Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Hatchery Operations Monitoring interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Hatchery Operations Monitoring Interview

Q 1. Explain the importance of maintaining optimal temperature and humidity levels during incubation.

Maintaining optimal temperature and humidity during incubation is absolutely crucial for successful chick development. Think of it like baking a cake – you need the precise temperature and moisture levels for it to rise properly. Deviation from the ideal range can lead to developmental abnormalities, reduced hatchability, and weaker chicks.

Temperature directly influences embryonic growth and metabolism. Too low, and development slows, potentially resulting in smaller, weaker chicks, or even embryonic death. Too high, and it can cause heat stress, leading to mortality or deformities. Humidity, on the other hand, affects the gas exchange across the eggshell. Insufficient humidity can lead to dehydration of the embryo, while excessive humidity can promote bacterial growth and increase the risk of infection.

For example, in a commercial setting, a precise temperature of around 37.5°C (99.5°F) and humidity of around 55-60% are usually maintained during the incubation period. Modern incubators use sophisticated sensors and control systems to monitor and maintain these parameters within a very narrow range, ensuring optimal conditions for embryonic growth.

Q 2. Describe the process of egg candling and its role in hatchery operations.

Egg candling is a simple yet essential process in hatchery operations. It involves holding an egg against a bright light source to examine its internal contents. This allows us to assess the embryo’s development, identify abnormalities, and cull infertile or compromised eggs.

The process reveals crucial information about the embryo’s growth and health. A fertile egg will show a developing embryo, blood vessels, and a clear air cell. Infertile eggs will show a clear yolk with no visible vascular network. Eggs with blood spots, cracks, or other abnormalities are also easily identified through candling.

Candling is typically performed at different stages of incubation. The first candling usually takes place a few days after incubation begins to identify infertile eggs. Subsequent candlings are performed later to monitor embryo development and further eliminate eggs exhibiting problems.

Imagine it as a ‘health check’ for each egg. Removing compromised eggs early prevents the spread of disease and improves overall hatchability rates. It’s a critical step in ensuring a healthy flock.

Q 3. What are the key indicators of chick quality and how are they assessed?

Key indicators of chick quality are assessed right after hatching. These include:

- Body weight: Healthy chicks have a consistent weight range appropriate for their breed. Underweight chicks suggest potential nutritional deficiencies or stress during incubation.

- Down quality: Dry, fluffy down indicates good health. Damp or matted down can indicate issues with humidity control during hatching.

- Activity level: Active, alert chicks with good mobility are a positive sign. Lethargic chicks may be weak or sick.

- Navel condition: The navel should be completely closed and dry. An open or infected navel suggests potential problems during the hatching process.

- Uniformity: Consistent size and development across a batch of chicks indicates successful incubation conditions.

Assessing these factors allows us to evaluate the overall success of the hatchery process and identify areas for improvement. For example, if we see a high percentage of underweight chicks, it might point to a problem with the incubation temperature or feed quality.

Q 4. How do you identify and address common hatchery issues such as bacterial contamination or poor air quality?

Bacterial contamination and poor air quality are significant threats in hatcheries. Addressing these issues requires a multi-pronged approach focused on prevention and remediation.

Bacterial contamination is often tackled through rigorous sanitation protocols. This includes regular disinfection of incubators, hatching trays, and the entire facility using approved disinfectants. Proper egg disinfection before incubation is also vital. Early identification of infected eggs via candling and their subsequent removal is crucial to prevent outbreaks. Implementing strict biosecurity measures, like controlled access and staff hygiene practices, is essential.

Poor air quality can be addressed by ensuring adequate ventilation within the hatchery. This removes excess moisture, ammonia, and carbon dioxide, creating a healthier environment for the developing embryos. Regular monitoring of air quality parameters like temperature, humidity, and gas levels is essential. Air filters and appropriate ventilation systems can also help in maintaining ideal conditions.

For instance, if we detect high ammonia levels, we would investigate the ventilation system, potentially adjusting airflow rates or replacing air filters to reduce ammonia buildup and improve overall air quality.

Q 5. Explain your experience with different incubation systems (e.g., single-stage, multi-stage).

I have extensive experience with both single-stage and multi-stage incubation systems. Single-stage systems maintain a consistent temperature and humidity throughout the entire incubation period. They are simpler to manage but can be less efficient in terms of energy consumption and might not perfectly match the evolving needs of the embryo at different stages.

Multi-stage systems, on the other hand, allow for adjustments in temperature and humidity at different stages of embryonic development, mirroring the natural incubation process more closely. This provides more optimal conditions, leading to improved hatchability and chick quality. These systems often incorporate features like turning mechanisms and controlled cooling periods to mimic natural conditions.

My experience involves selecting appropriate systems based on the specific needs of different species, production scale, and available resources. For example, multi-stage incubators might be preferred for large-scale commercial operations aiming for maximum hatchability, whereas single-stage systems could suffice for smaller, specialized hatcheries.

Q 6. Describe your experience with hatchery automation and data monitoring systems.

My experience with hatchery automation and data monitoring systems is extensive. I’m proficient in using various systems that monitor temperature, humidity, airflow, and other critical parameters within incubators and the overall hatchery environment. This allows for real-time monitoring and early detection of any deviations from ideal conditions.

These systems often generate comprehensive reports that track key performance indicators (KPIs) such as hatchability, chick quality, and energy consumption. This data is invaluable for continuous improvement and identifying areas for optimization. For instance, analyzing temperature data over several batches can reveal patterns and help fine-tune incubation parameters for optimal results.

I’m familiar with various data management software and can analyze the generated data to troubleshoot issues and make informed decisions. My experience extends to integration of different systems, creating comprehensive and efficient monitoring of the entire hatchery process, which helps in preventative maintenance and minimizes downtime.

Q 7. How do you ensure the biosecurity of a hatchery facility?

Biosecurity is paramount in a hatchery. It’s about protecting the chicks and the breeding stock from disease. My approach to ensuring biosecurity involves a layered strategy:

- Strict access control: Limiting access to authorized personnel only and implementing a strict visitor protocol with appropriate disinfection procedures.

- Hygiene protocols: Enforcing rigorous hygiene standards for staff, including dedicated clothing, handwashing stations, and foot baths.

- Sanitation procedures: Regular disinfection of all equipment, surfaces, and facilities using approved disinfectants. Following a strict cleaning and disinfection schedule is critical.

- Pest control: Implementing effective pest control measures to prevent the introduction of disease vectors.

- Waste management: Implementing safe and efficient waste disposal systems to minimize contamination risks.

- Quarantine procedures: Establishing quarantine areas for new birds or equipment to prevent the introduction of diseases.

By implementing these strategies, we significantly reduce the risk of disease outbreaks, protecting both the birds and the overall health of the facility. Think of it as building a strong ‘defense system’ against potential threats.

Q 8. What are the key performance indicators (KPIs) you track in hatchery operations?

In hatchery operations, we meticulously track several Key Performance Indicators (KPIs) to gauge efficiency and identify areas for improvement. Think of KPIs as the vital signs of our hatchery, telling us if everything is healthy and running smoothly.

- Hatch Rate: This is the percentage of fertile eggs that hatch successfully. A high hatch rate indicates optimal incubation conditions and efficient management. For example, a target of 85% or higher is often considered excellent.

- Chick Quality: We assess chick weight, uniformity, and vigor. Healthy chicks are more likely to survive and thrive. We use standardized scoring systems to ensure objective evaluations.

- Mortality Rate: This tracks the percentage of eggs and chicks lost during the incubation and hatching process. A low mortality rate demonstrates effective disease control and environmental management.

- Incubation Time: We monitor the time it takes for eggs to hatch. Deviations from the expected timeframe can signal issues with incubation temperature or humidity.

- Fertility Rate: The percentage of eggs that are fertilized, indicating the effectiveness of our breeding program and egg handling practices.

- Energy Consumption: Monitoring energy usage helps us identify inefficiencies and explore energy-saving strategies, lowering operational costs and environmental impact.

Regularly analyzing these KPIs allows us to proactively address problems and optimize hatchery processes, ultimately improving overall efficiency and profitability.

Q 9. How do you manage hatchery waste and ensure environmental compliance?

Managing hatchery waste and ensuring environmental compliance are paramount. We follow a comprehensive strategy encompassing waste reduction, proper disposal, and adherence to all relevant regulations.

- Waste Reduction: We implement strategies like optimized egg selection and incubation practices to minimize waste generation. Regular equipment maintenance also reduces waste associated with malfunctioning equipment.

- Waste Segregation: We meticulously segregate waste into categories like broken eggshells, dead embryos, and packaging materials. This allows for efficient recycling and proper disposal.

- Disposal Methods: Broken eggshells and dead embryos are typically composted or rendered, while packaging materials are recycled according to local regulations. We maintain detailed records of all waste disposal activities.

- Compliance Monitoring: We regularly review and update our procedures to comply with all applicable environmental regulations and industry best practices. This includes regular audits and training for staff to reinforce responsible waste management practices.

For instance, we partner with local composting facilities to ensure responsible disposal of organic waste, minimizing our environmental footprint. We also meticulously document all waste disposal processes to facilitate easy auditing and demonstrate our commitment to environmental responsibility.

Q 10. Describe your experience with hatchery sanitation and disinfection protocols.

Hatchery sanitation and disinfection are critical to preventing disease outbreaks and maintaining chick health. We utilize a rigorous, multi-step protocol that’s based on thorough cleaning and the application of appropriate disinfectants.

- Cleaning: All surfaces, equipment, and incubators are thoroughly cleaned using high-pressure washers and appropriate detergents. This removes visible dirt, organic matter, and potential pathogens.

- Disinfection: Once cleaned, all surfaces are disinfected using registered disinfectants effective against a broad spectrum of bacteria, viruses, and fungi. We follow manufacturers’ instructions carefully, ensuring sufficient contact time for effectiveness.

- Rodenticide and Insecticide Application: To prevent infestations, we utilize approved rodenticides and insecticides as needed, always following strict safety protocols.

- Monitoring: Regular microbial testing is performed to monitor the effectiveness of our sanitation and disinfection procedures. This proactive approach helps us detect and address any potential contamination issues early on.

Imagine a hospital—the same level of meticulous cleanliness and disinfection is required in a hatchery to safeguard chick health. We use color-coded cleaning equipment to prevent cross-contamination and maintain strict cleaning schedules to ensure all areas are sanitized regularly. For example, every incubator is completely disinfected between hatches.

Q 11. Explain your understanding of chick sexing and its importance.

Chick sexing is the process of determining the sex of day-old chicks. This is crucial in the poultry industry because it allows for efficient resource allocation. Male and female chicks often have different market values and raising requirements.

- Methods: Several methods exist, including visual inspection (often inaccurate), vent sexing (manual examination of the cloaca), and genetic sexing (DNA-based techniques).

- Importance: Accurate sexing allows farmers to separate male and female chicks for different rearing strategies. For example, broiler chickens (meat birds) are typically all raised together, but layer hens (egg-laying chickens) are usually separated from roosters.

- Impact on Efficiency: Accurate sexing minimizes resource waste by ensuring appropriate housing, feeding, and management practices for each sex.

For instance, if we’re supplying a farmer who needs only female chicks for egg production, accurately sexing at the hatchery prevents the unnecessary raising of male chicks, which saves the farmer money and resources. Efficient sexing is vital for profitability and efficient farm management.

Q 12. How do you manage hatchery personnel and ensure effective teamwork?

Effective hatchery management hinges on a highly skilled and collaborative team. I employ several strategies to foster a positive and productive work environment.

- Clear Communication: Open and consistent communication channels are established, encouraging feedback and problem-solving as a team. Regular team meetings are held to address issues and share best practices.

- Training and Development: Employees receive thorough training on all hatchery procedures, safety protocols, and biosecurity measures. Opportunities for professional development are provided to enhance skills and knowledge.

- Motivation and Recognition: We create a positive work atmosphere where individual contributions are recognized and valued. Incentive programs and employee appreciation are integral parts of our approach.

- Team Building Activities: We organize team-building activities to strengthen relationships, promote collaboration, and improve morale. This helps create a cohesive and supportive work environment.

For example, I’ve implemented a ‘Suggestion Box’ system to encourage employee feedback on operational improvements, and we regularly celebrate team successes to reinforce a shared sense of accomplishment.

Q 13. Describe your experience with hatchery record-keeping and data management.

Comprehensive and accurate record-keeping is essential in hatchery operations. We maintain detailed records for various aspects of the process using both manual and computerized systems.

- Egg Inventory: We meticulously track egg receipts, storage conditions, and usage. This ensures accurate inventory management and minimizes loss.

- Incubation Data: Detailed logs are kept on incubation parameters, including temperature, humidity, and turning schedules. This data is crucial for troubleshooting and optimization.

- Hatching Data: We record hatch rates, chick quality, and mortality rates. This data is vital for performance analysis and identifying areas for improvement.

- Chick Distribution: Records of chick shipments, including recipient farms, quantities, and delivery dates, are meticulously maintained.

- Biosecurity Records: We meticulously document all biosecurity measures, including sanitation and disinfection procedures, pest control, and staff training records.

- Data Management Software: We utilize specialized hatchery management software to facilitate data entry, analysis, and reporting. This streamlines data management and provides valuable insights for decision-making.

For example, our computerized system generates automated reports on key performance indicators, allowing for quick identification of trends and potential problems. This data-driven approach helps us make informed decisions and optimize hatchery performance.

Q 14. How do you troubleshoot equipment malfunctions in a hatchery environment?

Troubleshooting equipment malfunctions is a crucial aspect of hatchery management. Our approach involves a systematic process that blends practical knowledge with a methodical approach.

- Identify the Problem: First, we accurately identify the nature of the malfunction. This involves observing the equipment, checking for error messages, and assessing the impact on the hatching process.

- Check Basic Issues: Next, we check for simple issues such as power supply, circuit breakers, and proper connections. Often, a seemingly complex problem has a simple solution.

- Consult Manuals: We consult the equipment’s manuals and technical specifications to diagnose potential causes and follow recommended troubleshooting procedures.

- Seek External Expertise: If the problem persists, we contact the equipment manufacturer or a qualified technician for assistance. Timely intervention prevents more significant issues.

- Preventive Maintenance: Regular preventive maintenance is crucial to minimizing equipment breakdowns and extending the lifespan of hatchery equipment. This includes scheduled servicing and component replacements.

For example, if an incubator’s temperature control system fails, we first check power supply and fuses. If that doesn’t work, we consult the manual. If we can’t resolve it, we contact the supplier. A proactive approach to maintenance and troubleshooting ensures minimal downtime and safeguards chick health.

Q 15. What are the common causes of embryonic mortality and how do you mitigate them?

Embryonic mortality, sadly, is a common challenge in hatchery operations. It refers to the death of embryos during the incubation period. Several factors contribute to this, broadly categorized as:

- Genetic Factors: Infertile eggs or eggs with genetic defects are doomed from the start. Careful selection of breeding stock and rigorous egg quality assessment are crucial.

- Incubation Problems: Incorrect temperature, humidity, and turning regimes are major culprits. Even slight deviations can lead to significant mortality. For example, consistently low temperature can result in chilled embryos, while high temperatures cause heat stress and death.

- Egg Quality Issues: Factors like shell quality (cracks, porosity), egg size variations, and storage conditions significantly influence embryonic survival. Eggs stored for too long or under improper conditions often have reduced hatchability.

- Microbial Contamination: Bacterial or fungal infections can devastate an entire batch. Strict sanitation practices, including egg disinfection and hatchery hygiene, are paramount.

- Management Errors: Mishandling of eggs during collection, transportation, and setting can cause damage and mortality.

Mitigation strategies involve a multi-pronged approach: meticulous egg selection, precise incubation parameters monitoring and control (using automated systems whenever possible), rigorous sanitation protocols, and continuous training of hatchery staff. Regular monitoring of hatch rates and mortality data helps identify problem areas and guide corrective actions. For example, if we see a spike in early embryonic mortality, we’d investigate temperature and humidity settings, while late-stage mortality might indicate issues with ventilation or disease.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of incubation stages and the critical parameters at each stage.

Incubation is divided into distinct stages, each with its own critical parameters. These are:

- Stage 1: Pre-incubation (Egg Storage): Focus is on maintaining optimal egg temperature (around 15-18°C) and humidity to slow down embryonic development and prevent deterioration. Proper storage can significantly impact hatchability.

- Stage 2: Early Incubation (0-7 days): This phase is crucial for blastodisc formation and germ layer development. Precise temperature control (around 37.5-37.8°C) and relative humidity (55-60%) are key, along with regular egg turning to prevent embryo adhesion to the shell membrane.

- Stage 3: Mid-incubation (7-18 days): Vascular development and organogenesis occur rapidly. Maintaining a stable temperature and humidity is vital. Turning frequency might be adjusted based on the specific incubator design.

- Stage 4: Late Incubation (18-21 days): Embryonic growth and development near completion. Here, humidity is gradually increased to assist in pipping and hatching. Ventilation becomes extremely important to provide sufficient oxygen to the developing chicks.

- Stage 5: Hatching (21 days onwards): Chicks emerge from the shell. Optimal humidity and ventilation are necessary for easy hatching and chick health. Post-hatch handling is crucial to minimize chick stress.

Each stage requires meticulous monitoring using digital thermometers, hygrometers, and automated incubation systems. Deviations from the optimal parameters should be addressed promptly to avoid significant embryonic losses.

Q 17. Describe your experience with hatchery ventilation systems and their impact on chick health.

Ventilation is critical for maintaining appropriate temperature, humidity, and gas exchange within the incubator. Inadequate ventilation leads to a buildup of carbon dioxide and ammonia, which are toxic to developing embryos. Conversely, excessive ventilation can lead to desiccation.

My experience involves working with various ventilation systems, from simple natural ventilation in smaller hatcheries to sophisticated computer-controlled systems in large-scale operations. These advanced systems use sensors to monitor temperature, humidity, and gas levels, automatically adjusting ventilation rates to maintain optimal conditions. I’ve also worked on troubleshooting ventilation issues, identifying blockages, and calibrating sensors to ensure accurate operation. For instance, we once experienced high ammonia levels due to a malfunctioning exhaust fan. Quick identification and replacement of the fan prevented a large-scale mortality event.

Effective ventilation directly impacts chick health. A well-ventilated hatchery ensures healthy chicks with strong immune systems, leading to higher survival rates and better growth performance after hatch.

Q 18. How do you ensure the accurate and timely supply of eggs to the hatchery?

Ensuring a timely and accurate supply of eggs to the hatchery is paramount. This requires careful planning and coordination with the farms supplying the eggs.

My approach involves:

- Establishing clear communication channels: Regular meetings and daily updates with farm managers to track egg production and quality.

- Developing a robust schedule: Planning egg delivery routes and times to minimize transport time and prevent delays.

- Implementing quality control measures: Conducting regular egg inspections at the farm and upon arrival at the hatchery to ensure egg quality standards are met (e.g., checking for cracks, dirt, abnormal shapes).

- Using efficient transport systems: Maintaining a well-maintained fleet of refrigerated trucks to ensure eggs are transported at the correct temperature.

- Inventory management: Tracking egg quantities and predicting demand to avoid shortages or surpluses.

Utilizing software to manage egg flow across multiple farms helps to visualize data and facilitate communication. For example, discrepancies in egg quality from one farm can be promptly reported and addressed by the farm manager.

Q 19. Describe your experience with hatchery emergency response procedures.

Hatchery emergency response procedures are crucial for minimizing losses during unforeseen events. These procedures cover various scenarios, such as power outages, equipment malfunctions, and disease outbreaks.

My experience includes developing and implementing comprehensive emergency response plans, including:

- Power outage protocols: Utilizing backup generators to maintain incubation conditions. Emergency procedures also include manual egg turning or transferring eggs to alternate incubators in case of prolonged power failures.

- Equipment malfunction procedures: Having a team capable of handling immediate repairs. For instance, having access to spare parts and a quick-response team to fix faulty temperature sensors or fans.

- Disease outbreak protocols: Implementing biosecurity measures to prevent the spread of diseases, such as disinfection, isolation of affected batches, and contacting veterinary authorities.

- Communication protocols: Establishing a clear chain of command and communication channels to ensure efficient response and information sharing among staff members.

Regular drills and training sessions are key for ensuring that the staff is well-prepared to handle any emergency effectively and efficiently.

Q 20. How do you maintain accurate inventory control of hatching eggs and chicks?

Accurate inventory control is essential for efficient hatchery management. This involves tracking the number of hatching eggs received, incubated, and hatched, as well as the number of chicks produced and sold. This is achieved through a combination of manual and automated systems.

My experience involves using:

- Barcoding/RFID tagging: Tracking individual egg trays or containers from the farm to the hatchery, facilitating real-time monitoring of egg movements.

- Hatchery management software: This software helps track egg inventory, manage incubation parameters, and generate reports on hatch rates and chick production. Data includes egg receipts, incubator loading and unloading, and chick counts for each batch.

- Regular physical inventory checks: These checks validate the data obtained from automated systems to account for any potential discrepancies.

- First-In, First-Out (FIFO) system: Organizing egg storage and incubator loading based on egg age, to ensure that older eggs are incubated first. This strategy minimizes losses due to egg degradation.

Maintaining accurate records is crucial for financial planning, production analysis, and meeting regulatory requirements. For instance, we can identify potential bottlenecks in the hatchery process by analyzing historical data to improve efficiency.

Q 21. What are the regulatory requirements for operating a poultry hatchery in your region?

(Note: Regulatory requirements vary significantly by region. This answer provides a generalized overview. Specific regulations must be researched for your particular location.)

Operating a poultry hatchery typically involves compliance with several regulations, including:

- Biosecurity regulations: Strict protocols are in place to prevent the spread of avian diseases. These may include licensing requirements, disease surveillance programs, and disinfection protocols.

- Animal welfare regulations: Regulations concerning chick handling, transport, and overall welfare are enforced. Ensuring appropriate environmental conditions for chicks post-hatch is critical.

- Environmental regulations: Regulations covering waste management, water usage, and greenhouse gas emissions are applicable.

- Food safety regulations: Regulations regarding egg handling and chick hygiene are paramount to ensure food safety standards. Many jurisdictions require regular inspections.

- Record-keeping regulations: Maintaining detailed records of egg sources, incubation parameters, hatch rates, and chick disposal is often mandatory.

- Licensing and permits: Operating a hatchery typically requires licenses and permits from relevant government authorities.

Staying informed about local regulations and maintaining meticulous documentation are crucial for avoiding penalties and ensuring ethical and responsible operation.

Q 22. How do you ensure compliance with food safety regulations in a hatchery setting?

Ensuring food safety in a hatchery is paramount. It’s not just about complying with regulations; it’s about protecting public health. We achieve this through a multi-layered approach encompassing strict biosecurity protocols, rigorous sanitation practices, and meticulous record-keeping.

- Biosecurity: This involves controlling access to the hatchery, implementing strict hygiene measures for personnel (e.g., changing clothes, footwear, and handwashing), and preventing the introduction of pathogens through feed, water, or equipment. We regularly disinfect all surfaces and equipment using approved disinfectants. For example, we have a dedicated footbath system at each entrance and enforce a strict ‘no outside shoes’ policy.

- Sanitation: Daily cleaning and disinfection of incubators, hatchers, and all surfaces are essential. We use documented Standard Operating Procedures (SOPs) and regularly audit our processes to ensure consistency. We also conduct regular water quality testing to maintain optimal conditions.

- Record-Keeping: Meticulous record-keeping is critical. We meticulously track everything from egg source to hatchling dispatch, including temperature, humidity, and any medication or treatment administered. This allows for traceability in case of any contamination or disease outbreak. We utilize a computerized system to ensure data integrity and efficient retrieval.

- Compliance: We stay informed about all relevant food safety regulations (e.g., those set by the FDA or equivalent governing bodies) and ensure that our processes are compliant at all times. We conduct regular internal audits and welcome external audits to maintain our commitment to food safety.

Q 23. Explain your experience with hatchery training programs for employees.

I’ve been involved in developing and delivering hatchery training programs for several years. My approach centers around hands-on learning and practical application. It’s not enough to simply read a manual; employees need to understand the ‘why’ behind each procedure.

- Needs Assessment: We begin with a thorough needs assessment, identifying skills gaps and areas needing improvement. This involves observing employees at work and surveying their understanding of various tasks.

- Modular Training: Our training programs are modular, allowing for flexible learning paths tailored to individual employee roles and skill levels. For example, hatchery workers receive training on egg handling and cleaning, while supervisors focus on management and quality control.

- Hands-on Training: The bulk of our training is hands-on. Employees receive supervised practice in critical tasks, such as candling eggs, setting incubators, and handling hatchlings. This ensures they are confident and competent in their roles.

- Continuous Improvement: Training isn’t a one-time event. We incorporate regular refresher courses, workshops, and on-the-job coaching to keep knowledge current and address evolving best practices. We also use feedback surveys and performance reviews to continually assess and improve our training programs.

For example, we recently implemented a new training module on the use of our automated egg-turning system. This hands-on training drastically reduced errors and increased efficiency.

Q 24. Describe your approach to improving hatchery efficiency and productivity.

Improving hatchery efficiency and productivity requires a holistic approach focusing on optimization at every stage, from egg handling to chick dispatch. It’s about identifying bottlenecks and streamlining processes.

- Process Optimization: This involves analyzing each step in the hatchery process, identifying inefficiencies, and implementing improvements. For example, we might streamline egg handling to minimize damage or optimize incubation parameters to maximize hatch rates.

- Technology Adoption: Implementing new technologies, such as automated egg-turning systems, automated grading machines, and climate control systems, can significantly increase efficiency and reduce labor costs. We carefully assess the ROI (Return on Investment) before implementing any new technology.

- Preventive Maintenance: Regular preventive maintenance on equipment is crucial for minimizing downtime and ensuring reliable operation. We establish a preventative maintenance schedule and track equipment performance closely.

- Data Analysis: Using data analytics to identify trends and areas for improvement is essential. This involves tracking key performance indicators (KPIs), such as hatch rates, chick quality, and mortality rates, to pinpoint areas requiring attention.

- Employee Training: Ensuring staff are properly trained and skilled is essential for achieving operational excellence. Effective training reduces errors and improves efficiency.

For instance, by implementing a new egg-washing system, we reduced egg breakage by 15% and improved hatch rates by 3%, resulting in significant cost savings.

Q 25. How do you utilize data analysis to optimize hatchery operations?

Data analysis is the cornerstone of optimized hatchery operations. We collect data from various sources—incubator sensors, egg grading machines, and manual input—and analyze this data using specialized software and statistical methods.

- KPI Tracking: We monitor key performance indicators (KPIs) such as hatch rate, chick quality (weight, uniformity), mortality rate, and feed conversion ratio. We track these KPIs over time to identify trends and potential problems.

- Statistical Analysis: We use statistical tools to identify correlations between different variables. For example, we might analyze the relationship between incubation temperature and hatch rate or between egg size and chick weight.

- Predictive Modeling: We use predictive modeling to anticipate potential problems and optimize operations proactively. For instance, we might build a model that predicts the hatch rate based on various factors and use this model to adjust incubation parameters as needed.

- Data Visualization: We use dashboards and other visualization tools to present data in an accessible and understandable format. This helps us quickly identify problems and track progress towards improvement goals.

For example, by analyzing historical data on incubation parameters and hatch rates, we were able to identify an optimal temperature range that increased our hatch rate by 2%.

Q 26. What are the challenges associated with managing a large-scale hatchery?

Managing a large-scale hatchery presents several unique challenges, many of which stem from the sheer scale of operations and the sensitivity of the process.

- Disease Control: Preventing and controlling disease outbreaks is a major challenge in large hatcheries. Biosecurity is critical, requiring strict protocols and regular monitoring. The risk of disease spread is amplified in high-density settings.

- Capacity Management: Matching capacity to demand is crucial. Overcapacity leads to wasted resources, while undercapacity can impact profitability. Accurate forecasting and flexible operational plans are vital.

- Supply Chain Management: Managing the supply chain, including sourcing eggs, feed, and other supplies, can be complex, especially in a large operation. Reliable suppliers and efficient logistics are essential.

- Personnel Management: Effectively managing a large workforce requires strong leadership, clear communication, and well-defined roles and responsibilities. Employee training and motivation are crucial for success.

- Data Management: Analyzing and interpreting large volumes of data requires sophisticated systems and expertise. Data analysis is crucial for identifying trends, managing risks, and making informed decisions.

Q 27. Describe your experience with implementing new technologies or processes in a hatchery.

I have extensive experience implementing new technologies and processes in hatchery settings. My approach emphasizes careful planning, thorough testing, and comprehensive employee training.

- Needs Assessment: Before implementing any new technology or process, we carefully assess our needs and identify potential solutions. This involves evaluating the costs, benefits, and risks associated with each option.

- Pilot Testing: We conduct pilot tests of new technologies or processes on a smaller scale before full implementation. This allows us to identify potential problems and make adjustments before deploying them throughout the entire facility.

- Employee Training: Comprehensive employee training is essential for successful implementation. Employees need to be properly trained on how to operate and maintain the new technology or process.

- Monitoring and Evaluation: After implementation, we closely monitor the performance of the new technology or process. We track key performance indicators and make adjustments as needed to optimize results.

For example, we recently implemented a new automated egg-turning system. After careful testing and training, this system reduced labor costs and improved hatch rates significantly. We started with one incubator and only moved to all incubators after the successful pilot program.

Q 28. How do you stay current with advancements and best practices in hatchery management?

Staying current in hatchery management requires a multifaceted approach. The field is constantly evolving, with new technologies and best practices emerging regularly.

- Industry Publications: I regularly read industry publications and journals to stay informed about the latest advancements in hatchery technology and management. This includes attending webinars and reading scientific papers.

- Industry Conferences and Workshops: Attending industry conferences and workshops provides invaluable opportunities to network with other professionals, learn about new technologies, and share best practices. It allows for discussions on real-world challenges and solutions.

- Professional Organizations: Membership in professional organizations, such as the Poultry Science Association, provides access to valuable resources, including publications, training opportunities, and networking events. Staying connected to other experts in the field is invaluable.

- Online Resources: Utilizing online resources, such as reputable websites and databases, provides access to a wealth of information, including research papers, technical reports, and industry news.

- Collaboration: Collaborating with other hatchery professionals and experts is a great way to learn from others’ experiences and share best practices. It is a source of innovation and problem-solving.

Key Topics to Learn for Hatchery Operations Monitoring Interview

- Incubation Parameters: Understanding and interpreting temperature, humidity, ventilation, and gas levels within the incubator. Practical application: Analyzing data trends to identify potential issues and adjust settings for optimal hatching rates.

- Egg Handling and Processing: Proper techniques for egg selection, cleaning, candling, and setting. Practical application: Troubleshooting issues related to egg quality and identifying sources of contamination.

- Hatching Process Monitoring: Observing chick development, identifying abnormalities, and managing the hatching process. Practical application: Implementing corrective actions to address issues like delayed hatching or high mortality rates.

- Data Analysis and Reporting: Utilizing data logging systems and software to track key performance indicators (KPIs) and generate reports. Practical application: Identifying areas for improvement in hatchery efficiency and profitability through data-driven decision making.

- Biosecurity and Hygiene Protocols: Implementing and maintaining strict biosecurity measures to prevent disease outbreaks. Practical application: Developing and implementing cleaning and disinfection protocols to maintain a sanitary hatchery environment.

- Equipment Maintenance and Troubleshooting: Understanding the functionality of hatchery equipment and performing basic maintenance. Practical application: Identifying and resolving malfunctions in incubators, setters, hatchers, and other related equipment.

- Environmental Control Systems: Understanding how environmental factors influence hatching success and implementing strategies for optimal control. Practical application: Troubleshooting issues related to temperature and humidity fluctuations, and adjusting system parameters to maintain optimal conditions.

Next Steps

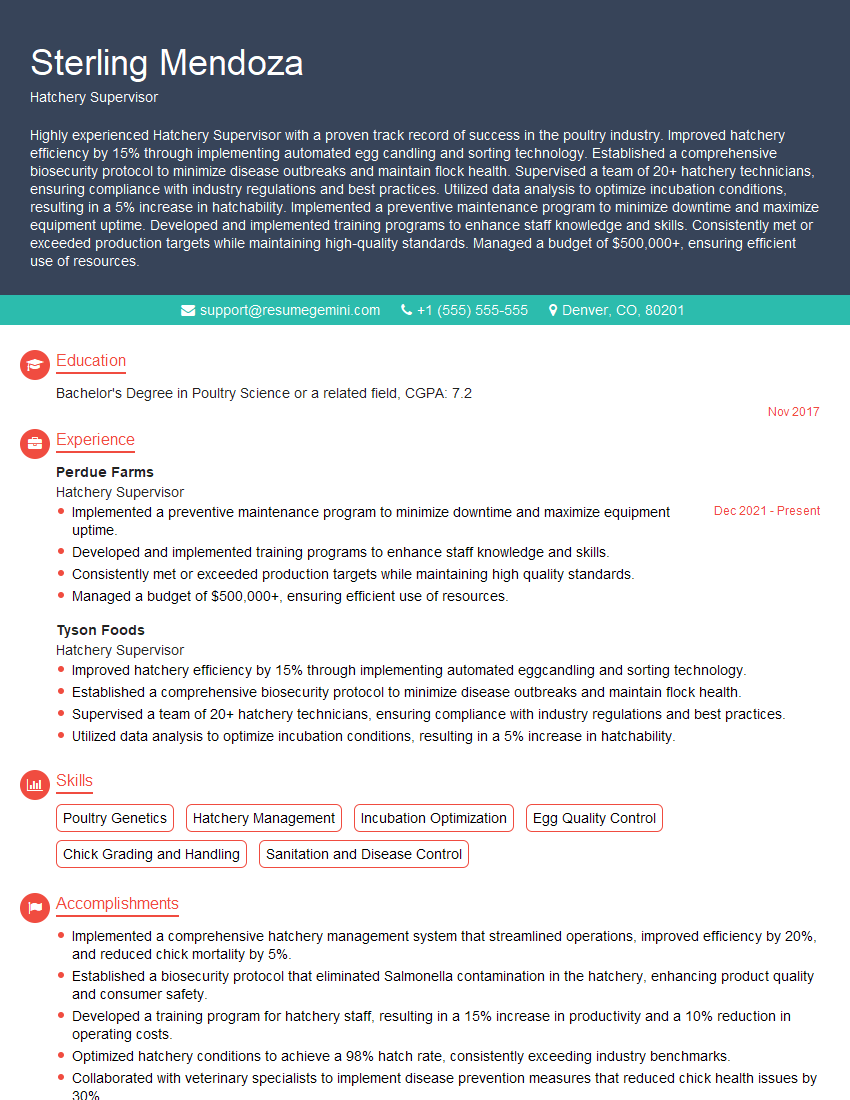

Mastering Hatchery Operations Monitoring is crucial for advancing your career in the poultry industry, opening doors to leadership roles and increased earning potential. A well-crafted resume is essential for showcasing your skills and experience to potential employers. Building an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. ResumeGemini is a trusted resource to help you create a professional and impactful resume that highlights your achievements and expertise. Examples of resumes tailored to Hatchery Operations Monitoring are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO