The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Handle Hazardous Materials Safely interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Handle Hazardous Materials Safely Interview

Q 1. Describe your experience handling hazardous materials.

Throughout my career, I’ve extensively handled various hazardous materials, ranging from corrosive chemicals in a laboratory setting to flammable solvents in an industrial environment. My experience includes not only the practical handling – pouring, mixing, and transferring – but also the crucial pre-handling planning and post-handling cleanup. For instance, during my time at Acme Chemical, I was responsible for the safe transfer of highly reactive materials, adhering strictly to safety protocols and ensuring meticulous documentation. This included detailed risk assessments, proper selection of PPE, and emergency response planning. In another role, I led a team in the decommissioning of a facility containing asbestos, which necessitated a highly structured approach to containment, removal, and disposal according to stringent regulatory requirements.

Q 2. What are the different classes of hazardous materials?

Hazardous materials are categorized into different classes based on their inherent hazards. The classification system, often based on the UN Globally Harmonized System of Classification and Labelling of Chemicals (GHS), helps in determining appropriate handling and transportation procedures. Key classes include:

- Class 1: Explosives – Substances or articles capable of mass explosion or projection of fragments.

- Class 2: Gases – Compressed, liquefied, or dissolved gases that may be flammable, toxic, or oxidizing.

- Class 3: Flammable Liquids – Liquids that readily ignite and burn.

- Class 4: Flammable Solids; Substances Liable to Spontaneous Combustion; Substances which, in contact with water, emit flammable gases – Solids that easily catch fire, or those that ignite spontaneously or react violently with water.

- Class 5: Oxidizing Substances and Organic Peroxides – Substances that readily release oxygen or other oxidizers, causing or contributing to combustion.

- Class 6: Toxic and Infectious Substances – Materials that are poisonous or cause disease.

- Class 7: Radioactive Materials – Materials that emit ionizing radiation.

- Class 8: Corrosive Substances – Materials that cause visible destruction or irreversible alterations to living tissue.

- Class 9: Miscellaneous Hazardous Materials – Materials that do not fit into the other classes but pose significant risks, such as environmentally hazardous substances.

Understanding these classifications is paramount for safe handling and ensures appropriate containment measures are in place.

Q 3. Explain the importance of Material Safety Data Sheets (MSDS).

Material Safety Data Sheets (MSDS), now often referred to as Safety Data Sheets (SDS), are crucial documents providing comprehensive information about hazardous materials. Think of them as the instruction manuals for chemicals. They contain vital details including the material’s identity, physical and chemical properties, health hazards, first aid measures, fire and explosion hazards, accidental release measures, handling and storage, exposure controls, personal protection, physical and chemical properties, stability and reactivity, toxicological information, ecological information, disposal considerations, and regulatory information. Without an MSDS, safe handling is impossible. For instance, knowing the flash point of a flammable liquid from the MSDS allows for appropriate ventilation and storage to prevent fire hazards. Understanding its toxicity dictates necessary PPE and safe handling practices. In short, the MSDS is the cornerstone of safe hazardous materials management.

Q 4. How do you identify and classify hazardous materials?

Identifying and classifying hazardous materials involves a multi-step process. Firstly, a visual inspection, including checking labels, markings, and placards on containers, is crucial. Next, consulting the material’s SDS is essential. This document provides the official classification. If the label is unclear or missing, laboratory testing may be necessary to identify the material and determine its hazardous properties. Proper labeling is critical, ensuring everyone understands the risks associated with the material. Labels adhere to standardized formats (like the Globally Harmonized System of Classification and Labelling of Chemicals or GHS) to help in quick identification of hazards, ensuring appropriate precautions are taken.

Q 5. What are the proper procedures for storing hazardous materials?

Storing hazardous materials requires a structured approach, focusing on segregation and containment. Incompatible materials should never be stored together – for example, oxidizers should be kept far away from flammable substances. Storage areas need to be well-ventilated to prevent the buildup of flammable vapors. Proper temperature control is crucial for temperature-sensitive materials. Containers must be properly sealed and stored in secondary containment to prevent leaks or spills. Appropriate signage must be prominently displayed to alert personnel to the hazards present. Furthermore, the storage area should be secured, restricting access to authorized personnel only. Regular inspections are essential to detect any damage to containers or signs of leakage.

Q 6. Describe your experience with spill response procedures.

My spill response experience is extensive. It involves immediate action to contain and mitigate the spill, prioritizing personal safety. This begins with assessing the situation, identifying the spilled material, and determining the level of hazard. Next, the appropriate PPE, determined by the SDS of the spilled material, is donned. Then, using absorbent materials, the spill is contained and cleaned up, following specific procedures detailed in the facility’s emergency response plan. Waste is collected and disposed of according to regulatory guidelines. Documentation of the incident, including the time, location, amount spilled, clean-up procedures, and personnel involved, is crucial. I’ve been involved in several spill response incidents, ranging from small solvent spills to larger chemical releases. In each instance, effective communication with emergency responders and adherence to the established protocols were vital for successfully resolving the situation.

Q 7. What PPE is required when handling hazardous materials?

The necessary PPE for handling hazardous materials varies considerably depending on the specific material’s hazards as indicated by the SDS. However, some common elements include:

- Eye protection: Safety glasses, goggles, or face shields to protect against splashes or fumes.

- Respiratory protection: Respirators, ranging from dust masks to self-contained breathing apparatus (SCBA), depending on the toxicity and concentration of airborne hazards.

- Hand protection: Gloves made from materials resistant to the specific chemical being handled (e.g., nitrile, neoprene, or butyl rubber).

- Body protection: Protective clothing such as aprons, coveralls, or Tyvek suits to prevent skin contact with the material.

- Foot protection: Safety shoes or boots with metatarsal guards to protect against falling objects or chemical spills.

Selecting the appropriate PPE isn’t a one-size-fits-all approach; it needs to be tailored to the specific risks involved. For instance, handling corrosive acids would demand more robust gloves and eye protection than handling less hazardous materials. Regular inspection and maintenance of PPE are crucial to ensure its effectiveness.

Q 8. Explain the different types of hazardous waste and their disposal methods.

Hazardous waste is classified into several categories depending on its physical, chemical, and biological properties. These categories require different disposal methods to ensure environmental safety and public health.

- Ignitable wastes: Substances that easily catch fire (e.g., solvents, oily rags). Disposal often involves incineration in specialized facilities.

- Corrosive wastes: Substances that corrode metals (e.g., acids, bases). Neutralization and then treatment or disposal in secure landfills are common methods.

- Reactive wastes: Substances that are unstable and readily undergo violent chemical changes (e.g., explosives, reactive metals). These require careful stabilization and often specialized disposal in secure facilities.

- Toxic wastes: Substances poisonous or harmful to human health or the environment (e.g., heavy metals, pesticides). Treatment methods might include chemical precipitation, solidification, or landfilling in specially designed hazardous waste landfills.

- Infectious wastes: Materials contaminated with pathogenic microorganisms (e.g., medical waste). These require sterilization (e.g., autoclaving) and often incineration.

The choice of disposal method depends heavily on the specific properties of the waste and relevant regulations. Improper disposal can lead to severe environmental contamination and health risks. For example, improperly disposed-of solvents could leach into groundwater, contaminating drinking water supplies. Always follow local, state, and federal regulations when dealing with hazardous waste disposal.

Q 9. What are the key regulations governing hazardous materials handling?

Several key regulations govern hazardous materials handling, ensuring worker safety and environmental protection. These regulations vary by location but often include:

- OSHA (Occupational Safety and Health Administration): Sets standards for workplace safety, including handling, storage, and transportation of hazardous materials. These standards cover hazard communication, personal protective equipment (PPE), and emergency response procedures.

- EPA (Environmental Protection Agency): Regulates the generation, transportation, treatment, storage, and disposal of hazardous waste under the Resource Conservation and Recovery Act (RCRA).

- DOT (Department of Transportation): Establishes regulations for the safe transportation of hazardous materials, including packaging, labeling, and emergency response planning (49 CFR).

- State and Local Regulations: Many states and localities have their own regulations, often stricter than federal requirements.

These regulations are crucial to prevent accidents, protect human health, and minimize environmental damage. Non-compliance can result in significant fines and legal repercussions.

Q 10. How do you ensure compliance with OSHA regulations for hazardous materials?

Ensuring compliance with OSHA regulations for hazardous materials requires a multi-faceted approach:

- Hazard Communication Program: Implementing a comprehensive program to identify and communicate the hazards associated with the materials used in the workplace. This includes Safety Data Sheets (SDS) accessibility and employee training.

- Personal Protective Equipment (PPE): Providing and ensuring the proper use of appropriate PPE, such as respirators, gloves, eye protection, and protective clothing, based on the specific hazards.

- Training: Regular and thorough training for all employees involved in handling hazardous materials on safe practices, emergency procedures, and the use of PPE.

- Record-Keeping: Maintaining meticulous records of training, inspections, incidents, and waste disposal. This documentation is vital for audits and demonstrating compliance.

- Regular Inspections: Conducting routine inspections to identify and correct any safety hazards or non-compliance issues.

- Emergency Response Plan: Developing and regularly practicing a comprehensive emergency response plan to handle spills, leaks, or other incidents involving hazardous materials.

For example, in a laboratory setting, compliance might involve ensuring fume hoods are properly functioning, chemical storage is organized according to compatibility, and spill kits are readily available and employees are trained in their use.

Q 11. Describe your experience with hazardous materials transportation.

My experience with hazardous materials transportation includes ensuring compliance with DOT regulations, including proper classification, labeling, packaging, and documentation of shipments. I’ve worked with various modes of transport, from truck and rail to air and sea. This involved:

- Proper Documentation: Preparing and reviewing shipping papers (e.g., bills of lading) to accurately describe the hazardous materials being shipped, including their UN numbers and hazard classes.

- Packaging and Labeling: Ensuring materials were packaged according to DOT regulations, using appropriate containers and labels that clearly indicate the hazards.

- Emergency Response Planning: Developing and implementing emergency response plans for potential incidents during transportation, including communication protocols and procedures for containment and cleanup.

- Driver Training: Ensuring drivers were properly trained in the safe handling and transportation of hazardous materials.

One specific instance involved overseeing the shipment of a large quantity of corrosive chemicals across state lines. This required meticulous attention to detail, ensuring compliance with all DOT regulations to prevent accidents and environmental damage.

Q 12. What is your experience with emergency response procedures involving hazardous materials?

My emergency response experience includes participating in and leading emergency drills and responding to actual incidents involving hazardous materials spills or releases. This involved:

- Incident Assessment: Quickly assessing the situation to identify the hazardous material involved, its potential hazards, and the extent of the spill or release.

- Containment and Control: Implementing procedures to contain the spill or release and prevent further spread or exposure.

- Emergency Response Team Coordination: Working effectively with emergency response teams, including fire departments, HAZMAT teams, and other relevant agencies.

- Decontamination: Supervising decontamination procedures for personnel and equipment exposed to hazardous materials.

- Post-Incident Reporting: Documenting the incident, including the cause, response actions, and any resulting injuries or environmental damage.

For example, I once participated in a response to a small chemical spill in a laboratory setting. My role involved safely containing the spill, coordinating with the campus emergency response team, and overseeing the decontamination of affected personnel and areas. Accurate and thorough record-keeping played a critical role in the post-incident investigation and prevention of future similar events.

Q 13. How do you conduct a risk assessment for hazardous materials?

Conducting a thorough risk assessment for hazardous materials is crucial for preventing accidents and protecting human health and the environment. This involves a systematic process:

- Hazard Identification: Identifying all potential hazards associated with the materials, including their physical, chemical, and biological properties.

- Exposure Assessment: Determining the potential for exposure to the hazardous materials, considering the frequency, duration, and intensity of exposure.

- Risk Evaluation: Evaluating the likelihood and severity of potential adverse health effects or environmental damage resulting from exposure.

- Risk Control: Developing and implementing control measures to reduce or eliminate the identified risks. This might include engineering controls (e.g., ventilation systems), administrative controls (e.g., work procedures), and PPE.

- Monitoring and Review: Regularly monitoring the effectiveness of the control measures and reviewing the risk assessment as needed.

A good risk assessment is not just a checklist; it’s a dynamic process. For instance, a risk assessment for a chemical laboratory would consider factors like the types of chemicals stored, the frequency of use, storage conditions, ventilation, and the training and experience of personnel. The assessment would identify potential risks, such as chemical spills, inhalation of hazardous vapors, and fire, and suggest appropriate control measures to minimize these risks.

Q 14. What are the potential health hazards associated with handling hazardous materials?

The potential health hazards associated with handling hazardous materials are numerous and vary widely depending on the specific materials involved. These hazards can include:

- Acute Effects: Immediate and short-term health effects, such as burns, skin irritation, eye damage, respiratory problems, or even death.

- Chronic Effects: Long-term health effects that develop over time, such as cancer, reproductive problems, neurological disorders, or organ damage.

- Specific Hazards: Some materials pose unique hazards. For instance, asbestos can cause lung cancer, while certain solvents can damage the liver and kidneys.

The severity of the health hazard depends on factors such as the toxicity of the material, the route of exposure (inhalation, skin contact, ingestion), the duration of exposure, and the individual’s susceptibility. Examples include:

- Exposure to Corrosive Chemicals: Can cause severe burns and tissue damage.

- Inhalation of Toxic Vapors: Can lead to respiratory problems, including lung damage and cancer.

- Exposure to Carcinogens: Can significantly increase the risk of developing cancer.

Therefore, proper training, engineering controls, PPE, and safe work practices are critical to minimize or eliminate these health risks.

Q 15. Explain the importance of proper labeling and signage for hazardous materials.

Proper labeling and signage are paramount in hazardous materials handling because they are the first line of defense against accidents. Think of them as the ‘warning signs’ of the chemical world. They communicate critical information at a glance, preventing accidental exposure and misuse.

- Labels: These are affixed directly to containers and provide specific hazard warnings (e.g., flammable, corrosive, toxic), safety precautions, and the chemical’s identity (e.g., chemical name, CAS number).

- Signage: These are larger, more permanent signs posted in areas where hazardous materials are stored, used, or transported. They indicate the presence of hazards, provide safety instructions (e.g., ‘No Smoking,’ ‘Protective Gear Required’), and may direct personnel to emergency exits or safety equipment.

For example, a brightly colored label with a skull and crossbones immediately alerts workers to a highly toxic substance. Similarly, signage warning of flammable materials in a specific area would prevent accidental ignition from sparks or open flames.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain accurate records for hazardous materials handling?

Maintaining accurate records is crucial for compliance, accountability, and emergency response. Imagine trying to track down the source of a chemical spill without proper documentation – it would be a nightmare!

Accurate records include:

- Inventory logs: A detailed list of all hazardous materials on-site, including quantity, location, and date of acquisition.

- Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS): These provide comprehensive information on each chemical’s hazards, handling procedures, and emergency response actions.

- Training records: Documentation of all personnel trained in hazardous materials handling procedures.

- Incident reports: Records of any spills, leaks, or accidents involving hazardous materials, including the cause, response actions, and corrective measures.

- Disposal records: Detailed information about hazardous waste disposal, including the quantity of waste, the disposal method, and the name of the disposal facility.

Using a digital database or specialized software can streamline record-keeping and ensure easy accessibility during audits or emergencies.

Q 17. Describe your experience with using respiratory protection equipment.

Respiratory protection is essential when working with hazardous materials that can be inhaled, such as airborne particulate matter, gases, or vapors. I have extensive experience using various types of respirators, including:

- N95 respirators: For protection against particulate matter.

- Half-mask respirators with cartridges: Offer protection against specific gases and vapors; cartridge type depends on the hazard.

- Full-face respirators: Provide the highest level of protection, covering the entire face and eyes.

My experience includes proper respirator selection based on hazard assessment, fit testing to ensure a proper seal, and training on respirator use, maintenance, and limitations. For instance, in a situation involving exposure to asbestos dust, the use of a properly fitted half-mask respirator with the correct particulate filter would be critical for protecting my respiratory health.

Q 18. What is your experience with hazardous waste disposal procedures?

Hazardous waste disposal is a highly regulated process that demands strict adherence to local, state, and federal regulations. My experience encompasses all aspects, from proper segregation and packaging to transportation and final disposal at permitted facilities.

This involves:

- Waste characterization: Determining the hazardous properties of the waste to ensure proper classification.

- Proper packaging: Utilizing compatible containers and labeling according to regulations.

- Transportation: Hiring licensed hazardous waste transporters and ensuring compliance with Department of Transportation (DOT) regulations.

- Disposal at permitted facilities: Selecting and using facilities authorized to handle the specific types of hazardous waste.

- Maintaining detailed records: Keeping thorough records of all aspects of the process for audit purposes.

For example, I have experience managing the disposal of used solvents, handling contaminated equipment, and coordinating with regulatory agencies to ensure full compliance. A key aspect is always ensuring that the chosen disposal method minimizes environmental impact.

Q 19. How do you manage hazardous materials in a confined space?

Working with hazardous materials in a confined space presents unique challenges due to the limited space and potential for rapid accumulation of harmful substances. Strict adherence to safety procedures is paramount.

Key aspects of my approach include:

- Atmospheric monitoring: Continuously monitoring the air quality for oxygen levels, flammable gases, and toxic substances before, during, and after work.

- Permit-required confined space entry (PERMIT-RCSE) procedures: Following strict protocols, including atmospheric testing, ventilation, and standby personnel.

- Appropriate Personal Protective Equipment (PPE): Utilizing specialized PPE, including respirators, protective suits, and eye protection, suited to the specific hazards.

- Emergency procedures: Establishing clear communication and rescue plans in case of an accident.

- Ventilation: Ensuring adequate ventilation to remove hazardous substances.

An example would be working in a tank to clean or repair it. Before entry, we’d perform atmospheric monitoring to check for toxic gases or oxygen deficiency. A standby person would monitor our condition and be ready to rescue us if needed.

Q 20. Describe your knowledge of emergency shutdown procedures for hazardous processes.

Emergency shutdown procedures are critical for preventing or mitigating the consequences of hazardous material incidents. These are pre-planned steps to quickly stop a process, isolate hazardous materials, and prevent further escalation.

My knowledge encompasses:

- Understanding process hazards: Identifying potential hazards within a process to anticipate potential emergencies.

- Developing shutdown procedures: Creating step-by-step procedures for shutting down equipment and isolating hazardous materials.

- Training and drills: Regularly training personnel on emergency shutdown procedures and conducting drills to ensure competence.

- Alarm systems: Understanding and utilizing alarm systems to detect anomalies and initiate appropriate responses.

- Emergency response plans: Integrating emergency shutdown procedures into broader emergency response plans.

For example, in a chemical reactor system, a sudden pressure increase could indicate a potential runaway reaction. The emergency shutdown procedure might involve automatically cutting off the reactants, venting pressure, and initiating cooling systems. Personnel are trained on the exact steps and actions required during such an event.

Q 21. What are your strategies for preventing hazardous material incidents?

Preventing hazardous material incidents is a proactive approach that prioritizes safety and minimizes risks. My strategies revolve around a multi-layered approach.

These include:

- Engineering controls: Implementing physical barriers, ventilation systems, and other engineering solutions to reduce exposure to hazardous materials. Think containment systems or automated safety shut-off valves.

- Administrative controls: Establishing clear procedures, training programs, and work permits to govern handling and use of hazardous materials. This could involve detailed Standard Operating Procedures (SOPs).

- Personal Protective Equipment (PPE): Providing and ensuring correct use of appropriate PPE.

- Regular inspections and maintenance: Conducting routine inspections of equipment and storage areas to identify and rectify potential hazards before they escalate.

- Employee training and education: Investing in comprehensive training programs to educate employees about hazards, safe handling practices, and emergency procedures.

- Emergency preparedness planning: Developing and regularly testing emergency response plans to ensure effective response capabilities.

Ultimately, a strong safety culture that prioritizes hazard identification, risk assessment, and preventative measures is crucial in minimizing incidents.

Q 22. How do you handle a situation where hazardous materials have been improperly stored?

Improperly stored hazardous materials pose significant risks. My immediate response involves a three-pronged approach: assessment, containment, and remediation.

- Assessment: I begin by assessing the situation to determine the specific hazardous materials involved, the extent of the improper storage, and any immediate dangers. This includes identifying potential hazards like leaks, spills, or exposure risks. I’d utilize personal protective equipment (PPE) appropriate for the specific materials, consulting the Safety Data Sheet (SDS) for guidance.

- Containment: My next step is to contain the materials to prevent further exposure. This might involve isolating the area, using absorbent materials to soak up spills, or transferring the materials to proper storage containers. The SDS will provide crucial information on appropriate containment methods. For example, flammable materials require different handling from corrosive ones.

- Remediation: Once the materials are safely contained, I move towards remediation. This involves the proper disposal or cleanup of the spilled or improperly stored materials. I ensure compliance with all relevant regulations and utilize approved disposal methods. This may involve contacting specialized waste disposal companies.

For example, if I discovered improperly stored acids, I’d immediately cordon off the area, don appropriate PPE (including acid-resistant gloves, eye protection, and lab coat), neutralize any spills with a safe agent according to the SDS, and then carefully transfer the acids to approved, labeled containers for proper disposal.

Q 23. Describe your understanding of the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) is a globally accepted system for classifying and communicating the hazards of chemicals. It aims to standardize the classification and labelling of chemicals, making it easier to understand and handle chemicals safely, regardless of their origin.

Key aspects of GHS include:

- Classification: Chemicals are classified based on their physical hazards (e.g., flammability, explosivity), health hazards (e.g., toxicity, carcinogenicity), and environmental hazards (e.g., aquatic toxicity). This classification determines the hazard statements and precautionary statements assigned.

- Labelling: The GHS requires specific labels on chemical containers. These labels include pictograms (symbols representing hazard classes), signal words (warning or danger), hazard statements (describing the specific hazards), and precautionary statements (advising on safe handling and prevention measures).

- Safety Data Sheets (SDS): The GHS also mandates comprehensive SDSs providing detailed information about the hazards of a chemical, its safe handling, and emergency procedures.

Imagine a bottle of cleaning solution. Under GHS, the label must clearly show its hazard class (e.g., corrosive) using a specific pictogram, a signal word (danger), hazard statements describing the corrosive nature, and precautionary statements explaining how to safely handle it, like wearing gloves and eye protection.

Q 24. How do you ensure the proper training and competency of personnel handling hazardous materials?

Ensuring personnel competency in handling hazardous materials is paramount. My approach involves a multi-faceted strategy focusing on initial training, ongoing competency assessment, and reinforcement of best practices.

- Initial Training: New employees receive comprehensive training tailored to the specific hazards they’ll encounter. This includes theoretical instruction on hazard identification, risk assessment, safe handling procedures, emergency response protocols, and the use of PPE. Hands-on training using mock scenarios and simulations reinforces the theoretical knowledge.

- Competency Assessment: Regular assessments, including written tests, practical demonstrations, and performance evaluations, track their understanding and skills. This ensures they maintain competency throughout their work. Any deficiencies are promptly addressed through further training.

- Reinforcement of Best Practices: I use regular toolbox talks, safety briefings, and updated documentation to keep the personnel updated on best practices, changes in regulations, and lessons learned from incidents. This continuous learning ensures consistent adherence to safety protocols.

For example, before allowing someone to handle a specific chemical, they must demonstrate their ability to correctly select and use the appropriate PPE, handle the chemical according to the SDS, and follow the emergency spill procedure. This ensures they are fully prepared to handle the materials safely.

Q 25. Explain your understanding of the transportation of hazardous materials by road, rail, sea and air.

Transportation of hazardous materials requires stringent adherence to regulations to prevent accidents and environmental damage. The regulations vary slightly depending on the mode of transport, but all modes share the common goal of safe and compliant transit.

- Road: Road transport involves adhering to specific packaging, labeling, and documentation requirements. Drivers need specialized training, and vehicles may require placards indicating the nature of the hazardous materials carried. Regular vehicle inspections are vital.

- Rail: Similar to road transport, rail transport has rigorous safety protocols and specific packaging standards. The materials must be secured properly to prevent shifting and accidents during transit. The railway infrastructure also needs to be adapted to accommodate hazardous materials.

- Sea: Maritime transport of hazardous materials is governed by international regulations like the International Maritime Dangerous Goods Code (IMDG Code). Ships must have specific safety features, and the materials are carefully stowed to prevent spills or accidents. Crew training is crucial.

- Air: Air transport is arguably the strictest, due to the confined space and potential for widespread consequences. The International Civil Aviation Organization (ICAO) Technical Instructions provide detailed guidelines. Packaging standards are particularly stringent, and only specific types of hazardous materials are allowed on passenger aircraft.

In all modes, accurate documentation, including shipping manifests and emergency response plans, is essential. This ensures accountability and facilitates effective response in case of an incident.

Q 26. What is your experience with different types of containment equipment for hazardous materials?

Containment equipment is crucial for handling hazardous materials safely. My experience encompasses a wide variety of containment equipment, tailored to specific hazards.

- Spill Kits: These kits contain absorbent materials, like pads and booms, to contain spills and prevent their spread. The composition of the kit varies depending on the expected hazards (e.g., acid spill kit vs. solvent spill kit).

- Drums and Containers: Appropriate drums and containers, made of compatible materials, are essential for safe storage and transportation. These containers must be properly labeled according to GHS regulations.

- Safety Cages: These protect fragile containers during transport or storage, preventing damage and potential leaks.

- Specialized Tanks and Vessels: For larger volumes or particularly hazardous materials, specialized tanks and vessels designed for specific chemical compatibility and pressure are required.

- Emergency Response Equipment: This includes respirators, protective suits, and specialized equipment like neutralization agents, depending on the nature of the hazard.

For example, when handling highly corrosive acids, I’d utilize secondary containment (e.g., a spill tray) within a larger storage area and choose containers made of chemically compatible materials like polyethylene or stainless steel. The use of acid-resistant gloves, eye protection, and respirators would also be necessary.

Q 27. Describe a time you had to deal with a hazardous materials incident. What steps did you take?

During a routine inspection, I discovered a leak in a container of concentrated sulfuric acid. The leak was small, but it posed a significant risk due to the corrosive nature of the acid. I immediately followed these steps:

- Evacuation: I immediately evacuated the immediate area, ensuring personnel were a safe distance away and out of the potential splash zone.

- PPE: I donned appropriate PPE, including acid-resistant gloves, safety glasses, a lab coat, and a respirator.

- Containment: I used absorbent pads to contain the leak and prevent further spillage. I also placed a spill tray under the container to catch any further leakage.

- Neutralization: Carefully, and following the instructions on the SDS, I used a suitable neutralizing agent (sodium bicarbonate solution) to neutralize the spilled acid.

- Cleanup: I ensured that all of the affected area was cleaned thoroughly and appropriately disposed of according to all regulations.

- Reporting: I documented the incident thoroughly, including the cause, actions taken, and any lessons learned. This report was crucial for future prevention and improvement of our safety procedures.

This incident highlighted the importance of regular inspections, proper containment measures, and the availability of appropriate emergency response equipment.

Q 28. How do you stay up-to-date on changes in regulations and best practices for hazardous materials handling?

Staying updated on regulations and best practices is critical in the field of hazardous materials handling. My approach to continuous learning includes:

- Subscription to Regulatory Updates: I subscribe to relevant newsletters and updates from agencies like OSHA (Occupational Safety and Health Administration) and other environmental protection agencies. This provides me with timely information on new regulations or changes to existing ones.

- Professional Organizations: I actively participate in professional organizations related to safety and hazardous materials management. Conferences, webinars, and networking opportunities provide insights into current best practices.

- Industry Publications and Journals: I read peer-reviewed journals and industry publications to stay abreast of the latest research and advancements in safe handling techniques.

- Manufacturer SDS review: Regular review of Safety Data Sheets from manufacturers for any changes in hazard classification, handling, or disposal procedures.

- Training Courses: I regularly participate in refresher courses and advanced training to maintain and enhance my knowledge and skills.

This multifaceted approach allows me to maintain a high level of expertise and ensure that my practices are consistently aligned with the latest safety standards and regulations.

Key Topics to Learn for Handle Hazardous Materials Safely Interview

- Hazard Identification and Classification: Understanding different hazard classes (flammable, corrosive, toxic, etc.) and their associated risks. This includes learning to interpret Safety Data Sheets (SDS).

- Personal Protective Equipment (PPE): Knowing the appropriate PPE for various hazards (respirators, gloves, eye protection, etc.) and how to properly don and doff them. Practical application involves understanding selection criteria based on specific hazards.

- Spill Response and Cleanup Procedures: Understanding containment strategies, decontamination processes, and the proper disposal methods for different hazardous materials. This includes practical scenarios involving different spill types and sizes.

- Emergency Response and Procedures: Familiarity with emergency response plans, communication protocols, and evacuation procedures in hazardous material incidents. This involves understanding your role within an emergency response team.

- Regulations and Compliance: Knowledge of relevant regulations (OSHA, EPA, etc.) and their impact on handling hazardous materials. This includes understanding reporting requirements and record-keeping.

- Transportation of Hazardous Materials: Understanding regulations and procedures for the safe transportation of hazardous materials, including proper packaging and labeling.

- Waste Management and Disposal: Safe and compliant disposal of hazardous waste, including understanding different disposal methods and their suitability for various waste types.

- Risk Assessment and Mitigation: Conducting thorough risk assessments to identify potential hazards and developing strategies to mitigate these risks. This involves practical application in various workplace scenarios.

Next Steps

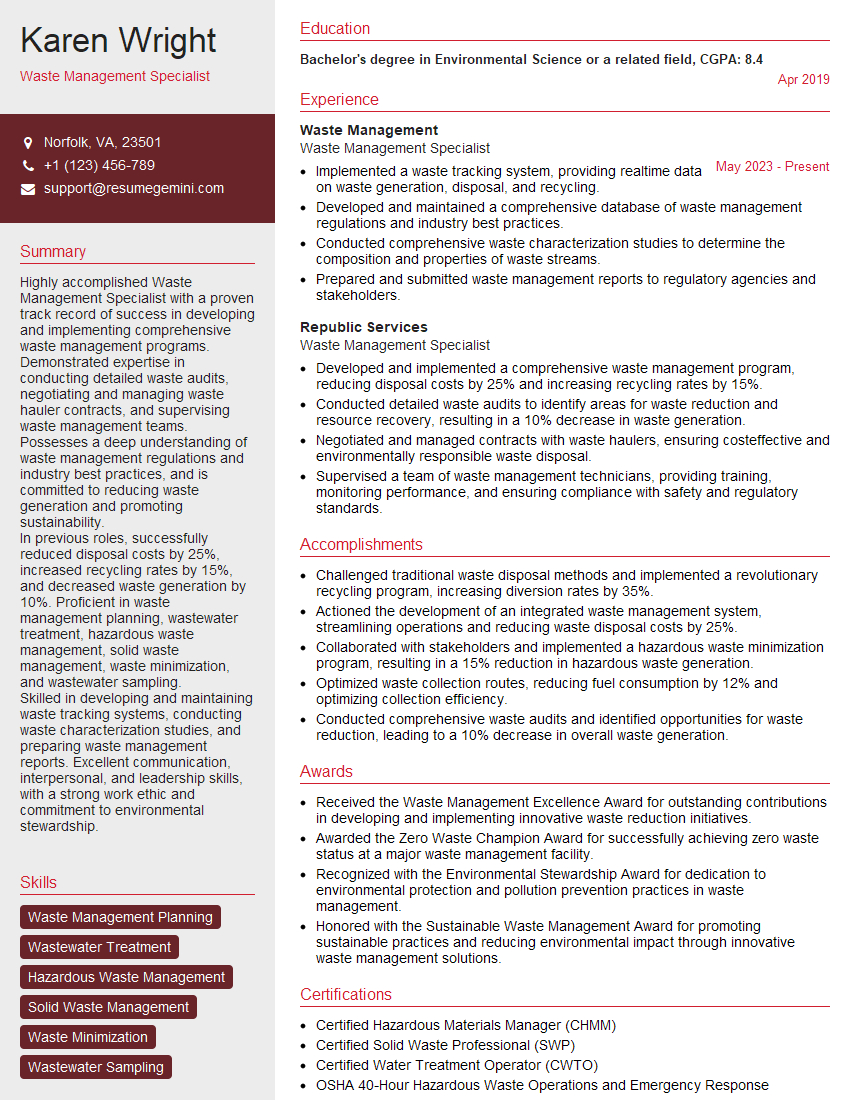

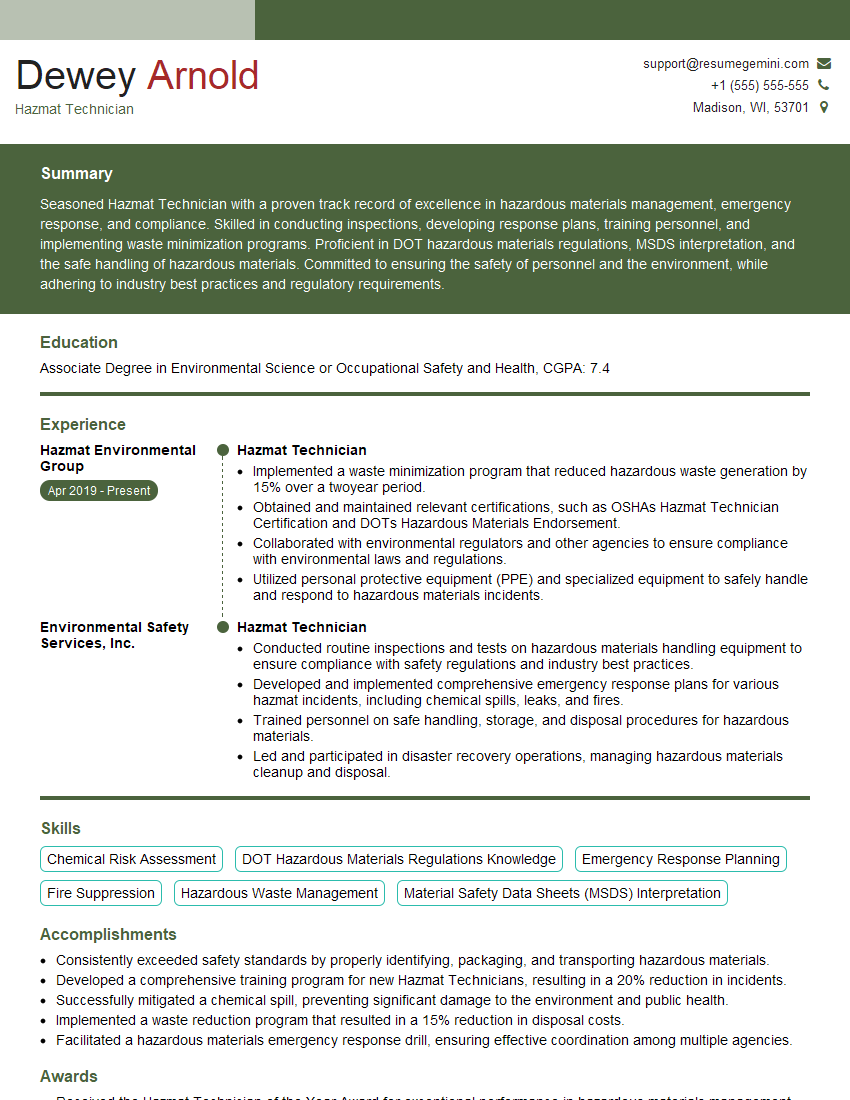

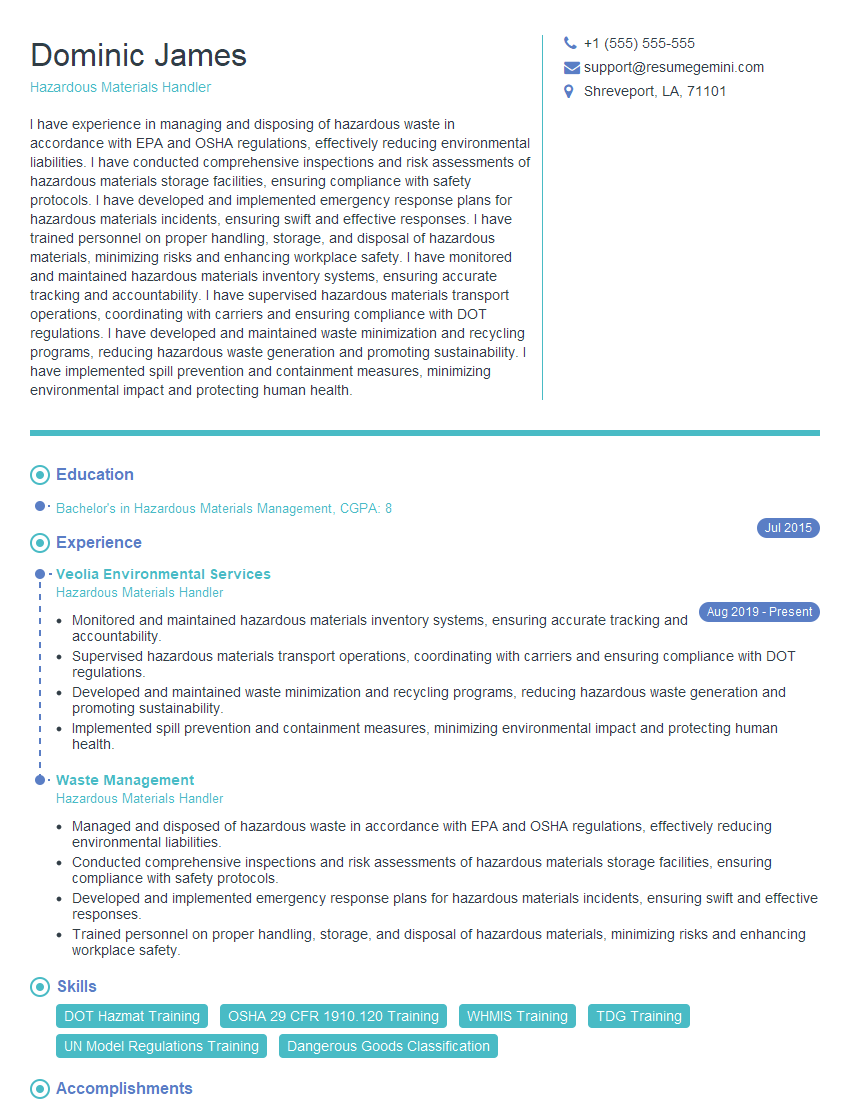

Mastering the safe handling of hazardous materials is crucial for career advancement in many industries, significantly boosting your employability and earning potential. A well-crafted resume is your key to unlocking these opportunities. Make sure your resume is ATS-friendly to ensure it gets noticed by potential employers. To help you create a compelling and effective resume, leverage the power of ResumeGemini. ResumeGemini provides a user-friendly platform to build professional resumes, and we offer examples of resumes tailored to the “Handle Hazardous Materials Safely” field to help guide you. Invest time in crafting a strong resume – it’s your first impression on a potential employer.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO