Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of automotive repair software interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of automotive repair software Interview

Q 1. Describe your experience with common automotive diagnostic software platforms (e.g., Mitchell 1, ALLDATA, Autologic).

My experience with automotive diagnostic software platforms like Mitchell 1, ALLDATA, and Autologic is extensive. I’ve used them daily throughout my career, working with a wide range of vehicle makes and models. Each platform offers unique strengths. Mitchell 1, for example, is known for its comprehensive repair information database and excellent wiring diagrams, which are invaluable when troubleshooting complex electrical issues. ALLDATA excels in providing detailed repair procedures and technical service bulletins (TSBs). Autologic, on the other hand, is particularly strong in its advanced diagnostic capabilities for specific vehicle brands, often providing access to manufacturer-level diagnostic information and allowing for more in-depth system analysis. My proficiency extends beyond simply accessing information; I’m comfortable utilizing their respective diagnostic tools to retrieve and interpret DTCs, perform module scans, and even execute bi-directional controls to test actuators and components.

I’ve successfully used these platforms to diagnose everything from a simple misfire in a gasoline engine to intricate transmission control module (TCM) problems in hybrid vehicles. The selection of the right platform often depends on the specific vehicle and the nature of the problem. For instance, when dealing with a sophisticated electronically controlled suspension system, Autologic’s advanced diagnostic features may be the most efficient approach. However, for a routine brake system diagnosis, Mitchell 1’s comprehensive repair information database might be sufficient.

Q 2. Explain the process of interpreting diagnostic trouble codes (DTCs).

Interpreting Diagnostic Trouble Codes (DTCs) is a crucial skill in automotive diagnostics. A DTC is essentially a numerical code that indicates a specific problem within a vehicle’s system. The process begins by retrieving the DTCs using a scan tool connected to the vehicle’s On-Board Diagnostics (OBD) port. These codes are usually composed of several digits, and their meaning is standardized across manufacturers, although specifics can vary.

Once retrieved, I cross-reference the DTCs with the repair information database of my chosen software (Mitchell 1, ALLDATA, etc.). The software provides detailed descriptions of the DTC, possible causes, and recommended diagnostic steps. For example, a code like P0171 (System Too Lean Bank 1) indicates a fuel delivery problem on one side of the engine. The software would then guide me through troubleshooting steps, such as checking fuel pressure, inspecting the air intake system for leaks, and testing oxygen sensors. It’s crucial to follow the diagnostic flowcharts provided by the software, as attempting repairs randomly can often lead to further complications and unnecessary work.

Sometimes, several DTCs might be related, suggesting a single underlying cause. For example, multiple misfire codes could point to a faulty ignition coil or a problem with the fuel delivery system.

Q 3. How do you troubleshoot a complex electrical fault using automotive repair software?

Troubleshooting a complex electrical fault using automotive repair software involves a systematic approach. I begin by retrieving all relevant DTCs using the scan tool. Then, I use the software’s wiring diagrams to trace the circuit related to the faulty system. Wiring diagrams are crucial – they visually represent the path of electrical signals, showing connectors, components, and ground points. Think of them as a roadmap for the electrical system.

The software also helps to identify the related control modules and their communication pathways. I’ll then utilize the software’s diagnostic features to perform component tests, including resistance checks, voltage measurements, and current monitoring. Many software packages allow bi-directional testing, enabling me to actuate components directly through the diagnostic port to verify their function. For example, if I suspect a faulty relay, I can use the software to activate the relay remotely and observe its response. If the relay doesn’t engage, that confirms a faulty relay. This eliminates guesswork and reduces the risk of replacing unnecessary components.

Throughout the process, I meticulously document all findings and measurements, ensuring a clear and complete record of my diagnostic steps. This detailed record aids future troubleshooting and provides a clear explanation of the repair process for clients.

Q 4. What strategies do you use to efficiently navigate and utilize the features of your preferred automotive diagnostic software?

Efficiently navigating and utilizing automotive repair software is about understanding its architecture and features. I use several strategies. Firstly, I take full advantage of the software’s search functions. Instead of manually browsing through vast amounts of information, I use keywords related to the DTCs or symptoms to pinpoint the relevant sections. The software’s advanced search capabilities are designed to find specific information quickly, saving valuable time.

Secondly, I familiarize myself with the software’s organizational structure. Understanding how the information is categorized – by system, component, or vehicle model – is key. This allows me to access the relevant information effectively. Thirdly, I customize the software’s display settings to my preference. For instance, I prefer large font sizes and clear visual representations of wiring diagrams and component locations.

Finally, I frequently update my software to ensure I have access to the latest information and diagnostic capabilities. Regular updates include new DTCs, TSBs, and diagnostic routines for newer vehicle models and technologies, maximizing diagnostic accuracy and keeping me ahead of the curve.

Q 5. Describe a situation where you had to interpret data from multiple diagnostic systems to pinpoint a vehicle issue.

I once encountered a situation with a hybrid vehicle that experienced intermittent power loss. The initial scan using the vehicle’s OBD system showed a generic DTC related to the high-voltage battery. However, this DTC was too broad to pinpoint the problem.

I then used manufacturer-specific diagnostic software (Autologic in this case) to access the hybrid system’s deeper diagnostic capabilities. This revealed several more specific DTCs within the battery management system, indicating communication errors between individual battery cells. Further investigation using a digital multimeter and the manufacturer’s diagnostic software’s data logging features revealed that one cell exhibited consistently higher resistance than others.

This case demonstrated the importance of using multiple diagnostic systems. The generic OBD system pointed towards a broad problem, while the manufacturer-specific software provided granular data to isolate the root cause, leading to the replacement of the faulty battery cell instead of the entire high-voltage battery pack – a considerably more cost-effective and efficient repair.

Q 6. How do you ensure the accuracy and reliability of data obtained from automotive repair software?

Ensuring the accuracy and reliability of data obtained from automotive repair software requires a multi-pronged approach. Firstly, I always verify the software’s version is up-to-date. Outdated software can lead to inaccurate or incomplete information. Regular software updates are crucial to get the latest TSBs, DTC information and repair procedures.

Secondly, I cross-reference the data obtained from the software with other sources, such as the vehicle’s owner’s manual and independent technical resources. This ensures that the information presented in the software aligns with other reliable sources. Thirdly, I always rely on hands-on measurements and testing using diagnostic equipment. The software provides guidance, but I must confirm its findings through practical testing.

Lastly, I carefully consider the context of the data. For example, a DTC might indicate a specific problem, but the underlying cause could be related to a different component or issue entirely. Using my experience and sound judgement is critical to avoid misdiagnosis.

Q 7. Explain your experience with calibrating sensors and actuators using diagnostic software.

My experience with calibrating sensors and actuators using diagnostic software is significant. Many modern vehicles rely on sophisticated sensors and actuators that require precise calibration for optimal performance. The process usually involves using the software’s specific calibration routines, which often guide you through a series of steps that can be as simple as initializing or adaption procedures, or as complex as performing multiple steps to verify the output of a sensor against known inputs.

For instance, calibrating a throttle position sensor (TPS) usually involves connecting the scan tool, initiating the calibration routine within the software, and then following the prompts on the screen, often involving cycling the throttle through a specific range of motion. The software monitors the sensor’s output, and once the calibration is complete, it stores the new calibration values in the vehicle’s control module. Similarly, calibrating an air flow sensor or a steering angle sensor involves using specific calibration procedures and software routines for accuracy.

It’s crucial to follow the manufacturer’s specifications precisely during calibration to avoid damaging the sensor or control module. Improper calibration can lead to performance issues or even safety hazards. The software acts as a guide, but understanding the underlying principles and procedures is crucial to ensure a successful and safe calibration.

Q 8. What is your process for documenting repair procedures and findings using automotive repair software?

My process for documenting repair procedures and findings using automotive repair software is methodical and comprehensive. It begins with a clear and concise description of the customer complaint. I then use the software to access vehicle-specific data, such as fault codes (DTCs) retrieved from the vehicle’s onboard diagnostic system (OBD-II).

Next, I meticulously document each step of my diagnostic process. This includes noting the specific tests performed, the tools used (e.g., scan tools, multimeters, oscilloscopes), and the corresponding results. Any relevant data, such as sensor readings or waveform captures, are saved directly within the software’s database. For example, if I find a faulty oxygen sensor, I document the sensor’s readings (both before and after replacement), along with relevant screenshots of the data stream. I use the software’s reporting features to generate a detailed report, including images and graphs, to clearly present my findings and the repair procedures undertaken. This report also includes parts used, labor time, and any relevant customer interactions.

Finally, I ensure the repair order is complete and accurate, reflecting the entire diagnostic and repair process. This detailed documentation is crucial for warranty claims, tracking repair history, and providing transparency for the customer.

Q 9. How familiar are you with advanced diagnostic techniques like oscilloscope analysis integrated with repair software?

I am very familiar with advanced diagnostic techniques, such as oscilloscope analysis, and their integration with repair software. Think of the oscilloscope as a powerful magnifying glass for electrical signals within the vehicle. It allows me to visually analyze waveforms – the patterns of voltage changes over time – from various sensors and actuators. This is invaluable in identifying intermittent problems or subtle issues that standard scan tool data might miss. For instance, a seemingly minor fluctuation in an injector’s signal might indicate a wiring issue or a problem within the injector driver circuit, something that is often difficult to catch with traditional fault codes.

Many modern repair software packages integrate directly with oscilloscopes. This integration allows me to seamlessly capture, store, and analyze waveform data alongside other diagnostic information, generating a comprehensive report. The software often provides tools for waveform analysis, such as measuring rise times, fall times, and frequency, which speeds up diagnostics considerably. This combined approach significantly increases the accuracy and efficiency of my diagnoses.

Q 10. How do you stay updated on new software features and diagnostic procedures?

Staying updated on new software features and diagnostic procedures is crucial in this rapidly evolving field. I achieve this through a multi-pronged approach.

- Manufacturer Training: I actively participate in manufacturer-specific training sessions, both online and in person, to learn about new vehicle technologies and the associated diagnostic software updates.

- Software Updates: I diligently install all software updates as they are released, ensuring I have access to the latest diagnostic capabilities and database information.

- Technical Publications: I regularly consult technical service bulletins (TSBs) and other relevant technical documentation published by vehicle manufacturers and software developers.

- Industry Conferences and Workshops: Attending industry events provides networking opportunities and exposure to the latest advancements in automotive diagnostics and repair software.

- Online Resources: I leverage reputable online forums and communities for discussions and insights into troubleshooting complex diagnostic challenges.

By combining these methods, I am confident that I remain current with the best and most efficient diagnostic approaches.

Q 11. Describe your experience with specific automotive repair software modules (e.g., emissions, body control, powertrain).

I have extensive experience with various automotive repair software modules, including emissions, body control, and powertrain systems. My experience isn’t limited to simply reading codes; I actively utilize the diagnostic capabilities of each module to pinpoint the root cause of issues.

- Emissions: I use emission-related modules to diagnose issues such as oxygen sensor malfunctions, catalytic converter failures, and evaporative emissions system (EVAP) leaks. I’m adept at interpreting data from various sensors, including oxygen sensors, mass airflow sensors (MAF), and barometric pressure sensors, to diagnose complex issues.

- Body Control: Within this module, I’m experienced in diagnosing problems with electrical components such as window regulators, door locks, lighting systems, and various body control modules (BCM). The software enables systematic testing of these components and helps trace wiring issues.

- Powertrain: This is where a deep understanding is essential. I’m comfortable navigating diagnostic trouble codes (DTCs), analyzing sensor data from various engine components such as crankshaft position sensors (CKP), camshaft position sensors (CMP), and throttle position sensors (TPS). I can use advanced functions like active tests and actuator control to pinpoint problems in fuel delivery, ignition timing, and various other powertrain-related functions. For example, I can use the software to command the fuel injectors to operate at a specific duty cycle to rule out injector problems.

My proficiency spans across different software platforms, allowing me to adapt quickly to new systems and troubleshoot effectively.

Q 12. What is your experience with remote diagnostic capabilities of automotive repair software?

My experience with the remote diagnostic capabilities of automotive repair software is significant. This functionality is increasingly important for efficient troubleshooting and reduces the need for multiple vehicle visits. I’ve used remote diagnostic tools that allow me to connect to a vehicle’s onboard computer system remotely via a secure connection, often using a telematics device installed in the vehicle. This allows me to retrieve diagnostic trouble codes (DTCs), monitor live data streams (e.g., engine RPM, coolant temperature, and fuel pressure), and even perform some basic actuator tests.

This remote capability has proven particularly useful for diagnosing intermittent problems or situations where a vehicle is geographically distant. For example, I have used remote diagnostics to identify a faulty sensor in a customer’s vehicle that was hundreds of miles away. I was able to guide the customer through basic checks and confirm the diagnosis before scheduling a repair appointment, thus optimizing repair time and reducing customer inconvenience.

Q 13. How do you handle software glitches or errors during a diagnosis?

Software glitches or errors during diagnosis are a reality. My approach is systematic and focuses on verification and alternative methods.

- Verify the Connection: I first verify that the software is properly connected to the vehicle’s OBD-II port and that all connections are secure. A loose connection or faulty interface can lead to erroneous data.

- Restart Software and Vehicle: A simple restart of both the software and the vehicle’s ignition system can often resolve minor glitches.

- Check for Updates: I ensure the diagnostic software is up-to-date, as outdated software can be prone to errors or lack compatibility with newer vehicle systems.

- Consult Technical Documentation: If the error persists, I consult the software’s documentation, or contact the software vendor for technical support, to explore possible causes and troubleshooting steps.

- Alternative Diagnostic Methods: If the software consistently produces unreliable data, I might employ alternative diagnostic methods, such as using a different scan tool or utilizing multimeter measurements to verify sensor readings directly.

- Document Everything: Regardless of the outcome, I meticulously document the error, the troubleshooting steps taken, and the final resolution in the repair order to facilitate future diagnostics and prevent similar issues.

Q 14. Have you ever experienced conflicting information from different diagnostic software platforms? How did you resolve it?

Yes, I have encountered situations where different diagnostic software platforms provided conflicting information. This often arises due to differences in the software’s databases, diagnostic algorithms, or even variations in how the software interprets data from the vehicle’s control modules. The key is to adopt a systematic approach to resolve the discrepancies.

- Verify Data Sources: I carefully examine the data from each platform, identifying any discrepancies in fault codes, sensor readings, or other relevant parameters. This helps determine whether the conflict is due to a real issue in the vehicle or a software interpretation problem.

- Cross-Reference with Other Data: I use additional diagnostic tools, such as multimeters or oscilloscopes, to independently verify sensor readings and other data points. This provides an independent check on the information obtained from the software.

- Consult Technical Resources: I consult technical service bulletins (TSBs), manufacturer documentation, and other reputable technical resources to see if there are known issues or discrepancies with the specific vehicle system or the software platforms themselves.

- Investigate Vehicle History: Sometimes, past repairs or modifications can impact diagnostic results. Reviewing the vehicle’s repair history can provide context and potential explanations for conflicting data.

- Expert Consultation: For complex issues, I might consult with more experienced technicians or seek assistance from the software vendors for expert guidance.

The goal is to reach a conclusive diagnosis by cross-referencing data from multiple sources and using my experience to synthesize the information correctly.

Q 15. How do you troubleshoot software-related issues in older vehicles?

Troubleshooting software issues in older vehicles presents unique challenges due to their simpler, often less standardized, diagnostic systems. Unlike modern vehicles with extensive OBD-II capabilities, older cars may require specialized adapters and software. My approach begins with a thorough understanding of the vehicle’s year, make, and model to select the appropriate diagnostic interface and software.

I first verify the connection between the scan tool and the vehicle’s diagnostic port (often located under the dashboard). A loose or faulty connection is a common culprit. If the connection is secure, I’ll attempt a basic communication check to see if the software can successfully communicate with the vehicle’s Electronic Control Units (ECUs).

If communication is established, I systematically check for diagnostic trouble codes (DTCs). These codes offer valuable clues to the problem’s source. However, interpreting these codes in older systems sometimes requires consulting manuals or online databases specific to that vehicle year and model. Finally, if DTCs don’t pinpoint the issue, more advanced techniques like data logging (discussed later) might be necessary to identify intermittent problems or subtle performance variations. It’s crucial to remember that patience and systematic troubleshooting are key when working with older vehicles, which may require more manual intervention than modern ones.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with data logging and analysis using automotive repair software.

Data logging and analysis is crucial for diagnosing intermittent issues and subtle performance problems. My experience involves utilizing various automotive repair software packages to capture real-time data from multiple ECUs simultaneously. For example, I’ve used software like Autologic and Snap-on Modis to monitor parameters like engine speed, throttle position, fuel trim, and oxygen sensor readings. This allows me to identify correlations between different sensor inputs and pinpoint the source of malfunction more effectively than simply reading static DTCs.

Once logged, the data is meticulously analyzed. I use the software’s graphing and trend analysis features to visually identify abnormalities. A simple example: If I’m investigating a rough idle, I might observe a fluctuating idle speed combined with erratic oxygen sensor readings, suggesting a problem with the air-fuel mixture. These software packages often offer tools to export the data in various formats (CSV, Excel etc.) for further detailed analysis in external tools, should more advanced data manipulation be necessary. The ability to generate custom reports and compare data from multiple test drives is invaluable in accurately identifying and resolving complex problems.

Q 17. What are the limitations of using automotive repair software, and how do you mitigate them?

Automotive repair software, while powerful, has limitations. One major limitation is the software’s reliance on accurate vehicle identification. Incorrectly selecting a vehicle model can lead to misinterpretations of DTCs and inaccurate data readings. Additionally, some software might lack support for newer vehicles or specific ECUs. Another limitation is the occasional lack of real-time, graphical data representation, which may make identifying subtle problems difficult.

To mitigate these limitations, I always carefully verify the vehicle’s year, make, model, and VIN before connecting any diagnostic software. I regularly update my software to ensure compatibility with newer vehicles and ECUs. I cross-reference information from multiple sources, such as manufacturer service bulletins, online forums, and my own experience, whenever I encounter ambiguous diagnostic results. If the software lacks specific functionalities I need, I utilize other tools to compensate. For example, while some diagnostic tools offer limited oscilloscope capabilities, I supplement them with a separate oscilloscope to analyze complex electrical signals. This multifaceted approach ensures accuracy and thoroughness in diagnostics.

Q 18. Explain your understanding of CAN bus systems and their interaction with diagnostic software.

The Controller Area Network (CAN) bus is a crucial communication system in modern vehicles, allowing different ECUs to exchange information. My understanding of CAN bus systems is essential for effective use of diagnostic software. Diagnostic software communicates with ECUs over the CAN bus, sending requests for data and receiving responses. This communication typically involves sending specific requests (messages) formatted according to the CAN protocol.

The software interprets these responses, decoding the data to extract meaningful information. The software needs to understand the specific CAN message IDs (identifiers) associated with different ECU parameters. For example, a specific ID might correspond to engine speed, while another ID corresponds to throttle position. If the software doesn’t correctly interpret these IDs or fails to communicate over the CAN bus, it won’t be able to access crucial data. Therefore, a solid grasp of CAN bus communication and the vehicle’s specific CAN bus architecture is critical for accurate diagnosis.

Q 19. How do you maintain data security and privacy when using automotive repair software?

Data security and privacy are paramount when using automotive repair software. This software often accesses sensitive vehicle data, including VIN, DTCs, and other potentially identifiable information. My practices focus on adhering to both company policies and relevant data protection regulations. These practices include, but are not limited to:

- Secure Software Updates: Regularly updating the diagnostic software and ensuring the software is obtained from trusted and legitimate sources.

- Limited Access: Using strong, unique passwords and restricting access to the software and data to authorized personnel only.

- Data Encryption: Utilizing software which employs encryption techniques to protect data both in transit and at rest.

- Data Disposal: Following strict procedures to securely erase or destroy any sensitive vehicle data after the diagnostic process is complete.

- Physical Security: Securing diagnostic tools and laptops to prevent unauthorized access.

Ultimately, my priority is to ensure that all customer data remains confidential and secure throughout the diagnostic process.

Q 20. Explain your experience with creating custom reports or data visualizations from diagnostic software.

I have extensive experience creating custom reports and data visualizations using automotive diagnostic software. Many diagnostic programs allow exporting data in various formats for further analysis. For instance, I’ve used this capability to generate reports detailing sensor data trends over time to identify potential issues before they cause major problems. I’ve also tailored reports to meet specific client needs.

An example is creating a custom report showing the correlation between fuel consumption and engine load to demonstrate the efficiency (or lack thereof) of a particular engine under various driving conditions. This involved exporting data, processing it using spreadsheets or dedicated data visualization tools like Tableau or Power BI, and finally generating a visually appealing report that effectively communicates technical information to non-technical audiences. The flexibility of these tools is critical for efficient problem-solving and client communication.

Q 21. How do you interpret sensor data trends to identify potential future problems?

Interpreting sensor data trends is crucial for predictive maintenance. I analyze data logs, looking for gradual changes or deviations from expected patterns. For example, a slowly decreasing fuel trim value could indicate a developing issue with the fuel injectors or oxygen sensor. Similarly, a gradual increase in engine oil temperature might suggest a problem with the cooling system.

My approach involves using the software’s graphing and trend analysis tools. I visually inspect graphs for consistent upward or downward trends, which could indicate impending issues. I also utilize statistical tools within some software packages to identify significant deviations from the mean. For instance, if a specific sensor consistently exceeds certain thresholds, or shows unusual variability, it alerts me to a potential future problem. This proactive approach helps prevent catastrophic failures and ensures vehicle reliability.

Q 22. Describe your approach to troubleshooting a no-start condition using automotive diagnostic software.

Troubleshooting a no-start condition begins with a systematic approach using automotive diagnostic software. It’s like detective work, systematically eliminating possibilities. I start by connecting the scan tool to the vehicle’s OBD-II port and retrieving any stored Diagnostic Trouble Codes (DTCs). These codes provide clues about potential problems. Then, I’d check the basics: battery voltage, cranking speed, and fuel pressure. The software will often allow me to monitor these parameters in real-time. For example, a low cranking speed might point to a bad starter motor, while low fuel pressure might indicate a fuel pump issue. If DTCs point towards specific modules (like the PCM or BCM), I’ll delve deeper into their data streams to analyze sensor readings and actuator commands. This might involve checking for communication errors between modules or examining live data for inconsistencies. For instance, if the crankshaft position sensor is not sending a signal, the engine won’t even attempt to crank. If there’s no communication, I’ll check the wiring, connectors, and fuses related to the concerned module. The process is iterative; resolving one issue might uncover another, requiring further investigation with the help of the software’s extensive diagnostic capabilities.

Q 23. What are the key differences between various automotive repair software packages?

Automotive repair software packages vary significantly in features, capabilities, and cost. Some are basic OBD-II scanners offering only DTC retrieval and live data, while others are comprehensive diagnostic suites offering advanced functions like bidirectional controls, sensor calibrations, and programming. For example, some packages may focus on domestic vehicles, while others are equipped to handle import vehicles, each with their unique communication protocols and data formats. Higher-end software packages often incorporate extensive repair databases, wiring diagrams, and technical service bulletins (TSBs) to assist technicians in understanding complex issues. The user interface also plays a crucial role; some packages are more intuitive and user-friendly than others. Finally, the level of OEM-specific support differs among packages, with some providing specialized capabilities for particular vehicle makes and models.

Q 24. Explain the importance of proper software updates and their impact on diagnostics.

Software updates are crucial for accurate and reliable diagnostics. Manufacturers continuously release updates that address bugs, improve performance, add support for newer vehicle models, and incorporate updated data, such as new DTC definitions and TSBs. Out-of-date software can lead to misdiagnosis, missed codes, or inaccurate data readings. Imagine relying on a map from 1990 to navigate a modern city; you would likely get lost. Similarly, outdated diagnostic software can’t interpret the complex data produced by modern vehicles’ sophisticated electronics. Regular updates ensure that the software has the most current information to properly interpret data, access advanced features, and avoid compatibility issues. They effectively keep your diagnostic tools current with ever-evolving vehicle technologies.

Q 25. How familiar are you with different communication protocols (e.g., OBD-II, J1939) and their use in diagnostic software?

I’m very familiar with various communication protocols used in automotive diagnostics. OBD-II is the standard for most vehicles produced since 1996, allowing for standardized communication between a scan tool and the vehicle’s onboard computer. J1939 is a more robust protocol commonly used in heavy-duty vehicles and commercial equipment, handling more data and supporting more complex systems. Understanding these protocols is essential because diagnostic software needs to properly communicate with the vehicle’s Electronic Control Units (ECUs). A scan tool must use the correct protocol to properly access the desired data. Mismatched protocols result in communication failures, preventing access to crucial diagnostic information. For example, attempting to use an OBD-II-only scanner on a vehicle using J1939 will likely fail to connect. My expertise extends to understanding the intricacies of various protocols and selecting the appropriate communication setting within the software for accurate diagnosis.

Q 26. Describe a challenging diagnostic issue you solved using automotive repair software, highlighting the steps you took.

One challenging case involved a vehicle that exhibited intermittent stalling. The customer reported the vehicle would suddenly stop while driving, with no warning lights. Initial OBD-II scans revealed no stored DTCs. Using advanced diagnostic software, I was able to monitor various sensor data streams in real-time. Through careful observation, I noticed erratic readings from the crankshaft position sensor (CKP sensor) only when the stalling occurred. The data showed the CKP signal dropping out intermittently before the stall. The software’s waveform analysis feature was crucial in visually identifying this pattern. Initially, I suspected a faulty CKP sensor. However, after replacing the sensor, the issue persisted. Using the wiring diagrams within the software, I meticulously traced the CKP sensor’s wiring harness, discovering a broken wire within the harness near the engine’s bell housing. Repairing the harness resolved the issue completely. This highlights the importance of combining sensor data analysis, waveform interpretation, and understanding wiring diagrams for effective diagnostics.

Q 27. What is your preferred method for managing and organizing diagnostic data?

I maintain organized diagnostic data using a combination of methods. For each vehicle, I create a digital folder containing all relevant information: scan reports, live data logs, pictures, and repair orders. Software often facilitates this through its reporting capabilities. I also utilize the software’s database functionality to store and retrieve diagnostic information efficiently. The software’s ability to tag and categorize data ensures easy retrieval and allows for searching across multiple vehicles. Using a standardized naming convention for files and folders helps me keep things consistent. This comprehensive approach ensures easy access to historical data for future reference and assists in building a database of past diagnostic cases that can aid in identifying patterns and solving future issues more efficiently.

Q 28. How would you explain the diagnostic process using automotive repair software to a non-technical client?

Imagine your car’s computer is like a brain. When something goes wrong, it sends out error messages, but in a code that only specialized tools can understand. Automotive repair software is like a translator that helps us understand these codes. We connect a device to your car, and this software reads the ‘error messages’ from your car’s computer. This helps us pinpoint the problem, like a faulty sensor or a malfunctioning component. We can also monitor your car’s systems in real-time using this software, much like a doctor monitoring your heartbeat, to diagnose the problem precisely. The software then helps us propose solutions and repairs, like replacing a part or reprogramming the computer, getting your car back on the road quickly and reliably.

Key Topics to Learn for Automotive Repair Software Interviews

- Diagnostic Software Proficiency: Understanding the functionalities of various diagnostic software platforms (e.g., Mitchell 1, ALLDATA, Autologic) including data retrieval, code interpretation, and system testing. Practical application: Describe your experience troubleshooting a complex diagnostic issue using specific software.

- Repair Information Systems: Familiarity with accessing and interpreting repair information, wiring diagrams, and technical service bulletins (TSBs) within the software. Practical application: Explain how you’ve used repair information to successfully complete a challenging repair.

- Estimating and Parts Ordering: Experience using software to generate repair orders, estimate labor times, and order necessary parts. Practical application: Detail your process for ensuring accurate estimates and timely parts procurement.

- Shop Management Software: Knowledge of shop management systems for tasks like scheduling, inventory control, and customer communication. Practical application: Describe how you’ve utilized shop management software to improve efficiency and customer satisfaction.

- Data Analysis and Reporting: Ability to analyze data generated by the software to identify trends, improve efficiency, and track key performance indicators (KPIs). Practical application: Explain how you’ve used software data to identify areas for improvement in a repair process.

- Software Updates and Troubleshooting: Understanding the importance of keeping software updated and troubleshooting technical issues within the software. Practical application: Describe your approach to resolving software glitches and ensuring smooth operation.

Next Steps

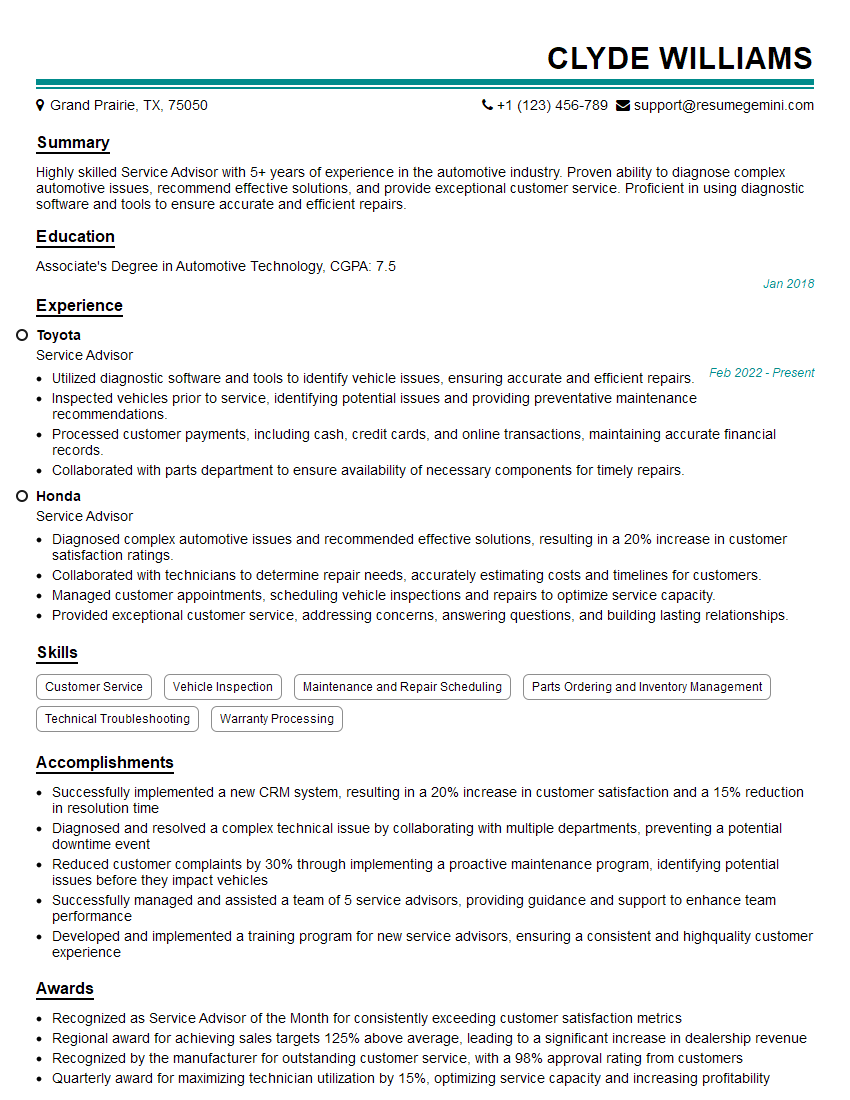

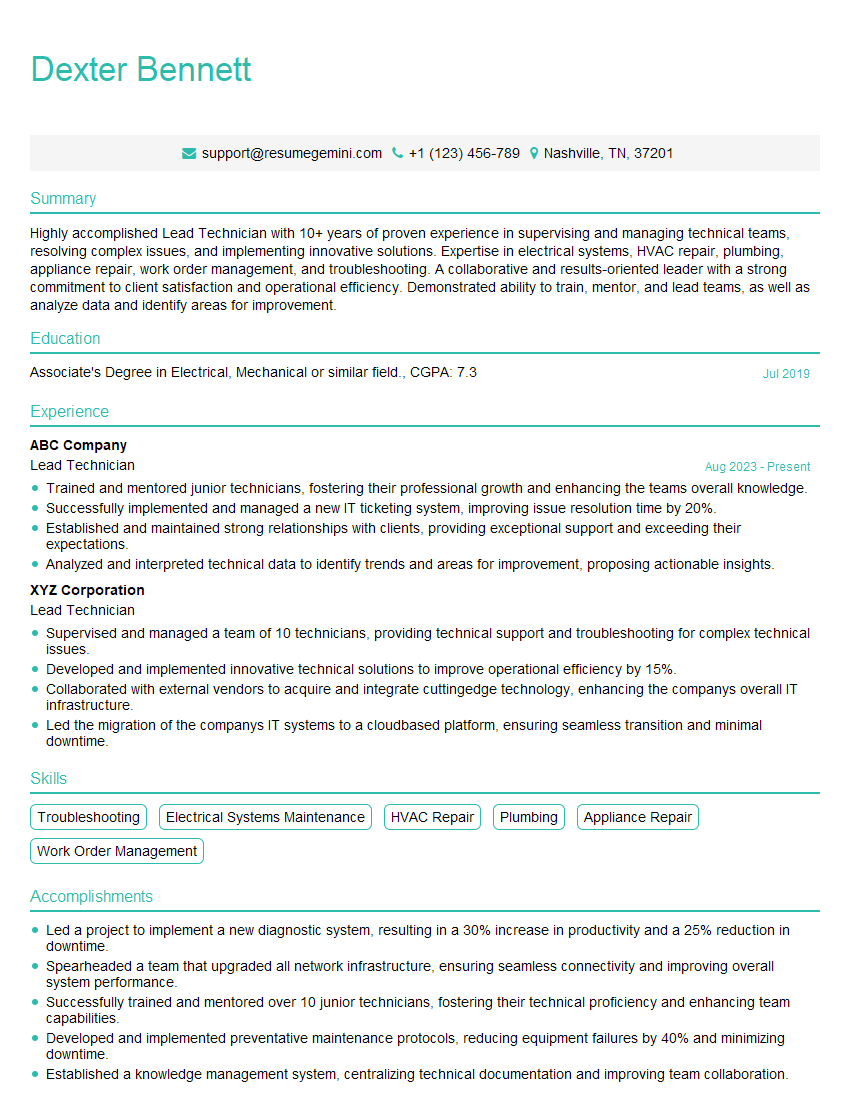

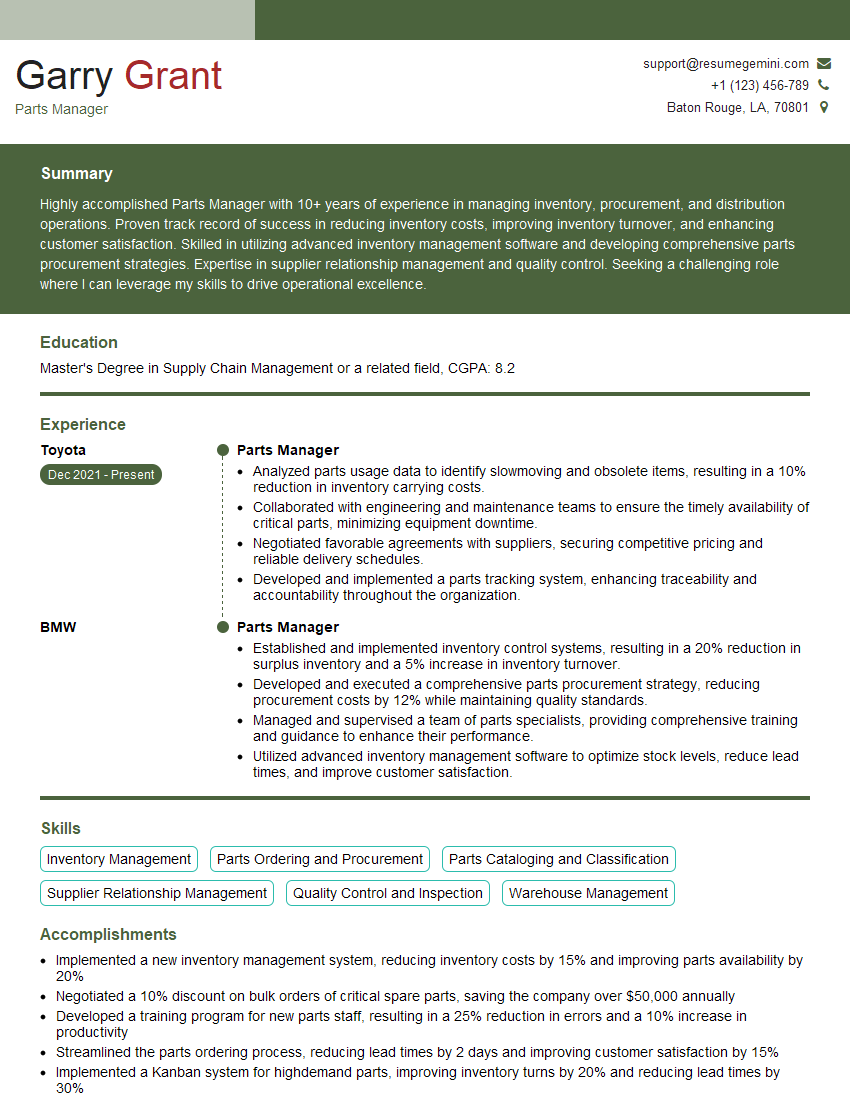

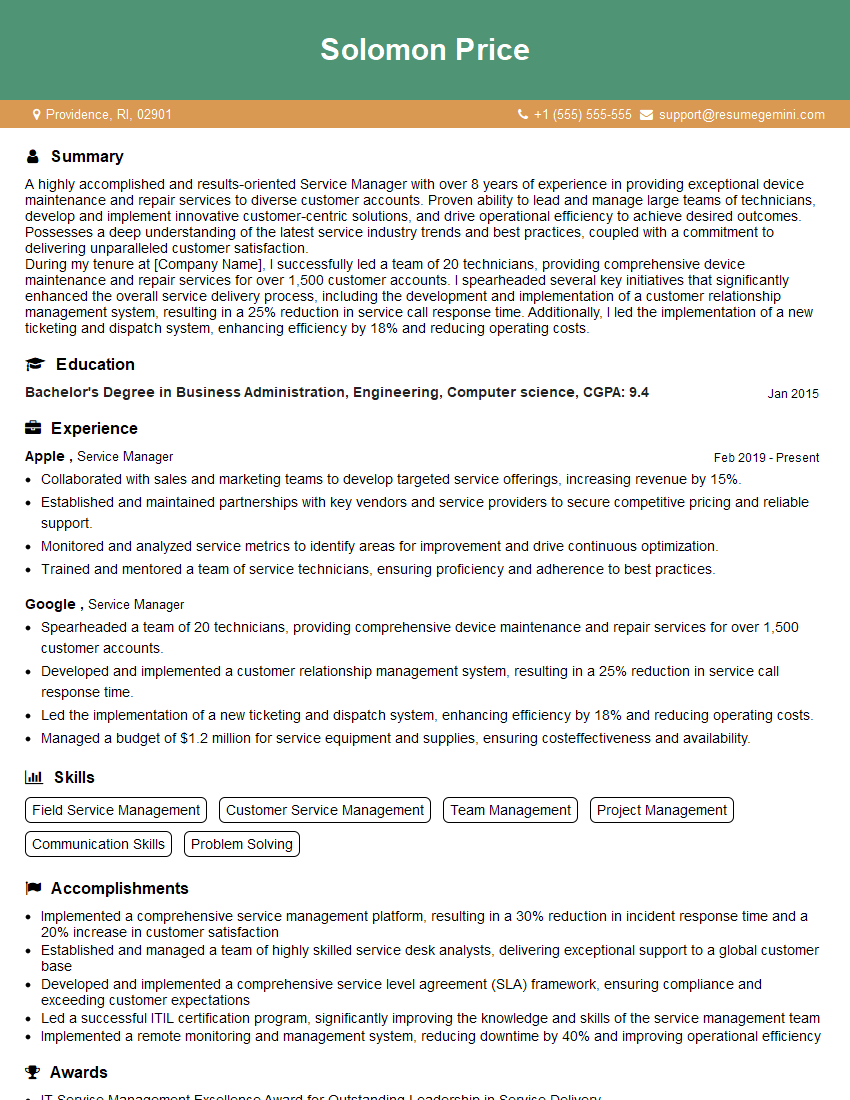

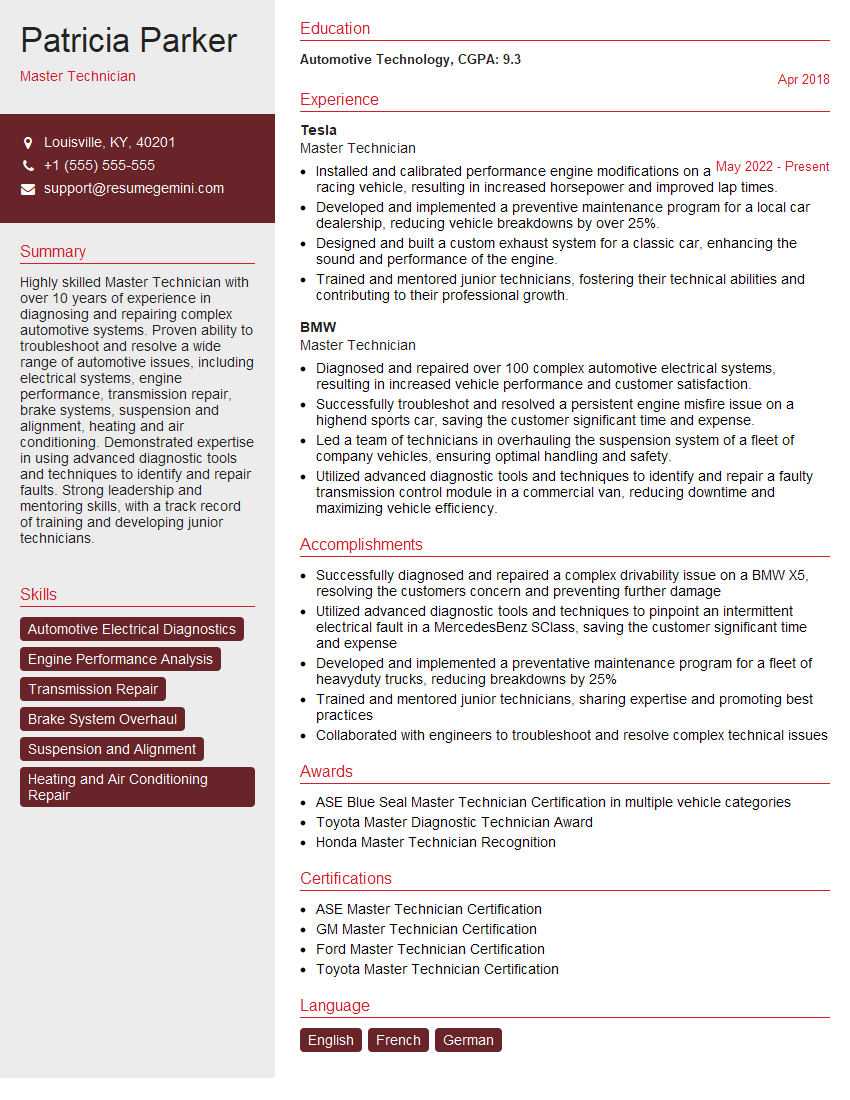

Mastering automotive repair software is crucial for career advancement in the automotive industry. Proficiency in these tools demonstrates technical expertise and efficiency, making you a highly valuable asset to any repair shop or dealership. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource for building professional resumes that get noticed. They provide examples of resumes tailored to automotive repair software expertise, helping you showcase your skills effectively and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.