Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Inspecting and sorting paper interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Inspecting and sorting paper Interview

Q 1. Describe your experience identifying different paper grades.

Identifying paper grades involves a keen eye and understanding of paper properties. It’s much like a wine tasting, but instead of aroma and taste, we focus on texture, weight, and visual characteristics. I’ve spent years honing this skill, starting with basic grades like bond (for printing), cover (for brochures), and newsprint (for newspapers), and progressing to more specialized types like cardstock and specialty papers with unique finishes.

For instance, I can distinguish between a high-quality coated paper, often used for glossy magazines, and an uncoated paper, typically found in textbooks, by simply feeling its surface. Coated paper is smooth and almost slick, while uncoated paper has a more porous feel. Similarly, I can identify the weight by holding a sheet – heavier weight feels substantial, while lighter weight feels flimsy. The visual inspection includes checking for brightness, opacity (how much light passes through), and any imperfections in the paper’s formation.

- Brightness: Measured using a brightness meter, it indicates how white or reflective the paper is.

- Opacity: This refers to the ability of the paper to prevent light from passing through it. It’s a crucial factor for double-sided printing.

- Formation: This refers to the uniformity of the paper’s structure; uneven formation can indicate inconsistencies in the manufacturing process.

Over time, I’ve developed a visual library of different paper grades, making identification quick and accurate. My experience also allows me to identify paper grades by their watermark, if present, which is a unique identifying feature embedded during manufacturing.

Q 2. How do you detect subtle variations in paper color or texture?

Detecting subtle variations in paper color or texture relies on a combination of visual acuity and tactile sensitivity, much like a skilled painter noticing slight differences in shades of paint. For color, I use consistent lighting conditions and compare samples side-by-side, paying attention to undertones (a hint of blue, yellow, etc.) that might be otherwise missed. I often use a calibrated light source to mitigate the effect of ambient lighting variations. For texture, I gently rub the paper between my fingers and thumb, feeling for differences in smoothness, roughness, or grain. This tactile examination is crucial for identifying inconsistencies, such as subtle variations in surface coating or texture that might not be immediately visible to the naked eye.

Think of it like comparing two seemingly identical pieces of fabric. While they might look similar at first glance, a closer inspection reveals one to have a slightly tighter weave or a softer hand. Similarly, I can detect subtle differences in paper texture that indicate variances in the manufacturing process or raw materials used. Using tools like a magnifying glass can further assist in identifying microscopic imperfections that may alter the surface texture and hence the feel.

Q 3. Explain your process for sorting damaged or defective paper.

Sorting damaged or defective paper is a systematic process that prioritizes efficient segregation and minimizes waste. The first step involves a visual inspection to identify the type and extent of damage. Common defects include creases, tears, holes, discoloration, and stains. Once identified, I then sort the paper into different categories based on the severity of the damage.

For example, papers with minor creases might be separated from those with significant tears. Papers with significant defects, such as large holes or extensive discoloration, might be discarded or recycled. This careful sorting allows for the reuse of less-damaged sheets, potentially for internal use or repurposing. We might utilize lightly creased sheets for internal printing drafts or cut them down to salvage usable portions. The systematic categorization allows for better tracking of waste generation, which is crucial for cost-effectiveness and environmental sustainability. It also involves understanding the recycling guidelines of the facility and adhering to those regulations strictly.

The process often involves using specialized tools like air blowers for removing smaller debris or paper sorting machines which can efficiently scan and sort papers based on pre-programmed defect criteria. This automated process ensures that high volumes can be handled quickly and accurately. The exact method of sorting depends on the specific nature and quantity of the damaged paper and the available resources.

Q 4. What are common defects found in paper during inspection?

Common paper defects encountered during inspection vary depending on the manufacturing process and handling. Some of the most frequently found defects include:

- Creases and wrinkles: These can result from improper handling or storage.

- Tears and holes: These can occur during the manufacturing process or transportation.

- Stains and discoloration: These can be caused by spills, exposure to moisture or chemicals, or defects in the manufacturing process.

- Caliper variations: This refers to inconsistencies in the thickness of the paper. This often leads to uneven printing or feeding problems.

- Surface imperfections: These can include bumps, scratches, or other irregularities in the paper’s surface.

- Curl: This is a warping of the paper sheet.

- Dust and debris: Paper can accumulate particles during storage and transportation.

- Poor formation: As mentioned before, refers to uneven distribution of fibers in the paper leading to weakened areas.

Identifying these defects accurately requires attention to detail and a thorough understanding of how these imperfections impact the printability and usability of the paper.

Q 5. How do you ensure accuracy and consistency in your paper sorting?

Ensuring accuracy and consistency in paper sorting involves a multi-pronged approach, combining standardized procedures, regular calibration, and continuous training. We use pre-defined quality control checklists that guide inspectors in assessing paper quality based on objective criteria. These checklists cover aspects such as color uniformity, texture, weight, and the presence of defects. This reduces subjective interpretation and ensures that different inspectors adhere to the same standard.

Regular calibration of measuring instruments, such as thickness gauges and colorimeters, is essential for maintaining consistent measurements. We also conduct regular training sessions for inspectors, focusing on visual acuity, tactile sensitivity, and the interpretation of the quality control checklists. This training helps keep inspectors’ skills sharp and ensures consistency in their judgments. Finally, we implement a system of quality checks and audits to monitor the accuracy of the sorting process and identify any areas for improvement. This might involve randomly sampling sorted batches for a detailed quality inspection, ensuring the integrity of the entire process.

Q 6. How familiar are you with different paper weight measurements?

I’m very familiar with various paper weight measurements, understanding both the basic units (like pounds per ream or grams per square meter) and the implications of different weights on paper properties and intended use. Paper weight is typically expressed as either basis weight (the weight of a ream of paper of a standard size) or grammage (the weight of one square meter of paper).

Understanding these measurements is crucial because paper weight directly impacts its stiffness, opacity, and printability. For example, a heavier weight paper like 200gsm cardstock will be much sturdier than a lighter weight paper like 80gsm newsprint, hence its use for things like business cards as opposed to newspapers. My experience encompasses converting between different measurement systems, interpreting specifications from clients or manufacturers, and knowing which weight is appropriate for a given application. This involves not only understanding the numerical values but also the feel and appearance associated with different weight categories.

Q 7. What are your methods for handling large volumes of paper efficiently?

Handling large volumes of paper efficiently requires a combination of strategic organization, automation, and optimized workflow. The process begins with proper storage and handling to prevent damage and ensure easy access. This involves using appropriate shelving and racking systems, maintaining clear pathways, and ensuring adequate space for movement. Once ready for sorting, the use of automated systems is crucial. This could include conveyors, automated sorting machines that can rapidly scan and categorize paper based on pre-programmed parameters like color, thickness, or presence of defects. These machines significantly increase throughput and reduce manual labor, boosting efficiency while maintaining accuracy.

Beyond automation, workflow optimization is key. This involves organizing the sorting area logically, minimizing unnecessary movement, and ensuring that all personnel are trained in the use of equipment and standard operating procedures. Regular maintenance of the equipment is essential for ensuring smooth, continuous operation. Careful planning, including assigning specific roles and responsibilities, can reduce bottlenecks and improve overall efficiency. The goal is a streamlined operation that minimizes handling time, reduces the risk of damage, and ensures rapid, accurate processing of large volumes of paper.

Q 8. Describe a time you had to resolve a discrepancy in paper quality.

Resolving discrepancies in paper quality often involves a systematic approach. I once encountered a batch of paper where the brightness was consistently lower than the specified standard. My first step was to visually inspect a sample, confirming the dullness. Then, I used a brightness meter, a common tool in paper quality control, to quantify the discrepancy. The reading confirmed a significant deviation. I then traced the issue back to the source – a slightly different pulp mixture had been used in the manufacturing process. To resolve the issue, I collaborated with the supplier and the production team to ensure the correct pulp was used for future batches. We also established clearer quality control checkpoints during production and implemented a more stringent testing protocol, which involved measuring the brightness of smaller samples at various stages of production. This prevented similar issues from recurring.

Q 9. How would you handle a situation where a large batch of paper is contaminated?

Handling contaminated paper is crucial to prevent further problems. If a large batch is contaminated, my first action is to immediately quarantine the affected paper to prevent cross-contamination. The next step depends on the nature of the contamination. If it’s a visible contaminant like ink spills, I’d segregate the affected sheets and perhaps try to salvage usable portions (if the contamination is localized). For instance, if the contamination is only on one corner, I might be able to cut off the spoiled section. For less obvious contamination like bacterial or chemical contamination, I would involve the appropriate safety and environmental teams to handle the disposal or remediation process according to safety protocols. Thorough documentation of the event, including the type and extent of the contamination, and the steps taken, is crucial. This documentation then helps to identify the root cause and prevent similar occurrences in the future. If we can identify the source of contamination, say a leaky container, we’d address that immediately. We’d also review and strengthen our current quality control measures and establish additional checks to prevent future contamination.

Q 10. What is your experience with using automated paper sorting equipment?

I have extensive experience with automated paper sorting equipment, including high-speed sorters that use optical sensors to identify and separate paper based on color, size, and other characteristics. I’m proficient in operating and maintaining these machines, understanding their calibration processes and troubleshooting common malfunctions. For example, I’ve worked with machines that use air jets to remove defective sheets, and I’m familiar with diagnosing and rectifying issues like inaccurate ejection or sensor misalignment. I know how to interpret the data generated by these machines, which can highlight trends in paper quality or machine performance. Regular maintenance, including cleaning the sensors and checking for wear and tear, is crucial for the accuracy and efficiency of automated sorters, which are essential for high-volume paper processing. This experience has greatly improved my efficiency and allowed for the processing of significantly larger volumes of paper in a shorter time.

Q 11. How do you maintain organization and cleanliness in your workspace?

Maintaining a clean and organized workspace is paramount for efficiency and safety. I use a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to keep my area organized. This involves regularly sorting through materials, storing tools and equipment in designated places, cleaning surfaces, and ensuring that everything has its place. I label containers clearly to help with quick identification. This method promotes efficiency, reduces the risk of accidents (like tripping over misplaced items), and makes it easier to locate items quickly. I also follow strict hygiene practices, especially when handling different batches of paper or using potentially contaminating tools. Regular cleaning of equipment is crucial to prevent the transfer of contaminants between paper batches.

Q 12. Describe your experience with quality control documentation.

My experience with quality control documentation is extensive. I am proficient in using various documentation methods, from simple checklists to sophisticated databases for tracking paper quality metrics. I understand the importance of accurate and consistent record-keeping to meet regulatory compliance and company standards. For example, I meticulously document every inspection, including details such as batch numbers, date, time, type of paper, observed defects, and any corrective actions taken. This data is crucial for identifying trends and areas for improvement. Using a standardized format for documentation ensures consistency and facilitates easy data analysis, which is essential for tracking quality metrics over time and for identifying potential problems early on. I’m also familiar with different software programs used for managing quality control data, allowing me to efficiently organize and report findings.

Q 13. How do you identify and report quality issues to your supervisor?

Reporting quality issues to my supervisor is done promptly and clearly. My approach is to use a consistent reporting method, often through a documented system or log. I provide detailed information, including the specific batch number, the type of defect observed, its frequency or severity, and any potential causes I’ve identified (e.g., machine malfunction, material defect). For instance, if I notice an unusual amount of paper jams due to a sizing issue, I wouldn’t just report the jams but would also include the specific machine, time of occurrence, and the probable cause. Providing supporting evidence, such as photos or samples of defective paper, can be extremely helpful. I always strive to suggest potential solutions or preventative measures, demonstrating proactive problem-solving skills.

Q 14. What are your skills in using paper testing tools or equipment?

My skills in using paper testing tools and equipment are comprehensive. I am proficient in using instruments such as brightness meters, caliper gauges (to measure paper thickness), grammage scales (to determine paper weight), and various tensile strength testers. I understand the principles behind each test and can interpret the results accurately to assess paper quality. For instance, I can use a caliper gauge to check for consistent thickness across a batch to identify potential inconsistencies. I know the limitations of each instrument and apply them appropriately, recognizing the potential for variations in results and the need for repeat measurements to ensure accuracy. I am also familiar with using more specialized equipment, depending on the specific requirements, and can quickly learn to operate new testing instruments as needed. This familiarity allows me to effectively assess various paper properties and to identify any discrepancies from defined standards.

Q 15. How familiar are you with different types of paper finishes (e.g., matte, gloss)?

Paper finishes significantly impact the final look and feel of a printed piece. Think of it like choosing the right fabric for a garment – the finish affects the texture and how the colors appear. Matte finishes offer a less reflective, softer look, often preferred for text-heavy documents or where a subtle, less glossy finish is desired. They’re less prone to fingerprints. Gloss finishes, on the other hand, produce vibrant, sharp colors and a sleek, polished look. They are popular for brochures and high-impact marketing materials. There are also variations like semi-gloss, which offers a happy medium between the two extremes. I’m very familiar with distinguishing these finishes through visual inspection and touch, as well as by understanding the printing process used to achieve them.

For example, I can quickly identify a matte finish by its lack of shine and slightly textured surface, while a glossy finish is immediately apparent due to its high sheen and smooth feel. Even subtle variations within matte or gloss finishes are noticeable with practice.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key characteristics of different paper types (e.g., bond, cover, cardstock)?

Different paper types possess unique characteristics that suit specific applications. It’s like choosing the right tool for a job. Bond paper, typically used for everyday printing and writing, is known for its strength, relatively smooth surface, and reasonable cost. Cover paper, thicker than bond, is designed for covers and durable applications. It often has a higher weight and a more pronounced texture or finish. Cardstock, even thicker still, provides exceptional rigidity and is ideal for business cards, postcards, and other projects needing substantial durability.

Key characteristics to consider include weight (measured in pounds or grams per square meter), thickness, texture (smooth, textured, etc.), opacity (how well it prevents ink from showing through), and the finish (matte, gloss, etc.). I routinely assess these factors to determine the appropriate handling and sorting procedures for each paper type. For example, heavier cardstock requires more careful handling to prevent bending or damage during sorting, unlike the more flexible bond paper.

Q 17. How do you prioritize tasks when handling multiple types of paper simultaneously?

Prioritizing tasks when handling multiple paper types requires a systematic approach. I typically utilize a combination of urgency and importance, similar to the Eisenhower Matrix. Urgent and important tasks, such as processing a time-sensitive print job needing specific paper, take precedence. Important but not urgent tasks, such as sorting a large batch of archived documents, are scheduled strategically to avoid bottlenecks. Urgent but not important tasks are delegated if possible. Finally, tasks that are neither urgent nor important are either postponed or eliminated. This approach ensures efficient workflow and prevents delays.

For instance, if I have a rush order for glossy brochures and a large quantity of standard bond paper needing sorting, I would prioritize the brochure order due to its time sensitivity. Then, I’d allocate resources to the sorting project, ensuring both jobs are completed effectively within their respective timeframes.

Q 18. Explain your understanding of paper manufacturing processes.

Paper manufacturing involves a complex process. It begins with the preparation of the pulp, typically made from wood fibers, which is then refined and cleaned to remove impurities. Next, the pulp is formed into a continuous sheet on a Fourdrinier machine, a massive piece of equipment that carefully controls water removal and sheet formation. The wet sheet is then pressed to remove excess water and passed through rollers for drying and smoothing. Depending on the desired properties, various treatments such as calendaring (smoothing), coating (for gloss or other finishes), and sizing (to improve ink absorption) are applied. Finally, the finished paper is inspected, cut, and packaged for distribution. I understand the impact of these processes on the final paper properties, and therefore the proper handling of the final product.

Q 19. Describe your experience with handling different paper sizes and formats.

My experience encompasses a wide range of paper sizes and formats, from standard letter and legal sizes to custom-cut sheets and various roll widths. I’m adept at handling both single sheets and large quantities. I can effortlessly identify and sort various sizes, recognizing standard formats such as A4, B5, and various US letter-size variations. Furthermore, I am accustomed to working with diverse paper formats, including folded sheets, perforated sheets, and those with die-cuts or other specialized treatments. This experience minimizes processing issues and optimizes efficiency. Understanding and complying with different paper sizes and formats is vital in any paper-handling role.

Q 20. How do you manage and prevent paper jams or other processing issues?

Preventing paper jams and processing issues involves a multifaceted approach. Regular maintenance of equipment, ensuring proper paper feeding, and careful attention to paper quality are crucial. For instance, detecting and removing any wrinkles, creases, or severely damaged sheets before processing significantly reduces the risk of jams. Understanding how different paper types and finishes might behave in specific machinery is essential to anticipate potential problems. If a jam occurs, I am trained to troubleshoot and clear it efficiently while minimizing damage to the paper and the machine.

For example, if I notice a machine is frequently jamming with a particular type of thick cardstock, I might adjust the feeding mechanism or reduce the amount of paper fed at once to prevent future jams.

Q 21. How do you ensure the proper storage and handling of inspected paper?

Proper storage and handling of inspected paper are vital to preserve its quality and prevent damage. This includes storing the paper in a cool, dry place away from direct sunlight and moisture to prevent warping, discoloration, or mildew. Appropriate packaging, such as archival-quality boxes or acid-free sleeves, is used to protect delicate or valuable documents. Paper should be stacked carefully to avoid crushing or bending. Heavy weights should be placed below lighter weights, with appropriate support to prevent bowing. Proper handling during transport, using appropriate carriers and avoiding harsh movements, also helps prevent damage.

For example, archival-quality photographs would be stored in acid-free envelopes within climate-controlled storage. This prevents degradation and ensures the longevity of the images. This demonstrates my commitment to preserving the condition of the paper entrusted to my care.

Q 22. What safety procedures do you follow while handling paper products?

Safety is paramount when handling paper products. My procedures begin with a thorough assessment of the work environment. This includes checking for any potential hazards like spills, obstructions, or damaged equipment. I always wear appropriate personal protective equipment (PPE), which typically includes safety glasses to protect my eyes from flying debris and gloves to prevent cuts or skin irritation from rough edges or chemicals. Proper lifting techniques are crucial, especially when dealing with large stacks of paper. I avoid twisting or bending at the waist and always lift with my legs, to minimize the risk of back injuries. Furthermore, I maintain a clean and organized workspace to prevent accidents and ensure efficient workflow. For example, I regularly clear away any scraps or excess paper to avoid tripping hazards. Finally, I’m always mindful of the surrounding environment and the potential for static electricity build-up, especially in dry conditions, which can cause fires.

Q 23. Explain your problem-solving skills in relation to paper quality issues.

Troubleshooting paper quality issues requires a systematic approach. I begin by visually inspecting the paper for defects, such as discoloration, wrinkles, tears, or inconsistencies in weight or texture. Then, I analyze the issue, considering potential causes like machine malfunctions, problems with raw materials, or variations in the manufacturing process. For example, if I consistently find a particular type of defect, like pinholes, I’ll investigate whether it’s due to problems with the paper-making machinery or inconsistencies in the pulp used. I often use tools like calipers and microscopes to conduct more detailed analysis. Data from previous batches and production records are critical to understanding recurring problems. Once I’ve identified the root cause, I implement corrective actions, which may involve adjusting machine settings, replacing faulty components, or modifying the manufacturing process. I also document my findings and the corrective actions taken, to prevent similar issues in the future. For instance, I might create a checklist for quality control inspectors to ensure consistent identification and reporting of defects.

Q 24. How do you adapt to changing work demands or priorities related to paper inspection?

Adaptability is crucial in this role. I prioritize tasks based on urgency and importance, using methods like prioritizing according to deadlines or client needs. I’m proficient in using different inspection methods, ranging from manual checks for large orders to automated systems for high-volume processing. If a new type of paper requires a different inspection method, I quickly learn the appropriate technique and adapt my approach accordingly. I also communicate effectively with team members and supervisors to stay informed about changing priorities and ensure seamless transitions between tasks. For instance, if a rush order comes in, I’ll adjust my workflow to prioritize that order while ensuring the other tasks continue to be completed efficiently. This might involve re-assigning certain tasks or working overtime, depending on the specifics of the situation. The key is remaining flexible and proactive.

Q 25. How do you stay updated on industry best practices in paper quality control?

Staying updated on industry best practices is an ongoing process. I regularly attend industry conferences and workshops, participate in professional development courses, and subscribe to trade publications focused on paper quality control. I actively seek out and network with other professionals in the field to share insights and best practices. Online resources, such as industry websites and professional forums, provide valuable updates on new technologies and techniques in paper inspection. I also keep abreast of any changes in industry standards and regulations to ensure compliance. For example, I recently completed a course on advanced paper testing techniques which allowed me to enhance my skills in using specialized equipment and analyzing data more efficiently.

Q 26. What metrics or KPIs would you use to track paper inspection efficiency?

Several metrics can track paper inspection efficiency. Key Performance Indicators (KPIs) I’d utilize include:

- Defect rate: The percentage of defective papers identified during inspection. A lower defect rate indicates higher efficiency.

- Inspection time per unit: The average time taken to inspect a single unit or batch of paper. Reducing this time reflects improved efficiency.

- Accuracy rate: The percentage of correctly identified defects. High accuracy ensures the quality of the inspection process.

- Throughput: The total volume of paper inspected within a given timeframe. Higher throughput indicates greater efficiency.

Q 27. How would you train a new employee on paper inspection and sorting procedures?

Training a new employee involves a structured approach. I’d start with a comprehensive overview of paper types, common defects, and industry standards. Hands-on training is crucial, where I’d guide the new employee through the inspection process, using various paper samples with different defects. I’d provide clear instructions and demonstrate proper techniques, emphasizing safety procedures. This would include using standardized checklists to ensure consistent and thorough inspection. The training would also include the use of any specialized equipment or software, with ample opportunities for practice and feedback. I would create a structured training program that includes written materials, videos, and practical exercises. Regular assessments would be conducted to monitor progress and provide constructive feedback. The goal is to ensure the new employee understands the procedures and can perform the task efficiently and safely.

Q 28. Describe your experience working under pressure and meeting tight deadlines.

I thrive under pressure and consistently meet tight deadlines. In my previous role, we experienced a significant increase in order volume during peak seasons. This required us to work extended hours and prioritize tasks effectively. My ability to maintain focus and accuracy under pressure enabled me to consistently meet deadlines without compromising the quality of the inspection process. I also utilize effective time management techniques, such as prioritizing tasks, breaking down large tasks into smaller, manageable steps, and utilizing checklists to ensure nothing is overlooked. I find that clear communication with team members is crucial for coordinating efforts and ensuring that everyone is aligned on priorities and deadlines. Collaboration and support within the team help distribute workload effectively and improve overall productivity, even under high pressure.

Key Topics to Learn for Inspecting and Sorting Paper Interview

- Paper Grades and Qualities: Understanding different paper types (e.g., coated, uncoated, recycled), their properties (weight, thickness, finish), and common defects.

- Defect Identification: Mastering the visual identification of common paper imperfections such as wrinkles, tears, holes, discoloration, and contamination. Practice distinguishing between acceptable variations and significant defects.

- Sorting Techniques and Efficiency: Familiarize yourself with various sorting methods, optimizing speed and accuracy while minimizing errors. Consider strategies for handling large volumes of paper efficiently.

- Quality Control Procedures: Understand the importance of adhering to quality control standards and protocols. Learn about documenting findings and reporting discrepancies.

- Safety Procedures and Equipment Operation: Demonstrate knowledge of safe operating procedures for relevant machinery and equipment (e.g., conveyor belts, sorting machines). Highlight your understanding of workplace safety regulations.

- Problem-Solving and Decision-Making: Be prepared to discuss how you would handle situations such as equipment malfunctions, unexpected defects, or inconsistencies in paper quality. Showcase your analytical and problem-solving skills.

- Teamwork and Communication: Discuss your ability to collaborate effectively with colleagues, communicate effectively about identified issues, and contribute to a positive team environment.

Next Steps

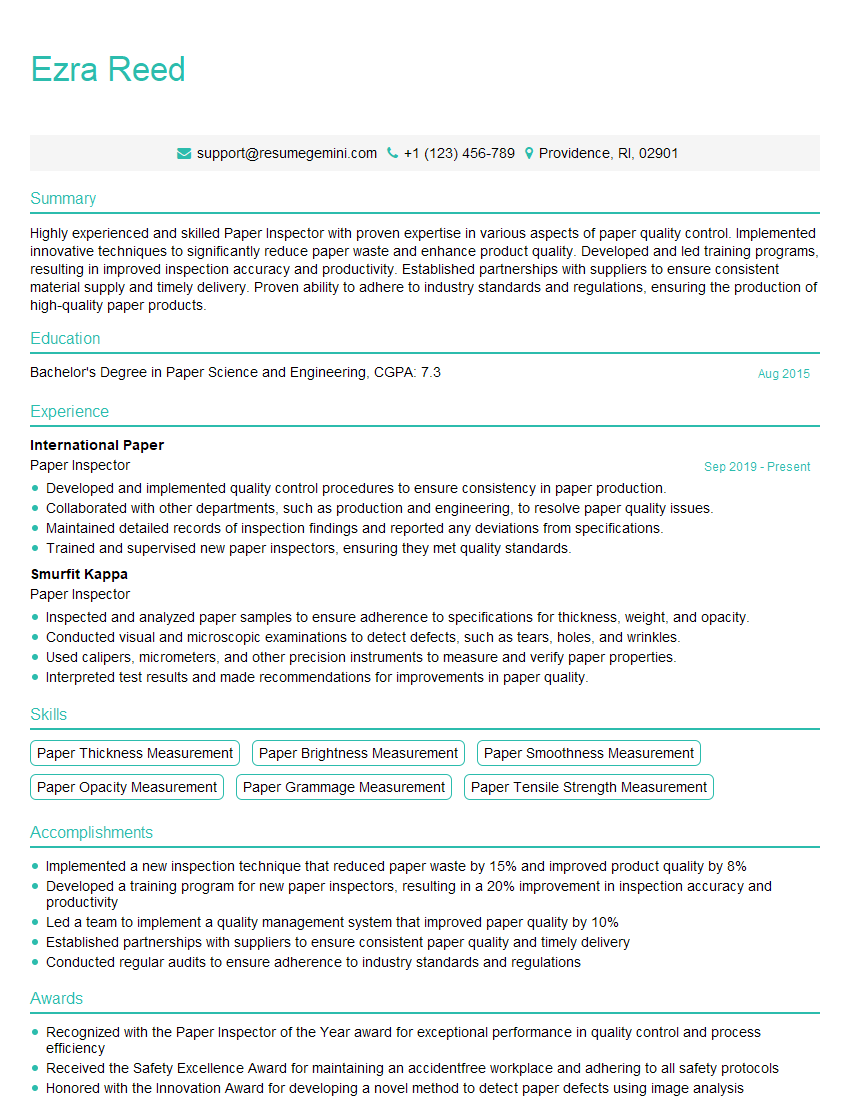

Mastering the skills of inspecting and sorting paper opens doors to various roles within the paper industry, offering opportunities for growth and specialization. A strong resume is crucial for showcasing your abilities to potential employers. Building an ATS-friendly resume increases your chances of getting your application noticed. ResumeGemini is a trusted resource to help you craft a professional and impactful resume. We provide examples of resumes tailored specifically to the Inspecting and Sorting Paper field to help you create a document that highlights your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO