The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Knowledge of Welding Techniques interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Knowledge of Welding Techniques Interview

Q 1. Explain the difference between MIG and TIG welding.

MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding are both arc welding processes using shielding gases to protect the weld from atmospheric contamination, but they differ significantly in their techniques and applications.

MIG Welding: Uses a consumable electrode (wire) that feeds continuously into the weld pool, acting as both the electrode and filler material. The wire melts and fuses with the base metal, creating the weld. It’s generally faster and easier to learn than TIG, making it suitable for mass production and less intricate work. Think of it like using a hot glue gun – continuous flow, relatively quick.

TIG Welding: Employs a non-consumable tungsten electrode to create the arc. Filler material is added separately by the welder. This offers much greater control and precision, allowing for cleaner welds on thinner materials and more intricate designs. Imagine it as using a tiny, precise flame to carefully join two pieces – slow and steady wins the race.

In short: MIG is faster and easier for larger projects, while TIG provides superior control and quality for more delicate work. The choice depends heavily on the material, thickness, and required weld quality.

Q 2. Describe the various types of welding joints.

Welding joints are classified by the way the base materials are positioned relative to each other. Common types include:

- Butt Joint: The edges of two pieces are butted together, creating a simple, straight weld. Think of joining two pieces of lumber end-to-end.

- Lap Joint: One piece overlaps the other, with the weld joining the overlapping surfaces. This is common for joining sheets of metal.

- T-Joint: One piece is perpendicular to another, forming a ‘T’ shape. This is used extensively in structural welding.

- Corner Joint: Two pieces are joined at a 90-degree angle. Think of the corner of a picture frame.

- Edge Joint: The edges of two pieces are aligned and welded along their edges. This is suitable for joining thin sheets.

- J-Joint and U-Joint: Variations providing greater weld surface area for thicker materials and improved weld strength.

The choice of joint depends on factors like material thickness, access, strength requirements, and the overall design of the component.

Q 3. What are the safety precautions you must take while welding?

Welding presents several significant hazards. Safety precautions are paramount:

- Eye and Face Protection: Always wear a welding helmet with appropriate shade lenses to protect against intense UV radiation and flying sparks.

- Respiratory Protection: Welding fumes can be toxic. Use a respirator or work in a well-ventilated area. Specific respirators are needed depending on the metals being welded.

- Clothing and Skin Protection: Wear flame-resistant clothing, gloves, and footwear to protect from burns and sparks. Welding spatter can be extremely hot.

- Fire Prevention: Keep flammable materials well away from the welding area. Have a fire extinguisher readily available.

- Electrocution Prevention: Ensure proper grounding and insulation of equipment. Be careful when working with wet conditions.

- Proper Ventilation: Welding generates fumes; make sure the area has adequate ventilation to remove these fumes.

- Handling of Cylinders: Always secure gas cylinders and follow safety regulations regarding handling and transport of compressed gases.

Furthermore, it’s crucial to receive proper training and adhere to all safety guidelines and regulations. Ignoring these precautions can result in serious injuries, including burns, eye damage, and respiratory problems.

Q 4. How do you identify different types of weld defects?

Weld defects can significantly compromise the strength and integrity of a weld. Identification often involves visual inspection, but sometimes requires more advanced techniques like radiography or ultrasonic testing.

- Porosity: Small holes or voids in the weld metal, often caused by gas entrapment during welding.

- Cracks: Fractures in the weld metal, caused by stress or improper welding techniques. These can be surface or internal.

- Incomplete Fusion: The weld metal does not properly fuse with the base metal, resulting in a weak joint.

- Undercut: A groove melted into the base metal adjacent to the weld, weakening the joint.

- Overlap: Weld metal extending beyond the edge of the joint.

- Slag Inclusions: Pieces of slag (waste material) trapped within the weld.

- Lack of Penetration: The weld does not penetrate to the required depth.

Visual inspection often utilizes magnification and proper lighting. Advanced techniques help reveal internal defects. Proper identification is critical for addressing the root cause and preventing future defects.

Q 5. What is the significance of preheating and post-heating in welding?

Preheating and post-heating are crucial for managing thermal stresses and improving weld quality, especially in thicker materials or those prone to cracking.

Preheating: Reducing the thermal gradient between the weld and the surrounding base metal. This helps to avoid rapid cooling which can induce cracking, especially in high carbon steel or other brittle materials. It’s like slowly warming up a cold engine to prevent damage during startup.

Post-heating: Helps to relieve residual stresses created during welding, also minimizing the risk of cracking and improving the overall microstructure and toughness of the weld. It’s like slowly cooling down the engine after a long drive to prevent excessive stress on parts.

The specific preheating and post-heating temperatures depend on the material being welded and the thickness of the joint. These temperatures are determined from the weld procedure specifications (WPS).

Q 6. Explain the concept of weld penetration and its importance.

Weld penetration refers to the depth to which the weld metal penetrates into the base metal. It is a crucial indicator of weld quality and strength.

Importance: Insufficient penetration results in a weak joint prone to failure. Excessive penetration can lead to burn-through and compromise the joint’s structural integrity. Proper penetration ensures complete fusion and creates a strong, reliable weld.

Achieving proper penetration depends on factors like welding parameters (current, voltage, travel speed), electrode type and size, and joint design. Visual inspection and potentially advanced testing (like radiography) can verify proper penetration.

Q 7. Describe the different types of filler metals used in welding.

Filler metals are essential in welding, adding material to fill the gap between the base metals and create a complete joint. The choice depends on the base metal and the desired properties of the weld.

- Steel Filler Metals: Widely used for steel welding, varying in carbon content to match the base metal. Low carbon steel fillers are commonly used for mild steels.

- Stainless Steel Filler Metals: Used for welding stainless steel, maintaining the corrosion resistance of the base metal.

- Aluminum Filler Metals: Used for aluminum welding, requiring specialized techniques due to aluminum’s high thermal conductivity and reactivity with oxygen.

- Nickel-based Filler Metals: Used for high-temperature applications or where corrosion resistance is critical.

- Copper Filler Metals: Used for joining copper and copper alloys.

Filler metals are classified by their chemical composition and mechanical properties. Choosing the right filler metal is crucial to achieving a strong, durable, and reliable weld.

Q 8. What are the common causes of weld porosity?

Weld porosity, the presence of small holes or voids within a weld, is a significant defect that compromises the strength and integrity of the weld. It’s like having tiny air bubbles trapped in a cake – it weakens the structure. Several factors contribute to this issue:

- Gas entrapment: Moisture in the base material, filler metal, or shielding gas can vaporize during welding, creating gas pockets that become trapped in the solidifying weld pool. Think of it like trying to bake a cake with wet ingredients – steam will form and create holes.

- Hydrogen embrittlement: Hydrogen from sources like moisture or oil contamination can dissolve in the molten weld metal and then be released during cooling, forming small pores. This is a serious concern, particularly in high-strength steels.

- Insufficient penetration: Improper welding parameters or poor joint design can lead to incomplete fusion, creating areas where gas can become trapped. Imagine trying to weld two pieces of metal together without properly melting them; gaps will remain.

- Arc blow: This electromagnetic force can cause turbulence in the weld pool, preventing the escape of gas and leading to porosity. It’s like stirring a pot too vigorously – you incorporate air.

- Contamination: Oxides, rust, paint, or other surface contaminants on the base material can also cause porosity. It’s crucial to have a clean surface before welding, just like preparing a clean baking surface.

Preventing porosity requires meticulous attention to cleanliness, proper welding technique, and appropriate parameters. Regular inspections are key to identifying and rectifying any issues.

Q 9. How do you select the appropriate welding process for a given material and application?

Selecting the right welding process depends on a number of factors, including material type, thickness, joint design, required weld quality, and the overall project constraints. It’s like choosing the right tool for a job – a screwdriver isn’t suitable for hammering a nail.

- Material: Stainless steel might require GMAW (Gas Metal Arc Welding) with a specialized filler wire and shielding gas, while mild steel can be readily welded with SMAW (Shielded Metal Arc Welding) or even MIG.

- Thickness: Thin materials may benefit from TIG (Gas Tungsten Arc Welding) for precise control, whereas thick sections might need a more powerful process like SAW (Submerged Arc Welding).

- Joint design: A butt joint might require different parameters than a fillet weld. The geometry dictates the penetration and weld bead shape.

- Weld quality: High-quality applications demand processes that offer superior control, such as TIG, while others may accept the higher deposition rate of GMAW or SAW.

- Cost and accessibility: Some processes are more expensive or require specialized equipment. SMAW is generally more portable and accessible than SAW.

Welding procedure specifications (WPS) often outline the correct process, parameters, and procedures for specific applications. It’s essential to consult these documents or qualified welding engineers to ensure the optimal choice.

Q 10. What is the difference between destructive and non-destructive testing methods in welding?

Destructive and non-destructive testing (NDT) methods serve different purposes in assessing weld quality. Destructive testing, as the name suggests, involves damaging the weld to evaluate its properties, while NDT methods allow for inspection without destroying the weld. Think of it like diagnosing a car: You can tear the engine apart to see what’s wrong, or you can use less invasive diagnostic tools.

- Destructive Testing (DT): This involves techniques like tensile testing (measuring strength), bend testing (evaluating ductility), hardness testing (determining resistance to indentation), and macro/micrographic examination (analyzing weld microstructure). DT gives precise quantitative data but consumes the tested sample.

- Non-Destructive Testing (NDT): This involves techniques like visual inspection, radiographic testing (X-ray or gamma ray inspection), ultrasonic testing (using sound waves), magnetic particle testing (detecting surface cracks in ferromagnetic materials), and dye penetrant testing (detecting surface cracks in any material). NDT allows for inspection of the entire weld, ensuring its integrity without compromising it.

Both DT and NDT are often used together to provide a comprehensive assessment of weld quality. DT provides quantitative data on specific weld properties, while NDT provides a broader picture of the overall integrity and detection of flaws.

Q 11. Explain the importance of proper electrode selection in stick welding.

Proper electrode selection in Stick welding (SMAW) is crucial for achieving a high-quality weld. The electrode acts as both the filler material and the current conductor. Choosing the wrong electrode is like trying to use the wrong type of paint for a surface – it won’t adhere properly and the result won’t be as intended.

- Base metal compatibility: The electrode must be compatible with the base metal being welded. Welding stainless steel requires a stainless steel electrode; using a mild steel electrode would lead to defects and poor weld properties.

- Welding position: Electrodes are designed for various welding positions (flat, vertical, overhead). An electrode designed for flat welding might struggle in an overhead position.

- Current type: Electrodes can be designed for AC or DC current, affecting the penetration and arc stability. The wrong choice will affect the weld bead profile and might even lead to poor weld quality.

- Weld strength and toughness requirements: Electrode coatings contain various alloying elements that influence the weld metal’s mechanical properties. Choosing an electrode with the correct properties is essential to meet the project requirements.

Electrode selection involves careful consideration of the base metal type, thickness, required weld strength, welding position, and available power source. Always consult the electrode’s specifications and manufacturers’ recommendations.

Q 12. Describe the principle of Gas Metal Arc Welding (GMAW).

Gas Metal Arc Welding (GMAW), also known as MIG welding, utilizes a continuous consumable electrode wire fed into the weld pool, using an electric arc to melt the base metal and the wire. The process is protected from atmospheric contamination by a shielding gas. This is a very efficient process and a great analogy would be a hot glue gun – it feeds continuously, melting the glue to make a bond.

The process involves:

- A constant voltage power source supplies the electrical current needed to create an arc between the wire and the work-piece.

- The shielding gas protects the weld pool from oxidation and contamination, ensuring the quality of the weld.

- The consumable wire melts, joining with the base metal to form the weld bead.

- The arc is typically short and relatively easy to control, making it well suited for higher deposition rates.

GMAW is versatile and widely used in various applications due to its high deposition rate, ease of operation, and relatively good weld quality. Factors like wire feed speed, voltage, and gas flow rate must be carefully controlled to achieve the desired weld characteristics.

Q 13. What are the benefits and limitations of using different shielding gases in welding?

Shielding gases play a critical role in GMAW and other arc welding processes by protecting the weld pool from atmospheric contamination which leads to poor welds. The choice of shielding gas influences the weld quality, appearance, and mechanical properties. Think of it as creating a protective blanket around the weld to prevent it from reacting with the air.

- Argon (Ar): Commonly used for welding aluminum and stainless steel. It provides excellent arc stability and penetration but can be relatively expensive.

- Carbon Dioxide (CO2): A cost-effective option for mild steel welding. It offers good penetration but can produce more spatter and a less aesthetically pleasing weld bead than Argon.

- Mixtures (e.g., Argon/CO2, Argon/Oxygen): These mixtures combine the benefits of individual gases. For example, adding CO2 to Argon improves penetration while maintaining good arc stability.

Benefits:

- Improved weld quality and appearance.

- Increased penetration and deposition rates.

- Protection from atmospheric contamination (oxidation and porosity).

Limitations:

- Cost: Some gases are more expensive than others.

- Weld properties: The choice of gas influences the mechanical properties of the weld.

- Availability: Access to specific shielding gases might be limited depending on location.

Selecting the right shielding gas depends on the material being welded, the welding process, and the desired weld properties. Consult welding procedure specifications for guidance.

Q 14. How do you determine the correct amperage and voltage settings for a specific welding process?

Determining the correct amperage and voltage settings is critical for achieving a good weld in any arc welding process. These settings influence factors such as arc stability, penetration, weld bead shape, and overall weld quality. Getting it wrong is like trying to bake a cake with the oven at the wrong temperature – the result will be unsatisfactory.

The optimal settings depend on several factors:

- Welding process: Different processes (GMAW, SMAW, GTAW) have different voltage and amperage requirements.

- Base metal: The type and thickness of the base metal significantly impact the required parameters. Thicker materials typically need higher amperage for adequate penetration.

- Filler material (if applicable): The type and diameter of the filler material can influence the current requirements.

- Joint design: Joint geometry affects the required penetration depth, and thus the amperage.

- Welding position: Overhead welding often needs lower amperage to prevent weld metal from dripping.

Determining the settings often involves:

- Consulting welding procedure specifications (WPS).

- Referring to manufacturer’s recommendations for equipment and consumables.

- Using experience and trial and error (always starting with a lower setting and gradually increasing as needed).

- Monitoring the weld bead appearance and quality – proper penetration, lack of burn-through, and a consistent bead profile are indicators of the correct settings.

Always prioritize safety and follow recommended procedures. If uncertain, it’s best to seek guidance from experienced welders or engineers.

Q 15. Explain the concept of weld shrinkage and how to minimize it.

Weld shrinkage is the reduction in length that occurs in a weld as the molten metal cools and solidifies. Imagine a metal bar being heated – it expands; conversely, as it cools, it contracts. This contraction, however, is not uniform across the entire piece due to the heat concentration in the weld area. This non-uniform contraction leads to distortion and residual stresses within the weldment.

Minimizing weld shrinkage involves several strategies:

- Preheating: Heating the base metal before welding reduces the temperature differential between the weld and the base metal during cooling, lessening the shrinkage. This is especially vital for thicker sections or materials susceptible to cracking.

- Intermittent Welding: Welding in short segments, allowing each segment to cool partially before proceeding, prevents excessive shrinkage buildup in one localized area. Think of it like taking short steps instead of one giant leap to reduce the chance of falling.

- Proper Joint Design: Selecting a joint design that minimizes the length of weld required is crucial. A properly designed joint minimizes material addition and hence reduces the potential for shrinkage.

- Tack Welding: Using multiple tack welds to secure the pieces before final welding reduces warping and distortion during the main welding operation.

- Post-Weld Heat Treatment (PWHT): In some cases, this process helps to relieve residual stresses and minimize distortion introduced by shrinkage. It’s like a relaxing massage for the weldment after strenuous activity.

- Using Fixturing: Rigidity provided by clamps, jigs, and fixtures during the welding process helps prevent distortion caused by shrinkage.

For example, in constructing a large steel structure, preheating the base metal and using intermittent welding techniques with proper fixturing are essential to manage weld shrinkage and ensure dimensional accuracy.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of welding equipment.

Throughout my career, I’ve gained extensive experience with a wide range of welding equipment, from basic stick welders to advanced robotic systems. My experience includes:

- Shielded Metal Arc Welding (SMAW): Also known as stick welding, this is a versatile process I’ve used extensively in various applications, from structural steel fabrication to repair work. I’m proficient in selecting appropriate electrodes for different base metals and applications.

- Gas Metal Arc Welding (GMAW): Often called MIG welding, this process offers higher deposition rates and smoother welds. My experience includes using different shielding gases (CO2, Argon/CO2 mixes) and wire feed speeds to optimize weld quality for different materials.

- Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, this precision process requires a higher skill level. I have significant experience with TIG welding, capable of producing high-quality welds on thin gauge materials and those requiring exquisite control over the weld bead. My expertise includes working with various filler metals and shielding gases.

- Flux-Cored Arc Welding (FCAW): This semi-automatic process is useful for outdoor applications where shielding gas might be affected by wind. I’ve used this extensively for applications requiring high deposition rates, such as pipeline welding.

- Robotic Welding Systems: I’ve programmed and operated robotic welding systems in high-volume production environments, setting up and optimizing programs for maximum efficiency and weld quality.

I’m comfortable working with both traditional and advanced equipment and continuously update my skills to stay current with the latest technology in the welding industry.

Q 17. What are the common welding symbols and their meanings?

Welding symbols are a standardized way to communicate weld requirements on engineering drawings. They provide concise information about weld type, size, location, and other crucial details, avoiding lengthy written descriptions. The symbols are typically placed on a reference line, with the arrow pointing to the joint being welded.

Common welding symbols include:

- Weld Type Symbols: These indicate the type of weld, such as fillet weld (represented by a triangle), groove weld (represented by a line), or spot weld (represented by a circle).

- Weld Size Symbols: These specify the size (leg length or throat thickness) of the weld, usually indicated by a number and sometimes a fraction.

- Weld Location Symbols: These indicate where the weld is to be located, such as on one side of the joint (indicated by a symbol on the arrow side of the reference line) or on both sides (indicated by a symbol on both sides of the reference line).

- Other Symbols: Other symbols may denote weld process, length, spacing, etc., all following the standard conventions (such as AWS D1.1).

Understanding welding symbols is crucial for accurate interpretation of drawings and ensures that welds are made to specification. Misinterpretation can lead to costly rework or even safety hazards.

For example, a simple fillet weld symbol might show a triangle with a number ‘6’ to indicate a 6 mm fillet weld on the arrow side.

Q 18. How do you interpret welding procedure specifications (WPS)?

Welding Procedure Specifications (WPS) are detailed documents that outline the parameters for a specific welding process to ensure consistent weld quality. They are like a recipe, providing all the essential ingredients and steps to create a successful weld. Interpreting a WPS requires careful attention to detail and understanding of welding processes.

I interpret a WPS by carefully reviewing the following information:

- Base Metal: The type and grade of material being welded (e.g., steel, aluminum, type of steel).

- Welding Process: The specific welding method to be used (e.g., GMAW, GTAW, SMAW).

- Filler Metal: The type and diameter of the filler material (e.g., ER70S-6 wire, E6010 electrode).

- Parameters: This includes the voltage, amperage, wire feed speed, travel speed, preheat temperature, etc.

- Joint Design: The type of joint preparation and dimensions (e.g., butt joint, T-joint, groove angle).

- Qualification Tests: The WPS will typically refer to qualifying tests that have been performed to demonstrate the effectiveness of the welding procedure.

Following the WPS precisely ensures consistent, high-quality welds. Deviation from the WPS requires a thorough assessment and potentially a new WPS and qualification.

For example, in pipeline welding, strict adherence to a qualified WPS ensures the integrity and safety of the entire system.

Q 19. What are the common causes of undercutting and how to prevent them?

Undercutting is a defect characterized by a groove or indentation along the edge of the weld, creating a weakened area. This defect occurs when the molten weld metal does not fully fuse with the base material, leaving an undercut. Imagine carving a little groove into the side of a cake – it’s similar to undercutting a weld.

Common causes of undercutting include:

- Excessive Current: Too much heat concentrates the arc, causing excessive melting of the base material and leaving a groove behind.

- Incorrect Travel Speed: Moving the torch too quickly results in insufficient fusion and creates undercutting.

- Incorrect Angle of the Electrode/Torch: A poor angle allows the molten metal to pull away from the base material.

- Contamination of the Base Material: Dirt, grease, or oxide layers on the base metal will prevent proper fusion.

- Insufficient Shielding Gas Coverage (for GMAW and GTAW): Allows atmospheric contamination to interfere with the weld pool.

Preventing undercutting involves:

- Optimizing Welding Parameters: Adjusting current, voltage, and travel speed to appropriate values for the material and joint geometry.

- Maintaining Proper Electrode/Torch Angle: Maintaining a consistent angle that ensures penetration and prevents excessive melting of the base metal.

- Thorough Joint Preparation: Clean the surfaces to be welded and prepare the joint geometry accurately.

- Adequate Shielding Gas Coverage: Ensure adequate gas coverage to prevent atmospheric contamination from affecting the weld.

- Using Proper Techniques: Good welding technique is paramount. Smooth, controlled movements and consistent arc length are key.

Q 20. Explain the importance of proper joint preparation before welding.

Proper joint preparation is fundamental to achieving high-quality welds. It’s like preparing the ingredients before cooking – you can’t expect a delicious dish without proper prep! Poor joint preparation directly impacts weld strength, appearance, and overall quality.

The importance of proper joint preparation lies in several factors:

- Ensuring Complete Penetration: Proper beveling or shaping of the joint edges ensures complete fusion between the base metal and the filler metal, leading to a strong, sound weld.

- Minimizing Defects: A well-prepared joint reduces the likelihood of defects such as porosity, slag inclusions, and lack of fusion.

- Optimizing Weld Bead Geometry: A correctly prepared joint facilitates the creation of a weld bead with the desired shape and size.

- Improving Weld Appearance: Proper preparation leads to a more aesthetically pleasing weld.

- Reducing Welding Time and Costs: Efficient joint preparation reduces the amount of time and material needed for welding.

Examples of proper joint preparation techniques include:

- Beveling: Creating an angled edge on the joint components.

- Edge Preparation: Cleaning the edges of oxides and other surface contaminants.

- Joint Alignment: Accurate alignment of joint parts.

- Root Opening (in groove welds): Creating a small gap between the parts of the joint to allow for complete weld penetration.

The specific preparation method depends on the joint design, material thickness, and welding process. Improper joint preparation can lead to cracks, incomplete fusion, and other serious weld defects. A well-prepared joint is crucial to achieving consistent high-quality results.

Q 21. How do you ensure the quality of your welds?

Ensuring weld quality involves a multifaceted approach, combining proper welding techniques, strict adherence to procedures, and thorough inspection. It’s not just about making a weld, it’s about making a *good* weld.

My approach to ensuring weld quality includes:

- Proper Welding Techniques: This starts with thorough understanding of the welding process, maintaining consistent arc length, proper travel speed, and accurate electrode angle. Practice and experience are key to mastering these techniques.

- Strict Adherence to WPS: Following the Welding Procedure Specification is crucial for consistent results. Any deviations should be documented and assessed.

- Visual Inspection: A thorough visual inspection of the weld is done to detect obvious defects such as cracks, porosity, undercutting, or lack of fusion.

- Non-Destructive Testing (NDT): Various NDT methods are used as needed, such as radiographic testing (RT), ultrasonic testing (UT), or magnetic particle inspection (MPI), to detect internal flaws that are not visible to the naked eye. The choice of NDT method depends on the criticality of the weld and the type of potential defects.

- Mechanical Testing: For critical applications, mechanical tests like tensile testing, bend testing, or hardness testing may be performed to verify the weld’s strength and ductility.

- Documentation: Maintaining accurate records of the welding process, including the WPS used, welder identification, parameters, and inspection results, ensures traceability and accountability.

For instance, in a critical infrastructure project like a bridge, the quality assurance measures would involve a stringent visual inspection, possibly supplemented with radiographic testing and subsequent mechanical tests to verify the integrity of the welds.

Q 22. Describe your experience with different types of welding materials (e.g., steel, aluminum, stainless steel).

My experience spans a wide range of welding materials, each requiring a unique approach. Steel, for instance, is a common material, and I’m proficient with various grades, from mild steel used in construction to high-strength low-alloy (HSLA) steels for demanding applications. I understand the importance of preheating for thicker sections of steel to avoid cracking. With aluminum, I’m experienced in managing its high thermal conductivity, requiring precise control of heat input to prevent burn-through. This often involves using a pulsed MIG setting or specialized filler materials. Stainless steel presents its own challenges due to its susceptibility to oxidation and the formation of chromium oxides. Therefore, I utilize specific techniques like using a TIG process with a pure argon shielding gas, selecting filler metals with appropriate chromium content, and meticulously controlling the heat input to achieve proper penetration and avoid porosity. I regularly adapt my techniques depending on the grade of stainless steel being used.

Q 23. What are your troubleshooting skills when encountering welding problems?

Troubleshooting welding problems is a crucial aspect of my expertise. My approach is systematic and involves a combination of visual inspection, understanding the welding process, and utilizing my knowledge of metallurgy. For example, if I encounter excessive spatter, I would first examine the parameters of the welding machine, such as current, voltage, and wire feed speed. I might also check for correct shielding gas flow and nozzle condition. Poor penetration could indicate insufficient current, incorrect travel speed, or issues with the joint preparation. Porosity, on the other hand, might stem from contamination of the base metal, improper cleaning, or inadequate shielding gas coverage. I approach each problem systematically, eliminating possibilities until I identify the root cause. I always document my findings and corrective actions to prevent recurrence. My methodical approach ensures that the issues are resolved efficiently and effectively.

Q 24. Describe your experience with different types of welding codes (e.g., ASME, AWS).

I have extensive experience working with various welding codes, most notably ASME Section IX and AWS D1.1. ASME Section IX is crucial for pressure vessels and piping, demanding rigorous adherence to procedures and qualifications. I understand the requirements for welder certification, procedure qualifications, and the importance of documentation. AWS D1.1, for structural welding, focuses on the structural integrity of welded joints and specifies requirements for materials, weld geometry, and inspection techniques. I’m also familiar with other relevant codes depending on the specific application, including those related to aerospace and other specialized industries. Understanding these codes is critical for ensuring the safety and quality of the welded components. It’s not just about following the rules; it’s about understanding the reasoning behind them to ensure the final product meets the highest standards.

Q 25. Explain the process of setting up a welding machine and its parameters.

Setting up a welding machine involves several key steps, starting with selecting the correct process (e.g., MIG, TIG, stick) based on the material and application. Once the process is chosen, the parameters must be set according to the welding procedure specification (WPS). This often involves adjusting the voltage, current, wire feed speed (for MIG), gas flow rate, and travel speed. For example, when MIG welding steel, I would select a specific voltage and current based on the thickness of the material and the desired penetration. I then carefully adjust the wire feed speed to maintain a stable arc and consistent weld bead. The gas flow rate is crucial for shielding the weld pool from atmospheric contamination, preventing defects like porosity. I always pre-test on scrap material to fine-tune the settings and ensure consistent results before proceeding to the actual weld. Regular calibration of the machine and maintenance of consumables are also vital for consistent and quality welds.

Q 26. How familiar are you with different types of non-destructive testing (NDT) methods used in welding?

My familiarity with non-destructive testing (NDT) methods is extensive. I regularly work alongside NDT specialists and understand the importance of their work in ensuring weld quality. I’m proficient in interpreting the results of various NDT techniques, including visual inspection (VI), radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), and liquid penetrant testing (PT). VI is often the first step, followed by more sophisticated methods like RT and UT for detecting internal flaws. MT and PT are particularly effective for detecting surface discontinuities. Understanding these techniques allows me to anticipate potential issues during the welding process and to collaborate effectively with the NDT team to verify the integrity of my work. My experience extends to interpreting NDT reports and using this information to improve my welding techniques and prevent future problems.

Q 27. What are the ethical considerations in welding practice?

Ethical considerations in welding are paramount. Safety is always the top priority; I always ensure I have the appropriate PPE (Personal Protective Equipment), such as a welding helmet, gloves, and protective clothing. I also ensure the safety of those around me by establishing safe working practices and following all safety regulations. Furthermore, integrity in my work is crucial. I never compromise on quality, always adhering to the welding codes and procedures. I accurately document my work, and I never misrepresent my qualifications or experience. Honesty about potential issues or limitations is essential, as is a commitment to continuous learning and improvement. Ethical welding ensures the safety of the public and maintains the trust placed in skilled professionals.

Q 28. Describe a situation where you had to solve a complex welding problem.

In one project, I encountered significant difficulty welding a complex stainless steel assembly for a pharmaceutical mixing tank. The design included multiple thin-walled sections and tight tolerances. Initial attempts resulted in inconsistent penetration, excessive heat input leading to warping, and even some cracking in the welds. To solve this, I systematically reviewed the WPS, meticulously checked the joint preparation and surface cleanliness, and optimized the TIG welding parameters, focusing on pulse welding to fine-tune the heat input. I experimented with different filler materials to better manage the alloy characteristics. Ultimately, by implementing a combination of meticulous cleaning procedures, adjustments to the pulse welding parameters, and slight modifications to the joint design (in consultation with the engineers), I successfully completed the weld without any defects, as confirmed by the subsequent NDT inspection. This experience reinforced the importance of meticulous preparation, problem-solving, and open communication within the project team.

Key Topics to Learn for a Knowledge of Welding Techniques Interview

- Welding Processes: Understanding the principles and applications of various welding processes (e.g., GMAW, SMAW, GTAW, FCAW). Be prepared to discuss their strengths, weaknesses, and suitability for different materials and applications.

- Joint Design and Preparation: Knowledge of different joint types (butt, lap, tee, corner) and their preparation for optimal weld quality. This includes understanding the importance of proper fit-up and cleanliness.

- Weld Defects and Their Causes: Familiarity with common weld defects (porosity, cracking, undercut, slag inclusion) and the factors that contribute to their formation. Be ready to discuss preventative measures and corrective actions.

- Material Selection and Properties: Understanding the impact of base metal properties (e.g., tensile strength, ductility, weldability) on weld selection and process parameters. Discuss how material compatibility influences the welding process.

- Welding Safety and Procedures: Demonstrate knowledge of safety regulations and procedures related to welding, including personal protective equipment (PPE) and hazard identification.

- Quality Control and Inspection: Explain your understanding of weld inspection methods (visual inspection, non-destructive testing) and the importance of quality control in ensuring structural integrity.

- Practical Application and Troubleshooting: Be ready to discuss real-world scenarios where you’ve applied your welding skills and how you approached troubleshooting issues related to weld quality or process efficiency.

- Advanced Welding Techniques (Optional): Depending on the role, you might be asked about specialized techniques like robotic welding, laser welding, or other advanced processes. Research these areas if applicable to the job description.

Next Steps

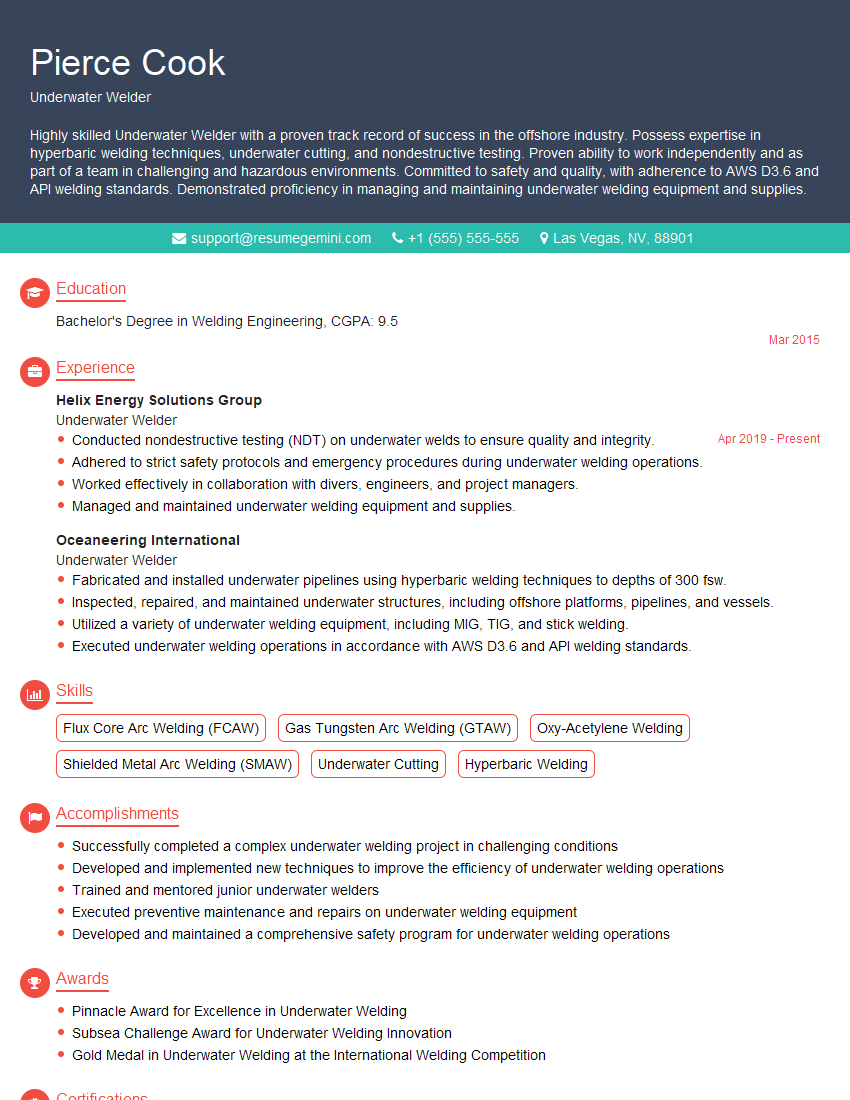

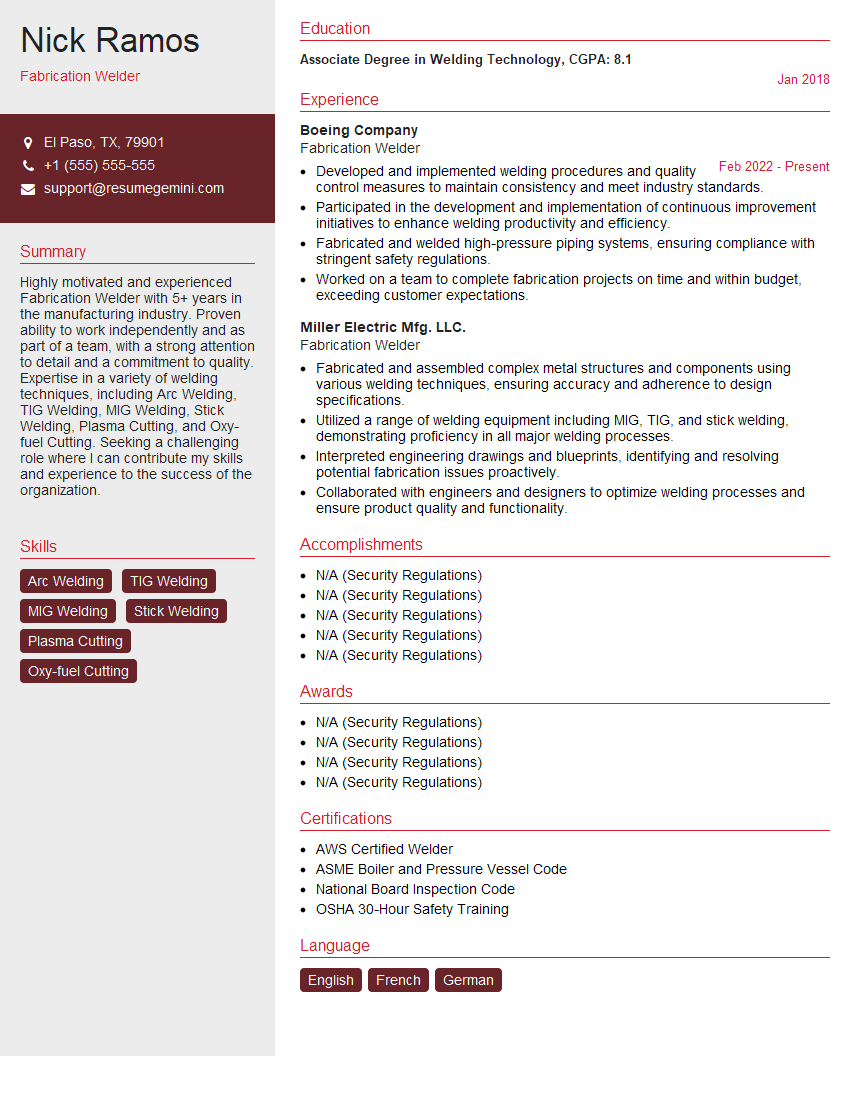

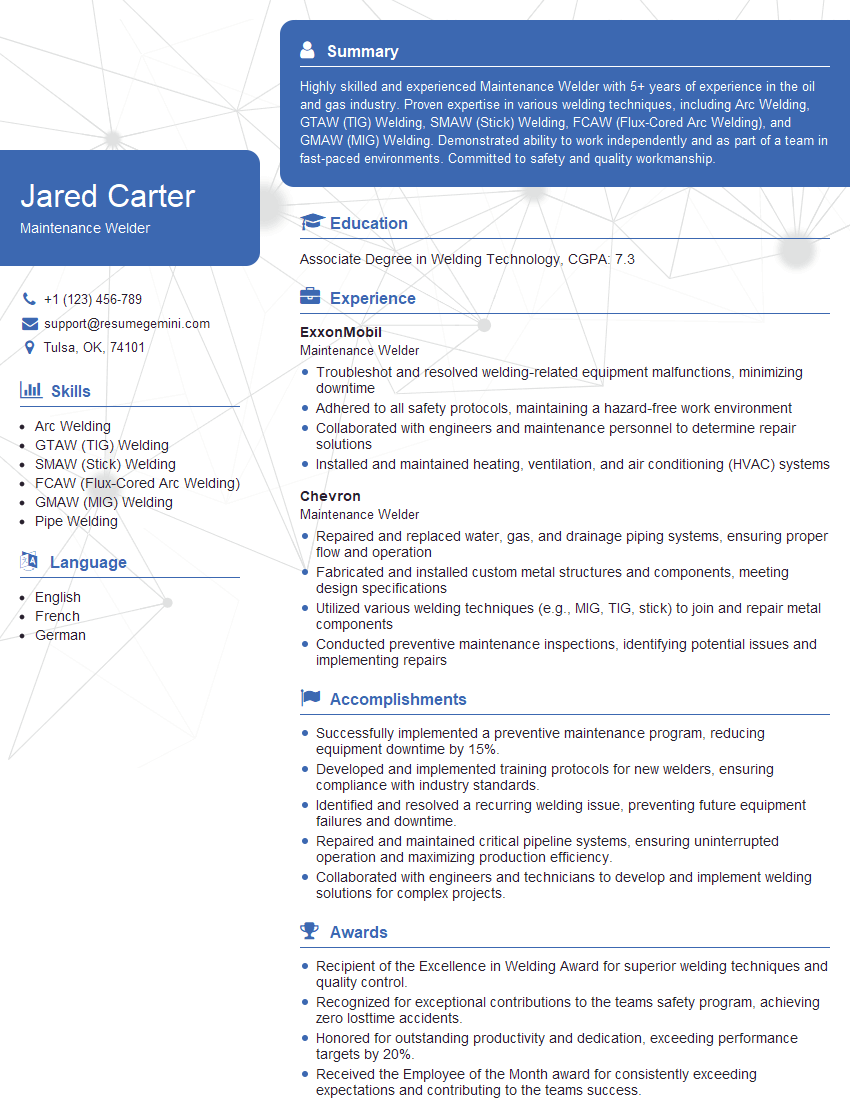

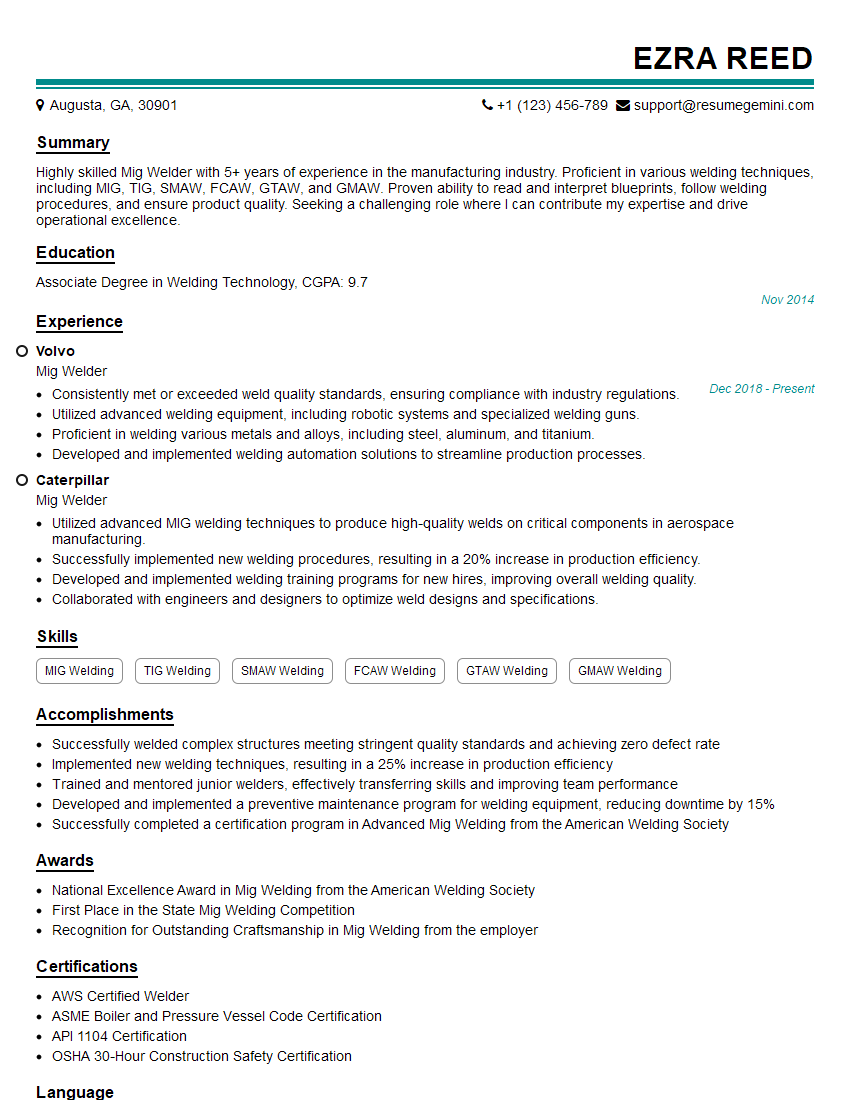

Mastering welding techniques is crucial for career advancement in this field, opening doors to higher-paying roles and specialized projects. A strong resume is essential for showcasing your skills and experience to potential employers. To maximize your job prospects, create an ATS-friendly resume that highlights your key competencies and achievements. ResumeGemini is a trusted resource that can help you build a professional and effective resume tailored to the demands of the welding industry. Examples of resumes specifically designed for candidates with knowledge of welding techniques are available to guide you. Take advantage of these resources to present yourself in the best possible light and secure your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO