The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Industrial Hygiene Sampling interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Industrial Hygiene Sampling Interview

Q 1. Describe the different types of air sampling methods used in industrial hygiene.

Industrial hygiene air sampling methods broadly fall into several categories, each with its strengths and weaknesses. The choice depends heavily on the specific hazard being monitored.

- Passive Sampling: These methods use a diffusion tube or badge that absorbs the contaminant over a set time period. They are simple to use and require minimal equipment, making them ideal for long-term monitoring or situations where active sampling is impractical. However, they’re generally less precise than active methods and are limited to specific types of contaminants.

- Active Sampling: Active sampling uses a pump to draw a known volume of air through a collection medium, like a filter or sorbent tube. This offers better control and greater accuracy than passive sampling. Examples include using a filter for particulate matter, charcoal tubes for organic vapors, and impingers for gases that are soluble in a liquid. Active sampling is more versatile but requires more equipment and expertise.

- Direct-Reading Instruments: These provide immediate readings of contaminant levels. Examples include photoionization detectors (PIDs) for volatile organic compounds (VOCs) and electrochemical sensors for gases like carbon monoxide. They are very useful for quick assessments and leak detection, but they often lack the precision and legal defensibility of laboratory analysis of samples collected using passive or active methods.

Imagine you’re investigating a suspected asbestos spill. Active sampling with a filter would be necessary to collect and quantify asbestos fibers for laboratory analysis. On the other hand, monitoring for VOCs during paint stripping might be best served by a quick scan with a PID.

Q 2. Explain the principles of personal air sampling.

Personal air sampling focuses on measuring the concentration of airborne contaminants in the breathing zone of a worker. This is crucial because it provides a realistic estimate of the worker’s actual exposure. The principle is to collect a representative air sample close to the worker’s nose and mouth throughout their workday. A calibrated pump draws air through a collection device (filter, sorbent tube, etc.) which is then sent to a laboratory for analysis. The sampling duration is critical and aligned with the worker’s shift.

Think of it like this: Imagine trying to measure the temperature of an oven by placing a thermometer in the middle of the kitchen instead of inside the oven itself. Personal sampling is like putting the thermometer directly inside where the heat is most intense – reflecting the actual exposure.

Q 3. What are the limitations of each sampling method?

Each sampling method has limitations:

- Passive Sampling: Limited accuracy, sensitive to environmental conditions (temperature, humidity), only suitable for specific contaminants, and sampling duration may be limited by the capacity of the sampling medium.

- Active Sampling: Can be more complex to set up and operate, requires careful calibration and maintenance of pumps, and can be expensive to run (particularly if high volume sampling is required). Incorrect pump flow rates can dramatically affect results.

- Direct-Reading Instruments: May be susceptible to interference from other substances, require regular calibration and maintenance, usually only offer real-time data without the possibility of later analysis of the sample, and frequently lack the precision needed for regulatory compliance.

For example, using a direct-reading instrument to measure benzene concentration might yield a quick estimate, but a laboratory analysis of an active sample collected over an eight-hour shift would provide a more accurate and legally sound time-weighted average (TWA) exposure.

Q 4. How do you select the appropriate sampling method for a specific hazard?

Selecting the appropriate sampling method requires careful consideration of several factors:

- Nature of the Hazard: Is it a particulate, vapor, gas, or mist? This dictates the type of collection medium required.

- Expected Concentration: This helps determine the appropriate sampling volume and duration.

- Regulatory Requirements: OSHA, NIOSH, and other agencies provide guidance and standards that may dictate the method.

- Feasibility and Practicality: Consider factors like worker cooperation, ease of use, environmental conditions, and available resources.

- Analytical Capabilities: The laboratory’s analytical capabilities will influence the choice of collection medium and sampling strategy.

If you are assessing exposure to silica dust, active sampling with a filter specifically designed for particulate matter collection is necessary. If you need to determine the concentration of a gas like hydrogen sulfide, an active sampling method using a specific sorbent tube is appropriate. Prioritizing a direct-reading instrument for a quick evaluation of a potential leak is also a viable strategy. However, for regulatory compliance, this should be followed by formal active sampling.

Q 5. What are the OSHA regulations regarding air sampling?

OSHA regulations pertaining to air sampling are extensive and detailed. They are primarily found in 29 CFR 1910, Subpart I (General Industry) and 29 CFR 1926, Subpart I (Construction). These regulations don’t specify particular sampling methods but set permissible exposure limits (PELs) for various hazards. Employers must monitor worker exposures when there is a potential for exceeding the PELs. OSHA also provides guidelines on sampling methodologies, requiring methods that are appropriate for the hazard and capable of providing accurate and reliable results. The selection of proper sampling methods and the adherence to OSHA guidelines are absolutely critical for avoiding citations and ensuring worker safety.

For instance, if an employer suspects workers are exposed to lead above the PEL, OSHA’s regulations mandate specific procedures for monitoring and air sampling to ensure compliance. Failing to follow OSHA’s guidelines can result in penalties and citations.

Q 6. How do you calculate the time-weighted average (TWA) for an exposure?

The time-weighted average (TWA) is a crucial metric in industrial hygiene, representing the average concentration of a contaminant over a specific time period (usually an 8-hour workday). It accounts for fluctuations in exposure during the workday. Calculating it involves summing the product of the concentration at each interval and the duration of that interval, then dividing by the total duration.

The formula is:

TWA = (C1 x T1 + C2 x T2 + ... + Cn x Tn) / TtotalWhere:

- Ci = concentration at interval i

- Ti = duration of interval i

- Ttotal = total sampling time

For example: If a worker is exposed to a concentration of 10 ppm for 4 hours and 20 ppm for 4 hours, the TWA is: TWA = (10 ppm x 4 hours + 20 ppm x 4 hours) / 8 hours = 15 ppm

Q 7. Explain the importance of proper sample chain of custody.

Maintaining proper sample chain of custody (COC) is paramount to ensuring the validity and legal defensibility of air sampling results. The COC documents the handling and transfer of the sample from collection to analysis, preventing any possibility of tampering, misidentification, or contamination. It involves detailed documentation of each step in the process, including the date, time, location, sampler’s identity, and any changes in the sample’s condition. This critical information is used to demonstrate that the results accurately reflect the worker’s exposure. A chain of custody record will typically include a unique sample identification number for tracking purposes. A break in the chain of custody can severely compromise the credibility of the results, leading to legal challenges if the data is used in regulatory settings or litigation. Proper COC procedures are central to protecting worker health and adhering to ethical and legal standards.

Imagine a court case relying on air sampling data to determine liability. A broken chain of custody would render the evidence inadmissible. Therefore, meticulously following COC procedures is critical to ensuring the data’s integrity and usefulness.

Q 8. How do you ensure the accuracy and reliability of your sampling results?

Ensuring accurate and reliable sampling results is paramount in industrial hygiene. It’s a multi-step process that begins even before sampling begins. We meticulously plan the sampling strategy, considering factors like the type of contaminant, its expected concentration, and the work practices involved. This includes selecting the appropriate sampling method, media, and equipment.

Accuracy hinges on proper calibration and maintenance of our equipment. For instance, I always check the flow rate of my sampling pump before, during (if possible), and after each sampling event using a calibrated flow meter, documenting every reading. This ensures consistent airflow throughout the sampling period, which directly impacts the amount of contaminant collected.

Quality control is critical. This includes using blank samples (media exposed to the environment but not the target contaminant) to detect any contamination during handling and transport. Furthermore, I maintain meticulous chain of custody documentation, tracking the sample from collection to analysis, ensuring its integrity remains uncompromised. Finally, I work closely with the analytical laboratory, selecting a reputable lab with validated analytical methods appropriate for the specific contaminants and ensuring accurate reporting and interpretation of the results.

Q 9. What are the common hazards encountered in industrial hygiene sampling?

Industrial hygiene sampling exposes us to a diverse range of hazards, both chemical and physical. Chemical hazards can include airborne particulate matter like dusts, fumes, and mists; gases such as solvents and carbon monoxide; and vapors from various sources. The specific hazards depend entirely on the workplace. For example, in a metal fabrication shop, I might encounter welding fumes containing hexavalent chromium or manganese, while in a paint factory, the concern might be volatile organic compounds (VOCs).

Physical hazards include noise, ionizing and non-ionizing radiation, and ergonomic stressors. For example, prolonged sampling in awkward postures can lead to musculoskeletal issues. Biological hazards are also a concern in certain industries (e.g., healthcare, agriculture), involving bacteria, viruses, or fungi. My experience has taught me to assess and mitigate these risks through proper personal protective equipment (PPE), appropriate sampling techniques, and adherence to strict safety protocols.

Q 10. Describe your experience with different types of sampling pumps.

My experience encompasses a wide range of sampling pumps, each suited to specific applications. I’m proficient with both low-flow and high-flow pumps, selecting them based on the sampling method and the concentration of the contaminant. For instance, a low-flow pump is ideal for collecting respirable dust using a filter, while a high-flow pump might be used for collecting large volumes of air for VOC analysis using sorbent tubes.

I’ve worked extensively with personal sampling pumps (worn by the worker), which provide time-weighted average (TWA) exposure measurements, reflecting the average exposure over a work shift. I also have experience with stationary or area sampling pumps, measuring contaminant levels in a specific location, rather than on an individual worker. Each pump type requires different calibration and maintenance procedures, which I meticulously follow.

Q 11. How do you calibrate and maintain sampling equipment?

Calibrating and maintaining sampling equipment is crucial for accurate results. Before each sampling event, I calibrate the flow rate of the pump using a primary standard flow meter, such as a bubble-tube calibrator or a digital flow meter, tracing it back to a NIST-traceable standard. I record the flow rate and any deviations from the manufacturer’s specifications.

Maintenance includes regular inspection for leaks, damage, or wear and tear. I meticulously clean and decontaminate the equipment after each use following established procedures, preventing cross-contamination. Filter cassettes are checked for integrity. For example, a damaged filter cassette may produce inaccurate results. Furthermore, I adhere to a rigorous preventative maintenance schedule that includes lubrication and periodic servicing by certified technicians.

Q 12. What are the safety precautions you take during industrial hygiene sampling?

Safety is my top priority. Before any sampling event, I thoroughly assess the work area for potential hazards, and I always use appropriate PPE, which can range from safety glasses and respirators to gloves and coveralls, based on the specific risks involved. This also includes hearing protection if noise levels are high.

I follow all safety protocols established by the company and regulatory agencies. This includes using proper lockout/tagout procedures when working near machinery. I’m trained in emergency response procedures and know how to handle unexpected events, such as equipment malfunction or a spill. I always work with a partner for safety when conditions warrant it. Communication and situational awareness are vital during industrial hygiene sampling.

Q 13. How do you interpret and report your sampling data?

Interpreting and reporting sampling data involves more than just presenting the raw numbers. I use a methodical approach to make sense of the data and translate it into actionable insights. First, I review the data for quality control, checking for any anomalies or outliers that might indicate problems with the sampling or analytical process.

Next, I compare the results to the relevant occupational exposure limits (OELs) set by regulatory agencies or company guidelines to determine if the exposure levels are within acceptable ranges. I use statistical methods to calculate the mean, standard deviation, and other relevant parameters. This gives a clearer understanding of the exposure and variation within the workforce. The final report is concise and comprehensive, clearly stating the sampling methods, results, conclusions, and any necessary recommendations for controlling worker exposures.

Q 14. Explain your experience with different types of analytical methods used in IH.

My experience encompasses various analytical methods employed in industrial hygiene. Gravimetric analysis is frequently used for determining the mass of particulate matter collected on filters. I have used this extensively for dust sampling. For example, I have collected respirable crystalline silica samples using this technique to assess worker exposures. Gas chromatography (GC) and high-performance liquid chromatography (HPLC) are frequently utilized for the analysis of volatile and semi-volatile organic compounds. Spectrophotometry is used for many different analyses, measuring the absorbance or transmission of light through a sample. This can be used to determine the concentration of many substances.

The choice of analytical method depends on the type of contaminant being analyzed. I always select a method with appropriate sensitivity, accuracy, and precision. I maintain strong relationships with the analytical laboratories to ensure that the analysis is performed according to accredited standards and to discuss any uncertainties or unexpected results. This collaborative approach ensures accurate and reliable interpretation of the data.

Q 15. Describe your experience with using and interpreting IH monitoring data.

Interpreting industrial hygiene (IH) monitoring data is crucial for assessing workplace hazards and ensuring worker safety. My experience encompasses a wide range of sampling methods and analytes, from air contaminants like silica and asbestos to noise and vibration. I’m proficient in using various software packages to analyze data, identify trends, and compare results against regulatory limits (e.g., OSHA PELs, ACGIH TLVs). For instance, in a recent project involving welding fumes, I used gravimetric analysis data to determine the concentration of hexavalent chromium, comparing it to the OSHA permissible exposure limit to assess the risk and recommend control measures. I also have experience with statistical analysis techniques to ensure the reliability and validity of the data, accounting for factors like sampling variability and uncertainty.

Beyond simply analyzing numbers, I focus on contextualizing the data. This includes considering factors like the task being performed, the worker’s exposure duration, and potential synergistic effects of multiple hazards. For example, high noise levels combined with particulate exposure might pose a greater risk than either hazard in isolation. This holistic approach allows for a more accurate risk assessment and the implementation of appropriate control measures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and control potential hazards?

Identifying and controlling potential hazards is a systematic process. It begins with a thorough workplace assessment, involving walkthrough surveys, interviews with workers, and a review of available safety data sheets (SDSs). This helps pinpoint potential hazards such as chemical exposure, noise, vibration, ergonomic risks, and biological agents.

Once hazards are identified, I prioritize them based on their severity and likelihood of exposure using a risk matrix. Control measures are then implemented following the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and lastly, personal protective equipment (PPE). For example, if a process generates hazardous dust, the first step might involve replacing the process with a safer alternative (substitution). If this isn’t feasible, engineering controls like local exhaust ventilation (LEV) would be implemented to remove the dust at its source. Administrative controls, such as limiting exposure time, might also be employed. PPE, such as respirators, is the last resort and should always be used in conjunction with other controls.

Regular monitoring and review are essential. Post-control monitoring ensures that the implemented measures are effective and that worker exposure remains below acceptable limits. This iterative process is key to maintaining a safe and healthy work environment.

Q 17. Explain your knowledge of different respiratory protection devices.

My knowledge of respiratory protection devices is extensive, covering various types and their applications. These include:

- Air-purifying respirators (APRs): These use filters or cartridges to remove contaminants from the air. Examples include N95 respirators (filtering particulate matter), half-mask respirators with organic vapor cartridges, and full-face respirators. The selection depends on the specific hazards present.

- Air-supplied respirators (ASRs): These provide breathable air from a separate source, such as a self-contained breathing apparatus (SCBA) or supplied-air respirator (SAR). ASRs are ideal for working in oxygen-deficient or immediately dangerous to life or health (IDLH) atmospheres.

- Powered Air-Purifying Respirators (PAPRs): These combine the filtration of APRs with a powered fan to provide a more comfortable and efficient breathing experience.

I understand the limitations of each type and the importance of proper fit testing, training, and maintenance to ensure effectiveness and worker safety. For example, I know that APRs are only effective when the air quality is sufficient and the contaminant concentration is below the respirator’s assigned protection factor (APF).

Q 18. How do you determine the appropriate respiratory protection for a worker?

Determining the appropriate respiratory protection involves a multi-step process. It starts with a thorough hazard assessment to identify the specific respiratory hazards present, their concentrations, and the duration of exposure. The next step is to consult the safety data sheets (SDSs) for the materials involved to understand their potential health effects.

Based on this assessment, we choose a respirator that provides adequate protection. This involves selecting the appropriate filter type and class to address the specific hazards. For example, an N95 respirator is suitable for particulates, while an organic vapor cartridge is needed for chemical vapors. The respirator’s assigned protection factor (APF) must be sufficient to reduce the worker’s exposure below the occupational exposure limit (OEL).

Finally, a proper fit test is crucial to ensure a secure seal and effective protection. Regular training and medical evaluations are also essential components of a comprehensive respiratory protection program. A poorly fitted or improperly used respirator offers little to no protection, highlighting the importance of this comprehensive approach.

Q 19. What is your experience with noise monitoring and dosimetry?

My experience in noise monitoring and dosimetry includes using sound level meters, integrating sound level meters, and personal noise dosimeters to assess worker noise exposure. I am familiar with various weighting networks (A-weighting being the most common) and how they relate to the perception of loudness. I understand the importance of accurately measuring noise levels under varying conditions and the impact of background noise on readings.

Dosimetry provides a more accurate measure of a worker’s daily noise exposure by averaging the sound levels throughout their work shift. I have experience analyzing dosimeter data to determine the equivalent continuous noise level (Leq) and comparing it to regulatory limits such as the Permissible Exposure Limit (PEL) established by OSHA or the Threshold Limit Value (TLV) published by ACGIH. This analysis helps to identify workers at risk of noise-induced hearing loss (NIHL) and support the implementation of hearing conservation programs.

Q 20. How do you conduct a noise survey?

Conducting a noise survey involves a systematic approach to identify and quantify noise sources within a workplace. It begins with a walk-through survey to identify potential noise sources and areas of concern. A sound level meter is then used to measure noise levels at various locations and times, considering factors like distance from the source, background noise, and the type of work being performed.

Measurements are typically taken using A-weighting to reflect human hearing sensitivity. I record the location, date, time, measurement method, and other relevant details for each measurement. For a comprehensive assessment, measurements should include both peak levels and equivalent continuous sound levels (Leq) over various time periods. The data collected is then analyzed to determine the overall noise levels within the workplace and to identify areas that require noise control measures. A map of the noise levels helps visualize the areas most affected, allowing for targeted interventions.

Q 21. Explain your knowledge of vibration monitoring.

Vibration monitoring involves measuring the intensity and frequency of vibrations transmitted to workers through hand-arm or whole-body exposure. I have experience using accelerometers to measure vibration levels on tools and equipment, as well as on the worker’s body. This data is then analyzed to determine the exposure levels and compare them to relevant standards such as those established by OSHA or the ISO.

Hand-arm vibration syndrome (HAVS) and whole-body vibration (WBV) are the primary health concerns associated with prolonged exposure to vibration. I understand the different types of vibration (frequency and amplitude) and their impact on the human body. Data analysis often involves calculating daily and weekly exposure values, considering factors like the duration and intensity of exposure. The results are used to recommend engineering controls, such as using vibration-dampening tools, or administrative controls, like reducing exposure time to mitigate the health risks.

Q 22. What is your experience with thermal stress monitoring?

Thermal stress monitoring involves measuring the combined effects of heat and humidity on workers to prevent heat-related illnesses. This isn’t just about air temperature; it considers factors like radiant heat, air movement, metabolic rate (the work being done), and personal protective equipment (PPE).

My experience includes using instruments like WBGT (Wet Bulb Globe Temperature) meters to assess the working environment. I’ve developed and implemented monitoring programs, including establishing heat index thresholds, recommending work-rest cycles, and providing training on heat illness recognition and prevention. For example, in a steel foundry, we used WBGT readings to determine when workers needed extra breaks and to justify investing in improved ventilation. In another project, involving road construction workers during a summer heatwave, we used the data to schedule work during cooler parts of the day and ensure adequate hydration. This involved not only the measurement itself but also analysis of the data and communication with management and workers to implement effective control measures.

Q 23. How do you assess and control ergonomic hazards?

Ergonomic hazard assessment involves identifying and evaluating physical factors in the workplace that can cause musculoskeletal disorders (MSDs). This includes analyzing postures, repetitive movements, forceful exertions, vibration, and contact stress. My approach involves using a combination of methods, including observation, interviews with workers, and detailed task analysis.

Control measures range from administrative controls (like job rotation and modified work schedules) to engineering controls (like redesigning workstations and tools). For instance, in a packaging facility, we identified repetitive wrist movements as a risk factor for carpal tunnel syndrome. Implementing engineering controls such as changing the conveyor height and introducing ergonomic tools significantly reduced reported MSD cases. We also trained workers on proper lifting techniques and body mechanics to further enhance the reduction.

Q 24. Explain your experience with asbestos sampling and analysis.

Asbestos sampling and analysis is a critical part of ensuring worker safety in environments where asbestos-containing materials (ACM) might be present. I’m experienced in using both bulk sampling (for identifying ACM) and air sampling (to measure airborne asbestos fibers). For air sampling, I utilize methods such as phase contrast microscopy (PCM) and transmission electron microscopy (TEM), which are crucial for accurate quantification.

My experience includes developing sampling strategies that comply with relevant regulations (such as OSHA and EPA guidelines). This includes selecting the appropriate sampling method based on the suspected level of asbestos and the type of work being performed. I’ve worked on projects involving asbestos abatement projects, where careful sampling and analysis are crucial for ensuring compliance with regulations and protecting workers. A recent project involved evaluating asbestos levels before and after remediation in an old school building to verify successful abatement.

Q 25. Describe your experience with lead sampling and analysis.

Lead sampling and analysis require meticulous attention to detail. I have experience using various methods for lead sampling, including air sampling (using personal sampling pumps and filters), surface wipe sampling, and blood lead level testing. Air sampling is typically performed using filters that are subsequently analyzed using techniques like atomic absorption spectroscopy (AAS) or inductively coupled plasma mass spectrometry (ICP-MS) for accurate quantification of lead concentrations.

In one project, we evaluated lead exposure levels in a battery recycling facility. This involved a comprehensive sampling plan encompassing air, surface wipes, and soil samples. The results guided us in implementing engineering controls like local exhaust ventilation and enhanced personal protective equipment (PPE), reducing worker exposure significantly. The ongoing monitoring helped maintain a safe working environment.

Q 26. What is your experience with silica sampling and analysis?

Silica sampling and analysis are crucial in industries involving processes that generate respirable crystalline silica (RCS), such as mining, quarrying, and construction. I’m proficient in using specialized sampling methods for RCS, often employing personal sampling pumps with cassettes containing filters, to collect respirable dust fractions. These samples are then analyzed in a laboratory using methods such as X-ray diffraction (XRD) for qualitative identification and gravimetric analysis for quantitative determination.

A recent project involved a sandblasting operation. We implemented a detailed sampling strategy to evaluate worker exposure, identifying areas needing improved engineering controls such as local exhaust ventilation systems and water suppression. The subsequent monitoring after these improvements demonstrated a significant decrease in worker exposure to respirable crystalline silica.

Q 27. How do you develop and implement an industrial hygiene monitoring program?

Developing and implementing an industrial hygiene monitoring program involves a systematic approach. It begins with a thorough hazard identification and risk assessment, considering all potential hazards present in the workplace. This assessment uses both qualitative and quantitative data, such as historical records, worker interviews, and preliminary sampling.

The next step is designing the monitoring strategy, selecting appropriate sampling methods, and determining the frequency of monitoring based on the identified risks and regulatory requirements. After sampling and analysis, the data is interpreted to assess the effectiveness of control measures and to identify areas requiring additional intervention. Finally, a report is created documenting findings, recommendations, and a plan for future monitoring. Ongoing monitoring and evaluation are critical to ensure the program’s effectiveness and to adapt to changing workplace conditions. Regular training for workers and management is also essential for a successful program.

Key Topics to Learn for Industrial Hygiene Sampling Interview

- Air Sampling Methods: Understand the principles and applications of various air sampling techniques (e.g., active vs. passive sampling, personal vs. area sampling) including selection criteria based on the target hazard.

- Sampling Instruments and Equipment: Become proficient with the operation, calibration, and maintenance of common industrial hygiene sampling instruments (e.g., pumps, filters, detectors). Be prepared to discuss troubleshooting common issues.

- Analytical Techniques: Familiarize yourself with the methods used for analyzing collected samples (e.g., gravimetric analysis, chromatography, spectroscopy). Understand the limitations and accuracy of different techniques.

- Regulatory Compliance: Demonstrate a strong understanding of relevant OSHA, NIOSH, and other regulatory standards related to industrial hygiene sampling and exposure limits (e.g., PELs, RELs, STELs).

- Data Analysis and Interpretation: Practice interpreting sampling data to assess worker exposure and identify potential hazards. Be prepared to discuss how to calculate time-weighted averages (TWA) and other relevant metrics.

- Health Hazard Evaluation: Understand how to use sampling data to conduct a health hazard evaluation, including identifying potential control measures and recommending appropriate safety protocols.

- Safety Procedures and Practices: Demonstrate a commitment to safety by understanding and applying proper safety procedures during sampling activities. This includes personal protective equipment (PPE) selection and usage.

- Sampling Strategy Development: Discuss the process of developing a comprehensive sampling strategy based on the specific workplace, potential hazards, and regulatory requirements. This includes sample size determination and location selection.

Next Steps

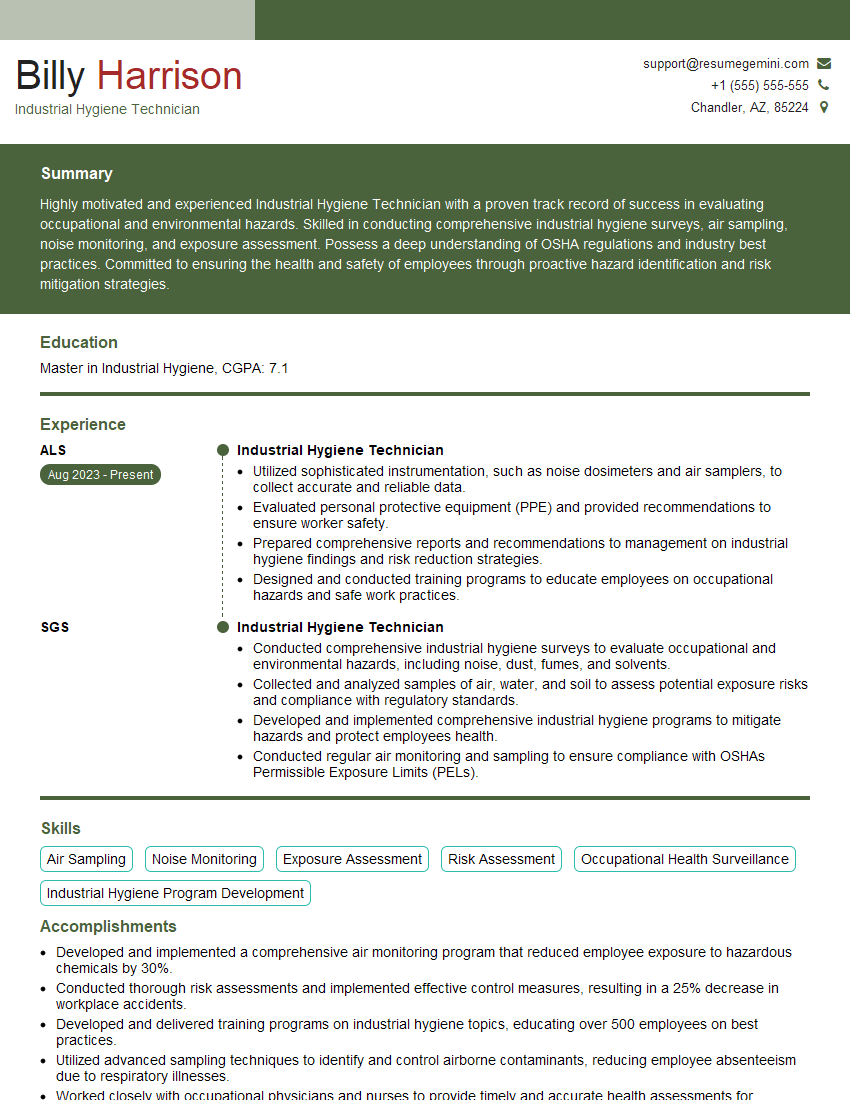

Mastering Industrial Hygiene Sampling is crucial for a successful and rewarding career, opening doors to specialized roles and increased earning potential. A well-crafted resume is your key to unlocking these opportunities. To ensure your qualifications shine, focus on building an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you create a compelling resume tailored to the specific demands of the Industrial Hygiene Sampling field. Examples of resumes specifically designed for Industrial Hygiene Sampling professionals are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO