Preparation is the key to success in any interview. In this post, we’ll explore crucial Light Mechanical Repair interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Light Mechanical Repair Interview

Q 1. Describe your experience troubleshooting malfunctioning mechanical equipment.

Troubleshooting malfunctioning mechanical equipment is a systematic process that involves careful observation, logical deduction, and a deep understanding of the machine’s workings. I begin by carefully examining the machine for any obvious signs of damage or malfunction, such as loose connections, leaks, or unusual noises. Then, I’ll consult schematics, manuals, or other documentation to understand the machine’s operational sequence and identify potential points of failure.

For example, if a conveyor belt is stalling, I might first check the motor for power, then inspect the belt for wear and tear or misalignment. If the problem isn’t immediately obvious, I use a multimeter to test voltage and current, listening for unusual sounds, and checking for signs of overheating. This methodical approach helps to pinpoint the root cause of the malfunction, whether it’s a simple loose bolt or a more complex electrical or mechanical issue. I’ve successfully diagnosed and repaired various issues in industrial machinery including conveyor systems, packaging equipment and small engine repair. I always document my findings and the steps I take to resolve the problem, creating a record for future reference.

Q 2. Explain the process of identifying and replacing worn or damaged parts.

Identifying and replacing worn or damaged parts requires a keen eye for detail and a thorough understanding of the machine’s components. I start by visually inspecting the suspect area. This often involves disassembling parts of the machine to get a closer look. I then use appropriate tools (calipers, micrometers) to measure dimensions and compare them to the manufacturer’s specifications, looking for deviations that indicate wear.

For instance, if a gear shows significant wear (e.g., teeth are rounded or chipped), I’d measure the gear’s dimensions, cross-reference it with the part number or manufacturer’s specifications to order a replacement. Once the new part arrives, I carefully install it, ensuring proper alignment and lubrication. I always use the correct tools and techniques to avoid causing further damage during replacement. After the replacement, I thoroughly test the machine to ensure that the repair was successful.

Q 3. How do you prioritize repairs when multiple machines require attention?

Prioritizing repairs when multiple machines are down involves a decision-making process based on several factors including the severity of the malfunction, the impact on production, and the urgency of the situation. I typically use a combination of qualitative and quantitative assessment to make informed decisions.

I use a system where I assess each machine based on factors such as: 1. Downtime Cost: How much money are we losing per hour this machine is down? 2. Safety Risk: Does this malfunction pose a safety hazard to employees or the environment? 3. Production Impact: Does this machine affect downstream processes or critical manufacturing steps? I list all malfunctioning machines and score them based on these factors. The highest-scoring machines are addressed first. This approach ensures that the most critical repairs are handled promptly, minimizing downtime and potential safety risks.

Q 4. What safety precautions do you routinely follow during mechanical repairs?

Safety is paramount in any mechanical repair. I always follow established safety protocols, which include wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, hearing protection, and steel-toe boots. Before starting any repair, I ensure that the power to the machine is completely disconnected and locked out/tagged out, preventing accidental energization. I inspect the work area for potential hazards, and keep the area clean and organized to prevent trips and falls.

I am also mindful of potential hazards specific to the task at hand such as working with pressurized systems or handling sharp tools or materials. For example, when handling chemicals or lubricants I carefully read the safety data sheets (SDS) and use appropriate handling procedures. Additionally, I always follow the manufacturer’s safety guidelines provided in the machine manuals.

Q 5. What experience do you have with preventative maintenance?

Preventative maintenance is crucial in extending the lifespan of mechanical equipment and preventing unexpected breakdowns. My experience includes developing and implementing preventative maintenance schedules based on manufacturers’ recommendations and historical equipment data. This typically involves regularly inspecting machines for wear and tear, lubricating moving parts, and replacing components before they fail.

For example, I’ve developed schedules for lubricating conveyor bearings weekly, inspecting motor belts monthly, and replacing filters quarterly. This approach ensures that potential problems are identified and addressed proactively, preventing costly repairs and ensuring smooth operations. Through diligent preventative maintenance, I’ve significantly reduced downtime and extended the service life of equipment in various industrial settings.

Q 6. Describe your familiarity with common hand tools and power tools.

I am proficient in using a wide range of both hand tools and power tools commonly used in light mechanical repair. Hand tools include screwdrivers (Phillips and flathead), wrenches (open-end, box-end, adjustable), pliers (needle-nose, slip-joint), hammers, and various measuring tools such as rulers, calipers, and micrometers. Power tools include drills, impact wrenches, grinders, saws (reciprocating, circular), and sanders.

I understand the safe and proper operation of each tool and am skilled in selecting the appropriate tool for each task. I also understand the importance of maintaining these tools, ensuring they are in good working condition and regularly sharpening or replacing worn parts. This ensures precision and efficiency in all repairs.

Q 7. Explain your understanding of basic mechanical principles, such as levers, pulleys, and gears.

My understanding of basic mechanical principles is fundamental to my work. I apply these principles daily when troubleshooting and repairing equipment. Levers, pulleys, and gears are simple machines that amplify force or change the direction of motion.

For example, a lever is used to increase the force applied to loosen a stubborn bolt (think of a wrench). A pulley system can be used to lift heavy objects with less effort, a common application in many industrial setups. Gears translate rotational motion, changing speed and torque. Understanding how these simple machines function within more complex equipment is crucial for effective troubleshooting and repair. I routinely analyze how these mechanisms work together to create a system and how any deviation from normal operation can trigger a failure.

Q 8. How do you diagnose mechanical problems using diagnostic equipment?

Diagnosing mechanical problems starts with a thorough understanding of the system’s operation. I begin by visually inspecting the equipment for obvious signs of damage, such as leaks, cracks, or loose components. Then, I utilize diagnostic equipment to gather more precise data. This could involve anything from simple tools like multimeters to check voltage and amperage, to more sophisticated equipment like vibration analyzers to detect bearing wear, or infrared cameras to identify overheating components. For example, if a motor is running inefficiently, a vibration analyzer might pinpoint an imbalance, a faulty bearing, or misalignment. A multimeter can help determine if the motor is receiving the correct voltage. I systematically check each component, comparing the readings to manufacturer specifications or established baselines to identify deviations indicating a problem. This methodical approach ensures accurate diagnosis and efficient repair.

Q 9. How do you document your repairs and maintenance procedures?

Detailed documentation is critical for accountability and future maintenance. I use a combination of methods for documenting repairs and maintenance procedures. This includes creating detailed written reports, often using standardized forms, which record the date, time, equipment involved, the problem encountered, the steps taken to diagnose the issue, parts replaced, and the final solution. I also take photographs or videos of the problem and the repair process to provide visual documentation. Sometimes, I’ll create simple sketches to illustrate complex issues. Finally, I utilize digital tools to record equipment usage hours and track maintenance schedules. These records allow for efficient troubleshooting in the future and provide a history of the equipment’s health, helping to predict and prevent potential failures.

Q 10. What is your experience with hydraulic and pneumatic systems?

I possess extensive experience working with both hydraulic and pneumatic systems. My experience ranges from troubleshooting leaks in hydraulic presses to repairing pneumatic actuators in automated machinery. In hydraulic systems, I’m adept at identifying leaks using dye penetrants, pressure testing components to find pressure drops, and understanding the importance of proper fluid levels and cleanliness. In pneumatic systems, I’m experienced in identifying air leaks using soapy water, checking for proper air pressure, and diagnosing issues with valves, cylinders, and other pneumatic components. For example, I once repaired a malfunctioning hydraulic lift by replacing a damaged seal, resulting in a restoration of its lifting capacity and avoiding costly downtime. Understanding the principles of fluid power is crucial in these systems and I am well-versed in this area.

Q 11. Describe your experience with various types of bearings and their applications.

My experience encompasses a wide range of bearings, including ball bearings, roller bearings (cylindrical, tapered, spherical), and sleeve bearings. The selection of a bearing depends heavily on the application’s specific needs. For instance, ball bearings are ideal for high-speed applications where rotational friction needs to be minimized, while roller bearings are better suited for high load applications. Tapered roller bearings are particularly effective at handling both radial and axial loads, often used in wheel assemblies. Sleeve bearings, on the other hand, are simpler and are usually found in low-speed, high-load applications. I’ve worked with all these types and understand how to select the correct bearing for a specific application based on factors like load, speed, operating temperature, and environmental conditions. I can also identify signs of wear and tear, such as noise or excessive play, and replace bearings as needed.

Q 12. What types of lubrication are you familiar with and how do you apply them?

I am familiar with a variety of lubricants, including greases, oils, and specialized lubricants. The selection of the appropriate lubricant is critical for optimal equipment performance and longevity. The choice depends on the application, the type of bearing or moving part, and the operating conditions (temperature, load, speed). For example, I’d use a high-temperature grease for bearings operating in high-heat environments. Oils are often preferred for fluid film lubrication in engines and other high-speed applications. I’m skilled in applying lubricants using appropriate methods, ensuring proper coverage and preventing over-lubrication which can lead to contamination and damage. For example, applying grease to a ball bearing with a grease gun requires knowing the correct amount and avoiding overfilling. I always refer to manufacturer specifications for guidance on lubricant type and application method.

Q 13. Explain your understanding of different types of fasteners and their applications.

Understanding fasteners is fundamental to mechanical repair. I’m experienced with various types, including bolts, screws, nuts, rivets, and other specialized fasteners. Each type has unique properties and applications. For example, bolts are typically used for easily removable connections, while rivets are used for permanent joining. Selecting the right fastener involves considering factors such as material strength, load requirements, and the need for reusability. I can identify different bolt grades (e.g., Grade 5, Grade 8), understand the importance of proper torque application to prevent damage, and recognize signs of fastener failure, such as stripping or corrosion. In many applications, I’ll use specialized tools, like torque wrenches, to ensure fasteners are properly tightened, preventing damage and ensuring a secure connection.

Q 14. How do you interpret mechanical drawings and schematics?

Interpreting mechanical drawings and schematics is crucial for effective repair and maintenance. I’m proficient in reading and understanding various types of drawings, including orthographic projections, isometric views, and assembly drawings. I can identify different components, understand their relationships, and determine the sequence of assembly or disassembly. I also understand the importance of dimensions, tolerances, and material specifications. For example, using a schematic diagram, I can trace the flow of fluids in a hydraulic system or electricity in an electrical circuit, allowing for efficient troubleshooting and repair. My ability to read and interpret these drawings efficiently allows for accurate and effective repair work, minimizing errors and improving overall efficiency.

Q 15. What is your experience with welding or soldering?

My experience with welding and soldering encompasses both techniques, though my proficiency leans more towards soldering for light mechanical repair. Welding is primarily used for joining thicker metal components, often requiring specialized equipment and safety precautions. In my work, I’ve utilized soldering extensively for repairing delicate components, circuit boards, and small metal parts. I’m skilled in various soldering techniques including through-hole soldering, surface mount soldering (SMT), and specialized soldering for electronics repair. For instance, I successfully repaired a faulty sensor in a conveyor system by carefully resoldering a loose connection, preventing a costly system shutdown. I’m comfortable with different solder types, including lead-free options, and I always prioritize safety, using appropriate ventilation and safety glasses.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with electrical systems related to mechanical equipment.

My experience with electrical systems in mechanical equipment is significant. I’m adept at troubleshooting issues in various systems, from simple motor controls to more complex PLCs (Programmable Logic Controllers). I’m proficient in diagnosing problems using multimeters, oscilloscopes, and other diagnostic tools. For example, I once diagnosed a malfunction in a robotic arm by tracing a faulty wire in the control cabinet, leading to a quick repair and minimal downtime. Understanding basic electrical schematics and wiring diagrams is crucial, and I can effectively interpret them to identify the source of an electrical fault. My knowledge also includes working safely with various voltages, adhering strictly to safety protocols to prevent electrical shocks or damage to equipment.

Q 17. How do you handle unexpected mechanical failures or emergencies?

Handling unexpected mechanical failures demands a calm and systematic approach. My first step is always safety – ensuring the area is secure and the equipment is isolated to prevent further damage or injury. Then, I conduct a thorough assessment of the situation, starting with visual inspection to identify the problem’s source. Next, I use my diagnostic skills to determine the root cause, often utilizing tools like multimeters, pressure gauges, or thermal cameras. Once identified, I prioritize repairs based on urgency and safety, implementing temporary fixes if necessary to restore partial functionality while I work towards a permanent solution. For example, I once had a pump fail unexpectedly during production. I quickly implemented a temporary bypass using an auxiliary pump, minimizing downtime while I diagnosed and repaired the primary pump.

Q 18. What is your experience with using Computerized Maintenance Management Systems (CMMS)?

My experience with Computerized Maintenance Management Systems (CMMS) includes using several industry-standard platforms to schedule maintenance, track repairs, and manage inventory. I’m proficient in entering work orders, updating equipment records, and generating reports. I understand the importance of accurate data entry for efficient maintenance planning and inventory control. I’ve used CMMS to schedule preventative maintenance tasks, helping to reduce equipment downtime and extend its lifespan. The ability to track historical repair data in a CMMS provides valuable insights into potential equipment weaknesses, allowing for proactive maintenance and improved system reliability.

Q 19. How do you stay updated on new technologies and techniques in light mechanical repair?

Staying current in light mechanical repair requires continuous learning. I regularly attend workshops and seminars offered by manufacturers and industry organizations. I also subscribe to relevant trade publications and online resources, keeping abreast of the latest technologies and best practices. I actively participate in online forums and communities, engaging with other professionals to share knowledge and learn from their experiences. Additionally, I actively seek opportunities to work with new equipment and technologies, gaining hands-on experience with the latest innovations. This approach allows me to adapt to the ever-evolving landscape of light mechanical repair and employ the most efficient and effective methods.

Q 20. Describe a time you had to solve a complex mechanical problem.

One challenging problem involved a conveyor system experiencing intermittent stoppages. Initial inspections revealed no obvious mechanical issues. After systematically checking sensors, motors, and the control system, I discovered a subtle problem with a poorly lubricated bearing within the conveyor’s drive mechanism. The intermittent nature of the issue was due to the varying load on the bearing, causing it to bind under stress. My solution involved disassembling the drive unit, cleaning the bearing, and applying the correct type of lubricant. I also recommended improvements to the lubrication schedule to prevent future occurrences. Solving this problem required not only technical skill but also a methodical approach to eliminate potential causes and a deep understanding of the system’s mechanics.

Q 21. What is your experience with different types of motors (AC/DC)?

My experience with AC and DC motors is extensive, encompassing both troubleshooting and repair. I understand the fundamental differences between the two motor types, including their operational principles, control methods, and common failure modes. I’m proficient in diagnosing issues such as faulty windings, bearing wear, and control circuit problems in both AC and DC motors. I’m familiar with different motor types, including induction motors, synchronous motors, and brushed and brushless DC motors. For example, I recently repaired a faulty AC induction motor in a pumping system by replacing a damaged capacitor, restoring the system to full operation. My knowledge includes safe working practices when dealing with high-voltage AC motors and ensuring proper grounding to prevent electrical hazards.

Q 22. How do you maintain and care for your tools?

Maintaining my tools is paramount to my work. It’s not just about keeping them clean; it’s about extending their lifespan and ensuring precision. My routine starts with cleaning after each use. I use appropriate solvents and brushes for removing grease, dirt, and debris. This prevents corrosion and ensures proper functioning.

- Storage: I store my tools in a well-organized manner, using tool chests with individual compartments or foam inserts to prevent damage and keep things easily accessible. Sharp tools are kept in sheaths or cases.

- Sharpening and Maintenance: Regularly sharpening blades, chisels, and other cutting tools is crucial. I use sharpening stones or honing guides, depending on the tool type, to maintain their sharpness. For powered tools, I follow manufacturer’s instructions for lubrication, oil changes (where applicable), and periodic inspection of belts and brushes.

- Calibration: Tools like torque wrenches require periodic calibration to ensure accuracy. I have them professionally calibrated at least once a year, or more frequently if used intensively.

- Inventory: Keeping an inventory of my tools allows me to quickly identify any missing or damaged tools and take appropriate action.

Think of it like this: a mechanic’s tools are like a surgeon’s scalpel – precision and care are critical for accurate and efficient work.

Q 23. What are some common causes of mechanical failure?

Mechanical failures stem from a variety of factors, often a combination of wear and tear, improper maintenance, and design flaws.

- Wear and Tear: This is the most common cause. Friction, vibration, and repeated stress eventually degrade components, leading to cracks, fatigue, and ultimately, failure. Think of the wear on a car’s brake pads or the gradual deterioration of a gear in a transmission.

- Improper Maintenance: Neglecting lubrication, failing to replace worn parts, or ignoring warning signs can accelerate the deterioration of mechanical systems. For example, a lack of lubrication in a bearing can lead to overheating and seizure.

- Overloading: Exceeding a machine’s design limits can cause immediate failure. Overloading a motor beyond its rated capacity can lead to burnout.

- Corrosion: Exposure to moisture or corrosive substances can weaken components and cause premature failure. This is a common issue in marine or outdoor equipment.

- Design Flaws: Although less frequent, manufacturing defects or poor design can predispose a machine to failure.

Effective preventative maintenance is key in mitigating these issues. Regular inspections, lubrication, and the timely replacement of worn parts significantly reduce the risk of mechanical failures.

Q 24. Explain your understanding of torque and its importance in mechanical repair.

Torque is the rotational force applied to an object. In simpler terms, it’s the twisting force that causes something to rotate. In mechanical repair, it’s incredibly important because it determines how tightly a fastener is secured.

Using too little torque can lead to loose components, vibrations, and potential failure. Too much torque can strip threads, break bolts, or damage the components themselves. Think of tightening a lug nut on a wheel – too loose and the wheel falls off; too tight and you strip the threads and risk damaging the wheel studs.

Torque wrenches are essential tools for applying the correct amount of torque. These wrenches are calibrated to provide a specific amount of rotational force, preventing over-tightening or under-tightening. The correct torque value is usually specified in the manufacturer’s manual for the specific equipment being repaired.

Knowing and using the correct torque values is critical for ensuring the safety and longevity of any repair. It directly impacts the structural integrity of the machinery and is a key factor in avoiding accidents and costly repairs down the line.

Q 25. Describe your experience with troubleshooting belt drives and chain drives.

I have extensive experience troubleshooting both belt and chain drives. Both systems are prone to various issues, but the troubleshooting approaches differ slightly.

- Belt Drives: Problems often include belt slippage, wear and tear, misalignment, and broken belts. Troubleshooting involves checking for belt tension, alignment of pulleys, and the condition of the belt itself (checking for cracks, glazing, or excessive wear). Alignment issues are crucial – misaligned pulleys cause premature belt wear and slippage. I would also check the condition of the pulleys themselves for wear or damage.

- Chain Drives: Common problems include chain stretching, worn sprockets, lubrication issues, and chain breakage. Troubleshooting focuses on checking chain tension (too tight or too loose can cause damage), inspecting sprockets for wear (worn sprockets affect chain life), and checking for proper lubrication. A properly lubricated chain operates more smoothly and efficiently, extending its lifespan. I look for any evidence of binding or unusual noise, which often indicates a problem.

In both cases, understanding the specific application and the operating conditions is important for diagnosis. The cause of a problem in a high-speed, high-load application might differ from that in a low-speed, low-load application.

Q 26. What is your experience with repairing pumps and valves?

My experience with pumps and valves is broad, encompassing various types and applications. I’m comfortable working on centrifugal pumps, positive displacement pumps, and different types of valves (ball valves, gate valves, globe valves, etc.).

Repairing pumps often involves diagnosing the cause of the problem, which might be related to leaks, seal failure, worn impellers, or motor issues. For example, a pump might fail to deliver adequate flow due to impeller wear. Troubleshooting could involve disassembling the pump, inspecting the impeller, replacing worn parts, and reassembling the unit. I always follow the manufacturer’s instructions and safety guidelines during these repairs.

Valve repair usually involves identifying the cause of leakage or malfunction. This could range from simple seat and stem repairs to complete valve replacement. Understanding valve types and their functions is essential to properly diagnose and fix valve problems.

Proper testing after repairs is essential for both pumps and valves to verify that the repairs have been successful and the units are functioning correctly.

Q 27. How do you ensure the quality of your repairs?

Ensuring quality in my repairs is a multifaceted process starting with a thorough understanding of the problem. I always perform a comprehensive inspection before and after any repair work.

- Diagnosis: Accurate diagnosis is critical. I use diagnostic tools and techniques to pinpoint the root cause of the malfunction, not just the symptoms.

- Proper Parts: I use only high-quality, OEM or equivalent replacement parts to guarantee durability and performance.

- Adherence to Specifications: I meticulously follow manufacturer’s specifications and guidelines during repair. This includes torque values, clearances, and other critical parameters.

- Testing: After the repair, I thoroughly test the repaired component or system to verify that it’s functioning correctly and meets the required performance standards.

- Documentation: I maintain clear and detailed records of the repair process, including parts used, procedures followed, and test results. This helps with future troubleshooting and also demonstrates accountability.

My commitment to quality isn’t just about fixing the immediate problem; it’s about ensuring the long-term reliability and safety of the repaired equipment.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience, skill set, and the demands of the position. Considering my extensive experience in light mechanical repair and my proven track record, I am seeking a competitive salary within the range of [Insert Salary Range Here]. I am confident that my contributions will significantly benefit your organization.

Key Topics to Learn for Light Mechanical Repair Interview

- Basic Hand Tools and Their Applications: Understanding the proper use and maintenance of common hand tools like wrenches, screwdrivers, pliers, and measuring instruments is fundamental. This includes knowing the differences between various types and selecting the appropriate tool for a specific task.

- Mechanical Principles: Grasping core concepts like levers, pulleys, gears, and simple machines is crucial for diagnosing and troubleshooting mechanical issues. Be prepared to explain how these principles apply in practical situations.

- Safety Procedures and Regulations: Demonstrate your knowledge of workplace safety protocols, including the proper use of personal protective equipment (PPE) and hazard identification. This is vital for any mechanical repair role.

- Preventive Maintenance and Inspection: Understanding the importance of routine maintenance and inspection procedures to prevent equipment failure and extend its lifespan is key. Be ready to discuss specific examples.

- Troubleshooting and Diagnostics: Develop your ability to systematically identify and solve mechanical problems. Practice explaining your diagnostic process and how you approach troubleshooting various mechanical issues.

- Blueprint Reading and Technical Drawings: Familiarity with interpreting technical drawings and blueprints is essential for understanding repair specifications and performing accurate repairs.

- Hydraulic and Pneumatic Systems (if applicable): Depending on the specific role, understanding basic hydraulic and pneumatic systems might be necessary. Focus on principles of pressure, flow, and components if relevant to the job description.

- Common Repairs and Maintenance Tasks: Prepare to discuss your experience with various light mechanical repair tasks, emphasizing your problem-solving skills and ability to work efficiently and effectively.

Next Steps

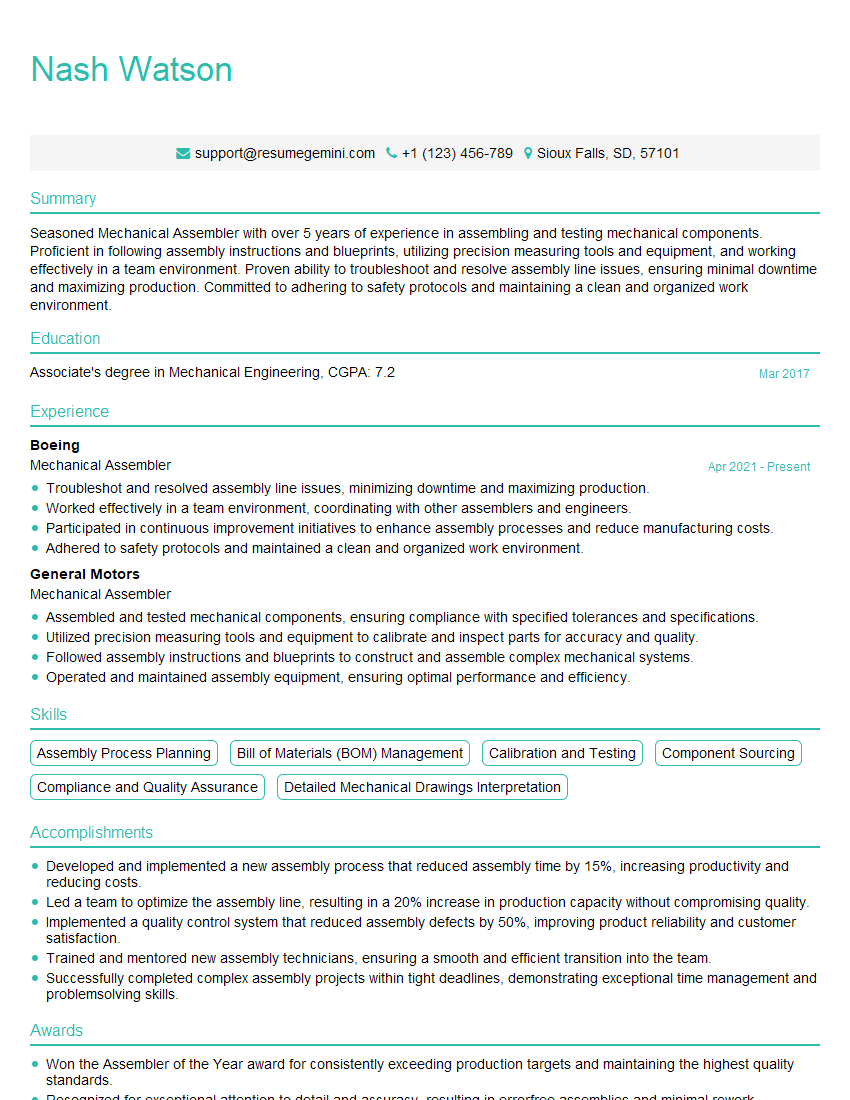

Mastering Light Mechanical Repair opens doors to a rewarding career with diverse opportunities for growth and specialization. Building a strong foundation in these key areas will significantly enhance your interview performance and increase your chances of landing your dream job. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that gets noticed by recruiters. Examples of resumes tailored to Light Mechanical Repair are available through ResumeGemini, allowing you to see best practices in action and tailor your own to perfection.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO