Unlock your full potential by mastering the most common Label and Packaging Prepress interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Label and Packaging Prepress Interview

Q 1. What file formats are commonly used in label and packaging prepress?

In label and packaging prepress, we work with several file formats, each with its strengths and weaknesses. The most common ones include:

- PDF (Portable Document Format): This is the industry standard, offering excellent compatibility across different software and printing devices. It’s crucial for preserving fonts, images, and color information accurately. We often use PDF/X-1a for print-ready files, ensuring consistent color reproduction.

- AI (Adobe Illustrator): This vector-based format is perfect for creating scalable artwork, particularly logos and illustrations, without any loss of quality. It’s ideal for sharp lines and detailed designs.

- PSD (Adobe Photoshop): This raster-based format is excellent for image manipulation and retouching. We use it for photorealistic elements, ensuring high-resolution images for accurate print reproduction.

- EPS (Encapsulated PostScript): A vector-based format, though less prevalent now, sometimes used for exchanging vector graphics, especially older designs.

- TIFF (Tagged Image File Format): A raster-based format often used for high-resolution images, suitable for packaging where fine details are crucial.

Choosing the right format depends on the complexity of the design and the printing process. For example, vector formats are preferable for flexographic printing, while high-resolution raster formats are often needed for offset printing.

Q 2. Explain the importance of color management in packaging prepress.

Color management is absolutely critical in packaging prepress. It ensures that the colors you see on your screen accurately translate to the printed product. Inconsistent color can lead to costly reprints and dissatisfied clients. Imagine a vibrant red logo appearing dull on the final packaging – that’s a disaster waiting to happen!

We achieve accurate color management through several key steps:

- Profile Creation: Each device (monitor, printer, press) has its unique color profile. Creating and using these profiles ensures accurate color representation throughout the workflow.

- Color Conversion: Converting between color spaces (RGB to CMYK) requires careful attention. Proper conversion ensures consistent color reproduction, avoiding unexpected shifts in hue and saturation.

- Proofing: Soft proofs and hard proofs are essential to verify the final color appearance. Soft proofs are digital versions, while hard proofs are physical prints that simulate the final output.

- Calibration: Regular calibration of monitors and printers ensures that they accurately represent colors.

By employing a robust color management system, we minimize discrepancies between digital designs and the final printed packaging, safeguarding brand identity and product quality.

Q 3. Describe your experience with different types of printing plates (e.g., flexo, offset).

My experience encompasses both flexographic and offset printing plates. Each has its own characteristics and applications.

- Flexographic Printing Plates: These are typically photopolymer plates used for flexible packaging materials like films, foils, and paperboard. I’ve worked extensively with various plate materials and thicknesses, understanding the impact on print quality and durability. Flexo plates require careful preparation, including screening techniques and dot gain compensation to achieve the desired print results. I’m familiar with both digital flexo platemaking and traditional methods.

- Offset Printing Plates: These metal plates are used in offset lithography, often preferred for high-volume printing of rigid packaging like cartons and boxes. I have experience with different types of offset plates, including those requiring chemical processing and those using computer-to-plate (CTP) technology. Understanding platemaking techniques, including image setting and exposure, is crucial for achieving high-fidelity reproduction.

My experience includes troubleshooting issues with both plate types, such as plate defects, improper registration, and ink adhesion problems. This involves a deep understanding of platemaking processes and the interactions between plates, inks, and substrates.

Q 4. How do you ensure the accuracy of color proofs?

Ensuring color proof accuracy is paramount. We use a multi-faceted approach:

- Using calibrated and profiled equipment: Both the monitor used for soft proofing and the proofing printer must be precisely calibrated to industry standards and have accurate color profiles.

- Employing standardized proofing methods: We use industry-standard proofing techniques and software to guarantee consistency and reproducibility. This includes using proofing systems compliant with ISO standards like ISO 12647.

- Comparing proofs against original artwork: We meticulously compare the proofs against the digital files, checking for any color discrepancies, ensuring accurate representation of the design.

- Visual inspection under controlled lighting conditions: Comparing proofs under standardized lighting conditions minimizes the impact of ambient light on color perception.

- Client approval: Before going into mass production, we always get the client’s approval on the final proof, which serves as the ultimate benchmark for color accuracy.

By utilizing these rigorous methods, we significantly reduce the risk of color errors in the final print, saving both time and resources. A single color mismatch can be expensive!

Q 5. What are your preferred software programs for prepress work?

My preferred software programs for prepress work include:

- Adobe Illustrator: For creating and editing vector-based artwork, especially logos and illustrations.

- Adobe Photoshop: For image retouching, color correction, and preparing raster-based artwork.

- Esko Suite: A comprehensive prepress workflow solution including tools for color management, trapping, imposition, and platemaking. It’s a powerhouse for efficient prepress processes.

- Color management software (e.g., X-Rite i1Profiler): For profiling monitors, printers, and presses.

- PDF editors (e.g., Adobe Acrobat Pro): For reviewing and preflighting PDF files before sending to print.

My proficiency in these applications allows me to handle diverse prepress tasks efficiently and accurately, streamlining workflows and enhancing overall output quality.

Q 6. Explain your understanding of color spaces (CMYK, RGB, Pantone).

Understanding color spaces is crucial for accurate color reproduction. Let’s break down the main ones:

- CMYK (Cyan, Magenta, Yellow, Key [Black]): This subtractive color model is used in most printing processes. It’s subtractive because inks are layered to absorb light, resulting in the final color. CMYK is the standard for printed materials.

- RGB (Red, Green, Blue): This additive color model is used for digital displays. It’s additive because light sources combine to create colors. RGB is what you see on your computer screen or phone.

- Pantone (Pantone Matching System): This is a proprietary color matching system that uses a specific library of spot colors. Each Pantone color has a unique number, guaranteeing consistent color reproduction across different printing methods and locations. It’s invaluable when precise color matching is required, like with brand colors.

Converting between these color spaces requires careful consideration. For instance, certain RGB colors may not have an exact equivalent in CMYK, so accurate conversion is essential to minimize color shifts during the printing process.

Q 7. Describe your experience with trapping and its importance in packaging.

Trapping is a crucial technique in packaging prepress. It involves intentionally overlapping adjacent colors to prevent gaps or misregistration between them. Misregistration, even by a tiny amount, can create unsightly gaps or ‘white lines’ between colors, especially on high-speed printing presses. This is especially noticeable with sharp lines and small text.

Imagine two bold colors next to each other on a label. Without trapping, even a slight misalignment during printing could reveal a thin white line between them. Trapping eliminates this by intentionally overlapping the colors slightly. This overlap compensates for any misregistration and ensures clean, crisp lines in the final product.

There are various trapping methods, including:

- Spread trapping: The lighter color spreads into the darker color.

- Choke trapping: The darker color encroaches on the lighter color.

The choice of trapping method depends on factors like the color combination, printing process, and substrate. Proper trapping ensures professional-looking prints and prevents costly reprints. I have experience with both manual and automated trapping techniques, employing software tools to optimize trapping for various printing scenarios.

Q 8. How do you handle prepress issues like incorrect bleeds or image resolution problems?

Incorrect bleeds and low image resolution are common prepress nightmares, but thankfully, preventable. Bleeds, the extra area extending beyond the trim line, ensure no white edges appear after cutting. Insufficient bleed leads to unsightly white borders. Resolution issues, on the other hand, result in pixelated or blurry images, especially noticeable on high-resolution printing.

My approach begins with a meticulous preflight check using dedicated software like PitStop Pro or Acrobat Pro. This automatically flags insufficient bleeds (typically 3mm for labels and packaging) and low-resolution images (ideally 300 DPI for most applications). For bleeds, I communicate with the designer to extend the artwork accordingly. For resolution, I discuss options with the client. This might involve sourcing a higher-resolution image, strategically cropping the area, or opting for a different print technique that’s less sensitive to lower resolution, if suitable for the project. Sometimes, clever masking or clever use of vector graphics can mitigate resolution issues in small areas.

For example, I recently worked on a project where the designer forgot to add bleeds. My preflight check caught it. We quickly resolved it by extending the background color and adding a half-millimeter buffer around critical design elements to prevent unforeseen cropping issues. Another time, we identified a low-resolution logo. This was addressed by requesting a vector version from the client, eliminating resolution concerns entirely.

Q 9. What is your experience with imposition software?

I’m proficient in several imposition software packages including Esko ArtiosCAD, CGS ORIS, and Adobe Impose. These are crucial for arranging individual label or package designs onto larger printing sheets efficiently. My experience spans optimizing imposition for various press types, such as flexographic, offset, and digital, tailoring the setup to minimize waste and maximize production speed.

For instance, Esko ArtiosCAD excels in creating complex die-cuts and ensuring accurate register for multi-layer packaging. I regularly use its nesting features to optimize sheet usage, minimizing material waste, especially critical with expensive substrates. With CGS ORIS, I perform advanced prepress tasks such as color management and proofing. Adobe Impose is particularly helpful for simpler imposition jobs, especially when working with digital printing presses, offering a straightforward interface for quick turnaround times. My choice of software is always dictated by the complexity of the project and the client’s specific needs and press requirements.

Q 10. Describe your workflow for preparing files for different printing processes.

My workflow adapts to the specific printing process. However, several common steps remain consistent. It starts with receiving the artwork, typically in a PDF format. I then perform a thorough preflight check, verifying color profiles, resolution, bleeds, and fonts. Next, I ensure all fonts are embedded and images are optimized for the chosen printing method. For flexographic printing, I might need to create specific plates or separations, optimizing the artwork for halftone screening and color accuracy. For digital printing, the process is often more streamlined, but still requires careful color management.

For offset printing, I would consider the number of colors used (CMYK, Pantone spot colors), verify the artwork’s compatibility with the press, and prepare for potential color corrections based on press proofs. When preparing for a high-volume flexo job, I might use specialized tools for halftone screening and creating optimized color separations to improve print quality and efficiency. After the preflight and adjustments, I create the imposition, ensuring correct orientation and the necessary details for efficient sheet finishing. Then, I produce a final PDF/X-4 ready for the print.

Q 11. How familiar are you with different types of substrates used in label and packaging?

My familiarity with substrates extends to various paper, film, and foil options. I’m knowledgeable about different types of paperboard (e.g., SBS, solid bleached sulfate) used in folding cartons, various films (BOPP, PET, PVC) used in flexible packaging, and different metallized and foil materials. I understand the implications of each substrate’s properties on printability, including its absorbency, surface finish, and opacity.

For instance, I know that BOPP (biaxially oriented polypropylene) is commonly used for labels due to its cost-effectiveness and gloss, while PET (polyethylene terephthalate) offers greater strength and barrier properties often preferred for food packaging. I also understand that the choice of substrate influences the inks and printing processes employed. For example, certain inks might not adhere properly to some plastic films, requiring a pre-treatment step. Choosing the right substrate based on the product and the client’s requirements is a crucial aspect of ensuring optimal results.

Q 12. How do you ensure the consistency of color across different print runs?

Color consistency across print runs relies heavily on robust color management. This involves using a standardized color profile throughout the process, from design to printing. I usually work with ICC profiles specific to the printing press, substrate, and inks. In addition, I incorporate spot color control where necessary, employing Pantone Matching System (PMS) colors for precise color reproduction and verification. Press proofs and color calibration are essential steps to guarantee consistent color reproduction between print runs.

I typically use a spectrophotometer to measure and match colors and compare them against the client-approved proofs. The data obtained allows for adjustments and corrections during the prepress stage, minimizing discrepancies between the designed color and the final printed product. Accurate color management also involves documenting and archiving color profiles and production parameters. This ensures that we can easily replicate colors in subsequent print runs.

Q 13. What quality control measures do you employ in your prepress workflow?

My quality control measures are integrated throughout the entire prepress workflow. It starts with a detailed preflight check, followed by thorough visual inspection of the imposed sheet and a final proof review, both digital and, ideally, a hard proof. I also conduct several spot checks during the different stages of preparation to ensure accuracy. I often use automated preflight tools that flag potential problems before printing even starts, allowing early identification and prevention of errors.

For example, I always check for image resolution, color profiles, font embedding, bleed settings, and color consistency, ensuring accuracy and compliance with print specifications. This multi-layered approach significantly reduces the likelihood of errors and the need for costly reprints. Furthermore, maintaining detailed records of the entire process, including all checks and approvals, allows for effective traceability and improved future performance. This diligent approach is essential for maintaining high-quality output, especially in the fast-paced world of label and packaging production.

Q 14. Explain your experience with PDF workflows, including preflighting and validation.

PDF workflows are central to my process, and I’m highly proficient in creating, preflighting, and validating PDF/X-4 compliant files. I use Acrobat Pro extensively for these tasks. Preflighting involves using automated checks to identify potential problems early. This includes verifying the color space, resolution, fonts, and bleeds, ensuring all elements are compatible with the chosen printing process. Validation confirms that the PDF meets the specified standards and is ready for print.

For instance, I often encounter issues with embedded fonts that are not suitable for printing. Preflighting identifies these, allowing me to replace them with suitable alternatives before any printing commences. I also regularly use preflight profiles that are customized for different printing processes. This targeted approach further reduces the risk of errors. By employing a rigorous preflight and validation procedure and following PDF/X standards, I ensure that the print-ready files are of high quality and consistent, contributing to efficiency and reducing errors.

Q 15. Describe your experience with die-cutting and its prepress requirements.

Die-cutting is a crucial process in packaging prepress where a sharp steel rule die cuts specific shapes and forms from a printed sheet. Think of it like using a cookie cutter, but on a much larger scale and with incredibly precise tolerances. The prepress requirements for die-cutting are critical to ensure accuracy and efficiency.

- Die Creation: This involves creating a digital representation of the die, often using a CAD program. This file is then sent to a die-maker who manufactures the physical die. Accuracy at this stage is paramount to avoid errors in the final product. For example, a misplaced cut on a cosmetic box can render the entire packaging unusable.

- Die-line Creation: A die-line is a crucial file showing exactly where each cut, crease, and perforation should be on the printed sheet. This serves as a blueprint for both the die maker and the printer. It’s usually a layered PDF file, with different layers representing different die elements. I’ve personally handled complex die-lines for intricate folding cartons, including multiple layers and various cut depths.

- Artwork Setup: The artwork must be precisely aligned to the die-line to guarantee the final product is as intended. This is typically done in Adobe Illustrator or similar software, using the die-line as a guide. A common mistake is improper bleed settings, leading to white space near cut edges.

- Material Considerations: The type of material being die-cut (cardboard, paperboard, etc.) dictates the sharpness and force required for the die-cutting process. Experience plays a vital role in selecting the right die and parameters for the material, ensuring clean cuts and avoiding damage.

I have extensive experience in managing the entire die-cutting prepress workflow, from creating and reviewing die-lines to ensuring accurate artwork placement. One project involved creating a unique die-cut for a promotional box with complex curves and intricate details—that required multiple iterations and close collaboration with the die-maker to achieve the desired results.

Career Expert Tips:

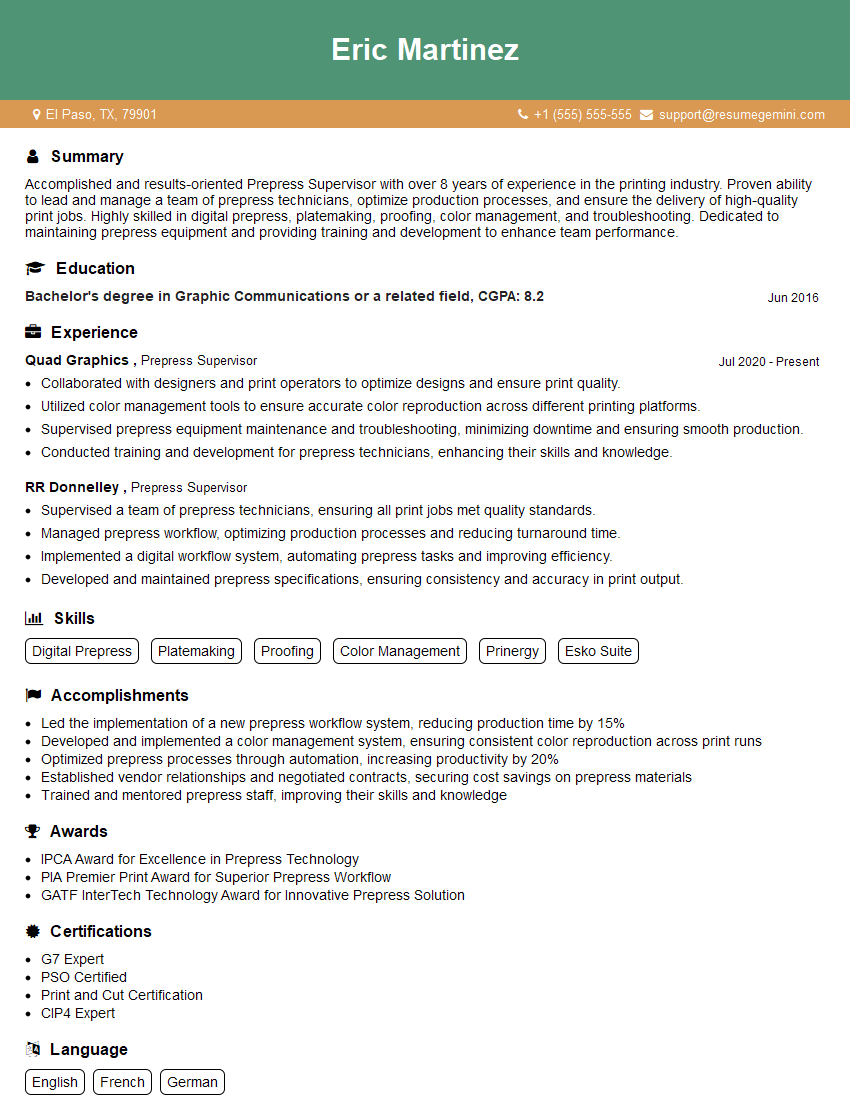

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle revisions and changes to packaging artwork?

Handling revisions is a daily part of packaging prepress. We use a version control system, usually a combination of software like Adobe Version Cue and a cloud-based file management system. A clear revision tracking system is critical to avoid confusion and ensure everyone is working on the most recent version.

- Version Control: Each revision is clearly labeled and dated (e.g., ‘Artwork_v2_2024-10-27’). This prevents accidental use of outdated files and allows for easy tracking of changes.

- Change Logs: For significant changes, a detailed change log is maintained, documenting who made the change, when it was made, and a description of the alteration. This can be a simple document or incorporated into the version control system.

- Communication: Clear communication with the client and internal teams is paramount. This includes sending timely updates about revision status and promptly addressing feedback. I often use annotated PDFs or video conferencing for quick feedback and to reduce misunderstandings.

- Proofing: After each revision, we generate updated proofs (soft and hard proofs, depending on the client’s preference) to allow for visual verification before the project proceeds to print. This helps catch errors early on, minimizing potential printing delays and costs.

In one instance, a major redesign was required after a client’s late-stage brand refresh. We managed this by efficiently updating all relevant files, meticulously tracking each change, and utilizing rapid prototyping through soft proofing to minimize time-to-market impact. This efficient revision management saved significant production time and cost.

Q 17. What is your experience with variable data printing?

Variable data printing (VDP) allows for personalized content on each printed piece, offering unique designs, serial numbers, or other data. This is invaluable in applications like personalized marketing materials, product serialization, and customized packaging. My experience with VDP includes preparing files for various print engines and implementing different data merge techniques.

- Data Integration: This involves integrating the variable data file (usually a CSV or database file) with the artwork template. This requires experience with software capable of handling data merges, such as Adobe InDesign or dedicated VDP software. Accurate data mapping is crucial to avoid errors in the final printed piece.

- File Preparation: Files must be carefully prepared to ensure the data correctly interacts with the template. This means using the correct data fields, properly formatting the data, and testing the merge process before sending the files for printing. I’ve encountered situations where poorly structured data fields caused widespread errors in the final output.

- Print Engine Knowledge: Different print engines have their own unique requirements for VDP files. Understanding these requirements ensures compatibility and optimizes the printing process. This includes knowledge of common print file formats like PDF/X and their suitability for VDP.

For example, I worked on a project involving personalized gift boxes, where each box featured a unique recipient name and message. This required meticulous data handling and testing to avoid printing mistakes. We used a robust database, a well-structured template, and rigorous testing to ensure the quality and accuracy of the personalized output.

Q 18. How familiar are you with different finishing techniques (e.g., lamination, embossing)?

Finishing techniques significantly enhance the look, feel, and functionality of packaging. My experience encompasses a wide range of processes, each impacting the prepress workflow differently.

- Lamination: Lamination adds a protective layer to the printed sheet, enhancing durability, gloss, or matte finish. Prepress considerations include selecting the appropriate lamination type and ensuring the artwork is designed to accommodate the added thickness.

- Embossing/Debossing: These techniques create raised or indented designs, adding texture and visual interest. Prepress requires creating digital embossing/debossing dies or providing detailed specifications to the finishing house.

- Foil Stamping: This involves applying metallic or colored foil to create a visually striking effect. The prepress process includes preparing the artwork with appropriate tolerances for the foil stamping process, and selecting the foil type and finish.

- UV Coating: UV coating provides a glossy or matte finish, enhancing durability and protection. Prepress considerations are similar to lamination, focusing on artwork bleed and avoiding interference with other finishing techniques.

I’ve personally overseen projects incorporating multiple finishing techniques, ensuring seamless integration and the creation of high-quality, visually impressive packaging. For instance, a recent project involved a premium wine box with foil stamping, embossing, and UV coating, requiring precise coordination between prepress and the various finishing stages.

Q 19. How do you manage large volumes of files and maintain an organized prepress library?

Managing large volumes of files requires a robust and organized system. We use a combination of techniques for efficient prepress library management.

- Cloud-Based Storage: We store all files in a cloud-based system, ensuring easy access for all team members and providing backups. This provides a central repository and improves team collaboration.

- File Naming Conventions: A strict, consistent file naming convention is essential (e.g., ClientName_ProjectName_FileVersion_Date). This ensures files are easily identifiable and searchable.

- Folder Structure: A logical folder structure categorizes files by client, project, and file type, improving organization and retrieval speed.

- Metadata: We use metadata to add more information about each file, such as project details, completion date, and relevant notes, allowing for efficient searching and filtering.

- Digital Asset Management (DAM) System: For extremely large volumes of data, a dedicated DAM system can provide enhanced organization, version control, and search capabilities.

I’ve developed and implemented a file management system that significantly improved our workflow, reducing search time and eliminating file duplication. This centralized system enables seamless collaboration across the team and ensures that we can quickly retrieve any file at any time.

Q 20. What are some common prepress errors and how do you prevent them?

Common prepress errors can lead to costly reprints and delays. Prevention is always better than cure.

- Incorrect Color Profiles: Using the wrong color profile can lead to significant color discrepancies between the soft proof, the printed sheet, and the final product. We use industry-standard profiles and carefully calibrate our monitors.

- Missing or Incorrect Bleed: Insufficient bleed can lead to unsightly white borders on the final product. We meticulously check bleed settings and ensure all artwork extends beyond the trim line.

- Low-Resolution Images: Using low-resolution images results in blurry and unprofessional-looking packaging. We always use high-resolution images suitable for print.

- Font Issues: Missing or improperly embedded fonts can lead to text rendering errors in the final output. We embed all fonts in our artwork files, making sure that they are outlined.

- Incorrect File Formats: Using incompatible file formats can cause issues during printing. We consistently use industry-standard file formats such as PDF/X.

We employ a rigorous preflighting process before every job to catch these errors early. This involves automated checks for low resolution images, missing fonts, and other potential problems. A thorough preflight combined with a careful review of the final artwork by experienced prepress professionals helps to significantly reduce the chance of errors.

Q 21. Describe your experience with proofing methods (e.g., soft proof, hard proof).

Proofing is essential to ensure the final product matches the client’s expectations. We employ both soft and hard proofing methods.

- Soft Proofing: This involves digitally reviewing the artwork on a calibrated monitor, often using specialized software like Adobe Acrobat Pro to simulate the final printed output. Soft proofing provides a quick and cost-effective way to review the artwork. I often use this method during the initial phases of design and revision cycles.

- Hard Proofing: This involves producing a physical printed sample, which provides a more accurate representation of the final printed product. We use high-quality proofing systems that closely mimic the final printing process. Hard proofing is crucial before mass production to catch color variations and printing defects. It’s particularly important for projects with complex color palettes or special finishing techniques.

The choice between soft and hard proof depends on the complexity of the project and the client’s requirements. For simpler projects, a soft proof might suffice, while complex projects demanding color accuracy often require a hard proof. I’ve successfully managed numerous projects, leveraging the advantages of both soft and hard proofing to deliver superior results that meet our clients’ high standards.

Q 22. How do you handle client communication and feedback regarding artwork?

Client communication is paramount in prepress. I establish clear communication channels from the outset, using a combination of email, phone calls, and project management software to keep everyone informed. I always confirm the brief thoroughly, ensuring I understand their design vision, target audience, and any specific requirements, like substrate type or special finishes.

When receiving feedback, I actively listen and ask clarifying questions to avoid misinterpretations. I meticulously track all changes, versioning artwork to maintain a clear history. For example, if a client wants a minor text adjustment, I create a new version clearly labeled as ‘Version 2 – Text Amendment’ and document the change in a detailed email for the record. This ensures transparency and avoids confusion.

I also prioritize prompt responses and keep clients updated on progress, anticipating potential roadblocks and proactively addressing them to maintain a smooth workflow. Clear, concise communication prevents costly mistakes and fosters trust.

Q 23. Explain your understanding of the importance of press-ready files.

Press-ready files are absolutely crucial; they’re the blueprint the printer uses to produce the final product. An improperly prepared file can lead to significant delays, costly reprints, and ultimately, a dissatisfied client. A press-ready file must be color-accurate, correctly sized to the final dimensions, with all fonts outlined, and images at the correct resolution. It needs to be in the appropriate file format (e.g., PDF/X-1a for high-quality print) and bleed and trim marks must be correctly positioned.

For instance, missing bleed (the extra area around the design that gets trimmed) will result in unsightly white edges on the finished product. Incorrect color profiles can lead to significant color shifts between the screen proof and the printed label. Preparing press-ready files meticulously ensures a seamless print run and a high-quality final product.

Q 24. What is your experience with barcodes and other identification markers?

I have extensive experience with barcodes and other identification markers, including GS1 barcodes (EAN, UPC), QR codes, and datamatrix codes. I understand the importance of accurately generating, placing, and verifying these markers according to industry standards. Incorrect barcode generation can render products unscannable, leading to serious logistical problems.

My workflow involves using specialized barcode generation software to ensure compliance with all relevant specifications. I always verify the barcode’s readability using a barcode verifier before sending the file to print. For example, I’ve worked with clients producing pharmaceuticals that require strict adherence to GS1 standards for tracking and traceability, and any error in those codes could compromise the supply chain and pose legal issues. I meticulously check checksums and ensure the correct symbology is used based on client requirements.

Q 25. How do you troubleshoot issues that arise during prepress production?

Troubleshooting is a key part of prepress. I approach problems systematically, starting with a thorough review of the artwork files. I check for common issues such as missing fonts, low-resolution images, incorrect color profiles, and missing bleed. I use color management software to ensure color consistency across different devices and monitor the print processes carefully.

If an issue arises during the proofing stage, I’ll work closely with the client to understand their concerns and propose solutions. For example, if a client finds a typo, I’ll correct the file, re-proof, and send them the updated version. If a color appears off, I investigate the color profile used and make adjustments to achieve the required accuracy. I document each step of the troubleshooting process, maintaining a detailed history to help resolve future problems efficiently.

Q 26. What are your strengths and weaknesses in a prepress environment?

My strengths lie in my meticulous attention to detail, my proficiency in various prepress software (Adobe Creative Suite, preflighting software, barcode generators), and my ability to quickly learn new technologies. I am a proactive problem-solver and excel at communicating technical information clearly to clients.

One area for continuous improvement is further expanding my knowledge of newer, highly specialized packaging software and techniques. While I’m adept at adapting and learning, dedicated training in these niche areas would enhance my efficiency and expertise even further. I am actively seeking opportunities to develop these skills.

Q 27. Describe a challenging prepress project and how you overcame the obstacles.

One challenging project involved a client with extremely complex, multi-layered packaging requiring intricate die-cutting and embossing. The artwork involved numerous elements, intricate fonts, and several different substrates. The initial files supplied by the client were poorly organized and lacked the necessary specifications for successful print production.

To overcome this, I initiated a series of meetings with the client to clarify their requirements. I then meticulously reorganized the files, creating a well-structured system for tracking different layers and elements. I worked closely with the client’s designers to ensure all aspects were correct and to resolve any issues concerning die lines and embossing specifications. Through clear communication and a detailed, step-by-step workflow, we managed to deliver a perfect press-ready file, and the project was completed successfully on time and to the client’s satisfaction. This project highlighted the importance of collaborative teamwork and a thorough understanding of client needs.

Q 28. How do you stay up-to-date with the latest technologies and trends in label and packaging prepress?

Staying updated in prepress is critical. I regularly attend industry conferences and workshops, participate in online courses and webinars, and actively follow industry publications and blogs. I also network with other professionals in the field to share best practices and stay abreast of new developments.

I leverage online resources and participate in professional organizations to keep my skills sharp and adapt to the ever-evolving technological landscape of label and packaging printing. This proactive approach ensures I’m always equipped with the most up-to-date knowledge and technologies, benefiting my work and contributing to the success of projects.

Key Topics to Learn for Label and Packaging Prepress Interview

- Color Management: Understanding color spaces (CMYK, RGB, Pantone), color profiles, and color separations. Practical application: Troubleshooting color discrepancies between proof and final product.

- File Formats and Pre-flighting: Proficiency in PDF, AI, EPS, and other relevant file formats. Practical application: Preparing files for optimal printing and identifying potential issues before they reach the press.

- Image Resolution and Scaling: Knowing the implications of low-resolution images and how to properly scale artwork for various label and packaging sizes. Practical application: Ensuring print quality and avoiding pixelation.

- Die-cutting and Finishing Techniques: Understanding die lines, perforations, embossing, and other finishing processes. Practical application: Preparing accurate die-line files and specifying finishing instructions for optimal results.

- Proofing and Quality Control: Familiar with different proofing methods (soft proof, hard proof) and quality control checks. Practical application: Identifying and correcting errors before printing to minimize waste and ensure accuracy.

- Workflow and Software Proficiency: Experience with prepress software like Adobe Illustrator, Acrobat, and other relevant applications. Practical application: Optimizing workflow processes for efficiency and accuracy.

- Print Processes: Understanding various printing methods used in label and packaging (flexography, offset, digital). Practical application: Selecting the appropriate printing method based on project requirements and budget constraints.

- Problem-Solving and Troubleshooting: Ability to identify and resolve technical issues related to file preparation, color management, and printing. Practical application: Demonstrate effective problem-solving skills in a hypothetical scenario.

Next Steps

Mastering Label and Packaging Prepress opens doors to exciting career opportunities in a dynamic industry. A strong understanding of these technical skills will significantly boost your earning potential and career advancement. To make your application stand out, create an ATS-friendly resume that highlights your key accomplishments and skills. ResumeGemini is a trusted resource for building professional resumes that catch the eye of recruiters. They offer examples of resumes tailored to the Label and Packaging Prepress industry to help you get started. Invest time in crafting a compelling resume—it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO