The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Knowledge of Business Operations interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Knowledge of Business Operations Interview

Q 1. Describe your experience with process improvement methodologies (e.g., Lean, Six Sigma).

My experience encompasses a wide range of process improvement methodologies, most notably Lean and Six Sigma. Lean focuses on eliminating waste in all forms – time, materials, effort – to streamline processes and maximize efficiency. I’ve used Lean principles in several projects, for example, optimizing a customer onboarding process by identifying and removing redundant steps, resulting in a 20% reduction in processing time. Six Sigma, on the other hand, is data-driven and uses statistical methods to identify and eliminate defects, aiming for near-perfection. I’ve applied DMAIC (Define, Measure, Analyze, Improve, Control) methodology to reduce error rates in a manufacturing process by 85%, leading to significant cost savings.

In both approaches, I emphasize collaboration and employee engagement. Successfully implementing these methodologies requires buy-in from all stakeholders and a focus on continuous improvement, not just one-time fixes. I believe in training team members on these techniques to foster a culture of ongoing optimization.

Q 2. Explain your understanding of key performance indicators (KPIs) and their application.

Key Performance Indicators (KPIs) are quantifiable measures that reflect the performance of a business or a specific process towards achieving its objectives. They are crucial for monitoring progress, identifying areas for improvement, and making data-driven decisions. The selection of KPIs depends on the specific goals; a marketing team might use website traffic and conversion rates, while a manufacturing plant might focus on production output and defect rates.

For example, in a previous role, we implemented a suite of KPIs including customer satisfaction scores (CSAT), order fulfillment time, and employee turnover rate. Tracking these metrics allowed us to pinpoint bottlenecks in our operations and implement targeted improvements. Regularly reviewing KPIs ensures that we stay aligned with our strategic goals and make necessary adjustments along the way.

Q 3. How would you analyze operational inefficiencies and propose solutions?

Analyzing operational inefficiencies involves a systematic approach. I typically begin by gathering data from various sources – production reports, customer feedback, employee interviews – to identify areas of concern. Then, I use tools like process mapping and value stream mapping to visualize the current state and pinpoint bottlenecks. This allows me to clearly see where time and resources are being wasted.

Once the inefficiencies are identified, I develop solutions using data analysis and root cause analysis techniques. This might involve automating repetitive tasks, optimizing workflows, improving employee training, or investing in new technology. For instance, I once identified an inefficiency in a supply chain caused by a lack of real-time inventory tracking. Implementing a new inventory management system solved the problem and reduced lead times by 30%.

Finally, I implement the solutions, monitor their effectiveness through KPIs, and make further adjustments as needed. Continuous monitoring and refinement are key to sustained improvement.

Q 4. Describe your experience with project management methodologies (e.g., Agile, Waterfall).

I’m proficient in both Agile and Waterfall project management methodologies. Waterfall is a sequential approach, suitable for projects with well-defined requirements and minimal anticipated changes. I’ve successfully managed several software development projects using this methodology, emphasizing thorough planning and documentation up front.

Agile, on the other hand, is iterative and emphasizes flexibility and collaboration. It is better suited for projects where requirements may evolve during development. I’ve used Agile (specifically Scrum) in several projects, leveraging daily stand-ups, sprints, and retrospectives to adapt to changing needs and deliver value incrementally. My experience demonstrates a flexibility to adapt my project management approach to the specific project needs.

Q 5. How do you prioritize competing demands and manage multiple projects simultaneously?

Prioritizing competing demands and managing multiple projects simultaneously requires a structured approach. I use techniques like prioritization matrices (e.g., Eisenhower Matrix) to classify tasks based on urgency and importance. This helps me focus on high-impact activities first. I also utilize project management software to track deadlines, allocate resources, and monitor progress across multiple projects.

Furthermore, I establish clear communication channels with stakeholders to ensure transparency and manage expectations. Regular status meetings and progress reports help keep everyone informed and aligned. Effective time management, delegation, and the ability to say ‘no’ to non-essential tasks are crucial for success in this area.

Q 6. How would you handle a sudden disruption to a critical business process?

Handling a sudden disruption to a critical business process requires a swift and decisive response. My approach involves a three-step process:

- Assess the situation: Immediately determine the nature and extent of the disruption, identifying the impact on operations and stakeholders.

- Implement contingency plans: Activate pre-defined contingency plans or develop temporary solutions to mitigate the disruption’s impact. This could involve rerouting workflows, deploying backup systems, or engaging additional resources.

- Investigate and prevent recurrence: Once the immediate crisis is resolved, conduct a thorough investigation to identify the root cause of the disruption. Implement corrective actions to prevent similar incidents in the future. This might involve improving infrastructure, updating processes, or enhancing training.

For example, during a major server outage, we swiftly switched to a backup system, minimizing downtime and customer impact. Following the incident, we implemented enhanced monitoring and redundancy measures to prevent future outages.

Q 7. What is your experience with budgeting and forecasting?

My experience with budgeting and forecasting involves developing and managing budgets aligned with organizational goals. I utilize various forecasting techniques, such as trend analysis and regression models, to predict future costs and revenues. I ensure alignment between the budget and strategic objectives, translating high-level goals into specific, measurable financial targets.

I’ve worked with various budgeting software and tools to track expenses, monitor performance against budget, and generate financial reports. For example, I successfully prepared an annual budget for a marketing campaign, accurately forecasting costs and achieving a positive ROI. Regular monitoring and variance analysis help me identify potential overspending or underperformance and take corrective actions early on. I believe in the importance of transparency and clear communication around budgets and financial performance.

Q 8. Explain your understanding of supply chain management.

Supply chain management (SCM) encompasses the entire process of designing, planning, executing, controlling, and monitoring the flow of goods and services from origin to consumption. It’s about optimizing the entire journey, from raw materials to the end customer. Think of it like a carefully orchestrated symphony where every instrument (supplier, manufacturer, distributor, retailer) plays its part perfectly to create a harmonious whole.

Effective SCM involves several key areas:

- Procurement: Sourcing raw materials and components.

- Production: Manufacturing or assembling products.

- Inventory Management: Optimizing stock levels to meet demand while minimizing costs.

- Logistics: Transportation, warehousing, and delivery of goods.

- Customer Service: Managing order fulfillment and customer interactions.

For example, consider a clothing company. Effective SCM ensures they have the right amount of cotton (procurement) at the right time for their factories (production), that finished garments are stored efficiently (inventory), and that they reach stores (logistics) on schedule to meet customer demand (customer service). A poorly managed supply chain can lead to delays, stockouts, increased costs, and unhappy customers.

Q 9. How do you ensure compliance with relevant regulations and policies?

Compliance is paramount in business operations. My approach involves a multi-faceted strategy:

- Proactive Monitoring: I stay updated on all relevant regulations – industry-specific, environmental, labor, and safety – through regular review of official publications, industry newsletters, and professional development.

- Policy Implementation: I ensure that our company’s policies and procedures are aligned with all legal and ethical requirements. This includes establishing clear guidelines for employees, providing training, and conducting regular audits.

- Risk Assessment: Identifying potential compliance risks and developing mitigation strategies to minimize those risks is a key aspect. This often involves creating checklists and workflows to guide employees and ensure adherence.

- Documentation: Meticulous record-keeping is vital. This includes maintaining detailed documentation of compliance procedures, audits, and any corrective actions.

- Continuous Improvement: Regulations and best practices evolve, so I’m committed to continuously improving our compliance systems through regular reviews and updates.

For instance, in a food manufacturing setting, rigorous adherence to food safety regulations (like HACCP) is crucial. Failure to comply can result in severe penalties, product recalls, and damage to reputation.

Q 10. Describe your experience with data analysis and reporting in a business context.

Data analysis and reporting are integral to effective business decision-making. My experience spans various analytical techniques, including:

- Descriptive Analytics: Using tools like Excel and SQL to summarize and visualize data, identifying trends and patterns. For example, tracking sales figures over time to understand seasonal variations.

- Predictive Analytics: Employing statistical modeling and machine learning algorithms (e.g., regression analysis, time series forecasting) to anticipate future outcomes. This could involve predicting customer demand to optimize inventory levels.

- Prescriptive Analytics: Utilizing optimization techniques to identify the best course of action. An example would be using linear programming to determine the optimal allocation of resources.

I’m proficient in creating dashboards and reports that effectively communicate key performance indicators (KPIs) to stakeholders at all levels. I also leverage data visualization tools like Tableau or Power BI to present complex information in a clear and concise manner. In my previous role, my data analysis led to a 15% reduction in inventory holding costs.

Q 11. How familiar are you with different ERP systems (e.g., SAP, Oracle)?

I have significant experience with several ERP systems, most notably SAP and Oracle. My familiarity extends beyond basic usage; I understand their underlying architectures, functionalities, and how to leverage them for business process optimization.

In previous roles, I’ve been involved in:

- Implementation Projects: Participating in the selection, configuration, and deployment of ERP systems.

- Process Improvement: Using ERP data to identify bottlenecks and inefficiencies in operational processes.

- System Integration: Connecting ERP systems with other enterprise applications to create a seamless data flow.

- Data Migration: Managing the transfer of data from legacy systems to new ERP systems.

My experience allows me to effectively navigate the complexities of these systems and leverage them to drive operational efficiency and strategic decision-making. For example, I’ve used SAP’s materials management module to improve procurement processes, resulting in significant cost savings.

Q 12. How do you measure the success of operational initiatives?

Measuring the success of operational initiatives requires a well-defined set of metrics tailored to the specific goals. I typically use a balanced scorecard approach, considering both financial and non-financial measures. This could include:

- Financial Metrics: Cost reduction, increased revenue, improved profitability, return on investment (ROI).

- Operational Metrics: On-time delivery, inventory turnover, order fulfillment rate, defect rate, production efficiency.

- Customer Metrics: Customer satisfaction, customer retention, Net Promoter Score (NPS).

- Employee Metrics: Employee satisfaction, safety record, productivity.

For example, when assessing the success of a lean manufacturing initiative, I would track metrics like cycle time reduction, waste reduction, and improved employee engagement. Each metric needs to be clearly defined and regularly monitored. The use of dashboards and regular reporting ensures that progress is visible and adjustments can be made as needed.

Q 13. Describe your experience with change management initiatives.

My experience with change management is extensive. I follow a structured approach based on established models like Kotter’s 8-step process or ADKAR (Awareness, Desire, Knowledge, Ability, Reinforcement). The key is to involve stakeholders at every stage.

My approach typically includes:

- Assessment: Understanding the current state, identifying the need for change, and determining the desired future state.

- Planning: Developing a comprehensive change management plan, including communication strategy, training programs, and resource allocation.

- Implementation: Executing the plan, providing ongoing support, and addressing challenges proactively.

- Monitoring & Evaluation: Tracking progress, measuring outcomes, and making adjustments as needed.

- Communication: Keeping all stakeholders informed throughout the process using various communication channels.

In one project, I successfully managed the implementation of a new warehouse management system. By carefully communicating the benefits, providing thorough training, and actively addressing employee concerns, I ensured a smooth transition with minimal disruption to operations.

Q 14. How would you improve communication and collaboration within an operational team?

Improving communication and collaboration within an operational team requires a multi-pronged approach:

- Establish Clear Roles & Responsibilities: Ensuring everyone understands their roles and how they contribute to the overall team goals.

- Regular Team Meetings: Implementing regular meetings (daily stand-ups, weekly progress reviews) for updates, problem-solving, and fostering a sense of community.

- Open Communication Channels: Using various communication channels (email, instant messaging, project management software) tailored to the need. This could include daily progress reports, meeting minutes, or project updates in a collaborative platform.

- Conflict Resolution Mechanisms: Establishing clear protocols for addressing conflicts and disagreements constructively.

- Team-Building Activities: Engaging in activities that build trust and rapport among team members.

- Feedback Mechanisms: Providing regular feedback and opportunities for open dialogue between team members and management.

For instance, using a collaborative project management tool allows everyone to access information, track progress, and communicate effectively, streamlining workflows and preventing misunderstandings. In addition, regular team-building exercises can foster stronger relationships.

Q 15. How do you identify and mitigate operational risks?

Identifying and mitigating operational risks is a crucial aspect of ensuring business continuity and success. It involves a proactive approach, combining risk assessment with preventative and reactive measures.

Risk Identification: This starts with a thorough understanding of your business processes. I typically use a combination of methods:

- SWOT Analysis: Identifying internal strengths and weaknesses, alongside external opportunities and threats, helps pinpoint potential risks.

- Failure Mode and Effects Analysis (FMEA): This systematic approach analyzes potential failures in a process and their impact. It allows for prioritizing risks based on severity and likelihood.

- Checklists and Audits: Regularly reviewing processes and comparing them against best practices or industry standards helps to uncover hidden vulnerabilities.

- Stakeholder Input: Gathering insights from employees at all levels provides a ground-up perspective on potential risks, often uncovering issues overlooked by management.

Risk Mitigation: Once risks are identified, we move to mitigation. This involves a multi-layered strategy:

- Avoidance: Eliminating the activity that poses the risk entirely, if feasible.

- Mitigation: Reducing the likelihood or impact of the risk through proactive measures, such as implementing stricter quality control or investing in backup systems.

- Transfer: Shifting the risk to a third party, like purchasing insurance.

- Acceptance: Acknowledging the risk and setting aside resources to address it if it occurs.

Example: In a previous role, we identified a potential supply chain disruption due to reliance on a single supplier. We mitigated this by diversifying our suppliers and building stronger relationships with alternative vendors.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with resource allocation and optimization.

Resource allocation and optimization are about making the most of available resources – people, budget, technology – to achieve maximum efficiency and effectiveness. It requires a strategic approach, balancing short-term needs with long-term goals.

My experience involves using various techniques:

- Prioritization Matrix (e.g., Eisenhower Matrix): Categorizing tasks based on urgency and importance to focus on high-impact activities.

- Budget Allocation: Developing and managing budgets, ensuring funds are directed towards initiatives that align with strategic objectives and deliver the highest return on investment.

- Workforce Planning: Forecasting future staffing needs, optimizing team structures, and managing employee performance to maximize productivity.

- Data-driven decision making: Leveraging data analytics to understand resource utilization, identify bottlenecks, and optimize resource deployment.

Example: In a previous project, we used data analytics to identify inefficiencies in our production process. By reallocating resources and streamlining workflows, we improved output by 15% without increasing staffing levels.

Q 17. How familiar are you with different business process modeling techniques?

I’m familiar with several business process modeling techniques, each offering unique advantages depending on the context. These techniques are invaluable for visualizing, analyzing, and improving business processes.

- BPMN (Business Process Model and Notation): This widely used standard provides a graphical representation of processes, making them easily understandable by stakeholders at all levels. I often use it to document ‘as-is’ processes and model ‘to-be’ improvements.

- Flowcharts: A simpler representation of processes, useful for high-level overviews or communicating complex processes to non-technical audiences.

- Swimlane Diagrams: Showing the roles and responsibilities within a process, highlighting handoffs and potential bottlenecks.

- Value Stream Mapping: A lean methodology focusing on identifying and eliminating waste in a process, focusing on value-added activities.

Example: In a previous role, we used BPMN to model our customer onboarding process. By analyzing the model, we identified several redundancies and bottlenecks, resulting in a 20% reduction in onboarding time.

Q 18. Describe your experience with strategic planning and execution in operations.

Strategic planning and execution in operations involve aligning operational activities with the overall business strategy. This requires a clear understanding of the business goals and translating them into actionable operational plans.

My experience includes:

- Strategic Goal Setting: Defining clear, measurable, achievable, relevant, and time-bound (SMART) operational goals aligned with the overarching business strategy.

- Developing Operational Plans: Creating detailed plans outlining how the operational goals will be achieved, including timelines, resources, and key performance indicators (KPIs).

- Monitoring and Evaluation: Regularly tracking progress against the plan, identifying deviations, and taking corrective actions to stay on track.

- Continuous Improvement: Implementing a system for continuous improvement, regularly reviewing processes and seeking opportunities for optimization.

Example: In a previous role, we developed a strategic plan to improve customer satisfaction. This involved setting specific targets for response times and resolution rates, implementing new customer relationship management (CRM) software, and providing additional training to customer service staff. We successfully achieved our targets within the planned timeframe.

Q 19. How do you handle conflict within a team or across different departments?

Conflict is inevitable in any team environment. My approach to handling conflict focuses on open communication, active listening, and finding mutually beneficial solutions.

My strategy involves:

- Identifying the Root Cause: Understanding the underlying issues driving the conflict, rather than just focusing on surface-level disagreements.

- Facilitating Communication: Creating a safe space for all parties to express their perspectives and concerns without interruption or judgment.

- Active Listening: Truly listening to understand each party’s perspective and validating their feelings.

- Collaborative Problem Solving: Working with all parties to develop solutions that address everyone’s concerns and needs. This often involves compromise and finding common ground.

- Mediation if Necessary: If unable to resolve the conflict independently, seeking help from a neutral third party to facilitate resolution.

Example: I once mediated a conflict between two departments regarding resource allocation. By facilitating open communication and helping them understand each other’s perspectives, we were able to reach a mutually agreeable solution that ensured both departments received the resources they needed.

Q 20. Explain your experience with cost optimization and reduction strategies.

Cost optimization and reduction strategies are essential for maintaining profitability and competitiveness. It’s not just about cutting costs, but about maximizing value for every dollar spent.

My experience includes:

- Process Efficiency Analysis: Identifying and eliminating waste in processes, streamlining workflows, and automating tasks to reduce operational costs.

- Negotiation with Suppliers: Negotiating favorable terms with suppliers to reduce the cost of goods and services.

- Technology Implementation: Implementing technology solutions to automate tasks, improve efficiency, and reduce labor costs.

- Waste Reduction Initiatives: Implementing lean manufacturing principles to reduce waste in materials, energy, and time.

- Benchmarking: Comparing costs against industry best practices to identify areas for improvement.

Example: In a previous role, we implemented a new inventory management system that significantly reduced our warehousing costs by optimizing storage space and reducing waste from obsolete inventory.

Q 21. How do you use technology to improve operational efficiency?

Technology plays a crucial role in improving operational efficiency. I leverage technology in various ways:

- Automation: Automating repetitive tasks using Robotic Process Automation (RPA) or other automation tools to free up human resources for higher-value activities.

- Data Analytics: Using data analytics tools to gain insights into operational processes, identify bottlenecks, and optimize performance.

- Cloud Computing: Utilizing cloud-based solutions to improve scalability, reduce IT infrastructure costs, and enhance collaboration.

- CRM and ERP Systems: Implementing CRM and ERP systems to streamline business processes, improve data management, and enhance customer relations.

- Project Management Software: Using project management software to track progress, manage tasks, and improve team collaboration.

Example: In a previous project, we implemented a cloud-based CRM system that improved customer communication and streamlined sales processes, resulting in a significant increase in sales conversion rates.

Q 22. Describe your experience with vendor management and negotiation.

Vendor management and negotiation are crucial for securing optimal resources and partnerships. My experience encompasses the entire lifecycle, from identifying needs and sourcing vendors to negotiating contracts and managing ongoing relationships. This includes:

- Sourcing and Selection: I leverage a combination of market research, RFPs (Requests for Proposals), and vendor referrals to identify potential suppliers. Careful evaluation of their capabilities, financial stability, and past performance is essential. For instance, in my previous role, we used a weighted scoring system to objectively compare competing bids for a new CRM system.

- Contract Negotiation: I’m skilled in negotiating favorable terms and conditions, including pricing, service level agreements (SLAs), and payment schedules. This often involves a delicate balance between securing the best possible deal and building a strong, collaborative relationship with the vendor. I’ve successfully negotiated contracts that resulted in significant cost savings while maintaining high service quality.

- Performance Management: Ongoing monitoring of vendor performance against agreed-upon SLAs is vital. This includes regular performance reviews, addressing any issues promptly, and implementing corrective actions when necessary. For example, I once had to renegotiate a contract with a logistics provider due to persistent delivery delays; we implemented a new KPI tracking system to improve transparency and accountability.

Q 23. How do you stay current with industry best practices and emerging trends in operations?

Staying abreast of industry best practices and emerging trends is paramount in operations. I utilize a multi-faceted approach:

- Professional Networks: I actively participate in industry conferences, webinars, and professional organizations (like APICS or PMI) to network with peers and learn about the latest advancements. This includes attending workshops and participating in online forums to engage in discussions and knowledge sharing.

- Industry Publications and Research: I regularly read industry journals, research reports, and reputable online publications like Harvard Business Review to stay updated on best practices and innovations. This provides invaluable insights into successful operational strategies and emerging challenges.

- Benchmarking: I utilize benchmarking techniques to compare our operational performance against industry leaders. This helps identify areas for improvement and inspires the adoption of best-in-class practices. This often involves studying case studies of successful companies in our sector.

- Continuous Learning: I am committed to ongoing professional development through online courses, certifications, and training programs focused on relevant operational technologies and strategies.

Q 24. Explain your experience with performance management and employee development within an operational context.

Performance management and employee development are integral to achieving operational excellence. My approach centers around:

- Setting Clear Expectations: I work with team members to establish clear, measurable, achievable, relevant, and time-bound (SMART) goals. This ensures everyone understands their role and how their contributions support overall operational objectives.

- Regular Feedback and Coaching: I provide regular feedback, both positive and constructive, to help employees improve their performance. This includes one-on-one coaching sessions to address specific skills gaps and support their professional growth.

- Performance Reviews: Formal performance reviews are conducted regularly to assess progress towards goals, identify areas for improvement, and develop individual development plans (IDPs). These are used to facilitate open communication and create an action plan for the next review period.

- Training and Development Opportunities: I actively seek and provide opportunities for employees to enhance their skills and knowledge through training programs, workshops, and mentoring. This might include cross-training to improve team versatility and resilience.

For instance, I once mentored a junior operations analyst who was struggling with data analysis. Through targeted coaching and training, they developed their skills significantly, becoming a valuable asset to the team.

Q 25. How would you implement a new operational system or process?

Implementing a new operational system or process requires a structured and phased approach:

- Needs Assessment: Thoroughly analyze the current operational challenges and identify the specific problems the new system or process aims to address. This often involves gathering data and feedback from stakeholders across the organization.

- Selection and Design: Research, evaluate, and select the most appropriate system or process. This might involve comparing different software solutions, consulting with industry experts, or developing a custom solution. Careful design is crucial to ensure the new system aligns with the organization’s goals and integrates smoothly with existing systems.

- Pilot Program: Implement the new system or process on a small scale (pilot program) to test its effectiveness and identify any potential issues before full-scale rollout. This allows for adjustments and refinements based on real-world feedback.

- Training and Communication: Develop comprehensive training materials and conduct thorough training sessions for all employees involved. Clear communication is essential to ensure buy-in and minimize resistance to change.

- Rollout and Monitoring: Gradually roll out the new system or process across the organization. Closely monitor its performance, collect data, and make adjustments as needed. This continuous monitoring allows for optimization and ensures the system delivers the expected results.

Q 26. Describe your experience with root cause analysis and problem-solving.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems. My experience leverages techniques like the 5 Whys, Fishbone diagrams, and Fault Tree Analysis. The process generally involves:

- Problem Definition: Clearly define the problem and gather relevant data. This often includes collecting information from different sources and stakeholders.

- Identify Potential Causes: Brainstorm potential causes using techniques like the 5 Whys (repeatedly asking “why” to drill down to the root cause) or a Fishbone diagram (visualizing potential causes categorized by factors like people, machines, methods, materials, etc.).

- Verify Root Causes: Analyze the potential causes to identify the root causes using data and evidence. This might involve examining historical data, conducting interviews, or testing hypotheses.

- Develop Solutions: Once the root causes are identified, develop and implement solutions to address them. This requires careful consideration of the impact of the solutions and the resources required to implement them.

- Monitor and Evaluate: Monitor the effectiveness of the implemented solutions and make adjustments as needed. This is an iterative process; sometimes the initial solution requires refinement.

For example, using the 5 Whys to analyze recurring equipment malfunctions, I was able to identify inadequate training for operators as the underlying cause, leading to a revised training program and a significant decrease in malfunctions.

Q 27. How would you measure the ROI of an operational improvement project?

Measuring the ROI (Return on Investment) of an operational improvement project requires a clear understanding of both the costs and benefits. This involves:

- Quantify Costs: Accurately determine all costs associated with the project, including implementation costs (software, hardware, training), personnel time, and any other expenses.

- Identify and Quantify Benefits: Identify both tangible and intangible benefits. Tangible benefits might include cost savings (reduced labor, waste, materials), increased efficiency (faster processing times, higher output), or revenue increases. Intangible benefits might include improved customer satisfaction, enhanced employee morale, or reduced risk.

- Calculate ROI: A common approach is to calculate ROI as:

(Total Benefits - Total Costs) / Total Costs. This provides a percentage representing the return on investment. For example, if a project costs $10,000 and generates $20,000 in savings, the ROI is 100%. - Consider Time Value of Money: For long-term projects, consider the time value of money using techniques like Net Present Value (NPV) or Internal Rate of Return (IRR) to account for the fact that money received in the future is worth less than money received today.

It’s important to track key metrics throughout the project lifecycle to accurately assess the impact of the improvements and justify the investment.

Q 28. Describe a time you had to make a difficult operational decision under pressure.

In a previous role, we faced a major system failure just days before a critical product launch. This created significant pressure and required immediate action. The initial reaction was panic, but I quickly established a structured approach:

- Assess the Situation: I immediately gathered the key team members and assessed the extent of the damage, identifying the immediate risks and potential consequences of the system failure. This involved contacting IT and evaluating the options for restoration.

- Develop Mitigation Strategies: We explored several options, including a temporary workaround, contacting external support, and potentially delaying the launch. We weighed the pros and cons of each option considering financial implications, reputational risks, and customer impact.

- Decision and Communication: After thorough deliberation, we opted for a combination of a temporary workaround and a partial delay to the launch. This was the most effective strategy to mitigate the risks and minimize the negative consequences. The decision was clearly communicated to all stakeholders, including the executive team and the marketing team, who needed to modify the launch strategy.

- Post-Incident Analysis: Following the successful resolution, we conducted a thorough post-incident analysis using root cause analysis techniques. This helped us identify the underlying causes of the failure and implement preventative measures to avoid similar incidents in the future.

This experience highlighted the importance of decisive leadership, effective communication, and a structured problem-solving approach during high-pressure situations.

Key Topics to Learn for Knowledge of Business Operations Interview

- Business Process Management (BPM): Understanding the design, analysis, measurement, management, and improvement of business processes. Consider practical applications like process mapping and identifying bottlenecks.

- Supply Chain Management (SCM): Analyzing the flow of goods and services, from raw materials to end consumers. Explore real-world examples of optimizing inventory management and logistics.

- Operations Strategy: Aligning operational capabilities with overall business objectives. Think about how operational decisions impact profitability and competitive advantage.

- Data Analysis in Operations: Utilizing key performance indicators (KPIs) and data visualization to track efficiency, identify trends, and make data-driven decisions. Explore techniques for interpreting operational data and making recommendations.

- Project Management Fundamentals: Understanding project lifecycles, resource allocation, risk management, and successful project delivery. Consider how project management principles apply to operational improvements.

- Change Management within Operations: Strategies for implementing and managing organizational changes within operational departments. Understand how to address resistance to change and ensure smooth transitions.

- Quality Management Systems (QMS): Implementing and maintaining processes to ensure consistent product or service quality. Explore different quality management methodologies and their practical applications.

- Lean Principles and Six Sigma Methodologies: Familiarize yourself with lean manufacturing principles and Six Sigma methodologies for process improvement and waste reduction. Consider how these approaches improve operational efficiency.

Next Steps

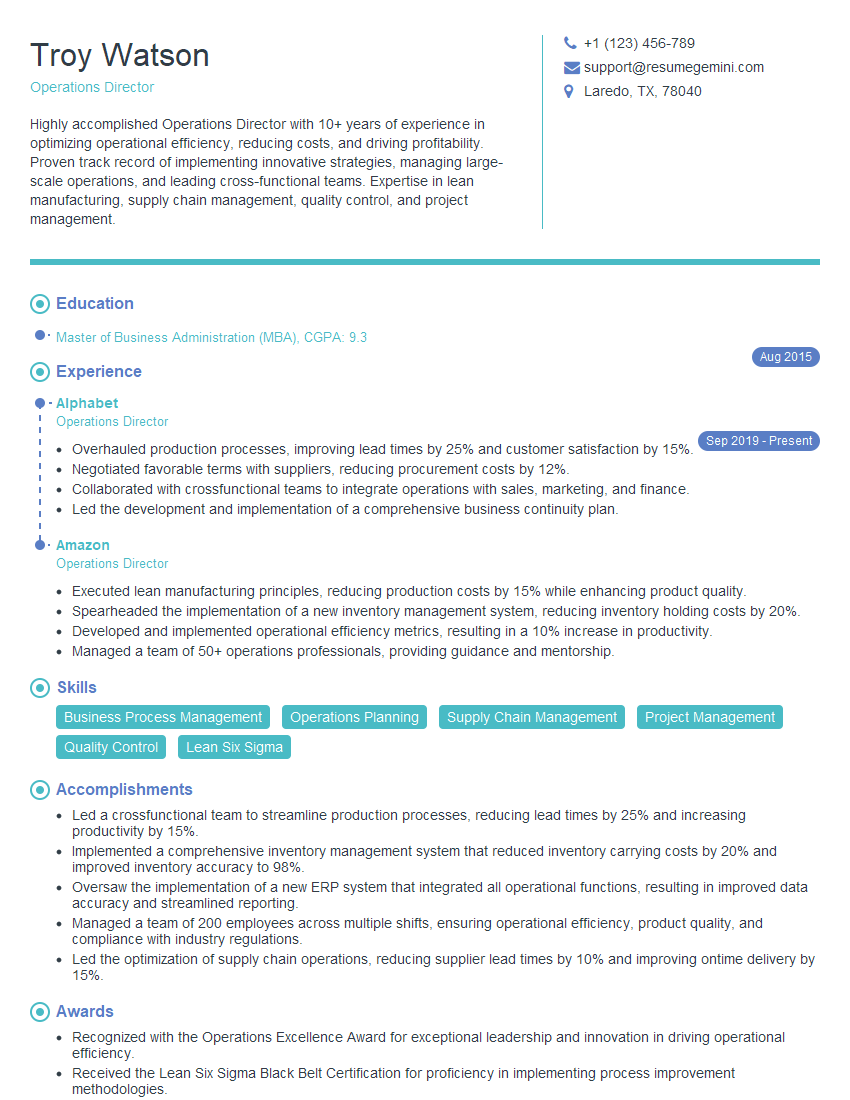

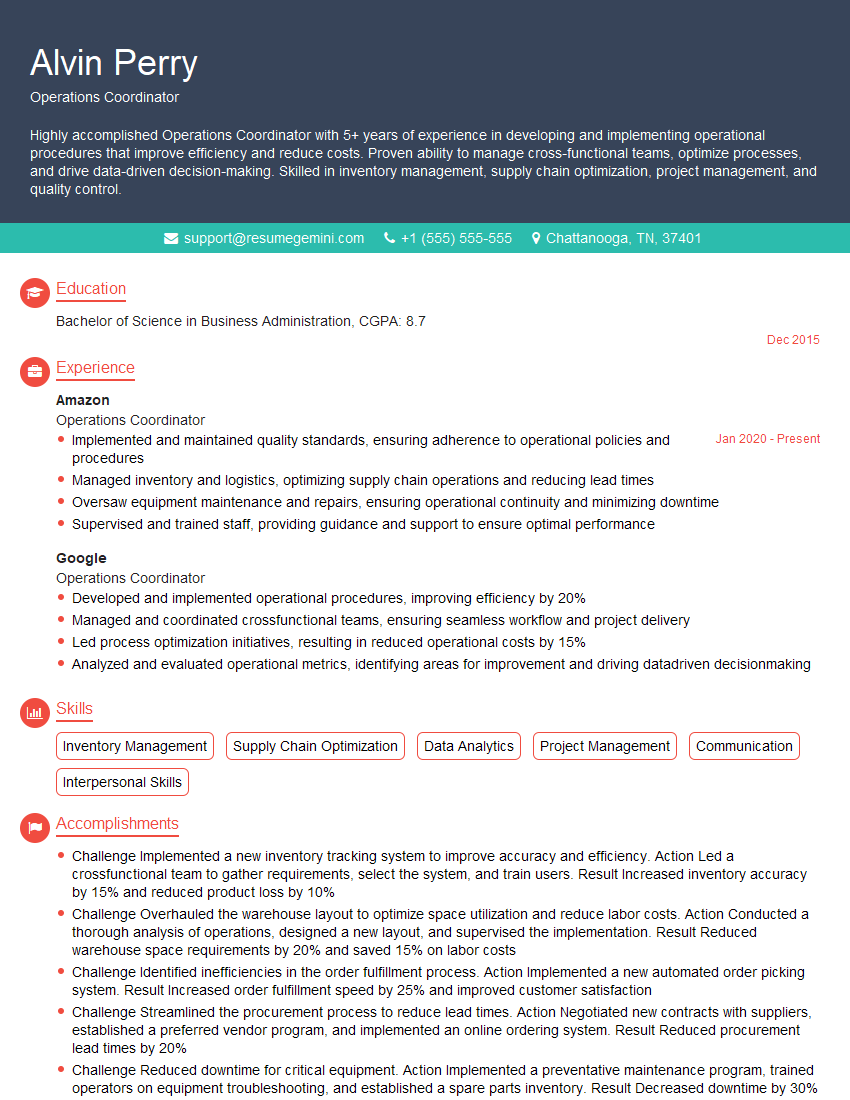

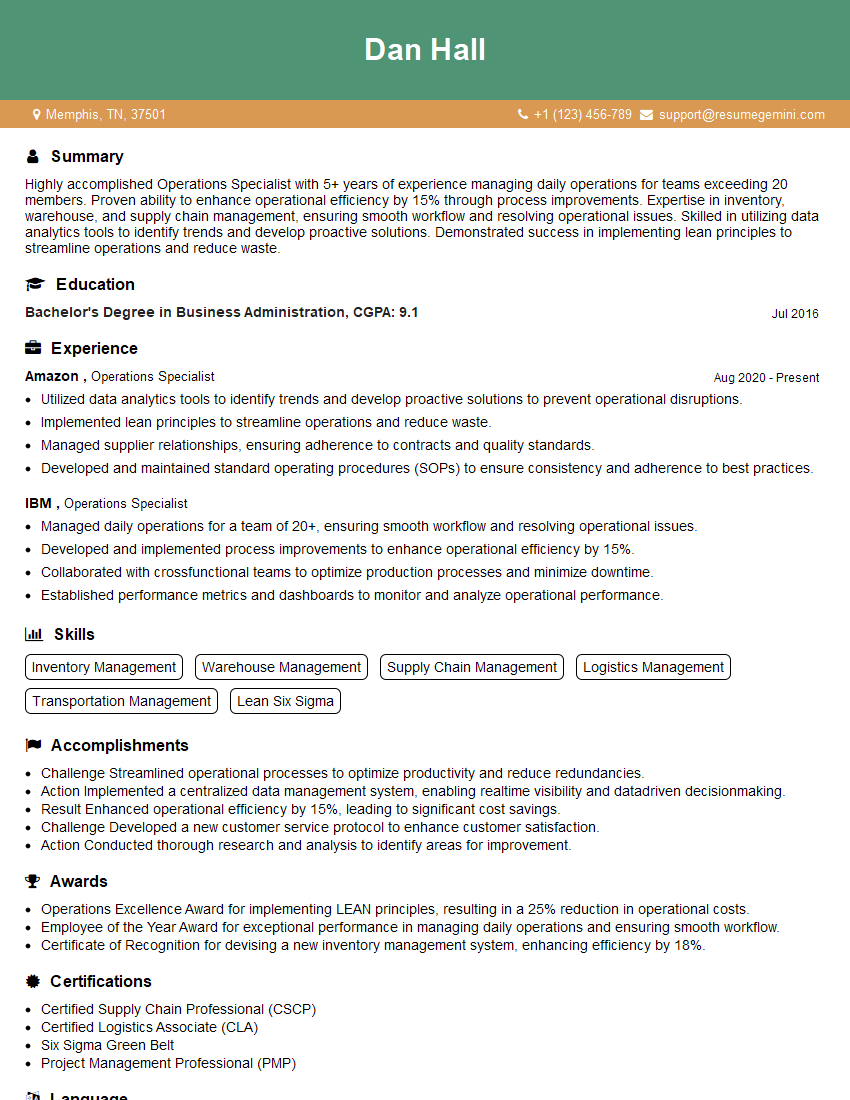

Mastering Knowledge of Business Operations is crucial for career advancement, opening doors to leadership roles and higher earning potential. A strong understanding of these concepts demonstrates your ability to contribute significantly to an organization’s success. To enhance your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Knowledge of Business Operations to help you showcase your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO