The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Knowledge of Printing and Binding interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Knowledge of Printing and Binding Interview

Q 1. Explain the difference between offset and digital printing.

Offset printing and digital printing are two fundamentally different methods of transferring images onto a substrate (like paper). Think of it like this: offset is like using a stamp to create many copies, while digital is like using a photocopier.

Offset printing is an indirect method that uses a printing plate to transfer ink onto a rubber blanket, and then from the blanket onto the paper. This allows for high-volume, high-quality printing at a relatively low cost per unit. It’s ideal for large print runs, like books, magazines, or brochures, because the initial setup cost is amortized over many prints. The image quality is typically superior for fine details and color gradients due to the higher resolution achievable.

Digital printing, on the other hand, is a direct method. The image is transferred directly from a digital file to the paper, one page at a time. This is perfect for short-run printing, personalized items, or variable data printing (like addressing mail). It’s faster for smaller projects because there’s no plate-making involved. However, the cost per unit is generally higher than offset for larger quantities, and the image quality might not reach the same level of detail as offset for very fine work.

- Offset: High volume, lower cost per unit, high image quality, longer setup time.

- Digital: Low volume, higher cost per unit, faster turnaround, personalized options.

Q 2. Describe the various types of binding methods and their applications.

Binding methods secure the pages of a document together. The choice depends on the project’s size, budget, and desired aesthetic. Here are some common methods:

- Saddle Stitch Binding: Pages are folded in half and stapled along the spine. Simple, cost-effective, good for booklets and magazines with a lower page count (typically under 64 pages).

- Perfect Binding: The edges of the pages are glued together, creating a square spine. Common for paperback books, softcover notebooks, and reports. Allows for a flatter lay-flat book.

- Wire-O Binding: Wire staples are inserted through punched holes along the spine, creating a professional and durable book that lays flat. Ideal for calendars, notebooks, and documents needing frequent use.

- Spiral Binding (Coil Binding): Plastic or metal coils are inserted through punched holes. Economical, lays flat, easy to turn pages. Suitable for reports, presentations, and smaller books.

- Case Binding: A hardcover option where the book’s pages are sewn together (sometimes using thread or adhesive) and then glued into a cover. Provides a robust and high-quality finish, often used for hardback books.

- PUR Binding (Polyurethane Reactive): A strong adhesive binding that allows for a smooth, lay-flat spine. Suitable for thicker books or those that require extra durability.

For example, a small booklet might use saddle stitch, while a textbook might require case binding for durability.

Q 3. What are the key considerations when selecting paper stock for a printing project?

Paper selection is crucial for a successful print job. Key considerations include:

- Weight (GSM): Grams per square meter indicates the paper’s thickness. Heavier paper (higher GSM) feels more luxurious but can increase printing costs and postage.

- Finish: The surface texture influences the look and feel. Common finishes include coated (glossy or matte), uncoated (natural texture), and textured (linen, etc.). Coated paper provides better image reproduction but can feel less tactile.

- Brightness: Measured in CIE whiteness, brightness affects the vibrancy of colors. Higher brightness usually makes colors appear more vivid.

- Color: White is the most common, but off-white or cream options are available for a more vintage feel.

- Opacity: How much light shines through the paper. Higher opacity prevents show-through, especially important for double-sided printing.

- Sustainability: Consider recycled or FSC-certified paper for eco-friendly printing.

For instance, a high-gloss coated paper is perfect for showcasing vibrant images in a brochure, while an uncoated paper provides a more natural feel for a wedding invitation.

Q 4. How do you ensure color accuracy in printing?

Ensuring color accuracy requires a multi-faceted approach throughout the printing process.

- Color Profile: Use a consistent color profile (like sRGB or Adobe RGB) from design to print. This ensures the colors appear as intended.

- Proofing: Soft proofs on screen and hard proofs (printed samples) help check color accuracy before committing to a full print run. Soft proofing requires careful calibration of your monitor.

- Color Management System (CMS): A CMS helps manage color across different devices and workflows. This is essential for maintaining consistency between design software, print files, and the printing press.

- Calibration: Regularly calibrate your monitor and printing equipment to ensure accurate color representation.

- Ink Selection: Choosing the right inks for the chosen paper type is critical for accurate color reproduction.

- Press Setup: Proper press calibration and maintenance are necessary for optimal color consistency during the printing process.

For example, a soft proof can help identify color variations before the print job begins, allowing for adjustments in the design phase.

Q 5. What are the common prepress processes involved in preparing a document for printing?

Prepress is the crucial preparation stage before printing. It involves:

- File Preparation: Ensuring the design file is in the correct format (like PDF/X-1a), resolution, and color space. This is vital for avoiding problems during printing.

- Imposition: Arranging pages to optimize paper usage and printing efficiency. This involves carefully planning how pages will be arranged on the sheet to minimize waste.

- Trapping: Adjusting the edges of colors to prevent gaps or misregistration between colors. This is particularly important when printing with multiple colors.

- Proofing: Creating soft and/or hard proofs to verify the accuracy of the design and color before printing.

- Platemaking (Offset): Creating printing plates that translate the image onto the press. For digital, this stage is less prominent.

- Quality Control Checks: Thoroughly inspecting the files and proofs to identify any potential errors before proceeding with printing.

For example, failing to correctly impose pages can result in pages being printed out of order.

Q 6. Explain the role of a color management system (CMS) in printing.

A Color Management System (CMS) is crucial for achieving color consistency across the entire printing workflow. It acts as a translator, ensuring that colors appear the same on your screen, in a proof, and on the final printed piece.

A CMS works by creating profiles for all the devices involved (monitor, printer, scanner, press) defining how each device represents color. This allows the CMS to convert color information between different color spaces, ensuring a uniform color representation. Without a CMS, colors can shift dramatically between stages, leading to inaccuracies.

For example, if you design a logo in Adobe RGB color space and print it on a press with an incorrect profile, the colors may appear vastly different. A well-implemented CMS would ensure consistent color representation throughout the process.

Q 7. Describe your experience with different types of printing inks.

My experience encompasses a range of printing inks, each with its own properties and applications:

- Process Inks (CMYK): Cyan, Magenta, Yellow, and Black are the foundation of most color printing. I’m highly proficient in managing and balancing these inks to achieve accurate color reproduction.

- Pantone Matching System (PMS): PMS colors offer precise spot colors, often used for branding and ensuring consistent color across different printing runs. I have extensive experience with PMS color matching and have worked with clients to accurately capture their brand colors.

- UV Inks: These inks cure instantly upon exposure to ultraviolet light, providing quick drying times and exceptional durability. They’re often used in packaging and outdoor signage.

- Water-Based Inks: Environmentally friendly and less harsh, water-based inks are suitable for projects focused on sustainability. I’m familiar with their characteristics and their specific needs during printing.

- Solvent-Based Inks: While possessing exceptional vibrancy, these inks require specialized handling due to their solvents. Safety measures and proper ventilation are crucial when working with them.

For example, choosing UV inks is crucial for outdoor banners because they offer excellent resistance to fading from sunlight, while water-based inks are ideal for printing projects where environmental impact is paramount.

Q 8. How do you troubleshoot common printing problems?

Troubleshooting printing problems involves a systematic approach. I start by identifying the type of problem – is it a hardware issue, a software glitch, a problem with the print file itself, or a media incompatibility?

- Hardware Issues: This could range from jammed paper to faulty printer heads. I’d check paper paths, toner/ink levels, and printer connections. A simple restart often resolves temporary glitches.

- Software Issues: Problems like incorrect printer drivers, insufficient memory, or corrupted print queues need addressing. I’d check the printer settings, update drivers, and clear the print queue. Sometimes, reinstalling the printer drivers is necessary.

- File Issues: Incorrect file formats, missing fonts, or corrupted image files can cause printing errors. I’d review the print file for errors, ensuring it’s compatible with the printer and its settings. Converting the file to a PDF often solves compatibility issues.

- Media Issues: Using the wrong type of paper or encountering issues with paper quality can lead to problems. I’d verify that the paper type is suitable for the printer and is correctly loaded. For example, using photo paper in a printer designed for standard paper can lead to jams or poor print quality.

For example, if a client reports blurry text, I’d first check the print resolution settings, then the toner/ink levels, and finally inspect the printer heads for any clogs or damage. A systematic approach ensures efficient problem resolution.

Q 9. What are the different types of finishing techniques used in print production?

Finishing techniques enhance the visual appeal and durability of printed materials. They range from simple trimming to complex embellishments.

- Cutting & Trimming: This is the most basic, involving precise cutting to the desired size and shape.

- Folding & Creasing: Folding creates brochures, leaflets, and booklets; creasing prevents cracking along fold lines.

- Binding: This secures pages together, with methods including saddle-stitch (stapling), perfect binding (gluing), wire-o binding (metal coils), and case binding (hard covers).

- Laminating: Applying a protective film enhances durability and water resistance.

- Die-Cutting: Creating custom shapes and designs, as discussed further in the next question.

- Embossing & Debossing: Raising or indenting designs for a tactile effect.

- Foil Stamping: Adding metallic or colored foil for a luxurious touch.

- UV Coating: Applying a protective UV coating for a glossy finish and added durability.

For instance, a high-end corporate report might use case binding, foil stamping, and UV coating to create a premium feel, while a simple flyer might only require cutting and folding.

Q 10. Explain the process of die-cutting.

Die-cutting is a process where a custom-shaped blade cuts through a sheet of paper, cardstock, or other material, creating unique shapes and designs. It’s like using a cookie cutter, but on a much larger and more precise scale.

The process begins with creating a die – a metal plate with sharp blades precisely shaped to the desired design. This die is then placed in a die-cutting machine. The material is fed into the machine, where the die presses down, cleanly cutting the shape.

Think of creating business cards with rounded corners – that’s die-cutting. Or intricate shapes for packaging, promotional items, or even custom-shaped invitations. The possibilities are vast. The complexity of the die determines the intricacy of the cut. Simple shapes are straightforward, while complex designs require more intricate dies and precise machine operation.

Q 11. What are some common quality control checks performed during printing and binding?

Quality control is paramount. Checks are performed at various stages:

- Pre-Press: This involves verifying the accuracy of the digital files, ensuring color consistency, and checking for any errors in text or images. Proofing is crucial here.

- During Printing: Regular checks are made to ensure color accuracy, image sharpness, and proper registration (alignment of colors). We’d monitor the printing press to check for any inconsistencies.

- Post-Press: This includes inspecting the finished product for any defects like misaligned folds, incorrect cuts, or binding issues. We’d check for blemishes, smudges, or imperfections.

- Random Sampling: Taking a sample of printed materials and checking them for consistent quality. This ensures that the entire run is up to standard.

For example, we might perform a color check at the beginning, middle, and end of a large print run to ensure consistent color across all printed pieces. A failed quality control check might lead to reprinting a batch or even the entire print run to maintain the required standards.

Q 12. How do you manage print jobs with tight deadlines?

Managing tight deadlines requires careful planning and efficient execution. My approach includes:

- Prioritization: Identifying critical tasks and prioritizing them to ensure timely completion. This includes prioritizing jobs based on urgency and complexity.

- Clear Communication: Maintaining open communication with the client, providing regular updates and addressing any potential roadblocks proactively.

- Efficient Workflow: Streamlining the production process to minimize delays. This might include using project management software to track progress.

- Resource Allocation: Effectively allocating personnel and equipment to optimize production efficiency. This might involve bringing in extra staff or utilizing equipment more efficiently.

- Contingency Planning: Having a backup plan in place to deal with unexpected problems or delays. This ensures that even if one part of the process falters, we can still meet the deadline.

For instance, if a job requires a fast turnaround, I might prioritize it over other jobs, even if it means slightly delaying less urgent tasks. Open communication with the client prevents misunderstandings and ensures everyone is on the same page.

Q 13. Describe your experience with different types of printing equipment.

My experience encompasses a wide range of printing equipment, including:

- Offset Printing Presses: I have extensive experience operating and maintaining both small and large format offset presses, proficient in handling various paper stocks and ink types.

- Digital Printing Presses: I’m well-versed in operating and maintaining various digital printing devices, from high-volume production printers to smaller, on-demand solutions. This includes experience with different print technologies like toner-based and inkjet systems.

- Large Format Printers: I have experience with wide-format printers used for posters, banners, and signage, familiar with different media types and finishing techniques used for this application.

- Finishing Equipment: I’m experienced with a wide variety of finishing equipment including cutting, folding, binding, laminating, and die-cutting machines. This includes both manual and automated systems.

This broad experience allows me to choose the most appropriate equipment and techniques for each job, ensuring optimal quality and efficiency. For example, if a client needs a large print run of brochures, I would recommend offset printing, while a small-scale, custom project might be better suited to digital printing.

Q 14. Explain your understanding of print specifications and how they impact the final product.

Print specifications are crucial – they dictate the final product’s quality and characteristics. These specifications include:

- Paper Type & Weight: This affects the feel, texture, and print quality. Choosing the right paper is crucial for the overall aesthetic.

- Dimensions & Orientation: These determine the size and layout of the printed piece.

- Color Mode (CMYK or RGB): CMYK is for print, RGB for screens. Using the wrong mode results in significant color shifts.

- Resolution (DPI): Higher DPI means sharper images. Insufficient resolution results in blurry prints.

- Bleeds & Margins: Bleeds extend images beyond the trim line, preventing white edges after cutting. Margins ensure text and important elements are not cut off.

- Finishing Requirements: This includes binding type, folding, laminating, and other finishing options.

For example, if a client requests a high-quality, glossy brochure, the specifications would include high-quality coated paper, specific dimensions, CMYK color mode with a high resolution, bleed margins, and perfect binding. Ignoring these specifications could result in a substandard product, not meeting client expectations.

Q 15. How familiar are you with different file formats used in prepress (e.g., PDF, TIFF, EPS)?

In prepress, we rely heavily on several key file formats, each with its strengths and weaknesses. Understanding these formats is crucial for ensuring print quality and a smooth workflow.

- PDF (Portable Document Format): This is the industry standard for final prepress files. It’s universally compatible, preserving fonts and vector graphics accurately. Different PDF versions exist (e.g., PDF/X-1a, PDF/X-4), with specific requirements for color management and data integrity, crucial for professional printing. For instance, PDF/X-1a ensures consistent color across different devices.

- TIFF (Tagged Image File Format): TIFF is excellent for high-resolution raster images, often used for photographs. Its support for various compression methods (like LZW) helps manage file sizes without compromising image quality. We often use TIFFs for images requiring precise color reproduction.

- EPS (Encapsulated PostScript): EPS files are primarily used for vector graphics, scalable without loss of quality. They are frequently embedded within other file formats, particularly InDesign files. While less common now than PDFs, they remain important for preserving the quality of logos and line art.

Choosing the right format depends heavily on the project’s specifics. For instance, a brochure might use a PDF/X-1a for the final print-ready file, incorporating TIFFs for high-resolution photography and EPS files for vector logos.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of binding machinery.

My experience encompasses a wide range of binding machinery, each suited for different applications and project requirements. This includes:

- Perfect Binding: This method, commonly used for paperback books and magazines, involves gluing the edges of the pages together and then applying a cover. I’m experienced with adjusting the glue settings for various paper stocks and ensuring a strong, clean bind.

- Saddle Stitch Binding: A cost-effective option for booklets and brochures, saddle stitch uses wire staples to secure folded pages. This necessitates accurate sheet folding and careful consideration of staple placement to avoid damaging the pages.

- Spiral Binding (Coil Binding): This is great for documents needing to lie flat, like reports or calendars. I understand the nuances of coil pitch, cover selection, and ensuring consistent spacing.

- Case Binding: Often used for high-end books and publications, this is a more robust method involving a separate cover that’s adhered to the text block. It requires expertise in various stages, from book sewing and gluing to cover attachment.

I’m also familiar with other binding types like wire-o binding and thermal binding, and I have the ability to recommend the most appropriate binding method based on the document type, budget, and client expectations.

Q 17. How do you handle customer requests or revisions during the printing process?

Handling customer requests and revisions is crucial. My approach involves a proactive and collaborative process:

- Clear Communication: Early and ongoing communication is paramount. I ensure that the client understands the timeline, potential issues, and any limitations.

- Version Control: Maintaining detailed records of all revisions is critical. I use a version control system, which allows me to easily track changes and revert to previous versions if needed.

- Proofing and Feedback: I provide clients with digital proofs for review at every crucial stage. This involves clearly indicating areas where changes might be needed.

- Time Management: I work with clients to manage expectations regarding turnaround times for revisions, ensuring realistic deadlines are set. Urgent requests are carefully assessed for feasibility and prioritized accordingly.

- Professionalism: Maintaining a calm and professional demeanor is essential. I handle client concerns patiently, providing clear explanations and solutions.

One time, a client requested a significant design change late in the process. By communicating openly about the implications on the timeline and cost, we collaboratively found a solution that satisfied both parties without compromising the project’s overall quality.

Q 18. What software are you proficient in using for prepress or post-press operations?

My software proficiency spans several crucial areas of prepress and post-press operations. This includes:

- Adobe Creative Suite (InDesign, Photoshop, Illustrator): I’m highly proficient in these industry-standard applications for design, image manipulation, and layout.

- Adobe Acrobat Pro: Essential for creating and managing PDFs, ensuring print-ready files meet specific standards like PDF/X.

- Color Management Software (e.g., X-Rite i1Profiler): Accurate color management is critical. I have extensive experience using color management tools to calibrate monitors and ensure consistent color across different devices.

- Prepress Workflow Software (e.g., Pitstop Pro): Software like Pitstop Pro allows me to preflight and check files for potential issues before sending them to the press, significantly reducing errors and production delays.

I’m also familiar with various RIP software and job ticketing systems depending on the printing devices used.

Q 19. Explain your understanding of different paper weights and finishes.

Understanding paper weight and finish is critical for choosing the right stock for any project. Paper weight, typically measured in GSM (grams per square meter), directly impacts the feel and durability of the finished product. Heavier paper (e.g., 300gsm) feels more substantial and luxurious, ideal for high-end brochures or business cards. Lighter paper (e.g., 80gsm) is suitable for everyday documents or leaflets.

Paper finishes significantly affect the aesthetic appeal and printability. Common finishes include:

- Matte: Provides a subtle, non-reflective surface, excellent for readability and detailed imagery. The reduced glare is good for text-heavy documents.

- Gloss: Offers a shiny, reflective finish. This enhances vibrancy and makes colors appear richer. Ideal for projects where visual impact is key, but it can sometimes make text harder to read.

- Uncoated: A natural, porous finish that provides a more textured feel. It’s eco-friendly but may absorb ink more, potentially affecting print quality.

- UV Coated: A protective layer that enhances durability and adds a smooth finish. This adds water and scratch resistance, protecting the print.

The best choice depends on the desired look, feel, and functionality of the final product. A high-quality business card might use a thick, glossy stock, while a newsletter might use a lighter, matte paper for readability.

Q 20. How do you ensure the efficient workflow within a print production environment?

Efficient workflow in print production is paramount. My approach centers around these key principles:

- Project Planning: Thorough upfront planning, including understanding the client’s requirements and timelines, is crucial. This prevents potential bottlenecks and ensures a smooth process.

- Job Ticketing: Using a robust job ticketing system helps track the progress of each job from submission to completion. It provides a centralized location for all relevant information and reduces confusion.

- Process Optimization: Continuously evaluating and improving processes is important to increase efficiency and reduce waste. This may involve streamlining steps or adopting new technologies.

- Teamwork and Communication: Effective communication and collaboration between different teams (design, prepress, press, post-press) is essential to ensure timely completion and prevent errors.

- Automation: Automating repetitive tasks where possible reduces manual intervention, leading to increased accuracy and reduced turnaround time.

For example, implementing a standardized checklist for preflighting files can significantly reduce errors in the prepress stage. By effectively prioritizing tasks and communicating clearly, I ensure the workflow remains as smooth and efficient as possible.

Q 21. Describe your experience with print cost estimation and budgeting.

Accurate print cost estimation and budgeting are essential for profitability. My approach involves a detailed breakdown of all relevant costs:

- Material Costs: This includes the cost of paper, ink, and any other materials required for the project. I take into account the specific paper weight, finish, and quantity needed.

- Labor Costs: This covers the time spent on design, prepress, printing, and post-press operations. I estimate this based on the complexity of the project and the resources required.

- Machine Costs: This includes the cost of running the printing presses and binding machinery, accounting for power consumption, wear and tear, and maintenance.

- Overhead Costs: This covers indirect costs such as rent, utilities, and administrative expenses.

- Profit Margin: A reasonable profit margin is added to ensure profitability. This is dependent on various factors such as the project’s complexity and market conditions.

I use specialized software and my experience to create accurate estimates. For instance, I might factor in potential overruns or variations in material costs based on market fluctuations. This ensures transparency and avoids unexpected cost overruns for the client.

Q 22. What are some common challenges faced in print production, and how have you addressed them?

Print production faces numerous challenges, often interlinked. Color consistency is a major hurdle; achieving the exact shade intended across different runs can be tricky due to variations in inks, paper, and press settings. Another common issue is meeting tight deadlines, especially with large-volume orders or complex projects requiring multiple stages. Unexpected equipment malfunctions or supply chain disruptions can further complicate matters. Finally, maintaining cost-effectiveness while delivering high-quality output is a constant balancing act.

In my experience, I’ve tackled these challenges using a multi-pronged approach. For color consistency, I implemented a rigorous color management system, including regular calibration of our equipment and the use of color profiles for each substrate. To manage deadlines, I employ project management software, allowing for meticulous tracking of progress, resource allocation, and potential bottlenecks. We also proactively maintain equipment and have contingency plans for supply chain issues, exploring alternative suppliers or materials when necessary. Cost-effectiveness is managed through efficient workflow optimization, waste reduction strategies, and negotiating favorable contracts with suppliers.

Q 23. What are your strategies for maintaining print quality consistency?

Maintaining print quality consistency is paramount. My strategies revolve around establishing and meticulously following standardized operating procedures (SOPs). This encompasses everything from pre-press checks – ensuring accurate color profiles, proper image resolution, and consistent file formats – to the precise calibration of printing presses and regular quality checks during the printing process itself. We use color control strips on each print run to monitor consistency. Regular maintenance of equipment, like cleaning rollers and replacing worn parts, is crucial. In addition, consistent training for print operators ensures that everyone understands and adheres to the SOPs. Finally, we keep detailed records of each print job, allowing for thorough analysis and troubleshooting if inconsistencies arise.

Q 24. How familiar are you with environmental concerns related to printing and what are your solutions to minimize environmental impact?

Environmental responsibility is a significant consideration in modern printing. The industry’s impact stems from ink and toner usage, paper consumption, and energy use during production. I’m deeply familiar with these concerns and implement various solutions to minimize environmental impact.

- Sustainable Materials: We prioritize using recycled paper and vegetable-based inks whenever possible. These options significantly reduce the environmental footprint compared to traditional materials.

- Waste Reduction: Implementing lean manufacturing principles helps minimize paper waste by optimizing printing processes and accurately estimating print quantities. We also recycle paper scraps and other materials.

- Energy Efficiency: Using energy-efficient equipment, embracing automation to streamline processes, and practicing responsible energy management help minimize energy consumption.

- Responsible Disposal: We follow proper disposal procedures for inks, solvents, and other printing consumables, ensuring compliance with environmental regulations.

By integrating these practices, we significantly reduce our carbon footprint and contribute to a more sustainable printing operation.

Q 25. Explain your experience working with different types of substrates, beyond paper.

My experience extends beyond standard paper substrates. I’ve worked extensively with various materials, including canvas, plastics (like PVC and PET), and fabrics. Each substrate requires a unique approach, tailored to its specific properties. For instance, printing on canvas requires inks formulated for this porous material to avoid bleeding or cracking. Plastics often demand specialized UV inks for superior adhesion and durability. Printing on fabrics necessitates inks that are flexible and won’t crack when the fabric is stretched or bent. Understanding the unique handling and printing requirements of each material is essential for producing high-quality results. I’ve also worked with substrates like metal sheets and wood, each presenting its own set of challenges and requiring specialized techniques and inks.

Q 26. Describe your experience with automated or semi-automated binding systems.

I have extensive experience with both automated and semi-automated binding systems. Automated systems, such as perfect binding machines and saddle-stitchers, significantly increase production speed and efficiency, especially for high-volume jobs. However, they typically require a higher initial investment. Semi-automated systems offer a balance between automation and manual control, providing flexibility for jobs with more specialized binding needs. I’m proficient in operating various types of binding equipment, including:

- Perfect Binding: Ideal for books and magazines.

- Saddle Stitching: Suitable for brochures and booklets.

- Wire-O Binding: Frequently used for calendars and notebooks.

- Spiral Binding: Commonly employed for reports and documents.

My experience includes troubleshooting malfunctions, performing routine maintenance, and optimizing the settings of these machines to achieve optimal binding quality and speed. I understand the importance of proper setup and the impact of various binding parameters on the final product’s quality and durability.

Q 27. How do you prioritize tasks and manage multiple projects simultaneously in a print production environment?

Managing multiple projects simultaneously in a fast-paced print production environment necessitates strong organizational skills and efficient prioritization. I use project management software to track deadlines, allocate resources, and monitor progress across all active projects. I prioritize tasks based on urgency, deadline, and client importance, using a system that combines urgency and importance (Eisenhower Matrix). This ensures that time-sensitive and crucial projects receive the necessary attention. Effective communication with the team and clients is key; regular updates and transparent communication regarding potential delays or challenges help to manage expectations and maintain a smooth workflow.

Q 28. What are your strategies for improving efficiency and reducing waste in a print shop?

Improving efficiency and reducing waste in a print shop requires a holistic approach. Implementing lean manufacturing principles, such as eliminating unnecessary steps and optimizing workflows, is crucial. This includes streamlining processes, reducing setup times, and minimizing material handling. We also invest in technologies like automated cutting and finishing systems to enhance efficiency and precision. Regular equipment maintenance prevents downtime and reduces waste caused by malfunctions. Accurate job estimation and efficient job scheduling are also essential to avoid overproduction and unnecessary material waste. Finally, employee training and empowerment are essential for fostering a culture of continuous improvement and waste reduction within the print shop. We regularly analyze our processes to identify areas for improvement and implement changes based on data and feedback.

Key Topics to Learn for Your Knowledge of Printing and Binding Interview

- Pre-press Preparation: Understanding file formats (PDF, TIFF, etc.), color profiles (CMYK, RGB), image resolution, and trapping techniques. Practical application: Explain how you would troubleshoot a low-resolution image provided for printing.

- Printing Processes: Familiarize yourself with various printing methods (offset, digital, screen, large format) and their respective strengths and weaknesses. Practical application: Discuss the advantages and disadvantages of offset printing versus digital printing for a specific project.

- Binding Techniques: Master different binding methods (perfect binding, saddle stitch, wire-o, case binding) and their suitability for different types of documents. Practical application: Explain how you would choose the optimal binding method for a large-format book versus a small brochure.

- Paper and Materials: Develop a strong understanding of paper types, weights, finishes, and their impact on print quality and overall project cost. Practical application: Describe how paper choice influences the final product’s feel and visual appeal.

- Finishing Techniques: Explore various finishing options like lamination, embossing, die-cutting, and their impact on the final product. Practical application: Explain how you’d choose finishing techniques to enhance the visual appeal and durability of a marketing brochure.

- Quality Control: Understand color management, proofing methods, and quality assurance processes to identify and correct printing errors. Practical application: Describe your process for identifying and resolving color inconsistencies in a printed piece.

- Industry Software and Technology: Demonstrate familiarity with relevant software and equipment used in the printing and binding industry (e.g., RIP software, cutting machines, binding equipment). Practical application: Describe your experience with a specific piece of printing or binding equipment.

- Production Management: Understand aspects of scheduling, cost estimation, and client communication within a print production environment.

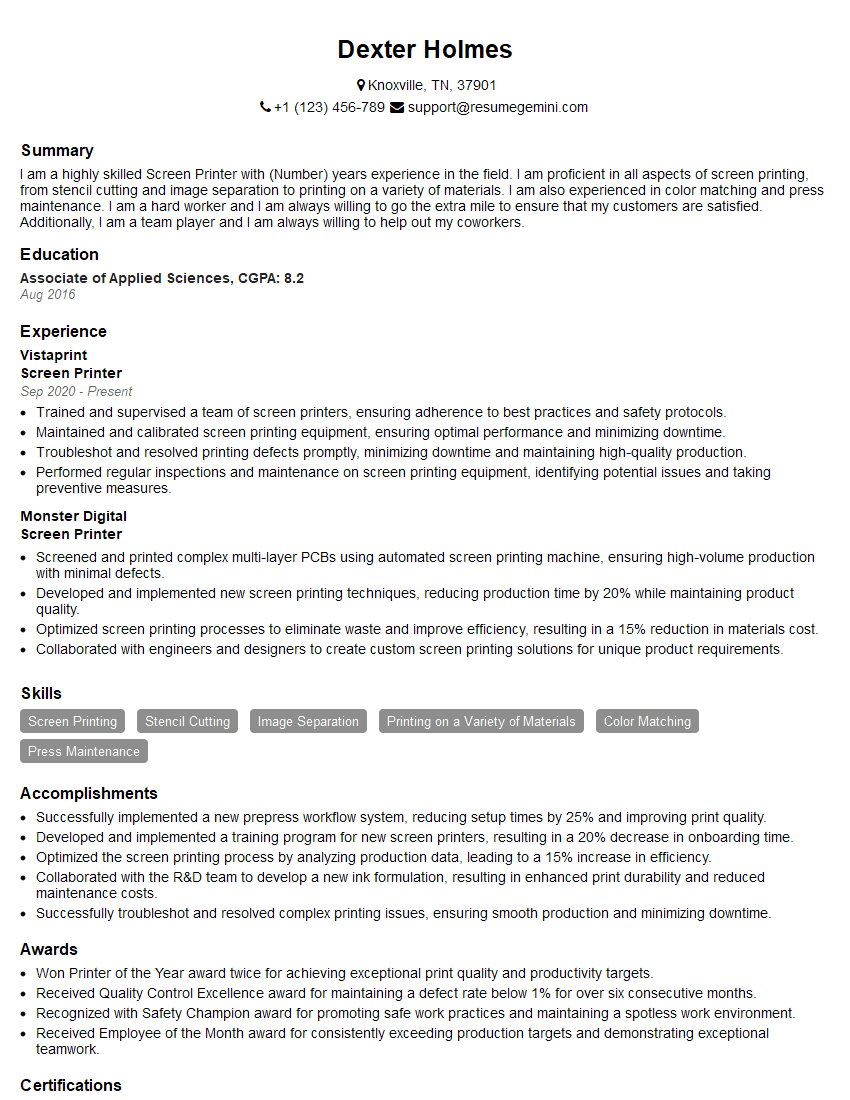

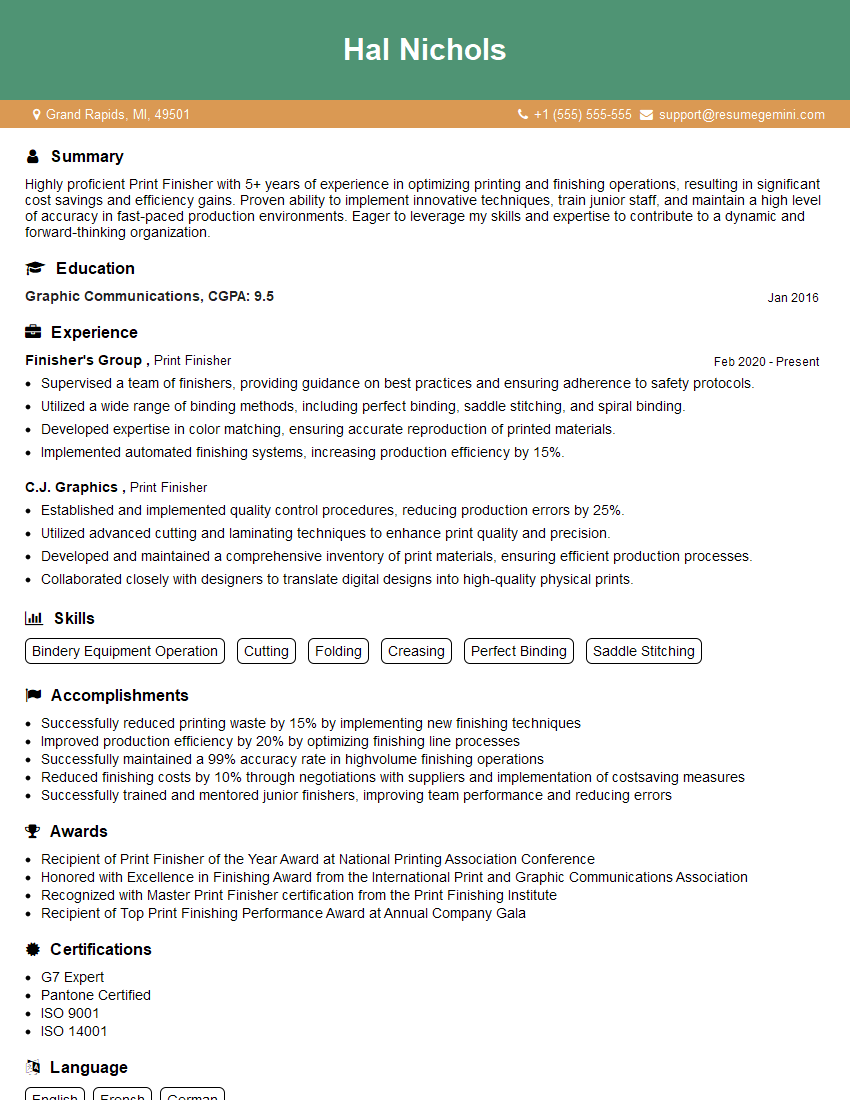

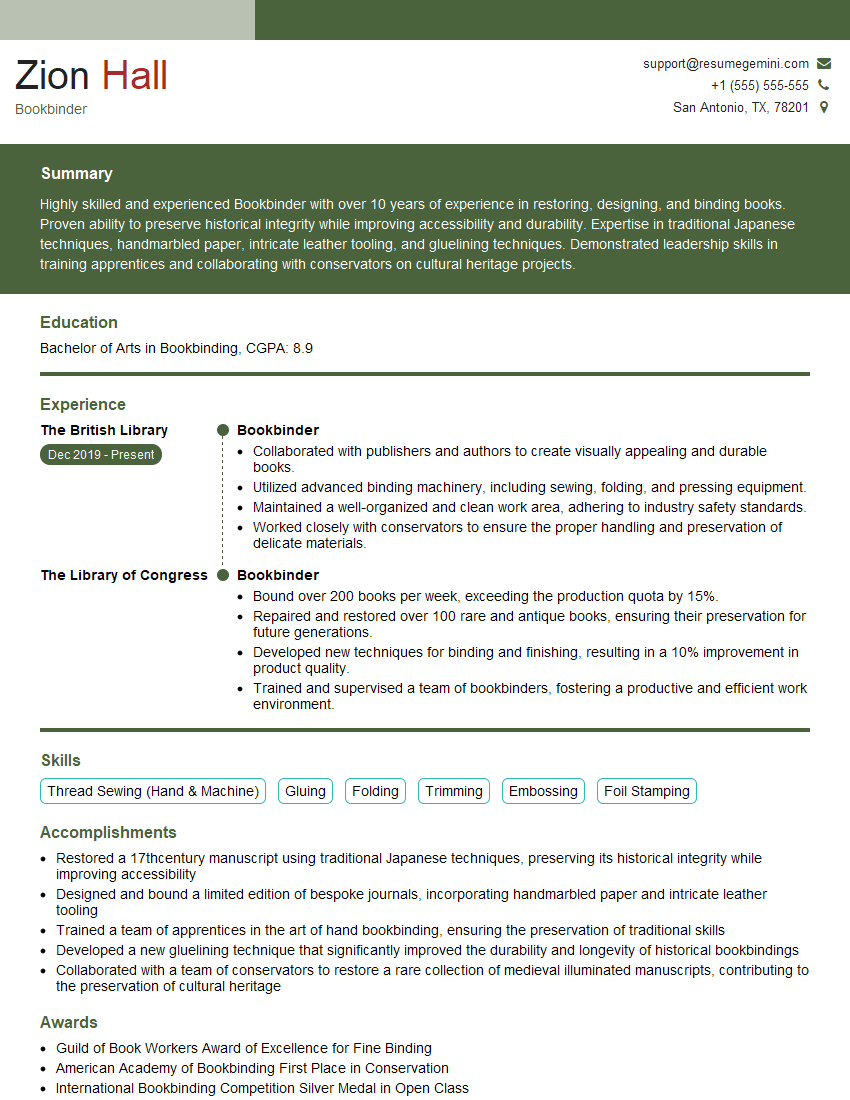

Next Steps

Mastering Knowledge of Printing and Binding is crucial for career advancement in this dynamic field. A strong understanding of these processes will significantly improve your job prospects and allow you to command competitive salaries. To maximize your chances, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes, and we provide examples of resumes tailored to the Knowledge of Printing and Binding industry to help you get started. Investing time in crafting a compelling resume is a significant step towards your next career opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO