Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Knowledge of engineering materials and their properties interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Knowledge of engineering materials and their properties Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both crucial measures of a material’s ability to withstand pulling forces, but they represent different points on the material’s stress-strain curve. Tensile strength is the maximum stress a material can withstand before it breaks. Imagine pulling on a rubber band until it snaps – that breaking point represents the tensile strength. Yield strength, on the other hand, is the stress at which the material begins to deform permanently. It’s the point beyond which the material won’t return to its original shape after the load is removed. Think of bending a paperclip – once you bend it past its yield strength, it stays bent. In essence, tensile strength signifies the ultimate load-bearing capacity, while yield strength indicates the onset of permanent deformation.

For example, a high-strength steel might have a tensile strength of 600 MPa and a yield strength of 350 MPa. This means it can withstand a maximum stress of 600 MPa before fracturing, but permanent deformation will begin at 350 MPa. Knowing both values is critical for selecting appropriate materials for engineering applications, ensuring that the material can both withstand the expected loads and maintain its shape and function.

Q 2. Describe the concept of fatigue failure in materials.

Fatigue failure is a progressive and localized structural damage that occurs when a material is subjected to cyclic loading. This means the material is repeatedly stressed and unstressed, even if the maximum stress in each cycle is well below the material’s tensile or yield strength. Over time, microscopic cracks form and propagate, eventually leading to catastrophic failure. Imagine repeatedly bending a wire back and forth; eventually, it’ll break, even if each bend doesn’t seem significant. This is fatigue failure in action.

Several factors influence fatigue failure, including the magnitude and frequency of the cyclic load, the material’s properties (e.g., microstructure, surface finish), and the presence of any stress concentrations (e.g., notches, holes). Fatigue failure is a significant concern in many engineering applications, particularly those involving rotating machinery (like aircraft engines or turbines) or components subject to vibrations. Proper material selection, design modifications (to reduce stress concentrations), and surface treatments (to improve fatigue life) are crucial for mitigating fatigue failure.

Q 3. What are the common types of corrosion and how can they be prevented?

Corrosion is the deterioration of a material due to its chemical reaction with its environment. Several types of corrosion exist, each with its own characteristics and prevention strategies.

- Uniform corrosion: This is a relatively predictable form of corrosion, where the material deteriorates evenly across its surface. Think of rusting on an iron fence. Prevention involves using corrosion-resistant materials (stainless steel, for example), protective coatings (paint, plating), or cathodic protection.

- Pitting corrosion: This involves the localized formation of small pits or holes on the material’s surface. It can be difficult to detect and can lead to premature failure. Preventing pitting often involves material selection, controlling the environment (e.g., reducing chloride ions in water), and using inhibitors.

- Crevice corrosion: This occurs in confined spaces, such as gaps or crevices, where stagnant solutions can accumulate and create a corrosive environment. Prevention focuses on designing to eliminate crevices or using materials resistant to crevice corrosion.

- Stress corrosion cracking: This occurs when a material is subjected to tensile stress in a corrosive environment. It’s a particularly dangerous form of corrosion as it can lead to sudden failure. Prevention involves using stress-relieving treatments, selecting more resistant materials, or modifying the environment.

Overall, corrosion prevention strategies often involve a combination of material selection, environmental control, and protective measures. The specific approach depends on the type of corrosion and the application.

Q 4. Explain the difference between ductile and brittle fracture.

Ductile fracture and brittle fracture describe two different modes of material failure under tensile stress. Ductile fracture is characterized by significant plastic deformation before failure. The material stretches and necks down considerably before eventually fracturing. This gives ample warning signs before complete failure. Think of pulling taffy – it stretches and thins before breaking. Brittle fracture, on the other hand, involves little to no plastic deformation before failure. The material fractures suddenly and catastrophically, often with minimal warning. Imagine snapping a dry twig – it breaks instantly with little deformation.

The difference stems from the material’s microstructure and its ability to accommodate plastic deformation. Ductile materials have a microstructure that allows for dislocation movement, facilitating plastic deformation. Brittle materials have less ability for dislocation movement, resulting in sudden fracture. The type of fracture is crucial in design considerations as it directly impacts safety and reliability. Ductile fracture is generally preferred as it provides warning signs, allowing for preventative measures.

Q 5. How does temperature affect the mechanical properties of materials?

Temperature significantly impacts the mechanical properties of materials. As temperature increases, many materials exhibit a decrease in strength and an increase in ductility. The atoms gain more kinetic energy, making them more prone to movement and deformation under stress. This is why many materials become softer and more easily deformed at higher temperatures. Conversely, at lower temperatures, materials often become stronger and more brittle, with reduced ductility. The atoms have less kinetic energy, limiting their ability to move and accommodate deformation. This can lead to increased susceptibility to brittle fracture.

This temperature dependence is critical in engineering design. For instance, aircraft components operating at high altitudes and low temperatures need materials that retain their strength and toughness at those conditions. Similarly, components in high-temperature environments (e.g., jet engines) require materials that can withstand the elevated temperatures without significant loss of strength or creep (slow deformation under constant load).

Q 6. What are the advantages and disadvantages of using composite materials?

Composite materials are formed by combining two or more constituent materials with significantly different properties. The resulting material often exhibits superior properties compared to the individual components. This makes them attractive for many advanced engineering applications.

- Advantages: High strength-to-weight ratio, improved stiffness, tailored properties (by adjusting the composition and arrangement of the constituents), enhanced resistance to fatigue and corrosion, design flexibility.

- Disadvantages: Can be expensive to manufacture, complex fabrication processes, potential for delamination (separation of layers), susceptibility to damage from impact, anisotropic behavior (properties vary depending on the direction of loading).

For example, carbon fiber-reinforced polymers (CFRPs) are widely used in aerospace due to their high strength-to-weight ratio. However, their high cost and susceptibility to impact damage need careful consideration during design and manufacturing.

Q 7. Describe different types of non-destructive testing methods for materials.

Non-destructive testing (NDT) methods allow for the evaluation of a material’s properties and integrity without causing damage. Various methods exist, each with its strengths and limitations.

- Visual inspection: A simple but effective method for detecting surface defects such as cracks, corrosion, or damage.

- Liquid penetrant testing: Used to detect surface-breaking flaws by applying a dye that penetrates the crack and is then revealed by a developer.

- Magnetic particle inspection: Detects surface and near-surface flaws in ferromagnetic materials by magnetizing the part and applying magnetic particles that are attracted to the flaws.

- Ultrasonic testing: Uses high-frequency sound waves to detect internal flaws. The echoes from the flaws provide information about their size, location, and orientation.

- Radiographic testing: Uses X-rays or gamma rays to penetrate the material and reveal internal flaws. This is often used for detecting weld defects or porosity.

- Eddy current testing: Uses electromagnetic induction to detect surface and near-surface flaws in conductive materials.

The choice of NDT method depends on factors such as the material type, the type of flaw being sought, and the accessibility of the component. NDT is crucial for ensuring the quality and safety of many engineering structures and components.

Q 8. Explain the concept of stress-strain curve and its significance.

A stress-strain curve is a graphical representation of a material’s response to applied force. It plots stress (force per unit area) against strain (deformation per unit length). The shape of this curve reveals crucial information about the material’s mechanical properties.

The curve typically shows several key regions: the elastic region (where the material returns to its original shape after the load is removed), the yield point (where plastic deformation begins), the plastic region (where permanent deformation occurs), and finally, ultimate tensile strength (the maximum stress the material can withstand before failure) and fracture point.

Significance: The stress-strain curve is essential for engineers to select appropriate materials for specific applications. For instance, a structure requiring high strength and stiffness would necessitate a material with a high yield strength and a steep elastic region. Conversely, a material for a shock absorber might need a large plastic deformation region before failure. Imagine designing a car – the steel in its body needs high tensile strength to withstand impacts, while the plastic bumpers need to deform under impact to absorb energy and prevent damage to the rest of the car. The stress-strain curve ensures we choose the right material for each part.

Q 9. What are the factors that influence the selection of a material for a specific application?

Material selection is a crucial step in any engineering design. Several factors influence this decision:

- Mechanical Properties: Strength, stiffness (Young’s modulus), ductility, toughness, hardness, fatigue resistance, and creep resistance are paramount. A bridge needs high tensile strength and stiffness, whereas a packaging material may prioritize flexibility and impact resistance.

- Physical Properties: Density, melting point, thermal conductivity, electrical conductivity, and magnetic properties are important depending on the application. For instance, a heat sink needs high thermal conductivity, while a lightweight aircraft component requires low density.

- Chemical Properties: Corrosion resistance, reactivity with the environment, and biocompatibility are vital. A pipeline transporting corrosive chemicals demands high corrosion resistance, while a medical implant needs to be biocompatible.

- Cost: The material’s cost and availability play a significant role. While some materials might offer superior performance, their high cost might make them unsuitable for mass production.

- Manufacturing Considerations: The ease of fabrication (machining, casting, welding, etc.) should be considered. For instance, complex shapes might be easier to create using injection molding with a plastic compared to forging a metal part.

- Environmental Impact: Sustainability and recyclability are becoming increasingly important factors in material selection.

The interplay of these factors determines the optimal material choice. For example, designing a bicycle frame requires balancing strength (high tensile strength steel or aluminum alloys) with weight (lightweight aluminum alloys) and cost.

Q 10. Describe different types of polymers and their applications.

Polymers are large molecules composed of repeating structural units called monomers. They are categorized based on their structure and properties:

- Thermoplastics: These polymers soften upon heating and harden upon cooling, allowing for repeated molding and reshaping. Examples include polyethylene (PE), used in plastic bags and bottles; polypropylene (PP), used in containers and fibers; and polyvinyl chloride (PVC), used in pipes and flooring.

- Thermosets: These polymers undergo irreversible chemical changes upon heating, forming a rigid cross-linked structure. They cannot be remelted or reshaped. Examples include epoxy resins, used in adhesives and coatings; polyester resins, used in fiberglass; and phenolic resins, used in electrical components.

- Elastomers: These polymers exhibit high elasticity and flexibility. Examples include natural rubber and synthetic rubbers like styrene-butadiene rubber (SBR), used in tires and other flexible applications.

- Engineering Plastics: These polymers exhibit high strength, stiffness, and heat resistance, making them suitable for demanding applications. Examples include polycarbonate (PC), used in safety glasses and CDs; and polyamide (nylon), used in fibers and mechanical parts.

The application of a polymer depends heavily on its properties. For example, the high flexibility of polyethylene makes it ideal for plastic bags, while the high strength and heat resistance of polycarbonate make it suitable for bulletproof windows.

Q 11. Explain the difference between thermosetting and thermoplastic polymers.

The key difference between thermosetting and thermoplastic polymers lies in their response to heat and their molecular structure:

- Thermoplastics: Have linear or branched molecular chains. Upon heating, these chains soften and become more mobile, allowing the polymer to be reshaped. Cooling solidifies the material again. Think of it like spaghetti – you can heat it, bend it, and cool it again, and it will hold its new shape.

- Thermosets: Have a cross-linked network structure. Upon heating, they undergo an irreversible chemical reaction forming strong covalent bonds between chains. This creates a rigid, three-dimensional network. The polymer cannot be remelted or reshaped. Imagine a cooked egg – once cooked, you cannot uncook it.

This difference significantly impacts their applications. Thermoplastics are recyclable and can be remolded, making them suitable for many consumer products. Thermosets, due to their high strength and heat resistance, are often used in applications where high performance is required, such as in aircraft components or electrical insulation, even if they are not recyclable.

Q 12. How would you determine the appropriate material for a high-temperature application?

Selecting a material for a high-temperature application requires considering its high-temperature strength, oxidation resistance, and thermal stability. Here’s a step-by-step approach:

- Define the temperature range: Determine the maximum operating temperature and any temperature fluctuations.

- Identify required mechanical properties: Consider the necessary strength, stiffness, and creep resistance at the operating temperature.

- Assess oxidation resistance: Determine the material’s resistance to oxidation and degradation at high temperatures.

- Consider thermal stability: Ensure the material maintains its properties without significant degradation over time at high temperatures.

- Evaluate candidate materials: Based on the above criteria, select potential materials like superalloys (nickel-based, cobalt-based), refractory metals (tungsten, molybdenum), ceramics (silicon carbide, alumina), or high-temperature polymers (polyimides).

- Conduct material testing: Perform high-temperature tensile tests, creep tests, and oxidation tests to verify the selected material’s performance.

For example, designing a turbine blade for a jet engine requires a material with exceptional high-temperature strength, creep resistance, and oxidation resistance. Superalloys based on nickel or cobalt are often preferred due to their excellent performance in these demanding conditions.

Q 13. Describe the process of creep in materials.

Creep is the time-dependent deformation of a material under sustained stress at elevated temperatures. Imagine a metal wire hanging under its own weight – over a long period, the wire might sag slightly. That’s creep. It’s a permanent deformation, unlike elastic deformation which is recoverable.

The process involves three stages:

- Primary Creep: The creep rate decreases with time. Initially, the material’s resistance to deformation is relatively high.

- Secondary Creep: A steady-state creep occurs with a constant creep rate. This is the most important stage for determining the material’s long-term performance at high temperatures.

- Tertiary Creep: The creep rate accelerates rapidly until the material eventually fractures. This stage is characterized by damage accumulation, such as grain boundary cavitation and crack propagation.

Factors influencing creep include temperature, stress level, material properties (grain size, alloying elements), and microstructure. High temperatures significantly accelerate creep, whereas lower stresses lead to slower creep rates. Designing components for high-temperature applications (like gas turbines or nuclear reactors) requires careful consideration of creep to ensure long-term structural integrity.

Q 14. What are the different types of crystal structures in metals?

Metals are crystalline materials, meaning their atoms are arranged in a regular, repeating pattern called a crystal lattice. Several common crystal structures exist:

- Body-Centered Cubic (BCC): Each unit cell has atoms at each of the eight corners and one atom in the center. Examples include iron (α-iron), chromium, and tungsten. BCC structures often exhibit high strength and hardness at room temperature but lower ductility.

- Face-Centered Cubic (FCC): Each unit cell has atoms at each of the eight corners and one atom at the center of each of the six faces. Examples include aluminum, copper, nickel, and austenitic stainless steels. FCC structures usually possess good ductility, malleability, and corrosion resistance.

- Hexagonal Close-Packed (HCP): Atoms are arranged in a close-packed hexagonal structure. Examples include titanium, magnesium, and zinc. HCP metals are generally less ductile than FCC metals.

The crystal structure significantly influences a metal’s mechanical, physical, and chemical properties. For example, the difference in ductility between BCC and FCC metals stems from the different ways their crystal structures can accommodate deformation. Understanding crystal structures is fundamental to predicting and controlling the properties of metallic materials.

Q 15. Explain the concept of grain size and its effect on material properties.

Grain size refers to the average diameter of the crystals (grains) in a polycrystalline material. Imagine a chocolate bar: the individual squares are like grains in a metal. Smaller grains generally mean a material has more grain boundaries – the interfaces between the crystals. These boundaries act as obstacles to dislocation movement, which are essentially imperfections in the crystal structure that cause deformation.

The effect on material properties is significant. Smaller grain size typically leads to increased strength and hardness because the dislocations have more difficulty moving through the many grain boundaries. It also often results in increased toughness (resistance to fracture) and improved fatigue resistance (ability to withstand repeated loading). However, smaller grain sizes can sometimes lead to reduced ductility (ability to deform before breaking) and increased brittleness.

For example, consider steel. By controlling the cooling rate during solidification, metallurgists can influence grain size. A rapidly cooled steel will have finer grains than a slowly cooled one, resulting in a stronger and harder material, suitable for applications requiring high strength, such as high-strength steels used in automotive parts.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you analyze a material failure?

Analyzing material failure involves a systematic approach combining visual inspection, microscopy, and mechanical testing. First, we need to carefully document the failure site, taking detailed photographs and notes. This includes the fracture surface’s appearance (brittle, ductile, fatigue), the location of the failure, and any surrounding damage.

Next, we’ll use microscopy techniques like scanning electron microscopy (SEM) to examine the microstructure at higher magnifications. This helps identify potential flaws, such as inclusions, voids, or cracks that initiated or propagated the failure. Mechanical testing, such as tensile or impact testing, may be performed on undamaged samples of the same material to determine the mechanical properties. Comparing these properties to the failed part helps establish whether the failure was due to a material defect, design flaw, or excessive loading.

Finally, fracture mechanics principles can be used to quantify stress intensity factors and assess crack propagation. By combining all this information, we can develop a comprehensive understanding of the failure mechanism and recommend improvements in material selection, design, or manufacturing processes to prevent similar failures in the future. For example, identifying fatigue cracks in an aircraft component would require a detailed analysis to determine the crack initiation site and growth rate to prevent catastrophic failure.

Q 17. What are some common material testing standards?

Many standards govern material testing, ensuring consistent and reliable results worldwide. Some prominent examples include:

- ASTM International (ASTM): Develops and publishes numerous standards for materials, including metals, polymers, and ceramics. Examples include ASTM E8 (Tensile testing), ASTM E18 (Hardness testing), and ASTM D638 (Tensile properties of plastics).

- ISO (International Organization for Standardization): Develops international standards for various fields, including material testing. These standards ensure consistency in test methods across different countries.

- ASME (American Society of Mechanical Engineers): Establishes standards related to pressure vessels, boilers, and other mechanical components, often including specific material testing requirements.

- SAE International (Society of Automotive Engineers): Develops standards related to automotive materials and components.

The choice of standard depends on the material being tested, the required properties, and the application. Using recognized standards is crucial for ensuring that test results are comparable and reliable across different laboratories and manufacturers.

Q 18. Explain the concept of hardness testing and different methods used.

Hardness testing measures a material’s resistance to indentation. It’s a relatively simple and non-destructive method for assessing material strength and is widely used for quality control. Several methods exist, each using a different indenter and applying a specific load:

- Brinell Hardness Test: Uses a hardened steel ball indenter and measures the diameter of the indentation. It’s suitable for softer materials.

- Rockwell Hardness Test: Uses a diamond cone or steel ball indenter and measures the depth of penetration. This method is popular due to its speed and simplicity, offering various scales (e.g., Rockwell A, B, C) suitable for different hardness ranges.

- Vickers Hardness Test: Uses a diamond pyramid indenter and measures the diagonal length of the square indentation. It provides highly precise and reproducible results across a wide range of hardness. It’s suitable for both hard and soft materials and smaller specimens.

- Shore Durometer: Measures the resistance to indentation using a specific indenter that falls from a certain height. This method is used mostly for rubber and other elastomers.

The choice of method depends on the material’s hardness and the required accuracy. For example, Rockwell hardness testing is often used for quality control in manufacturing, while Vickers testing might be preferred for research applications requiring high precision.

Q 19. What are the properties of ceramics that make them suitable for certain applications?

Ceramics, including oxides, carbides, and nitrides, possess a unique combination of properties that make them suitable for diverse applications. Key properties include:

- High hardness and strength: Ceramic materials exhibit exceptional resistance to scratching and wear, making them suitable for cutting tools, grinding wheels, and protective coatings.

- High melting points and thermal stability: Their ability to withstand high temperatures makes them ideal for applications in high-temperature environments like furnace linings and engine components.

- Chemical inertness: Many ceramics are resistant to corrosion and chemical attack, making them suitable for chemical processing equipment and biomedical implants.

- Electrical insulation: Ceramics are excellent electrical insulators, making them suitable for electrical components and insulators.

- Low thermal conductivity: This property makes them suitable for thermal insulation applications.

However, ceramics are also known for their brittleness, which limits their use in applications involving impact or shock loading. For instance, alumina (Al2O3) is used in high-strength cutting tools and biomedical implants, while zirconia (ZrO2) is used in oxygen sensors and dental crowns, leveraging their hardness and biocompatibility respectively.

Q 20. Describe the process of heat treatment for metals.

Heat treatment involves carefully controlled heating and cooling of metals to alter their microstructure and, consequently, their mechanical properties. The process typically involves several stages:

- Heating: The metal is heated to a specific temperature within a controlled atmosphere to allow for diffusion and phase transformations.

- Soaking: The metal is held at the elevated temperature for a specific time to ensure that the desired changes in microstructure occur uniformly.

- Cooling: The metal is cooled at a controlled rate, often using quenching (rapid cooling) or annealing (slow cooling). The cooling rate significantly influences the final microstructure and properties.

Different heat treatments, such as annealing, quenching, tempering, and normalizing, are used to achieve specific properties. For example, annealing relieves internal stresses and improves ductility, while quenching and tempering increase hardness and strength. The specific heat treatment parameters (temperature, time, cooling rate) depend on the material, desired properties, and application. For example, quenching and tempering of steel is essential for achieving the high strength and toughness required in springs and tools.

Q 21. What are the effects of alloying elements on the properties of metals?

Alloying elements significantly alter the properties of base metals by changing their microstructure and electronic structure. The effects can be dramatic, enhancing strength, corrosion resistance, or other properties. Let’s look at a few examples:

- Carbon in Steel: Adding carbon to iron (creating steel) dramatically increases its strength and hardness. Higher carbon content increases hardness but reduces ductility.

- Nickel in Stainless Steel: Nickel additions to steel improve corrosion resistance significantly, making stainless steels suitable for harsh environments. Nickel also contributes to strength and toughness.

- Aluminum in Copper: Adding aluminum to copper forms aluminum bronze, enhancing its strength and corrosion resistance compared to pure copper.

- Chromium in Stainless Steel: Chromium enhances corrosion resistance by forming a passive chromium oxide layer on the surface.

Alloying elements can also modify other properties like electrical conductivity, thermal conductivity, and magnetic properties. The precise effects depend on the base metal, the alloying element, its concentration, and the processing techniques used. For instance, the specific composition and heat treatment of high-speed steels are crucial for their performance in cutting tools, where both hardness and wear resistance are critical.

Q 22. Explain the different types of bonding in materials (ionic, covalent, metallic).

Materials are held together by different types of bonding, each influencing their properties significantly. Think of it like different types of glue holding things together – some are strong and rigid, others are flexible and weak.

- Ionic Bonding: This involves the electrostatic attraction between oppositely charged ions. One atom loses electrons (becoming a positive ion or cation) and another gains electrons (becoming a negative ion or anion). This is like magnets attracting each other. A classic example is sodium chloride (NaCl), common table salt, where sodium loses an electron to chlorine.

- Covalent Bonding: This occurs when atoms share electrons to achieve a stable electron configuration. Think of it as two people sharing a resource. This creates strong bonds, leading to materials that are often hard and have high melting points. Diamond, with its strong carbon-carbon covalent bonds, is an excellent example.

- Metallic Bonding: This type of bonding involves a ‘sea’ of delocalized electrons shared among a lattice of positive metal ions. The electrons are free to move throughout the structure. This is like a communal pool of electrons that allows for high electrical and thermal conductivity. Copper, used extensively in electrical wiring, demonstrates excellent metallic bonding.

The strength and type of bonding directly influence properties like melting point, hardness, electrical conductivity, and ductility. For example, ionic materials tend to be brittle due to the strong directional bonds, while metallic materials are often ductile due to the ability of the electron sea to accommodate deformation.

Q 23. How does microstructure influence the mechanical properties of materials?

Microstructure, the arrangement of grains and phases within a material, significantly impacts its mechanical properties. Imagine a brick wall – if the bricks are laid neatly, the wall is strong; if they’re haphazard, it’s weaker. Similarly, the size, shape, and orientation of grains in a material influence its strength, ductility, and toughness.

- Grain Size: Smaller grains generally lead to higher strength and hardness due to increased grain boundary area, hindering dislocation movement (dislocations are defects in the crystal structure that allow for plastic deformation). Think of smaller grains acting like obstacles, making it harder for the material to deform.

- Grain Orientation: Preferred grain orientation can lead to anisotropy, where properties vary with direction. For example, a rolled metal sheet will have different strength properties in the rolling direction compared to the transverse direction.

- Phases: The presence of different phases within a material, for instance, in a steel alloy, can affect its strength and toughness. The distribution and morphology of these phases are crucial. For example, a dispersed second phase can significantly strengthen the material by hindering dislocation motion.

Controlling microstructure through techniques like heat treatment (annealing, quenching, tempering) allows engineers to tailor material properties for specific applications. For instance, heat treatment can be used to increase the hardness of steel for tools or improve its ductility for sheet metal forming.

Q 24. What are some common material degradation mechanisms?

Material degradation is the deterioration of a material’s properties over time due to various factors. This is like aging – materials wear down and lose their effectiveness. Several common mechanisms include:

- Corrosion: This is the chemical or electrochemical degradation of a material due to its interaction with its environment. Rusting of iron is a classic example of corrosion. This is often accelerated by moisture and oxygen.

- Creep: This is the time-dependent deformation of a material under constant stress at elevated temperatures. It’s like slowly bending under a constant load over time. Turbine blades in jet engines experience creep at high temperatures.

- Fatigue: This is the failure of a material under cyclic loading, even if the stress is below the yield strength. Imagine bending a paper clip back and forth – eventually, it will break. Fatigue is a major concern in many engineering applications, including bridges and aircraft.

- Wear: This involves the removal or degradation of material from the surface due to friction and abrasion. Tire wear is a familiar example of material wear.

- Stress Corrosion Cracking: This occurs when a material is simultaneously exposed to a corrosive environment and tensile stress. It’s a combination of corrosion and stress that accelerates failure. This is a critical concern in pipelines and other high-pressure systems.

Understanding these degradation mechanisms is crucial for designing materials and structures that can withstand their operating environments and prevent premature failure.

Q 25. Describe the role of surface treatments in enhancing material performance.

Surface treatments modify the surface properties of materials to enhance performance. It’s like giving a material a protective coat of armor. These treatments can improve corrosion resistance, wear resistance, lubricity, or adhesion.

- Coatings: Applying a protective layer, like paint or a metallic coating (e.g., galvanizing steel with zinc), can shield the base material from environmental attack. This increases corrosion resistance.

- Surface Hardening: Techniques like carburizing or nitriding increase the hardness of the surface layer, improving wear resistance. Think of hardening a knife blade to make it sharper and more durable.

- Oxidation: Controlled oxidation can create a protective oxide layer, enhancing corrosion resistance. Anodizing aluminum creates a hard, corrosion-resistant oxide layer.

- Chemical treatments: Processes like phosphating or chromating can create a conversion coating, improving adhesion and corrosion resistance.

Choosing the appropriate surface treatment depends on the specific application and desired properties. For instance, a coating designed for a marine environment needs to be highly corrosion-resistant, whereas a coating for a high-wear application needs to be exceptionally hard.

Q 26. How would you investigate a case of unexpected material failure in a product?

Investigating unexpected material failure requires a systematic approach. It’s like detective work – finding clues to determine the root cause.

- Visual Inspection: Begin by carefully examining the failed component to identify fracture surfaces, cracks, or other visible signs of damage.

- Microscopic Analysis: Use optical or electron microscopy to analyze the microstructure and identify any defects or anomalies that might have contributed to the failure.

- Chemical Analysis: Perform chemical analysis (e.g., X-ray diffraction, spectroscopy) to determine the material composition and identify any impurities or changes in chemistry that could have weakened the material.

- Mechanical Testing: Conduct tensile, fatigue, or impact tests on similar material samples to assess its mechanical properties and compare them to the expected values.

- Environmental Analysis: Evaluate the operating environment of the component to identify any factors (temperature, humidity, chemicals) that could have accelerated material degradation.

- Finite Element Analysis (FEA): In some cases, computer simulations using FEA can help analyze stress distributions and predict failure modes.

By combining these techniques, you can systematically eliminate potential causes and determine the root cause of the failure, allowing for corrective actions to prevent future occurrences.

Q 27. Explain the importance of material compatibility in design.

Material compatibility is paramount in design, ensuring that different materials in contact do not negatively interact. It’s like ensuring that different ingredients in a recipe don’t react badly with each other.

- Chemical Compatibility: Materials should not chemically react with each other, leading to corrosion or degradation. For instance, using dissimilar metals in contact can lead to galvanic corrosion if not properly protected.

- Thermal Compatibility: Materials should have compatible thermal expansion coefficients to avoid stress build-up during temperature changes. Think of using different metals in a high-temperature environment – the mismatch in expansion could cause cracking.

- Mechanical Compatibility: Materials should have compatible mechanical properties to avoid problems like stress concentrations or wear. Using a soft material against a hard one can lead to excessive wear of the softer material.

Ignoring material compatibility can lead to premature failure, leakage, and other problems. Careful material selection is critical for reliable and long-lasting products. For example, in aerospace applications, meticulous attention to material compatibility is crucial for safety and performance.

Q 28. What are some emerging trends in materials science and engineering?

Materials science and engineering are constantly evolving, driven by the need for improved performance and sustainability. Some emerging trends include:

- Additive Manufacturing (3D Printing): This technology enables the creation of complex parts with intricate geometries, opening up possibilities for lightweight, high-performance components and customized designs.

- Biomaterials: The development of biocompatible materials for implants, drug delivery systems, and tissue engineering is a rapidly growing area, improving healthcare and quality of life.

- Nanomaterials: Materials at the nanoscale exhibit unique properties, leading to advancements in electronics, energy storage, and catalysis. Graphene, with its exceptional strength and conductivity, is a prime example.

- Sustainable Materials: There’s an increasing focus on developing eco-friendly materials with reduced environmental impact, utilizing recycled materials and bio-based resources.

- Smart Materials: Materials that can sense and respond to changes in their environment, such as shape-memory alloys or self-healing materials, are gaining traction in various applications.

These trends are transforming industries and pushing the boundaries of what’s possible, leading to innovative solutions for various challenges.

Key Topics to Learn for Knowledge of engineering materials and their properties Interview

- Mechanical Properties: Stress-strain relationships, tensile strength, yield strength, ductility, hardness, fatigue, creep. Consider practical applications like selecting materials for a bridge or a prosthetic limb based on required strength and durability.

- Thermal Properties: Thermal conductivity, specific heat, thermal expansion. Think about applications like choosing materials for heat sinks or insulation in buildings and vehicles.

- Electrical Properties: Conductivity, resistivity, dielectric strength. Explore examples such as selecting materials for wiring or capacitors.

- Material Selection: Understanding the trade-offs between different material properties and how to select the optimal material for a given application. Practice problem-solving scenarios involving material selection based on cost, performance, and environmental considerations.

- Material Processing: Familiarize yourself with common manufacturing techniques like casting, forging, machining, and their impact on material properties. Consider the effects of different processing methods on the final product.

- Failure Analysis: Understand common failure mechanisms like fatigue, creep, fracture, and corrosion. Practice analyzing scenarios where material failure occurred and propose solutions to prevent future failures.

- Material Characterization Techniques: Become familiar with techniques like microscopy (optical, SEM, TEM), X-ray diffraction, and mechanical testing methods used to determine material properties.

- Composite Materials: Understand the properties and applications of composite materials, such as fiber-reinforced polymers, and how their properties differ from their constituent materials.

Next Steps

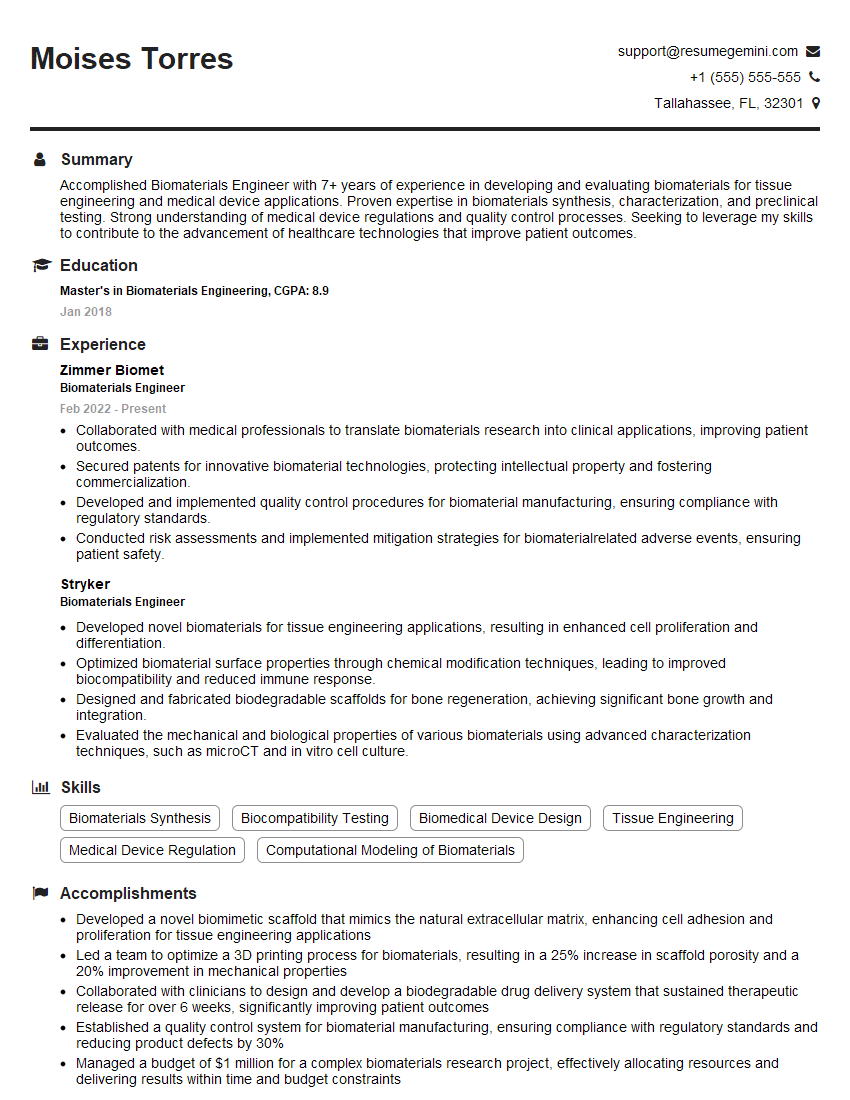

Mastering knowledge of engineering materials and their properties is crucial for career advancement in numerous engineering disciplines. A strong understanding of these concepts opens doors to exciting opportunities and demonstrates your ability to solve complex engineering challenges. To maximize your job prospects, creating a well-structured, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to showcase expertise in knowledge of engineering materials and their properties are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO