Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Load Handling and Logistics interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Load Handling and Logistics Interview

Q 1. Explain the difference between LTL and FTL shipping.

LTL (Less than Truckload) and FTL (Full Truckload) shipping are two distinct approaches to transporting goods, differing primarily in the amount of cargo shipped and how it’s priced. FTL involves reserving an entire truck for a single shipper’s goods, making it ideal for large shipments. Think of it like renting a whole apartment – you get the entire space and control over it. This approach is cost-effective for large volumes but can be expensive for smaller shipments. LTL, on the other hand, consolidates smaller shipments from multiple shippers onto a single truck. It’s like sharing a house – you only pay for your portion of the space, resulting in lower individual shipping costs but potentially longer transit times due to multiple stops and handling.

Example: Imagine you’re a furniture manufacturer. Shipping 100 sofas across the country would likely be FTL. But shipping only 5 sofas might be more economical using LTL, sharing space with other furniture manufacturers’ smaller orders.

Q 2. Describe your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) spans over eight years, encompassing implementation, configuration, and daily operational use within both large-scale distribution centers and smaller facilities. I’ve worked extensively with various WMS platforms, including Oracle WMS, Manhattan Associates WMS, and Blue Yonder. My expertise involves optimizing inventory management, tracking and tracing goods, managing receiving and shipping processes, and generating key performance indicators (KPIs) to monitor efficiency. For instance, I successfully implemented a new WMS at a previous company, resulting in a 15% reduction in order fulfillment time and a 10% decrease in inventory discrepancies. This involved not just configuring the system but also training warehouse staff and integrating it with our existing ERP (Enterprise Resource Planning) system. I’m proficient in using WMS to manage everything from putaway strategies and cycle counting to automated order picking and reporting.

Q 3. How do you optimize load planning for efficient transportation?

Optimizing load planning is crucial for efficient transportation. It involves strategically placing items in the vehicle to maximize space utilization, minimize weight distribution imbalances, and ensure the safety and security of the cargo. My approach focuses on several key aspects:

- Cube Optimization: Using software and understanding the dimensions of each item to ensure maximum space utilization within the vehicle. This often involves stacking and nesting items strategically.

- Weight Distribution: Balancing the weight across the truck’s axles to prevent overloading and ensure stability during transit. Heavy items are placed lower and near the center of gravity.

- Fragility and Sensitivity: Prioritizing the placement of fragile or sensitive items to minimize the risk of damage during transportation. Padding and secure strapping are employed.

- Delivery Sequence: Sequencing the placement of goods based on delivery points to minimize handling and improve efficiency. Items destined for the same location are grouped together.

Example: When loading a truck with furniture, large, heavy items like sofas and beds are placed at the bottom and towards the center, while smaller, lighter items are placed on top. Fragile items are padded and secured to prevent damage.

Q 4. What are the key safety regulations for load handling?

Key safety regulations for load handling are multifaceted and vary by jurisdiction but generally focus on preventing accidents involving equipment, personnel, and the cargo itself. These regulations often include:

- Load Securement: Properly securing loads to prevent shifting or falling during transit. This often involves using straps, chains, and other securing devices. Regulations usually specify the type and quantity of securement devices needed based on the weight and type of cargo.

- Weight Limits: Adhering to weight limits specified for vehicles and lifting equipment to prevent overloading and structural damage. Overloading is a major cause of accidents.

- Equipment Maintenance: Regular inspection and maintenance of all handling equipment, such as forklifts and cranes, to ensure safe operation. This includes regular safety checks and operator training.

- Personal Protective Equipment (PPE): The mandatory use of PPE, including safety helmets, high-visibility clothing, and safety shoes, by all personnel involved in load handling operations.

- Training and Certification: Operators of material handling equipment must receive proper training and certification to ensure they are competent and understand safety procedures.

Non-compliance can lead to hefty fines, insurance issues, and most importantly, serious injuries or fatalities.

Q 5. Explain your experience with different types of material handling equipment.

My experience encompasses a broad range of material handling equipment, including:

- Forklifts: Proficient in operating various types, including counterbalance, reach trucks, and order pickers, adhering strictly to safety protocols.

- Conveyors: Experience with various conveyor systems, from roller conveyors to belt conveyors and automated guided vehicles (AGVs). This includes troubleshooting and maintenance.

- Cranes: Familiar with overhead cranes and their safe operation, including load capacity calculations and proper rigging techniques.

- Pallet Jacks: Extensive use in manual material handling, emphasizing safe lifting practices.

- Automated Systems: Experience integrating and managing automated storage and retrieval systems (AS/RS) within warehouse environments. This includes programming and problem-solving.

I am always updated on the latest technologies and best practices in material handling, and I always prioritize safety in equipment operation and maintenance. For example, I implemented a new system of preventative maintenance on forklifts at one company, reducing downtime and improving safety.

Q 6. How do you handle inventory discrepancies?

Handling inventory discrepancies requires a systematic approach focusing on identification, root cause analysis, and corrective actions. My process typically involves:

- Regular Cycle Counting: Implementing a robust cycle counting program to regularly verify inventory levels against the WMS data.

- Discrepancy Investigation: Thoroughly investigating any discrepancies identified during cycle counting, examining potential causes such as data entry errors, misplacements, theft, or damage.

- Root Cause Analysis: Identifying the root cause of recurring discrepancies to prevent future issues. This often involves analyzing processes and workflows.

- Corrective Actions: Implementing corrective actions to address the identified root causes. This could include improvements in training, process changes, or system upgrades.

- Documentation: Maintaining detailed records of all discrepancies, investigations, and corrective actions taken.

For instance, I once identified a recurring discrepancy involving a specific product. After investigation, we discovered a labeling issue that was leading to misplacement. Addressing the labeling problem completely eliminated the discrepancy.

Q 7. Describe your process for managing damaged goods.

Managing damaged goods involves a process that balances minimizing losses, maintaining safety, and complying with regulations. My process typically includes:

- Damage Assessment: Immediately assessing the extent of the damage to determine whether the goods can be salvaged, repaired, or need to be discarded.

- Documentation: Thoroughly documenting the damage, including photographs, descriptions, and the likely cause of the damage. This is crucial for insurance claims and investigations.

- Segregation: Segregating damaged goods from undamaged inventory to prevent further damage or contamination.

- Salvage or Disposal: Determining whether the goods can be salvaged through repair or repurposing, or whether they must be disposed of in accordance with environmental regulations. This may involve contacting recyclers or waste disposal services.

- Root Cause Analysis: Analyzing the cause of the damage to prevent similar incidents in the future. This might involve improved handling procedures, better packaging, or improved transportation methods.

- Insurance Claims: Filing insurance claims if appropriate, providing all necessary documentation to support the claim.

For example, if a shipment of electronics arrives with cracked screens, we’d document the damage, segregate the units, explore repair options, and investigate whether the damage occurred during handling or transit to prevent future issues.

Q 8. What metrics do you use to measure the efficiency of load handling operations?

Measuring the efficiency of load handling operations requires a multi-faceted approach, focusing on both speed and resource optimization. Key metrics include:

- Throughput: This measures the volume of goods handled per unit of time (e.g., tons per hour, units per day). A higher throughput indicates greater efficiency. For example, tracking the number of containers unloaded from a ship per hour allows us to benchmark performance against previous operations and identify areas for improvement.

- Order fulfillment rate: This metric tracks the percentage of orders processed and delivered accurately and on time. A high fulfillment rate showcases efficient order management and timely delivery.

- Inventory turnover: This shows how quickly goods are moved through the supply chain. A faster turnover suggests efficient inventory management and reduced storage costs. For instance, a high turnover rate for perishable goods minimizes spoilage and maximizes profitability.

- Cost per unit handled: This metric tracks the direct and indirect costs associated with handling each unit of goods, helping us identify areas for cost reduction. Analyzing this data can reveal inefficiencies in labor, equipment, or storage.

- Damage rate: This indicates the percentage of goods damaged during handling and transportation. A low damage rate demonstrates efficient and careful handling practices, minimizing losses and customer complaints.

- On-time delivery rate: This crucial metric measures the percentage of shipments delivered within the scheduled timeframe, reflecting the overall efficiency and reliability of the operation. Tracking this metric is crucial for meeting customer expectations and maintaining business relationships.

By tracking these metrics and regularly analyzing the data, we can identify bottlenecks, optimize processes, and improve overall efficiency.

Q 9. How do you ensure the security of goods during transportation?

Ensuring the security of goods during transportation involves a layered approach combining physical security measures with robust documentation and tracking systems. This includes:

- Secure packaging: Using appropriate packaging materials and techniques to protect goods from damage and theft. This might involve using tamper-evident seals, reinforced containers, or specialized packaging for fragile items.

- Vehicle security: Employing vehicles equipped with GPS tracking, alarm systems, and tamper-resistant locks. Regular vehicle maintenance is also crucial to prevent breakdowns that could leave goods vulnerable.

- Route security: Planning routes that avoid high-crime areas and using secure loading and unloading facilities. This often involves analyzing risk maps and selecting the safest and most efficient routes.

- Insurance: Obtaining adequate cargo insurance to cover potential losses due to theft, damage, or other unforeseen events. This acts as a financial safety net for both the shipper and the receiver.

- Documentation and tracking: Maintaining detailed records of shipments, including waybills, invoices, and proof of delivery. Real-time tracking systems allow us to monitor the location and status of goods throughout the journey. This is particularly important for high-value or time-sensitive shipments.

- Security personnel: In some cases, employing security personnel to escort high-value shipments or to monitor loading and unloading activities. This is particularly useful for high-risk shipments.

By implementing these measures, we can significantly reduce the risk of loss or damage to goods during transportation.

Q 10. Explain your experience with various transportation modes (e.g., truck, rail, air).

My experience encompasses a broad range of transportation modes, each with its own strengths and limitations. I’ve worked extensively with:

- Truck transport: Ideal for shorter distances and door-to-door delivery, offering flexibility and speed, particularly for smaller shipments. I’ve managed numerous trucking operations, negotiating rates with carriers and optimizing routes for cost-effectiveness and timeliness.

- Rail transport: Cost-effective for large volumes and long distances, making it suitable for bulk commodities. My experience includes coordinating rail shipments, ensuring timely loading and unloading and managing any potential delays caused by rail network issues.

- Air transport: The fastest mode, critical for time-sensitive goods like pharmaceuticals and perishables. However, it’s more expensive. My work here has involved securing appropriate air freight contracts, complying with aviation regulations, and closely monitoring shipment progress to minimize delays.

I understand the nuances of each mode and can effectively select the optimal mode based on factors such as distance, cargo type, urgency, and cost considerations. I’ve successfully managed complex multi-modal shipments, leveraging the strengths of each mode to create efficient and cost-effective delivery solutions.

Q 11. How do you prioritize tasks during peak periods?

Prioritizing tasks during peak periods requires a structured approach combining efficient planning and effective communication. My strategy involves:

- Prioritization matrix: Categorizing tasks based on urgency and importance (using a matrix like Eisenhower’s Urgent/Important). This ensures that critical tasks are addressed first, while less urgent tasks are scheduled accordingly.

- Capacity planning: Accurately forecasting demand and allocating resources accordingly. This involves analyzing historical data, considering seasonality and potential disruptions.

- Real-time tracking and monitoring: Utilizing technology to monitor progress and identify potential bottlenecks. This allows for proactive adjustments and minimizes delays.

- Effective communication: Keeping the team informed about priorities and any changes in schedule. Clear communication is crucial to maintain efficiency and coordination during peak periods.

- Flexibility and adaptability: Being prepared to adjust plans as needed in response to unexpected events or changes in demand. This might involve re-allocating resources or adjusting delivery schedules.

For example, during the holiday season, we would prioritize time-sensitive orders with short delivery windows, ensuring that gift deliveries reach customers on time. Less urgent shipments would be scheduled for off-peak periods.

Q 12. Describe your experience with customs regulations and documentation.

My experience with customs regulations and documentation is extensive. I have a thorough understanding of the complexities involved in international shipping, including:

- Tariff classification: Accurately classifying goods according to the Harmonized System (HS) code to ensure correct duty and tax calculations. Incorrect classification can lead to delays and penalties.

- Documentation preparation: Preparing accurate and complete documentation, including commercial invoices, packing lists, certificates of origin, and other required forms. This requires attention to detail and adherence to specific regulations of each country involved.

- Customs clearance procedures: Understanding the customs clearance processes in different countries and working with customs brokers to ensure smooth and efficient clearance of goods. This might include providing additional documentation or responding to customs inquiries.

- Compliance with regulations: Staying up-to-date on changes in customs regulations and ensuring that all shipments comply with relevant laws and regulations. This is particularly important given the frequent changes in international trade regulations.

I have successfully navigated complex customs procedures in numerous countries, ensuring timely delivery of goods while maintaining full compliance with all applicable regulations. I’ve also dealt with instances of customs audits and successfully addressed any outstanding queries or concerns.

Q 13. How do you manage supplier relationships to ensure timely deliveries?

Managing supplier relationships effectively is critical for timely deliveries. My approach focuses on:

- Clear communication: Maintaining open and transparent communication with suppliers, establishing clear expectations and regularly sharing updates. This ensures everyone is on the same page and potential issues are addressed proactively.

- Performance monitoring: Tracking supplier performance using key metrics such as on-time delivery rates, quality of goods, and responsiveness. This allows for identifying potential issues and addressing them early.

- Collaboration and partnership: Developing strong working relationships with suppliers, fostering collaboration and trust. This helps build a strong foundation for effective communication and problem-solving.

- Continuous improvement: Regularly reviewing supplier performance and identifying opportunities for improvement. This might involve implementing new processes, sharing best practices, or exploring alternative suppliers.

- Conflict resolution: Having a clear process for resolving disagreements or conflicts with suppliers. This involves addressing issues promptly, fairly, and professionally, minimizing disruptions to the supply chain.

For example, by proactively monitoring delivery lead times and communicating potential delays with our customers, I have been able to mitigate potential disruptions and maintain customer satisfaction. Working collaboratively with suppliers, we have also implemented process improvements that have led to significant increases in on-time delivery rates.

Q 14. What is your experience with route optimization software?

I have extensive experience using route optimization software, significantly improving efficiency and reducing costs. My experience includes using various software packages that perform:

- Route planning: These tools allow for the creation of efficient delivery routes, considering factors such as distance, traffic, and delivery time windows. They calculate the most optimal routes, minimizing travel time and fuel consumption.

- Real-time tracking: Monitoring the location and status of vehicles in real-time, allowing for proactive adjustments to routes in response to unexpected events such as traffic congestion or accidents.

- Delivery scheduling: Optimizing delivery schedules to ensure efficient allocation of resources and timely delivery of goods. This often involves considering driver availability, delivery time windows, and the capacity of vehicles.

- Reporting and analytics: Generating reports on key performance indicators such as fuel consumption, delivery times, and mileage. This data allows for identifying areas for improvement and optimizing delivery operations further.

For example, I’ve used [Software Name - Example] to optimize delivery routes, resulting in a 15% reduction in fuel consumption and a 10% improvement in on-time delivery rates. The software’s real-time tracking capabilities have also allowed us to proactively manage unexpected delays, minimizing their impact on delivery schedules.

Q 15. How do you handle unexpected delays in the supply chain?

Unexpected delays are unfortunately a common occurrence in supply chains. My approach involves a multi-pronged strategy focused on proactive risk mitigation and reactive problem-solving.

- Proactive Measures: This includes robust supplier relationship management, diversifying sourcing to mitigate single-point failures, real-time tracking and monitoring of shipments using technologies like GPS and RFID, and maintaining strong communication channels with all stakeholders. For example, if a key supplier is known to be prone to delays, we build in buffer time into our schedules and explore alternative suppliers.

- Reactive Measures: When delays occur, I immediately initiate a situation assessment. This involves identifying the root cause of the delay, evaluating the impact on downstream processes, and then selecting the best course of action. This could involve rerouting shipments, negotiating with carriers for expedited service, informing customers about potential delivery delays, and exploring alternative solutions like air freight to minimize disruptions. The key here is transparency and quick decision-making. For instance, during a port congestion issue, we successfully rerouted a significant shipment through a less congested port, minimizing the delay to only a few days.

Essentially, it’s about anticipating potential problems and having contingency plans in place while maintaining flexible and responsive processes to address unexpected events.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to solve a complex logistics problem.

During a large-scale product launch, we faced a critical challenge: the primary transportation provider unexpectedly went bankrupt mid-transit, leaving several key shipments stranded. This presented a significant risk to our launch timeline.

My solution involved a three-step process:

- Assessment: We immediately assessed the number of affected shipments, their location, and their contents. This involved gathering information from various sources, including the bankrupt carrier’s records (to the extent possible), our internal tracking systems, and communication with our suppliers and customers.

- Action: We then engaged multiple alternative carriers, negotiating favorable rates under time-sensitive conditions. We had to prioritize shipments based on their criticality to the launch. Simultaneously, we worked with our warehouse teams to prepare for rapid unloading and redistribution of shipments upon arrival. This involved coordinating schedules, staffing, and efficient handling procedures.

- Communication: Transparent and proactive communication with both internal stakeholders (our team, warehouse staff) and external ones (customers, suppliers) was crucial. Keeping everyone informed about the situation and our progress was essential in mitigating potential negative impacts.

This situation required swift action, collaborative problem-solving, and excellent communication. We managed to successfully recover all shipments within a few days and deliver the product on time, demonstrating our ability to handle complex logistical emergencies.

Q 17. What is your experience with inventory forecasting and planning?

Inventory forecasting and planning is crucial for efficient operations. My experience encompasses using a variety of techniques, from simple moving averages to sophisticated statistical models like ARIMA and exponential smoothing.

The process usually involves:

- Data Collection and Analysis: This includes historical sales data, market trends, seasonality, promotional campaigns, and economic indicators. Accurate data is paramount for effective forecasting.

- Model Selection: Choosing the right forecasting model depends on the data characteristics and the desired level of accuracy. Some products might benefit from simple models, while others require more complex approaches.

- Forecast Generation: Once a model is selected, it’s used to generate demand forecasts for a specific timeframe (e.g., monthly, quarterly).

- Inventory Optimization: The forecasts are then used to determine optimal inventory levels, factoring in lead times, safety stock, storage costs, and potential stockouts. Tools like inventory management systems (IMS) are vital here.

- Continuous Monitoring and Adjustment: Forecasts are not static; they need to be continuously monitored and adjusted based on actual sales and market changes. Regular review and refinement are essential to maintain accuracy.

I have successfully implemented these processes in several organizations, resulting in reduced inventory holding costs, minimized stockouts, and improved customer service levels.

Q 18. How do you ensure compliance with all relevant safety and regulatory standards?

Compliance with safety and regulatory standards is non-negotiable. My approach emphasizes proactive adherence rather than reactive remediation.

This involves:

- Thorough Understanding of Regulations: Staying updated on all relevant regulations, including those related to transportation, warehousing, hazardous materials handling, and workplace safety (e.g., OSHA, DOT, IATA).

- Implementation of Safety Procedures: Developing and implementing robust safety protocols across all operations, including proper training for staff, regular safety inspections, use of appropriate safety equipment, and maintaining meticulous documentation.

- Regular Audits and Assessments: Conducting internal audits to ensure adherence to standards and identifying areas for improvement. We also collaborate with external auditors to validate our compliance.

- Documentation and Record Keeping: Maintaining accurate and complete records of all safety procedures, training, inspections, and incidents to facilitate traceability and compliance verification.

Failure to comply with these standards can result in significant legal repercussions, financial penalties, and reputational damage. Therefore, ensuring compliance is not just a matter of best practice but a critical operational requirement.

Q 19. Explain your understanding of different types of warehousing (e.g., cross-docking, bulk storage).

Different warehousing types are chosen based on specific operational needs and the nature of the goods being stored.

- Cross-Docking: This involves receiving goods from suppliers, quickly sorting them, and then directly transferring them to outgoing shipments, minimizing storage time. It’s ideal for high-volume, fast-moving goods where storage space is a premium and speed is essential. Think of a distribution center for a large retailer handling fast-moving consumer goods.

- Bulk Storage: This focuses on storing large quantities of goods in a relatively less organized manner. It’s suitable for commodities like grains or raw materials where access frequency is lower. Think large warehouses storing pallets of raw materials for a manufacturing facility.

- Automated Warehouses: These utilize automated systems like conveyor belts, robotic arms, and automated guided vehicles (AGVs) to optimize storage and retrieval processes. They are best suited for high-volume, high-velocity operations where efficiency and accuracy are paramount. Think of a large e-commerce fulfillment center.

- Bonded Warehouses: These are used for goods that are imported and stored duty-free until they are released into the domestic market. They are commonly used in international trade.

The choice of warehousing type depends on factors such as product characteristics, volume, turnover rate, and cost considerations. Selecting the right type is vital for optimal supply chain efficiency.

Q 20. What is your experience with different types of packaging and its impact on load handling?

Packaging plays a vital role in load handling and directly impacts efficiency, safety, and cost. Different packaging materials and designs offer varying levels of protection, stackability, and ease of handling.

- Material Types: Corrugated cardboard is common for its cost-effectiveness and recyclability. Plastic pallets offer durability and reusability, while wooden pallets are a more traditional and widely used option. Specialized materials like insulated containers are used for temperature-sensitive goods.

- Design and Construction: The design of packaging affects its ability to withstand stacking and transportation stresses. Features like reinforced corners, sturdy bases, and proper cushioning protect goods from damage.

- Impact on Load Handling: Well-designed packaging optimizes space utilization within shipping containers or trucks, minimizing wasted space and maximizing load capacity. It also makes handling easier for warehouse workers, reducing the risk of injury and improving efficiency.

- Sustainability Considerations: The environmental impact of packaging materials is increasingly important. Choosing recyclable or biodegradable materials minimizes the carbon footprint of the supply chain.

For example, transitioning from individual boxes to palletized shipments significantly improves handling efficiency and reduces transportation costs. Similarly, using appropriate cushioning materials protects fragile goods and reduces damage claims. Selecting the right packaging material is critical for successful load handling and cost-effectiveness.

Q 21. How do you manage returns and reverse logistics?

Reverse logistics, the process of managing returns, is a critical yet often overlooked aspect of supply chain management. Effective reverse logistics involves a structured approach focused on efficiency and cost reduction.

My experience includes:

- Clear Return Policies and Procedures: Establishing clear and simple return policies that are easily accessible to customers. This includes specifying acceptable reasons for return, outlining the return process, and communicating the timeline for refunds or replacements.

- Efficient Return Processing: Implementing streamlined processes for handling returns, including labeling, sorting, inspection, and processing of refunds or exchanges. The use of technology, like barcodes and RFID tags, can help optimize this process.

- Product Disposition: Determining the appropriate disposition of returned goods. This includes repairing, refurbishing, reselling, recycling, or disposing of products appropriately, minimizing waste and environmental impact.

- Cost Optimization: Analyzing all aspects of reverse logistics to identify opportunities for cost reduction, such as optimizing transportation routes and negotiating favorable rates with carriers.

- Data Analysis: Using data analytics to identify trends and patterns in returns, such as common reasons for returns or defective products. This helps to proactively address issues and prevent future returns.

Effective reverse logistics not only improves customer satisfaction but also presents opportunities to recover value from returned goods and reduce overall supply chain costs.

Q 22. What are your strategies for reducing transportation costs?

Reducing transportation costs is crucial for profitability in logistics. My strategies focus on optimizing several key areas:

Route Optimization: I utilize advanced route planning software that considers factors like traffic patterns, delivery windows, and fuel prices to determine the most efficient routes. For example, I’ve successfully implemented a system that reduced delivery times by 15% and fuel consumption by 10% for a major client by dynamically adjusting routes based on real-time traffic data.

Load Consolidation: Maximizing the capacity of each vehicle is paramount. This involves careful planning and coordination to ensure that shipments are grouped together efficiently. I’ve implemented strategies that increased average load utilization by 20%, directly impacting fuel costs and the number of trips required.

Negotiating Carrier Rates: Building strong relationships with carriers and leveraging volume discounts are vital. I regularly analyze market rates and negotiate favorable contracts to secure the best possible pricing. In one instance, I successfully negotiated a 12% reduction in our annual transportation spend by strategically consolidating our carrier base and leveraging our shipping volume.

Mode Selection: Choosing the most cost-effective transportation mode (truck, rail, sea) for each shipment is essential. Factors like distance, urgency, and cargo type are carefully considered. For instance, we successfully transitioned some long-haul shipments from trucking to rail, resulting in significant cost savings.

These strategies, implemented collaboratively with clients and carriers, ensure a holistic approach to cost reduction while maintaining service quality.

Q 23. How do you utilize technology to improve load handling efficiency?

Technology plays a pivotal role in enhancing load handling efficiency. My experience encompasses using a range of tools and systems:

Transportation Management Systems (TMS): TMS software automates many tasks, such as route planning, load optimization, and shipment tracking, significantly reducing manual effort and errors. For example, a TMS we implemented reduced order processing time by 40% and improved on-time delivery rates.

Warehouse Management Systems (WMS): WMS streamlines warehouse operations, optimizing inventory management, order fulfillment, and picking processes. This reduces storage costs and improves order accuracy. One client saw a 25% reduction in picking errors after implementing a new WMS.

GPS Tracking and Telematics: Real-time tracking of vehicles and shipments provides valuable data for optimizing routes, identifying delays, and improving driver safety. We’ve used this data to proactively address potential delivery issues and prevent costly delays.

RFID and Barcode Technology: Automating inventory tracking and identification through RFID tags and barcodes drastically improves the speed and accuracy of warehouse operations, reducing errors and improving efficiency.

Data Analytics and Business Intelligence: Analyzing data from various sources (TMS, WMS, GPS) enables identifying bottlenecks, optimizing processes, and making data-driven decisions to improve overall efficiency.

The strategic integration of these technologies results in a highly efficient and responsive load handling operation.

Q 24. Describe your experience with lean logistics principles.

Lean logistics focuses on eliminating waste and maximizing efficiency throughout the supply chain. My experience involves applying these principles in several key areas:

Value Stream Mapping: I’ve utilized value stream mapping to identify and eliminate non-value-added activities in the logistics process. This involves visualizing the entire flow of goods and services to pinpoint areas for improvement. For instance, we identified a significant bottleneck in the receiving process of a client’s warehouse and redesigned the layout to reduce processing time by 30%.

5S Methodology: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) in warehouse and transportation operations creates a more organized and efficient workspace, reducing errors and improving safety. We’ve applied 5S in multiple warehouse environments, resulting in improved space utilization and reduced search times.

Kaizen Events: Participation in Kaizen events (continuous improvement workshops) has allowed for collaborative problem-solving and the implementation of small, incremental improvements throughout the logistics process. We’ve successfully used Kaizen to reduce lead times and improve order fulfillment accuracy.

Just-in-Time (JIT) Inventory Management: Implementing JIT principles reduces inventory holding costs by ensuring that materials and products arrive only when needed. We’ve worked with clients to optimize their supply chain to reduce lead times and minimize inventory levels.

Lean principles are not just about cost reduction; they improve overall efficiency, quality, and responsiveness.

Q 25. How do you ensure accurate tracking of goods throughout the supply chain?

Accurate tracking is essential for maintaining visibility and control throughout the supply chain. My approach combines technology and robust processes:

Barcode and RFID Tracking: Using barcodes and RFID tags on individual packages and pallets enables real-time tracking from origin to destination. This data feeds into our TMS and WMS for complete visibility.

GPS Tracking of Vehicles: Real-time location data from GPS trackers on delivery vehicles provides accurate shipment location and estimated time of arrival (ETA).

Integrated Systems: Our TMS, WMS, and other systems are integrated to provide a single source of truth for all shipment data. This eliminates data silos and ensures consistency.

Automated Data Entry: Reducing manual data entry minimizes errors and speeds up the process. Automated systems capture data directly from scanners and other devices.

Regular Audits and Reconciliation: Regular audits and reconciliation of shipment data ensure accuracy and identify any discrepancies. This process involves comparing data from various sources to identify and resolve inconsistencies.

Combining these methods provides a highly accurate and reliable system for tracking goods throughout the supply chain, enabling proactive problem-solving and improved customer satisfaction.

Q 26. What is your experience with implementing and improving logistics processes?

I have extensive experience in implementing and improving logistics processes, focusing on optimization and efficiency. This includes:

Process Mapping and Re-engineering: I’ve successfully mapped existing logistics processes, identified bottlenecks and inefficiencies, and implemented process improvements resulting in significant cost savings and improved service levels.

Warehouse Layout Optimization: I’ve redesigned warehouse layouts to optimize workflow, maximize space utilization, and improve efficiency of picking, packing, and shipping processes. One such project resulted in a 15% increase in order fulfillment speed.

Technology Implementation: I have experience implementing and integrating various logistics technologies, including TMS, WMS, and GPS tracking systems, resulting in improved visibility, efficiency, and cost savings.

Supply Chain Network Design: I’ve assisted clients in designing and optimizing their supply chain networks to reduce transportation costs, improve delivery times, and enhance overall responsiveness.

Performance Measurement and Reporting: I’ve developed and implemented key performance indicators (KPIs) to monitor and track logistics performance, enabling data-driven decision-making and continuous improvement.

My approach is always collaborative, involving stakeholders to ensure buy-in and successful implementation of improvements. The focus is always on measurable results and achieving a demonstrable return on investment.

Q 27. How do you handle customer complaints related to load handling or delivery?

Handling customer complaints effectively is crucial for maintaining positive relationships. My approach involves:

Active Listening and Empathy: I start by actively listening to the customer’s concerns, demonstrating empathy and understanding their frustration.

Thorough Investigation: I conduct a thorough investigation into the complaint, gathering all relevant information from various sources (tracking data, delivery notes, communication logs) to understand the root cause.

Transparent Communication: I keep the customer informed throughout the investigation process, providing regular updates on progress and explaining any delays.

Resolution and Compensation: Once the root cause is identified, I work to resolve the issue promptly and fairly. This might involve providing a replacement, refund, or other appropriate compensation.

Proactive Prevention: After resolving the complaint, I analyze the situation to identify potential systemic issues and implement preventative measures to avoid similar occurrences in the future.

Building trust and maintaining open communication are essential to ensuring customer satisfaction and turning negative experiences into opportunities for improvement.

Key Topics to Learn for Load Handling and Logistics Interview

- Warehouse Management Systems (WMS): Understanding how WMS software optimizes inventory management, order fulfillment, and warehouse operations. Practical application includes explaining your experience with different WMS platforms and their impact on efficiency.

- Inventory Control & Optimization: Mastering techniques for accurate inventory tracking, minimizing stockouts, and managing excess inventory. Practical application includes describing methods used to reduce waste and improve inventory turnover.

- Supply Chain Management Principles: Grasping the fundamentals of supply chain design, planning, and execution. Practical application involves explaining your understanding of different supply chain models and their suitability for various scenarios.

- Transportation Management Systems (TMS): Knowledge of TMS software and its role in optimizing transportation routes, scheduling, and cost management. Practical application could include discussing experience with route optimization software or strategies for efficient fleet management.

- Load Planning & Optimization: Understanding the principles of safe and efficient load securing, weight distribution, and maximizing space utilization in vehicles and containers. Practical application includes describing your experience with load planning software or manual load planning techniques.

- Health and Safety Regulations: Familiarity with relevant health and safety regulations concerning load handling, including hazard identification, risk assessment, and the use of appropriate safety equipment. Practical application involves detailing your experience implementing safety protocols in a logistics environment.

- Logistics Technology & Automation: Understanding emerging technologies like robotics, automated guided vehicles (AGVs), and AI’s role in optimizing logistics processes. This could include discussing your familiarity with specific technologies or your views on future automation trends.

Next Steps

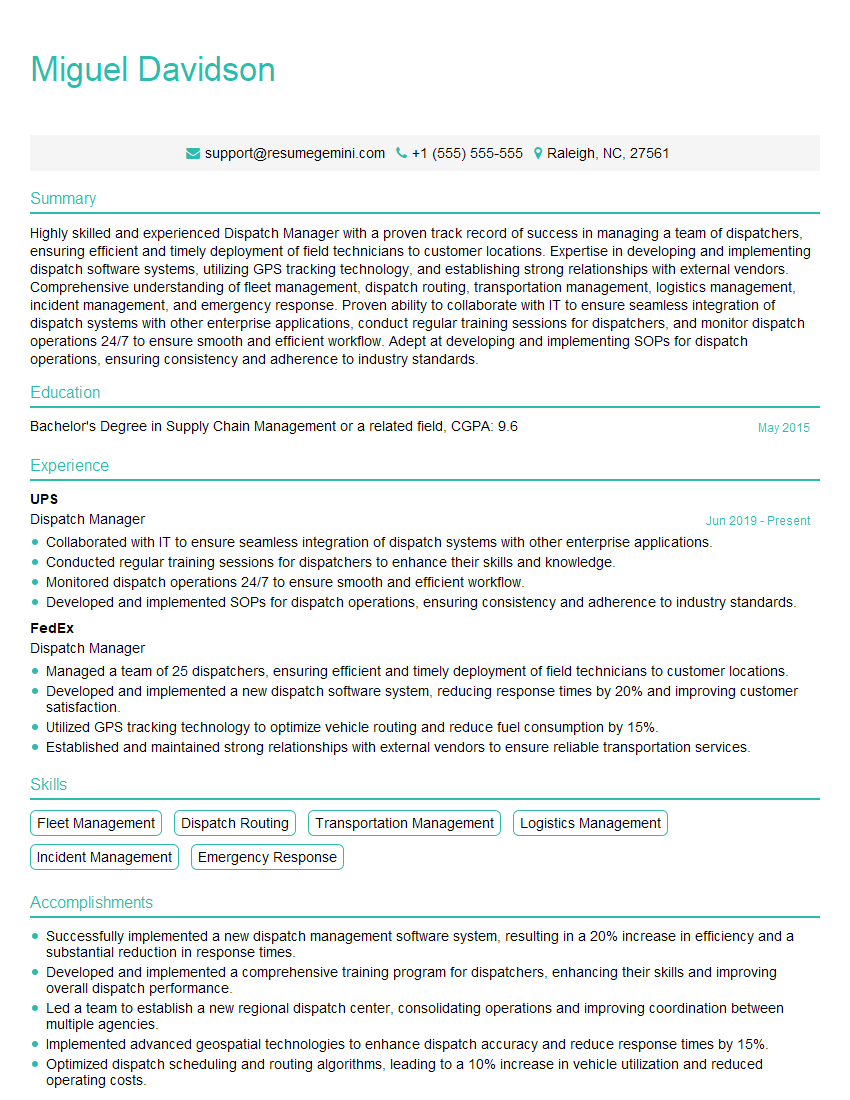

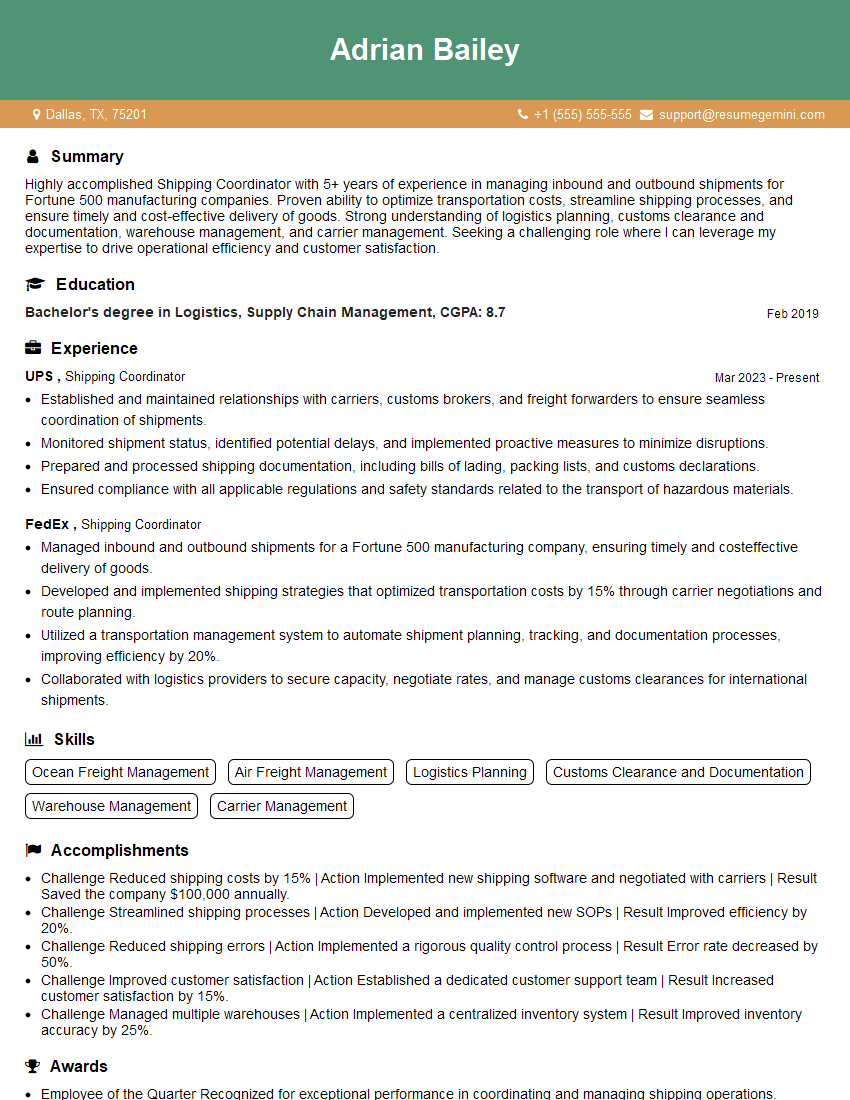

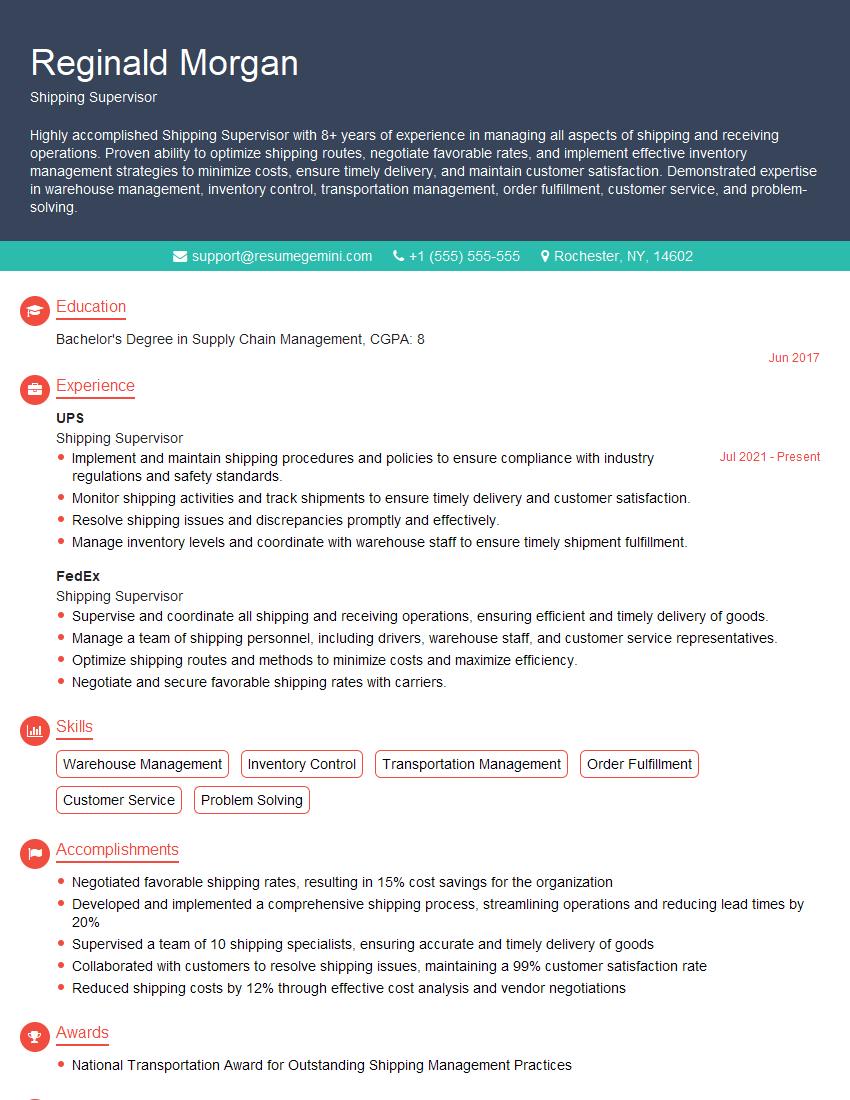

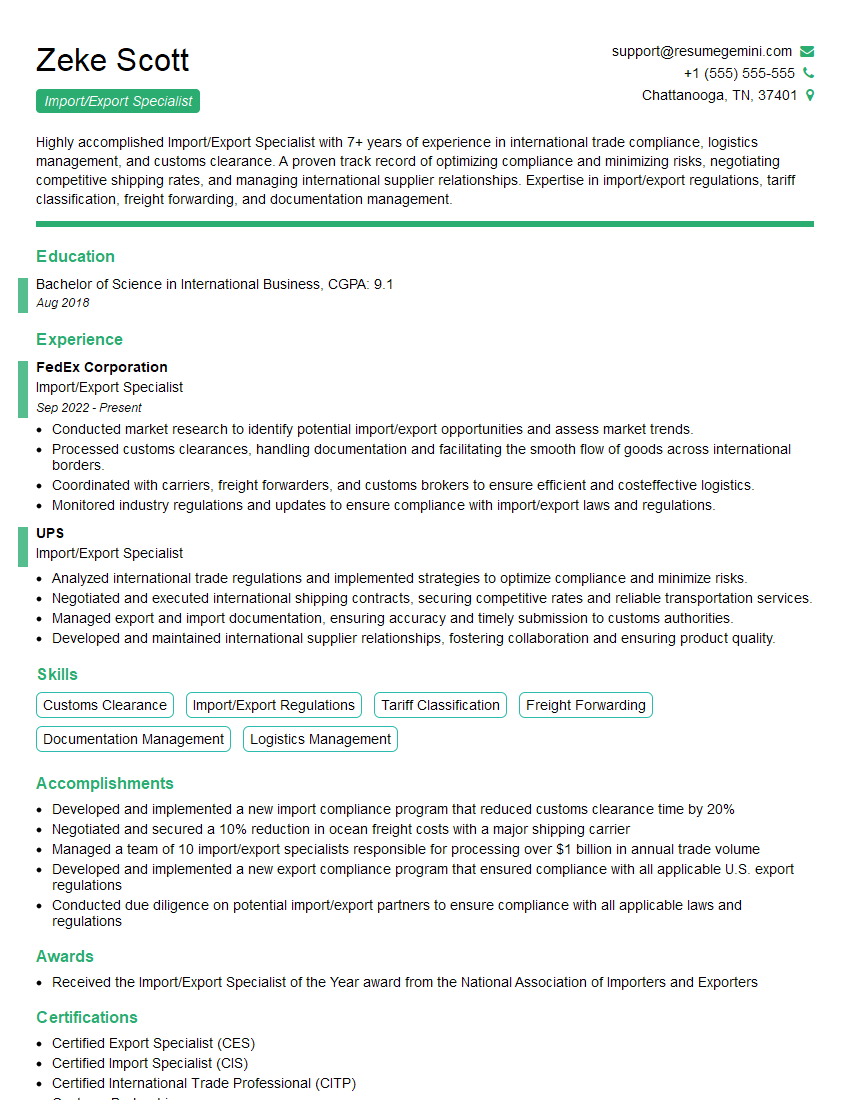

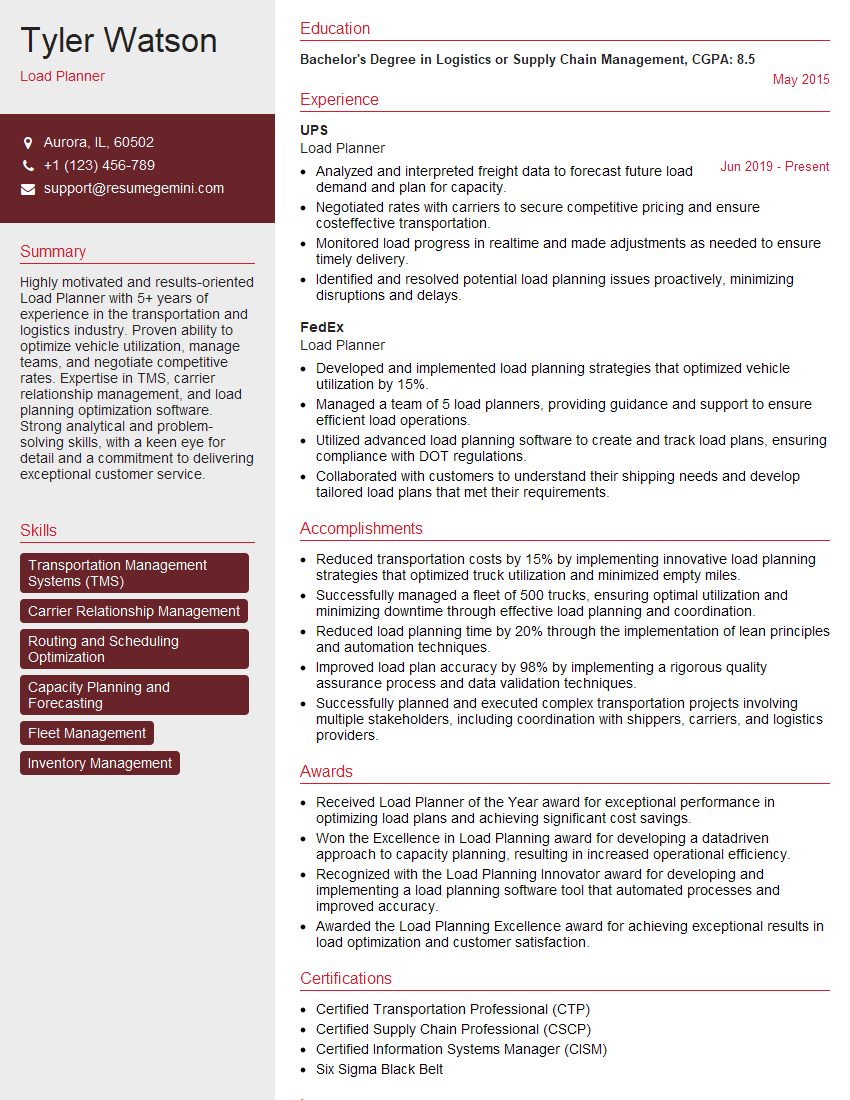

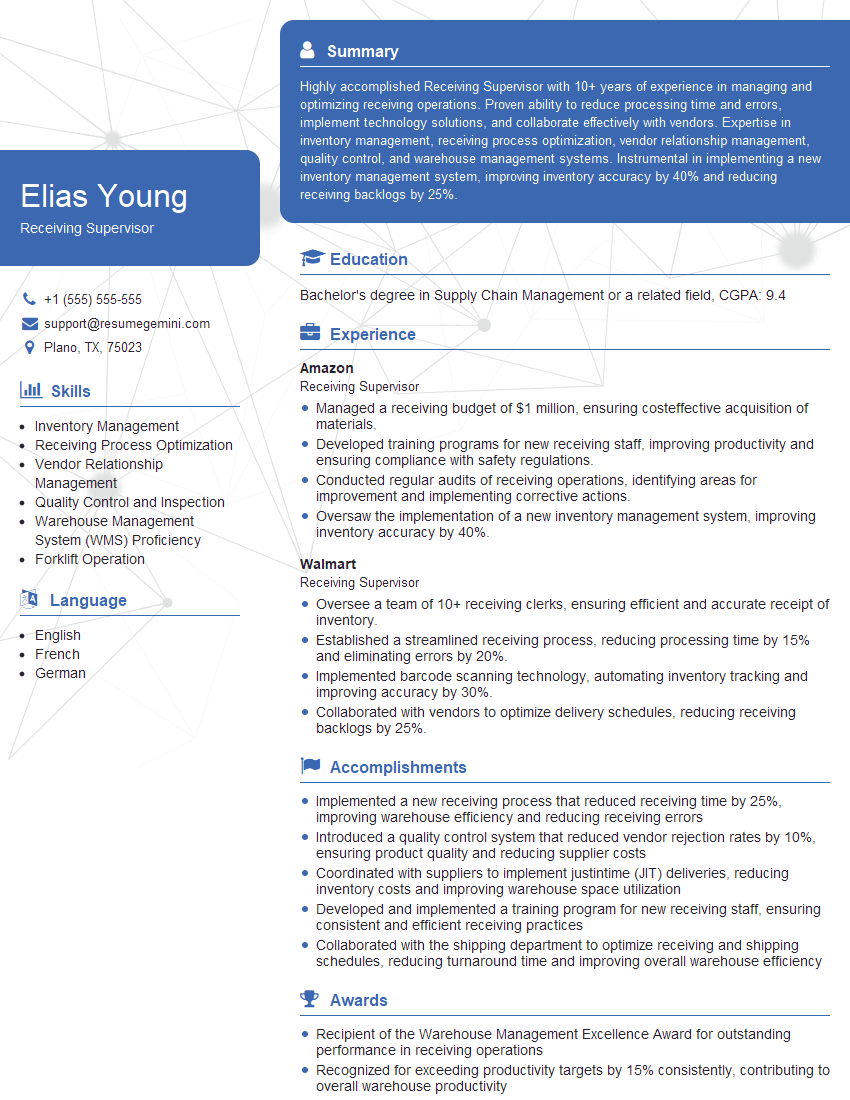

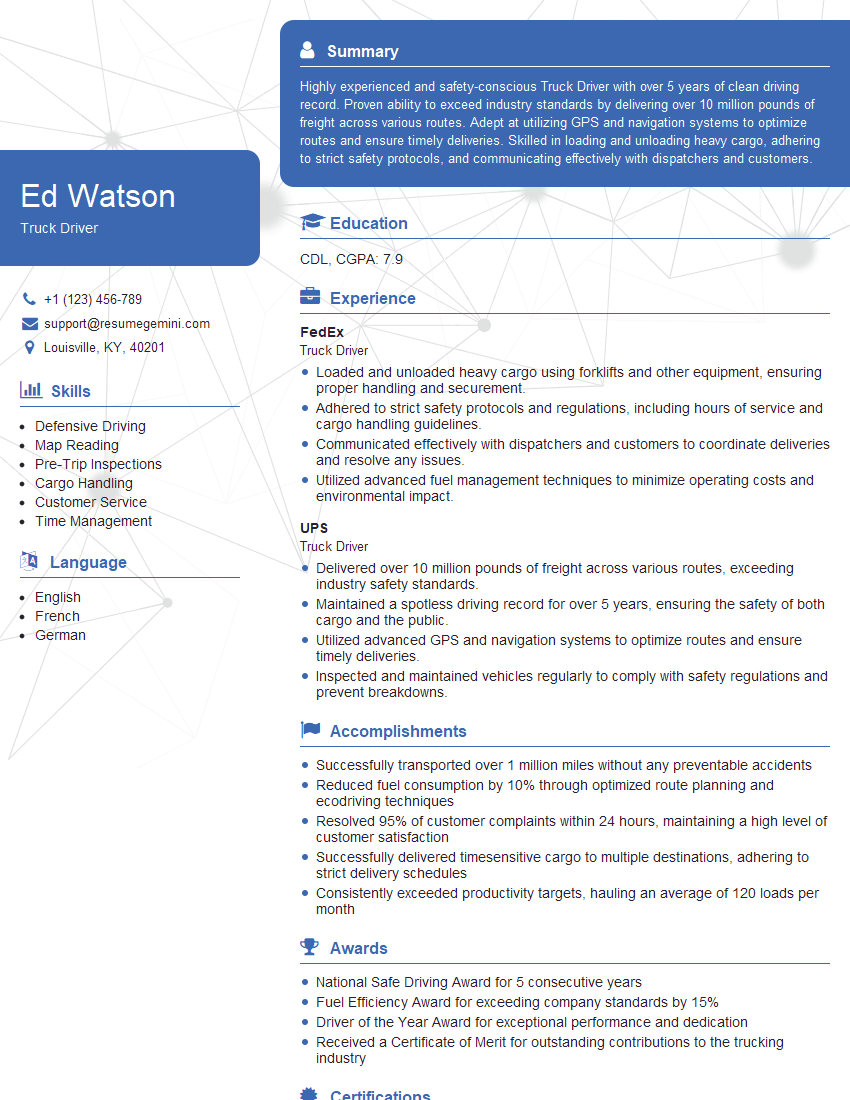

Mastering Load Handling and Logistics opens doors to exciting career opportunities with significant growth potential. A strong understanding of these principles is crucial for success in this dynamic field. To stand out, you need a compelling resume that showcases your skills and experience effectively. Building an ATS-friendly resume is vital for getting your application noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your achievements. ResumeGemini provides examples of resumes tailored to Load Handling and Logistics to help you create the perfect document, setting you apart from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO