Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Knowledge of Folder Machine Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Knowledge of Folder Machine Operation Interview

Q 1. Describe your experience operating different types of folder machines (e.g., sheetfed, rotary).

My experience encompasses a wide range of folder machines, from simple sheetfed models ideal for smaller print runs to high-speed rotary folders used in large-scale commercial printing. Sheetfed folders, like the ones I’ve used from manufacturers such as Heidelberg and MBO, are excellent for handling diverse paper stocks and intricate folding patterns, though their speed is often limited. On the other hand, rotary folders, such as those by Horizon and Müller Martini, excel in speed and efficiency for large-volume jobs, often incorporating sophisticated features like in-line stitching and stacking. I’m proficient in operating both types, understanding their unique capabilities and limitations. For example, I’ve successfully managed projects requiring complex six-panel folds on a sheetfed machine and high-volume newspaper inserts using a rotary folder, adapting my techniques to the specific machine and project demands.

Q 2. Explain the process of setting up a folder machine for a specific job.

Setting up a folder machine for a specific job is a meticulous process requiring precision and attention to detail. It begins with a thorough review of the job specifications – the paper size, type, weight, the desired folding pattern (e.g., half-fold, letter fold, roll fold), and the final product’s dimensions. I’ll then consult the machine’s operational manual to determine the correct settings for the chosen folding pattern. This often involves adjusting the feeder’s paper guides, the folding rollers’ position and pressure, and the delivery system. For instance, if I’m creating a tri-fold brochure, I carefully adjust the rollers to ensure the correct fold positions are achieved. I always perform a test run with a small sample of paper to verify the settings and make any necessary adjustments before proceeding with the full job. This iterative approach minimizes waste and guarantees quality.

Q 3. How do you ensure accurate folding and alignment of printed materials?

Accurate folding and alignment are critical for a professional finish. Several key factors contribute to this. First, maintaining proper paper feed is crucial. Ensuring consistent paper flow prevents misalignments. Second, careful adjustment of the folding rollers is essential. The pressure and position of these rollers directly affect the accuracy of the fold. Too much pressure can cause creasing or tearing; too little can result in inaccurate folds. Third, regular cleaning and maintenance are vital. Accumulated dust or debris can obstruct the rollers and cause misalignments. Finally, using high-quality paper that’s consistently cut and sized significantly contributes to accuracy. Think of it like building a house – a strong foundation (consistent paper feed and quality) is crucial for a well-structured final product (accurate folding).

Q 4. What are the common causes of jams or misfeeds in a folder machine?

Jams and misfeeds are common occurrences, often stemming from several factors. One frequent cause is improper paper handling; wrinkles or creases in the paper can easily cause jams. Another common issue is incorrect machine settings, such as incorrect roller pressure or misaligned guides. Problems with the paper itself, such as variations in thickness or moisture content, can also lead to misfeeds. Additionally, accumulated dust or debris in the machine can hinder proper paper movement. Finally, worn or damaged components, such as rollers or belts, can contribute to jamming. Addressing these potential issues through proactive maintenance and careful operator attention can significantly reduce downtime and improve productivity.

Q 5. How do you troubleshoot and resolve common folder machine malfunctions?

Troubleshooting involves a systematic approach. I begin by identifying the type of malfunction: Is it a jam, a misfeed, or something else? I then consult the machine’s manual to pinpoint potential causes and recommended solutions. If the issue stems from a simple jam, I carefully remove the jammed sheets. If it’s a misfeed, I check the paper guides, roller settings, and paper quality. More complex malfunctions might involve checking the sensors, belts, or other mechanical components. For electrical issues, I might need to call a technician. Throughout the process, I meticulously document my actions to help resolve future issues quickly. I believe in a ‘first-things-first’ approach; checking the simple, obvious things before delving into complex mechanical or electrical problems.

Q 6. Describe your experience with different types of folding patterns (e.g., half-fold, letter fold).

My experience includes a wide array of folding patterns. Half-folds and letter folds are common, straightforward folds. However, I’m also proficient in more complex patterns such as roll folds, parallel folds, and gate folds, often required for brochures and booklets. I’ve worked on jobs requiring intricate combinations of these folds, creating multi-panel leaflets and other complex print materials. Each pattern requires precise adjustment of the machine’s components; for instance, a gate fold needs careful calibration of the folding blades to achieve a clean, crisp fold, avoiding any creases or misalignments. Understanding the nuances of each folding pattern allows me to efficiently set up the machine and ensure a high-quality final product.

Q 7. How do you maintain and perform preventative maintenance on a folder machine?

Preventative maintenance is essential to ensure smooth operation and avoid costly repairs. My routine includes regular cleaning of the machine, removing dust and debris that can accumulate in the rollers and other components. I inspect the belts and rollers for wear and tear, replacing them as needed. Lubrication of moving parts, according to the manufacturer’s recommendations, is also critical. I also regularly check the sensors and other electrical components to ensure proper functioning. This proactive approach minimizes downtime, extends the machine’s lifespan, and ultimately, ensures consistent high-quality output. Think of it as regular car maintenance – small preventative steps save you from larger, more expensive problems down the road.

Q 8. What safety precautions do you follow when operating a folder machine?

Safety is paramount when operating a folder machine. Before even approaching the machine, I always ensure I’m wearing appropriate personal protective equipment (PPE), including safety glasses to protect my eyes from flying debris and potentially sharp objects, and hearing protection to mitigate the noise levels. I meticulously check the machine for any loose parts, damaged components, or potential hazards before powering it on. I also ensure that the machine’s safety guards are in place and functioning correctly. During operation, I maintain a safe distance from moving parts, and I never reach into the machine while it’s running. Regular safety checks throughout the operation and a thorough shutdown procedure are essential. I always familiarize myself with the emergency stop button location and how to use it effectively. For example, during a recent job involving a high-volume run, I noticed a slight misalignment in the feed tray, and instead of attempting to adjust it on the fly, I immediately shut down the machine and corrected the issue, prioritizing safety over speed.

Q 9. How do you monitor the quality of folded products and identify defects?

Quality control is continuous throughout the folding process. I begin by visually inspecting a sample of folded products immediately after the machine’s initial setup to ensure the fold alignment, sharpness, and overall quality are to specification. This initial check helps identify and rectify any initial setup issues. Throughout the run, I regularly inspect the finished products, looking for defects like misfeeds, creases, incorrect folds, or jams. I’m trained to recognize various types of fold defects based on their causes – for example, creasing might indicate issues with the paper’s moisture content or blade sharpness, while inconsistent folds may be due to incorrect machine settings. I use a calibrated gauge to measure the dimensions of the finished product to ensure it meets the specified requirements. If I identify a defect pattern, I immediately analyze the cause – whether it’s a machine malfunction, a paper problem, or a setup error – and adjust accordingly before proceeding. For example, once I discovered several misaligned products were caused by a worn roller, I promptly replaced it to maintain consistent quality.

Q 10. Explain your experience with different types of paper and their impact on folding.

My experience encompasses a wide range of paper types, each affecting the folding process differently. Heavier papers, such as cardstock, require more pressure and potentially slower speeds to avoid tearing or jamming. Lighter papers, such as newsprint, might need adjustments to the suction system to ensure reliable feeding. Coated papers can be more susceptible to scratching or marking during folding, requiring careful handling and potentially softer rollers. The paper’s moisture content significantly impacts its foldability; excessively damp paper tends to wrinkle or crease, whereas overly dry paper is more brittle and prone to cracking. Understanding the paper’s grain direction is also crucial; folding against the grain can lead to cracking or breaking. For instance, I recently worked with a client who supplied unusually absorbent paper. The folding process was initially marred by jamming until I adjusted the machine’s feed rollers and the suction settings, allowing for a smooth and defect-free operation.

Q 11. How do you adjust the machine settings to accommodate different paper weights and sizes?

Adjusting a folder machine for different paper weights and sizes involves several key steps. The paper size is adjusted via the feed tray and output mechanisms. The paper weight is adjusted via the machine’s pressure settings. For heavier papers, increased pressure is needed on the folding rollers and blades to ensure a clean and crisp fold. Conversely, lighter papers require less pressure to avoid damage. The speed of the machine usually needs adjustment; heavier paper requires slower speeds to avoid jams, while lighter paper can handle higher speeds. The suction settings may also need adjustment; stronger suction helps ensure reliable feeding for lighter papers. For example, when switching from 80lb cover stock to 20lb bond, I reduced the pressure on the folding rollers, increased the speed, and adjusted the suction to achieve optimal performance. These adjustments are often made using digital controls on modern folder machines, and I have a thorough understanding of those systems.

Q 12. What is your experience with using different types of adhesives in folder-gluer machines?

My experience with adhesives in folder-gluer machines includes various types, each with unique characteristics. Hot melt adhesives are common for their quick drying time and strong bond, but require careful temperature control to prevent clogging or burning. Water-based adhesives are more environmentally friendly and offer good adhesion but have a slower drying time. Pressure-sensitive adhesives offer instant bonding and are often used for lighter applications. The choice of adhesive depends on the type of application, paper stock, and desired bond strength. I understand the properties of each adhesive and know how to adjust the machine’s settings, such as the application rate and drying time, to accommodate them. For instance, when working with a particularly sensitive paper stock, I opted for a water-based adhesive with a gentler application setting to prevent damage.

Q 13. Describe your process for cleaning and maintaining the various components of a folder machine.

Regular cleaning and maintenance are crucial for optimal performance and longevity of a folder machine. My cleaning process starts with a complete shutdown and unplugging of the machine. I then systematically clean each component, beginning with the feed tray and rollers. Compressed air is often used to remove debris and dust from hard-to-reach areas. I use appropriate cleaning solutions to remove glue residue or ink stains. The blades and knives are carefully cleaned and inspected for wear or damage, and replaced as needed. I lubricate moving parts according to the manufacturer’s recommendations using the appropriate lubricants. I thoroughly inspect the belts and pulleys for wear and tear. A log book detailing each cleaning and maintenance event is meticulously maintained. For example, I discovered a buildup of glue in a critical area during a routine inspection. I promptly cleaned the area, which prevented a potential jam during a large production run.

Q 14. How familiar are you with the different types of knives and blades used in folder machines?

I’m familiar with various types of knives and blades used in folder machines, each designed for specific folding styles and paper types. These include creasing blades, scoring blades, and cutting blades. Creasing blades create a defined fold without cutting the paper, while scoring blades create a partial cut to assist with folding. Cutting blades are used to cut the paper completely. The choice of blade material (e.g., steel, carbide) and its sharpness are crucial for the quality of the fold and overall efficiency. Dull blades can lead to poor folds, misfeeds, and paper damage. Regular inspection and sharpening or replacement of blades are part of my routine maintenance procedures. For example, I recently noted that the crispness of the folds was deteriorating, which led me to replace the creasing blades, restoring the quality of the final product.

Q 15. How do you ensure consistent speed and productivity while maintaining high-quality output?

Maintaining consistent speed and high-quality output on a folder machine is a balancing act. It relies on a combination of proper machine setup, operator skill, and preventative maintenance.

- Consistent Setup: Before each run, I meticulously check and adjust settings like feed speed, fold plates, and registration marks. Small variations in these settings can lead to significant quality issues or jams. For example, if the feed speed is too fast for the machine’s capabilities, it could cause misfeeds and creases. A slower, more deliberate feed ensures accuracy.

- Preventative Maintenance: Regular lubrication, cleaning of rollers, and inspection of wear parts are crucial. A well-maintained machine runs smoothly and produces consistent results. Ignoring this can lead to breakdowns and inconsistent output, costing time and materials.

- Operator Skill: Years of experience have taught me to anticipate potential problems and adjust settings proactively. I’m constantly monitoring the machine’s performance, looking for subtle changes in sound or operation that might indicate an issue. It’s like learning to ‘listen’ to the machine to predict and prevent problems.

- Quality Control Checks: I perform frequent quality checks throughout the run, inspecting for misfolds, wrinkles, or inconsistencies. Addressing small problems promptly prevents them from escalating into larger issues. Think of it as continuous improvement—small adjustments during the run lead to a superior final product.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience working with different types of folder machine controls (e.g., PLC, HMI).

I have extensive experience with various folder machine control systems, including PLCs (Programmable Logic Controllers) and HMIs (Human Machine Interfaces). My experience ranges from older, simpler systems to modern, sophisticated control panels.

- PLCs: I’m proficient in troubleshooting PLC programs, identifying and resolving errors through diagnostics and adjustments. For example, I once resolved a consistent misfeed issue by analyzing the PLC program and identifying a timing discrepancy in the feed mechanism control.

- HMIs: I utilize HMIs to monitor machine parameters in real-time, making adjustments as needed to optimize speed and quality. HMIs provide a visual representation of machine status, helping operators quickly identify problems. I’m comfortable with different HMI interfaces and navigation, making it easy for me to adapt to new machines.

- Different Control Systems: My experience spans different brands and models, from Heidelberg to Bobst, each with its unique control system. This adaptability is a key strength, allowing me to quickly understand and operate any new folder-gluer I encounter.

Q 17. Describe your experience with different types of folding machine feeders.

My experience includes working with a variety of folder machine feeders, each designed to handle different paper types and weights.

- Sheet Feeders: These are commonly used for lighter weight papers and are usually more sensitive to paper variations. I understand how to adjust the suction and feeder settings to accommodate different paper stocks and prevent jams. For instance, thinner paper requires gentler suction to prevent damage.

- Roll Feeders: These are suitable for higher-volume jobs with heavier paper stocks. I’m skilled in managing the roll tension and paper path to ensure a consistent feed. Understanding the importance of proper web tension is critical to preventing wrinkles and jams.

- Other Specialized Feeders: I’ve also worked with specialized feeders designed for unusual formats or materials, requiring specific adjustments and troubleshooting skills.

Understanding the nuances of each feeder type is critical for efficient and trouble-free operation. Selecting the right feeder for the job is crucial for maximizing productivity and minimizing waste.

Q 18. How do you manage and resolve conflicts with production targets and quality standards?

Balancing production targets with maintaining quality standards is a critical aspect of my role. It’s not about rushing; it’s about smart, efficient operation.

- Prioritization: I always prioritize quality. Meeting production targets without compromising quality is paramount. Compromising quality leads to costly rework or even product rejection.

- Root Cause Analysis: When conflicts arise, I perform a thorough root cause analysis to identify the bottleneck. This could involve analyzing machine settings, identifying operator errors, or even uncovering material-related issues.

- Communication: I communicate clearly with supervisors about potential delays and implement solutions proactively. Sometimes, it might involve adjusting the production plan or requesting additional resources.

- Process Improvement: I look for opportunities to improve efficiency without compromising quality. This might involve suggesting changes to the workflow, optimizing machine settings, or recommending better material selection.

The key is to establish a clear understanding of what constitutes acceptable quality and to work strategically to balance that with production demands.

Q 19. What is your understanding of the relationship between folder machine settings and the final product?

The relationship between folder machine settings and the final product is direct and crucial. Precise settings are essential for achieving the desired folds, creases, and overall product quality.

- Fold Plates: The positioning and adjustment of fold plates dictate the type of fold (e.g., half-fold, letter fold) and the accuracy of the fold. Incorrect settings can lead to misfolds or uneven creases.

- Registration Marks: Accurate registration is vital, particularly for jobs that require precise alignment of printed elements. Settings related to registration impact the final product’s aesthetic appeal and functionality.

- Feed Speed & Timing: These settings directly influence the consistency and speed of the folding process. Incorrect settings can lead to misfeeds, jams, and inconsistent product quality.

- Pressure Settings: The pressure applied during folding affects the sharpness and clarity of the creases. Insufficient pressure can result in weak creases, while excessive pressure can damage the paper.

Understanding these relationships allows for fine-tuning the settings to achieve optimal results. It’s akin to being a precision instrument technician, making minute adjustments for perfect results.

Q 20. How do you handle unexpected breakdowns or equipment malfunctions?

Unexpected breakdowns require a calm and systematic approach. My experience allows me to quickly assess the situation and take appropriate action.

- Safety First: My immediate priority is to ensure the safety of myself and others around the machine. This includes immediately shutting down the machine and isolating any potential hazards.

- Assessment & Diagnosis: I systematically assess the problem, looking for obvious signs of malfunction (e.g., loose belts, damaged parts, error codes). I consult the machine’s manual and utilize any diagnostic tools available.

- Troubleshooting: I attempt to troubleshoot the problem based on my knowledge and experience. This could range from simple repairs like replacing a broken part to more complex issues requiring deeper investigation.

- Reporting & Communication: I promptly report the breakdown and my findings to supervisors. If I am unable to resolve the issue, I communicate the need for professional maintenance assistance.

- Preventative Measures: After the breakdown is resolved, I analyze the root cause to prevent similar issues from occurring in the future. This might involve suggesting improvements in maintenance protocols or identifying areas for improvement in machine operation.

Q 21. What are the key performance indicators (KPIs) you monitor while operating a folder machine?

Several key performance indicators (KPIs) are crucial for monitoring folder machine performance. These provide a clear picture of efficiency and quality.

- Uptime: This represents the percentage of time the machine is actively running versus downtime due to breakdowns or maintenance. High uptime indicates efficient operation.

- Speed (ppm): Pieces per minute is a critical measure of productivity. It helps track the machine’s efficiency and output rate.

- Waste Rate: This reflects the percentage of materials lost due to misfeeds, jams, or defects. Lower waste rates indicate efficient material utilization.

- Defect Rate: The percentage of finished products with defects (e.g., misfolds, wrinkles, creases) indicates the overall quality of the output. A low defect rate is a key goal.

- Setup Time: This measures the time taken to prepare the machine for a new job. Efficient setup times minimize downtime between runs.

Regularly monitoring these KPIs allows for proactive identification of areas for improvement, optimizing machine performance and overall productivity. It’s like having a dashboard for the machine’s health and effectiveness.

Q 22. Describe a time you had to troubleshoot a complex folder machine issue. What was the outcome?

During my time at PrintPro, we experienced a recurring issue with our Heidelberg Stahlfolder TH 82-P. The machine was producing consistently misaligned folds on a large print run of brochures. Initially, we suspected a problem with the folding knives. However, after careful inspection, the knives were sharp and properly aligned. We then systematically checked every component, starting with the most likely culprits: the grippers, the chain delivery, and the folding rollers. We discovered that a small amount of accumulated debris had caused a slight misalignment in one of the folding rollers. This seemingly insignificant issue had a significant impact on the final product’s accuracy. The solution was straightforward – a thorough cleaning and realignment of the offending roller. Once this was done, the misalignment disappeared, and we were able to complete the job with consistently accurate folds. This highlighted the importance of meticulous maintenance and a systematic troubleshooting approach, starting with the most probable causes and progressively investigating less likely issues.

Q 23. How do you ensure the safe and efficient transfer of finished products from the folder machine?

Safe and efficient transfer of finished products is paramount. We employ a multi-step process. Firstly, the folder machine is equipped with a delivery system, typically a conveyor belt or stacker, that gently accumulates the folded sheets. This system is crucial in preventing damage to the finished products. Secondly, we use appropriate stacking methods, which vary depending on the type and quantity of finished products. For large runs, we might utilize an automated stacking system. For smaller runs, careful manual stacking with appropriate padding prevents damage. Finally, we use specialized carts or containers designed to prevent slippage and damage during transportation. Regular inspection of the delivery systems, ensuring proper function and timely cleaning to remove any debris, is essential for maintaining this process.

Q 24. What are the different types of scoring used in folding and their applications?

Scoring is a crucial pre-folding process that creates a weakened area in the paper, allowing for clean and precise folds. There are several types:

- Perforation Scoring: Creates a series of small holes, suitable for tear-out applications like coupons or perforated sheets.

- Creasing Scoring: Creates a subtle indentation to facilitate folding, improving the overall sharpness of the fold. This is often used for standard brochures and leaflets.

- Half-Tone Scoring: Uses a pattern of smaller indentations to create a smoother fold on thicker stocks that are prone to cracking with a simple crease.

- Valley Scoring: Used to create an inward fold (valley fold).

- Mountain Scoring: Used to create an outward fold (mountain fold).

The choice of scoring method depends heavily on paper stock, desired fold type, and the final application. For instance, perforation scoring is used extensively for tear-away sections, while creasing scoring is preferred for clean folds on thinner papers.

Q 25. Explain the importance of proper paper handling in preventing machine jams and misfeeds.

Proper paper handling is absolutely critical in avoiding jams and misfeeds. Think of it like this: the folder is a very precise machine; even a slight irregularity in the paper can lead to problems. Several factors are crucial:

- Paper Quality: Consistent paper weight, moisture content, and surface finish are essential. Variations can cause misalignment, jams, or wrinkling.

- Paper Stacking: The paper should be neatly stacked, free from wrinkles or debris. A skewed stack can cause feeding issues right from the start.

- Paper Feed: The paper feed tray must be clean and properly adjusted. Insufficient paper or incorrect alignment can lead to jams.

- Paper Condition: Avoiding overly humid or dry environments is crucial, as it directly affects the paper’s moisture content and its ability to smoothly pass through the machine.

Regular cleaning of the feed trays, proper paper storage, and diligent attention to paper quality ensures smooth and efficient operation, avoiding costly downtime.

Q 26. What is your experience with performing quality checks during and after the folding process?

Quality checks are an integral part of my workflow. During the folding process, I regularly monitor the machine for signs of misalignment or other issues. This involves visually inspecting the folded sheets for accuracy and consistency. After the folding process, a more thorough inspection is carried out, usually involving a random sample check of a specific percentage of the finished product. We use standardized checklists to ensure that all relevant aspects, including fold accuracy, registration, and overall quality, are assessed. Any discrepancies or defects are documented and reported, allowing for immediate corrective actions. We often use magnification tools to detect subtle misalignments. This rigorous quality control ensures that only high-quality products are delivered to the client.

Q 27. How do you stay updated on new technologies and advancements in folder machine operation?

Staying updated is crucial in this industry. I actively participate in industry trade shows and workshops to learn about the latest advancements in folder machine technology. I subscribe to relevant industry publications and online forums, keeping abreast of new innovations and best practices. Furthermore, I engage in online training courses offered by manufacturers to enhance my knowledge of specific machines and their functionalities. Manufacturers often provide detailed maintenance manuals and software updates which I make sure to utilize. This continuous learning approach ensures that I maintain my expertise and adapt to the ever-evolving technological landscape.

Q 28. Describe your experience working as part of a team in a fast-paced production environment.

In our fast-paced production environment, teamwork is key. I’ve consistently worked collaboratively with press operators, quality control personnel, and other team members. Effective communication is paramount. We often face tight deadlines, and clear, concise communication ensures everyone understands their roles and responsibilities. I’m adept at problem-solving collaboratively, drawing on the expertise of others to find efficient and effective solutions. During peak production periods, we often re-allocate tasks to ensure efficiency, and this requires excellent teamwork and adaptability. For instance, on one occasion, we were faced with a major backlog. By communicating efficiently and proactively assisting the press operators, we managed to meet our deadline without compromising quality.

Key Topics to Learn for Knowledge of Folder Machine Operation Interview

- Machine Setup and Configuration: Understanding the various components of a folder machine, their functions, and how to properly set them up for different jobs. This includes paper size adjustments, feeder settings, and folding patterns.

- Folding Techniques and Patterns: Mastering different folding techniques (e.g., half-fold, letter fold, parallel fold) and understanding how to program the machine to achieve specific folding patterns. Practical experience in troubleshooting common folding issues is crucial.

- Safety Procedures and Maintenance: Demonstrating a thorough understanding of safety protocols related to operating and maintaining folder machines is vital. This includes lockout/tagout procedures, routine maintenance tasks, and identifying potential hazards.

- Troubleshooting and Problem Solving: Interviewers will likely assess your ability to diagnose and resolve common machine malfunctions. Prepare to discuss your experience identifying the source of jams, misfeeds, or incorrect folds and the steps taken to correct them.

- Quality Control and Efficiency: Explain your understanding of quality control measures implemented during folder machine operation to ensure consistent output and minimal waste. Highlight your experience in optimizing machine settings for increased efficiency and productivity.

- Material Handling and Workflow: Discuss your knowledge of proper material handling techniques, including the safe loading and unloading of paper stacks, to maintain a smooth and efficient workflow.

Next Steps

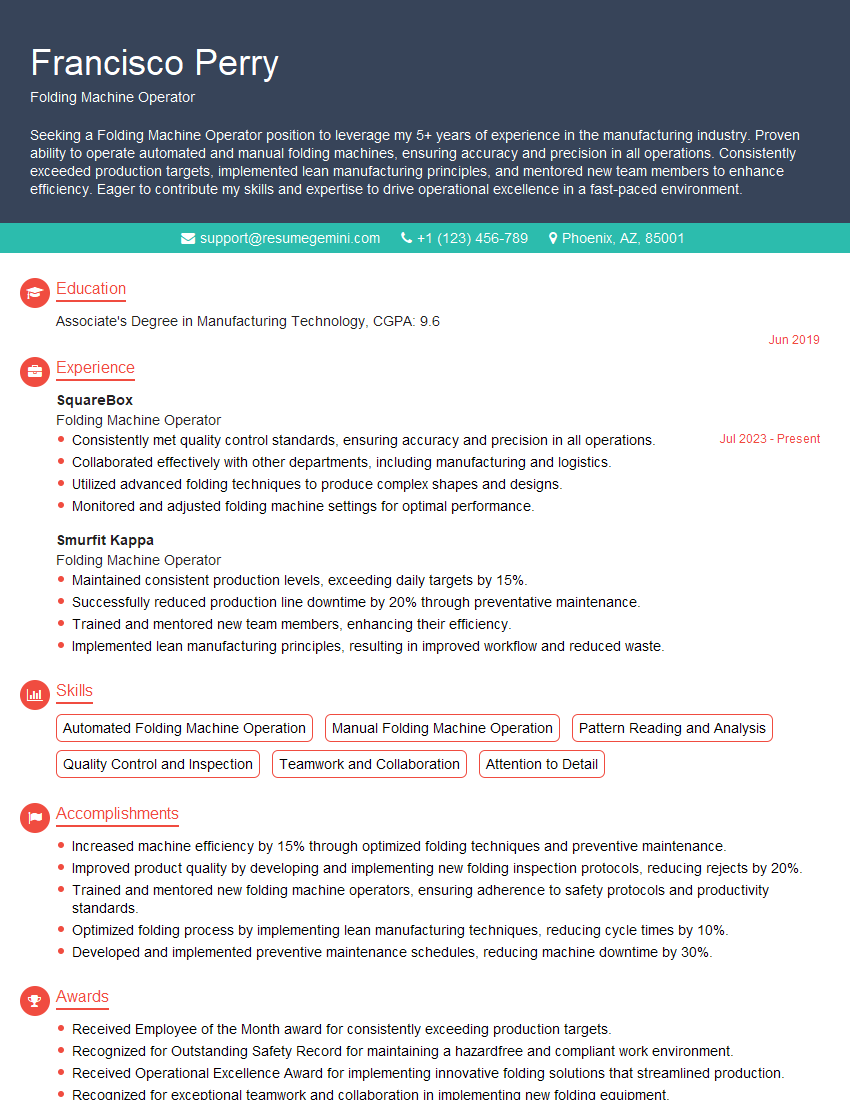

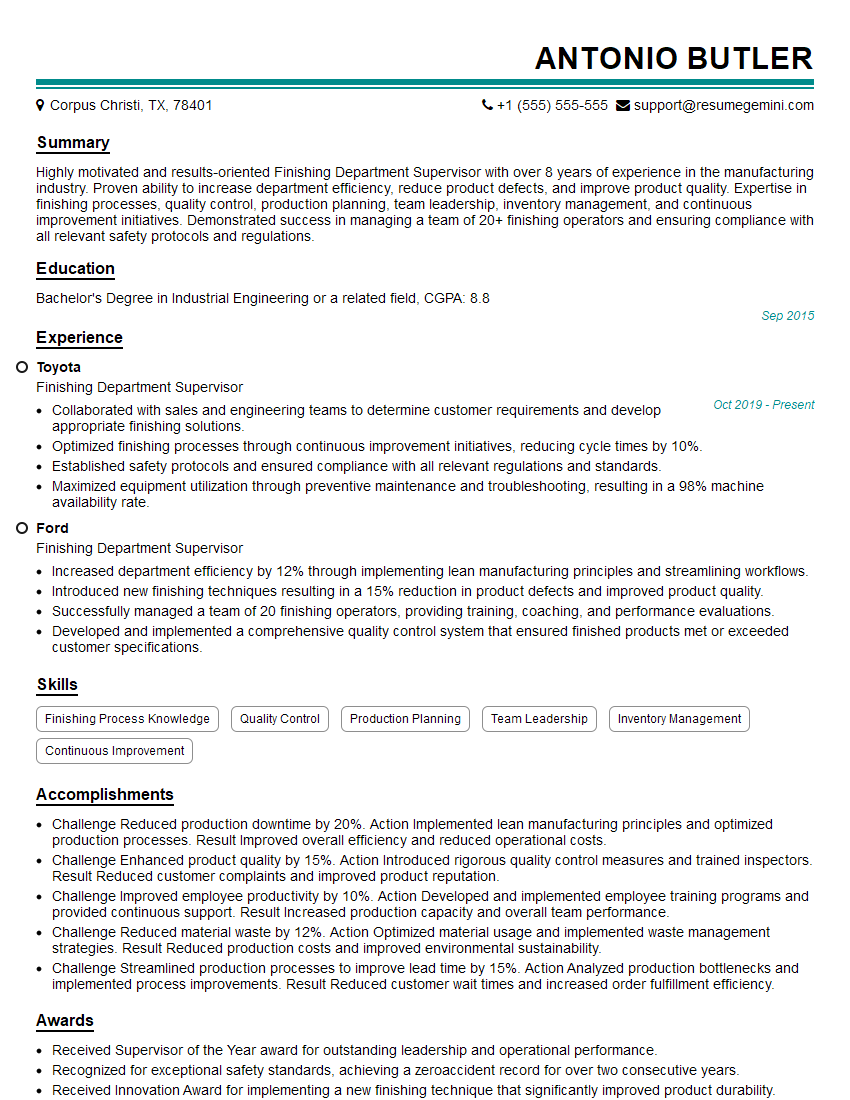

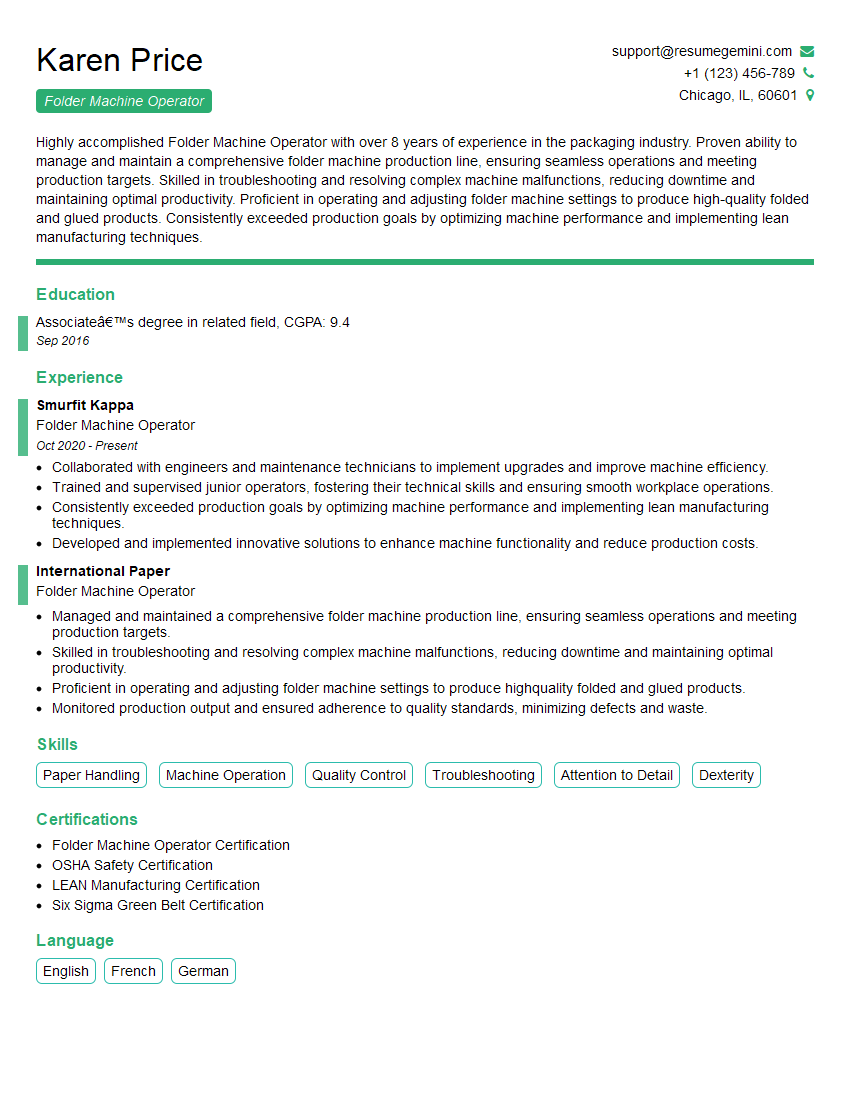

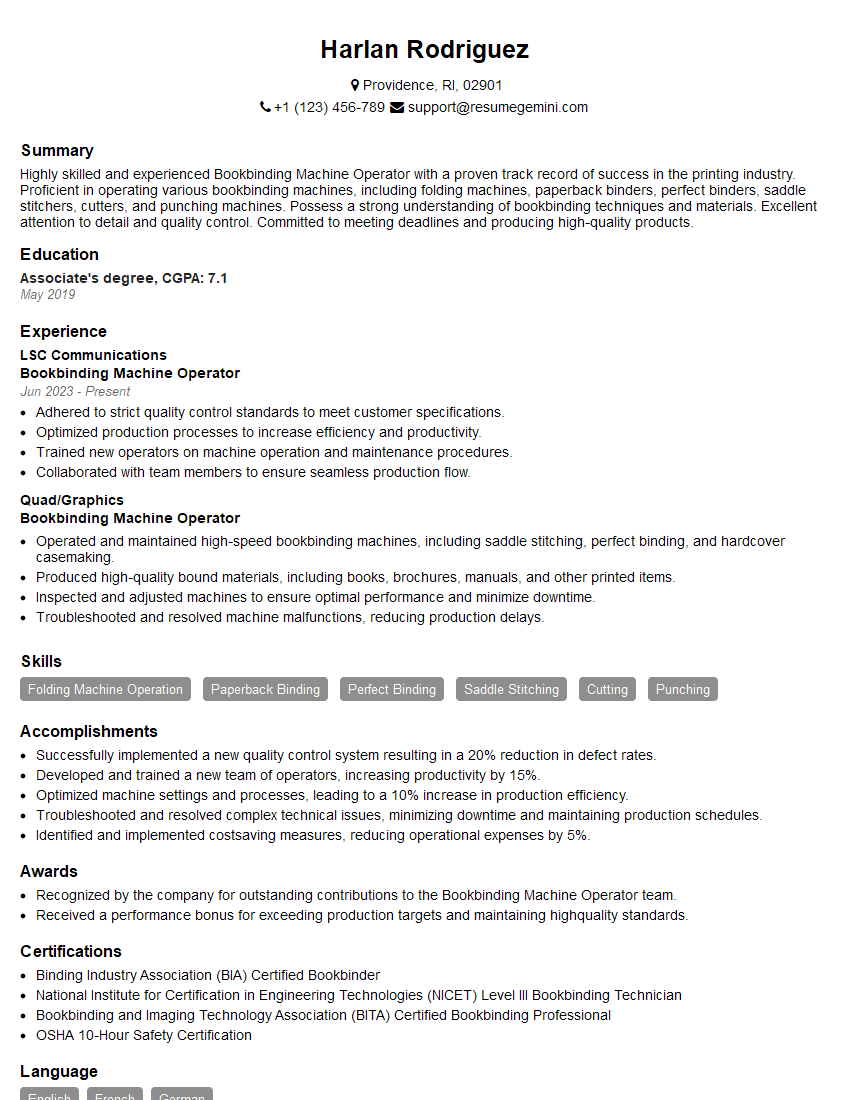

Mastering folder machine operation opens doors to rewarding careers in print production, packaging, and related industries. A strong understanding of these machines demonstrates valuable technical skills and problem-solving abilities, making you a highly competitive candidate. To further enhance your job prospects, creating an ATS-friendly resume is key. ResumeGemini is a trusted resource that can help you craft a professional and effective resume, highlighting your skills and experience. We provide examples of resumes tailored to Knowledge of Folder Machine Operation to guide you through the process. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO