acidic smells may indicate contamination), and the presence of visible particulate matter. Subtler signs might include unusual fuel viscosity or changes in the fuel’s density.

My response to suspected contamination follows a strict protocol:

- Immediate Stoppage: I’d immediately halt the refueling operation. Safety is paramount.

- Sample Collection: A representative sample of the suspect fuel would be taken following established procedures, ensuring proper labeling and chain of custody.

- Laboratory Analysis: The sample would be sent to a certified laboratory for comprehensive analysis to identify the contaminant and its concentration.

- Contaminated Fuel Handling: Procedures for safe disposal or remediation of the contaminated fuel would be followed strictly, adhering to all relevant environmental regulations.

- Investigation: A thorough investigation would commence to determine the source of the contamination—was it in the storage tank, the refueling equipment, or introduced during transfer?

- Corrective Actions: Corrective measures, which could range from cleaning tanks and pipelines to replacing faulty equipment, would be implemented to prevent future occurrences.

- Documentation: Meticulous documentation of the entire incident, including samples, test results, corrective actions, and personnel involved, would be maintained.

For example, during a recent operation, we noticed a slightly off-color fuel. A sample confirmed the presence of water. We immediately stopped fueling, followed the contamination protocol, and discovered a leak in a fuel storage tank’s seal. This was promptly repaired, preventing further incidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you troubleshoot a fuel pump malfunction?

Troubleshooting a fuel pump malfunction requires a systematic approach. First, I’d assess the situation for safety hazards, ensuring the area is secured before commencing any diagnostic work.

My troubleshooting steps would typically include:

- Visual Inspection: Check for obvious issues like loose connections, damaged wiring, leaks, or physical obstructions.

- Power Supply Check: Verify power is reaching the pump using a multimeter. A simple voltage test can quickly rule out a power problem.

- Pressure Checks: Measuring fuel pressure at various points in the system using appropriate gauges can reveal blockages or pressure drops indicating a problem within the pump or related components.

- Fluid Level Check: Ensure there is adequate fuel in the tank to prevent cavitation, which can damage the pump.

- Listen for Unusual Sounds: Abnormal noises like grinding, humming, or clicking can pinpoint internal pump problems.

- Check Pump Filters: Clogged filters can restrict fuel flow, causing the pump to work harder and eventually fail. These would be inspected and cleaned or replaced as needed.

- Check Bypass Valve (if applicable): Some systems use bypass valves. Ensure they are functioning correctly and not bypassing the pump inappropriately.

If the problem isn’t readily apparent, more specialized tools or the expertise of a qualified technician may be required. I’d document all findings and steps taken throughout the troubleshooting process.

For example, once, a fuel pump’s performance decreased gradually. Through systematic checks, I found a partially clogged filter. Replacing the filter restored the pump’s performance to specifications, averting a potential fueling delay.

Q 17. What is your experience with hydrant fueling systems?

I have extensive experience with hydrant fueling systems, having worked with both fixed and mobile hydrant systems at various airports. Hydrant fueling, which uses an underground network of pipelines to deliver fuel directly to aircraft, offers significant advantages in terms of efficiency and safety compared to traditional tanker truck refueling.

My experience encompasses:

- System Operation: I’m proficient in operating hydrant dispensers, understanding pressure management, flow control, and fuel quality monitoring within the system.

- Maintenance Procedures: I’m familiar with the preventive maintenance schedules and procedures for hydrant systems, including regular inspections, leak detection, and filter changes. This is critical for system reliability and safety.

- Emergency Response: I have participated in emergency drills and responded to minor system malfunctions such as leaks or pressure fluctuations, employing proper isolation and repair procedures.

- System Integration: I understand the integration of hydrant fueling systems with other airport infrastructure, including fuel storage facilities and aircraft fueling control systems.

Working with hydrant systems requires a higher level of training and expertise compared to other refueling methods. It’s not just about fueling the aircraft; it’s about understanding and maintaining a complex network to ensure a safe and efficient operation.

Q 18. Explain the importance of fire prevention measures during refueling.

Fire prevention is paramount during refueling operations. Aviation fuel is highly flammable, and a single spark could lead to a devastating fire.

Critical fire prevention measures include:

- Grounding and Bonding: Preventing static electricity buildup through proper grounding and bonding of the aircraft and refueling equipment is crucial. This eliminates the risk of static discharge igniting fuel vapors.

- No Smoking and Ignition Sources: Strict enforcement of no smoking and the elimination of all potential ignition sources (open flames, sparks, hot work) within the refueling area is mandatory.

- Spill Prevention and Containment: Using appropriate spill containment measures, such as absorbent pads and berms, prevents fuel spills from spreading and creating fire hazards.

- Emergency Response Preparedness: Having readily accessible fire extinguishers of appropriate type (e.g., foam extinguishers for fuel fires), emergency response plans, and trained personnel are essential.

- Regular Inspections: Equipment inspections for leaks, damage, or worn parts ensure the integrity of the refueling system and minimize fire risks.

- Proper Ventilation: Adequate ventilation is needed to prevent the buildup of flammable fuel vapors.

Imagine a scenario where a fuel spill occurs because of a damaged hose. The proper use of spill containment materials would limit the spill’s spread and prevent a potential fire. A well-rehearsed emergency plan would ensure a quick and efficient response, minimizing damage and injury.

Q 19. How do you ensure the safety of personnel and equipment during fueling operations?

Ensuring the safety of personnel and equipment during refueling is my top priority. A multi-layered approach is required:

- Risk Assessment: A thorough risk assessment is performed before each refueling operation, identifying potential hazards and implementing appropriate control measures.

- Pre-Fueling Inspection: A rigorous pre-fueling inspection of both the aircraft and the refueling equipment is carried out to identify any potential leaks or damage. This also includes a visual check for obstructions.

- Personal Protective Equipment (PPE): All personnel involved wear appropriate PPE, including flame-resistant clothing, safety shoes, gloves, and eye protection.

- Clear Communication: Effective communication between fueling personnel and aircraft crew is essential to coordinate activities and prevent accidents.

- Emergency Shutdown Procedures: Clear and well-rehearsed emergency shutdown procedures are in place for handling equipment malfunctions or unexpected events.

- Training and Competency: All personnel are adequately trained and competent in safe refueling procedures and emergency response protocols.

- Signage and Warning Systems: Appropriate signage and warning systems are utilized to create a safe working environment and alert personnel to potential hazards.

For instance, if a hose develops a leak during fueling, the emergency shutdown procedure would be immediately initiated, and the area would be evacuated until the leak is contained. Comprehensive training ensures that every member of the team understands their role in a safe and efficient emergency response.

Q 20. Describe your experience with emergency procedures in ground refueling.

My experience with emergency procedures in ground refueling is extensive. I’ve participated in numerous drills and responded to real-world incidents.

Emergency procedures typically involve:

- Spill Response: Containing and cleaning up fuel spills using absorbent materials, berms, and specialized equipment.

- Fire Suppression: Using fire extinguishers or calling emergency services to extinguish fuel fires.

- Emergency Shutdown: Quickly shutting down refueling equipment to prevent further incidents.

- Evacuation: Evacuating personnel from the refueling area to a safe location.

- Incident Reporting: Following established procedures for reporting incidents, including completing incident reports and notifying relevant authorities.

- Post-Incident Investigation: Participating in post-incident investigations to determine the root cause of the incident and identify areas for improvement.

In one specific incident, we experienced a sudden fuel leak from a tanker truck. Following emergency procedures, the leak was quickly contained using absorbent pads and the area was secured. Emergency services were notified as a precaution, though the fire suppression systems weren’t required. The incident highlighted the importance of regular equipment inspections and the value of well-practiced emergency response drills. We revised our preventative maintenance schedule as a result.

Q 21. What is your experience with different types of fuel storage tanks?

I have experience with various types of fuel storage tanks used in ground refueling, each with its own characteristics and safety considerations.

These include:

- Aboveground Storage Tanks (ASTs): These are commonly used for smaller storage capacities and offer ease of access for inspection and maintenance. However, they are more vulnerable to damage from external factors.

- Underground Storage Tanks (USTs): These offer better protection against environmental factors and are often preferred for larger storage capacities. They require more rigorous monitoring and leak detection systems.

- Hydrant Fueling Systems (as discussed previously): These use an underground network of pipelines connected to larger storage facilities. They offer efficiency and safety benefits but require a higher level of specialized maintenance and expertise.

- Tank Farms: These large-scale facilities often house multiple tanks, with advanced safety features such as fire suppression systems and secondary containment.

The choice of tank type depends on factors like storage capacity, environmental regulations, and site-specific considerations. Regardless of the tank type, strict adherence to safety regulations and regular inspections are crucial to prevent leaks, spills, and other hazards.

Q 22. How do you handle different weather conditions during refueling?

Weather significantly impacts ground refueling operations. Safety is paramount, and procedures adapt based on conditions.

High Winds: Strong winds can make connecting the refueling hose difficult and potentially dangerous. We use specialized equipment like windbreaks or delay refueling until conditions improve. For instance, if wind speeds exceed the specified limit for a particular aircraft type, we’ll postpone refueling and inform the flight crew. We might also need to adjust the refueling rate to prevent hose whip.

Rain/Snow: Precipitation can create slippery conditions, increasing the risk of accidents. We ensure all personnel use appropriate safety footwear and maintain extra caution. We may also need to take additional measures to prevent fuel spills.

Lightning: Refueling is strictly prohibited during lightning storms. We follow established safety protocols, halting operations and seeking shelter until the storm passes. This is a non-negotiable safety measure.

Extreme Temperatures: Both extreme heat and cold affect fuel properties (density and viscosity) and can impact equipment performance. We make adjustments to our procedures and equipment based on temperature readings. For instance, we may need to pre-heat or cool fuel lines during extreme temperatures.

Q 23. What is your understanding of the different fuel grades and their properties?

Different fuel grades possess unique properties impacting aircraft performance and engine health. Common grades include Jet A, Jet A-1, and Jet B.

Jet A and Jet A-1: These are kerosene-based fuels, widely used for their stability and low freezing point. Jet A-1 has stricter specifications than Jet A. I’ve personally worked extensively with both and the key difference I find is the tighter control over contaminants in Jet A-1.

Jet B: This fuel is a wide-cut naphtha-kerosene blend with a lower freezing point, making it suitable for very cold climates. It has a higher energy content but is less commonly used due to potential issues with compatibility and compatibility with different aircraft engines.

Understanding these differences is critical for preventing fuel contamination and ensuring the correct fuel is dispensed for each aircraft type. A wrong fuel grade can have catastrophic consequences.

Q 24. Describe the steps you take to perform a pre-flight fuel check.

A pre-flight fuel check is a crucial safety procedure. It involves a thorough inspection of the aircraft’s fuel system before flight.

Visual Inspection: I start by visually checking for any fuel leaks, damage to the fuel tanks or lines, or signs of contamination.

Fuel Quantity Verification: I use the aircraft’s fuel gauges and the fuel quantity indication system to check the fuel levels against the flight plan requirements. If there are discrepancies, I investigate before proceeding.

Fuel Quality Check: If possible, I inspect the fuel sample for contamination. This might involve checking clarity and inspecting for water or debris.

Documentation: I meticulously document all findings, including fuel levels, any observed anomalies, and the time of the check. This information is then passed to the flight crew for verification.

Imagine a scenario where a minor leak was undetected. A pre-flight check prevents a potentially disastrous situation in flight. Every detail matters.

Q 25. How do you calculate the required fuel quantity for an aircraft?

Calculating required fuel involves several factors.

Flight Distance: This is the primary factor, determined using navigation charts and flight planning software.

Fuel Consumption Rate: The aircraft’s fuel consumption rate (in gallons or liters per hour) varies depending on the aircraft type, weight, altitude, and weather conditions. This data is obtained from the aircraft’s flight manual.

Reserve Fuel: Regulations mandate carrying sufficient reserve fuel to account for unforeseen circumstances, such as delays or diversions. This is typically expressed as a specific flight time, such as 30 minutes or an hour, of additional fuel.

Taxi Fuel: Fuel required for taxiing to and from the runway is also factored in.

Required Fuel = (Flight Distance / Fuel Consumption Rate) + Reserve Fuel + Taxi Fuel

For example, if a flight needs 200 gallons for distance, 50 gallons for reserve, and 10 gallons for taxi, the total required fuel is 260 gallons. It’s always better to err on the side of caution, rather than run low on fuel.

Q 26. What are your strategies for managing time constraints during peak hours?

Peak hours demand efficient workflow management.

Prioritization: We prioritize aircraft based on urgency and flight schedules. Emergency flights take precedence. We use a queuing system to manage requests.

Teamwork and Communication: Clear communication between team members, pilots and ground control is vital. We might split tasks amongst the team to accelerate the process. For instance, one person focuses on pre-flight checks, and another manages the fuel trucks.

Equipment Readiness: Ensuring that all fueling equipment is in top working condition and readily available minimizes downtime. Regular maintenance checks are critical.

Process Optimization: We constantly analyze our procedures to identify bottlenecks and optimize workflows. Using the appropriate checklists reduces the chances of error and speeds up the process.

During peak times, it’s like a well-orchestrated dance; every person plays their role in ensuring smooth and safe operation.

Q 27. Explain your experience with the use of electronic fuel monitoring systems.

Electronic fuel monitoring systems (EFMS) have revolutionized ground refueling.

Accuracy: EFMS provides highly accurate fuel quantity readings, eliminating the potential errors associated with manual measurements. This enhances fuel management efficiency.

Automation: Many EFMS systems automate parts of the refueling process, reducing manual labor and the chance of human error. The system can automatically shut off the fuel flow once the pre-set quantity is reached.

Data Recording: EFMS provides detailed records of fuel quantities dispensed, time of refueling, and other relevant data. This data is valuable for auditing, inventory management, and fuel consumption analysis.

Integration: Some systems integrate with other airport systems, enabling seamless data sharing between various stakeholders.

In my experience, implementing EFMS has significantly improved both efficiency and safety in ground refueling. It is a true step up from manual practices.

Q 28. How do you prioritize tasks and manage multiple refueling requests simultaneously?

Managing multiple requests involves careful task prioritization and resource allocation.

Urgency and Schedule: We prioritize based on the flight schedule, giving precedence to flights with imminent departure times and emergency situations.

Aircraft Type: Different aircraft types may have different refueling needs and complexities, influencing prioritization.

Fuel Type and Quantity: Requests involving larger fuel quantities or specialized fuel types might require more time and resources.

Resource Allocation: We allocate personnel and equipment based on the demands of each request, optimizing the use of available resources. We might assign a team to handle several requests simultaneously based on their skill and availability.

A good analogy is a traffic controller managing aircraft traffic – we prioritize tasks and allocate resources to ensure smooth and safe operations.

Key Topics to Learn for Ground Refueling Interview

- Safety Procedures and Regulations: Understanding and applying all relevant safety regulations, including those related to fuel handling, personal protective equipment (PPE), and emergency response protocols. This includes theoretical knowledge of hazard identification and risk assessment.

- Fuel Handling Equipment: Familiarization with various types of refueling equipment, their operational procedures, and routine maintenance checks. Practical application involves understanding the mechanics of pumps, hoses, and nozzles, and troubleshooting common issues.

- Aircraft Refueling Procedures: Mastering the step-by-step process of aircraft refueling, including pre-flight checks, connection procedures, fueling techniques, and post-fueling inspections. This includes understanding different aircraft types and their specific refueling requirements.

- Fuel Quality Control: Knowledge of fuel quality testing methods, contamination prevention, and procedures for handling fuel-related discrepancies. Practical application includes understanding how to identify and report potential fuel contamination.

- Communication and Teamwork: Effective communication skills are crucial in ground refueling. Understanding how to communicate clearly and concisely with pilots, other ground crew, and supervisors is vital. This includes practicing active listening and conflict resolution skills.

- Emergency Procedures: Thorough understanding and practice of emergency response protocols for fuel spills, fires, or other incidents. This includes theoretical knowledge of emergency response plans and practical application of emergency procedures.

- Documentation and Reporting: Accurate and timely documentation of all refueling activities, including fuel quantities, aircraft identification, and any observed discrepancies. This includes understanding the importance of accurate record-keeping and reporting procedures.

Next Steps

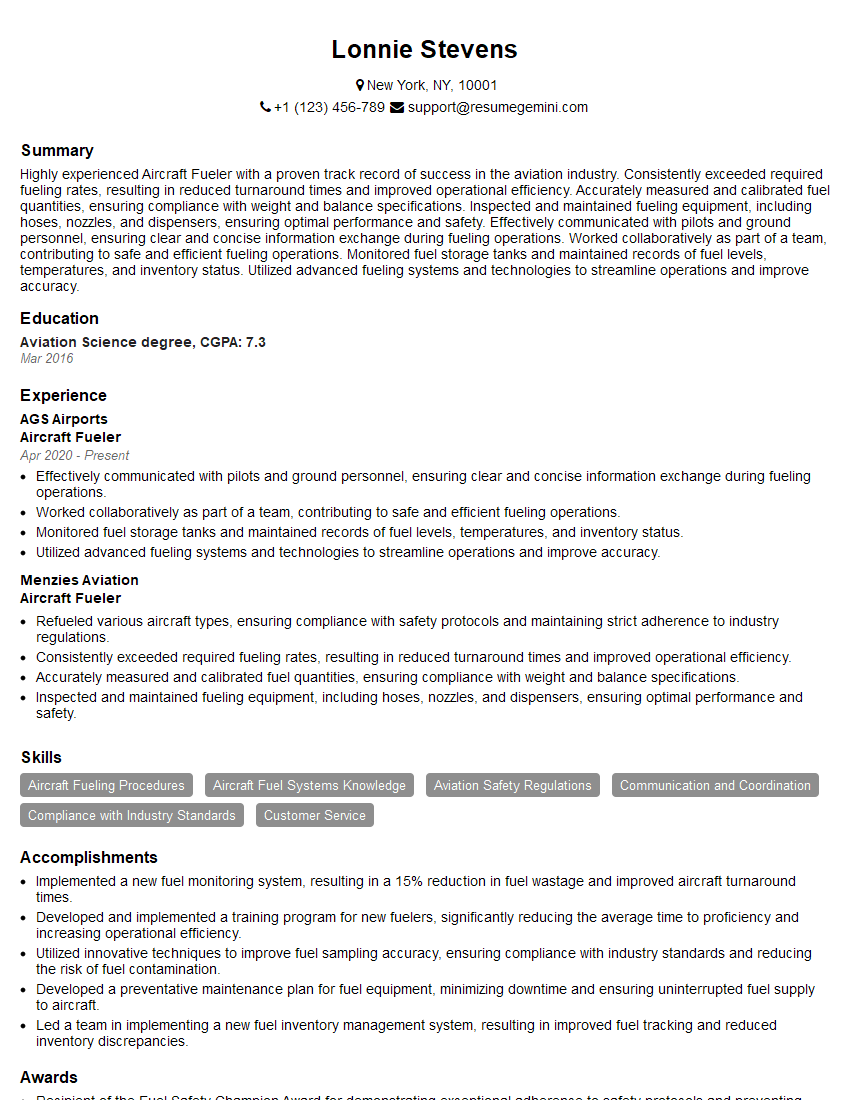

Mastering ground refueling opens doors to a rewarding career with significant growth potential within the aviation industry. To maximize your job prospects, crafting a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored specifically to the ground refueling field are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO