Are you ready to stand out in your next interview? Understanding and preparing for Knowledge of robotics and automation interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Knowledge of robotics and automation Interview

Q 1. Explain the difference between industrial robots and collaborative robots (cobots).

The core difference between industrial robots and collaborative robots (cobots) lies in their safety features and intended interaction with humans. Industrial robots, often large and powerful, are designed for high-speed, high-precision tasks in isolated environments. Safety is achieved through physical barriers like cages, preventing human access during operation. Think of the massive robotic arms used in automotive assembly lines – these are quintessential industrial robots.

Cobots, on the other hand, are designed for direct collaboration with humans. They incorporate safety features like force sensors and compliant actuators, enabling them to stop safely if they encounter unexpected contact. This allows them to work alongside human operators without the need for safety cages. Examples include robots used in smaller manufacturing settings for tasks like assembly or packaging, where human dexterity is still needed, or in healthcare assisting surgeons.

In essence: Industrial robots prioritize speed and efficiency in isolated settings, while cobots prioritize safety and collaboration in shared workspaces.

Q 2. Describe different types of robot manipulators and their applications.

Robot manipulators are the physical arms of a robot, responsible for interacting with the environment. They come in various types, each suited for specific tasks:

- Cartesian robots (Gantry robots): These move along three linear axes (X, Y, Z) like a rectangular coordinate system. They’re ideal for pick-and-place operations with a large work envelope, such as in CNC machining or 3D printing.

- Cylindrical robots: They have one rotational axis and two linear axes. This configuration is useful for applications needing a combination of linear and rotational movement, like machine tending or spot welding.

- Spherical (Polar) robots: These have one linear axis and two rotational axes. Their reach resembles a sphere, making them suitable for applications requiring movement in a spherical volume, such as painting or arc welding.

- Articulated robots (Revolute robots): These are the most common type, featuring multiple rotary joints mimicking a human arm. Their flexibility and dexterity are well-suited for complex assembly tasks, material handling, and painting, similar to a human arm’s flexibility.

- SCARA robots (Selective Compliance Assembly Robot Arm): These are designed for high-speed assembly tasks requiring precision and compliance in the XY plane, with stiffness in the Z axis. They’re commonly found in electronics assembly.

The choice of manipulator depends on the specific application’s requirements regarding workspace, speed, precision, and payload capacity.

Q 3. What are the key components of a robotic system?

A robotic system isn’t just a robot arm; it’s a collection of interconnected components:

- Manipulator (Robot Arm): The physical arm carrying out the tasks.

- End-Effector: The tool attached to the manipulator, performing the actual work (grippers, welding torches, spray guns, etc.).

- Controller: The brain of the system, processing instructions and managing the robot’s movements. This includes software and hardware for motion control, sensors, and communication.

- Sensors: Provide feedback to the controller about the robot’s position, environment, and task status (e.g., force sensors, vision systems, proximity sensors).

- Power Supply: Provides electricity to operate the motors and electronics.

- Programming Interface: Software used to program and control the robot’s actions.

- Safety Systems: Emergency stops, safety interlocks, and other mechanisms to prevent accidents.

The interaction and integration of these components are crucial for a functional and safe robotic system.

Q 4. Explain the concept of degrees of freedom in robotics.

Degrees of freedom (DOF) in robotics refer to the number of independent movements a robot can make. Each joint in a robot typically contributes one DOF. A robot with six DOFs can move in six independent directions: three linear movements (X, Y, Z) and three rotational movements (roll, pitch, yaw). This is often sufficient to position and orient an end-effector in 3D space.

Think of your own arm: your shoulder has three DOFs (flexion/extension, abduction/adduction, internal/external rotation), your elbow has one (flexion/extension), and your wrist has three. This gives your arm a total of seven DOFs, enabling complex movements.

The number of DOFs required depends on the task. A simple pick-and-place robot might only need three DOFs, while a complex assembly robot might require six or more.

Q 5. What are common robot programming languages?

Robot programming languages vary depending on the robot manufacturer and application. Some common languages include:

- RAPID (ABB): ABB’s proprietary language, known for its structured programming capabilities.

- KRL (KUKA): KUKA’s language, using a syntax similar to Pascal.

- VAL (Unimation): One of the earliest robot programming languages.

- ROBOLanguage (Fanuc): Fanuc’s proprietary language.

- Python: An increasingly popular language for robot control, often used with ROS (Robot Operating System).

Many modern robots also offer teach pendants or intuitive graphical interfaces for simpler programming tasks. The choice of language often depends on the robot manufacturer and the level of complexity required for the task.

Q 6. Describe different robot control architectures (e.g., joint-level, Cartesian).

Robot control architectures dictate how the robot’s movements are planned and executed. Two common types are:

- Joint-Level Control: This focuses on controlling the individual joints of the robot. Each joint’s position, velocity, or torque is specified separately. This is simpler to implement but can be less efficient for complex tasks requiring precise end-effector positioning.

- Cartesian Control (or Task-Space Control): Here, the robot’s position and orientation are specified in a Cartesian coordinate system (X, Y, Z, roll, pitch, yaw). The controller calculates the necessary joint angles to achieve the desired end-effector pose. This is more intuitive for tasks defined in Cartesian space, like pick-and-place operations.

Other architectures include hybrid approaches combining joint-level and Cartesian control, or advanced techniques like force control, which allows robots to react to forces encountered during interaction with the environment.

Q 7. Explain the concept of robot kinematics and dynamics.

Robot kinematics deals with the geometry of robot motion, focusing on the relationship between joint angles and the robot’s end-effector position and orientation. It answers questions like: ‘Given a set of joint angles, where is the end-effector?’ or ‘What joint angles are needed to move the end-effector to a specific location?’ Forward kinematics solves the first problem, while inverse kinematics solves the second (often more complex).

Robot dynamics deals with the forces and torques required to move the robot. It considers factors like inertia, gravity, and friction. It answers questions like: ‘How much torque is needed at each joint to achieve a specific acceleration?’ This knowledge is crucial for designing efficient and robust robot controllers.

Understanding both kinematics and dynamics is critical for designing, controlling, and simulating robots. They are fundamental to path planning, trajectory generation, and motion control algorithms. Imagine a robot arm lifting a heavy object: kinematics determines its position, while dynamics ensures it has the necessary strength to do so.

Q 8. How do you perform robot calibration and what are the challenges?

Robot calibration is the process of precisely measuring and correcting the robot’s position, orientation, and other kinematic parameters. Think of it like carefully tuning a musical instrument – you need to ensure every part is in the right place to produce accurate and consistent results. This involves determining the actual relationship between the robot’s joint angles and its end-effector’s position and orientation in the workspace. It’s crucial for accurate task execution, especially in applications requiring high precision, like assembly or welding.

We typically use a combination of techniques, including:

- Forward and Inverse Kinematics Calibration: This involves mathematically relating the joint angles to the end-effector pose. Discrepancies between the model and reality are identified and corrected.

- Sensor-Based Calibration: Utilizing sensors like laser trackers or vision systems to accurately measure the robot’s position and orientation at various points in its workspace. This data is then used to refine the kinematic model.

- Parameter Identification: Using optimization algorithms to estimate the parameters of the robot’s kinematic model that best fit the measured data. This often involves minimizing errors between predicted and measured positions.

Challenges in robot calibration include:

- Model Complexity: Accurately modeling the robot’s mechanics, including elasticity and thermal effects, can be extremely complex.

- Sensor Noise and Uncertainty: Sensors are never perfectly accurate, introducing noise that needs to be filtered and accounted for.

- Environmental Factors: Temperature fluctuations, vibrations, and other environmental factors can impact calibration accuracy.

- Computational Cost: Calibration algorithms can be computationally intensive, especially for complex robots.

For example, in a robotic welding application, inaccurate calibration can lead to inconsistent weld quality and potential damage to the workpiece. A well-calibrated robot ensures consistent and high-quality welds.

Q 9. Describe different robot sensors and their applications (e.g., vision, force/torque).

Robots utilize a variety of sensors to perceive their environment and interact with it. These sensors provide crucial feedback for control and decision-making. Think of them as the robot’s senses, allowing it to ‘see,’ ‘feel,’ and ‘understand’ its surroundings.

- Vision Sensors (Cameras): These provide visual information about the environment. Applications include object recognition, pose estimation (determining the position and orientation of objects), and navigation. Examples include 2D cameras for simple tasks and 3D cameras (like structured light or time-of-flight) for more complex tasks requiring depth perception.

- Force/Torque Sensors: These measure the forces and torques applied to the robot’s end-effector. They are crucial for tasks requiring precise interaction with the environment, such as assembly, polishing, or delicate manipulation. Imagine a robot carefully inserting a small part – force/torque sensors help prevent damage by stopping the action if excessive force is detected.

- Proximity Sensors: These detect the presence of objects without physical contact. Types include ultrasonic, infrared, and capacitive sensors. Applications range from simple obstacle avoidance to precise positioning near objects.

- Laser Scanners (LIDAR): These create a 3D point cloud representing the surrounding environment. Crucial for autonomous navigation and mapping in robotics.

- Inertial Measurement Units (IMUs): Measure acceleration and angular velocity. Useful for determining the robot’s orientation and movement, particularly in mobile robots.

- Encoders (Joint Sensors): Measure the angle and velocity of each joint. Essential for controlling the robot’s movement and position.

The choice of sensors depends on the specific application. A simple pick-and-place robot might only require joint encoders and proximity sensors, while a surgical robot demands highly accurate force/torque and vision sensors.

Q 10. Explain different path planning algorithms used in robotics.

Path planning is the process of determining a collision-free trajectory for a robot to move from a starting point to a goal point. Think of it as creating a map for the robot to follow, avoiding obstacles along the way.

- A* Search: A graph search algorithm that efficiently finds the shortest path between two nodes. It uses a heuristic function to estimate the distance to the goal, guiding the search towards the optimal path. Popular for its efficiency in finding optimal paths, especially in grid-based environments.

- Dijkstra’s Algorithm: Finds the shortest path in a graph with non-negative edge weights. While effective, it can be computationally expensive for large graphs.

- Rapidly-exploring Random Trees (RRT): A probabilistic algorithm that efficiently explores the search space by randomly sampling configurations. It’s well-suited for high-dimensional spaces and complex environments. It’s particularly useful for robots navigating in cluttered or unknown environments.

- Potential Field Method: Creates an artificial potential field where the goal is a point of attraction and obstacles are points of repulsion. The robot follows the gradient of this field to navigate towards the goal while avoiding obstacles. Intuitive but can get stuck in local minima.

- Hybrid Methods: Many practical path planning algorithms combine elements of different methods, leveraging the strengths of each approach. For instance, an RRT might be used for initial path exploration, and then A* or another algorithm might be used to refine the path.

The choice of algorithm depends on factors like the complexity of the environment, the computational resources available, and the specific requirements of the application. For instance, a robot operating in a highly dynamic environment might benefit from an RRT’s ability to adapt to changing obstacles, while a robot working in a structured factory setting might use A* for optimal pathfinding.

Q 11. What are the safety considerations for designing and implementing robotic systems?

Safety is paramount in robotics. Designing and implementing robotic systems requires careful consideration of potential hazards to both humans and the equipment. This involves implementing safety measures at every stage of the design process.

- Emergency Stop Mechanisms: Multiple, easily accessible emergency stop buttons should be provided. These should immediately halt all robot motion.

- Safety Sensors: Using sensors like light curtains, laser scanners, and proximity sensors to detect the presence of humans or obstacles in the robot’s workspace. These triggers safe shutdowns or speed reductions.

- Speed and Force Limits: Programming limits on the robot’s speed and the force it can exert. This reduces the risk of injury if a collision occurs.

- Redundancy and Fail-safes: Implementing redundant systems and fail-safe mechanisms to ensure that the robot operates reliably even in the event of component failure. For example, having backup power sources or duplicate sensors.

- Risk Assessment and Mitigation: Conducting a thorough risk assessment to identify potential hazards and implement appropriate mitigation strategies. This may involve using physical guards, interlocks, or other safety measures.

- Operator Training: Providing adequate training to operators on the safe operation and maintenance of the robotic system.

- Compliance with Safety Standards: Adhering to relevant safety standards and regulations, such as those defined by organizations like ISO and OSHA.

For example, in a collaborative robot (cobot) application, where humans and robots share a workspace, safety considerations are especially critical. Cobots typically employ sensors and software that allows them to adjust their behavior in response to human proximity, ensuring safe interaction.

Q 12. Describe your experience with robot simulation software (e.g., ROS, Gazebo).

I have extensive experience with Robot Operating System (ROS) and Gazebo, powerful tools for robot simulation and development. ROS provides a flexible framework for building robotic applications, allowing for modularity and reusability. Gazebo simulates the physical environment and robot dynamics, enabling testing and debugging of algorithms without the need for physical hardware. This significantly reduces development time and cost, and minimizes risks associated with testing on physical hardware. Think of it like a test environment where you can run thousands of simulations before deploying your robot into the real world.

In my previous projects, I’ve utilized ROS to create:

- Modular Control Systems: Developed modular nodes and packages to manage robot locomotion, sensor data processing, and task planning. This allowed us to easily test and swap different components.

- Simulated Environments: Built realistic Gazebo environments that mimic the real-world conditions of the robot’s intended operating space. These were key for developing navigation algorithms and testing controller performance before real-world deployment.

- Algorithm Testing: Tested various path planning algorithms, control strategies, and sensor fusion algorithms in simulation before deploying them to real robots. This saved considerable time and avoided potential damage during initial testing phases.

For example, I used ROS and Gazebo to simulate an autonomous mobile robot navigating a warehouse environment. This allowed me to thoroughly test the robot’s navigation algorithms, sensor fusion, and obstacle avoidance strategies in a safe and controlled environment before deploying it in a real warehouse.

Q 13. How do you troubleshoot robotic system malfunctions?

Troubleshooting robotic system malfunctions requires a systematic approach. It’s like detective work – you need to gather clues and systematically eliminate possibilities until you find the root cause.

My troubleshooting process typically involves:

- Identify the Symptom: Precisely define the problem. What is the robot doing (or not doing)? Is it failing to reach a specific point? Is there an error message? This step is crucial for focusing the investigation.

- Gather Data: Collect as much data as possible. This could include error logs, sensor readings, video recordings of the malfunction, and other relevant information.

- Check for Obvious Issues: Look for simple problems, such as power supply issues, loose connections, or software glitches. These are often easy to fix and can save significant time.

- Isolate the Problem: Systematically test different components to pinpoint the source of the malfunction. This could involve isolating software modules, disconnecting sensors or actuators, or examining specific parts of the robot’s hardware.

- Consult Documentation: Refer to the robot’s manuals, schematics, and software documentation for troubleshooting guidance.

- Use Diagnostic Tools: Utilize debugging tools and software to analyze data, trace code execution, and identify errors.

- Simulate the Problem: If possible, try to reproduce the malfunction in a simulation environment. This can help isolate the problem and test potential solutions without risking damage to the physical hardware.

- Seek External Assistance: If necessary, consult with colleagues, experts, or the robot manufacturer for assistance.

For example, if a robot arm is moving erratically, I might first check the power supply, then examine the encoders for signal problems, then look at the controller software for errors. Using a combination of diagnostics and systematic testing, I can usually isolate the malfunctioning component and find the best course of action to fix it.

Q 14. Explain different types of robot end-effectors and their selection criteria.

Robot end-effectors are the tools attached to the robot’s wrist, allowing it to interact with its environment. The selection of the end-effector depends heavily on the specific task the robot needs to perform. Think of it as choosing the right tool for a job – you wouldn’t use a screwdriver to hammer a nail.

- Grippers: These are used for grasping and manipulating objects. They come in various designs, including parallel grippers, three-fingered grippers, and vacuum grippers. The choice depends on the shape, size, and material properties of the objects being handled.

- Welding Torches: Used for robotic welding applications. They require precise control and often incorporate sensors for monitoring the welding process.

- Spray Painting Nozzles: Used for painting applications. They need to be able to distribute paint evenly and consistently.

- Tools for Assembly Tasks: These include specialized tools for inserting screws, placing components, or performing other assembly operations.

- Surgical Instruments: Used in robotic surgery, these require extreme precision and dexterity.

Selection criteria include:

- Payload Capacity: The maximum weight the end-effector can handle.

- Reach and Workspace: The size and shape of the workspace the end-effector can access.

- Degrees of Freedom: The number of independent movements the end-effector can perform.

- Object Handling Capabilities: The ability of the end-effector to grasp, manipulate, or interact with specific types of objects.

- Precision and Accuracy: The level of precision and accuracy required for the task.

- Durability and Reliability: The end-effector should be robust enough to withstand the demands of the application.

For instance, in a pick-and-place application involving delicate electronic components, a soft gripper with force sensing capabilities would be preferable to a hard, rigid gripper that could damage the components.

Q 15. What are the advantages and disadvantages of different robot drive systems (e.g., hydraulic, pneumatic, electric)?

Robot drive systems are the heart of a robot’s movement, and the choice depends heavily on the application’s needs. Let’s compare hydraulic, pneumatic, and electric systems:

- Hydraulic Systems: These use pressurized fluid to power actuators.

- Advantages: High power-to-weight ratio, making them ideal for heavy lifting and high-force applications. They can also handle large loads and have good shock absorption.

- Disadvantages: They’re less precise than electric systems, require significant maintenance due to leaks and fluid degradation, are less environmentally friendly (due to oil usage), and are generally noisy.

- Example: Large industrial robots in automotive manufacturing used for heavy parts handling.

- Pneumatic Systems: These utilize compressed air to power actuators.

- Advantages: Simple, relatively inexpensive, and inherently safe in hazardous environments (due to the non-flammable nature of air). They are also quite clean.

- Disadvantages: Lower power output compared to hydraulics and electrics. They are susceptible to environmental conditions like temperature and humidity, and can be noisy.

- Example: Small robots used for pick-and-place tasks in packaging or material handling, often where precise movements aren’t critical.

- Electric Systems: These use electric motors and controllers.

- Advantages: High precision and repeatability, relatively clean, easy to control, programmable, and energy-efficient. They are quieter and require less maintenance than hydraulic or pneumatic systems.

- Disadvantages: Can be more expensive upfront, and may not be as powerful as hydraulic systems for very large loads.

- Example: Most modern industrial robots in electronics assembly, precision machining, and collaborative robotics applications.

The best system is dictated by the specific application. For instance, a heavy-duty press would likely benefit from a hydraulic system, while a delicate assembly line would opt for electric actuators.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of robot workspace and its limitations.

A robot’s workspace is the three-dimensional volume within which it can freely move its end-effector (the tool at the end of the robot arm). This is defined by its physical reach, joint limits, and any obstacles within its environment. Limitations arise from:

- Physical Constraints: The robot’s arm length and joint angles inherently restrict its reach. Think of a human arm – there are obvious limits to how far it can extend in various directions.

- Joint Limits: Each joint has a range of motion. Exceeding these limits can damage the robot or lead to unexpected behavior. This is like bending your elbow too far, causing pain and potentially injury.

- Singularities: Certain configurations of the robot’s joints might lead to a loss of dexterity or even complete immobility. This is analogous to trying to touch your back with your hand while your elbow is completely straight.

- Obstacles: The presence of equipment, walls, or other robots within the workspace can restrict the robot’s movement. This is like navigating a crowded room.

Understanding workspace limitations is crucial for robot programming and cell design. Careful planning is required to ensure that the robot can perform its tasks without collisions or exceeding its physical capabilities. Simulation software is frequently used to model the robot’s workspace and identify potential issues before deployment.

Q 17. How do you ensure the accuracy and repeatability of robotic movements?

Accuracy and repeatability are vital characteristics for industrial robots. Accuracy refers to how close the robot’s end-effector gets to its programmed target, while repeatability describes how consistently it can return to the same point after multiple attempts. Several methods ensure both:

- High-Precision Components: Using high-quality motors, encoders, and reduction gears minimizes errors in joint positioning.

- Calibration: Regular calibration procedures, often involving laser trackers or other precision measurement devices, compensate for wear and tear and ensure accuracy. This process involves systematically measuring the robot’s actual position against its commanded position.

- Advanced Control Algorithms: Sophisticated control algorithms, such as those based on inverse kinematics and trajectory planning, optimize robot movement for accuracy and smoothness.

- Sensor Feedback: Utilizing sensors like force/torque sensors and vision systems provides real-time feedback, allowing the robot to adjust its movements based on actual conditions. For instance, a force sensor can detect when a part is inserted correctly, while a vision system can verify the part’s position and orientation before grasping.

- Regular Maintenance: Preventative maintenance, including lubrication and cleaning of moving parts, helps maintain the robot’s mechanical integrity and accuracy over time.

Imagine a surgeon performing a delicate operation: high precision and consistency are paramount. Similar requirements apply in many automated manufacturing scenarios.

Q 18. Describe your experience with PLC programming and its role in automation.

I have extensive experience with PLC (Programmable Logic Controller) programming, a cornerstone of industrial automation. PLCs are essentially industrial computers that control machinery and processes. My experience includes designing, programming, and troubleshooting PLC programs using various languages like Ladder Logic, Structured Text, and Function Block Diagram.

In automation, PLCs act as the central nervous system. They receive inputs from sensors (e.g., limit switches, pressure sensors, temperature sensors), process that information based on the programmed logic, and send output signals to actuators (e.g., motors, valves, solenoids) to control the process.

For example, I’ve used PLCs to orchestrate complex manufacturing sequences, including coordinating the actions of multiple robots, conveyors, and other machinery. I’ve also incorporated safety features, such as emergency stops and interlocking mechanisms, to ensure safe operation. A typical task might involve writing a PLC program to control a pick-and-place robot, monitoring sensor signals to ensure proper part positioning, and managing the robot’s movements in synchronization with the conveyor belt.

// Example Ladder Logic (Illustrative): // Input: Sensor detecting part presence // Output: Robot activation signal // ---[Sensor]---( )---[Output]--- // | | // | | // Normally Open Normally Open

My expertise extends to optimizing PLC programs for efficiency and reliability, minimizing downtime and maximizing throughput. Proficiency in PLC programming is vital for integrating robots and other automated systems into a seamless and effective manufacturing workflow.

Q 19. Explain different types of industrial automation systems (e.g., SCADA, DCS).

Industrial automation systems manage and control industrial processes. SCADA (Supervisory Control and Data Acquisition) and DCS (Distributed Control System) are two prominent examples:

- SCADA: SCADA systems are used to monitor and control geographically dispersed processes, often across large areas. They typically involve a central supervisory system that receives data from remote sites via communication networks (e.g., Ethernet, Modbus). SCADA is great for monitoring and controlling things like pipelines, power grids, and water distribution networks. The emphasis is on high-level overview and supervisory control.

- DCS: DCS systems excel in controlling complex, high-integrity processes that require precise control and safety. They use multiple controllers distributed throughout the process, interconnected via high-speed communication networks. Each controller handles a specific part of the process, offering high redundancy and fault tolerance. DCS is commonly found in applications like refineries, chemical plants, and power generation facilities, where safety and reliability are critical.

The choice between SCADA and DCS depends on the specific application’s needs. SCADA is generally suitable for less critical and geographically dispersed operations, while DCS is more appropriate for high-integrity, complex processes needing precise and reliable control. Often, hybrid systems are deployed, combining elements of both SCADA and DCS to leverage their strengths.

Q 20. What are the challenges of integrating robots into existing manufacturing processes?

Integrating robots into existing manufacturing processes can present several challenges:

- Retrofitting Existing Equipment: Integrating robots may require modifications to existing machinery and infrastructure, which can be costly and time-consuming. Existing equipment might not be designed for robotic integration.

- Safety Considerations: Robots can pose safety risks to human workers if not properly integrated and safeguarded. Implementing safety measures, such as light curtains, emergency stops, and interlocks, is crucial.

- Programming and Integration Complexity: Programming robots to interact with existing equipment and processes can be complex, requiring expertise in robotics, PLC programming, and system integration.

- Production Line Disruption: Integrating robots can disrupt existing production lines, leading to downtime and reduced output during the transition period. Careful planning and phasing are essential to minimize disruptions.

- Training and Skill Gaps: Workers may need retraining to operate and maintain the new robotic systems. There might also be a shortage of skilled technicians capable of performing the necessary integration and maintenance tasks.

Addressing these challenges often involves a phased approach, starting with a pilot project on a smaller scale before broader implementation. Thorough risk assessments, detailed planning, and strong collaboration between engineering, operations, and maintenance teams are key to a successful integration.

Q 21. Describe different methods for robot vision system calibration.

Robot vision system calibration is essential for accurate object recognition and manipulation. Several methods exist:

- Two-Point Calibration: This involves identifying two known points in the robot’s workspace and the corresponding pixel coordinates in the camera image. A transformation matrix is then calculated to map points from the robot coordinate system to the camera coordinate system. This is a simple method, but its accuracy can be limited.

- Three-Point Calibration (or more): Similar to two-point, but using multiple reference points to increase accuracy and robustness. More points lead to better accuracy, especially when compensating for lens distortion.

- Chessboard Calibration: A common approach using a printed chessboard pattern with known dimensions. The camera captures the chessboard image, and specialized software algorithms (like OpenCV) are used to detect the chessboard corners and compute the camera parameters (intrinsic and extrinsic parameters).

- Calibration Targets: Using specially designed calibration targets with known geometries, the position and orientation of the camera relative to the robot are calculated through precise measurements.

The choice of method depends on the required accuracy, complexity, and available resources. The chessboard method is widely used due to its simplicity and relatively high accuracy. Regardless of the chosen method, regular recalibration is essential due to potential drift or changes in the camera’s position or orientation.

Q 22. Explain the concept of artificial intelligence (AI) in robotics.

AI in robotics involves imbuing robots with the ability to learn, reason, and make decisions, mimicking human intelligence. This isn’t about simply programming a robot with specific instructions; it’s about enabling it to adapt to unforeseen circumstances and solve problems autonomously. Think of it like this: a traditional robot follows a rigid script; an AI-powered robot can improvise within its parameters.

AI algorithms, like machine learning and deep learning, are used to train robots to perform complex tasks. For example, machine learning can allow a robotic arm to learn the optimal way to pick and place objects of varying shapes and sizes by analyzing numerous data points. Deep learning can be used for image recognition, allowing robots to navigate complex environments and identify objects without explicit programming. Computer vision, a crucial aspect, allows robots to “see” and understand their surroundings.

Consider a self-driving car. This is a prime example of AI in robotics. The car uses AI algorithms to interpret sensor data (cameras, lidar, radar), make real-time decisions about navigation (lane keeping, obstacle avoidance), and adapt to changing conditions (traffic, weather). It’s not simply following programmed routes; it’s making intelligent choices based on its perceptions.

Q 23. How do you ensure the reliability and maintainability of robotic systems?

Ensuring reliability and maintainability of robotic systems is paramount. It’s a multi-faceted approach that starts at the design stage and continues throughout the system’s lifecycle. Redundancy is key; having backup systems in place minimizes downtime in case of component failure. This can range from redundant actuators and sensors to multiple communication pathways.

Robust error handling and diagnostics are crucial. The system should be designed to detect and diagnose errors, allowing for corrective actions or graceful degradation. This involves implementing sophisticated monitoring systems that track key parameters and alert operators to potential problems. Predictive maintenance, using data analytics to predict when maintenance is needed before failures occur, is increasingly important for reducing downtime.

Modular design also enhances maintainability. Components should be easily replaceable and interchangeable, minimizing repair time and costs. Standardized interfaces and well-documented software greatly simplify maintenance and troubleshooting. Finally, rigorous testing and validation are critical. Systems should undergo extensive testing to ensure they can withstand various operational conditions and potential failures before deployment.

Q 24. Describe your experience with different types of robotic grippers.

My experience encompasses a wide range of robotic grippers, each tailored to specific tasks and environments. I’ve worked with:

- Parallel Grippers: These are simple and reliable, ideal for handling objects of consistent size and shape. They’re often used in pick-and-place applications in manufacturing.

- Angle Grippers: Useful for gripping objects at an angle, they are versatile and can handle a wider variety of shapes than parallel grippers.

- Vacuum Grippers: Excellent for handling smooth, flat objects, these grippers use suction to lift and hold the workpiece. Their application depends on the surface properties of the object.

- Three-Fingered Grippers: Provide a more adaptable grip than simpler designs, allowing for handling objects of varying shapes and sizes. They require more sophisticated control systems.

- Adaptive Grippers: These are highly sophisticated and utilize sensors and AI to adapt their grip based on the object’s shape and properties. They’re particularly useful in handling unpredictable or fragile items.

The choice of gripper depends entirely on the specific application. For example, in a delicate assembly process, an adaptive gripper might be preferred, while in a high-throughput manufacturing line, a simple parallel gripper may suffice.

Q 25. What are some common challenges in implementing robotic process automation (RPA)?

Implementing Robotic Process Automation (RPA) presents several common challenges:

- Legacy Systems Integration: Integrating RPA with older, less standardized systems can be complex and time-consuming. These systems often lack robust APIs, requiring workarounds.

- Data Extraction and Transformation: Extracting relevant data from various sources and transforming it into a usable format for the RPA bot can be challenging, particularly with inconsistent or poorly structured data.

- Exception Handling: RPA bots need robust exception handling mechanisms to deal with unexpected situations or errors. Improper handling can lead to process failures.

- Scalability and Maintainability: As the number of automated processes grows, scaling and maintaining the RPA infrastructure becomes crucial. This requires careful planning and management.

- Security Concerns: RPA bots interact with sensitive data, necessitating stringent security measures to prevent unauthorized access or data breaches.

- Change Management: Introducing RPA often requires significant organizational change, necessitating careful planning and communication to ensure smooth adoption by employees.

Addressing these challenges often requires a combination of technical expertise, process understanding, and careful planning.

Q 26. Explain your experience with different robot operating systems (ROS, etc.).

My experience with Robot Operating Systems (ROS) is extensive. I’ve used ROS extensively in various projects, leveraging its powerful tools and libraries for robot control, simulation, and data processing. ROS provides a flexible and modular framework for building complex robotic systems.

I’m proficient in using ROS tools like roslaunch for managing multiple nodes, rostopic for publishing and subscribing to topics, and rviz for robot visualization. I have experience with various ROS packages, including those for navigation, perception, and control. I’ve also worked with ROS-Industrial, which provides specialized packages for industrial robotics applications. My work involved creating custom ROS nodes for specific tasks, integrating various sensors and actuators, and developing control algorithms using ROS.

For example, I developed a ROS-based system for autonomous navigation of a mobile robot in a warehouse environment. This involved using sensor data (lidar, cameras) for localization and mapping, path planning algorithms, and control algorithms to navigate the robot around obstacles.

Q 27. Describe your understanding of Industry 4.0 and its impact on robotics and automation.

Industry 4.0, also known as the Fourth Industrial Revolution, is characterized by the increasing integration of cyber-physical systems, the Internet of Things (IoT), and intelligent automation in manufacturing and other industries. This has a profound impact on robotics and automation, leading to significant advancements in several areas.

Increased Connectivity: Robots are becoming increasingly interconnected, allowing for seamless data exchange and collaborative operations. This facilitates real-time monitoring, predictive maintenance, and remote control.

Advanced Analytics: Data from various sources (robots, sensors, machines) is analyzed using advanced analytics techniques to optimize processes, predict failures, and improve overall efficiency.

AI-Powered Robotics: The integration of AI is enabling robots to perform more complex tasks, adapt to changing environments, and collaborate more effectively with humans.

Human-Robot Collaboration: Collaborative robots (cobots) are designed to work safely alongside humans, increasing productivity and improving working conditions.

Digital Twins: Virtual representations of physical systems allow for simulation, testing, and optimization of robotic processes before deployment. This reduces the risk of errors and improves efficiency.

Industry 4.0 is driving the development of more intelligent, adaptable, and collaborative robots, leading to increased automation and productivity across various industries. The integration of these technologies transforms manufacturing, logistics, and other sectors, leading to more efficient, flexible, and resilient operations.

Key Topics to Learn for Your Robotics and Automation Interview

- Robotics Fundamentals: Understand fundamental robotic concepts like kinematics, dynamics, control systems, and sensor integration. Consider the different types of robots and their applications.

- Automation Technologies: Explore Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, and industrial automation networks. Understand their roles in automating industrial processes.

- Programming and Software: Familiarize yourself with robotic programming languages (e.g., ROS, RAPID) and relevant software tools for simulation and control. Be prepared to discuss your experience with specific programming languages.

- Machine Learning and AI in Robotics: Explore how machine learning algorithms are used to enhance robotic perception, decision-making, and control. Understand the integration of AI into automation systems.

- Safety and Risk Assessment: Demonstrate your understanding of safety protocols and risk mitigation strategies within robotic systems and automated environments. This includes both hardware and software safety considerations.

- Practical Applications: Be ready to discuss real-world applications of robotics and automation in various industries, such as manufacturing, logistics, healthcare, and agriculture. Prepare examples showcasing your understanding of the practical challenges and solutions.

- Problem-Solving and Troubleshooting: Practice describing your approach to problem-solving in a robotics context. Be prepared to discuss scenarios where you’ve identified and resolved issues in robotic systems or automation processes.

Next Steps

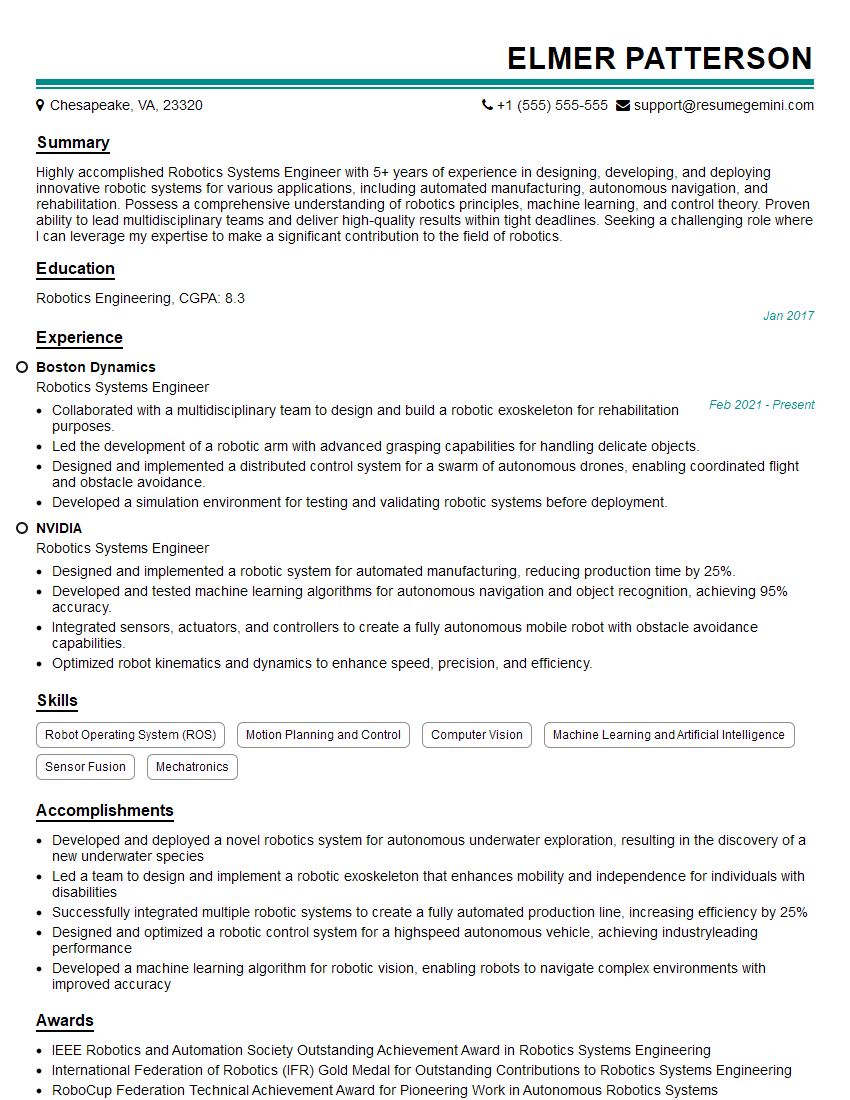

Mastering robotics and automation positions you at the forefront of a rapidly growing and innovative field. This expertise is highly sought after, offering significant career advancement opportunities and competitive salaries. To maximize your chances of securing your dream role, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini can significantly enhance your resume-building experience, helping you create a professional document that effectively highlights your skills and experience. We offer examples of resumes tailored specifically to robotics and automation roles to help you get started. Invest time in crafting a strong resume; it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO