Preparation is the key to success in any interview. In this post, we’ll explore crucial Knowledge of survey equipment calibration and maintenance interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Knowledge of survey equipment calibration and maintenance Interview

Q 1. Explain the process of calibrating a total station.

Calibrating a total station involves a rigorous process to ensure its accuracy in measuring angles and distances. Think of it like tuning a precision instrument – we need to check and adjust its internal workings to match known standards. The process typically begins with a thorough inspection of the instrument for any physical damage or loose components. Next, we perform a series of tests, often using a calibrated target at a known distance.

- Collimation adjustment: This ensures the optical axis of the telescope is perfectly aligned with the rotation axis of the instrument. We achieve this by using a collimator or by observing a distant target at different positions.

- Horizontal and vertical circle indexing: We check the accuracy of the readings on the horizontal and vertical circles. This often involves pointing at known targets and comparing the readings to their known coordinates. Discrepancies are adjusted accordingly.

- Distance measurement calibration: We verify the accuracy of the EDM (Electronic Distance Measurement) system by measuring known distances using calibrated tapes or other precision instruments. Any discrepancies are then adjusted using internal calibration routines.

- Leveling: Accurate leveling is crucial. We use a precise level to ensure the instrument is perfectly level.

The entire calibration process is documented meticulously, recording all measurements and adjustments made. Calibration certificates are then issued, providing a record of the instrument’s accuracy and the date of its last calibration.

Q 2. Describe the different types of errors encountered in surveying equipment and their causes.

Survey equipment can suffer from various errors, broadly categorized as systematic or random. Systematic errors are consistent and repeatable, while random errors are unpredictable and vary in magnitude. Let’s look at some examples:

- Instrumental Errors: These stem from imperfections in the equipment itself. For example, a poorly calibrated level can consistently produce inaccurate readings, while a misaligned total station can cause systematic errors in angle measurements.

- Natural Errors: These are caused by environmental factors. Refraction (bending of light) in the atmosphere affects both optical and EDM measurements, particularly over longer distances. Temperature variations can also significantly impact the accuracy of EDM measurements.

- Personal Errors: These are caused by human mistakes, such as incorrect leveling, faulty readings, or misidentification of targets. These are reduced through careful procedures and teamwork.

- Accidental Errors: These are gross errors caused by things like mistakes in recording data, misreading scales, or even accidental damage to the equipment. They are usually easily spotted during quality control checks.

Understanding the source of these errors is critical for proper data processing and analysis. For instance, we can apply corrections for atmospheric refraction or use statistical methods to mitigate the effects of random errors.

Q 3. How do you ensure the accuracy of GPS measurements?

Ensuring the accuracy of GPS measurements involves several key steps. First, we need to understand that the accuracy isn’t just about the GPS receiver itself; it’s a combination of factors.

- Receiver Quality: Using a high-quality, appropriately configured GPS receiver is paramount. More sophisticated receivers offer improved signal processing and error mitigation techniques.

- Satellite Geometry: The arrangement of satellites in the sky (the geometry) affects the accuracy of the position calculation. We aim for a high PDOP (Position Dilution of Precision) value to minimize the impact of satellite positioning.

- Atmospheric Conditions: Ionospheric and tropospheric delays can significantly affect signal travel time. Differential GPS (DGPS) or Real-Time Kinematic (RTK) GPS techniques use reference stations to correct for these delays, significantly improving accuracy.

- Multipath Errors: Signals can reflect off surfaces like buildings or trees before reaching the receiver, causing errors. Careful site selection and techniques like antenna placement can minimize this.

- Data Post-Processing: After collecting data, post-processing techniques using specialized software can improve accuracy by using more data points and sophisticated corrections.

For instance, when surveying in a dense urban area, RTK GPS is highly preferred due to its ability to achieve centimeter-level accuracy, compensating for the multipath and atmospheric challenges.

Q 4. What are the common maintenance procedures for a leveling instrument?

Maintaining a leveling instrument is crucial for ensuring its accuracy and longevity. It’s like regularly servicing your car – preventing small issues from becoming major problems.

- Cleaning: Regularly cleaning the instrument is fundamental. Dust and debris can affect the accuracy of the level bubble and the optical components. Use a soft cloth and lens cleaning solution.

- Leveling Screws Adjustment: Make sure the leveling screws move smoothly and accurately. Any binding or stiffness should be addressed.

- Bubble Adjustment: The level bubble should be centered properly. Slight adjustments might be needed over time. However, this is a delicate process, and usually requires professional attention if it’s not accurate.

- Optical System Check: Check the clarity of the telescope and ensure there is no dirt or damage to the lenses. This involves visually inspecting the optics and making sure that the image is clear and focused.

- Storage: When not in use, the instrument should be stored in a dry, secure location to protect it from dust, moisture, and accidental damage. The instrument should be stored in its case with the protective caps in place.

Remember, regular, preventative maintenance is far more effective and cost-efficient than dealing with major repairs. It also ensures the continued accuracy of your measurements.

Q 5. What are the safety precautions you should take while working with survey equipment?

Safety is paramount when working with surveying equipment. Here are some key precautions:

- Site Safety: Assess the site before starting any work. Be aware of potential hazards like traffic, uneven terrain, overhead power lines, and other obstacles. Proper signage and safety barriers should be used.

- Equipment Handling: Always handle the equipment carefully to prevent damage. Use proper lifting techniques and avoid dropping or jarring the instruments.

- Personal Protective Equipment (PPE): Use appropriate PPE such as safety glasses, hard hats, and high-visibility clothing, depending on the environment and task.

- Working at Heights: If working at heights, take appropriate safety measures, such as using harnesses and fall protection systems.

- Weather Conditions: Be aware of weather conditions and postpone work if conditions become hazardous (e.g., thunderstorms, heavy rain, extreme temperatures).

- Teamwork and Communication: Always work as a team and communicate clearly to avoid accidents.

A safe working environment is crucial not only for the safety of the surveyors but also for the integrity of the data collected.

Q 6. How often should survey equipment be calibrated?

The frequency of calibration depends on several factors, including the type of equipment, its usage intensity, and the required accuracy. There’s no one-size-fits-all answer.

As a general guideline, total stations and levels might require calibration every 6 to 12 months, or even more frequently if used intensively in challenging conditions. GPS receivers may need calibration less often, perhaps annually, but their performance should be regularly monitored through quality control checks. Calibration is often a requirement for any project requiring a high level of accuracy.

However, it’s crucial to consult the manufacturer’s recommendations for specific equipment and adhere to relevant industry standards. Keeping a meticulous calibration log for all equipment is essential for maintaining quality control and ensuring legal compliance.

Q 7. Describe your experience with different types of survey equipment.

Throughout my career, I’ve had extensive experience with a variety of surveying equipment, including:

- Total Stations: I’m proficient in operating and maintaining various makes and models, from basic to advanced instruments with features like robotic tracking and atmospheric correction.

- Levels: I’m skilled in using both automatic and digital levels, and I’m familiar with different leveling techniques.

- GPS Receivers: My experience ranges from basic single-frequency receivers to more sophisticated RTK systems capable of centimeter-level accuracy. I’m also experienced in post-processing GPS data.

- EDM instruments: I’m skilled in using EDM instruments and understanding their different modes of operation, and applying necessary corrections.

- Traditional Surveying Tools: I also have experience with traditional surveying tools, such as theodolites, levels, tapes, and measuring rods, which is a valuable asset when dealing with equipment failure or in more challenging terrain.

This diverse experience allows me to effectively troubleshoot issues, implement proper calibration procedures, and choose the most appropriate equipment for various surveying tasks, based on project requirements.

Q 8. What software or tools do you use for data analysis and calibration?

Data analysis and calibration in surveying rely heavily on specialized software. For data processing, I commonly use industry-standard packages like Trimble Business Center, Leica GeoMos, or MicroSurvey CAD. These platforms allow me to import raw data from various instruments, perform adjustments, and generate accurate maps and drawings. For calibration itself, the specific software depends on the instrument. Many modern total stations and GNSS receivers have built-in calibration routines and diagnostic tools accessible through their own proprietary software, often loaded onto a data collector. In addition to this, independent calibration software might be used for certain specialized instruments or to cross-check results.

For example, when calibrating a level, I might use a dedicated software to analyze the readings from a series of leveling runs. The software then calculates the instrument’s collimation error and other parameters, providing a detailed calibration report.

Q 9. How do you troubleshoot a malfunctioning total station?

Troubleshooting a malfunctioning total station requires a systematic approach. First, I’d check the obvious: battery levels, proper instrument setup (e.g., tripod stability, correct centering), and clear sightlines. Then, I would move to more advanced diagnostics. This often begins with reviewing the instrument’s error messages. These are usually displayed on the screen. Understanding these error codes is critical. Some common issues include:

- Battery issues: Low battery power can lead to erratic readings or instrument shutdowns. A simple battery change often solves this.

- Internal errors: These often require a factory reset or firmware update, sometimes necessitating contact with the manufacturer’s support.

- Optical or electronic problems: Problems with the internal components may require professional repair. Careful inspection for any signs of physical damage would be necessary.

- Improper EDM (Electro-optical Distance Measurement) alignment: This can result in inaccurate distance measurements and could involve realigning the internal components, a task best left to trained technicians.

A methodical process, using the instrument’s built-in diagnostics and manufacturer’s troubleshooting guide, is essential to correctly identify and resolve the problem.

Q 10. Explain the importance of proper documentation in equipment calibration and maintenance.

Proper documentation is paramount in survey equipment calibration and maintenance for several reasons. First, it ensures traceability – a detailed record allows us to track the equipment’s history, from purchase to disposal, including all calibrations and repairs. This is essential for quality control and to comply with industry standards and legal requirements. Second, comprehensive documentation helps identify trends or patterns in equipment performance, allowing for preventative maintenance. For example, consistent adjustments for the same error in a total station might indicate an underlying mechanical issue. Finally, proper records streamline troubleshooting. When a problem arises, having a detailed history makes it easier to diagnose and resolve.

Imagine a situation where a survey is challenged legally. Accurate, well-maintained calibration records serve as irrefutable proof of the equipment’s accuracy and reliability at the time of the survey, protecting against potential disputes and ensuring project success.

Q 11. How do you handle discrepancies in calibration results?

Discrepancies in calibration results require careful investigation. First, I would review my procedures to ensure they were followed meticulously. This includes verifying the instrument’s setup, environmental conditions, and data recording. Then, I would repeat the calibration process, ideally under the same conditions, to see if the discrepancies are consistent. If the discrepancies persist, I’d look for possible sources of error: were there any environmental influences (temperature, humidity, atmospheric pressure) significantly affecting the readings? Were there any external factors that might impact the accuracy?

If the error is within the instrument’s allowable tolerance, it might not require immediate action. However, if the error exceeds the tolerance, the instrument may require repair or adjustment by a qualified technician. Any discrepancies and subsequent actions must be meticulously documented.

Q 12. What are the key performance indicators (KPIs) for survey equipment maintenance?

Key Performance Indicators (KPIs) for survey equipment maintenance focus on ensuring accuracy, reliability, and longevity. These include:

- Calibration interval adherence: Maintaining regular calibration schedules, as recommended by the manufacturer.

- Mean error: Tracking the average error in measurements over time, indicating the overall accuracy.

- Downtime: Minimizing the time equipment is out of service for repairs or maintenance.

- Repair costs: Monitoring the cost of repairs over time, potentially helping to optimize preventative maintenance strategies.

- Equipment lifespan: Extending the operational life of the equipment through diligent maintenance.

By regularly monitoring these KPIs, we can identify potential problems early and implement preventative measures to improve efficiency and data quality.

Q 13. Describe your experience with different calibration methods.

My experience encompasses various calibration methods, both in the field and in controlled environments. For total stations, this involves using established procedures to check and adjust parameters like collimation, zenith index, and EDM (Electro-optical Distance Measurement) constants. These methods often involve precise leveling and referencing to known points using high-precision leveling instruments and/or GPS base stations. GNSS (Global Navigation Satellite System) receivers are calibrated using base stations to determine precise coordinates and assess the integrity of the signal. Leveling instruments are calibrated by measuring a series of known distances, allowing for the calculation of collimation errors. Each instrument has specific calibration procedures outlined by the manufacturer and adhering to these is crucial for accurate results.

For example, calibrating a total station might involve using a precisely measured baseline to assess the EDM’s accuracy, and employing a collimation test to identify and correct any errors in the vertical axis alignment.

Q 14. How do environmental factors affect the accuracy of survey equipment?

Environmental factors significantly impact survey equipment accuracy. Temperature variations affect the instrument’s internal components, potentially causing dimensional changes and leading to inaccurate measurements. Extreme temperatures can also damage sensitive electronic components. Humidity can impact EDM performance, particularly in the case of water vapor absorption. Atmospheric pressure affects the speed of light, influencing the accuracy of EDM measurements. Strong winds can affect the stability of the instrument, leading to inaccurate readings, especially with long-range measurements. Sunlight can create glare, affecting the precision of optical instruments.

For instance, high temperatures can cause the measuring tape to expand slightly, leading to errors in measured distances. Similarly, extreme humidity can affect the refraction of light, thereby influencing the accuracy of total stations.

Mitigation strategies involve using instruments with temperature compensation features, shielding instruments from direct sunlight, and making measurements during periods of minimal wind and humidity.

Q 15. Explain your understanding of error propagation in surveying.

Error propagation in surveying refers to how uncertainties in individual measurements accumulate and affect the accuracy of final survey results. Imagine you’re measuring the sides of a triangle to calculate its area. A small error in measuring just one side will lead to a larger error in the calculated area. This is error propagation. It’s crucial because even small individual measurement errors can significantly impact the overall precision of a survey, leading to potentially costly mistakes in construction or land management.

We use statistical methods to quantify and manage error propagation. For instance, if we’re using the Pythagorean theorem (a² + b² = c²) to calculate the hypotenuse (c) of a right-angled triangle, small errors in measuring ‘a’ and ‘b’ will propagate into an error in ‘c’. The magnitude of the propagated error depends on the specific formula used and the uncertainties associated with each individual measurement. We often express these uncertainties as standard deviations, and sophisticated error propagation calculations using partial derivatives help to estimate the overall uncertainty in our final results.

In practice, we carefully select equipment with high accuracy, employ precise measurement techniques, and rigorously document all measurements and their associated uncertainties. This allows us to understand and control error propagation, producing more reliable survey data.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine when a piece of equipment needs repair versus calibration?

Differentiating between equipment repair and calibration requires careful assessment. Calibration addresses systematic errors, those consistent biases in measurements. Repair, on the other hand, tackles malfunctioning components or physical damage. Think of it like this: calibration is like tuning a piano – adjusting the notes to ensure they are accurate. Repair is like fixing a broken string – addressing a physical defect.

Here’s a decision-making framework:

- Check for systematic errors: If measurements consistently deviate from expected values even after repeated checks, calibration is likely necessary. For example, if a total station consistently reads distances slightly shorter than the true values, a calibration is needed.

- Assess physical damage: Look for obvious signs of damage such as cracks, dents, or loose components. If you find these, repair is needed. This could be a broken prism on a level staff or a damaged display on a GPS receiver.

- Perform a diagnostic test: Some equipment has built-in diagnostic routines that can highlight problems. These tests can point to the need for either repair or calibration.

- Compare measurements to known standards: If possible, compare your equipment’s measurements against known standards or values, this can help identify the problem.

If you’re unsure, always err on the side of caution and consult the equipment’s manual or contact a qualified technician. Incorrect calibration can be just as problematic as a malfunctioning instrument.

Q 17. What are the different types of calibration standards used in surveying?

Calibration standards in surveying ensure our equipment accurately measures distances, angles, and elevations. They can range from simple physical objects to sophisticated electronic systems. Different standards are appropriate for different instruments and applications.

- National standards: These are highly precise reference standards maintained by national metrology institutes (like NIST in the US). They provide the ultimate traceability for calibrations.

- Manufacturer’s standards: Equipment manufacturers usually supply their own standards for routine calibration checks. These standards are often less precise than national standards but are sufficient for day-to-day field operations.

- Certified reference materials (CRMs): These are materials with certified values for specific properties (e.g., length standards for measuring tapes). They are commercially available and provide traceability to national standards.

- In-situ calibration: Some instruments can be calibrated using known points in the field. This is often used for GPS receivers and involves comparing measurements with established control points.

The choice of calibration standard depends on the precision required for a given project. Higher precision projects necessitate using standards traceable to national standards, while less stringent projects might utilize manufacturer’s standards.

Q 18. How do you manage and organize calibration records?

Managing calibration records is vital for maintaining compliance, ensuring data quality, and improving operational efficiency. A well-organized system is key.

Our firm uses a dedicated software system to manage all calibration records. This system tracks:

- Equipment details: Serial number, make, model, and purchase date.

- Calibration history: Dates of calibration, calibration results (including tolerances and uncertainties), and the name of the calibrating technician.

- Calibration certificates: Digital copies of certificates are stored and easily accessible.

- Repair history: Records of any repairs, including dates, descriptions of repairs, and supporting documentation.

- Due dates: Automated reminders alert us of upcoming calibration deadlines.

The system also provides reports for audits and allows for easy searching and retrieval of information. We maintain a strict policy of documenting everything – this minimizes errors and strengthens our compliance with all relevant regulations.

Q 19. How do you stay up-to-date with the latest advancements in survey equipment technology?

Staying current in survey equipment technology is critical for competitiveness and accuracy. I actively pursue this through several methods:

- Professional organizations: Membership in organizations like the American Congress on Surveying and Mapping (ACSM) provides access to journals, conferences, and networking opportunities.

- Industry publications and websites: I regularly read industry publications and websites to stay informed on new developments and technological advancements.

- Manufacturer websites and training: I take advantage of training courses and webinars provided by manufacturers of surveying equipment.

- Conferences and workshops: Attending industry conferences allows me to learn firsthand about the latest technology and network with other professionals.

- Online courses and webinars: Many reputable institutions offer online courses related to surveying technologies. This allows me to learn at my own pace and on demand.

By actively pursuing these methods, I am equipped with the knowledge to select, operate, and maintain the most up-to-date and efficient equipment for various survey projects.

Q 20. Describe a time you had to troubleshoot a complex equipment issue.

During a large-scale construction project, our robotic total station unexpectedly started exhibiting erratic angle readings. Initial checks revealed no obvious physical damage. We systematically troubleshooted by following these steps:

- Verify basic settings: We confirmed the correct units, coordinate systems, and prism constants were set.

- Check alignment: We ensured the instrument was properly leveled and oriented.

- Environmental factors: We considered potential interferences from nearby structures or electromagnetic fields.

- Internal diagnostics: We ran the instrument’s built-in diagnostic routines, which indicated a possible problem with the internal angle encoder.

- Contact manufacturer support: Since internal diagnostics pointed to a potential hardware failure, we contacted the manufacturer’s support team. They guided us through further tests and ultimately determined that the encoder needed replacement.

The prompt diagnosis and efficient support from the manufacturer minimized project downtime. This experience underscored the importance of thorough troubleshooting, relying on diagnostic tools, and collaborating with the manufacturer’s support team for complex issues.

Q 21. What are the legal and regulatory requirements related to survey equipment calibration?

Legal and regulatory requirements for survey equipment calibration vary depending on location and the type of survey work being performed. However, several common themes prevail:

- Accuracy standards: Many jurisdictions have established accuracy standards for surveys used in legal or official capacity (e.g., property boundary surveys). Meeting these standards necessitates using properly calibrated equipment.

- Calibration certificates: Often, survey plans must include calibration certificates verifying the accuracy of the equipment used.

- Maintenance logs: Keeping detailed records of equipment maintenance and calibration is usually required. These records may be subject to audits.

- Licensing and qualifications: Surveyors are often required to hold licenses or certifications, which may include specific requirements for equipment calibration and maintenance.

- Liability: Inaccurate surveys can lead to legal liability, making properly calibrated and maintained equipment a crucial aspect of risk management.

It is essential to understand and comply with all relevant local, state, and national regulations regarding survey equipment calibration and maintenance to ensure legal compliance and project accuracy. Consulting with relevant authorities or professional organizations provides guidance on specific requirements.

Q 22. How do you prioritize maintenance tasks based on equipment criticality?

Prioritizing maintenance tasks hinges on understanding the criticality of each piece of survey equipment. We use a risk-based approach. Equipment crucial for high-precision work, like a total station used for land surveying for a major construction project, receives top priority. Less critical equipment, such as a hand-held GPS used for preliminary site reconnaissance, receives lower priority but still requires regular attention.

We typically use a matrix system that factors in:

- Frequency of use: Heavily used equipment requires more frequent maintenance.

- Cost of failure: A failure in a high-precision level could cost thousands in project delays, compared to a less precise tool.

- Safety implications: Faulty equipment can lead to accidents, so safety-critical instruments have top priority.

This system allows us to schedule maintenance proactively, preventing costly downtime and ensuring accuracy.

Q 23. Explain the difference between internal and external calibration.

Internal calibration involves adjusting the instrument’s internal settings to ensure it’s functioning within its specified tolerances. It’s typically performed in-house using built-in self-diagnostic tools or reference standards. Think of it as a ‘tune-up’ – addressing minor drift or inconsistencies.

External calibration, on the other hand, compares the instrument’s readings to known, traceable standards external to the instrument itself. This typically involves sending the equipment to a specialized calibration laboratory that is accredited to specific standards. It provides a far more rigorous assessment and verification of accuracy, generating a formal calibration certificate.

Imagine a car’s speedometer. Internal calibration might be adjusting the sensor slightly to make it align better with the internal calculations, while external calibration involves comparing the speedometer’s readings against a precisely measured speed on a test track. The external calibration provides a far more reliable assessment of the speedometer’s accuracy.

Q 24. What is your experience with different types of electronic levels?

My experience encompasses a range of electronic levels, from basic digital levels to sophisticated automatic levels with advanced features. I’m proficient with:

- Digital Levels: These offer enhanced precision and data recording capabilities compared to traditional optical levels. I’ve used them extensively for setting out building foundations and road construction.

- Automatic Levels: These levels automatically compensate for minor tilts, increasing efficiency. I’ve used these extensively on large-scale infrastructure projects where speed and precision are essential.

- Laser Levels: These project a laser beam for leveling and alignment tasks, particularly useful for applications requiring long-range leveling such as setting out pipelines or long building structures. I’m comfortable with their safety precautions.

- Rotating Laser Levels: These provide a rotating laser beam useful for controlling grade on large projects, especially in earthmoving or construction.

I am familiar with the strengths and limitations of each type and select the appropriate instrument based on project requirements and environmental conditions.

Q 25. How do you ensure the security and integrity of survey data?

Data security and integrity are paramount. We implement a multi-layered approach:

- Data backups: Regular backups of survey data are stored in multiple secure locations, both on-site and off-site, using cloud storage and external hard drives.

- Access control: Strict access control procedures restrict data access to authorized personnel only. We use password-protected files and encrypted drives.

- Data validation: We implement rigorous data validation procedures to detect and correct errors. This often involves multiple checks and cross-referencing data from different sources.

- Chain of custody: A clear chain of custody documents the handling of data from acquisition to archiving. This ensures the data’s authenticity and prevents tampering.

- Metadata management: Detailed metadata is attached to each dataset, recording information like date, time, location, instrument used and personnel involved.

By combining these measures, we ensure the confidentiality, integrity, and availability of our survey data.

Q 26. Describe your experience with preventative maintenance programs.

My experience with preventative maintenance programs involves developing and implementing schedules for routine inspections and servicing of survey equipment. This goes beyond simply reacting to equipment failures. We follow manufacturer’s recommendations, but tailor the frequency to the specific usage patterns of each instrument.

Our preventative maintenance program includes:

- Regular cleaning and inspection: Inspecting equipment for physical damage, loose connections, and signs of wear and tear.

- Calibration checks: Regularly checking the calibration status of instruments and performing internal calibration checks as necessary.

- Software updates: Ensuring that the software on all electronic instruments is updated to the latest version.

- Component replacement: Proactive replacement of parts nearing end-of-life, to minimize unexpected downtime.

- Detailed record keeping: Maintaining a comprehensive log of all maintenance activities, including dates, personnel, and any issues found.

This structured approach extends the lifespan of our equipment, reduces downtime, and most importantly, ensures the accuracy of our survey data.

Q 27. What are some common causes of inaccurate readings from a total station?

Inaccurate readings from a total station can stem from several sources:

- Instrument miscalibration: The most common cause. Regular calibration is crucial to maintaining accuracy.

- Improper setup: Incorrect leveling or centering of the instrument can lead to significant errors.

- Atmospheric conditions: Temperature fluctuations, high humidity, and refraction can affect the accuracy of the readings.

- Poor target quality: Using damaged or unsuitable targets can lead to inaccurate measurements.

- Reflector prism constant: Incorrect prism constant inputs into the total station’s software can affect measurements.

- Obstacle interference: Obstacles between the total station and the prism can interrupt the signal.

- Internal instrument errors: Malfunctioning components within the instrument itself can cause inaccurate readings.

Troubleshooting involves systematically checking each of these aspects before concluding instrument malfunction.

Q 28. How do you verify the accuracy of a newly calibrated instrument?

Verifying the accuracy of a newly calibrated instrument involves performing a series of checks using known control points and comparing the instrument readings against the known values. This involves setting up the instrument at a known point and measuring distances and angles to other known points.

The process includes:

- Independent checks: Using multiple independent methods or instruments to verify the results.

- Comparison against standards: Comparing the measured values against the known values to assess the accuracy.

- Residual analysis: Analyzing the differences (residuals) between measured and known values to identify potential systematic errors.

- Redundant measurements: Taking multiple measurements to improve accuracy and detect gross errors.

- Reference points: Using well-established and accurately surveyed reference points for verification.

Any significant discrepancies highlight potential issues and may require further investigation or recalibration. We document all verification procedures and results meticulously.

Key Topics to Learn for Knowledge of Survey Equipment Calibration and Maintenance Interview

- Understanding Calibration Principles: Grasp the fundamental concepts of accuracy, precision, and error in surveying instruments. Learn about different calibration methods and their applications.

- Equipment Specifics: Develop a strong understanding of the calibration procedures for various survey equipment, including total stations, GPS receivers, levels, and theodolites. This includes knowing the tools and techniques involved.

- Maintenance Procedures: Familiarize yourself with routine maintenance tasks, troubleshooting common malfunctions, and recognizing when professional repair is necessary. Understand the importance of preventative maintenance.

- Calibration Standards and Documentation: Learn about relevant industry standards and best practices for calibration and documentation. Understand the importance of accurate record-keeping.

- Data Analysis and Error Detection: Know how to analyze calibration data to identify potential errors and biases. Understand how to interpret calibration reports and make adjustments as needed.

- Safety Procedures: Understand and adhere to all relevant safety regulations and procedures when handling and maintaining survey equipment. This includes appropriate handling, storage, and personal protective equipment.

- Impact of Environmental Factors: Recognize how environmental conditions (temperature, humidity, etc.) can affect the accuracy of survey equipment and the importance of compensating for these factors.

- Troubleshooting and Problem-solving: Develop your ability to diagnose and resolve common problems encountered during the calibration and maintenance of surveying equipment. Practice using a methodical approach to troubleshooting.

Next Steps

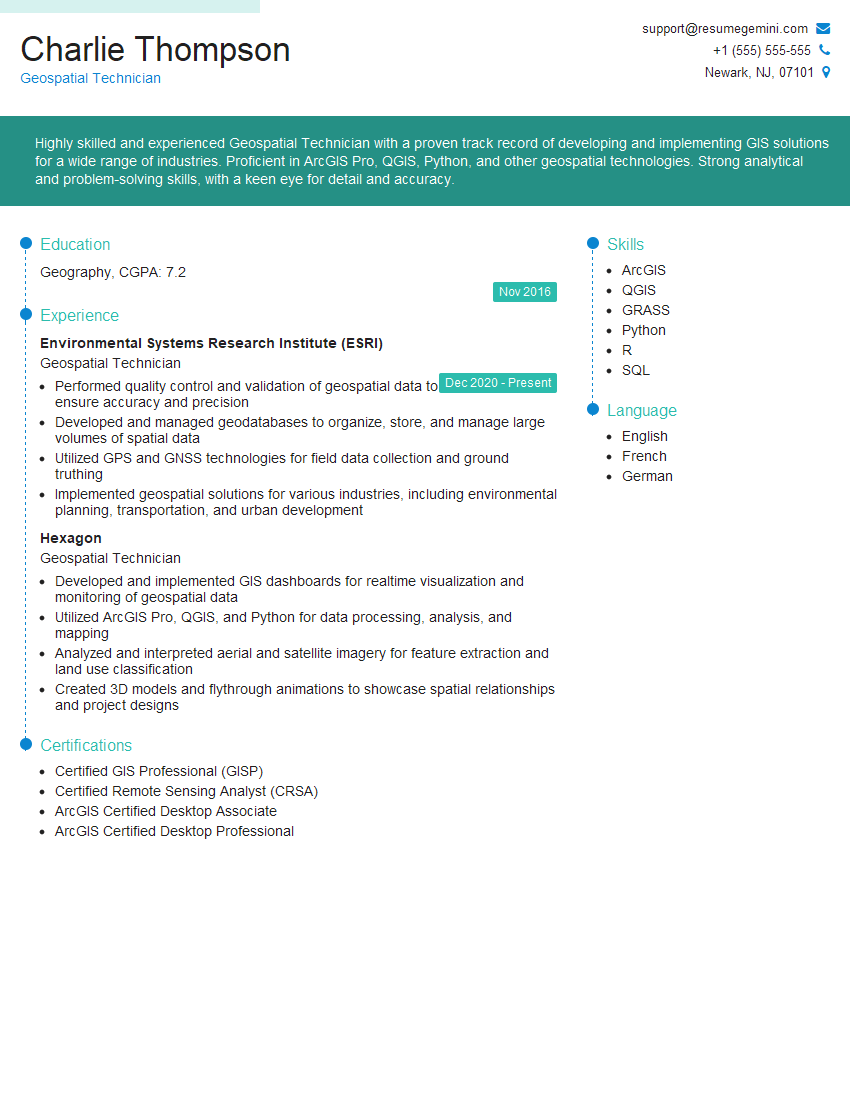

Mastering knowledge of survey equipment calibration and maintenance is crucial for career advancement in the surveying field. It demonstrates a commitment to accuracy, precision, and safety, opening doors to more challenging and rewarding roles. To significantly improve your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you craft a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to showcasing expertise in survey equipment calibration and maintenance are available through ResumeGemini, assisting you in presenting your qualifications compellingly to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO