Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Knowledge of coal mining terminology interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Knowledge of coal mining terminology Interview

Q 1. Define ‘longwall mining’ and explain its advantages and disadvantages.

Longwall mining is a highly efficient method of underground coal extraction where a long, continuous coal face is mined using a shearer, a large machine that cuts coal from the seam. Imagine a giant, mechanized wall of coal being systematically sliced away. The shearer moves along the face, extracting coal, while a system of powered supports, known as powered roof supports, advances behind it, ensuring the safety of miners and preventing roof collapse. The entire longwall system moves progressively across the coal panel.

Advantages:

- High Production Rates: Longwall mining boasts significantly higher production rates compared to other methods.

- High Coal Recovery: It achieves a high percentage of coal extraction, leaving minimal coal in the ground.

- Improved Safety: The mechanized nature of the process and the use of powered supports reduce the number of miners required underground, leading to enhanced safety.

Disadvantages:

- High Capital Investment: Setting up a longwall system requires a substantial initial investment in equipment.

- Geological Limitations: Longwall mining is suitable only for specific geological conditions, such as relatively flat and thick coal seams.

- Complex Infrastructure: Requires extensive infrastructure development, including roadways, ventilation systems, and power supplies.

Q 2. What is the difference between continuous and discontinuous mining?

The key difference between continuous and discontinuous mining lies in how the coal is extracted. Continuous mining uses large, mechanized equipment to continuously extract coal from the seam. Think of it as a constant, steady flow of coal. Examples include longwall mining (as described above) and continuous miner systems which use large rotating cutting drums to extract coal in relatively smaller sections. In contrast, discontinuous mining involves the extraction of coal in a series of discrete steps or cuts. This approach often employs drilling and blasting or other cutting methods to break up the coal before removal. Room-and-pillar mining is a classic example of discontinuous mining.

In essence, continuous mining aims for a constant, uninterrupted flow of coal, whereas discontinuous mining involves cycles of cutting, blasting, and then extracting the loosened coal.

Q 3. Explain the concept of ‘pillar extraction’ in coal mining.

Pillar extraction is a crucial phase in room-and-pillar mining. In the initial mining phase, large pillars of coal are left strategically in place throughout the mine to support the roof and prevent collapses. These pillars act like structural columns in a building. Once a significant portion of the coal has been extracted, the pillars themselves are selectively removed in a controlled manner. This extraction often involves careful planning and monitoring to ensure stability. The process is often sequenced such that the extraction of some pillars might support the stability of other pillars around it. This carefully planned removal of the pillars allows for the recovery of additional coal, but it requires meticulous planning and monitoring to prevent catastrophic roof collapse.

Imagine a honeycomb pattern – the coal extracted is the space between the ‘honeycomb’ and then, later, the honeycomb structures (pillars) are carefully removed.

Q 4. Describe various methods used for ground control in underground coal mines.

Ground control in underground coal mines is critical for safety and productivity. Several methods are used, including:

- Roof Bolting: Steel bolts are anchored into the roof to strengthen it and prevent collapse. Think of them as giant screws securing the ceiling.

- Powered Roof Supports: These hydraulically powered supports are used in longwall mining to provide immediate roof support as the coal face advances.

- Caving Methods: In certain circumstances, controlled caving of the roof is allowed, using the weight of the overlying strata to compact the worked out area, reducing pressure on the surrounding areas.

- Fill Methods: Waste materials or other fill materials are placed into worked-out areas to help maintain ground stability and reduce subsidence.

- Ground Reinforcement: Techniques like grouting (injecting cement or other materials) into the rock mass can help to strengthen the ground.

The choice of ground control methods depends heavily on the specific geological conditions of the mine and the mining method used.

Q 5. What are the key components of a mine ventilation system?

A mine ventilation system is vital for the safety and health of miners. Its key components include:

- Intake Airways: These are passages that bring fresh air into the mine.

- Return Airways: These passages carry the contaminated air out of the mine.

- Fans: These are used to circulate air throughout the mine.

- Airlocks: These structures help control air movement and prevent the spread of methane.

- Monitoring Equipment: Sensors throughout the mine measure air quality (methane, oxygen, carbon monoxide etc.).

- Ventilation Controls: These systems allow for the regulation of airflow to meet changing conditions.

A well-designed ventilation system ensures adequate oxygen supply, removes harmful gases such as methane and carbon monoxide, and maintains appropriate temperature and humidity levels.

Q 6. Explain the role of methane drainage in coal mines.

Methane drainage is a crucial safety measure in coal mines. Methane, a highly flammable gas, is often present in coal seams. Methane drainage systems use various techniques to extract methane from the coal seam before it enters the mine workings, thereby reducing the risk of explosions. This is achieved through a network of strategically placed boreholes and pipelines that allow the gas to be removed from the seam and either vented safely or potentially used as an energy source. It reduces the risk of explosions which are a major hazard in coal mines.

Think of it as proactively removing a dangerous ingredient from a potentially explosive mixture.

Q 7. What are the safety regulations concerning the use of explosives in coal mining?

Safety regulations concerning the use of explosives in coal mining are extremely stringent. These regulations vary somewhat by jurisdiction but generally include:

- Licensing and Training: Only properly licensed and trained personnel are allowed to handle explosives.

- Storage and Handling: Strict rules govern the storage, transportation, and handling of explosives to prevent accidents.

- Blasting Procedures: Detailed procedures must be followed for each blasting operation, including pre-blast surveys, the placement of explosives, and the initiation of blasts.

- Emergency Response Plans: Mines must have detailed emergency plans in place to deal with any accidents involving explosives.

- Regular Inspections: Frequent inspections of the mine and related infrastructure are needed to assure safety.

These regulations are designed to minimize the risk of accidents, injuries, and damage to the mine and surrounding areas. Non-compliance can lead to severe penalties.

Q 8. Describe different types of coal seams and their impact on mining methods.

Coal seams, the layers of coal within the earth, vary significantly in their characteristics, directly influencing the mining methods employed. These variations include thickness, inclination (dip), depth, and the nature of the surrounding rock strata (the ‘roof’ and ‘floor’).

- Thick, relatively flat seams: These are ideal for open-cast or surface mining, where large-scale earthmoving equipment can efficiently extract the coal. Think of it like slicing a cake – easy to get a large, even piece.

- Thin, steeply dipping seams: These necessitate underground mining techniques, often involving room-and-pillar or longwall methods. Room-and-pillar leaves pillars of coal in place to support the roof, while longwall uses a massive shearer to extract coal in long faces, allowing the roof to collapse behind. It’s like carefully extracting honey from a steep honeycomb.

- Seam complexity: Multiple seams at different depths or with intervening layers of rock (interburden) complicate the process, requiring tailored extraction strategies to minimize risks. This is akin to mining through a complex network of caves – detailed planning and precision are crucial.

- Seam quality: The presence of impurities like sulfur or rock inclusions affects both the mining method and the subsequent coal preparation process. Imagine baking a cake – you need to remove any stones or lumps before you can use the ingredients effectively.

For example, a thick, relatively flat seam in Wyoming might be mined using a dragline excavator in a surface mine, while a thin, steeply dipping seam in Appalachia might require a longwall mining operation underground.

Q 9. What is the significance of strata control in underground mining?

Strata control in underground coal mining refers to the techniques and measures used to manage the stability of the surrounding rock formations (strata) above and below the coal seam. It’s paramount for worker safety and efficient mining. Roof collapse is a significant hazard, and uncontrolled ground movement can damage equipment and disrupt mining operations.

Effective strata control involves a combination of strategies:

- Geological surveys: Detailed mapping and analysis of the strata to identify weak zones and potential instability.

- Roof support systems: Implementing various support systems like timber cribs, steel sets, or resin bolting to reinforce the roof and prevent collapse. These act as artificial supports to replace the natural strength of the strata.

- Ground control monitoring: Continuous monitoring of ground movement using instruments like extensometers and convergence meters to detect early signs of instability.

- Mine design and planning: Careful design of mining layouts and extraction sequences to minimize stress on the surrounding rock mass.

Failure to implement proper strata control can lead to catastrophic roof collapses, endangering miners and halting production. It’s like building a house – you need a solid foundation and structural support to prevent the building from collapsing.

Q 10. Explain the process of coal preparation and beneficiation.

Coal preparation and beneficiation encompass the processes used to clean and upgrade raw coal to improve its quality and marketability. Raw coal often contains impurities like rock, sulfur, and ash, which reduce its energy content and can cause environmental problems.

The process generally involves these steps:

- Crushing and sizing: Breaking the raw coal into smaller, uniform pieces to facilitate subsequent processing.

- Cleaning: Separating the coal from impurities using techniques like dense-medium separation (using liquids of specific density to separate coal from heavier waste), froth flotation (using air bubbles to selectively lift coal particles), and washing (using water to remove fine particles).

- Drying: Removing excess moisture to improve the coal’s heating value and handling properties.

- Screening and sizing: Separating the cleaned coal into different sizes to meet customer specifications.

Beneficiation significantly improves the quality of coal, increasing its calorific value and reducing emissions during combustion. It’s like refining crude oil into gasoline – you remove unwanted components to make a more valuable product.

Q 11. What are the environmental concerns associated with coal mining?

Coal mining has significant environmental impacts, including:

- Habitat destruction and land degradation: Surface mining removes topsoil and vegetation, leading to erosion and loss of biodiversity. Imagine clearing a forest to create a large pit – the ecological damage is substantial.

- Air pollution: Mining operations and coal combustion release greenhouse gases (CO2, methane), particulate matter, and other pollutants that contribute to climate change and respiratory problems. The smoke from coal-fired power plants is a stark reminder of this.

- Water pollution: Acid mine drainage from abandoned mines contaminates water sources with heavy metals and sulfuric acid, harming aquatic life and human health. This is akin to a slow-acting poison released into the environment.

- Greenhouse gas emissions: The burning of coal is a major source of greenhouse gas emissions, exacerbating climate change. This is a global problem with far-reaching consequences.

- Waste disposal: Large amounts of waste rock and tailings are generated during mining and processing, requiring careful management to prevent environmental damage. These can represent huge areas of land scarred by mining activities.

Mitigating these impacts requires adopting sustainable mining practices, including land reclamation, water treatment, and the development of cleaner coal technologies.

Q 12. Describe various methods used for mine water management.

Mine water management is crucial for both safety and environmental protection. Underground mines often encounter large volumes of groundwater, which can inundate workings, causing damage and endangering miners. Surface mines can generate significant runoff that needs control to prevent pollution.

Methods include:

- De-watering: Pumping groundwater out of the mine workings to maintain a safe and dry environment. This is a constant battle against the inflow of water.

- Water treatment: Treating contaminated water before it’s discharged to prevent pollution of surface water bodies. This could involve neutralizing acidic water or removing heavy metals.

- Impoundments and dams: Constructing dams and impoundments to control surface water runoff and prevent sediment from entering streams. These act as reservoirs for treated or controlled water.

- Groundwater monitoring: Monitoring groundwater levels and quality to detect potential problems and ensure effective management. This provides early warning of potential problems.

- Mine sealing and reclamation: Sealing abandoned mines to prevent water infiltration and surface water runoff. This is part of the mine’s eventual restoration back to a natural state.

Effective mine water management is essential to avoid environmental damage and ensure safe mining operations. It’s a long-term commitment, extending even beyond the mine’s operational lifetime.

Q 13. What are the different types of roof supports used in underground coal mines?

Roof support systems in underground coal mines are designed to prevent roof collapse and ensure worker safety. The choice of support depends on factors like the strength of the strata, the mining method, and the depth of the mine.

- Timber sets: Traditional support using wooden beams and posts. Cost-effective but less durable and require frequent maintenance. Think of it as a simple, yet effective wooden scaffolding.

- Steel sets: Stronger and more durable than timber sets, often used in areas of high stress. These provide a more robust support framework.

- Resin bolting: Reinforcing the roof by injecting resin into drilled holes, creating strong anchors. This method is particularly effective for weaker roofs.

- Cable bolting: Using steel cables to reinforce the roof, similar to resin bolting but using cables instead of resin. This offers additional support for unstable strata.

- Hydraulic supports: Advanced support systems used in longwall mining that adapt to changes in roof pressure. This provides a dynamic response to shifting ground.

The selection of roof support systems is a critical design aspect that directly impacts miner safety and the overall efficiency of the operation. It’s a constant balancing act between cost, effectiveness, and safety.

Q 14. Explain the importance of geological surveys in coal mine planning.

Geological surveys are fundamental to coal mine planning. They provide essential information about the location, extent, and quality of coal seams, as well as the characteristics of the surrounding rock strata. This knowledge is critical for safe and efficient mining.

Geological surveys involve:

- Surface mapping: Identifying potential coal deposits through surface geological observations.

- Drilling and core sampling: Obtaining samples of coal and rock to assess coal quality, seam thickness, and the nature of the surrounding strata.

- Geophysical surveys: Using techniques like seismic surveys to identify subsurface geological features. These provide a subsurface image of the geology.

- Geological modeling: Creating 3D models of the coal deposit and surrounding strata to aid in mine planning and design.

- Hydrogeological studies: Assessing the groundwater conditions to plan for effective mine dewatering and water management.

Thorough geological surveys are vital for designing safe and efficient mining plans, minimizing environmental impacts, and ensuring the long-term economic viability of the operation. It’s like creating a blueprint for the mine before starting construction. Without it, risks are significantly higher, and operational efficiency is greatly reduced.

Q 15. What are the key performance indicators (KPIs) used to measure the efficiency of a coal mine?

Key Performance Indicators (KPIs) in coal mining are crucial for evaluating operational efficiency, safety, and profitability. They’re used to track progress, identify areas for improvement, and make informed decisions. These KPIs can be broadly categorized into production, safety, and cost metrics.

- Production KPIs: These focus on the quantity and quality of coal extracted. Examples include tons of coal produced per day/month/year, percentage of planned production achieved, coal quality parameters (e.g., ash content, sulfur content), and overall mining recovery rate (percentage of coal extracted from the reserve).

- Safety KPIs: Prioritizing safety is paramount. KPIs in this area include the lost time injury frequency rate (LTIFR), number of reportable incidents, and compliance with safety regulations. A low LTIFR indicates a safer working environment.

- Cost KPIs: These metrics assess the economic viability of the mining operation. Examples include cost per ton of coal produced, operating costs (labor, energy, maintenance), and capital expenditure (CAPEX) versus return on investment (ROI).

For example, a mine might set a target of producing 10,000 tons of coal per month. By tracking actual production against this target, they can identify any deviations and implement corrective measures. Similarly, consistently high LTIFR would signal the need for improved safety protocols.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the different types of mining equipment used in surface and underground coal mining.

Coal mining equipment varies significantly depending on whether it’s surface (open-pit) or underground mining.

Surface Mining Equipment:

- Power shovels/Draglines: Massive excavators used to remove overburden (the layer of rock and soil above the coal seam) and load coal onto trucks.

- Bucket-wheel excavators: Rotating wheels with buckets used for continuous excavation of large volumes of material.

- Dump trucks: Heavy-duty vehicles used to transport excavated material and coal to processing facilities.

- Bulldozers/Graders: Used for land clearing, material handling, and road construction within the mine site.

Underground Mining Equipment:

- Continuous miners: Machines that cut and load coal simultaneously, creating a continuous flow of coal to conveyors.

- Longwall shearers: Used in longwall mining, these machines cut coal from a long face (wall) and convey it to the surface.

- Roof bolters: Install roof bolts to support the mine roof and prevent collapses.

- Shuttle cars: Small, battery-powered vehicles used to transport coal from the mining face to conveyor belts.

- Conveyor belts: Transport coal efficiently over long distances underground.

The specific equipment selection depends on factors such as the coal seam’s depth, thickness, geology, and overall mine layout. A large open-pit mine will require different equipment compared to a small underground operation.

Q 17. What are the various methods for assessing and managing mine hazards?

Assessing and managing mine hazards is critical for ensuring worker safety and operational continuity. This involves a multi-faceted approach.

- Hazard Identification and Risk Assessment: Systematic identification of potential hazards (e.g., ground instability, methane gas, dust) using methods like walk-through surveys, job safety analyses, and historical data review. A risk assessment quantifies the likelihood and severity of each hazard, prioritizing risk mitigation efforts.

- Engineering Controls: These controls physically remove or reduce the hazard. Examples include installing ventilation systems to dilute methane gas, ground support systems to prevent roof falls, and using explosion-proof equipment in hazardous areas.

- Administrative Controls: These involve changes to work practices, training, and procedures. Examples include implementing safe work permits, providing comprehensive safety training, establishing clear communication protocols, and using standardized operating procedures.

- Personal Protective Equipment (PPE): Providing workers with appropriate PPE like hard hats, safety glasses, respirators, and self-rescue devices is essential for mitigating risks.

- Monitoring and Surveillance: Continuous monitoring of critical parameters (e.g., methane levels, air quality, ground movement) is crucial. Sensors and automated monitoring systems are used to detect potential problems early on.

- Emergency Response Planning: Developing and regularly practicing emergency response plans is vital. This includes procedures for evacuations, first aid, and communication during emergencies.

Imagine a mine experiencing high methane levels. Engineering controls would involve improving ventilation; administrative controls might involve restricting access to the area until methane levels decrease; and PPE would involve providing respirators to workers who must enter the area.

Q 18. Explain the concept of ‘highwall mining’.

Highwall mining is a surface mining technique where coal is extracted from a highwall, a steep, near-vertical face of exposed coal seam. It’s primarily used in thinner coal seams that are not deep enough to justify traditional open-pit mining methods but are too deep for conventional strip mining.

The process typically involves creating a bench (a horizontal step) along the highwall. Then, mining equipment, such as continuous mining machines or smaller excavators, work from this bench to extract coal. The highwall is left exposed. This method requires careful consideration of ground stability and environmental impacts due to the exposed highwall.

An advantage is that it minimizes the amount of overburden that needs to be removed compared to conventional strip mining, resulting in lower costs and reduced environmental disruption in some cases. However, it carries higher risk of ground instability, increased environmental hazards and stricter regulations.

Q 19. What are the regulations regarding dust control in coal mines?

Regulations regarding dust control in coal mines are stringent due to the serious health risks associated with coal dust inhalation (e.g., black lung disease). These regulations vary by country and region but generally focus on prevention and mitigation.

- Ventilation: Adequate ventilation is crucial to dilute and remove coal dust from the mine atmosphere. This involves strategically placed ventilation shafts, fans, and air ducts.

- Water sprays: Using water sprays at various points in the mining process helps to suppress dust generation at the source. These sprays are commonly used near cutting and hauling equipment.

- Dust collection systems: Installing dust collection systems on mining equipment, such as continuous miners and crushers, helps capture dust particles before they can disperse into the air.

- Respirators: Providing appropriate respirators to miners working in dusty areas is essential to protect against dust inhalation. Regular respirator fit testing is crucial.

- Monitoring: Regular monitoring of dust levels in the mine atmosphere is mandatory to ensure compliance with regulatory limits. This typically involves using dust sampling equipment and analyzing the samples in a certified laboratory.

- Regular inspections and maintenance: Regular inspection of dust control equipment and implementation of preventative maintenance is paramount.

Failure to comply with dust control regulations can lead to significant fines, operational shutdowns, and even legal repercussions for the mining company. The emphasis is on creating a dust-free or low-dust environment to protect miners’ health.

Q 20. Describe the process of mine reclamation.

Mine reclamation is the process of restoring mined land to a stable and productive condition after mining operations cease. It’s a crucial aspect of responsible mining, aiming to minimize environmental impacts and restore the land to a usable state.

The reclamation process involves several stages:

- Land shaping: Reshaping the mined land to create a stable topography, often involving grading and contouring to mimic the pre-mining landscape.

- Soil replacement and amendment: Replacing the topsoil removed during mining and adding amendments to improve soil fertility and structure.

- Revegetation: Planting native vegetation to stabilize the soil, prevent erosion, and restore biodiversity. This involves selecting appropriate plant species for the local climate and soil conditions.

- Water management: Managing water runoff and erosion, often involving constructing drainage systems and implementing water control measures.

- Monitoring and maintenance: Monitoring the reclaimed land over time to ensure the success of the reclamation efforts. This may involve periodic inspections and ongoing maintenance.

The specific reclamation methods used will depend on the type of mining, the environmental conditions, and local regulations. The ultimate goal is to restore the land to a condition that supports ecological functions and potentially allows for future land uses, such as agriculture or forestry.

Q 21. What are the different types of coal (e.g., anthracite, bituminous)?

Coal is classified based on its rank, which reflects the degree of coalification (the transformation of plant material into coal) it has undergone. Higher rank coals have undergone more intense heat and pressure, resulting in higher carbon content and different properties.

- Anthracite: The highest rank coal, anthracite is hard, shiny, and has the highest carbon content (over 86%). It burns with a very clean flame and produces little smoke.

- Bituminous coal: A medium-to-high-rank coal, bituminous coal is more abundant than anthracite. It has a higher moisture content and produces more smoke and heat compared to anthracite. It’s widely used for electricity generation and industrial applications.

- Subbituminous coal: A lower-rank coal, subbituminous coal has a lower carbon content than bituminous coal and higher moisture content. It burns with a longer flame and produces more smoke than bituminous coal.

- Lignite (brown coal): The lowest rank coal, lignite has a low carbon content, high moisture content, and low energy density. It’s often used in local power generation near the mine.

The rank of coal affects its properties, including its heating value, ash content, and sulfur content. These properties determine the coal’s suitability for different applications. For example, anthracite, with its high carbon content and clean burn, is well-suited for residential heating, while bituminous coal is widely used in power plants.

Q 22. Explain the concept of ‘backfilling’ in mining.

Backfilling in mining is the process of filling excavated voids, typically underground, with suitable material. Think of it like carefully refilling a hole you’ve dug, but on a massive scale. This isn’t just about tidying up; it’s crucial for several reasons.

- Ground Stability: Filling the voids prevents ground subsidence, which can damage surface structures, roads, and even cause sinkholes. Imagine a building slowly sinking because the ground beneath it is collapsing – backfilling prevents that.

- Preventing Water Infiltration: Backfill acts as a barrier against water seeping into the mine, preventing flooding and improving safety.

- Environmental Protection: Proper backfilling reduces the environmental impact of mining by minimizing surface damage and preventing water contamination.

- Mine Closure and Reclamation: Backfilling is an essential part of mine closure and land reclamation, helping to restore the land to its pre-mining state or a suitable alternative use.

Materials used for backfilling vary depending on the specific conditions, but commonly include waste rock, tailings (the leftover material from ore processing), and sometimes even fly ash (a byproduct from power plants). The selection depends on factors such as compaction properties, environmental impact and availability.

Q 23. What is the role of a mine surveyor?

A mine surveyor plays a vital role in ensuring the safe and efficient operation of a coal mine. They’re essentially the mine’s spatial architects and safety inspectors. Their responsibilities include:

- Mapping the Mine: Creating detailed three-dimensional maps of the underground workings, accurately depicting tunnels, shafts, and other features. This is critical for navigation, ventilation planning, and resource estimation.

- Monitoring Ground Movement: Using advanced surveying techniques to detect any ground movement or deformation that could indicate instability. This helps to prevent collapses and other accidents.

- Setting Out and Monitoring Development: Guiding the excavation process by precisely marking out the location of new tunnels and ensuring they are dug to the correct specifications. This ensures efficient resource extraction and avoids unexpected obstacles.

- Volume Calculations: Accurately calculating the volume of coal extracted, which is crucial for production planning and financial accounting.

- Ensuring Compliance: Making sure the mine’s operations adhere to all relevant safety regulations and legal requirements.

Imagine building a complex network of tunnels in the dark; the surveyor is the guide, ensuring everything is built correctly, safely, and efficiently.

Q 24. Describe various techniques for roof bolting.

Roof bolting is a crucial technique for supporting the mine roof and preventing collapses. Different techniques exist, catering to various geological conditions and roof types.

- Cable Bolting: This involves drilling holes into the roof and installing strands of high-tensile steel cables that are grouted (filled with a bonding agent) to secure the roof strata.

- Resin Bolting: This technique uses resin capsules or cartridges injected into the drilled holes to bond the bolt to the surrounding rock, providing strong support. It is particularly effective in weaker or fractured roof conditions.

- Split-Set Bolting: This involves using a split-set anchor, which expands after insertion into the hole, creating a strong mechanical bond with the rock mass. It’s frequently used in softer rock conditions.

- Combination Bolting: Many mines employ a combination of techniques, such as resin bolting in weaker sections and cable bolting for overall support.

The choice of technique depends on the specific geology of the mine, the strength of the roof strata, and the overall mine design. For example, in a mine with weaker roofs, a combination of resin bolting and cable bolting might be utilized to ensure maximum stability.

Q 25. Explain the importance of regular mine inspections.

Regular mine inspections are paramount for maintaining safety and preventing accidents. They serve as a crucial preventative measure, identifying potential hazards before they escalate into serious incidents. Inspections should cover various aspects:

- Ground Conditions: Checking for signs of roof or wall instability, water leaks, or other geological hazards.

- Ventilation Systems: Ensuring adequate ventilation to prevent the buildup of harmful gases like methane.

- Equipment: Inspecting all machinery and equipment for proper functioning and safety features. Regular maintenance is essential.

- Electrical Systems: Checking for electrical hazards such as exposed wires or faulty equipment.

- Emergency Procedures: Verifying the functionality of emergency equipment such as escape routes and communication systems.

- Compliance: Checking for adherence to safety regulations and best practices.

Think of it as a regular health checkup for the mine. Early detection of problems through regular inspections can prevent costly accidents and save lives. The frequency of inspections varies based on the mine’s complexity and risk profile, but they should be a routine part of operations.

Q 26. What are the challenges associated with deep coal mining?

Deep coal mining presents a unique set of challenges compared to surface or shallow mining. These challenges encompass geological, technical, and logistical aspects:

- Geological Complexity: Deep coal seams are often subjected to higher pressure and temperature, increasing the risk of ground instability, water ingress, and methane emissions.

- High Temperatures: The intense heat at depth makes working conditions difficult and requires specialized cooling systems. The heat also affects the strength and properties of the surrounding rocks.

- Ground Stress: The immense pressure at depth makes roof and wall control significantly more challenging, demanding sophisticated support systems.

- Logistics and Infrastructure: The depth requires extensive and robust infrastructure for transportation of personnel, equipment, and extracted coal. Shaft sinking, for instance, is a major undertaking.

- Increased Costs: Deep mining is inherently more expensive due to higher capital investment, complex infrastructure, and the need for specialized equipment and personnel.

- Safety Concerns: The increased risk of ground instability, methane emissions, and other hazards demands meticulous safety planning and stringent enforcement of safety protocols.

For instance, maintaining ventilation in a deep mine requires significantly more power and larger diameter shafts compared to shallow mines. Deep coal mining is a complex undertaking that requires careful planning, significant investment, and advanced technological solutions.

Q 27. What are the different types of blasting techniques used in coal mining?

Several blasting techniques are employed in coal mining to efficiently extract the coal from the seam. The choice depends on factors such as coal seam thickness, geological conditions, and environmental concerns.

- Conventional Blasting: This involves drilling holes into the coal seam and loading them with explosives. The explosives are detonated, breaking the coal into manageable pieces. This is a widely used method, but it can create significant vibrations and noise.

- Controlled Blasting: Techniques like pre-splitting or smooth blasting are used to minimize vibrations and improve the size and shape of the broken coal. This reduces the amount of fine coal produced, maximizing efficiency.

- Non-Explosive Techniques: In specific circumstances, methods such as hydraulic fracturing or hydro-mining might be used to break the coal without explosives. These can be preferable in environmentally sensitive areas.

- Directional Blasting: This involves carefully controlling the direction and energy of the blast, allowing for more precise fracturing of the coal, minimizing damage to surrounding rock.

Safety is paramount in all blasting operations. Stringent regulations govern the use of explosives, and meticulous planning and execution are essential to prevent accidents. The type of blasting technique also affects the fragmentation characteristics, which in turn influences subsequent extraction processes.

Q 28. Explain the concept of ‘coalbed methane (CBM)

Coalbed methane (CBM) is natural gas that is stored within coal seams. Unlike conventional natural gas found in underground reservoirs, CBM is adsorbed onto the surface of coal particles and held in place by the pressure of the overlying rock formations. It’s primarily methane, but can also contain smaller amounts of other gases like carbon dioxide and nitrogen.

Extraction: CBM is extracted by reducing the pressure in the coal seam, allowing the methane to desorb (be released) from the coal and flow to the surface through wells. This process is similar to oil and gas production from conventional reservoirs.

Importance: CBM is a significant energy resource, and its extraction presents both opportunities and challenges. On the positive side, it’s a relatively clean-burning fuel compared to coal, reducing greenhouse gas emissions when used as a substitute for coal in power generation. However, it also presents safety risks, as methane is a highly flammable gas, and its uncontrolled release can lead to explosions. Therefore, careful extraction and management practices are crucial.

Environmental Aspects: CBM extraction can also have environmental impacts, particularly affecting groundwater resources and causing land subsidence if not managed properly. Therefore, responsible and sustainable CBM development requires thorough environmental assessments and mitigation plans.

Key Topics to Learn for a Coal Mining Terminology Interview

- Coal Seam Geology: Understanding coal formation, rank, and properties. Practical application: Interpreting geological maps and data to predict coal quality and quantity.

- Mining Methods: Familiarization with various extraction techniques (e.g., longwall, room and pillar, continuous mining). Practical application: Assessing the suitability of different methods based on geological conditions and safety regulations.

- Mine Ventilation: Principles of airflow management and its impact on safety and productivity. Practical application: Understanding ventilation plans and identifying potential hazards related to methane and dust.

- Ground Control: Techniques for managing roof and sidewall stability. Practical application: Analyzing ground control data to prevent roof collapses and other ground-related accidents.

- Mine Safety Regulations and Procedures: Knowledge of relevant health and safety legislation and best practices. Practical application: Implementing and adhering to safety protocols to minimize workplace risks.

- Equipment and Machinery: Understanding the operation and maintenance of common mining equipment (e.g., continuous miners, shuttle cars, roof bolters). Practical application: Troubleshooting equipment malfunctions and ensuring efficient operation.

- Mine Planning and Design: Principles of mine layout, production scheduling, and resource management. Practical application: Developing efficient and safe mining plans.

- Environmental Considerations: Understanding the environmental impact of coal mining and mitigation strategies. Practical application: Implementing responsible mining practices to minimize environmental damage.

Next Steps

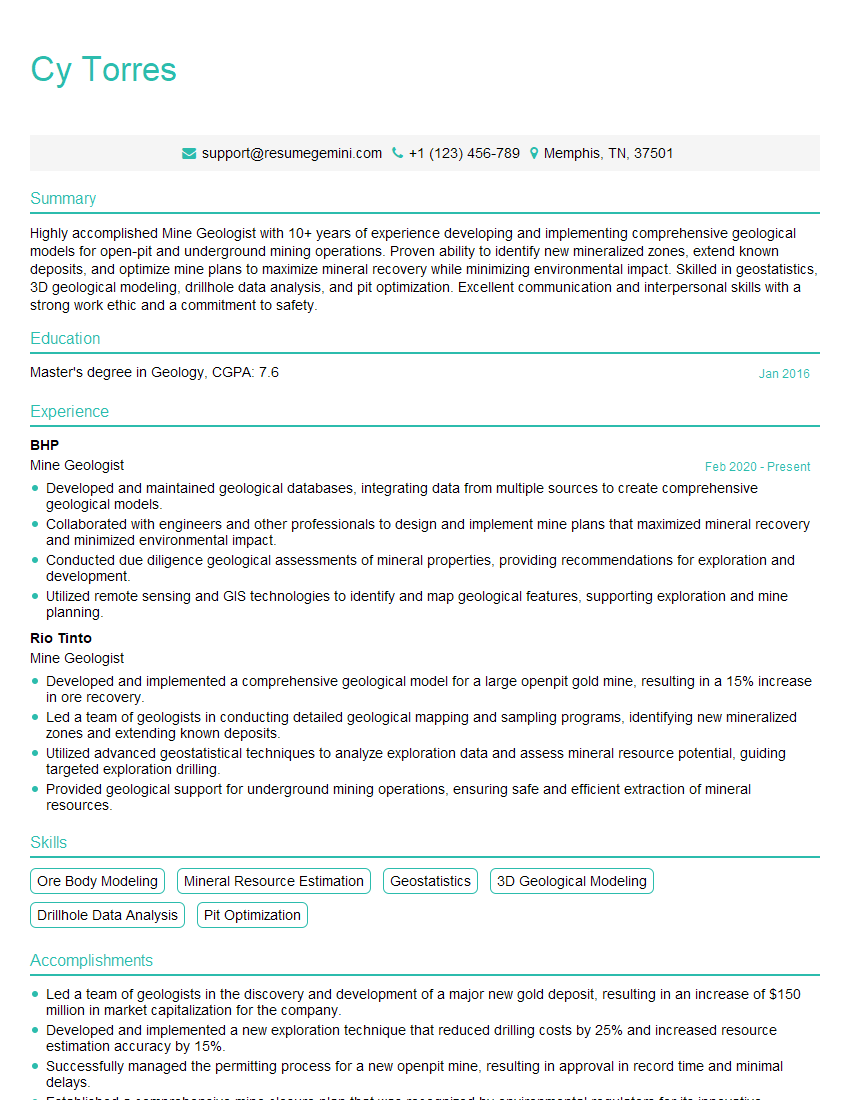

Mastering coal mining terminology is crucial for advancing your career in this demanding yet rewarding industry. A strong understanding of these concepts demonstrates your technical expertise and commitment to safety, increasing your attractiveness to potential employers. To further enhance your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the coal mining industry. Examples of resumes specifically designed for candidates with knowledge of coal mining terminology are available to guide you. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO