Preparation is the key to success in any interview. In this post, we’ll explore crucial Industrial Truck Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Industrial Truck Operation Interview

Q 1. What types of industrial trucks have you operated?

Throughout my career, I’ve had extensive experience operating a variety of industrial trucks. This includes counterbalance forklifts (both gas and electric), reach trucks, order pickers, and pallet jacks. I’m proficient in operating both sit-down and stand-up models, adapting my technique to the specific requirements of each machine and the task at hand. For instance, in a previous role at a distribution center, I regularly used reach trucks to access high-bay racking, while in a smaller warehouse setting, I relied more heavily on counterbalance forklifts for general material handling. My experience spans different load capacities and truck makes and models, ensuring I’m adaptable to various warehouse environments.

Q 2. Describe your experience with pre-operation safety checks.

Pre-operation safety checks are paramount to preventing accidents. My routine is meticulous and covers all key areas. I begin by visually inspecting the truck for any obvious damage, checking tires for wear and proper inflation, and ensuring all fluid levels (hydraulic fluid, engine oil, coolant) are within the acceptable range. I then check the functionality of the lights, horn, and safety features like seatbelts and emergency stops. I test the brakes, steering, and lift mechanism to confirm they are responsive and operate smoothly. Finally, I check the load backrest, ensuring it’s securely in place. Think of it like a pre-flight checklist for an airplane – a thorough check ensures the safe operation of the machine. If any issues are identified, I immediately report them to my supervisor before operating the truck. For example, once I noticed a slight leak in the hydraulic system during my pre-operation check, and I immediately reported it to prevent a potentially dangerous failure later.

Q 3. Explain the proper procedures for loading and unloading goods.

Loading and unloading goods safely requires careful planning and execution. First, I assess the load – its weight, dimensions, and stability. I make sure the pallet is properly secured and the load is evenly distributed to avoid tipping. Then, I carefully position the forks under the pallet, ensuring they are fully engaged and centered. Next, I slowly lift the load to a safe height, checking for any instability. During transportation, I maintain a slow and controlled speed, avoiding sudden movements or sharp turns. When unloading, I reverse the process, lowering the load gently and placing it securely in the designated area. I always maintain awareness of my surroundings and ensure no obstacles or personnel are in the path of the forklift. If I’m handling oversized loads, I’ll use appropriate load-securing techniques such as straps or nets, always ensuring the load is well-balanced and stable. For example, when unloading glass panes, I took extra precautions to prevent breakage, using specialized forklift attachments and ensuring support throughout the entire process.

Q 4. How do you ensure the safe operation of a forklift in a busy warehouse?

Safe operation in a busy warehouse requires constant vigilance and adherence to strict safety protocols. I always maintain a safe speed, keeping my distance from other workers and equipment. I use audible warnings (horn) and visual cues (lights) to alert others to my presence. I prioritize pedestrians by yielding the right-of-way and slowing down in congested areas. I never operate the forklift while distracted, and I maintain clear visibility at all times. I also follow designated traffic routes and abide by all posted safety signs. Maintaining awareness of my surroundings is critical; I’m constantly scanning for potential hazards, such as pallet obstructions or pedestrian movement. Think of it as driving defensively – anticipating potential issues and reacting proactively. For example, I’ve often adjusted my route to avoid crowded aisles during peak times, ensuring a smoother and safer workflow.

Q 5. What are the common causes of forklift accidents?

Forklift accidents often stem from a combination of factors, most commonly operator error. Unsafe speeds, improper loading techniques, inadequate training, and inattention to surroundings are major contributors. Mechanical failures, such as brake issues or hydraulic leaks, can also lead to accidents. Poor warehouse layout, obstructed aisles, and inadequate lighting can exacerbate risks. For example, improper load securing can easily result in toppling of the load, causing accidents. A lack of proper training can lead to mistakes in operation and maintenance of the equipment, increasing the chances of an accident. Finally, driving under the influence of drugs or alcohol is extremely dangerous and must be strictly avoided.

Q 6. How do you handle different types of loads (e.g., palletized, oversized)?

Handling different load types requires adapting my technique to ensure stability and safety. For palletized goods, I follow standard loading procedures, ensuring even weight distribution. For oversized loads, I use appropriate attachments, such as extensions or special clamps, to secure the load safely and prevent damage. Before moving any oversized or unusual load, I consult with my supervisor to determine the most efficient and safest method for handling it and ensure the forklift is adequately sized for the task. For instance, I’ve used specialized attachments to transport large rolls of paper or long metal beams, carefully planning the route and using appropriate safety measures to secure the loads. Safety is paramount; even seemingly simple adjustments require thorough planning and consideration.

Q 7. Describe your experience with inventory management systems.

I’m experienced with various inventory management systems, from manual stocktaking to utilizing modern warehouse management systems (WMS). My experience includes using handheld scanners to track inventory, updating stock levels in real-time, and locating items within the warehouse using WMS software. This includes using systems to manage picking lists, optimize routes for efficient order fulfillment, and track inventory movement. A strong understanding of these systems allows me to contribute to efficient warehouse operations, minimizing delays and errors. In a previous role, for example, using WMS improved our picking efficiency by 15% by optimizing routes and reducing unnecessary travel.

Q 8. What is your experience with RF scanners or other warehouse technology?

My experience with RF scanners and other warehouse technologies is extensive. I’m proficient in using various RF scanners for inventory management, tracking, and order fulfillment. This includes both handheld scanners and those integrated into forklift systems. I’ve used these devices to accurately scan barcodes and RFID tags, ensuring efficient picking and put-away processes. I’m also familiar with Warehouse Management Systems (WMS) and how they integrate with RF scanners to optimize workflow and minimize errors. For example, I’ve used scanners to verify product location and quantity before loading onto a pallet, preventing discrepancies and improving overall order accuracy. I also have experience troubleshooting scanner malfunctions and connectivity issues.

Beyond RF scanners, I’m comfortable with other technologies such as voice-picking systems, where verbal commands guide picking tasks, and automated guided vehicles (AGVs), which I’ve collaborated with to ensure safe and efficient material movement within the warehouse.

Q 9. Explain your understanding of load capacity and weight distribution.

Understanding load capacity and weight distribution is crucial for safe and efficient forklift operation. Load capacity refers to the maximum weight a forklift can lift safely, while weight distribution focuses on how that weight is balanced across the forks. Exceeding the load capacity can lead to equipment failure, potential damage to goods, and serious injury. Uneven weight distribution can cause instability, increasing the risk of tipping.

To illustrate, imagine you’re lifting a pallet of bricks. The forklift’s data plate will specify its load capacity, say 5,000 lbs. If the pallet weighs 6,000 lbs, you would immediately know it’s unsafe to lift. Even if the weight is within capacity, ensuring the load is evenly distributed across the forks is paramount. If most of the weight is concentrated on one side, the forklift may tilt, leading to an accident. Therefore, proper load centering, using fork extensions if necessary, and visually inspecting the load before lifting are essential practices. Many forklifts also have load capacity indicators to assist the operator in safe lifting.

Q 10. How do you maintain a safe working distance from other equipment and personnel?

Maintaining a safe working distance from other equipment and personnel is a top priority, and I strictly adhere to all safety regulations. This involves always being aware of my surroundings, utilizing mirrors and backup alarms on the forklift, and maintaining a safe speed appropriate for the conditions. I never operate the forklift in areas where visibility is obstructed without a spotter. I also ensure I’m always giving pedestrians and other equipment plenty of space; the three-point turn is a common maneuver I’ll use to avoid unnecessary proximity.

Before commencing any movement, I perform a complete 360-degree visual check. Think of it like driving a car; you always check your surroundings before driving off. In a warehouse, this is even more critical due to the presence of other forklifts, pedestrians, and potential obstacles. I use hand signals and verbal communication to coordinate movements with other workers. It’s a team effort – preventing accidents depends on collaboration and awareness.

Q 11. What is your experience with different types of forklift attachments?

I have experience with a variety of forklift attachments, each designed for specific tasks. These include:

- Standard forks: Used for general palletized goods.

- Side shifters: Allow for lateral movement of the forks, facilitating precise placement of pallets.

- Clamp attachments: Ideal for handling materials like paper rolls or lumber.

- Rotators: Rotate loads 90 degrees, facilitating efficient storage.

- Carriage attachments: Expand the capacity of the forklift to handle longer and heavier loads.

- Push-pull attachments: For handling heavier materials such as large bins or containers.

My experience encompasses both the safe operation of these attachments and their proper maintenance. Understanding the limitations of each attachment and its suitability for different materials is vital for preventing damage to both the goods and the equipment.

Q 12. How do you handle challenging situations, such as obstructed pathways or damaged goods?

Handling challenging situations like obstructed pathways or damaged goods requires a calm and methodical approach. If I encounter an obstructed pathway, I’ll first assess the situation to determine the safest way to navigate around the obstacle. This might involve seeking an alternate route or requesting assistance to clear the obstruction. Safety is paramount; if the obstacle cannot be easily bypassed, I will not attempt to move the forklift through it.

Dealing with damaged goods requires careful handling to prevent further damage or injury. I’ll assess the extent of the damage and use appropriate techniques to move the damaged goods safely. For example, if a pallet is partially damaged, I might use additional support or secure the load differently to prevent it from shifting during transport. In the event of extensive damage, I’ll mark the goods accordingly and report the issue to the relevant personnel. Good communication during these challenging times is key.

Q 13. What is your experience with different types of warehouse layouts?

My experience covers various warehouse layouts, including:

- High-bay warehouses: These typically utilize narrow-aisle forklifts and other specialized equipment to maximize vertical space.

- Conventional warehouses: Wider aisles and less vertical storage make for easier maneuverability.

- Block stacking warehouses: Used for bulk storage and often employs larger material handling equipment.

Adapting to different layouts is a crucial skill. Understanding the specific challenges and optimizing operations for each type of layout is essential for productivity and safety. This involves knowing which types of forklifts and equipment are most suitable for a given layout, as well as understanding the flow of materials and potential congestion points.

Q 14. What are your strategies for efficient material handling?

Efficient material handling involves optimizing several key aspects:

- Route planning: Minimizing travel distance by carefully planning routes is crucial. I would use the most efficient routes, understanding the warehouse layout to avoid unnecessary turns or traffic congestion.

- Load optimization: Maximizing the number of pallets or units per trip within load capacity and weight distribution guidelines.

- Proper stacking techniques: Ensures stability and efficient storage.

- Communication and coordination: Working collaboratively with warehouse personnel to ensure a smooth flow of goods.

- Regular maintenance of equipment: Well-maintained equipment leads to fewer breakdowns and delays.

By meticulously following these strategies, material handling operations can be significantly improved, leading to reduced operational costs, faster order fulfillment, and a safer work environment.

Q 15. Explain your understanding of warehouse safety regulations.

Warehouse safety regulations are paramount to preventing accidents and injuries. They cover a wide range of aspects, from the safe operation of industrial trucks like forklifts to the proper storage of materials and the maintenance of a clean and organized workspace. These regulations are often based on OSHA (Occupational Safety and Health Administration) guidelines in the US, or equivalent standards in other countries.

- Traffic Management: Designated walkways, clear signage, speed limits for forklifts, and the use of pedestrian safety devices are crucial. Imagine a busy warehouse – clear pathways are essential to prevent collisions between pedestrians and forklifts.

- Equipment Maintenance: Regular inspections and preventative maintenance are mandatory to ensure forklifts are in optimal working condition. This includes checks on brakes, lights, horns, and load-handling mechanisms. Ignoring maintenance is like driving a car with faulty brakes – extremely risky!

- Load Handling: Safe load capacity limits must always be observed, and proper load securing techniques are crucial to prevent spills or accidents. Overloading a forklift is like overloading a truck – it significantly increases the risk of a rollover or load shift.

- Personal Protective Equipment (PPE): Employees must wear appropriate PPE, including safety shoes, high-visibility clothing, and sometimes safety helmets, depending on the task. PPE is your first line of defense, protecting you from potential hazards.

- Training and Certification: Operators must undergo comprehensive training and obtain certifications to demonstrate competency before operating industrial trucks. This is like getting a driver’s license – it shows you have the skills and knowledge to operate the equipment safely.

Violation of these regulations can lead to serious consequences, including accidents, injuries, fines, and even legal action. Therefore, a thorough understanding and strict adherence to warehouse safety regulations are non-negotiable.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What steps do you take to prevent damage to goods during handling?

Preventing damage to goods during handling involves a multi-faceted approach, emphasizing careful planning and execution. It starts long before the forklift even touches the goods.

- Proper Assessment: Before lifting any load, I carefully assess its weight, dimensions, and condition to ensure it’s suitable for handling with the forklift and that the forklift is appropriately rated for the weight. This is crucial; lifting an unsuitable load can result in damage or an accident.

- Secure Load Placement: I use appropriate forks and attachments to handle the load and ensure it’s properly secured. This prevents shifting and damage during transportation. I’ve seen instances where improperly secured loads caused significant damage.

- Safe Transportation: I drive the forklift at a safe speed, maintaining awareness of my surroundings to avoid collisions with other equipment or personnel. Smooth movements are key to reducing the risk of sudden jolts that could damage the goods.

- Careful Placement: I ensure that the load is placed carefully in its designated area, avoiding any potential obstacles or hazards. This could include making sure there’s sufficient space and that the load is appropriately stacked or arranged for safe storage.

- Regular Inspections: I frequently inspect the goods for any signs of damage during and after handling. If I find any damage, I immediately report it following established procedures.

By following these steps, I contribute significantly to minimizing damage to goods and ensuring the integrity of the warehouse’s inventory.

Q 17. Describe your experience with reporting accidents or near misses.

Reporting accidents or near misses is a critical component of workplace safety. My experience involves promptly documenting every incident using the company’s established reporting system, which usually involves filling out detailed incident reports. These reports include detailed accounts of the event, the contributing factors, and any injuries or damage.

- Immediate Reporting: I report all accidents and near misses immediately to my supervisor. This allows for a prompt response, potentially mitigating further damage or preventing future incidents.

- Detailed Documentation: I ensure that my reports include precise information, such as times, locations, and witness statements where available. Accuracy is critical for investigation and preventative measures.

- Root Cause Analysis: I actively participate in any investigations following an accident or near miss, contributing to the identification of root causes and suggesting corrective actions. This collaborative approach is crucial for improving workplace safety.

- Follow-up: I follow up on reported incidents to ensure that appropriate corrective actions are implemented and that any necessary training or improvements are made.

Effective reporting isn’t just about fulfilling a requirement; it’s about learning from mistakes, preventing recurrences, and maintaining a safe working environment for everyone.

Q 18. How do you maintain your forklift operator certification?

Maintaining my forklift operator certification involves ongoing compliance with the requirements set forth by the certifying body. This usually includes a combination of refresher training, practical assessments, and potentially written exams.

- Refresher Courses: I regularly participate in refresher training courses, usually annually or as required by my company’s policies. These courses cover safety protocols, updated regulations, and best practices for forklift operation.

- Practical Assessments: I undergo periodic practical assessments to demonstrate proficiency in safe and effective forklift operation. These assessments evaluate my ability to handle various scenarios and to respond safely to unexpected situations.

- Record Keeping: I meticulously maintain my certification records, ensuring that all training and assessment documents are up-to-date and readily available for review. This helps me stay compliant with all requirements.

- Continuous Learning: I am always seeking opportunities to improve my skills and stay informed about changes in regulations and technologies related to forklift operation.

Maintaining my certification is not just about compliance; it’s about demonstrating my commitment to safety and my dedication to maintaining the highest standards of professional practice.

Q 19. What is your experience with operating forklifts in different environments (e.g., cold storage, outdoors)?

My experience operating forklifts extends to diverse environments, each presenting unique challenges and requiring adaptable operational techniques.

- Cold Storage: Operating forklifts in cold storage environments demands extra caution. Reduced visibility due to condensation and potential for ice buildup necessitate slower speeds and heightened awareness. Specialized cold-weather gear is also essential for operator safety and comfort.

- Outdoors: Operating outdoors introduces challenges such as uneven terrain, varying weather conditions (rain, snow, wind), and potential obstructions like pedestrians and other vehicles. It requires increased vigilance and careful adjustment of driving techniques based on the environmental factors.

- Different Floor Types: I am experienced handling forklifts on various floor surfaces – concrete, asphalt, and even uneven ground in some outdoor applications. Each surface requires adjusted driving techniques to ensure safe and efficient handling.

Adaptability is key in this area. I’ve learned to modify my operating techniques according to the environment, prioritizing safety above all else.

Q 20. How familiar are you with different types of forklift fuel systems?

I’m familiar with several forklift fuel systems, each with its own characteristics and safety considerations.

- LPG (Liquefied Petroleum Gas): LPG forklifts are relatively clean-burning and efficient but require careful handling of the propane tanks. Regular inspection and maintenance are crucial to prevent leaks.

- Gasoline: Gasoline forklifts are powerful but produce significant emissions. They require careful refueling procedures to prevent spills and fires.

- Diesel: Diesel forklifts offer high power and are suitable for heavy-duty applications, but they also produce significant emissions and require careful handling of fuel.

- Electric: Electric forklifts are clean, quiet, and require less maintenance than combustion engine-powered forklifts, but they have limited run-times and require regular charging.

Understanding the strengths and weaknesses of each fuel system allows for informed selection and safe operation, tailored to the specific application and work environment.

Q 21. Explain the process of properly fueling and maintaining a forklift.

Proper fueling and maintenance are crucial for ensuring the safe and efficient operation of a forklift. These processes are distinct but interconnected.

Fueling:

- Safety First: Before fueling, always ensure the engine is switched off and the area is well-ventilated. Never fuel a forklift indoors unless specifically designed for such environments.

- Proper Technique: Use the correct nozzle and handle the fuel carefully to avoid spills. Wipe up any spills immediately. Spilled fuel poses a significant fire hazard.

- Refueling Procedures: Follow the manufacturer’s refueling instructions meticulously. This ensures proper filling levels and prevents any damage to the forklift’s fuel system.

Maintenance:

- Regular Inspections: Conduct daily pre-operational checks, including inspecting the tires, brakes, lights, and fuel levels. Regularly inspect fluid levels, hoses, and belts.

- Preventative Maintenance: Follow the manufacturer’s scheduled maintenance recommendations, which include replacing filters, lubricating moving parts, and carrying out other preventative measures. Preventative maintenance is far cheaper than emergency repairs.

- Professional Service: Seek professional service for major repairs or maintenance that exceed your skills and experience. Attempting complex repairs without sufficient knowledge can lead to further damage or unsafe conditions.

By diligently following these procedures, you maintain not only the operational efficiency of the forklift but also significantly enhance workplace safety.

Q 22. Describe your experience with using different types of pallet jacks.

My experience with pallet jacks spans various types, from the most basic manual jacks to electric and powered models. I’m proficient in using both pump-style and hydraulic pallet jacks, understanding their nuances and limitations. Manual jacks require significant physical strength and proper technique to avoid strain and injury – I’ve learned to efficiently leverage my body mechanics to move even the heaviest loads safely. Electric pallet jacks offer significant advantages in terms of speed and reduced physical effort, especially in high-volume environments. I’m adept at operating them safely, including the proper use of the controls, battery management, and pre-operational checks. I’ve also worked with powered pallet jacks that include features like weight scales and load indicators which improve accuracy and efficiency in inventory management. For example, in my previous role at Acme Warehouse, I was responsible for moving over 500 pallets daily using a mix of these jack types. Mastering each type allowed me to optimize my workflow and meet the daily demands of the warehouse.

Q 23. How do you prioritize tasks in a fast-paced warehouse environment?

In a fast-paced warehouse, prioritization is key. My approach is based on a combination of urgency and importance. I use a system similar to a Kanban board, mentally prioritizing tasks based on due dates, delivery deadlines, and order fulfillment requirements. For example, I’d always prioritize urgent orders marked ‘rush’ or those needed for immediate shipment. If multiple high-priority tasks are concurrent, I assess which one has the most significant impact on the overall warehouse operations. This usually involves assessing which task’s delay would cause the biggest bottleneck downstream. Furthermore, I consistently communicate with my team and supervisors to ensure I’m tackling the right tasks in the correct sequence. This proactive communication prevents errors and ensures smooth workflow. I also aim for a flow state, where I complete tasks in sequence in an optimized and efficient way.

Q 24. Describe your experience working with a team in a warehouse setting.

Teamwork is crucial in a warehouse environment. In my previous roles, I’ve always worked collaboratively with other operators, order pickers, and shipping clerks. For instance, during peak season, we relied heavily on effective communication to keep the operation running smoothly. I’ve actively participated in cross-training colleagues, sharing best practices, and assisting those who were struggling. This collaboration minimizes downtime and maximizes efficiency. Moreover, I’ve worked on several projects that required collaboration between different teams; these involved open and clear communication to ensure a unified effort and the efficient completion of the project. This improved the overall performance of the entire warehouse.

Q 25. How do you handle difficult or demanding customers or supervisors?

Handling difficult customers or supervisors requires a calm, professional approach. I focus on active listening, understanding their concerns, and providing solutions where possible. For example, if a customer is upset about a delayed order, I empathize with their frustration and explain the situation clearly and concisely. I try to find common ground and present potential solutions, keeping my tone polite and respectful throughout. If a supervisor is demanding, I clarify their requests to ensure complete understanding and deliver to their expectations. I believe in proactive communication; I proactively address potential issues before they escalate, and I also don’t hesitate to ask for clarification or support when needed.

Q 26. What are your strengths and weaknesses as an industrial truck operator?

My strengths as an industrial truck operator include my safety record, efficiency, and ability to work effectively both independently and as part of a team. I am also highly adaptable and proficient in operating various types of equipment. I consistently meet, and often exceed, daily productivity targets. My weakness, if I had to identify one, is perhaps my tendency to be a bit of a perfectionist. I always strive for accuracy and efficiency, which sometimes means taking slightly longer to complete a task than necessary. However, I’m working on balancing my attention to detail with time management skills through various techniques like time blocking and prioritization.

Q 27. What are your salary expectations?

My salary expectations are in line with the industry standard for experienced industrial truck operators in this region, considering my skills, experience, and proven track record of consistent high performance. I am open to discussing a competitive compensation package that reflects my value and contributions to your company.

Q 28. Do you have any questions for me?

Yes, I have a few questions. First, can you describe the typical day-to-day responsibilities of this position? Second, what opportunities for professional development are available within the company? Finally, what are the company’s safety procedures and training programs for industrial truck operators?

Key Topics to Learn for Industrial Truck Operation Interview

- Safe Operating Procedures: Understanding and applying all relevant safety regulations, pre-operation checks, and emergency procedures for various industrial truck types.

- Truck Operation Techniques: Mastering maneuvering skills in different environments (narrow aisles, loading docks, uneven terrain), efficient load handling, and understanding load capacity limitations.

- Types of Industrial Trucks: Familiarizing yourself with the operational characteristics and safety features of different truck types (forklifts, pallet jacks, reach trucks, order pickers etc.) and their appropriate applications.

- Preventive Maintenance: Knowledge of basic preventative maintenance tasks, recognizing potential mechanical issues, and reporting any malfunctions promptly.

- Load Stability and Securing: Understanding principles of load stability, proper load securing techniques to prevent accidents, and recognizing unsafe load configurations.

- Warehouse/Yard Layout and Navigation: Efficient and safe navigation within warehouse or yard environments, understanding traffic patterns and pedestrian safety protocols.

- Refueling and Battery Charging (where applicable): Safe procedures for refueling propane/gas trucks or charging electric batteries.

- Regulations and Compliance: Awareness of OSHA regulations and company-specific safety policies related to industrial truck operation.

- Problem-solving and Troubleshooting: Demonstrating the ability to identify and address minor operational issues and when to escalate more serious problems.

- Communication and Teamwork: Highlighting your ability to communicate effectively with supervisors, colleagues, and other warehouse personnel.

Next Steps

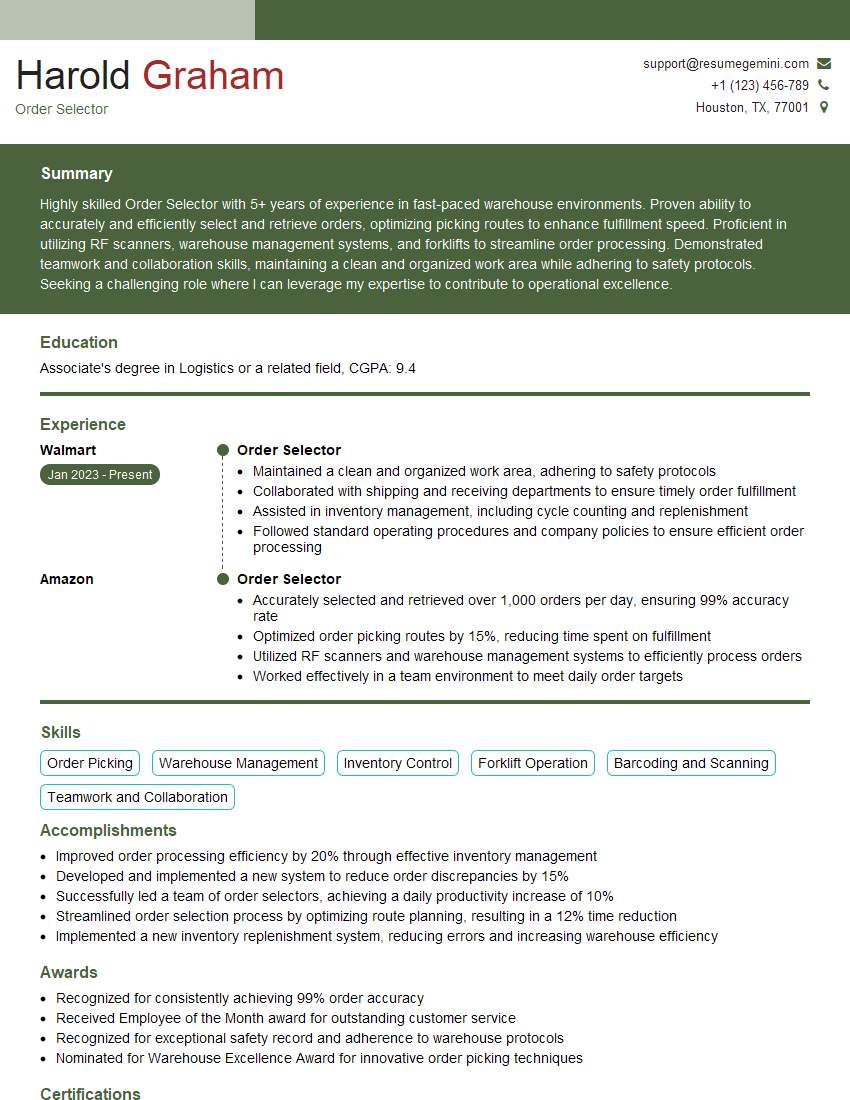

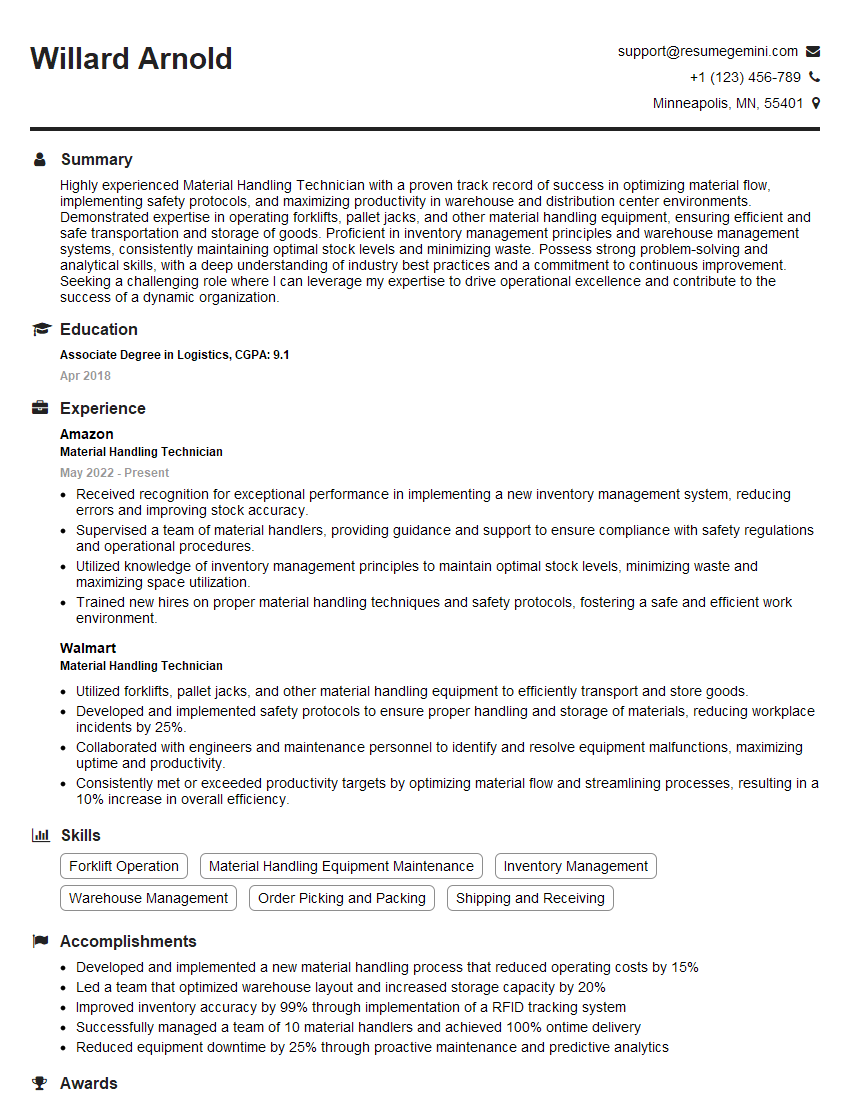

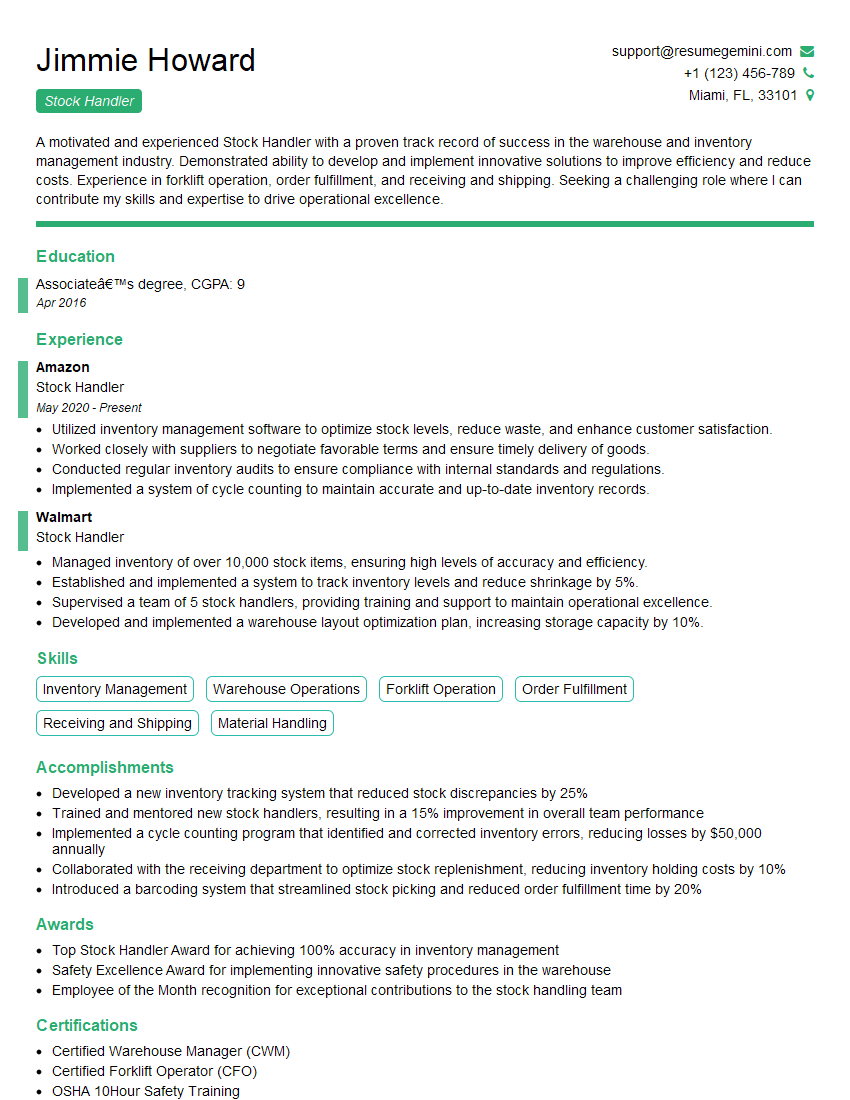

Mastering industrial truck operation opens doors to rewarding careers in logistics, warehousing, and manufacturing, offering opportunities for advancement and increased earning potential. A strong resume is crucial for showcasing your skills and experience to potential employers. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional, impactful resume that highlights your abilities. Examples of resumes tailored to Industrial Truck Operation are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO