Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Knowledge of ISO 9001 Standards interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Knowledge of ISO 9001 Standards Interview

Q 1. Explain the core principles of ISO 9001.

ISO 9001 is built upon several core principles that guide organizations in establishing and maintaining an effective Quality Management System (QMS). These principles aren’t merely suggestions; they are fundamental to achieving consistent results and continuous improvement. Think of them as the pillars supporting a robust QMS structure.

- Customer Focus: Understanding and meeting customer needs and expectations is paramount. This involves actively soliciting feedback and ensuring products and services consistently meet or exceed requirements.

- Leadership: Leaders at all levels must demonstrate commitment to the QMS and actively promote a culture of quality. This includes setting clear objectives, providing resources, and fostering a positive work environment.

- Engagement of People: Empowering employees at all levels is crucial. A QMS thrives when individuals feel valued, involved, and responsible for quality. Training and development play a vital role here.

- Process Approach: Defining, managing, and improving processes is essential. A systematic approach ensures efficiency, consistency, and predictability in delivering products and services.

- Improvement: Continuous improvement is the lifeblood of a QMS. Regularly reviewing performance, identifying areas for improvement, and implementing corrective actions are critical for long-term success.

- Evidence-based Decision Making: Decisions must be based on data and analysis, not assumptions. This requires meticulous record-keeping and regular monitoring of key performance indicators (KPIs).

- Relationship Management: Building strong relationships with suppliers and other stakeholders is important for ensuring consistent quality throughout the supply chain. Transparency and collaboration are key.

For example, a manufacturing company might use customer feedback surveys to understand customer needs (customer focus), empower its production team to make quality-related decisions (engagement of people), and track defect rates to identify areas needing improvement (evidence-based decision-making).

Q 2. Describe the PDCA cycle and its application in a QMS.

The PDCA cycle, or Plan-Do-Check-Act cycle, is a powerful iterative framework for continuous improvement. It’s a cornerstone of any robust QMS. Imagine it as a continuous loop of refinement.

- Plan: This stage involves defining objectives, establishing processes, and identifying resources needed to achieve those objectives. For example, if a company wants to reduce production defects, this stage might involve analyzing the root causes of defects and developing a corrective action plan.

- Do: This is the implementation phase. The planned actions are executed, and data is collected to monitor progress. In our example, this might involve implementing the corrective actions, like improved training or new equipment.

- Check: This stage involves analyzing the results of the implemented actions. Data is evaluated to determine whether the objectives were met. The company might analyze the defect rate after implementing the corrective actions.

- Act: Based on the analysis, decisions are made to either standardize successful improvements or revise the plan if necessary. If the defect rate decreased significantly, the process improvement might be standardized. If not, the plan needs revision.

The PDCA cycle isn’t a one-time event but an ongoing process applied to various aspects of the QMS, from process improvement to management review.

Q 3. What is a Quality Management System (QMS)?

A Quality Management System (QMS) is a structured set of processes, procedures, and practices designed to ensure an organization consistently meets customer requirements and enhances customer satisfaction. It’s more than just a document; it’s a living, breathing system that guides the organization’s actions related to quality.

Think of it as a comprehensive roadmap for achieving quality. It encompasses everything from setting quality objectives and defining responsibilities to implementing processes, monitoring performance, and making improvements. A well-designed QMS is crucial for building trust with customers, meeting regulatory requirements, and improving efficiency and profitability.

A QMS typically includes documented procedures, work instructions, forms, records, and training materials. It’s not a static document but a dynamic system that adapts to the organization’s changing needs and the evolving expectations of customers.

Q 4. How does a QMS contribute to organizational success?

A well-implemented QMS significantly contributes to an organization’s success in several ways. It’s a catalyst for sustainable growth.

- Enhanced Customer Satisfaction: By consistently meeting and exceeding customer expectations, a QMS builds customer loyalty and increases customer retention.

- Improved Efficiency and Productivity: Streamlined processes and reduced waste lead to increased efficiency and productivity, resulting in cost savings and higher profitability.

- Reduced Risks and Costs: Proactive identification and mitigation of risks minimize potential problems, reducing costs associated with rework, recalls, and complaints.

- Increased Market Competitiveness: ISO 9001 certification, a testament to a robust QMS, can provide a significant competitive advantage, enhancing the organization’s reputation and credibility.

- Improved Employee Morale: When employees are empowered and involved in the QMS, their morale and job satisfaction typically increase, leading to improved performance and reduced staff turnover.

- Compliance and Regulatory Adherence: A well-defined QMS ensures compliance with relevant regulations, standards, and legal requirements, minimizing the risk of penalties and legal issues.

For instance, a company with a strong QMS might achieve significant cost reductions by eliminating defects early in the production process and reducing the need for rework. This translates directly into increased profitability and a stronger market position.

Q 5. What are the key elements of an effective internal audit program?

An effective internal audit program is essential for evaluating the effectiveness of the QMS. It’s a critical mechanism for identifying areas for improvement and ensuring ongoing compliance. Think of it as a regular health check for your QMS.

- Scope and Planning: Clearly define the scope of the audit, including the areas to be audited, the objectives, and the criteria against which performance will be evaluated. A well-defined plan ensures efficiency and focus.

- Auditor Competence: Auditors must possess the necessary knowledge, skills, and experience to conduct effective audits. Training and certification are crucial to ensure objectivity and competence.

- Audit Methodology: A systematic approach to conducting audits, including using checklists, documenting findings, and conducting interviews, is essential for consistency and thoroughness.

- Objective Evidence: Auditors must gather sufficient and reliable objective evidence to support their findings. This could include reviewing documents, observing processes, and interviewing personnel.

- Reporting and Follow-up: Audit findings should be documented clearly and concisely, identifying non-conformances and potential areas for improvement. Follow-up is critical to ensure that corrective actions are implemented and verified.

- Management Review: Audit results should be presented to management for review and decision-making regarding corrective actions and continuous improvement initiatives.

For example, an effective internal audit might uncover a weakness in a specific process, leading to the implementation of a new procedure and improved training to address the issue.

Q 6. Explain the concept of corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) are crucial components of a robust QMS, focused on addressing issues and preventing their recurrence. They are essential for continuous improvement.

- Corrective Action: Addresses existing non-conformances or defects. It’s a reactive approach focused on fixing a problem that has already occurred. For example, if a product is found to be defective, corrective action might involve repairing or replacing the product and investigating the root cause of the defect.

- Preventive Action: Focuses on preventing potential non-conformances or defects from occurring in the future. It’s a proactive approach aimed at preventing problems before they happen. For example, after identifying a recurring defect, preventive action might involve improving training, updating equipment, or revising a process to eliminate the root cause of the defect.

The key difference is that corrective action addresses a problem *after* it has occurred, while preventive action aims to stop the problem *before* it happens. Effective CAPA processes are crucial for minimizing the impact of non-conformances and continuously improving the QMS. They are often documented and tracked within the QMS.

Q 7. Describe your experience with conducting internal audits.

Throughout my career, I’ve been extensively involved in conducting internal audits within various organizational settings. My experience encompasses diverse industries, from manufacturing to healthcare. I’ve led and participated in numerous audits, focusing on various aspects of the QMS.

My approach involves a thorough understanding of the audit scope and objectives, followed by careful planning and preparation. I utilize a combination of techniques, including document review, process observation, and interviews with personnel at all levels. I meticulously document my findings and ensure that sufficient objective evidence supports my observations. I am skilled at identifying root causes of non-conformances and assisting in developing effective corrective and preventive actions.

I’ve consistently focused on objectivity and professionalism in my audit conduct, ensuring fairness and impartiality. My reports are clear, concise, and actionable, providing management with the information needed to drive continuous improvement. I value building strong working relationships with auditees, fostering open communication and promoting a culture of continuous improvement.

For instance, during an audit of a pharmaceutical manufacturing facility, I identified a weakness in their change management process, which could potentially lead to product contamination. My findings resulted in the implementation of a new, more robust change management procedure, preventing potential risks and improving product safety.

Q 8. How do you ensure the effectiveness of a QMS?

Ensuring the effectiveness of a Quality Management System (QMS) is a continuous process, not a one-time event. It requires a proactive approach focused on continual improvement and demonstrating that the system consistently delivers intended results. This involves several key aspects:

- Regular Internal Audits: These audits provide an objective evaluation of the QMS’s conformity to the ISO 9001 standard and its effectiveness in meeting organizational objectives. They identify gaps and areas for improvement.

- Management Review: A periodic management review is critical to assess the QMS’s performance, suitability, adequacy, and effectiveness. This involves reviewing key performance indicators (KPIs) and making necessary adjustments.

- Corrective and Preventive Actions (CAPA): A robust CAPA process ensures that nonconformities are addressed promptly, and preventive actions are implemented to stop similar problems from recurring. This process should include root cause analysis to address the underlying issue.

- Monitoring and Measurement: Regularly monitoring and measuring processes and outputs against defined metrics allows you to track performance, identify trends, and make data-driven decisions for improvement. This could involve tracking customer satisfaction, defect rates, or lead times.

- Continual Improvement: ISO 9001 emphasizes continual improvement. The QMS should be regularly reviewed and updated to reflect changes in the business environment, customer needs, and technological advancements. This can involve implementing new methodologies or adopting better practices.

For example, in a manufacturing setting, regularly monitoring defect rates and implementing corrective actions when defects exceed a certain threshold ensures product quality and customer satisfaction, thus demonstrating QMS effectiveness.

Q 9. What is the role of management in maintaining a QMS?

Management plays a crucial role in maintaining a QMS. Their commitment and involvement are essential for its success. Their responsibilities include:

- Leadership and Commitment: Management must demonstrate clear leadership and commitment to the QMS by allocating necessary resources, establishing objectives, and promoting a culture of quality throughout the organization. This sets the tone and prioritizes quality at all levels.

- Resource Provision: Management is responsible for providing the necessary resources – financial, human, and technological – to effectively implement and maintain the QMS. This includes investing in training, equipment, and software.

- Establishing Quality Objectives: Management defines and communicates quality objectives that align with the overall business strategy. These objectives should be measurable, achievable, and relevant to the organization’s context.

- Overseeing the QMS: Management regularly reviews the QMS’s performance through management reviews, internal audits, and analysis of KPIs. They ensure the system remains effective and suitable for the organization’s purpose.

- Promoting a Quality Culture: Management fosters a culture of continuous improvement and quality awareness across the entire organization. This includes empowering employees to identify and address quality issues.

Imagine a scenario where upper management doesn’t actively participate in QMS activities. This could lead to insufficient resources, lack of clear direction, and a lack of commitment from employees, ultimately undermining the system’s effectiveness.

Q 10. Explain the importance of documented information in ISO 9001.

Documented information is the cornerstone of a robust ISO 9001 compliant QMS. It serves as evidence that processes are being performed as planned, providing traceability and enabling continuous improvement. This includes:

- Process Descriptions: Documented procedures and work instructions detail how activities are conducted, ensuring consistency and repeatability. This helps standardize work and reduce errors.

- Records: Records document the execution of processes, providing evidence of compliance and performance. This could include inspection reports, calibration certificates, and training records.

- Quality Manual: The quality manual provides an overview of the QMS, including its policies, procedures, and responsibilities. It serves as a central repository of information.

- Forms and Templates: Standardized forms and templates streamline data collection and ensure consistency in data recording.

- Control of Documented Information: A system must be in place to control the creation, review, approval, distribution, access, update, retrieval, and storage of documented information. This is crucial to ensure accuracy and prevent outdated information from being used.

For example, a documented procedure for handling customer complaints ensures consistent and professional handling of all complaints, regardless of who is handling them. Without documented information, inconsistencies and failures in processes are harder to identify and rectify.

Q 11. How do you handle nonconformities within a QMS?

Handling nonconformities effectively is crucial for maintaining a robust QMS. A well-defined process should be in place, including:

- Identification and Reporting: Establishing clear procedures for identifying and reporting nonconformities at all levels of the organization. Employees should be empowered to report issues without fear of retribution.

- Investigation and Analysis: Thoroughly investigate each nonconformity to determine its root cause. This may involve interviewing involved personnel, reviewing data, and conducting testing.

- Corrective Action: Implement corrective actions to address the immediate nonconformity and prevent recurrence. This could involve repairs, replacements, or retraining.

- Preventive Action: Implement preventive actions to address the root cause and prevent similar nonconformities from happening in the future. This might involve process improvements or changes to procedures.

- Verification: Verify the effectiveness of the corrective and preventive actions. This might involve monitoring the relevant KPIs to ensure the implemented actions have solved the problem.

Imagine a scenario where a manufacturing company finds defects in its product. A robust nonconformity process would ensure that the defects are investigated, the root cause is identified (e.g., faulty equipment, insufficient training), corrective actions are implemented (e.g., repairing the equipment, retraining staff), and preventative measures are put in place to avoid similar defects in the future.

Q 12. Describe your experience with root cause analysis.

Root cause analysis (RCA) is a crucial tool for identifying the underlying causes of nonconformities and implementing effective corrective and preventive actions. My experience involves utilizing several techniques including:

- 5 Whys: This simple yet effective technique involves repeatedly asking “Why?” to uncover the root cause. This helps to drill down through layers of symptoms to identify the underlying issue.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps to brainstorm potential causes of a problem, categorized by categories like materials, methods, manpower, machinery, measurement, and environment. It helps visualize relationships between potential causes.

- Fault Tree Analysis (FTA): A top-down, deductive reasoning approach to systematically identify potential causes leading to a specific failure.

- Pareto Analysis: Focuses on identifying the most significant factors contributing to a problem. It helps prioritize efforts on the most impactful causes.

In a previous role, we used 5 Whys to analyze a recurring customer complaint about late deliveries. By repeatedly asking ‘why’ (Why were the deliveries late? Why was the production process delayed? Why was there a shortage of materials?), we identified a problem with our supplier’s delivery schedule as the root cause. This allowed us to address the issue directly with the supplier and prevent further delays.

Q 13. How do you measure the effectiveness of a QMS?

Measuring the effectiveness of a QMS involves regularly monitoring and evaluating various metrics to assess its performance against objectives. Key indicators include:

- Customer Satisfaction: Measuring customer satisfaction through surveys, feedback forms, and reviews provides valuable insights into the quality of products or services.

- Defect Rates: Tracking the number of defects in products or processes reveals areas for improvement and indicates the effectiveness of quality control measures.

- Internal Audit Findings: The number and severity of nonconformities identified during internal audits highlight the effectiveness of the QMS in preventing and detecting problems.

- Corrective and Preventive Actions (CAPA) Effectiveness: Measuring the effectiveness of CAPA actions in reducing the recurrence of nonconformities.

- Process Performance Metrics: Monitoring key process parameters such as cycle time, throughput, and efficiency provides insights into process performance and areas for optimization.

- Compliance Rates: Monitoring compliance with relevant standards, regulations, and legal requirements.

Using a balanced scorecard approach helps to track a range of metrics encompassing financial, customer, internal process, and learning & growth perspectives. Data visualization tools are essential to effectively communicate the QMS’s performance and highlight areas needing improvement.

Q 14. What are the key differences between ISO 9001:2008 and ISO 9001:2015?

ISO 9001:2015 represents a significant shift from the 2008 version, moving towards a more risk-based approach and emphasizing the importance of context and leadership. Here are some key differences:

- Risk-Based Thinking: ISO 9001:2015 integrates risk-based thinking throughout the QMS, requiring organizations to identify and address potential risks and opportunities. The 2008 version focused more on reactive problem-solving.

- Process Approach: While both versions emphasized a process approach, the 2015 version is more focused on managing interdependencies and interactions between processes.

- Leadership Commitment: The 2015 version strongly emphasizes the role of top management in demonstrating leadership and commitment to the QMS. This is less explicitly defined in the 2008 version.

- Customer Focus: Both versions emphasize customer focus, but the 2015 version places greater emphasis on understanding and meeting evolving customer needs and expectations.

- Documented Information (instead of Documentation): The term ‘documented information’ replaced ‘documentation,’ emphasizing that the focus is on the information itself, rather than the format. The 2015 version offers more flexibility in how information is managed.

- Continual Improvement: While both versions promoted continual improvement, the 2015 version integrates this concept more holistically throughout the QMS, with a greater emphasis on data-driven decision-making.

In essence, ISO 9001:2015 shifts from a primarily compliance-focused approach to a more proactive, risk-aware, and results-oriented system. It is more flexible, allowing organizations to tailor their QMS to their specific context and needs.

Q 15. Explain the concept of risk-based thinking in ISO 9001.

Risk-based thinking in ISO 9001 is a proactive approach to identifying, analyzing, and managing risks and opportunities that can affect the Quality Management System (QMS) and its ability to consistently meet customer requirements and enhance customer satisfaction. It’s about moving beyond simply reacting to problems and instead anticipating and addressing potential issues before they arise.

Imagine building a house. A reactive approach would be to wait for the roof to leak before fixing it. Risk-based thinking would involve assessing the risk of leaks – considering factors like weather, material quality, and construction techniques – and taking preventative measures, such as using high-quality materials and implementing proper waterproofing, before construction even begins.

In a QMS context, this involves systematically identifying potential risks (e.g., supplier failure, outdated technology, employee turnover) and opportunities (e.g., new technology, market expansion, improved training programs). Then, you analyze the likelihood and impact of each risk, and determine appropriate controls to mitigate the risks and capitalize on opportunities. This is documented and regularly reviewed.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with implementing a QMS.

I’ve been involved in the implementation of several QMSs across diverse industries, including manufacturing and software development. In one project for a manufacturing company, we implemented a QMS based on ISO 9001. This involved a thorough gap analysis against the ISO 9001 standard, defining processes, documenting procedures, developing control plans, and establishing internal audits. We trained employees on the new QMS, implemented a document control system, and monitored key performance indicators (KPIs) to measure effectiveness. A crucial element was securing buy-in from all levels of the organization, making it a collaborative process rather than a top-down mandate. The result was a more efficient and streamlined operation with demonstrably improved product quality and customer satisfaction.

Another project involved implementing a QMS for a software company focusing on process improvement and risk management. We used agile methodologies in combination with the structure provided by ISO 9001. This allowed us to adapt quickly to changing requirements, manage sprints effectively, and measure software quality through consistent testing and code review processes. The combination proved highly successful in delivering high-quality software products.

Q 17. How do you ensure compliance with ISO 9001 requirements?

Ensuring compliance with ISO 9001 requires a multi-faceted approach. It begins with a thorough understanding of the standard itself and the specific requirements applicable to the organization. This understanding forms the basis for developing and implementing a robust QMS. Key elements include:

- Process mapping and documentation: Clearly defining all key processes and documenting them in a way that is accessible and understandable to all employees.

- Internal audits: Conducting regular internal audits to identify gaps and non-conformances and ensure compliance. This is a crucial step in identifying weaknesses before an external audit.

- Corrective and preventive actions (CAPAs): Establishing a system for investigating non-conformances, implementing corrective actions to address immediate issues, and preventive actions to stop similar problems from recurring. This requires a systematic approach to root cause analysis.

- Management review: Regularly reviewing the effectiveness of the QMS, identifying areas for improvement, and ensuring that the system remains aligned with the organization’s strategic goals and customer expectations. This high-level review is vital for sustained compliance.

- Record keeping: Maintaining meticulous records of all aspects of the QMS, including processes, audits, and CAPAs. This is essential for demonstrating compliance during audits and for continuous improvement efforts.

By diligently addressing these areas, an organization can effectively maintain ISO 9001 compliance and build a culture of quality.

Q 18. What is your experience with ISO 9001 certification audits?

I have extensive experience with ISO 9001 certification audits, having participated in numerous audits both as an internal auditor and as a member of management teams undergoing external audits. This includes preparing for audits, managing audit findings, implementing corrective actions, and participating in closing meetings. I understand the importance of clear documentation, trace-ability, and evidence of process adherence.

During audits, I’ve observed firsthand the challenges organizations face, such as inadequate record-keeping, incomplete process documentation, and a lack of awareness regarding the ISO 9001 requirements. I also have experience in preparing for and successfully navigating major non-conformances. Successful audits are a testament to the effectiveness of a robust QMS and a culture of quality. Understanding the auditor’s perspective is as important as understanding the standard itself.

Q 19. How do you manage changes within a QMS?

Managing changes within a QMS is crucial for maintaining its effectiveness and compliance with ISO 9001. A well-defined change management process is essential. This typically involves:

- Identifying the need for change: This could stem from various factors – new regulations, process improvements, or customer feedback.

- Assessing the impact of the change: Evaluating the potential effects of the change on other processes and the overall QMS.

- Planning the change: Developing a detailed plan outlining the steps needed to implement the change, including timelines, responsibilities, and resources.

- Implementing the change: Carrying out the planned changes while ensuring proper communication and training for affected personnel.

- Verifying the change: Confirming that the implemented change has achieved the desired results and has not created unintended negative consequences.

- Documenting the change: Updating all relevant documentation to reflect the changes made to the QMS.

This structured approach ensures that changes are implemented smoothly and efficiently, minimizing disruption and maintaining the integrity of the QMS.

Q 20. What is your experience with continuous improvement methodologies?

My experience with continuous improvement methodologies is extensive. I’ve successfully applied various approaches, including Plan-Do-Check-Act (PDCA), Six Sigma, and Lean methodologies, to optimize processes within QMS frameworks. The PDCA cycle is particularly relevant to ISO 9001. It provides a systematic approach to identifying areas for improvement, implementing changes, monitoring results, and taking corrective actions.

For instance, in one project, we utilized Lean principles to identify and eliminate waste in a manufacturing process. By mapping the value stream and eliminating unnecessary steps, we significantly reduced lead times and improved overall efficiency. Data analysis is crucial in these methodologies; tracking key performance indicators (KPIs) helps to monitor progress and identify areas needing further improvement. Continuous improvement is not a one-time project; it’s an ongoing process of refinement and optimization.

Q 21. How do you ensure customer satisfaction within a QMS?

Ensuring customer satisfaction within a QMS is paramount and directly tied to the effectiveness of the system. This requires a customer-centric approach throughout the entire process. It starts with understanding customer needs and expectations, which can be done through surveys, feedback forms, and direct communication.

Key aspects include:

- Proactive communication: Keeping customers informed about the status of their orders, any potential delays, and any other relevant information.

- Effective complaint handling: Establishing a robust system for handling customer complaints, investigating the root causes, and implementing corrective actions to prevent similar issues from happening again. Customer feedback should be viewed as an opportunity for improvement.

- Product/service quality: Focusing on delivering high-quality products or services that meet or exceed customer expectations.

- Meeting deadlines: Consistently meeting or exceeding deadlines to demonstrate reliability and build trust.

- Customer relationship management: Building strong, lasting relationships with customers through consistent and personalized communication.

By prioritizing customer satisfaction, organizations can build loyalty, enhance their reputation, and drive business success. It’s vital to remember that customer satisfaction is not just a goal; it’s a key indicator of the overall effectiveness of the QMS.

Q 22. Explain your understanding of process mapping and its relevance to ISO 9001.

Process mapping is a visual representation of a process, showing the steps involved, the flow of materials or information, and the individuals or departments responsible. In the context of ISO 9001, it’s crucial for understanding, analyzing, and improving processes to meet quality management system (QMS) requirements. Think of it as a roadmap for your processes.

For example, a process map for “Order Fulfillment” might show steps like receiving an order, verifying availability, picking the items, packing, shipping, and updating the customer. Each step could be further broken down into sub-processes. ISO 9001 emphasizes understanding and controlling processes, and process mapping provides a powerful tool for this.

Relevance to ISO 9001: ISO 9001 requires organizations to identify, understand, and manage their processes. Process maps facilitate this by:

- Identifying bottlenecks and areas for improvement.

- Facilitating communication and understanding across departments.

- Providing a basis for process documentation and control.

- Supporting continuous improvement initiatives.

By using process mapping, organizations can ensure they meet the requirements of clause 4.4, which demands the effective planning and control of the processes necessary for the QMS.

Q 23. Describe your experience with document control in a QMS.

My experience with document control in a QMS encompasses the entire lifecycle, from creation and approval to revision, distribution, and eventual archiving. I’ve implemented and maintained document control systems using both paper-based and electronic methods. This included developing and implementing procedures for:

- Document creation and review: Establishing clear templates, ensuring consistency, and conducting thorough reviews to guarantee accuracy and completeness before approval.

- Approval and authorization: Defining clear roles and responsibilities for document approval and ensuring traceability of approvals.

- Distribution and dissemination: Implementing systems for efficient and controlled distribution of documents to relevant personnel, both internally and externally, ensuring everyone has access to the most current versions. This often involved using a document management system (DMS).

- Revision control: Establishing version numbering, change logs, and processes for managing revisions to ensure only the latest version is used. Clear indication of obsolete documents was crucial.

- Archiving and retrieval: Implementing a system for secure and retrievable storage of both active and obsolete documents to satisfy audit trails and legal requirements.

In one instance, I helped a company transition from a paper-based system to an electronic DMS, which significantly improved efficiency and reduced the risk of using outdated documents.

Q 24. How do you maintain records and ensure traceability within a QMS?

Maintaining records and ensuring traceability in a QMS is vital for demonstrating compliance with ISO 9001 and for continuous improvement. This involves establishing a system that:

- Clearly identifies all records: Each record is uniquely identified, allowing for easy retrieval and referencing. This can be through a numbering system, or a DMS-assigned ID.

- Defines record retention policies: Specifies how long each type of record must be kept, considering legal, regulatory, and audit requirements.

- Ensures secure storage: Records are stored securely, preventing unauthorized access, modification, or loss. This can involve physical storage, electronic backups, and version control in a DMS.

- Facilitates easy retrieval: A system is in place to quickly locate and retrieve any record when needed, often through keyword searches or metadata within a DMS.

- Maintains audit trails: Records are linked to specific processes, showing who created, modified, or accessed them, providing a clear history and demonstrating accountability.

For example, a calibration record would link to the equipment it pertains to, the person who performed the calibration, and the date. This traceability allows us to confirm the accuracy and validity of measurements made with that equipment.

Q 25. Explain your understanding of the scope of a QMS.

The scope of a QMS defines the boundaries within which the organization operates its quality management system. It specifies the products, services, processes, and locations covered by the QMS. It’s essentially a statement of what the QMS manages. This needs to be clearly defined and documented.

For instance, a company manufacturing two product lines – say, widgets and gadgets – might define one scope for widgets production, and a separate scope for gadgets, even if both are in the same factory. Alternatively, a company could choose to have a single scope encompassing both, but the definition would still need to be exact.

Defining the scope correctly is crucial because:

- It prevents scope creep and ensures focus.

- It provides clarity for internal and external stakeholders.

- It determines the extent of the audit and certification process.

- It ensures that the implemented system is appropriate and effective for the chosen activities.

Failing to properly define the scope can lead to confusion, inefficiencies, and non-conformances during audits.

Q 26. What are some common challenges encountered in implementing ISO 9001, and how have you overcome them?

Common challenges in implementing ISO 9001 include:

- Resistance to change: Employees may be resistant to adopting new processes and procedures.

- Lack of management commitment: Without strong top-down support, implementation efforts can stall.

- Inadequate training: Employees need thorough training to understand and apply the QMS effectively.

- Poor communication: Clear communication is essential to keep everyone informed and engaged throughout the implementation process.

- Insufficient resources: Implementing a QMS requires time, money, and personnel.

I’ve overcome these challenges by:

- Building a strong case for change: Demonstrating the benefits of ISO 9001 certification to all stakeholders.

- Securing management commitment: Obtaining buy-in from leadership through clear communication and demonstration of value.

- Providing comprehensive training: Designing and delivering effective training programs that cater to different learning styles.

- Utilizing effective communication strategies: Regularly communicating progress, challenges, and solutions to all involved parties.

- Allocating sufficient resources: Planning carefully and prioritizing tasks based on urgency and importance.

I’ve found that a phased approach, focusing on small, manageable steps, helps to build momentum and avoid overwhelming the organization.

Q 27. Describe a situation where you had to resolve a quality-related issue. What was your approach?

In a previous role, we experienced a significant increase in customer complaints regarding a specific product defect. My approach involved:

- Data collection and analysis: We systematically gathered all relevant data, including customer complaints, internal inspection reports, and production records. We analyzed the data to identify the root cause of the defect.

- Root cause analysis: We utilized tools like the 5 Whys and Fishbone diagrams to pinpoint the underlying causes. In this case, we found a problem with a supplier’s raw material.

- Corrective action: We immediately implemented corrective actions to address the root cause, including working with the supplier to improve their quality control processes and implementing stricter incoming inspection procedures.

- Preventative action: We developed and implemented preventative measures to prevent similar issues from recurring, such as more robust supplier selection and qualification processes and more frequent quality checks during production.

- Communication and follow-up: We communicated the findings and actions taken to management, the supplier, and affected customers. We also implemented a system to monitor the effectiveness of the corrective and preventative actions.

The result was a significant reduction in customer complaints and an improvement in product quality. The focus was not just on fixing the immediate problem but on preventing it from happening again.

Q 28. How do you stay up-to-date on changes and revisions to ISO 9001 standards?

Staying current with ISO 9001 revisions is essential for maintaining a robust and compliant QMS. I utilize several strategies:

- Subscription to ISO publications: I subscribe to updates and newsletters from ISO and other reputable quality management organizations.

- Participation in professional development activities: Attending seminars, conferences, and webinars focused on ISO 9001 keeps me updated on recent changes and interpretations.

- Networking with other quality professionals: Connecting with colleagues through industry groups and forums provides insights into practical applications and emerging trends.

- Review of industry journals and publications: Regularly reading articles and publications covering ISO 9001 helps me stay abreast of best practices and recent developments.

- Monitoring ISO’s official website: Checking the official ISO website for announcements, news, and updates on standard revisions.

This multi-faceted approach allows me to stay informed about significant changes and adapt our processes accordingly.

Key Topics to Learn for Your ISO 9001 Standards Interview

Ace your interview by focusing on these key areas of ISO 9001. Remember to think about how these concepts apply in real-world scenarios.

- Understanding the ISO 9001 Quality Management System (QMS): This includes the core principles, structure, and overall purpose of the standard. Be prepared to discuss the Plan-Do-Check-Act (PDCA) cycle and its application within a QMS.

- Context of the Organization: Demonstrate your understanding of how organizations determine the internal and external issues that affect their ability to deliver quality products or services. Discuss the importance of understanding stakeholder needs and expectations.

- Leadership and Commitment: Explain the role of leadership in establishing and maintaining a QMS. Be ready to discuss the importance of leadership commitment to quality and continuous improvement.

- Risk-Based Thinking: This is crucial. Show your ability to identify, analyze, and address risks and opportunities that can affect the QMS’s effectiveness. Prepare examples of risk assessment and mitigation strategies.

- Resource Management: Explain how resources (human, infrastructure, etc.) are managed to ensure the effectiveness of the QMS. Discuss competency assessment and training programs.

- Product and Service Realization: Understand the processes involved in designing, developing, producing, delivering, and servicing products and services. Be ready to discuss different stages and their quality controls.

- Performance Evaluation: Explain how organizations monitor, measure, analyze, and evaluate the effectiveness of their QMS. Discuss the importance of key performance indicators (KPIs) and data analysis.

- Improvement: Showcase your knowledge of the continuous improvement processes within ISO 9001, such as corrective actions, preventive actions, and management review.

Next Steps: Unlock Your Career Potential

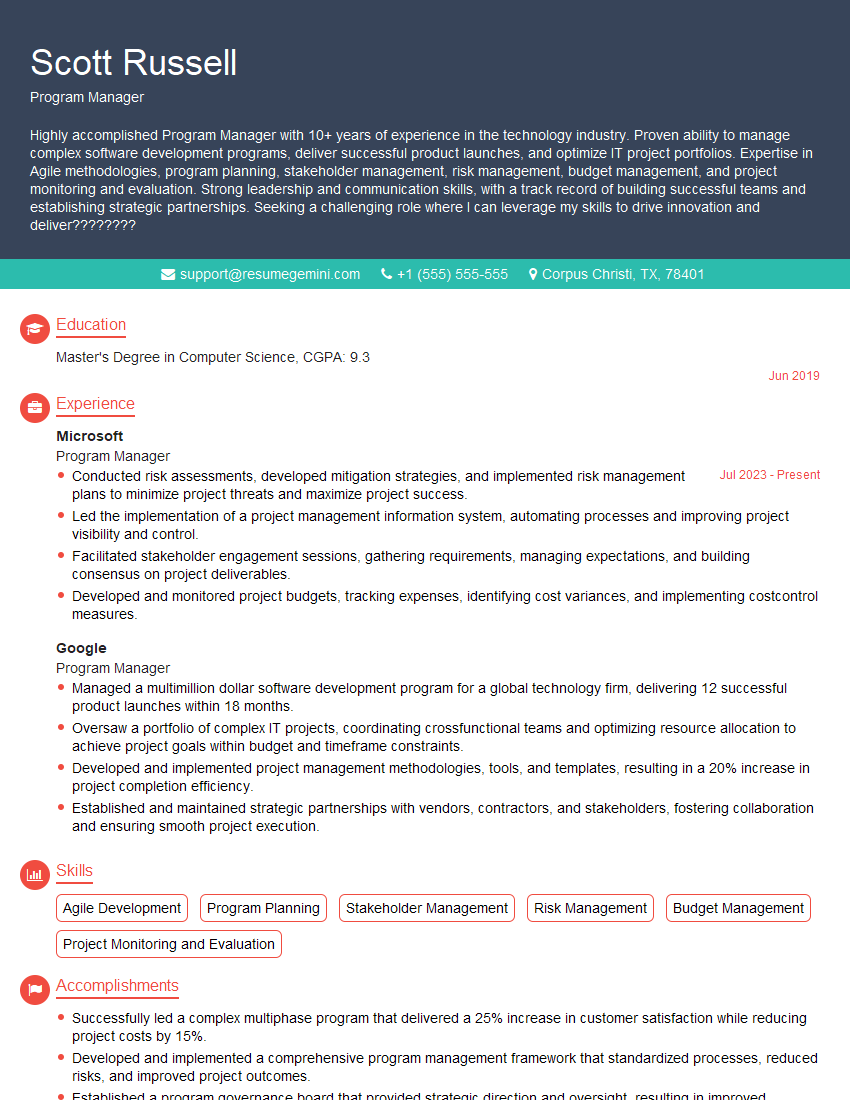

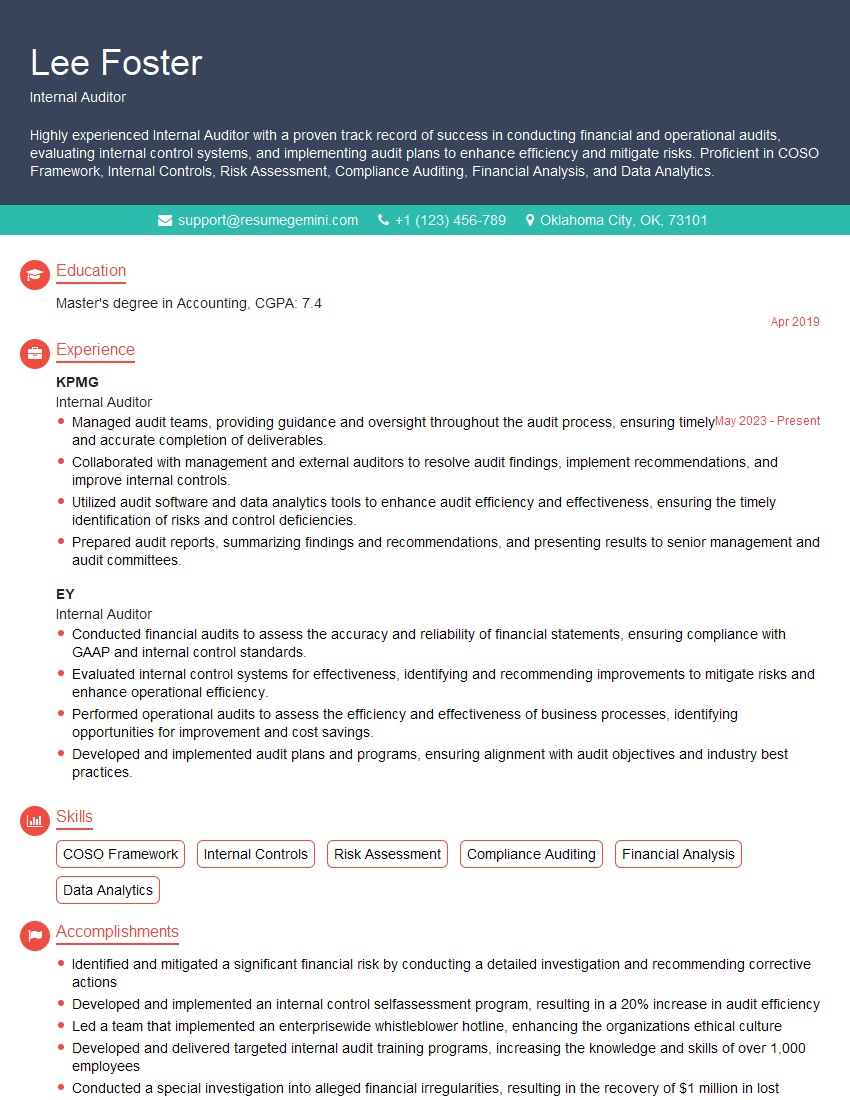

Mastering ISO 9001 knowledge significantly enhances your career prospects, opening doors to rewarding roles in quality management and related fields. A strong resume is your key to unlocking these opportunities. Make sure yours is ATS-friendly to maximize its impact.

To create a compelling and effective resume that highlights your ISO 9001 expertise, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and valuable resources to help you build a professional resume that stands out. Examples of resumes tailored to ISO 9001 expertise are available through ResumeGemini to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO