Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Inspect and Document Equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Inspect and Document Equipment Interview

Q 1. Explain your experience with different types of inspection methods (visual, dimensional, functional).

Inspection methods are crucial for ensuring equipment reliability and safety. I’m experienced in three primary types: visual, dimensional, and functional inspections.

- Visual Inspection: This is the most fundamental method, involving a thorough visual examination of the equipment for any signs of damage, wear, corrosion, leaks, or misalignment. Think of it like a doctor’s initial assessment – looking for obvious problems. For example, checking for cracks on a pressure vessel or frayed wires on a machine.

- Dimensional Inspection: This method uses precision measuring tools to verify that the equipment’s dimensions conform to the manufacturer’s specifications. This is crucial for ensuring proper fit and function. Examples include using calipers to measure the diameter of a shaft or a micrometer to check the thickness of a plate. Deviations from specifications could indicate wear or damage requiring attention.

- Functional Inspection: This involves testing the equipment’s operational capabilities to confirm it performs as intended. This could involve anything from checking the pressure of a hydraulic system to testing the accuracy of a sensor. For instance, verifying the temperature readings of a thermostat or confirming the speed and torque of a motor.

My experience encompasses a wide range of equipment, from simple hand tools to complex machinery, requiring me to adapt my inspection approach to the specifics of each item. I often combine these methods for a comprehensive assessment. For instance, a visual inspection might reveal surface corrosion on a pump, followed by dimensional checks to measure the extent of material loss and a functional test to assess performance degradation.

Q 2. Describe your proficiency in using various inspection tools (calipers, micrometers, boroscopes).

I’m proficient in using a variety of inspection tools, and my skill level is regularly calibrated and validated. My experience includes:

- Calipers: I utilize both vernier and digital calipers for accurate measurements of linear dimensions, inside and outside diameters, and depths. I’m adept at selecting the appropriate caliper based on the measurement required and ensuring zero error before each measurement.

- Micrometers: I use micrometers for precise measurements with very high accuracy, often down to micrometers (millionths of a meter). I understand the importance of proper handling and maintaining a light, consistent touch to avoid measurement errors.

- Boroscopes: I utilize boroscopes for visual inspection of internal components and hard-to-reach areas, providing detailed observations of things like internal corrosion or cracks that would be impossible to see otherwise. I am familiar with both rigid and flexible boroscopes and their appropriate applications.

Beyond these, I’m also experienced with other specialized tools such as dial indicators, pressure gauges, and multimeters, depending on the specific equipment and inspection requirements. I’m meticulous in the calibration and maintenance of all tools, ensuring accurate and reliable readings in each inspection.

Q 3. How do you ensure accuracy and consistency in your equipment inspections?

Accuracy and consistency are paramount in equipment inspections. I employ several strategies to ensure these qualities:

- Calibration of Tools: All measuring instruments are regularly calibrated against traceable standards to maintain accuracy. I meticulously document calibration dates and results.

- Standard Operating Procedures (SOPs): I strictly adhere to pre-defined SOPs for each inspection, ensuring consistent procedures are followed regardless of the inspector.

- Checklists: I use detailed checklists to guide the inspection process, preventing omissions and ensuring complete coverage. Checklists are customized to suit the specific type of equipment.

- Multiple Measurements: I perform multiple measurements for critical dimensions and record all readings. This provides statistical data to validate accuracy and identify potential outliers.

- Documentation: Thorough and accurate documentation is essential. I record all observations, measurements, and test results meticulously. This ensures traceability and allows for analysis of trends over time.

Furthermore, regular internal audits of my inspection procedures help to identify areas for improvement and maintain a high standard of quality.

Q 4. What documentation standards are you familiar with (e.g., ISO 9001, GMP)?

My experience includes working within the frameworks of several documentation standards. I’m very familiar with:

- ISO 9001: I understand the requirements for quality management systems, focusing on consistent inspection practices, documentation control, and corrective actions for non-conformances.

- GMP (Good Manufacturing Practices): I’m versed in GMP regulations for industries like pharmaceuticals and food processing, understanding the need for meticulous documentation to ensure product safety and compliance.

Other standards I have worked with include OSHA (Occupational Safety and Health Administration) guidelines for workplace safety and specific industry standards relevant to the type of equipment inspected.

Q 5. How do you handle discrepancies or non-conformances found during inspections?

When discrepancies or non-conformances are identified, a structured approach is crucial:

- Immediate Reporting: I immediately report all findings to the appropriate personnel, escalating critical issues to management immediately.

- Detailed Documentation: I clearly document the nature of the discrepancy, including location, severity, and supporting evidence (photos, measurements). Using clear, concise language avoids ambiguity.

- Root Cause Analysis: I help identify the underlying cause of the non-conformity. This might involve collaborating with maintenance personnel or engineers.

- Corrective Actions: I participate in developing and implementing corrective actions to address the identified problems and prevent recurrence. This may include recommending repairs, replacements, or procedural changes.

- Verification: Once corrective actions are implemented, I verify their effectiveness through re-inspection.

A well-documented process ensures accountability and prevents similar issues from reoccurring. Following the documented procedures and adhering to company protocols is crucial throughout this process.

Q 6. Describe your experience with creating and maintaining equipment inspection reports.

Creating and maintaining equipment inspection reports is a critical part of my role. My reports are comprehensive, clear, and easy to understand. They typically include:

- Equipment Identification: A clear and unambiguous identification of the inspected equipment (serial number, location, etc.).

- Inspection Date and Time: Accurate recording of when the inspection was performed.

- Inspection Method: A description of the inspection methods used (visual, dimensional, functional).

- Observations: A detailed description of all observations, including any discrepancies or non-conformances, with supporting photographic evidence.

- Measurements: Accurate recording of all measurements taken, clearly indicating units.

- Test Results: Record of any functional tests performed and their results.

- Recommendations: Suggestions for corrective actions or maintenance required.

- Inspector’s Signature and Date: Verification of the inspection.

I use a variety of reporting tools, from simple spreadsheets to specialized software, depending on the complexity and requirements. The reports are consistently formatted and easy to interpret to ensure effective communication of inspection findings. The aim is for the report to be easily understood by both technical and non-technical personnel.

Q 7. Explain your process for identifying and mitigating potential equipment hazards.

Identifying and mitigating potential equipment hazards is a critical aspect of my work. My process typically involves:

- Hazard Identification: This is done through a systematic review of the equipment, considering potential failure modes, energy sources, and operating conditions. I use various techniques including checklists, hazard and operability studies (HAZOPs), and risk assessments.

- Risk Assessment: Once potential hazards are identified, I assess their likelihood and severity to determine the overall risk level. This assessment often considers factors like frequency of exposure, potential consequences, and the effectiveness of existing safeguards.

- Mitigation Strategies: Based on the risk assessment, I recommend appropriate mitigation strategies. These strategies could include engineering controls (guards, interlocks), administrative controls (procedures, training), or personal protective equipment (PPE).

- Implementation and Verification: I ensure that the recommended mitigation strategies are effectively implemented and verified through follow-up inspections. Documentation of all mitigation actions and their effectiveness is essential.

A proactive approach to hazard identification and mitigation is crucial for preventing accidents and ensuring a safe working environment. My experience in various industrial settings allows me to anticipate potential hazards and develop comprehensive mitigation plans.

Q 8. How do you prioritize inspection tasks based on equipment criticality and risk?

Prioritizing inspection tasks hinges on a risk-based approach, combining equipment criticality and potential consequences of failure. We use a scoring system, often a matrix, that considers factors like safety implications, production impact, and environmental risks. For instance, a critical piece of machinery on a production line with a high failure probability (leading to significant downtime) would score much higher than a less crucial piece with a low failure rate.

- Criticality: This considers the equipment’s role in the overall process. Is it essential for production, safety, or environmental compliance? A vital component gets higher priority.

- Risk: This assesses the likelihood and severity of failure. We consider factors like age, operating conditions, past maintenance records, and manufacturer recommendations. Equipment showing signs of wear or operating beyond its design parameters gets higher priority.

- Consequences: What are the potential consequences of failure? Consider downtime costs, safety hazards, environmental damage, or reputational harm. Higher potential consequences lead to higher priority.

This matrix allows us to objectively rank inspection tasks, ensuring that the most critical equipment receives the most frequent and thorough inspections. We regularly review and adjust the matrix based on changes in operations, equipment performance, and risk assessments.

Q 9. What software or systems have you used for managing inspection data?

I’ve extensively used Computerized Maintenance Management Systems (CMMS) like IBM Maximo and SAP PM. These systems are crucial for managing inspection data effectively. They allow for scheduling inspections, recording findings, generating reports, and tracking corrective actions. I’m also proficient with more specialized software for specific equipment, such as software integrated with vibration analysis systems for predictive maintenance.

For example, in a previous role, we used Maximo to schedule and track inspections of critical pumps in a chemical processing plant. The system automated the generation of inspection reports, alerts for overdue inspections, and integration with our maintenance work orders. This ensured a smooth workflow and comprehensive records management.

Beyond CMMS, I’m also comfortable using spreadsheets and databases to manage inspection data when a full-fledged CMMS isn’t available. However, I always advocate for a structured system to ensure data integrity and efficient reporting.

Q 10. How familiar are you with preventive maintenance schedules and their relation to inspections?

Preventive maintenance (PM) schedules are intrinsically linked to inspections. Inspections inform the PM schedule, and the PM schedule dictates the frequency and scope of inspections. Regular inspections reveal potential problems before they escalate into major failures, ensuring that the PM schedule addresses these emerging issues effectively.

Think of it like a car’s maintenance schedule. Regular inspections (like checking oil levels and tire pressure) reveal potential issues (low oil, worn tires). This information then informs the PM schedule (oil change, tire rotation). Ignoring these inspections can lead to unexpected failures (engine damage, flat tire), far exceeding the cost of preventative maintenance.

In practice, I use inspection data to fine-tune PM schedules. For example, if an inspection reveals a particular component consistently showing wear beyond expectations, we might adjust the PM schedule to include more frequent inspections or replacement of that component.

Q 11. Describe your experience with root cause analysis for equipment failures.

Root cause analysis (RCA) is fundamental to preventing equipment failures. I’m experienced using various RCA methodologies, including the ‘5 Whys’ technique, fault tree analysis (FTA), and fishbone diagrams (Ishikawa diagrams). The goal isn’t simply to fix the immediate problem but to identify the underlying cause to prevent recurrence.

For example, if a pump fails, the ‘5 Whys’ approach might unfold as follows:

1. Why did the pump fail? – Because the bearings seized.

2. Why did the bearings seize? – Because of insufficient lubrication.

3. Why was there insufficient lubrication? – Because the lubrication system was clogged.

4. Why was the lubrication system clogged? – Because of inadequate filtration.

5. Why was the filtration inadequate? – Because the filter wasn’t replaced according to the PM schedule.

This reveals the root cause: failure to adhere to the PM schedule. Addressing this systemic issue, rather than just replacing the bearings, prevents future pump failures.

Q 12. Explain how you ensure the integrity of inspection records and data.

Ensuring inspection record integrity is paramount. This involves several key steps:

- Clear Procedures: We have documented procedures for conducting inspections, including checklists, data recording methods, and photographic evidence.

- Trained Personnel: Inspectors receive thorough training on proper inspection techniques and documentation procedures.

- Data Validation: Inspection data is reviewed and validated by a supervisor to identify and correct any inconsistencies or errors.

- Version Control: We use software systems (like CMMS) that allow for version control of inspection reports, preventing unauthorized changes.

- Secure Storage: Inspection records are stored securely, both physically and digitally, with appropriate access controls to prevent unauthorized access or modification.

- Auditing: Regular audits ensure adherence to procedures and data integrity. This involves reviewing a sample of inspection reports and comparing them to the equipment’s actual condition.

By implementing these measures, we ensure the accuracy and reliability of our inspection data, which is critical for informed decision-making regarding maintenance and repairs.

Q 13. How do you communicate inspection findings to different stakeholders (e.g., management, technicians)?

Communication of inspection findings is crucial. I tailor my communication style to the audience:

- Management: I provide concise summaries focusing on high-level risks, potential downtime, and cost implications. I use dashboards and visual reports to highlight key issues.

- Technicians: I provide detailed reports outlining specific findings, including photographic evidence and recommendations for corrective actions. The reports are clear, actionable, and use terminology technicians understand.

I also utilize regular meetings and briefings to discuss critical findings and address any questions or concerns. Proactive communication prevents misunderstandings and ensures everyone is on the same page. For example, I’ve presented findings in management meetings using concise PowerPoint slides, while providing detailed reports to technicians for corrective work.

Q 14. Describe your experience with equipment calibration procedures and documentation.

Equipment calibration is vital for ensuring accurate and reliable measurements. I’m familiar with various calibration procedures and documentation methods. This includes understanding the calibration intervals specified by manufacturers, maintaining calibration certificates, and using calibrated instruments.

The process usually involves comparing the equipment’s readings to a known standard. Any discrepancies are documented, and adjustments or repairs are made to bring the equipment within acceptable tolerances. I ensure all calibration activities are documented thoroughly, including the date, standard used, results, and any corrective actions taken. This documentation forms an essential part of our quality control and compliance programs.

Failure to properly calibrate equipment can lead to inaccurate measurements, impacting the reliability of inspections and potentially leading to incorrect maintenance decisions. A well-maintained calibration program ensures that our inspections are accurate and reliable.

Q 15. How do you manage your workload effectively during periods of high inspection volume?

Managing a high volume of inspections requires a structured approach. I prioritize tasks using a system that combines urgency and importance. This often involves a combination of tools like a prioritized task list and a detailed schedule. I break down large inspections into smaller, manageable chunks, focusing on completing one segment before moving to the next. This prevents feeling overwhelmed and ensures thoroughness. For example, if I have five large pieces of equipment to inspect, I’ll allocate specific time slots for each, focusing on key areas in each slot to stay on track. I also leverage technology; using scheduling software helps visualize the workload and identify potential bottlenecks. Finally, if absolutely necessary, I will communicate with my supervisor about the increased workload and explore options for prioritization or resource allocation, such as delegating less urgent tasks or requesting additional support.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What safety procedures do you follow when inspecting equipment?

Safety is paramount during equipment inspections. My procedures always begin with a thorough site-specific risk assessment. This involves identifying potential hazards, like energized electrical components, moving parts, or hazardous materials. I always use the appropriate personal protective equipment (PPE), including safety glasses, gloves, hard hats, and safety shoes, as required by the specific inspection. Lockout/Tagout (LOTO) procedures are followed diligently before inspecting any equipment with the potential for unexpected energy release. I maintain a clear communication line with my team and site personnel, keeping everyone informed of my location and activities. Additionally, I regularly review the equipment’s operational and safety manuals to stay updated on potential hazards and safe operating procedures. Documentation of all safety measures taken is meticulously maintained in my inspection reports.

Q 17. How do you stay up-to-date with changes in industry standards and best practices for inspections?

Staying current with industry standards and best practices is crucial. I actively participate in professional development activities, including attending conferences and workshops. I subscribe to industry publications and online resources, such as those published by relevant professional organizations (e.g., ASME, API). I regularly review updated codes and standards, like those from OSHA and relevant national or international bodies. I also actively seek mentorship from experienced colleagues and experts in the field, engaging in discussions and knowledge sharing. Moreover, I continuously review and update my own inspection checklists and procedures, ensuring they are in alignment with the latest standards and best practices. Finally, I actively seek out and participate in training courses that cover new technologies, methodologies, and updated regulations to refine my skills.

Q 18. Describe a situation where you had to adapt your inspection methods due to unexpected circumstances.

During an inspection of a large industrial boiler, we encountered unexpected damage to a critical component which made using our standard procedures impossible. The damage was extensive and made safe access to certain areas difficult. Instead of proceeding as planned, we adapted our methodology. We used remote inspection technology, such as drones with high-resolution cameras and thermal imaging capabilities, to assess the damage from a safe distance. We also employed specialized robotic inspection tools to gather detailed images and data from otherwise inaccessible areas. This allowed us to safely and thoroughly document the damage extent, ensuring the safety of the inspection team, while still delivering comprehensive results to inform repair decisions. The use of these alternative methods proved highly efficient and ensured the integrity of the inspection.

Q 19. How do you handle situations where you disagree with a supervisor’s assessment of an inspection finding?

Professional disagreement requires a respectful and constructive approach. I would first gather all relevant data and documentation to support my assessment, including photos, measurements, and any reference materials. I would then schedule a private meeting with my supervisor to discuss the discrepancy. I would clearly and calmly explain my findings, highlighting the evidence that supports my assessment. I would actively listen to their perspective and acknowledge their expertise while respectfully explaining my reasoning and the basis for my conclusions. The goal is not to win an argument but to reach a shared understanding and consensus on the most appropriate course of action, ensuring the safety and efficiency of the equipment’s operation. If the disagreement persists, I would document everything meticulously and escalate the issue through the appropriate channels within the company’s organizational structure, adhering to established protocol.

Q 20. Explain your experience with working in a team environment during equipment inspections.

Teamwork is essential during equipment inspections, particularly with complex machinery. I’ve been part of teams ranging from two to ten individuals, with various skill sets. My role often involves coordinating the team, assigning tasks based on individual strengths and expertise, and ensuring consistent data collection methodologies. Effective communication is key; I rely on regular briefings, shared documentation, and open discussions to maintain clarity and address any challenges. I actively participate in discussions, contributing my knowledge and offering support to my teammates. A successful inspection is the product of collaborative effort, where each member contributes towards a common goal of delivering a thorough and accurate report. For example, in a recent inspection of a refinery, one team member was specializing in electrical systems, while another focused on mechanical systems. Our close collaboration enabled a comprehensive assessment, capturing potential issues across different equipment aspects.

Q 21. How do you prioritize repairs and maintenance based on your inspection findings?

Prioritizing repairs and maintenance is based on a risk assessment framework. I utilize a system that considers several factors: the severity of the identified defect, the potential consequences of failure (safety risks, production downtime, environmental impact), and the cost of repair or replacement. I generally use a matrix system to categorize findings based on these parameters. Critical safety issues receive the highest priority; these require immediate attention to prevent accidents. Equipment malfunctions impacting production efficiency also receive high priority as they can lead to significant financial losses. The matrix allows me to clearly communicate the urgency and importance of each item to the maintenance team, enabling efficient allocation of resources. Minor defects, that don’t pose immediate risks, can be scheduled for maintenance during planned downtime. This framework ensures that resources are allocated effectively to address the most critical issues first while maintaining a planned approach to overall equipment maintenance.

Q 22. Describe your experience using digital inspection tools and software.

My experience with digital inspection tools and software is extensive. I’m proficient in using various applications, from simple mobile apps for capturing images and videos with integrated annotation features, to sophisticated software packages for 3D modeling and advanced data analysis. For instance, I’ve used Fluke Connect to remotely monitor equipment readings and create reports, and AssetWise APM for managing asset information and integrating inspection data. These tools significantly improve efficiency by automating data collection, reducing manual errors, and enhancing data accessibility. For example, using a thermal imaging camera integrated with software allows for the quick identification of overheating components, something that would take significantly longer using traditional methods. I’m also comfortable using cloud-based platforms for secure data storage and collaboration.

In one project involving a large industrial plant, we transitioned from paper-based inspection reports to a digital system. This drastically improved reporting turnaround time, allowing for quicker identification and resolution of potential issues. The centralized database also facilitated better trend analysis, allowing us to proactively address recurring problems.

Q 23. How do you ensure the confidentiality and security of inspection data?

Confidentiality and security of inspection data are paramount. I adhere to strict protocols to ensure compliance with relevant regulations and company policies. This includes using secure data storage solutions, access control measures (role-based access), and robust encryption techniques for data both in transit and at rest. For example, I utilize cloud storage solutions with encryption at rest and in transit, such as AWS S3 with server-side encryption. Furthermore, all digital inspection records are password-protected and only accessible to authorized personnel. I also implement version control to track changes and prevent unauthorized modifications. Regular security audits and employee training on data security best practices are crucial for maintaining a secure environment.

In a project involving sensitive equipment for a pharmaceutical company, we had to ensure compliance with strict FDA regulations. By implementing multi-factor authentication, encrypted storage, and detailed audit trails, we ensured the integrity and confidentiality of all inspection data.

Q 24. Explain your experience with different types of equipment documentation (e.g., drawings, manuals, schematics).

My experience encompasses a wide range of equipment documentation, including mechanical drawings, electrical schematics, pneumatic diagrams, hydraulic schematics, operational manuals, parts lists, and maintenance logs. I can interpret and utilize these documents effectively to understand the equipment’s function, identify components, and trace the flow of energy or fluids. I’m familiar with various CAD software packages, including AutoCAD and SolidWorks, and can use them to review and annotate drawings. Understanding the interrelationship between these different documents is critical for comprehensive equipment evaluation. For example, comparing a piping and instrumentation diagram (P&ID) with the actual piping layout during an inspection can reveal discrepancies and potential hazards.

In a recent project involving a legacy manufacturing system, I had to rely heavily on outdated schematics and manuals. By carefully cross-referencing information across different documents, I could accurately identify and assess the condition of the system’s components, allowing for effective maintenance planning.

Q 25. How do you interpret and apply technical specifications during inspections?

Interpreting and applying technical specifications is fundamental to my work. I meticulously review specifications to understand the design parameters, performance criteria, and safety requirements for each piece of equipment. This involves deciphering technical jargon, interpreting drawings and diagrams, and understanding the implications of deviations from the specifications. During inspections, I meticulously compare the equipment’s actual condition against the stated specifications, noting any discrepancies and assessing their potential impact. This involves using precision measuring instruments and test equipment to verify parameters such as dimensions, tolerances, and performance metrics.

For example, during an inspection of a high-pressure valve, I would carefully examine the valve’s specifications for pressure rating, temperature limits, and material composition. Then, using appropriate testing equipment, I’d verify that the actual valve parameters meet the specifications. Any deviations would be carefully documented and assessed for their safety implications.

Q 26. Describe your experience with conducting inspections in different environments (e.g., industrial, manufacturing, field).

I have extensive experience conducting inspections in diverse environments, including industrial plants, manufacturing facilities, offshore platforms, and field operations. Adapting to different environments requires awareness of safety regulations, environmental conditions, and unique operational challenges. In industrial plants, for example, I would need to be familiar with lockout/tagout procedures and personal protective equipment (PPE) requirements. In field operations, weather conditions and remote locations might pose additional challenges. My experience includes working with various types of equipment, from complex machinery in manufacturing settings to simpler equipment used in field operations. I’m adept at adapting my inspection methods and reporting to suit the specifics of each environment.

One memorable project involved conducting inspections on offshore oil rigs. I had to adapt to the challenging environmental conditions and strict safety protocols, and I employed specialized tools and techniques to accurately assess the equipment in a potentially hazardous setting.

Q 27. How do you manage your time effectively during inspections to ensure efficiency?

Effective time management during inspections is crucial. I employ a structured approach that includes pre-inspection planning, prioritizing tasks based on risk assessment, and utilizing efficient inspection techniques. This involves creating a detailed inspection checklist tailored to the specific equipment and adhering to a schedule. I also leverage digital tools to streamline data collection and reporting, minimizing paperwork and maximizing time spent on actual inspections. Prioritizing critical components based on their impact on overall system performance and safety helps focus efforts where they are most needed. Regular breaks to prevent fatigue are also important for maintaining focus and ensuring accuracy.

In a recent inspection, I used a pre-defined checklist and digital reporting system that reduced the inspection time by approximately 30%, allowing for more efficient use of my time and resources.

Q 28. How familiar are you with using CMMS (Computerized Maintenance Management System) software for inspections and maintenance tracking?

I am highly familiar with CMMS software, having used several systems such as IBM Maximo, SAP PM, and Fiix. I understand how to input inspection data into the system, generate reports, and track maintenance activities. CMMS software is invaluable for managing maintenance schedules, tracking equipment history, and predicting potential failures. I can use the data generated by the CMMS system to improve the efficiency of inspection planning and to identify trends that might indicate recurring problems or potential equipment failures. Integrating inspection data with CMMS ensures a complete and easily accessible record of equipment maintenance history.

In a previous role, we implemented a new CMMS system that drastically improved our ability to manage maintenance and track equipment performance. This led to significant cost savings and improved equipment reliability.

Key Topics to Learn for Inspect and Document Equipment Interview

- Equipment Functionality: Understanding the operational principles of various equipment types. This includes knowing how they work, their limitations, and common malfunctions.

- Inspection Techniques: Mastering visual inspection methods, utilizing appropriate tools (e.g., calipers, multimeters), and applying safety procedures during inspections.

- Documentation Standards: Familiarity with industry-standard documentation formats, including creating accurate and detailed reports, using checklists, and adhering to regulatory compliance.

- Data Analysis & Reporting: Interpreting inspection data, identifying trends, and effectively communicating findings through clear and concise reports. This includes using data to support maintenance decisions.

- Preventive Maintenance: Understanding the principles of preventative maintenance and how thorough inspection contributes to equipment longevity and reduced downtime.

- Troubleshooting & Problem Solving: Developing systematic approaches to identify equipment issues, analyze root causes, and propose effective solutions based on inspection findings.

- Safety Regulations & Compliance: Knowledge of relevant safety regulations and best practices related to equipment inspection and maintenance.

- Software & Technology: Familiarity with any relevant software used for equipment documentation, data analysis, or maintenance scheduling.

Next Steps

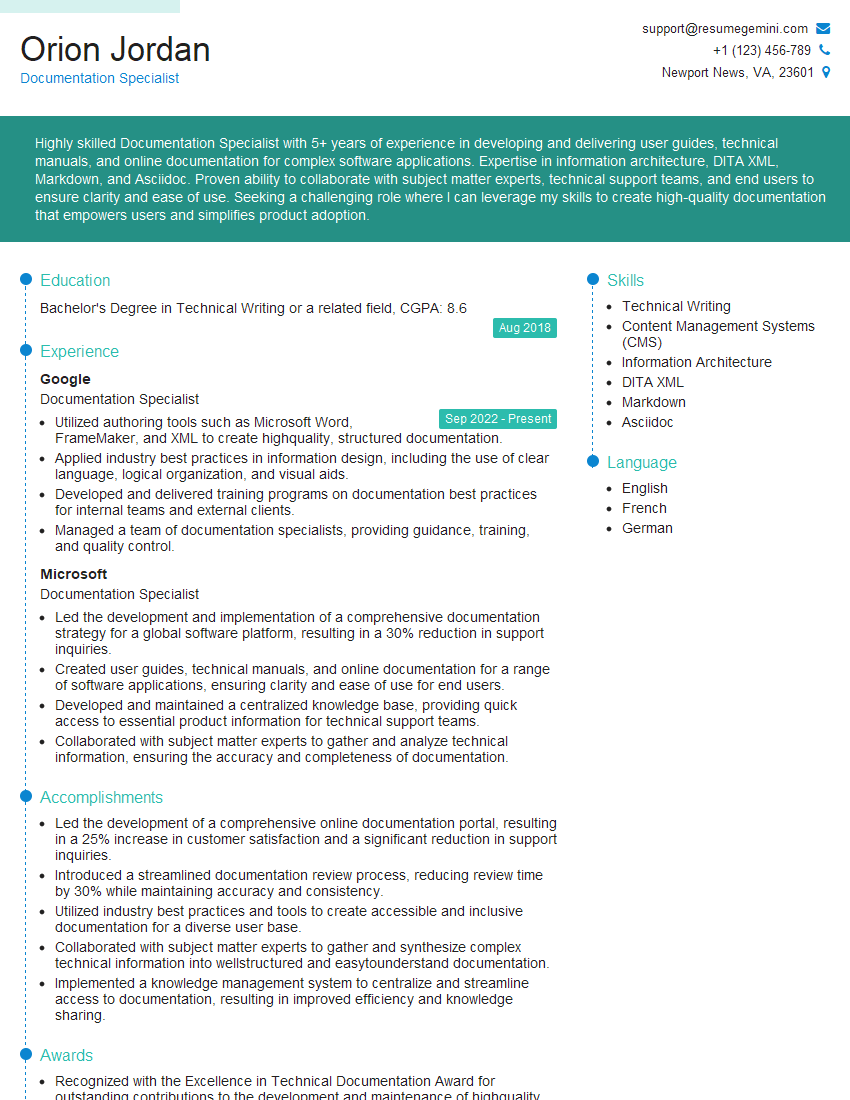

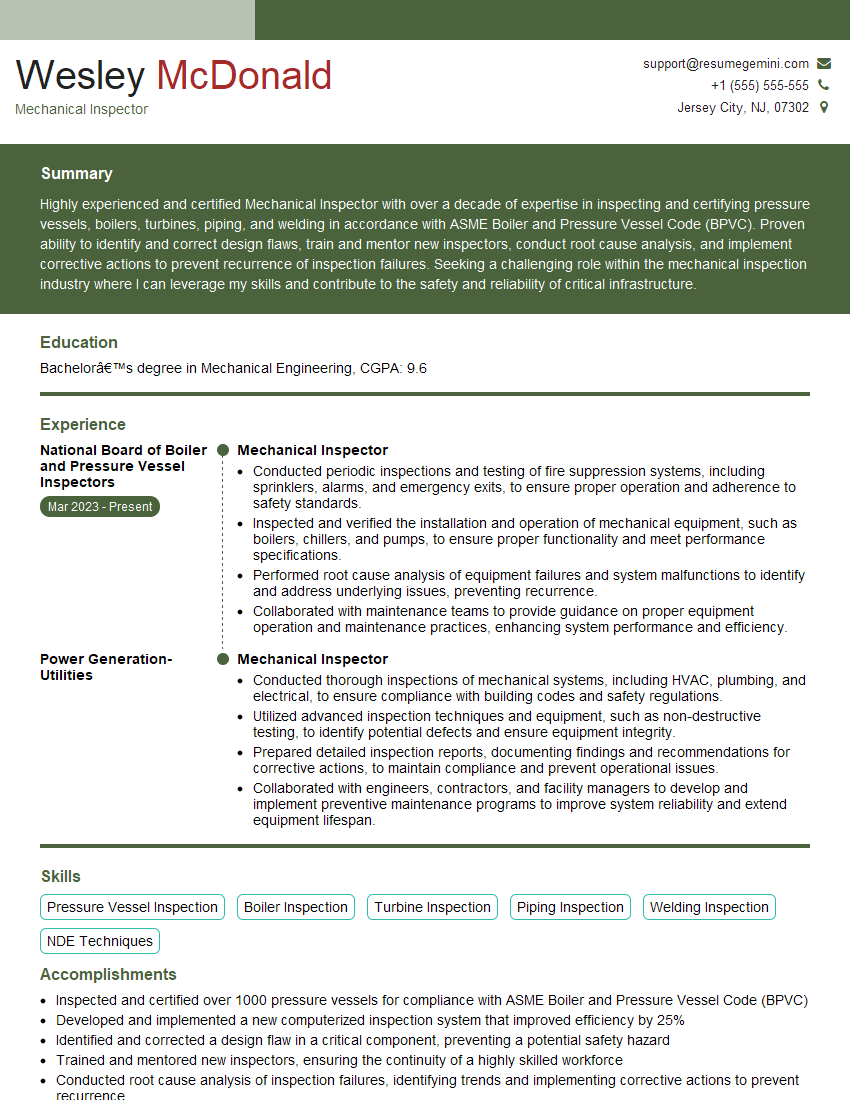

Mastering the skills of inspecting and documenting equipment is crucial for career advancement in many technical fields. A strong understanding of these processes demonstrates reliability, attention to detail, and a commitment to safety – qualities highly valued by employers. To significantly improve your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to the Inspect and Document Equipment field are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO