Are you ready to stand out in your next interview? Understanding and preparing for Jackhammer operation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Jackhammer operation Interview

Q 1. What are the different types of jackhammers and their applications?

Jackhammers, also known as demolition hammers, come in several types, each suited for specific applications. The main categories are pneumatic, electric, and hydraulic.

- Pneumatic Jackhammers: These are powered by compressed air and are known for their powerful impact. They’re ideal for heavy-duty demolition work like breaking up concrete, asphalt, and rock in large-scale projects. Think of highway construction or large building demolitions. Their portability is a benefit in areas without readily available electricity.

- Electric Jackhammers: These are powered by electricity and offer a quieter and cleaner operation compared to pneumatic models. They are suitable for smaller projects and tasks that require less brute force, such as chipping away at concrete or breaking up smaller sections of pavement. You’ll frequently see them used in smaller construction or renovation jobs.

- Hydraulic Jackhammers: These are the most powerful type, usually employed for extremely tough demolition tasks and large-scale projects where immense breaking force is needed. They’re commonly used in specialized demolition work like dismantling reinforced concrete structures or mining.

The choice depends entirely on the job’s scale and the material being broken. A small renovation might use an electric model, whereas a highway project would undoubtedly need pneumatic or even hydraulic jackhammers.

Q 2. Describe the safety procedures you follow when operating a jackhammer.

Safety is paramount when operating a jackhammer. My procedure always starts with a thorough pre-operation check. This includes inspecting the jackhammer for any damage, ensuring the air hose (if pneumatic) is in good condition and properly connected, and verifying that the bit is securely attached. I always wear the proper PPE (Personal Protective Equipment), which includes safety glasses, hearing protection (earplugs or muffs), a hard hat, work gloves, and steel-toed boots.

Before starting work, I assess the area for hazards, ensuring there are no underground utilities or obstacles that could be hit. I also establish a safe working distance from other workers and bystanders. During operation, I maintain a firm grip on the jackhammer and avoid applying excessive force. I take regular breaks to prevent fatigue, which can lead to accidents. After completing the work, I carefully shut down the jackhammer, disconnect the air hose or power cord, and store the equipment in a safe location. I always ensure the work area is clean and free of debris.

Q 3. How do you maintain a jackhammer to ensure optimal performance?

Maintaining a jackhammer is crucial for its longevity and optimal performance. Regular maintenance includes inspecting the machine for any wear and tear, lubricating moving parts according to the manufacturer’s recommendations, and regularly cleaning the machine to remove dust and debris. The air filter (for pneumatic models) needs frequent cleaning or replacement. The bit should be inspected for damage and replaced when necessary. If the jackhammer is electric, the power cord should be regularly inspected for damage. For hydraulic models, hydraulic fluid levels and condition must be checked routinely. Preventive maintenance ensures a safer and more efficient operation, reducing the risk of malfunctions and downtime.

Q 4. What are the signs of a malfunctioning jackhammer?

Several signs indicate a malfunctioning jackhammer. Reduced impact force is a common symptom, suggesting issues with air pressure (pneumatic), motor problems (electric), or hydraulic system failure (hydraulic). Excessive vibration beyond normal operation might indicate a worn-out bearing or an internal problem. Unusual noises, such as grinding or squealing, suggest mechanical issues that require attention. Leaking air or oil warrants immediate attention as it can lead to accidents or damage. If the jackhammer stalls frequently or fails to start, there’s clearly a major problem that needs prompt investigation by a qualified technician.

Q 5. Explain the process of selecting the right jackhammer bit for a specific task.

Choosing the right jackhammer bit is crucial for efficient and safe operation. Different bits are designed for different materials and applications. For example:

- Chisel bits: Ideal for breaking up concrete, asphalt, and other hard materials.

- Bull point bits: Used for more aggressive demolition or creating larger holes.

- Flat bits: Suitable for light chipping or removing surface material.

- Spades bits: Designed for breaking up heavier materials and masonry.

The selection depends on the material’s hardness and the required hole size or surface preparation. A harder material requires a more robust bit capable of withstanding the stress. I always consult the manufacturer’s specifications to ensure the bit is compatible with my jackhammer model. Choosing the incorrect bit can lead to damage to the tool, reduce efficiency, or even cause injury.

Q 6. How do you handle different ground conditions while operating a jackhammer?

Ground conditions significantly impact jackhammer operation. Hard rock requires a more powerful jackhammer and a robust bit capable of withstanding the stress. Soft ground, on the other hand, might not require as much force and may even cause the bit to get bogged down. I adjust my technique accordingly, using more controlled force in softer ground and increasing the force for harder materials. The angle of attack also needs to be considered; a different angle might be necessary for different materials or ground conditions to achieve the optimal breaking effect. Understanding the ground’s composition and adapting the operation and bit choice is essential for efficient and safe demolition.

Q 7. What are the potential hazards associated with jackhammer operation?

Jackhammer operation poses several potential hazards. The most significant risks are hearing loss due to the intense noise, hand-arm vibration syndrome (HAVS) from prolonged use, and injuries from flying debris. There’s also the risk of striking underground utilities or hidden objects, leading to damage or injury. Additionally, the powerful impact force can cause injury if not handled correctly. Working at heights adds further risk of falls. Therefore, strict adherence to safety procedures, including the use of appropriate PPE and careful work practices, is absolutely non-negotiable.

Q 8. How do you ensure your own safety and the safety of others while using a jackhammer?

Safety is paramount when operating a jackhammer. It’s not just about following rules, it’s about developing a safety-first mindset. My approach is multifaceted.

- Personal Protective Equipment (PPE): I always wear safety glasses or a face shield to protect against flying debris, hearing protection to mitigate the significant noise, a hard hat to prevent head injuries from falling objects, and sturdy work boots with steel toes to protect my feet. Gloves are essential to prevent blisters and vibrations from damaging my hands.

- Work Area Assessment: Before I even start, I carefully assess the work area. This involves checking for underground utilities (using a call-before-you-dig service), unstable ground, overhead hazards, and ensuring there’s enough space to maneuver safely. I also establish a clear safety zone around the work area to keep bystanders at a safe distance.

- Proper Technique: Using the jackhammer correctly is crucial. This means maintaining a firm grip, avoiding fatigue-induced poor posture, and using the correct bit for the material being worked on. I always take regular breaks to avoid fatigue.

- Communication: Effective communication is key, especially in team environments. I use hand signals or a designated spotter to ensure everyone is aware of the jackhammer’s operation and potential hazards. Clear communication prevents accidents.

- Emergency Procedures: I’m familiar with emergency procedures and have a plan in place for dealing with unexpected situations, such as equipment malfunction or injury. This includes knowing where first aid supplies are and how to contact emergency services.

Q 9. What are the regulations and safety standards you must adhere to?

Adherence to regulations and safety standards is non-negotiable. These vary by location but typically include OSHA (Occupational Safety and Health Administration) guidelines in the US or equivalent regulations in other countries. Key aspects I always follow include:

- Regular Equipment Inspections: I thoroughly inspect the jackhammer before each use, checking for damage, loose parts, and proper functioning. This includes verifying the air pressure is within the recommended range.

- Training and Certification: I have completed all required training on safe jackhammer operation, including understanding lockout/tagout procedures for maintenance and repair.

- Permitting: Where necessary, I obtain the required permits before commencing work, especially for projects involving excavation or working near utilities.

- Fall Protection: If working at heights, I utilize appropriate fall protection equipment, such as harnesses and safety lines.

- Confined Space Entry Procedures: When working in confined spaces, I follow strict protocols, including proper ventilation, atmospheric monitoring, and having a designated attendant.

Non-compliance can result in serious penalties, both legally and in terms of safety. My priority is always safe, compliant operation.

Q 10. Describe your experience with different jackhammer models and brands.

My experience spans several jackhammer models and brands, including Ingersoll Rand, Atlas Copco, and Hilti. Each brand has its strengths and weaknesses. For instance, Ingersoll Rand is known for its durability, while Hilti models often emphasize ergonomics. I’ve worked with both pneumatic (air-powered) and electric jackhammers. Pneumatic models are powerful but require an air compressor, while electric models are quieter and cleaner but may be less powerful for extremely tough applications. The choice of model depends heavily on the specific job requirements.

I’m adept at adapting my technique based on the specific model. For example, some models have vibration dampening systems that require a different grip and operating style compared to older, less-refined models. I can effectively maintain and troubleshoot various models, having gained expertise through years of hands-on experience.

Q 11. How do you troubleshoot common jackhammer problems?

Troubleshooting jackhammer problems is a crucial skill. My approach is systematic:

- Safety First: Always disconnect the air supply or power before attempting any repairs. Never work on a live jackhammer.

- Listen Carefully: Unusual noises, such as squealing, grinding, or knocking, often indicate a specific problem. A change in the jackhammer’s operational characteristics (reduced power, jerky operation) can also point towards an issue.

- Visual Inspection: Thoroughly examine the jackhammer for any visible damage, loose parts, or leaks. Check the air hoses for cracks or damage (for pneumatic models). Inspect the bit for wear and tear or damage.

- Check Air Pressure (Pneumatic): If using a pneumatic model, ensure the air pressure is within the manufacturer’s recommended range. Insufficient or excessive air pressure can lead to malfunctions.

- Power Cord/Battery (Electric): If using an electric model, check the power cord for damage and the battery charge level (if applicable).

- Common Problems & Solutions: Some common problems include worn bits, air leaks, damaged seals, or internal mechanical issues. I have the knowledge to replace bits, repair minor leaks, and identify when more significant repairs are needed. If the problem is beyond my expertise, I will contact a qualified technician.

My experience allows me to quickly identify and address most common issues, minimizing downtime.

Q 12. How do you manage fatigue and maintain productivity during extended jackhammer use?

Fatigue is a significant concern during extended jackhammer use, both physically and mentally. To manage this and maintain productivity:

- Regular Breaks: I take frequent, scheduled breaks to rest and rehydrate. This is crucial to prevent fatigue-related injuries and maintain efficiency. I follow the recommended break times as per the job site and safety regulations.

- Proper Posture and Technique: Maintaining proper posture and using the correct operating technique minimizes strain and fatigue. This includes avoiding twisting movements and using the jackhammer’s weight to assist in the breaking process rather than relying solely on brute strength.

- Physical Fitness: Being physically fit significantly enhances endurance and reduces fatigue. Regular exercise improves strength and stamina, allowing me to work more efficiently over extended periods.

- Hydration and Nutrition: Staying well-hydrated and maintaining a balanced diet are crucial. Dehydration and poor nutrition exacerbate fatigue.

- Rotation of Tasks: If possible, alternating jackhammer use with other tasks can help prevent repetitive strain and reduce fatigue build-up.

Prioritizing safety through proper breaks and techniques is not just about productivity; it’s about avoiding serious injury.

Q 13. Describe your experience working in various environments (e.g., confined spaces, extreme weather).

I’ve worked in diverse environments, each presenting unique challenges:

- Confined Spaces: Working in confined spaces requires extra precautions. This includes ensuring adequate ventilation, wearing appropriate respiratory protection, and having a designated attendant outside the confined space to monitor my condition and provide assistance if needed.

- Extreme Weather: Extreme heat or cold significantly impacts performance and safety. In hot conditions, I take more frequent breaks, drink plenty of fluids, and wear appropriate clothing. In cold conditions, I dress in layers to stay warm, use hand and foot warmers, and take breaks in sheltered areas.

- Uneven Terrain: Working on uneven terrain requires extra care to maintain balance and avoid falls. I adjust my stance and footing as necessary and use appropriate safety measures.

Adaptability and careful planning are essential for safe and efficient operation in various settings. I prioritize situational awareness and adjust my techniques as needed to mitigate risks.

Q 14. How do you handle unexpected equipment failures?

Unexpected equipment failures can happen. My response is always methodical and safety-focused:

- Immediate Shutdown: Immediately shut down the jackhammer and disconnect the power source or air supply.

- Assess the Situation: Carefully assess the nature of the failure and the potential hazards. This might involve determining if there are any visible signs of damage or leaks.

- Secure the Area: Establish a safe perimeter to prevent access to the malfunctioning equipment and to protect bystanders.

- Report the Failure: Report the failure to my supervisor or relevant authority. This ensures appropriate actions are taken for repair or replacement.

- Follow Procedures: Adhere to established procedures for dealing with equipment failure, including lockout/tagout procedures if necessary.

- Do Not Attempt Unauthorized Repairs: Unless I’m qualified to perform repairs, I will not attempt any unauthorized repairs. This prevents potential injury and further damage to the equipment.

My goal is to prioritize safety and ensure the issue is properly addressed by qualified personnel.

Q 15. What is your experience with preventative maintenance of a jackhammer?

Preventative maintenance is crucial for jackhammer longevity and operator safety. It’s akin to regularly servicing a car to prevent major breakdowns. My approach involves a daily, weekly, and monthly inspection schedule.

- Daily: I check for loose bolts, fuel leaks (for pneumatic models), damage to the hose (pneumatic), and the overall condition of the chisel. I also listen for any unusual noises during operation. For example, a grinding sound could indicate worn-out internal parts.

- Weekly: A more thorough inspection includes lubricating moving parts according to the manufacturer’s specifications. This often involves applying grease to the piston or other moving components. I also inspect the air filter (if pneumatic) and replace it if necessary.

- Monthly: This involves a more in-depth examination, potentially including checking for internal wear by a qualified technician. I document all checks and maintenance performed in a log book.

By following this proactive maintenance approach, I significantly reduce the risk of unexpected downtime and ensure the jackhammer operates efficiently and safely.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What type of personal protective equipment (PPE) do you use when operating a jackhammer?

Safety is paramount when operating a jackhammer. The PPE I consistently utilize includes:

- Hard Hat: Protects against falling debris.

- Safety Glasses or Goggles: Shields eyes from flying particles and dust.

- Hearing Protection: Earplugs or muffs are essential to mitigate the considerable noise generated by the jackhammer.

- Gloves: Protect hands from vibrations and potential injuries.

- Steel-Toed Boots: Protect feet from dropped objects and impacts.

- High-Visibility Vest: Enhances visibility on the job site, especially in areas with heavy machinery or traffic.

I always ensure my PPE is in good condition and properly fitted before starting any work. Neglecting PPE is not an option – it’s a critical component of safe jackhammer operation.

Q 17. How do you determine the appropriate operating speed for a jackhammer based on the task?

Choosing the right operating speed depends entirely on the material being worked and the desired outcome. It’s not a one-size-fits-all situation. Think of it like adjusting the speed on a drill – you wouldn’t use the same speed for drilling wood as you would for metal.

- Hard Materials (e.g., concrete): Require a slower, more powerful impact rate to effectively break the material. Using a higher speed may damage the chisel or the jackhammer itself.

- Softer Materials (e.g., asphalt): Can tolerate a higher operating speed, allowing for faster work completion. However, excessive speed can lead to unnecessary material damage and increased vibration.

I always start with a lower speed and gradually increase it as needed, constantly monitoring the effectiveness and the machine’s performance. Experience and understanding of the material are crucial in making this determination.

Q 18. What are your methods for communicating effectively with your team and supervisors?

Effective communication is the cornerstone of a safe and productive work environment. I employ several methods to communicate with my team and supervisors:

- Pre-Job Briefings: Before starting work, I participate in briefings to review safety procedures, task assignments, and potential hazards. This ensures everyone is on the same page.

- Clear and Concise Instructions: When delegating tasks or requesting assistance, I use straightforward language, avoiding jargon. I ensure all instructions are understood.

- Regular Check-Ins: I communicate regularly with my team to check on progress and address any concerns. This helps identify and resolve potential problems quickly.

- Incident Reporting: If any incidents or near misses occur, I immediately report them to my supervisor, documenting all details. This helps improve safety procedures and prevent future occurrences.

- Written Communication: I use work orders, daily reports, and email to document all activities and communicate complex information.

Open and honest communication ensures a safer and more efficient workflow for the entire team.

Q 19. How do you assess the risk of ground vibration and take necessary precautions?

Ground vibration from jackhammer operation can cause damage to nearby structures and discomfort to people. Assessing this risk requires careful consideration:

- Proximity to Structures: I assess the distance between the operating area and any buildings or sensitive structures. Closer proximity increases the risk of damage.

- Soil Type: Different soil types transmit vibrations differently. Denser soils transmit vibrations more effectively.

- Operating Duration: Longer periods of operation increase the risk of vibration-related damage.

- Vibration Monitoring (if available): Some projects use specialized equipment to monitor ground vibrations. This provides quantitative data to assess risk.

Precautions: To mitigate risk, I might use techniques like:

- Dampening Materials: Placing dampening mats or pads on the ground can reduce vibration transmission.

- Reduced Operating Time: Using shorter bursts of operation with breaks in between can minimize vibration impact.

- Alternative Techniques: Exploring alternative demolition methods, such as quieter tools or hydraulic breakers, if appropriate for the project.

- Warning Signs: Posting clear warning signs to alert nearby individuals.

Understanding the specific risks and implementing appropriate precautions is key to responsible jackhammer operation.

Q 20. Explain your understanding of OSHA regulations related to jackhammer operation.

My understanding of OSHA regulations regarding jackhammer operation is comprehensive. I know that OSHA focuses heavily on hearing protection, vibration exposure, and general safety procedures. Key regulations I follow include:

- Hearing Conservation Program: OSHA mandates hearing protection programs in noisy environments. This involves regular hearing tests and the provision of appropriate hearing protection.

- Vibration Exposure Limits: OSHA sets limits on hand-arm vibration exposure. Excessive vibration can lead to hand-arm vibration syndrome (HAVS). Regular breaks and proper handling techniques are crucial.

- Personal Protective Equipment (PPE): I adhere to OSHA’s requirements for PPE, ensuring I always use the appropriate gear while operating a jackhammer.

- Training: OSHA emphasizes the importance of proper training before operating heavy machinery like jackhammers. I’ve undergone the necessary training and am familiar with all safety guidelines.

- Safe Work Practices: OSHA outlines safe work practices to prevent accidents. These include using appropriate tools, conducting regular inspections, and maintaining a clean and organized workspace.

I am committed to working within all relevant OSHA regulations to ensure a safe work environment for myself and others.

Q 21. How do you maintain accurate records and logs related to jackhammer use?

Maintaining accurate records is essential for accountability and demonstrating compliance with regulations and company procedures. My record-keeping practices include:

- Daily Log Book: I maintain a detailed log book documenting each day’s jackhammer usage, including the time of operation, location, type of material worked, any maintenance performed, and any incidents or near misses.

- Maintenance Records: I meticulously document all maintenance activities, including dates, types of maintenance, and parts replaced. This ensures easy access to the jackhammer’s maintenance history.

- Equipment Inspection Checklists: Using checklists ensures I cover all aspects of the pre-operation inspection, making it easier to identify potential issues early on.

- Digital Documentation (where applicable): Many companies utilize digital platforms to manage equipment records and track maintenance. I am proficient in using such systems.

Accurate records are critical for preventing future issues, tracing potential problems, and ensuring efficient maintenance scheduling. I always adhere to the company’s record-keeping policy.

Q 22. Describe your experience with different jackhammer fuels (if applicable).

Most jackhammers I’ve worked with are pneumatic, powered by compressed air, not fuel in the traditional sense like gasoline or diesel. There’s no fuel tank or combustion engine involved. However, the air compressor that supplies the compressed air does require a power source, typically electricity or a diesel engine. My experience has encompassed working with compressors powered by both. With electric compressors, the primary concern is consistent power supply; with diesel compressors, regular maintenance and fuel efficiency are key to keeping the operation running smoothly and cost-effectively.

Q 23. How do you ensure efficient fuel consumption?

Efficient fuel consumption, when referring to the air compressor powering the jackhammer, hinges on several factors. First, regular maintenance is crucial. A well-maintained compressor operates at peak efficiency, minimizing wasted energy. This includes checking and changing air filters regularly, lubricating moving parts as per the manufacturer’s recommendations, and ensuring proper cooling. Second, operating the compressor at its optimal working pressure is important; running it higher than necessary wastes energy. Finally, choosing the right size compressor for the job is critical. An oversized compressor will consume more fuel than necessary for the task.

For example, on one project, we replaced a poorly maintained diesel compressor with a newer, more efficient model. This resulted in a significant reduction (approximately 15%) in fuel consumption without affecting our operational capacity. It’s all about planning and maintenance.

Q 24. What is your experience working with other heavy equipment on a job site?

I’ve worked extensively with other heavy equipment operators on various construction sites. Coordination is essential for safety and efficiency. I’ve collaborated with excavators, crane operators, and loaders, often working in close proximity. Clear communication, especially through hand signals and radio communication, is paramount to avoid accidents. Understanding the operational range and limitations of each piece of equipment helps anticipate potential issues and coordinate movements efficiently. For example, on a recent demolition project, I worked closely with an excavator operator. He would loosen large chunks of concrete, and I would then use the jackhammer to break them down further into manageable sizes for removal. Seamless communication prevented delays and ensured worker safety.

Q 25. How do you handle noise pollution concerns while operating a jackhammer?

Noise pollution is a major concern when operating a jackhammer. Several strategies mitigate this. First, I always use hearing protection, and I ensure that all my team members working nearby also use appropriate hearing protection such as earplugs or earmuffs. Second, when possible, I use noise dampening techniques, such as working during off-peak hours or using sound barriers when available. Third, I utilize jackhammers with noise-reduction features whenever possible. Finally, keeping my jackhammer in excellent condition – well-maintained equipment operates more smoothly and generally produces less noise.

On a recent project near a residential area, we scheduled our jackhammer work for the middle of the day, when ambient noise levels are higher, minimizing the impact on local residents. We also used temporary sound barriers to further reduce the noise level.

Q 26. Describe your experience working within tight deadlines and under pressure.

I thrive under pressure and have consistently met tight deadlines. I’m adept at prioritizing tasks, managing time effectively, and remaining calm under stress. For instance, on one project, we had a very short window to complete demolition before the next phase could begin. Through careful planning, efficient work, and close collaboration with the team, we finished ahead of schedule. Adaptability and problem-solving skills are essential in these high-pressure situations. This includes identifying and addressing potential obstacles proactively to maintain efficiency.

Q 27. How do you contribute to the overall team efficiency?

I contribute to team efficiency by maintaining a clean and organized work area, which reduces the risk of accidents and improves overall productivity. I always complete my tasks thoroughly and on time, ensuring that the work proceeds smoothly. I also actively communicate any potential issues or delays to my supervisor and team members to address them promptly. Furthermore, I’m always willing to help others on the team when needed, fostering a collaborative and efficient work environment. A simple example is keeping my tools organized, allowing others to access them without searching – which saves a team time.

Q 28. What are your career goals related to jackhammer operation and equipment operation?

My career goals involve advancing my skills in heavy equipment operation, possibly specializing in demolition techniques. I aim to obtain certifications to expand my capabilities and work on increasingly complex projects. Ultimately, I aspire to become a supervisor or foreman, using my expertise to guide and mentor others in the field. Continuous learning and professional development are key to achieving these goals. This includes staying updated on new technologies, safety regulations, and best practices in the construction industry.

Key Topics to Learn for Jackhammer Operation Interview

- Jackhammer Mechanics: Understanding the internal workings of different jackhammer types (pneumatic, electric, gasoline), including their components and functions. This includes knowledge of piston action, valve mechanisms, and power transmission.

- Operational Safety Procedures: Mastering safe operating practices, including pre-operation checks, personal protective equipment (PPE) usage, and emergency procedures. This also covers understanding and adhering to relevant safety regulations and best practices.

- Effective Operation Techniques: Developing proficiency in various breaking and demolition techniques, adapting your approach based on the material (concrete, asphalt, rock etc.) and desired outcome. This includes understanding the impact of different operating pressures and techniques on efficiency and material damage.

- Maintenance and Troubleshooting: Familiarizing yourself with routine maintenance tasks, identifying common malfunctions, and performing basic troubleshooting procedures. This includes understanding the importance of lubrication, regular inspections, and preventative maintenance schedules.

- Material Selection and Application: Understanding the different types of materials jackhammers are used on and how to select the appropriate jackhammer and technique for the job. This involves understanding material properties and potential challenges.

- Environmental Considerations: Understanding the environmental impact of jackhammer operation, including noise pollution, dust control, and vibration management. This also encompasses knowledge of mitigation strategies and best practices for minimizing environmental disruption.

Next Steps

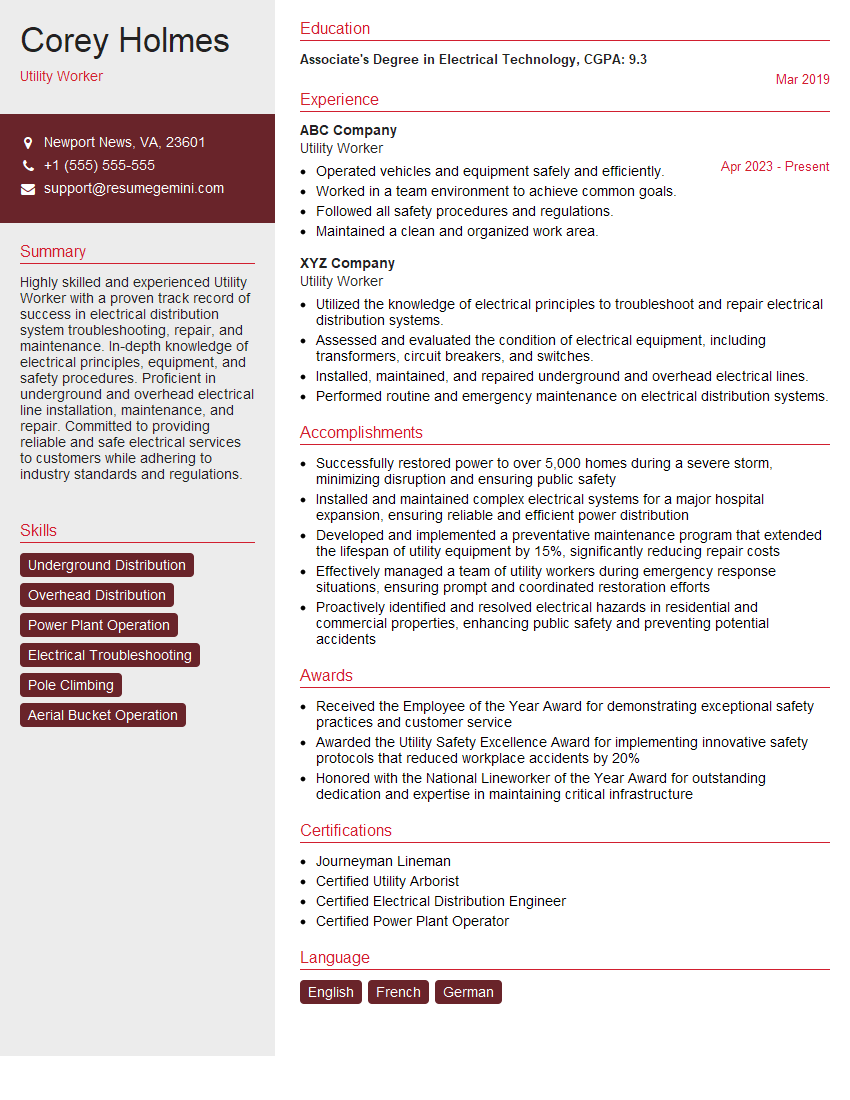

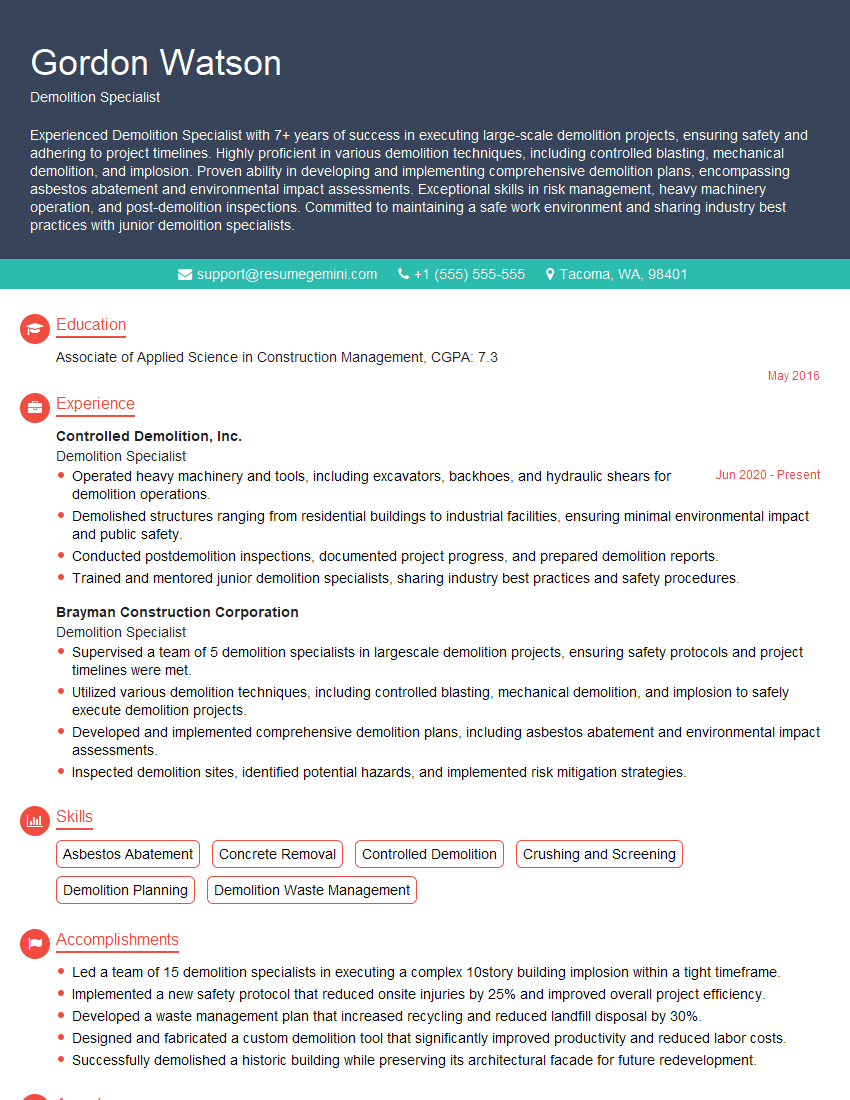

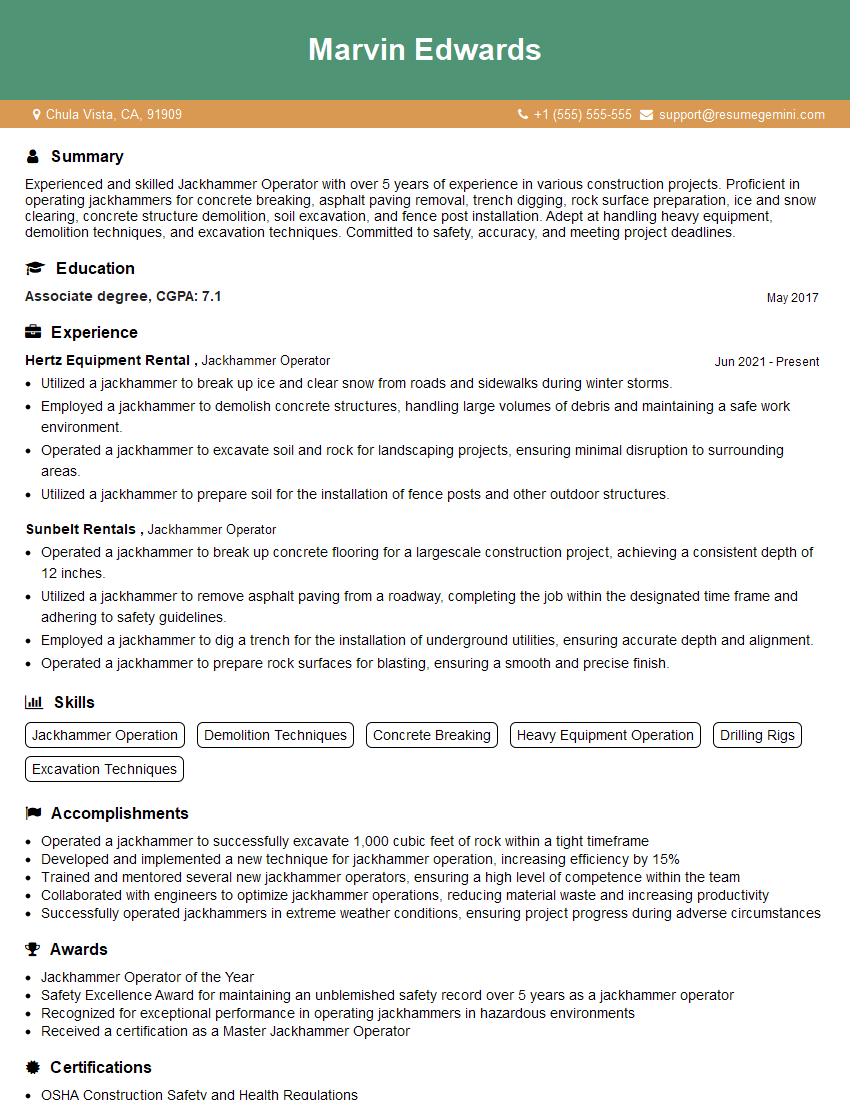

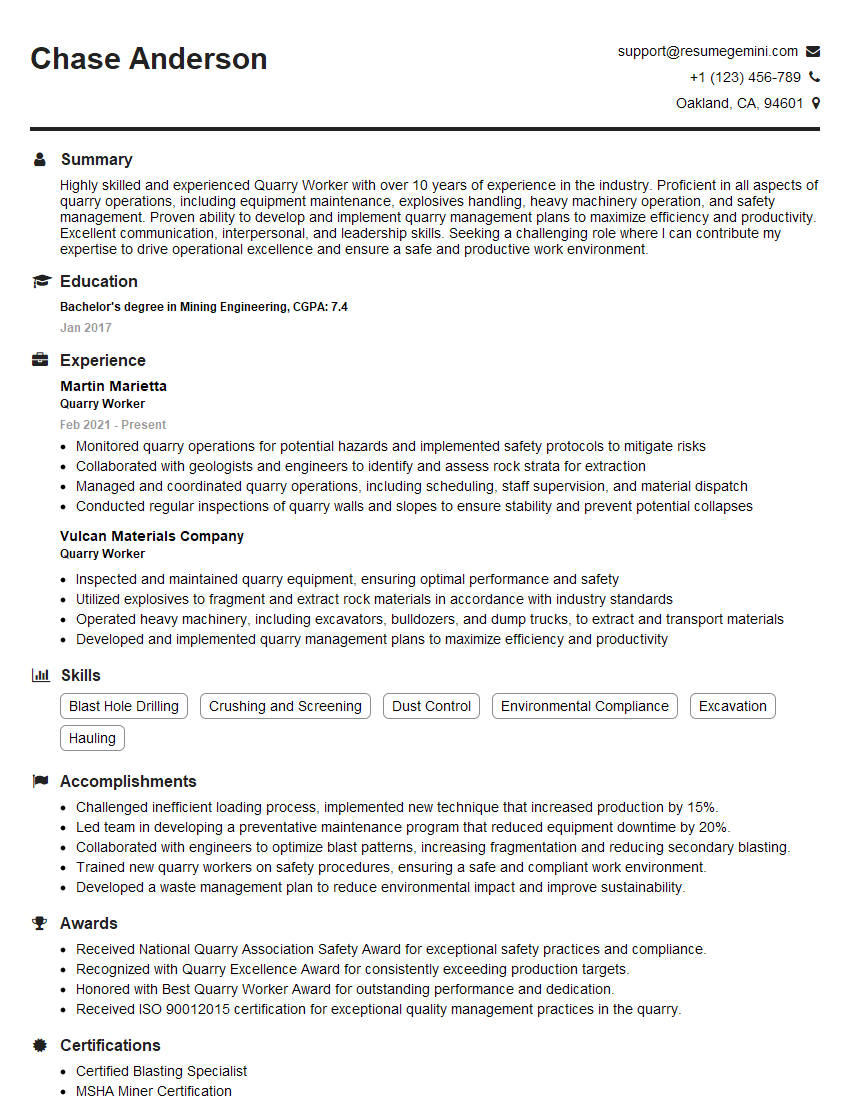

Mastering jackhammer operation opens doors to rewarding careers in construction, demolition, and infrastructure development, offering opportunities for specialization and advancement. To maximize your job prospects, it’s crucial to create a professional, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your expertise. We provide examples of resumes tailored to jackhammer operation to guide you in creating a standout application. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO