Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top GxP Regulatory Compliance interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in GxP Regulatory Compliance Interview

Q 1. Explain the principles of Good Manufacturing Practices (GMP).

Good Manufacturing Practices (GMP) are a set of guidelines that ensure the consistent production of high-quality products that meet predefined standards of safety and purity. Think of it as a recipe for manufacturing, ensuring every batch is consistent and safe for its intended use. These guidelines cover all aspects of production, from the raw materials used to the final product packaging and distribution. The core principles focus on preventing contamination, ensuring product quality, and maintaining accurate documentation. They are not simply rules, but rather a system built on minimizing risks and maximizing product safety and efficacy.

- Quality Control: Regular testing and monitoring throughout the manufacturing process to catch errors and inconsistencies early.

- Sanitation and Hygiene: Maintaining a clean and sterile environment to prevent contamination.

- Personnel Training: Ensuring all staff are adequately trained in GMP principles and procedures.

- Equipment Calibration and Maintenance: Ensuring all equipment used in manufacturing is properly calibrated and maintained.

- Documentation: Meticulous record-keeping of all processes and quality control checks. This forms the audit trail, demonstrating compliance.

For example, in pharmaceutical manufacturing, GMP ensures that medications are free from contaminants, have the correct potency, and are packaged correctly to maintain their effectiveness. A deviation from GMP could lead to product recalls, regulatory sanctions, and, critically, harm to patients.

Q 2. Describe the differences between GMP, GLP, and GCP.

While all three – GMP, GLP, and GCP – are crucial for regulatory compliance within the life sciences industry, they apply to different aspects of the product lifecycle:

- GMP (Good Manufacturing Practices): Focuses on the manufacturing process of pharmaceuticals, medical devices, food, and other regulated products. It ensures the quality and safety of the final product. Imagine this as the final stage, ensuring the product leaving the facility meets all standards.

- GLP (Good Laboratory Practices): Governs the conduct of non-clinical laboratory studies, such as toxicology and efficacy testing of pharmaceuticals. It guarantees the reliability and integrity of data generated in these studies. This is the stage where the product is tested before manufacturing.

- GCP (Good Clinical Practices): Applies to the design, conduct, performance, monitoring, auditing, recording, analyses, and reporting of clinical trials of pharmaceuticals and medical devices in humans. It protects the rights, safety, and well-being of trial participants while ensuring the quality and integrity of clinical trial data. This is how the product’s efficacy and safety are tested in humans.

In essence, GLP provides data to support the development of a product, GCP ensures the product is safe and effective in humans, and GMP guarantees that the product is consistently manufactured according to the high standards set in the previous phases.

Q 3. What are the key elements of a quality management system (QMS)?

A Quality Management System (QMS) is a comprehensive framework that helps organizations consistently meet customer requirements and regulatory expectations. It’s a structured approach to ensuring quality throughout an entire organization. Think of it as the backbone of any compliant organization. Key elements include:

- Quality Policy: A formal statement outlining the organization’s commitment to quality.

- Quality Objectives: Specific, measurable, achievable, relevant, and time-bound (SMART) goals that support the quality policy.

- Risk Management: A proactive approach to identifying, assessing, and mitigating potential risks affecting quality.

- Change Control: A formal procedure for managing and approving changes to processes, equipment, or documentation.

- Document Control: A system for creating, reviewing, approving, distributing, and archiving documents.

- Internal Audits: Regular assessments to evaluate the effectiveness of the QMS.

- Corrective and Preventive Actions (CAPA): A process for addressing quality issues and preventing recurrence.

- Management Review: Periodic reviews by management to assess the performance of the QMS and make necessary improvements.

- Continuous Improvement: A commitment to continually improving the QMS.

A robust QMS integrates seamlessly across all departments and is crucial for achieving and maintaining regulatory compliance.

Q 4. How do you ensure compliance with 21 CFR Part 11?

21 CFR Part 11, a US FDA regulation, establishes the criteria for electronic records and signatures in regulated industries. Ensuring compliance necessitates a multifaceted approach:

- System Validation: Rigorous testing to ensure the electronic system meets the requirements of 21 CFR Part 11. This verifies the system consistently produces accurate and reliable results.

- Access Control: Implementing robust user authentication and authorization mechanisms to track who accesses and modifies data. This might include unique usernames, passwords, and role-based access.

- Audit Trails: Maintaining detailed records of all system activities, including who made changes, what changes were made, and when. This is essential for demonstrating compliance and tracing data back to its source.

- Data Integrity: Implementing measures to ensure data accuracy, completeness, consistency, and trustworthiness. This can involve data validation checks and regular backups.

- Electronic Signatures: Ensuring that electronic signatures meet the criteria for legal equivalence to handwritten signatures. This usually involves using secure digital signatures with appropriate authentication mechanisms.

For example, a failure to properly validate a system or adequately control access could lead to data breaches, compromised data integrity, and regulatory enforcement actions. Comprehensive documentation throughout the entire process is essential for demonstrating compliance.

Q 5. What is a CAPA (Corrective and Preventive Action) and how is it implemented?

A Corrective and Preventive Action (CAPA) is a systematic process for investigating quality issues, implementing corrective actions to address the immediate problem, and preventive actions to stop similar issues from recurring. It’s a crucial element for continuous improvement in any GxP compliant organization.

Implementation typically follows these steps:

- Identify the Issue: This could be a deviation from a standard operating procedure, a failed quality control test, or a customer complaint.

- Investigate the Root Cause: Conduct a thorough investigation to determine the underlying cause(s) of the issue. This may involve interviewing staff, reviewing documentation, and analyzing data.

- Implement Corrective Actions: Take immediate steps to address the immediate issue and prevent further occurrences. This may include repairing equipment, retraining staff, or revising procedures.

- Implement Preventive Actions: Implement actions to prevent recurrence. This might involve changing procedures, implementing new controls, or improving training programs.

- Verify Effectiveness: Monitor the effectiveness of the corrective and preventive actions to ensure they have solved the problem and prevented recurrence.

- Document Everything: Maintain detailed documentation of the entire CAPA process, including the issue, investigation, actions taken, and verification of effectiveness.

For instance, if a batch of medication fails a potency test, a CAPA would be initiated to determine the root cause (e.g., faulty equipment, incorrect mixing procedure), implement corrective actions (e.g., repair or replace equipment, retrain personnel), and preventive actions (e.g., improve equipment maintenance, implement stricter SOPs).

Q 6. Describe your experience with conducting audits.

Throughout my career, I have conducted numerous audits, both internal and external, across various GxP regulated environments. My experience includes leading audits, participating as a team member, and providing remediation support. I’m proficient in applying various audit methodologies, such as risk-based auditing and focusing on critical processes. I’ve audited aspects encompassing GMP, GLP, GCP, and general quality systems.

For example, during a recent GMP audit of a pharmaceutical manufacturing facility, I reviewed documentation, observed production processes, and interviewed staff. I identified some minor deviations from SOPs, some issues with calibration records, and a deficiency in the CAPA system. I documented the findings and provided clear recommendations for corrective action to the management team. My audit reports are detailed, objective, and actionable, offering constructive feedback to improve quality systems and enhance compliance.

My audit approach is always collaborative and focuses on helping auditees improve their systems rather than simply identifying deficiencies. I believe in fostering a culture of continuous improvement and risk management.

Q 7. Explain your understanding of change control processes.

Change control is a crucial process for managing and approving any changes to processes, equipment, documentation, or systems within a regulated environment. It is designed to ensure that changes are implemented safely, effectively, and without compromising product quality or compliance.

A robust change control system typically involves these stages:

- Proposal Submission: A formal request to make a change, including a justification and impact assessment.

- Review and Assessment: Evaluation of the proposed change’s impact on quality, compliance, and other relevant factors.

- Approval or Rejection: Decision on whether to approve or reject the proposed change based on the risk assessment.

- Implementation: Controlled implementation of the approved change, often with specific instructions and timelines.

- Verification: Confirmation that the change has been implemented correctly and effectively.

- Documentation: Maintaining complete and accurate documentation of the entire change control process.

For example, a change to a manufacturing process might require a thorough change control process. This involves detailed risk assessments, approvals from relevant personnel (including quality control and regulatory affairs), validation to ensure the change does not negatively affect product quality, and comprehensive documentation of all changes made. Effective change control is essential to avoid unforeseen problems and ensure continued regulatory compliance.

Q 8. How do you handle deviations from established procedures?

Handling deviations is crucial in GxP compliance. A deviation is any unplanned event that deviates from established procedures, specifications, or standards. My approach involves a systematic investigation to understand the root cause, implement corrective actions, and prevent recurrence. This involves immediately documenting the deviation, notifying appropriate personnel, conducting a thorough investigation including reviewing batch records, equipment logs and interviewing relevant personnel. The investigation aims to identify the root cause using tools like Fishbone diagrams or 5 Whys. Corrective actions, preventive actions, and changes to Standard Operating Procedures (SOPs) are then documented and implemented. For example, if a deviation occurred during a weighing process due to an inaccurate balance calibration, the investigation would involve reviewing the balance calibration records, retraining staff on proper calibration procedures, recalibrating the balance, and potentially implementing an additional check step in the weighing SOP.

- Immediate Action: Secure the affected materials and notify management.

- Investigation: Identify root cause using appropriate tools (e.g., 5 Whys, Fishbone Diagram).

- Corrective Action: Address the immediate problem.

- Preventive Action: Prevent recurrence (e.g., revise SOPs, improve training).

- Documentation: Thoroughly document the entire process, including findings and actions taken.

Q 9. What is your experience with documentation and record-keeping in a GxP environment?

Documentation and record-keeping are fundamental pillars of GxP compliance. In my experience, this involves meticulous attention to detail, ensuring accuracy, completeness, and adherence to ALCOA+ principles (Attributable, Legible, Contemporaneous, Original, Accurate + complete, consistent, enduring and available). This means every action, observation, and deviation must be accurately documented. I’ve been involved in implementing and maintaining electronic document management systems (EDMS) to streamline this process and ensure version control. This includes training staff on proper documentation techniques, establishing clear SOPs, and conducting regular audits. For example, in a pharmaceutical manufacturing setting, this involves maintaining accurate batch records, equipment logs, calibration records, cleaning validation reports, and deviation reports. I have experience in developing and implementing data management systems that ensure data traceability, and compliance with 21 CFR Part 11 where applicable.

Maintaining an audit trail is essential. It provides traceability and allows us to reconstruct the history of data and events. A strong audit trail ensures data integrity and accountability.

Q 10. Describe your experience with validation activities.

Validation is the process of demonstrating that equipment, systems, and processes consistently perform as intended. My experience encompasses a wide range of validation activities, including computer system validation (CSV), process validation, equipment qualification (IQ,OQ,PQ), and cleaning validation. I have participated in the development and execution of validation protocols, reviewing validation reports, and presenting findings to regulatory agencies. For example, I have been involved in validating a new high-performance liquid chromatography (HPLC) system, which included installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ). This involved testing the system’s functionality, accuracy, and precision according to pre-defined acceptance criteria. In process validation, I’ve been involved in developing and executing validation protocols to demonstrate the consistency and reproducibility of manufacturing processes. This might involve running multiple batches under different conditions to assess the process robustness and ensure consistent product quality.

Q 11. How do you ensure data integrity in a GxP environment?

Data integrity in a GxP environment is paramount. It means ensuring that data is complete, consistent, accurate, trustworthy, and attributable throughout its lifecycle. My approach focuses on implementing and enforcing robust data management systems, including adherence to ALCOA+ principles. This includes implementing controls to prevent data manipulation, ensuring proper training for personnel, and establishing a culture of data integrity. We use various techniques to maintain data integrity, such as electronic signatures, access controls, audit trails, and data backups. Regular data integrity audits and checks are conducted to identify and address any potential gaps. For instance, we might conduct periodic reviews of raw data to ensure it’s consistent with the final reported data, or review user access logs to identify any unauthorized access attempts.

Think of it like building a house – each brick needs to be perfectly placed and accounted for. If even one brick is missing or incorrectly placed, the structure’s integrity is compromised.

Q 12. What is your experience with risk assessment and management?

Risk assessment and management are vital for proactive GxP compliance. This involves identifying potential risks to product quality, patient safety, and regulatory compliance. We utilize various risk assessment methodologies, such as Failure Mode and Effects Analysis (FMEA) and Hazard Analysis and Critical Control Points (HACCP) to systematically evaluate these risks. Once identified, we prioritize them based on their likelihood and impact, and develop mitigation strategies to reduce or eliminate the risk. These strategies are documented and implemented. For example, in a pharmaceutical manufacturing facility, we might conduct a risk assessment of a specific process to identify potential sources of contamination. This could lead to the implementation of improved cleaning procedures, enhanced environmental monitoring, or stricter control over raw materials.

Q 13. Explain your understanding of deviation investigations.

Deviation investigations are a critical part of GxP compliance. They’re a systematic approach to understand why a deviation from established procedures occurred. The goal is to identify the root cause, implement corrective actions, and prevent recurrence. My experience involves leading and participating in investigations, utilizing tools like 5 Whys, Fishbone diagrams, and fault tree analysis to systematically trace the sequence of events that led to the deviation. We then develop and implement CAPAs (Corrective and Preventive Actions) to address the immediate problem and prevent it from happening again. This includes reviewing data, interviewing personnel, and analyzing relevant documents and processes. A comprehensive report documenting the deviation, investigation, root cause analysis, corrective and preventative actions, and effectiveness verification is created and reviewed by management.

Think of it like solving a mystery – we need to piece together the clues to understand what happened and prevent similar incidents.

Q 14. How do you handle non-conformances?

Non-conformances are any instance where a product, process, or system doesn’t meet established requirements. Handling non-conformances requires a similar systematic approach to deviation investigations. This involves immediately isolating the non-conforming material or product, conducting a thorough investigation to determine the root cause, and deciding on appropriate actions based on the severity of the non-conformance. Actions can range from reworking or rejecting the non-conforming material to implementing corrective actions and preventive actions to prevent recurrence. The process involves complete documentation of the non-conformance, investigation, actions taken, and effectiveness verification. This ensures traceability and accountability. For example, if a batch of tablets fails dissolution testing, the non-conforming batch will be quarantined, a thorough investigation will be conducted to determine the root cause (e.g., faulty equipment, incorrect formulation), corrective actions such as equipment repair or formula adjustment will be implemented, and the effectiveness of the corrective actions will be verified.

Q 15. What is your experience with supplier audits?

Supplier audits are a critical component of GxP compliance, ensuring that materials and services procured from external sources meet the required quality and regulatory standards. My experience encompasses conducting both on-site and remote audits, covering various aspects such as quality management systems (QMS), manufacturing processes, and documentation review. I’m proficient in developing audit plans tailored to specific supplier risks and regulatory requirements. This includes reviewing supplier documentation like certificates of analysis (CoA), manufacturing records, and quality agreements. For instance, I once audited a supplier of active pharmaceutical ingredients (APIs) and uncovered a gap in their change control process, which we addressed collaboratively to mitigate potential risks. The audit process followed a structured approach, involving pre-audit planning, on-site assessment, report generation, and follow-up actions to ensure corrective and preventative actions (CAPAs) were implemented effectively.

My approach prioritizes a collaborative, risk-based audit methodology, fostering open communication with the supplier to help identify areas for improvement rather than solely focusing on non-compliance. This results in strengthened supplier relationships and improved product quality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with the implementation of new GxP regulations.

Implementing new GxP regulations requires a systematic and proactive approach. My experience involves leading and participating in cross-functional teams to ensure seamless transition and adherence to new regulations. This includes thorough gap analysis to identify potential non-compliances, development and implementation of new procedures and training programs, and validation of new systems. For example, the implementation of the EU’s Falsified Medicines Directive (FMD) required significant changes to our serialization and aggregation processes. We developed a comprehensive plan, including system validation, operator training, and process qualification. I played a crucial role in leading this project, ensuring the timely and successful implementation, meeting the regulatory deadlines, and ultimately preventing product recalls and ensuring patient safety.

The key to successful implementation lies in thorough planning, stakeholder engagement, and a robust change management strategy. Regular communication and effective training are critical to ensure the buy-in and understanding of all employees involved.

Q 17. How do you ensure compliance with data security regulations?

Data security is paramount in GxP environments. My approach to ensuring compliance involves a multi-layered strategy. This begins with implementing robust access controls, restricting access to sensitive data based on the principle of least privilege. We use role-based access controls (RBAC) to enforce this. Regular security audits and vulnerability assessments are performed to identify and mitigate potential threats. We implement strong data encryption, both in transit and at rest, protecting against unauthorized access and data breaches. Moreover, we maintain detailed audit trails to track all data access and modifications, enabling efficient investigation and accountability. We also conduct regular employee training on data security policies and procedures, emphasizing the importance of password management and phishing awareness. In addition, we adhere to data retention policies to maintain compliant storage and secure disposal of data.

Think of it like a fortress: multiple layers of defense (access controls, encryption, audits) protect the valuable data (the crown jewels) within. Each layer adds security and creates redundancy, significantly reducing the risk of compromise.

Q 18. Explain your understanding of electronic signatures and their regulatory implications.

Electronic signatures (e-signatures) are increasingly prevalent in GxP environments, offering efficiency and improved workflow. However, their regulatory implications are significant. To ensure compliance, a thorough validation process is necessary, demonstrating the system’s reliability, integrity, and authenticity. This involves establishing a robust system for identity verification, ensuring that only authorized individuals can apply e-signatures. The system must also maintain a comprehensive audit trail, documenting who signed what, when, and from where. Additionally, the e-signature system must comply with relevant regulations, such as 21 CFR Part 11 in the US, and equivalent regulations in other regions. For example, a proper e-signature system needs to be able to prevent unauthorized modification of signed documents. Moreover, the system must be capable of detecting and preventing tampering or forgery.

Choosing a validated e-signature system that meets all regulatory requirements is essential. The system’s functionality should then be thoroughly validated, documenting the tests performed and the results obtained. Continuous monitoring and maintenance are also critical to ensure the system’s long-term compliance.

Q 19. What is your experience with quality metrics and reporting?

Quality metrics and reporting are indispensable for monitoring compliance and identifying areas for improvement. My experience involves developing and implementing key performance indicators (KPIs) that reflect critical aspects of the quality system, such as the number and severity of deviations, the effectiveness of CAPAs, and the compliance rate of audits. This data is then analyzed to identify trends and potential problems. I use various tools and techniques to visualize and present this data, creating clear and concise reports for management and regulatory authorities. For example, a control chart illustrating the trend of deviations over time can quickly reveal a potential systemic issue. By using a data-driven approach, we can identify patterns, prioritize improvements and ultimately reduce risk and enhance quality.

Data visualization is key – making the metrics easily understandable and actionable enables rapid decision-making and problem-solving.

Q 20. How do you manage and resolve conflicts related to compliance?

Compliance-related conflicts often arise from differing interpretations of regulations or priorities. My approach to conflict resolution is based on collaboration and clear communication. I start by gathering all relevant information and understanding the perspectives of all parties involved. I then facilitate a structured discussion, promoting open dialogue and identifying common ground. When necessary, I consult with subject matter experts or legal counsel to clarify regulatory requirements or address complex issues. My aim is to find a mutually acceptable solution that ensures compliance while preserving relationships and maintaining operational efficiency. Documentation of the conflict, the resolution process, and the final agreement are crucial for future reference and transparency.

Think of it like mediation: facilitating a productive conversation to find a mutually beneficial and compliant solution. The process is documented to ensure future clarity and accountability.

Q 21. Describe a situation where you identified a compliance gap and how you addressed it.

During a routine audit of our batch record review process, we discovered a compliance gap. We found that not all batch records were being reviewed within the required timeframe, violating our internal SOPs and potentially impacting product quality. To address this, I first conducted a thorough root cause analysis (RCA) using techniques like the 5 Whys to understand the underlying reasons for the delay. We discovered that the review process was cumbersome and lacked efficiency, leading to bottlenecks and delays. We then developed and implemented a streamlined process with improved workflow, including automation of certain steps and clearer assignment of responsibilities. We also provided additional training to personnel involved in the batch record review. Finally, we put in place a robust monitoring system to track compliance with the revised process and ensure that the problem didn’t reoccur. The situation was reported to senior management, and corrective actions were documented and reviewed during follow up audits.

The key here was a systematic approach – identifying the root cause, implementing a practical solution, and implementing monitoring to prevent recurrence. Transparency with all stakeholders was also essential.

Q 22. What is your experience with training and awareness programs related to GxP compliance?

My experience encompasses the entire lifecycle of GxP training and awareness programs, from needs assessment and curriculum development to delivery and effectiveness evaluation. I’ve designed and implemented programs for various roles, including manufacturing, quality control, and research and development, tailoring content to specific job functions and regulatory requirements. For example, in a previous role, I developed a comprehensive training program for Good Manufacturing Practices (GMP) that incorporated interactive modules, case studies, and practical exercises to enhance knowledge retention and application. This program resulted in a significant improvement in compliance scores during subsequent internal audits. I also have experience utilizing Learning Management Systems (LMS) to track training completion, manage records, and generate reports for regulatory inspections. Furthermore, I’ve developed and delivered refresher training programs to address emerging compliance challenges and regulatory updates, ensuring that our teams remained current with the latest best practices.

Q 23. Explain your understanding of the importance of traceability in a GxP environment.

Traceability in a GxP environment is paramount; it’s the ability to track and document the history, location, and transformation of materials, processes, and data throughout their lifecycle. Think of it like leaving a clear breadcrumb trail. This ensures data integrity, facilitates investigations, and supports regulatory inspections. Without robust traceability, it becomes nearly impossible to identify the root cause of a non-conformity, to recall affected products, or to demonstrate compliance to regulatory bodies. For instance, if a batch of medication is found to be contaminated, comprehensive traceability allows you to pinpoint the exact source of the contamination – perhaps a specific raw material supplier or a process step – allowing for immediate corrective and preventive actions. Specific examples include serializing products, meticulously documenting all manufacturing steps and personnel involved, and employing electronic batch records (EBR) for complete data capture and audit trails.

Q 24. How do you stay up-to-date with changes in GxP regulations?

Staying current with ever-evolving GxP regulations requires a multi-pronged approach. I actively subscribe to reputable regulatory newsletters and publications from agencies like the FDA and EMA. I also attend industry conferences and webinars, network with other compliance professionals, and actively participate in professional organizations focused on GxP compliance. Furthermore, I regularly review updated guidance documents and interpretative letters released by regulatory authorities. Finally, I utilize advanced search strategies and utilize alert systems to be notified of significant changes to regulations that impact my area of responsibility. This ensures I am proactively addressing potential compliance gaps and keeping our operations compliant.

Q 25. Describe your experience with working with regulatory agencies (e.g., FDA, EMA).

I have extensive experience interacting with regulatory agencies such as the FDA and EMA, including participation in inspections and responding to observations. In one instance, I led a team through a successful FDA inspection, proactively addressing all observations and demonstrating our commitment to compliance. This involved meticulous preparation, including the thorough documentation of our quality system and procedures. We even created a comprehensive ‘inspection readiness’ checklist for efficient execution of the inspection. This experience highlighted the importance of thorough preparation and transparent communication with inspectors. My interactions with regulatory bodies have always been characterized by a proactive and collaborative approach; addressing any concerns promptly and thoroughly. This approach fosters a positive and productive relationship, minimizing potential issues.

Q 26. How do you handle pressure and tight deadlines in a compliance-focused role?

Working in a compliance-focused role often means managing tight deadlines and significant pressure. My approach is to prioritize tasks effectively, utilizing tools like risk assessment matrices to identify critical path activities. I build in buffer time to accommodate unexpected delays, and I encourage open communication within my team to share workload and address potential challenges collaboratively. For example, I once faced the challenge of completing a significant regulatory submission under an extremely tight deadline. By clearly delegating responsibilities, establishing regular communication updates, and working extended hours as a team, we successfully met the deadline without compromising quality or compliance.

Q 27. Explain your experience with the implementation of a new quality system.

I have led the implementation of several new quality systems, including a recent transition to a new electronic Quality Management System (eQMS). This involved a phased approach starting with a comprehensive gap analysis against the target state, defining clear project goals, creating detailed timelines, and assigning responsibilities. We conducted extensive user training and conducted thorough validation and verification activities to ensure the new system met regulatory requirements. The successful implementation required meticulous planning, effective communication, and strong change management skills. Throughout this process, we closely monitored key performance indicators (KPIs) to ensure adherence to project objectives and the effective transition to the new system. Post implementation, we conducted thorough assessments to ensure that the new system is meeting its intended purpose.

Q 28. What is your experience with internal and external audits?

My experience with internal and external audits is extensive. I’ve led internal audit programs, developing audit plans, conducting audits, and reporting findings to management. This included creating corrective and preventive action (CAPA) plans to address identified non-conformances. I’ve also participated in numerous external audits conducted by regulatory agencies and third-party certification bodies, coordinating audit preparations and responses, and ensuring that all necessary documentation was readily available. A key success in an external audit involved identifying and remediating a potential non-conformity before the auditors arrived. This proactive approach demonstrated our strong commitment to quality and compliance, resulting in a positive audit outcome. The key to successful audits is preparation, documentation, and transparency.

Key Topics to Learn for GxP Regulatory Compliance Interview

- Good Manufacturing Practices (GMP): Understand the core principles of GMP, including documentation, quality control, and deviation management. Consider practical applications like batch record review and CAPA (Corrective and Preventive Action) implementation.

- Good Laboratory Practices (GLP): Explore the regulations governing non-clinical laboratory studies, focusing on data integrity, quality assurance, and study conduct. Think about real-world scenarios involving data handling and audit preparedness.

- Good Clinical Practices (GCP): Learn the ethical and scientific quality requirements for designing, conducting, recording, and reporting clinical trials. Consider case studies involving informed consent, data management, and regulatory reporting.

- Data Integrity: This is a crucial aspect across all GxP areas. Understand the principles of ALCOA+ (Attributable, Legible, Contemporaneous, Original, Accurate + Complete, Enduring, Available) and how to apply them in practice. Prepare to discuss potential data integrity breaches and mitigation strategies.

- Quality Systems: Familiarize yourself with the establishment and maintenance of effective quality management systems, including risk assessment, internal audits, and continuous improvement initiatives. Be ready to discuss examples of quality system failures and how to prevent them.

- Regulatory Inspections: Understand the process of regulatory inspections, including preparation, execution, and follow-up. Consider how to effectively respond to inspector queries and address observations.

- Specific GxP Regulations (e.g., 21 CFR Part 11, Annex 11): Depending on the specific role, you may need in-depth knowledge of particular regulations. Research relevant regulations and be prepared to demonstrate your understanding of their requirements.

Next Steps

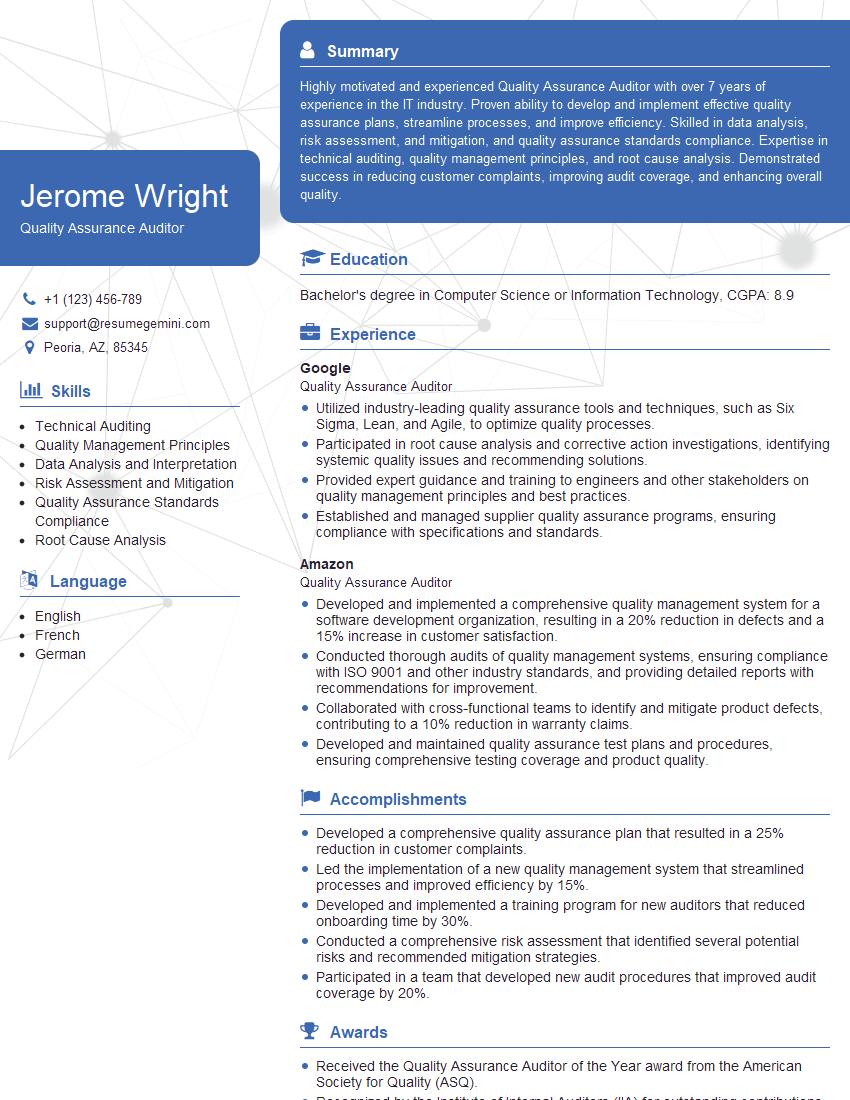

Mastering GxP Regulatory Compliance is crucial for a successful and rewarding career in the pharmaceutical, biotech, and medical device industries. It demonstrates a commitment to quality, patient safety, and regulatory adherence – highly sought-after qualities in today’s competitive job market. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to GxP Regulatory Compliance roles to guide you through the process, ensuring your application stands out from the crowd.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.