Preparation is the key to success in any interview. In this post, we’ll explore crucial Key Cutting interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Key Cutting Interview

Q 1. What types of key cutting machines are you familiar with?

Over my years in the key cutting business, I’ve become proficient with a variety of machines. This includes both manual and automated key cutting machines. Manual machines, like the Silca Unica, require more skill and precision, relying on the operator’s judgment to match the key’s profile. These are great for smaller shops or for intricate, less common keys. Automated machines, such as those from the Ilco brand or the newer generation of electronic machines from companies like JMA, use computer-controlled cutting technology. These are faster, more efficient, and capable of cutting a much wider range of keys, including those with complex patterns or specialized cuts, like laser cut keys. I’m comfortable using machines from various manufacturers and adapting my technique to the specific machine’s capabilities. The key is understanding the machine’s limitations and strengths to ensure a quality cut every time.

- Manual Machines: Offer precision for specialized keys, require high skill.

- Automated Machines: Faster, more efficient, ideal for high-volume cutting.

Q 2. Explain the process of cutting a standard flat key.

Cutting a standard flat key is a relatively straightforward process, but accuracy is paramount. First, you identify the correct key blank – the un-cut piece of metal – matching the original key’s dimensions and type. Next, using a key machine (either manual or automated), you clamp the blank securely in place. If using a manual machine, I would carefully align the blank with the cutting bit according to the key’s bitting depth and spacing. Then, following the code or pattern provided (either physically or digitally via software on automated machines), I progressively cut the teeth into the blank. Each cut must be precise to the correct depth and spacing. The process involves multiple cuts, progressively deepening and shaping the teeth until the key’s profile matches the specifications. With automated machines, this process is often fully automated once you input the key code. The machine accurately cuts the teeth according to the provided specifications. After the cutting, I’d always test the key to ensure it functions correctly in the lock before handing it to the customer.

Q 3. How do you identify different key blanks?

Identifying key blanks requires attention to detail and a good knowledge of key systems. Key blanks are usually marked with identifying codes and sometimes even the manufacturer’s logo. I utilize a combination of visual inspection and referencing catalogs or databases. Visual inspection involves checking the blank’s shape, size, and any markings stamped on it. The markings typically include manufacturer codes and keyway types (e.g., for different car makes or models). Furthermore, I also rely on detailed catalogs which show different types of key blanks, often organized by manufacturer and keyway type. These catalogs are crucial in matching blanks to specific locks. Finally, specialized databases provide key blank information linked to vehicle make, model, and year, particularly useful when working with car keys. For instance, a common blank for house keys might be a Y12, but a car key blank will likely have a more specific code related to the car’s make and model.

Q 4. Describe your experience with key code systems.

Key code systems are essential for accurate key duplication, especially for vehicle keys. These are alphanumeric or numerical codes representing the specific depths and positions of the key’s cuts. My experience encompasses various systems, including those used by automotive manufacturers, like Ford’s PATS (Passive Anti-Theft System) or General Motor’s VATS (Vehicle Anti-Theft System), and residential lock manufacturers like Schlage or Kwikset. I’m adept at decoding these codes, using code readers to retrieve the information from existing keys, and then utilizing the code on the appropriate key cutting machine. I understand the security implications involved in these systems; they’re designed to deter unauthorized duplication. Therefore, I follow strict protocols and maintain detailed records to ensure security and compliance. Experience with key code systems allows me to deal quickly and efficiently with many common and less common types of keys.

Q 5. How do you handle difficult or damaged keys?

Dealing with difficult or damaged keys requires patience and specialized techniques. For broken keys, I might need to use key extraction tools to remove the broken fragment from the lock. Sometimes, reconstructing a key from broken pieces is possible, but this is a more specialized skill. If a key is severely corroded, I might need to use cleaning agents to prepare it for reading. For keys with worn-down teeth, accurate duplication is difficult, and I would advise the customer that the new key may require some adjustments to work perfectly. Using advanced key cutting machines with specialized features for scanning or copying damaged or worn keys, for example those using laser technology, often helps overcome such situations. Each case is unique and demands a tailored approach based on the extent of the damage. Sometimes I must determine whether duplication is feasible or if replacement is necessary.

Q 6. What safety precautions do you follow when using key cutting machinery?

Safety is my top priority. When operating key cutting machinery, I always wear safety glasses to protect my eyes from flying debris. I ensure the machine is properly maintained and all guards are in place. I never operate the machine if I’m tired or distracted. Long hair is always tied back to avoid entanglement. I make sure the area around the machine is clear of obstructions. Proper handling of key blanks and finished keys is crucial to prevent cuts. And finally, I always follow the manufacturer’s safety instructions for the specific machine being used. These machines are powerful and require conscientious handling, and I always err on the side of caution.

Q 7. How do you ensure accuracy in key cutting?

Accuracy in key cutting is achieved through a combination of factors. Firstly, selecting the correct key blank is critical. Then precise alignment of the key blank in the machine is crucial, particularly on manual machines. Following the key code or profile exactly is non-negotiable. Regular machine maintenance helps ensure the cutting bits are sharp and aligned. After cutting, I always perform thorough testing of the new key in the corresponding lock to ensure it operates smoothly. Even small errors in depth or spacing can prevent the key from working correctly. My experience allows me to recognize subtle deviations from perfection and make necessary adjustments to achieve the highest quality result. A methodical approach, combined with a sharp eye and precision in using the machines, guarantees a high level of accuracy.

Q 8. What are the common problems encountered during key cutting and how do you troubleshoot them?

Common problems in key cutting often stem from incorrect blank selection, machine malfunction, or operator error. Troubleshooting involves a systematic approach.

Incorrect Blank: If the cut key doesn’t work, the first check is the key blank itself. Was it the correct type for the lock? Sometimes, a seemingly minor difference in blank dimensions can lead to failure. I always double-check the manufacturer’s markings and compare it to the original key before cutting.

Machine Malfunction: Problems like dull cutters, misaligned jaws, or faulty sensors can lead to inaccurate cuts. This requires checking the machine’s alignment, replacing worn cutters, and potentially calling for a service technician to diagnose electronic issues. Regular maintenance, as I’ll discuss later, is key to preventing these issues.

Operator Error: This includes incorrect depth settings, improper key blank insertion, or insufficient clamping. I meticulously verify my settings against the key code or the original key before starting the cutting process. Practicing precision and attention to detail is crucial to minimize this type of error. For instance, I often use a magnifying glass for intricate keyways.

Jammed Key: If the key gets jammed during the cutting process, immediately stop the machine. Never attempt to force it. Identify the cause of the jam (e.g., a chip of metal, improper blank alignment), clear it carefully, and then resume operation.

Ultimately, a methodical approach, starting with the simplest possibilities and progressing to more complex machine-related issues, ensures effective troubleshooting.

Q 9. Explain the difference between different key types (e.g., tubular, flat, dimple).

Different key types cater to various security needs and lock mechanisms. Each has a unique profile and cutting method.

Flat Keys: These are the most common type, featuring a flat, often serrated blade. The cuts vary widely, from simple bitting to complex profiles like those found in higher security locks. The depth and spacing of the cuts determine the lock’s functionality.

Tubular Keys: Instead of a flat blade, tubular keys have a cylindrical shape with multiple pins arranged around the core. These keys are often used for cabinets, lockers, or older vehicle ignitions. Cutting requires specialized tools and expertise due to the key’s delicate structure.

Dimple Keys: Also known as sidewinder keys, these have small dimples or indentations along the blade’s sides, making them more resistant to picking. The precise depth and positioning of these dimples create a highly specific profile, requiring precise cutting and sophisticated machinery.

Laser Cut Keys: These feature incredibly precise cuts created by a laser, resulting in high security. These keys are extremely difficult to copy without specialized equipment.

Understanding these differences allows for proper blank selection and prevents costly mistakes during cutting. Improper blank selection for a dimple key in a flat key machine will result in a non-functional key, for instance.

Q 10. How do you deal with customer requests for keys with limited information?

Dealing with limited information requires careful questioning and a systematic approach. I would start by asking the customer for any identifying information on the lock or key, such as the manufacturer’s name, model number, or any markings on the key.

Visual Inspection: If the customer has the old key, even a broken one, a visual inspection can provide clues about the keyway. I use a magnifying glass and sometimes a key decoder to identify the keyway type.

Lock Identification: If possible, asking the customer to bring the lock itself allows for a direct examination of the keyway. I can then use my experience and tools to identify the key’s profile.

Trial and Error (with caution): In some cases, a careful trial-and-error approach may be necessary, but only after exhausting other options. I may begin with the most common key blanks and make small, incremental cuts, testing the key frequently. This requires extensive experience and should always be done with the customer’s consent. This approach risks damaging the lock.

Ultimately, patience and thorough communication with the customer are essential when working with limited information. It is far better to take extra time to find the solution correctly than to create an incorrect key.

Q 11. What is your experience with laser key cutting?

I have extensive experience with laser key cutting. Laser key cutting offers superior precision and security compared to traditional methods. The process uses a laser to precisely etch the key’s profile onto the blank. This allows for the creation of intricate and highly secure keys.

Advantages: Laser key cutting generates very precise cuts, leading to superior key performance and enhanced security. It is also significantly faster than some traditional methods.

Disadvantages: The initial investment for laser key cutting machines is high, and specialized training is required to operate them efficiently and safely. The specialized blanks can be more expensive.

Applications: I use laser key cutting for high-security automotive keys, including transponder keys and keys with electronic components. I also use it for making duplicate keys from originals where precision is paramount.

My proficiency extends to maintaining and troubleshooting laser key cutting machines, ensuring consistent high-quality output.

Q 12. Are you familiar with different keyway types?

Yes, familiarity with various keyway types is fundamental to my work. A keyway is the pattern of cuts in a lock cylinder that corresponds to the key’s profile. Different manufacturers and lock types utilize distinct keyways.

Examples: Common keyway types include Schlage, Kwikset, Yale, and many more proprietary designs. Each requires a specific key blank and often requires specialized tools or machines.

Identification: I identify keyways through visual inspection of the lock cylinder or the existing key. I utilize resources such as keyway charts and catalogs to determine the correct blank and cutting method.

Accurate keyway identification is crucial for producing a functioning key. Incorrect identification can result in a key that won’t operate the lock correctly.

Q 13. How do you maintain and clean key cutting machines?

Regular maintenance is crucial for ensuring the accuracy and longevity of key cutting machines. My routine includes:

Daily Cleaning: I clean the machine’s cutting area and jaws using compressed air and a soft brush to remove metal shavings. This prevents build-up that can affect the cutting precision.

Weekly Inspection: I inspect the cutters for wear and tear, sharpening or replacing them as needed. I also check the machine’s alignment and adjust it if necessary. This is crucial for maintaining accurate cuts.

Lubrication: I lubricate the moving parts according to the manufacturer’s instructions. This reduces friction and prolongs the machine’s lifespan.

Software Updates: For digitally controlled machines, I regularly check for and install software updates to enhance machine performance, add new keyways, and resolve any identified bugs.

Proper maintenance not only ensures the machine functions optimally but also contributes to creating high-quality, precisely cut keys, which is paramount for customer satisfaction.

Q 14. Describe your experience with automotive key cutting.

Automotive key cutting is a specialized area requiring advanced knowledge and equipment. It encompasses a wide range of key types and security systems.

Transponder Keys: These keys contain a microchip that communicates with the vehicle’s immobilizer system. Cutting the key is only part of the process; programming the transponder chip is equally crucial. I have experience with various programming tools and techniques for various car makes and models.

Laser Cut Keys: As discussed previously, I have experience in creating highly precise laser-cut automotive keys. These are increasingly common in modern vehicles.

Smart Keys and Keyless Entry: My experience also extends to working with smart keys and keyless entry systems, which involve advanced electronic components and coding procedures. Working on this requires specialized tools and diagnostics.

Working on automotive keys demands a deep understanding of vehicle security systems and the ability to troubleshoot various problems that can arise during the process. This area is continuously evolving with new technologies; continuous learning is required to keep up-to-date.

Q 15. How do you handle situations where you cannot duplicate a key?

There are several reasons why I might be unable to duplicate a key. Sometimes, the key is too worn or damaged to accurately read its profile. Other times, the key might be a highly specialized type requiring specialized equipment I don’t have access to, such as certain high-security keys or patented designs. Finally, the customer might not provide the correct key blank, which is essential for creating an accurate duplicate.

My process in these situations begins with a thorough examination of the key. I assess the condition and identify any damage. If the key is simply worn, I might be able to carefully cut a duplicate, but I’ll always be upfront about potential limitations. For keys requiring specialized equipment or key blanks, I explain this to the customer and, if possible, provide alternative solutions, such as recommending a locksmith specializing in that particular key type or suggesting obtaining a replacement key from the original manufacturer or retailer.

For instance, I recently encountered a customer with a heavily corroded car key. While I could partially make out the profile, the accuracy would have been compromised, potentially leading to malfunctions. Instead, I advised them to contact their car dealership for a replacement transponder key.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the legal implications of key duplication?

The legal implications of key duplication are significant and vary by jurisdiction. Generally, it’s legal to duplicate keys for your own use or for items you own. However, duplicating keys without authorization is illegal and can lead to serious consequences. This includes duplicating keys to access someone else’s property, vehicle, or other secured areas without their explicit consent.

In my practice, I strictly adhere to legal requirements and always ask for proof of ownership or authorization before duplicating keys. I refuse to make copies if the request seems suspicious or if I have any doubts about the legality of the duplication. This proactive approach helps avoid legal trouble and ensures responsible key duplication practices. For example, if someone presents a key without proof of ownership to a property, I will not duplicate the key.

The penalties for unauthorized key duplication can range from fines to imprisonment depending on the severity of the offense and the intent. I clearly communicate these risks to customers, reinforcing the ethical and legal importance of obtaining consent before duplicating keys.

Q 17. Describe your experience with transponder key programming.

Transponder key programming is a crucial aspect of modern key duplication, especially for vehicles. These keys contain microchips that communicate with the car’s immobilizer system. Simply cutting the key isn’t enough; the transponder must be correctly programmed for the car to recognize it.

My experience encompasses a wide range of transponder key systems. I utilize specialized diagnostic tools and software to read the existing transponder codes and program new keys. This involves connecting to the car’s onboard system, uploading the relevant information, and then writing the new code to the transponder chip in the new key. I have worked with various car makes and models, each with its unique programming protocols.

For instance, recently I programmed a key for a 2018 Honda Civic. The process involved using a specific code reader that interfaced with the car’s computer system. The process requires precision to avoid damaging the vehicle’s electrical system or potentially locking the vehicle entirely.

Q 18. How do you ensure the security of keys you cut?

Security is paramount in key cutting. I employ several measures to ensure the safety of keys both during and after the cutting process. First, I maintain a clean and organized workspace, reducing the risk of misplaced or stolen keys. Second, I immediately dispose of any key fragments or waste material that could potentially reveal information about a key’s profile. Third, I utilize secure storage for customer keys during and after the duplication process to prevent unauthorized access.

Furthermore, I maintain a detailed record of every key cut, though I strictly protect customer privacy and ensure that this record is not readily accessible to unauthorized individuals. This record helps trace any potential issues related to key duplication. I also strongly encourage customers to take precautions with their keys, emphasizing the importance of secure storage and vigilance against theft or loss.

I even keep a close eye on any suspicious behavior during the key cutting process, because an alert professional can deter potential criminal activity.

Q 19. What is your experience with key extraction?

Key extraction involves removing a broken key from a lock. It requires a delicate touch and specialized tools, as forceful attempts can damage the lock mechanism, making it more difficult and expensive to repair.

My experience includes using various extraction techniques depending on the type of lock and the extent of the breakage. These techniques can range from using specialized key extraction hooks and pliers to employing more advanced methods such as lock disassembling for difficult cases. My goal is always to extract the broken key without damaging the lock cylinder.

For example, I recently extracted a broken car key from the ignition using a specialized extraction tool that gently gripped the remaining key fragment and pulled it out without damaging the ignition switch. In a separate instance, a snapped off house key required me to carefully disassemble the lock cylinder to retrieve the broken pieces.

Q 20. How do you handle customer complaints regarding key cutting services?

Handling customer complaints is crucial for maintaining a positive reputation. My approach involves actively listening to the customer’s concerns, showing empathy, and ensuring they feel heard. I objectively assess the situation, identifying the root cause of the problem and determine if the issue is due to a genuine fault on my part or some other factor.

If the complaint is justified, I apologize for the inconvenience and offer a solution, such as re-cutting the key or offering a refund depending on the severity of the issue. I aim to resolve the issue quickly and efficiently, ensuring customer satisfaction. If the problem arises due to customer error, I explain the situation in a calm and understanding manner, offering advice to prevent similar issues in the future.

For example, I once had a customer complain that their newly cut key didn’t work in their car. After investigation, it turned out the key blank they provided was for a different car model. I calmly explained the situation, offering to cut a new key with the correct blank at no extra charge. The customer was satisfied with my response and resolution.

Q 21. What is your knowledge of different lock mechanisms?

Understanding various lock mechanisms is fundamental to effective key cutting. My knowledge encompasses different types of pin tumbler locks (the most common type), wafer locks, lever locks, and disk detainer locks, each with its unique internal structure and key profiles.

Pin tumbler locks, for example, operate using a set of pins that must be aligned correctly for the lock to open. The key’s cuts are designed to precisely lift these pins, allowing the lock to turn. Wafer locks, on the other hand, use thin wafers to control the lock’s operation, while lever locks employ a series of levers, each needing to be lifted by the key’s corresponding notches.

My knowledge extends to understanding the differences in keyways (the shape of the key’s cut), which are crucial in determining the correct key blank and ensuring proper duplication. This detailed knowledge allows me to correctly identify and efficiently cut keys for a wide array of locks.

Q 22. How do you stay up-to-date on advancements in key cutting technology?

Staying current in key cutting demands continuous learning. I actively participate in industry workshops and seminars offered by organizations like the Associated Locksmiths of America (ALOA). These events provide hands-on training with the latest key cutting machines and techniques. I also subscribe to trade publications and online forums, keeping abreast of new technologies and best practices. For example, I recently attended a workshop focusing on laser key cutting and its applications in high-security automotive keys. This allowed me to immediately implement improved techniques and expand my service offerings.

Furthermore, I regularly review manufacturer documentation for key cutting equipment and software updates. These updates often include improvements to algorithms for key duplication, new bitting codes for emerging key systems, and troubleshooting guides for common issues. This proactive approach ensures I’m always using the most efficient and accurate methods available.

Q 23. What is your understanding of key code databases?

Key code databases are essentially digital catalogs of key bitting information. They contain thousands, if not millions, of codes that correspond to specific key types and manufacturers. These databases are crucial for creating keys from codes, a common practice when replacing lost keys. They allow locksmiths to generate keys for a wide variety of locks without needing a physical sample key.

Access to these databases is often subscription-based and requires authorization, to prevent unauthorized key duplication. Think of it as a highly secure library of key blueprints. Different databases cater to various lock brands and key systems, and it’s common for professional locksmiths to have subscriptions to multiple databases to cover a broader range of keys.

For example, a database might contain information such as the bit depth and spacing for a specific vehicle’s ignition key, allowing for precise key duplication from code alone. Accurate and up-to-date database access is vital for precise key duplication and is a critical part of my daily work.

Q 24. Describe your experience working independently and as part of a team.

I’m comfortable working both independently and collaboratively. Independent work requires strong problem-solving skills, something I honed over years of troubleshooting complex lock mechanisms. I can manage my workload effectively, prioritising tasks, and delivering projects to a high standard on my own. For instance, I recently had to extract a broken key from a high-security lock, which required patience, precision, and specialized tools, all completed independently.

Teamwork is also essential in this field. When dealing with a particularly complex job or a rush of orders, being able to communicate effectively and collaborate with colleagues to streamline the process is crucial. In a past role, we had to manage a large-scale key duplication project for a new office building. Collaboration ensured efficient task delegation and timely completion.

Q 25. What is your understanding of the ethical responsibilities of a locksmith?

Ethical responsibilities for a locksmith are paramount. They center around honesty, integrity, and respect for the law. This includes refusing to create keys without proper authorization, adhering to all relevant legal requirements regarding key duplication, and respecting customer privacy. This means never duplicating keys for someone who cannot provide valid identification or authorization.

It’s crucial to understand the legal ramifications of unauthorized key duplication and to operate within the bounds of the law. This also extends to the responsible disposal of sensitive information such as key codes and customer details. For example, I never keep records of customer codes unnecessarily and ensure data is stored securely, complying with all data protection regulations.

Q 26. What is your experience with high-security key systems?

I have extensive experience with high-security key systems, including those using patented technologies like dimple keys, laser-cut keys, and sidewinder keys. These systems offer enhanced security compared to standard pin tumbler locks due to their complex designs and unique key profiles. I’m proficient in using specialized equipment for their creation and duplication, often employing advanced code-reading devices and key-cutting machines programmed with the specific algorithms required for each system.

For example, I’ve worked extensively with automotive high-security keys, requiring the use of dedicated programming devices to both cut and program the electronic components embedded within the key. This work demands a thorough understanding of automotive security protocols, which I’ve gained through years of hands-on experience and continuing education.

Q 27. How do you ensure the longevity of cut keys?

Ensuring the longevity of a cut key involves several factors. Firstly, using high-quality key blanks is critical. These are made from durable materials that resist wear and tear. Secondly, proper key cutting techniques are essential to avoid damage during the cutting process. This requires precision equipment and expertise to get the most accurate cut possible, minimizing any stress points that could cause premature failure.

Finally, proper key care is important. Avoid dropping or bending keys and keep them stored properly in a protective case. For keys that are subject to regular use, it’s advisable to occasionally check for wear and have them re-cut if necessary to avoid issues with the lock mechanism.

Q 28. What measures do you take to prevent key duplication fraud?

Preventing key duplication fraud requires strict adherence to ethical practices and legal compliance. This includes always requesting valid identification from customers before duplicating keys, particularly for high-security systems. Refusing to copy keys without proof of ownership is crucial. I also maintain a detailed record of all key duplication activities, which helps in tracking and preventing any potential fraudulent activity.

Furthermore, regular audits of my equipment and software are crucial to ensure there are no vulnerabilities that could be exploited. Finally, maintaining an up-to-date knowledge of the latest security threats and best practices is essential in preventing fraud. This vigilance protects both my business and my customers from potentially damaging situations.

Key Topics to Learn for Your Key Cutting Interview

- Key Types and Blanks: Understanding different key types (e.g., house keys, car keys, padlock keys), their corresponding blanks, and how to identify them.

- Key Cutting Techniques: Mastering various key cutting methods, including manual and automated techniques, and understanding the precision required for each.

- Machine Operation and Maintenance: Familiarity with key cutting machines, their functionalities, safety procedures, and basic maintenance tasks.

- Code Cutting and Duplication: Understanding how to cut keys from codes, using key code systems, and duplicating keys accurately and efficiently.

- Troubleshooting and Problem-Solving: Developing the ability to identify and solve common issues encountered during key cutting, such as jammed machines or improperly cut keys.

- Safety Procedures and Regulations: Adherence to safety regulations, proper use of equipment, and handling of sharp tools.

- Customer Service and Communication: Effective communication with customers, understanding their needs, and providing exceptional service.

- Inventory Management: Basic understanding of stock control, ordering supplies and managing inventory of key blanks and tools.

- Security and Ethical Practices: Understanding the importance of responsible key duplication, avoiding illegal copying and maintaining customer confidentiality.

Next Steps

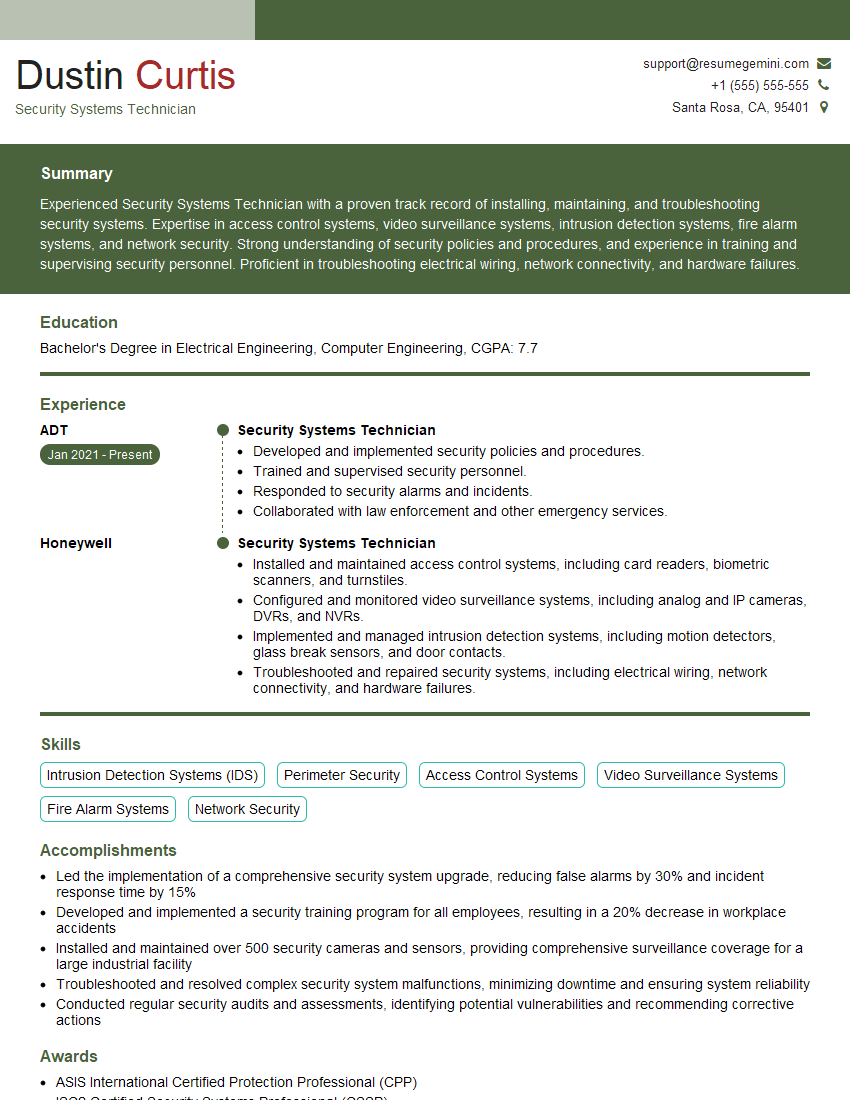

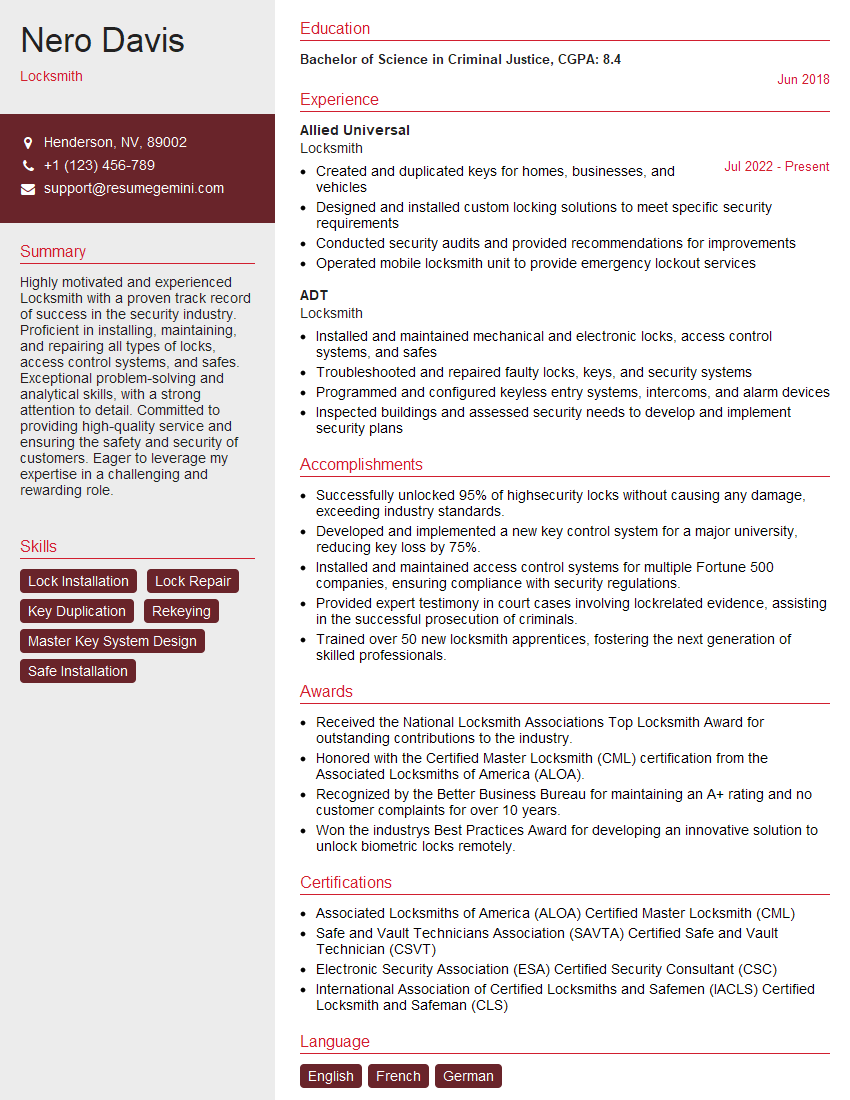

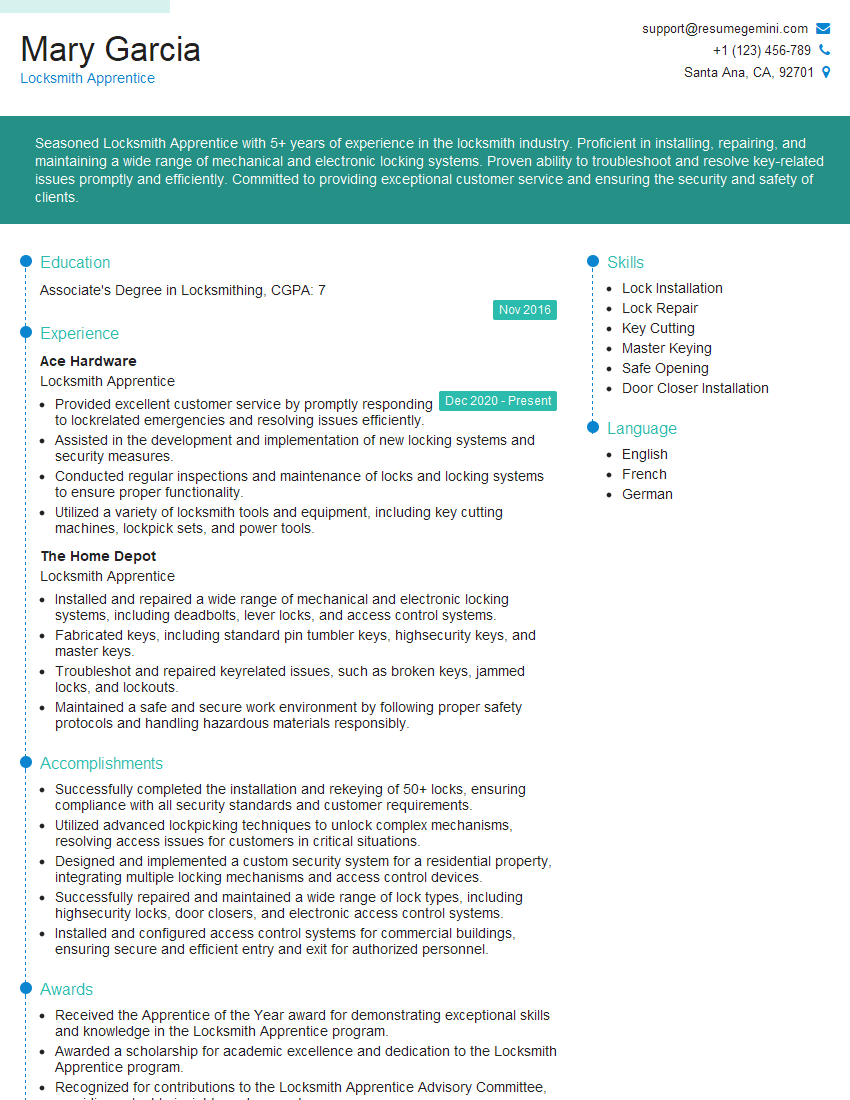

Mastering key cutting opens doors to a rewarding career with opportunities for advancement and specialization. A strong resume is crucial for showcasing your skills and experience to potential employers. To maximize your chances, create an ATS-friendly resume that highlights your key competencies. ResumeGemini is a trusted resource for building professional and effective resumes. We offer examples of resumes tailored specifically to the key cutting industry to help you get started. Invest the time to craft a compelling resume – it’s your first impression and a key factor in securing your ideal position.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO