Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Hydraulic brake bleeding interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Hydraulic brake bleeding Interview

Q 1. Explain the process of bleeding hydraulic brakes.

Bleeding hydraulic brakes is the process of removing air bubbles from the brake lines. Air in the system compromises braking performance, leading to a spongy pedal or even complete brake failure. The process forces brake fluid through the system, pushing out the trapped air. This is crucial for restoring optimal braking power and safety.

The fundamental principle involves using a helper to pump the brake pedal while you open and close bleed valves at each caliper or wheel cylinder. This creates pressure within the system, pushing the fluid and air towards the bleed valve. The air escapes, and fresh fluid enters, restoring full hydraulic pressure.

Think of it like squeezing toothpaste from a tube – you need to push from one end (brake pedal) to get the air out the other (bleed valve).

Q 2. What tools are required for bleeding hydraulic brakes?

The tools needed for bleeding hydraulic brakes are fairly straightforward but crucial for a successful and safe operation. You’ll need:

- A wrench that fits the bleed valve at each caliper or wheel cylinder (usually 8mm or 10mm).

- A clear tube (about 1/4 inch inner diameter) long enough to reach a container, to allow you to visually confirm that fluid is flowing and to see when air is expelled.

- A container to collect the old brake fluid – use a clear one to better monitor the fluid.

- Brake fluid – Always use the correct type specified for your vehicle in your owner’s manual. Using the wrong type can damage seals and components.

- Gloves to protect your hands from brake fluid, which is corrosive and can damage skin.

- Shop rags or paper towels to clean any spills.

- A helper is often necessary, especially for methods requiring pedal pumping.

- Optional: A brake bleeder tool which utilizes a pump to avoid needing a helper. These are generally recommended for professional work.

Q 3. Describe the difference between bleeding a single-line and a dual-line brake system.

The primary difference lies in the number of brake lines leading to each wheel. A single-line system sends fluid to one brake caliper per wheel, while a dual-line system uses two lines per wheel, each acting on a separate piston within the caliper. This provides redundancy and improved braking performance. Bleeding procedures differ as a result.

In a single-line system, you simply bleed each wheel individually, following a sequence (usually starting from the furthest wheel from the master cylinder). In a dual-line system, you must bleed both lines at each wheel, often using a specific sequence to ensure both circuits are properly bled. Failure to do so may result in uneven braking force and diminished stopping power. For instance, on a dual-line system, a typical sequence might alternate between the left and right lines.

Always consult your vehicle’s repair manual for the correct bleeding sequence for your specific system.

Q 4. How do you identify air in a hydraulic brake system?

Air in a hydraulic brake system manifests in several ways:

- Spongy brake pedal: The pedal feels soft or mushy, requiring more travel before engaging the brakes. This is the most common sign.

- Low brake pedal: The pedal sits lower than normal when not depressed.

- Uneven braking: The vehicle pulls to one side during braking. This indicates air in only one part of the system.

- Hard brake pedal: While less common, air can prevent the system from fully functioning resulting in a hard pedal that gives little resistance.

- Brake fluid leaks: Leaks provide entry points for air into the system.

- Visual inspection of the fluid in the reservoir tank: Air bubbles might be visible upon refilling or if the level is very low.

If any of these symptoms are present, a thorough brake system check, including bleeding, is essential.

Q 5. What are the common causes of air in a hydraulic brake system?

Several factors can introduce air into a hydraulic brake system:

- Low brake fluid levels: A low fluid level allows air to be drawn into the system.

- Leaking brake lines or components: Damaged lines, calipers, or wheel cylinders allow fluid leakage and air ingress.

- Improper repair or maintenance: If not done correctly, replacing brake components, lines, or working on the master cylinder can introduce air.

- Wear and tear: Over time, seals in components might degrade, leading to micro-leaks and air infiltration.

- Corrosion within the brake system: Rusted lines and components are more prone to leaking.

Addressing these underlying issues is crucial, not just bleeding the brakes. Otherwise, the problem will likely reoccur.

Q 6. Explain the importance of proper bleeding sequence.

Proper bleeding sequence is vital for ensuring complete air removal from the brake system. The sequence depends on the brake system design (single or dual-line) and the vehicle. The general principle is to start from the furthest point from the master cylinder and work your way closer. This ensures that air is pushed out systematically. Bleed the furthest wheel (or caliper line) first and move closer to the master cylinder at each step. This prevents air from becoming trapped in the lines. This prevents air from being trapped in the lines.

Ignoring the proper sequence can result in incomplete bleeding, leaving air pockets that will affect the braking performance. This can create uneven braking, a spongy feel, or even brake failure.

Always consult your vehicle’s repair manual for the specified sequence; this is crucial for optimal performance and safety.

Q 7. How do you troubleshoot a spongy brake pedal?

A spongy brake pedal is a clear indicator of air in the brake system, but several other factors can contribute.

- Air in the brake lines: This is the most common cause. Bleed the brakes using the proper procedure for your vehicle.

- Low brake fluid: Check the brake fluid reservoir and add fluid if necessary. However, ensure that your fluid level is not consistently low, which could point to a leak.

- Worn brake pads or shoes: Worn pads or shoes can reduce braking efficiency and give a spongy feel. Inspect the brake pads and replace if necessary.

- Damaged master cylinder: A damaged master cylinder can cause inconsistent brake pressure. This requires professional diagnosis and repair.

- Leaking brake lines, calipers, or wheel cylinders: Leaks can also result in a spongy brake pedal. You’ll need to locate and repair any leaks. Often, this will require professional help.

- Faulty brake booster: A vacuum leak in the booster will impair braking power and provide a spongy sensation.

Troubleshooting a spongy pedal is a step-by-step process: Check the fluid level, inspect the brake pads, and then bleed the brakes. If the problem persists, seek professional help to diagnose more complex issues.

Q 8. How do you troubleshoot a hard brake pedal?

A hard brake pedal usually indicates a problem with the hydraulic braking system. It means you’re not getting the proper hydraulic pressure to your brake calipers or wheel cylinders. Think of it like trying to squeeze a toothpaste tube that’s almost empty – very little comes out. This could stem from several issues.

Air in the lines: This is the most common cause. Air is compressible, unlike brake fluid, so it reduces braking effectiveness and leads to a spongy or hard pedal.

Low brake fluid: Insufficient fluid means less pressure can be generated. Check your brake fluid reservoir – it’s usually a clear or translucent container, allowing you to easily see the fluid level.

Leaking brake lines or components: A leak prevents the system from building and maintaining sufficient pressure. Look for fluid leaks around calipers, wheel cylinders, lines, and the master cylinder.

Master cylinder failure: The master cylinder is the heart of the system. If it’s faulty, it won’t effectively convert pedal pressure into hydraulic pressure. This often manifests as a hard pedal, especially if it’s failing gradually.

Brake caliper or wheel cylinder issues: Seized pistons or internal leaks within these components can restrict the flow of fluid, resulting in a hard pedal.

Troubleshooting involves systematically checking each of these areas. Start with the simplest – checking fluid level and for obvious leaks – before moving to more complex diagnoses like air in the lines or component failure. If you suspect air in the lines, bleeding the brakes is the next step.

Q 9. Describe the process of bleeding anti-lock braking system (ABS) brakes.

Bleeding ABS brakes is more complex than bleeding conventional brakes because of the ABS modulator. The modulator is a sophisticated valve assembly that controls the flow of brake fluid to individual wheels during ABS operation. Simply bleeding the lines at each wheel won’t suffice. You’ll usually need a specialized scanner or a pressure bleeder to activate the ABS modulator, forcing the air out. These tools mimic the conditions the ABS system sees during actual braking.

The process typically involves:

Connecting a scan tool: This tool allows you to command the ABS pump to cycle, forcing fluid and any trapped air through the system.

Opening bleeder valves: You’ll need to systematically open and close the bleeder valves on each wheel, following the manufacturer’s specifications. The order is crucial for efficient bleeding.

Cycling the ABS pump: The scan tool activates the ABS pump, which pressurizes and moves fluid and air through the system. The air is purged through the open bleeder valves.

Monitoring fluid: Pay close attention to the fluid exiting the bleeder valves. Initially, you may see some air bubbles, but the fluid should eventually become clear and free of bubbles.

Improper bleeding of ABS brakes can lead to erratic braking performance or ABS malfunction. It’s strongly recommended to consult a repair manual specific to your vehicle or seek assistance from a qualified technician if you’re not familiar with ABS systems.

Q 10. What are the safety precautions when bleeding hydraulic brakes?

Safety is paramount when working with brake systems. Brake fluid is corrosive and can damage paint and other materials. Always wear appropriate safety glasses and gloves. Brake fluid is also hygroscopic – it absorbs moisture from the air – which can negatively impact braking performance. Avoid getting brake fluid on your skin or clothing.

Proper ventilation: Work in a well-ventilated area. Brake fluid fumes can be irritating and hazardous.

Cleanliness: Keep the area clean to prevent contamination of the brake system.

Correct fluid: Use the correct type of brake fluid specified by the vehicle manufacturer. Using the wrong fluid can damage the system.

No smoking or open flames: Brake fluid is flammable and should be kept away from any ignition sources.

Vehicle stability: Ensure the vehicle is securely supported and stable – using jack stands, never rely on just a jack – before performing any brake work.

Proper tools: Use the correct tools for the job to avoid damaging brake components. A proper wrench for the bleeder screw and a clean container for collecting the old fluid are essential.

Remember that improper bleeding can compromise the braking system’s integrity. If you are uncomfortable or lack experience, seek help from a qualified mechanic.

Q 11. How do you diagnose a brake fluid leak?

Diagnosing a brake fluid leak requires a methodical approach. Look for wet spots under the vehicle, typically near the wheels. Brake fluid is usually a dark, oily liquid. Look closely at brake lines, calipers, wheel cylinders, and the master cylinder itself.

Visual inspection: Carefully inspect the entire braking system from the master cylinder to the calipers/wheel cylinders, checking for any signs of leaks or wet spots.

Pressure testing: A pressure test can help pinpoint the exact location of a leak. A pressure gauge is attached to the system, and pressure is applied. Any significant pressure drop indicates a leak.

Fluid level check: Monitor the brake fluid reservoir level. A gradual drop in fluid level is a strong indicator of a leak somewhere in the system.

Once you’ve identified the leak, the repair will depend on the source. It could involve replacing a damaged brake line, a caliper, wheel cylinder, or even the master cylinder in severe cases. It’s crucial to repair leaks promptly, as they compromise braking performance and could potentially lead to brake failure.

Q 12. What is the proper method for refilling the brake fluid reservoir?

Refilling the brake fluid reservoir is a simple but important procedure. Never let the reservoir run completely dry, as this can introduce air into the system. Use only the correct type of brake fluid specified by your vehicle’s manufacturer.

Locate the reservoir: Typically found under the hood and clearly marked.

Check the fluid level: The reservoir usually has minimum and maximum fill lines.

Add fluid slowly: Use a clean funnel to avoid contaminating the fluid. Only add enough fluid to reach the maximum fill line. Avoid overfilling.

Clean up spills: Immediately wipe up any spilled brake fluid to prevent corrosion.

After refilling, check for leaks and, if necessary, bleed the brakes to remove any air that may have entered the system during the refilling process.

Q 13. What type of brake fluid is appropriate for different vehicle types?

Different vehicle types may require different types of brake fluid, determined by their operating temperature and performance requirements. The standards are usually indicated by a DOT number, such as DOT 3, DOT 4, or DOT 5.1. Never mix different types of brake fluids.

DOT 3: Commonly used in older vehicles, it has a lower boiling point.

DOT 4: More common in modern vehicles, it has a higher boiling point and better performance characteristics.

DOT 5.1: Offers even better high-temperature performance and is often used in high-performance vehicles. Note: DOT 5 is silicone-based and should not be mixed with DOT 3 or 4.

Always check your vehicle’s owner’s manual to determine the correct type of brake fluid to use. Using the incorrect fluid can damage your brake system components and reduce performance.

Q 14. How often should hydraulic brakes be bled?

There isn’t a universally fixed interval for bleeding hydraulic brakes. It’s more dependent on usage and conditions. However, it’s generally good practice to check your brake fluid level regularly as part of your routine vehicle maintenance. The brake fluid itself absorbs moisture over time, negatively affecting its effectiveness.

Consider bleeding your brakes:

After brake work: Any time work is performed on the brake system (e.g., replacing components, repairing lines), bleeding is necessary to remove air from the lines.

If you suspect air in the lines: Symptoms like a spongy or hard brake pedal often indicate air in the system.

If fluid is noticeably dark or contaminated: Dark brake fluid is a strong indicator of moisture absorption and reduced effectiveness.

Every 2-3 years (or as recommended by your vehicle manufacturer): This is a preventative measure, especially if you live in a humid environment.

Regular inspection and timely maintenance will help ensure your braking system remains safe and efficient.

Q 15. Explain the concept of brake pressure.

Brake pressure is the force exerted on the brake system components to slow or stop a vehicle. Think of it like squeezing a toothpaste tube – the harder you squeeze (apply force to the brake pedal), the more toothpaste (brake fluid) is pushed out, creating greater pressure throughout the system. This pressure acts on the brake calipers or wheel cylinders, forcing the brake pads against the rotors or drums, generating friction and slowing the wheels.

This pressure isn’t uniform; it varies depending on several factors, including the amount of pedal force applied, the condition of the brake components, and even the vehicle’s speed. For example, applying firm pressure to the brake pedal at high speed will generate significantly higher brake pressure than a gentle touch at low speed. Proper brake bleeding ensures this pressure is evenly distributed throughout the system for optimal braking performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of the master cylinder in the braking system?

The master cylinder is the heart of the hydraulic braking system. It’s a hydraulic pump that converts the force from your brake pedal into hydraulic pressure. When you press the brake pedal, it pushes a piston inside the master cylinder. This piston displaces brake fluid, sending pressure throughout the brake lines to the wheel cylinders or calipers at each wheel.

Imagine a water pump in your garden. The master cylinder is like that pump. Your pedal acts as the handle, and the brake fluid is like the water; your foot’s pressure makes the water flow to where it’s needed to water your plants (stop your wheels). A faulty master cylinder can lead to spongy brakes, brake failure, or inconsistent braking performance. Regular maintenance and prompt attention to any leaks or signs of wear are crucial for safe operation.

Q 17. How does a vacuum booster assist in braking?

A vacuum booster assists braking by significantly reducing the effort required to press the brake pedal. It uses engine vacuum to multiply the force applied to the master cylinder. Essentially, it’s a power assist for your brakes.

Think of it like using a lever to lift a heavy object. The lever increases your mechanical advantage. The vacuum booster does the same thing, but with vacuum pressure. It makes braking much easier, especially at low speeds or during emergency stops. A malfunctioning vacuum booster will make the brake pedal feel very hard, requiring significantly more force to stop the vehicle – a clear indication of a problem needing immediate attention.

Q 18. Describe the function of a pressure regulator in a braking system (if applicable).

While not present in all braking systems, a pressure regulator is used in some vehicles, especially those with anti-lock braking systems (ABS) or complex brake configurations. Its primary function is to manage and distribute brake pressure to individual wheels to maintain optimal braking performance and stability. It prevents wheel lock-up under hard braking by reducing pressure to a specific wheel if it starts to lock. It also ensures balanced braking across all wheels, preventing uneven stopping power.

A pressure regulator is a sophisticated component that’s key to safety features like ABS. Its malfunction can lead to unpredictable braking performance, such as uneven stopping or increased stopping distances.

Q 19. What is the impact of using the wrong brake fluid?

Using the wrong brake fluid is extremely dangerous and can severely compromise your braking system. Brake fluids are categorized by their boiling point and compatibility with system components. Using an incompatible fluid can cause seals and other internal components to swell, degrade, or fail completely. Lower boiling point fluids can boil under extreme braking conditions, leading to vapor lock (the formation of gas bubbles in the brake lines), which results in complete brake failure.

For instance, using DOT 3 fluid in a system designed for DOT 5.1 fluid might seem like a minor detail, but it can lead to catastrophic brake failure. Always consult your vehicle’s owner’s manual to identify the correct brake fluid specification and never compromise on quality or type.

Q 20. Explain the consequences of incomplete bleeding.

Incomplete bleeding leaves air trapped within the brake lines. Air is compressible, unlike brake fluid. This means that when you press the brake pedal, some of the force is used to compress the trapped air instead of pushing the brake fluid to the calipers or wheel cylinders, resulting in a spongy or soft brake pedal.

The consequences are reduced braking effectiveness, longer stopping distances, and a significantly increased risk of accidents. In severe cases, complete brake failure can result. Thorough bleeding is crucial to ensure proper brake function and safety.

Q 21. How do you identify a failing brake component during bleeding?

During bleeding, several signs can indicate a failing brake component. If you experience difficulty bleeding a specific caliper or wheel cylinder, this often suggests a problem within that component. It could indicate a leak, a damaged seal, or even a blockage within the line or component itself.

Other indicators include: unusually slow fluid return during bleeding, unusually low fluid pressure, or the presence of unusual discoloration in the brake fluid (such as metallic particles or very dark fluid).

If any of these issues arise during bleeding, you should cease the process and investigate the cause before continuing. Ignoring these warning signs could lead to a catastrophic brake failure. A visual inspection of each component, and if necessary, a pressure test, should be done to confirm the issue and ensure the safety and integrity of the system.

Q 22. What is the significance of checking brake fluid level?

Checking brake fluid level is paramount for ensuring the safe and effective operation of your braking system. Brake fluid is the lifeblood of your brakes, transmitting pressure from your pedal to the calipers or wheel cylinders to stop your vehicle. Low fluid levels indicate a potential leak somewhere in the system, compromising braking performance and potentially leading to brake failure. Think of it like the coolant in your car’s engine; a low level signals a problem that needs immediate attention.

Regularly checking the fluid level in the brake fluid reservoir, usually located under the hood, is crucial. The reservoir has minimum and maximum markings; the level should ideally be between these marks. If it’s low, it’s a clear sign that you need to investigate the cause—a leak in a hose, a damaged caliper seal, or even a failing master cylinder are possibilities.

Q 23. Describe the function of calipers and wheel cylinders.

Calipers and wheel cylinders are the actuators in your braking system, responsible for converting hydraulic pressure into mechanical force to stop the wheels. They’re located at each wheel.

Calipers: These are typically found on disc brakes (most modern vehicles). When brake fluid pressure is applied, the caliper pistons squeeze brake pads against the rotating disc, creating friction and slowing the wheel. Calipers are usually more complex, incorporating multiple pistons and sometimes anti-rattle mechanisms.

Wheel Cylinders: These are used in drum brakes (less common now, primarily found on older vehicles or on rear axles of some). Inside the drum, wheel cylinders have two pistons that push outward against the brake shoes when pressurized by brake fluid, causing them to rub against the inside of the drum, slowing the wheel. Wheel cylinders are generally simpler in their design.

Both calipers and wheel cylinders require regular maintenance; worn seals or damaged pistons can lead to brake fluid leaks and ultimately, brake failure. The integrity of their seals is critical to maintain the proper hydraulic pressure within the system.

Q 24. Explain how a proportioning valve works (if applicable).

A proportioning valve is a safety device often found in vehicles with rear drum brakes or different sized front and rear brakes. Its primary function is to regulate the amount of braking force applied to the rear wheels compared to the front. It does this by reducing the hydraulic pressure sent to the rear brakes.

This is important because the rear wheels tend to lock up more easily than the front wheels during hard braking. The proportioning valve prevents rear-wheel lock-up, improving stability and preventing skidding, especially during panic stops. It achieves this by sensing the pressure difference between the front and rear braking systems and reducing the rear pressure if the rear wheels are on the verge of locking up. Think of it as a pressure-sensitive regulator, ensuring that the braking force is distributed effectively between the front and rear axles.

Q 25. What are the symptoms of low brake fluid?

Low brake fluid manifests in several ways, and it’s vital to address these issues immediately:

Spongy or soft brake pedal: This indicates a lack of sufficient pressure in the braking system, making it harder to stop the vehicle effectively. The pedal may travel much farther than normal before braking action is felt.

Low brake fluid level in the reservoir: This is the most direct indicator. Regularly checking the fluid level is part of responsible vehicle maintenance.

Brake warning light: Many modern vehicles are equipped with a brake warning light that illuminates when the fluid level falls below a certain point. This is a clear signal of a problem.

Uneven braking: If one wheel brakes more effectively than others, it may point to a problem with that specific caliper or wheel cylinder.

Grinding or squealing noises during braking: While not always directly related to low fluid, it could be an indirect symptom as it might signify worn brake pads, causing the braking system to compensate for the loss and creating further issues.

Any of these symptoms warrant immediate attention. Driving with low brake fluid is extremely dangerous.

Q 26. Describe your experience troubleshooting brake system problems.

Throughout my career, I’ve encountered various brake system problems. One memorable instance involved a vehicle with a spongy brake pedal. Initial inspection revealed no obvious leaks. I systematically tested each component using a pressure tester. This process eventually pinpointed a failing master cylinder, the heart of the braking system. It was leaking internally, resulting in a reduced braking pressure. Replacing the master cylinder resolved the issue completely. Other cases involved pinpointing leaks in brake lines, replacing damaged calipers, and fixing faulty wheel cylinder seals. I firmly believe in a methodical approach, starting with a visual inspection, progressing to pressure tests, and employing diagnostic tools when needed, always adhering to safety protocols.

Q 27. How do you ensure the proper functioning of the brake system after bleeding?

After bleeding the brakes, it’s vital to verify proper functioning. This involves several steps:

Check for leaks: Carefully examine all brake lines, calipers, and wheel cylinders for any signs of leaks. Look for wet spots or brake fluid dripping.

Test the brake pedal: Pump the brake pedal several times. It should feel firm and responsive, offering consistent stopping power. A spongy or soft pedal suggests trapped air or a more serious issue.

Road test the vehicle: Perform a low-speed test to ensure that all brakes are engaging evenly. Pay attention to the feel of the brakes, noticing any pulling or uneven stopping performance. If all is well, brakes should be responsive and firm, without any noticeable pulling or unevenness.

Check the brake fluid level: Make sure the fluid level in the reservoir is still within the acceptable range. If its low after bleeding, that might indicate a leak somewhere and require further attention.

These steps confirm the effectiveness of the bleed procedure and guarantee your safety.

Q 28. Explain how to use a pressure bleeder.

A pressure bleeder is a valuable tool for bleeding brakes. Unlike the traditional gravity method, it uses compressed air to maintain consistent pressure within the brake system, ensuring efficient removal of air bubbles. This leads to quicker and more thorough bleeding. It typically consists of a reservoir, a pressure gauge, and a hose that connects to the master cylinder.

Here’s how to use it:

Fill the pressure bleeder: Fill the bleeder reservoir with fresh brake fluid of the correct type for your vehicle. Ensure that the reservoir is at a slightly higher level than the master cylinder, allowing for positive pressure.

Connect the bleeder: Attach the bleeder hose to the master cylinder. Properly securing the connection prevents air from entering.

Pressurize the system: Use the pump to pressurize the system to the recommended pressure—usually indicated on the pressure bleeder itself. Maintain this pressure consistently throughout the bleeding process.

Open bleeder valves: At each wheel, open the bleeder valve while carefully monitoring the fluid flow from the bleeder valve. This will allow air bubbles to escape.

Close bleeder valves: Close the bleeder valve once the fluid flow is clear and free from air bubbles. Repeat the process at each wheel until the fluid is clean and free from bubbles.

Check for leaks: After bleeding, always check for leaks around all connections and components of the brake system.

Using a pressure bleeder significantly speeds up the bleeding process and ensures a more thorough removal of air, leading to a more responsive and safer braking system.

Key Topics to Learn for Hydraulic Brake Bleeding Interview

- Understanding Hydraulic Systems: Master the fundamental principles of hydraulic pressure, fluid dynamics, and Pascal’s Law as they relate to braking systems.

- Brake System Components: Thoroughly understand the function of master cylinders, calipers, wheel cylinders, brake lines, and pressure sensors within the hydraulic brake system.

- Bleeding Procedures: Learn various bleeding techniques (gravity bleeding, pressure bleeding, vacuum bleeding), their applications, and the tools required for each method. Understand when each method is most appropriate.

- Identifying Air in the System: Know how to recognize the symptoms of air in the brake lines (spongy pedal, inconsistent braking) and the implications for safety.

- Troubleshooting Common Issues: Develop problem-solving skills to diagnose and rectify common brake bleeding problems, such as leaks, faulty components, and incorrect bleeding procedures.

- Safety Precautions: Understand and articulate the importance of safety procedures during brake bleeding, including proper handling of brake fluid and the use of personal protective equipment (PPE).

- Different Brake System Types: Gain familiarity with various brake system configurations (e.g., ABS, disc brakes, drum brakes) and how bleeding procedures may differ.

- Fluid Types and Properties: Understand the characteristics of different brake fluids (DOT 3, DOT 4, etc.) and their impact on system performance and maintenance.

- Maintaining Brake System Integrity: Discuss preventative maintenance procedures to minimize the frequency of brake bleeding and ensure optimal brake system performance.

Next Steps

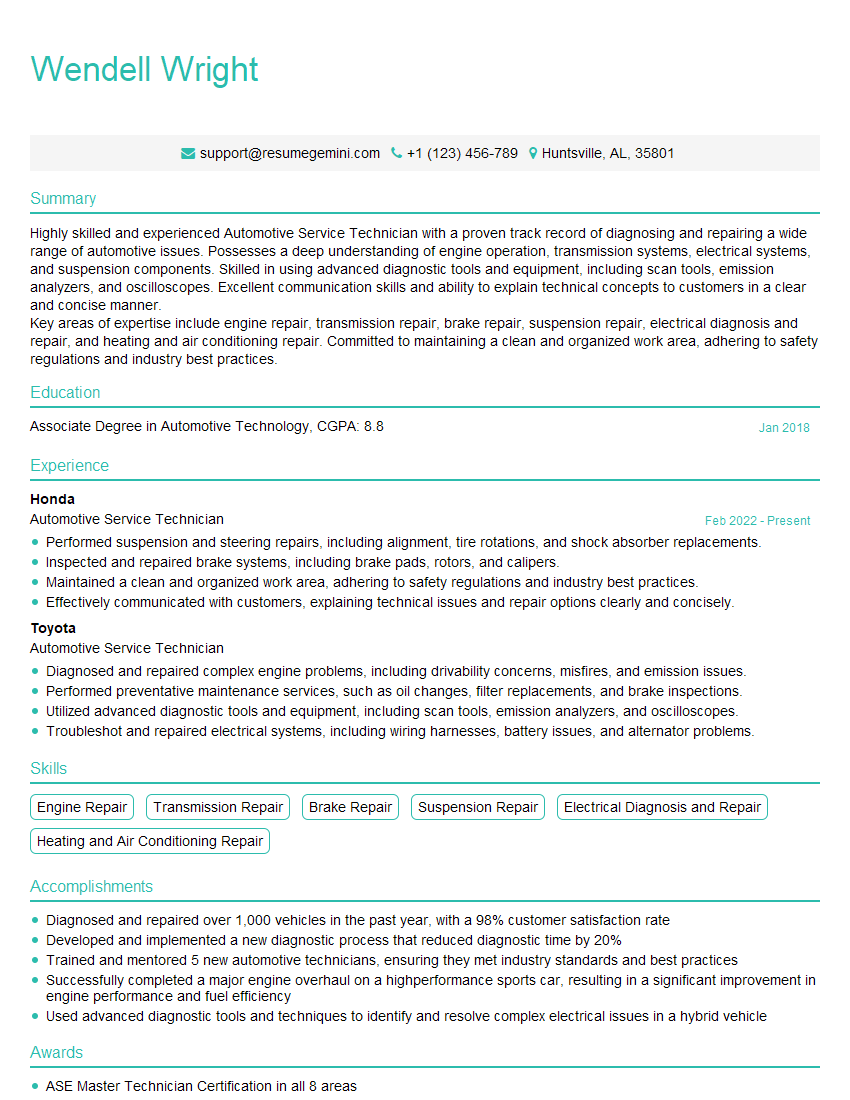

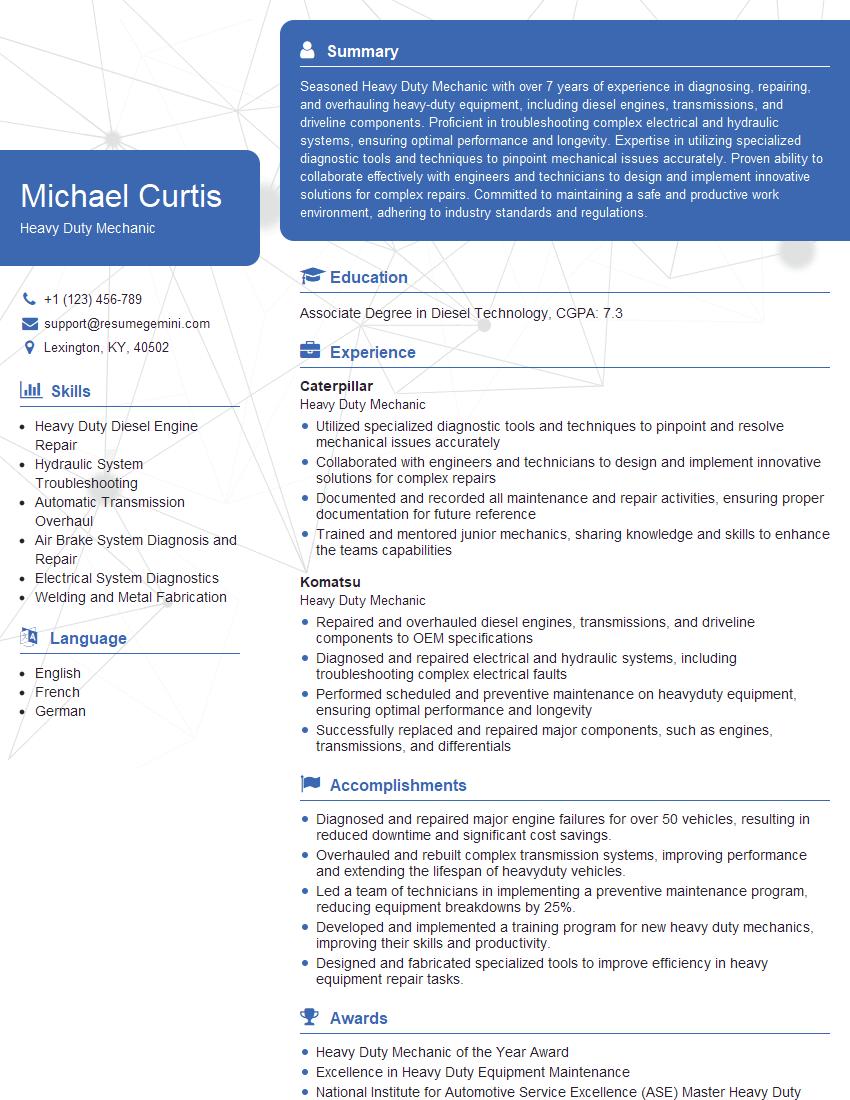

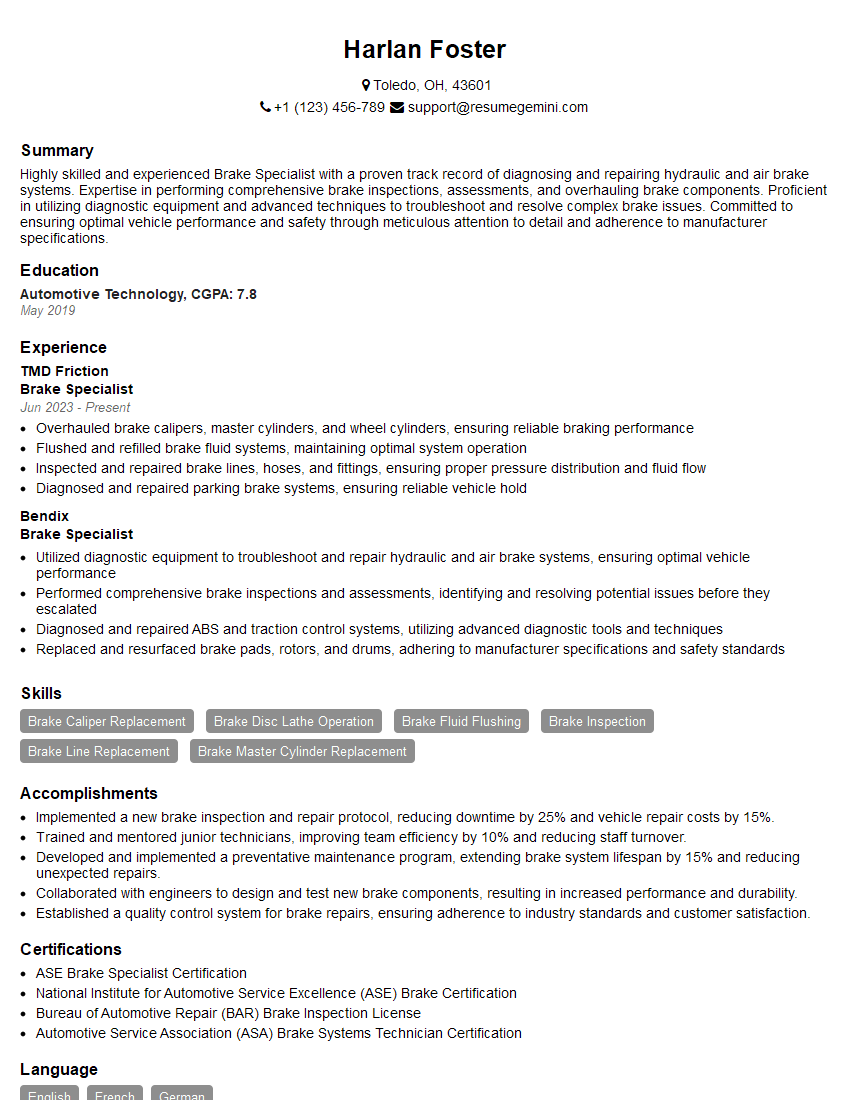

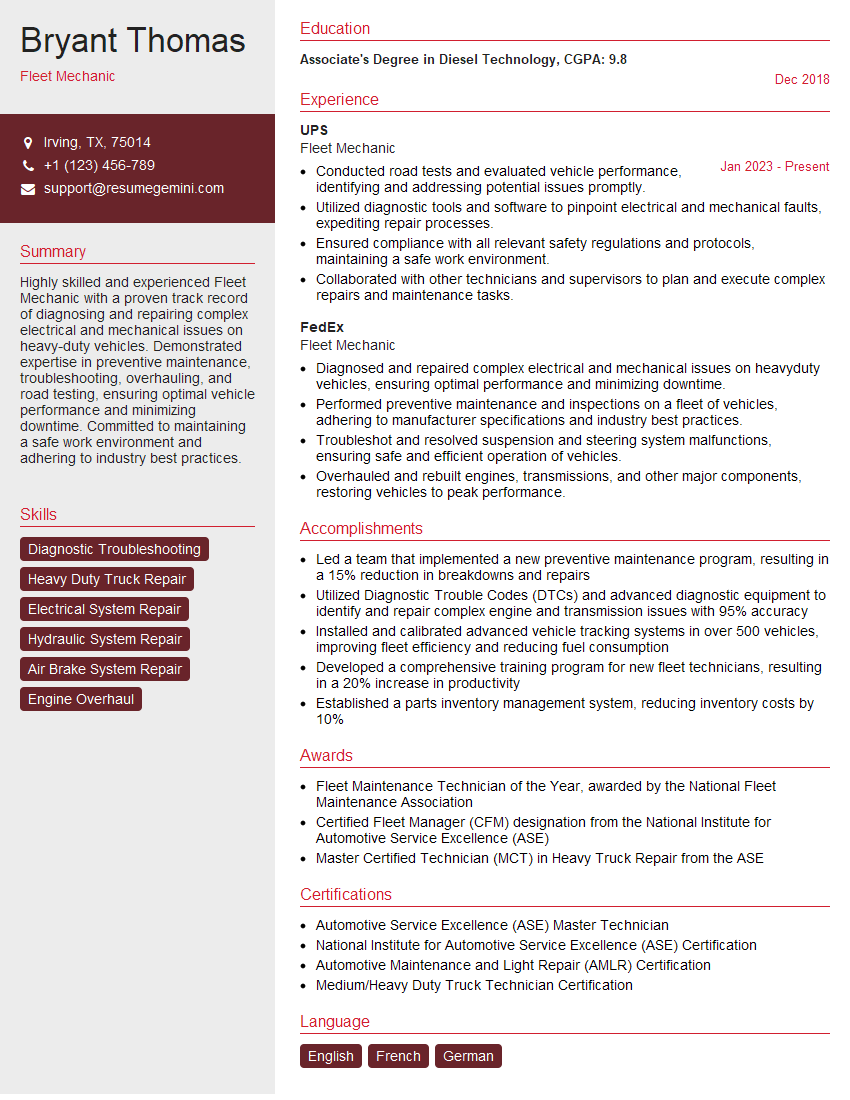

Mastering hydraulic brake bleeding is crucial for a successful career in automotive maintenance and repair. A strong understanding of this skill demonstrates competence and attention to detail, highly valued by employers. To enhance your job prospects, create an ATS-friendly resume that effectively highlights your expertise. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to hydraulic brake bleeding to help you showcase your skills effectively. Invest time in crafting a compelling resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO