Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Load Handling Equipment interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Load Handling Equipment Interview

Q 1. What are the different types of load handling equipment?

Load handling equipment encompasses a wide variety of machines and tools designed to move, lift, and position materials safely and efficiently. These can be broadly categorized into several types:

- Cranes: These are the workhorses of heavy lifting, ranging from small jib cranes to massive tower cranes, each with specific applications (e.g., overhead cranes for factories, mobile cranes for construction). They utilize various lifting mechanisms like hooks, magnets, or specialized grapples.

- Forklifts: These versatile machines are essential in warehouses and logistics, used for transporting palletized goods. They come in various types, including counterbalanced, reach trucks, and order pickers, each optimized for different environments and tasks.

- Hoists: Hoists are lifting devices typically used for smaller, more precise lifting operations. They can be electric, manual (chain hoists), or pneumatic, and are often incorporated into cranes or other lifting systems.

- Conveyors: These systems move materials continuously along a set path, streamlining production lines and warehousing. Types include belt conveyors, roller conveyors, and screw conveyors, each suitable for specific material types and handling needs.

- Jacks: Used for lifting and supporting heavy loads during maintenance or repair, jacks range from simple mechanical jacks to hydraulic jacks capable of lifting significant weight.

- Lifting Beams: These are structural components used to distribute the weight of a load across multiple lifting points, enhancing stability and safety during heavy lifts.

The choice of equipment depends on the specific load characteristics (weight, dimensions, fragility), the work environment, and the required level of precision and speed.

Q 2. Explain the principles of safe load handling.

Safe load handling hinges on a multi-faceted approach that prioritizes risk assessment and preventative measures. Key principles include:

- Proper Assessment: Before any lifting operation, accurately assess the weight, dimensions, and center of gravity of the load. Use calibrated scales and understand the load’s stability.

- Equipment Selection: Choose the appropriate equipment with a safe working load (SWL) significantly exceeding the actual load weight. Account for potential environmental factors like wind or uneven terrain.

- Operator Training: Properly trained and certified operators are crucial. They must understand the equipment’s limitations, safety procedures, and emergency response protocols.

- Pre-Operational Inspection: Always inspect the equipment before use, checking for any damage, wear, or malfunction. Document any issues.

- Load Securing: Use appropriate slings, chains, or other rigging equipment to secure the load, ensuring it’s balanced and won’t shift during lifting. Never overload slings or use damaged ones.

- Clear Communication: Maintain clear communication between the operator, riggers, and anyone in the vicinity of the lifting operation. Use hand signals or two-way radios.

- Emergency Procedures: Establish clear emergency procedures and ensure everyone is aware of them. This includes identifying escape routes and designated personnel for emergencies.

Think of it like building a house: a solid foundation (assessment), the right tools (equipment), skilled builders (operators), and a detailed plan (procedures) are all essential for a safe and successful outcome.

Q 3. Describe the different types of crane hooks and their applications.

Crane hooks are crucial load-bearing components, and different types cater to diverse applications:

- Standard Crane Hooks: These are the most common type, typically made of forged steel, with a simple design. They’re versatile but may not be suitable for all load types.

- Clevis Hooks: These hooks have a clevis (a U-shaped component) at the end, allowing for easy attachment of slings or other lifting accessories. This is advantageous for quicker hook-ups and flexibility.

- Eye Hooks: These have a loop or eye at the end, often used for attaching shackles or other rigging components. They are designed for loads that need to be suspended directly from the hook.

- Grab Hooks: These are designed to securely grasp and lift unusual or irregularly shaped objects. They are often used for demolition work or scrap metal handling.

- Self-Closing Hooks: Designed with a mechanism that automatically closes around the load, securing it during lifting operations. They’re commonly found in container handling.

The selection of a crane hook depends on factors such as the type of load, the lifting method (e.g., slings, chains), and the required safety factor. Using the incorrect hook type can lead to accidents.

Q 4. What are the safety regulations surrounding forklift operation?

Forklift operation is governed by strict safety regulations worldwide, varying slightly by jurisdiction, but generally encompassing these key areas:

- Operator Training and Certification: Operators must receive adequate training and often require certification demonstrating competence in safe operation.

- Pre-Operational Inspection: A thorough pre-operational check is mandatory before each use, covering aspects like tires, brakes, forks, and fluid levels.

- Load Capacity: Never exceed the forklift’s rated load capacity. This information is clearly marked on the machine.

- Load Stability: Ensure the load is properly balanced and secured to prevent tipping or shifting. Avoid high stacking without proper training and equipment.

- Speed and Maneuvering: Operate at safe speeds, appropriate to the environment and load. Avoid sudden stops or turns.

- Pedestrian Safety: Prioritize pedestrian safety by using horns, signaling intentions, and maintaining awareness of surroundings. Designated pedestrian walkways are essential in high-traffic areas.

- Maintenance: Regular maintenance according to manufacturer’s recommendations is vital to prevent mechanical failures. Proper maintenance records should be kept.

- Personal Protective Equipment (PPE): Operators must wear appropriate PPE, including safety glasses, gloves, and high-visibility clothing.

Ignoring these regulations can lead to serious accidents, including injuries, property damage, and even fatalities. Following these regulations creates a safer work environment for everyone.

Q 5. How do you perform a pre-operational inspection of a forklift?

A pre-operational inspection of a forklift is a systematic check to identify any potential hazards before operation. A checklist should be used to ensure consistency. Here’s a step-by-step procedure:

- Visual Inspection: Visually inspect the entire forklift, looking for any obvious damage, leaks, or loose parts. Check the tires for wear and damage, the forks for cracks or bends, and the mast for any signs of instability.

- Fluid Levels: Check the levels of engine oil, hydraulic fluid, coolant, and battery water (if applicable). Low fluid levels indicate potential problems.

- Brakes and Steering: Test the brakes and steering to ensure they are functioning correctly. Listen for unusual noises or vibrations.

- Horn and Lights: Verify the horn and lights are working properly. This is essential for safety in the workplace.

- Safety Devices: Inspect safety features such as seatbelts, emergency stops, and the overhead guard for damage or malfunction.

- Forks and Attachments: Check the forks for alignment and stability, and any attached equipment should be securely mounted and in good condition.

- Documentation: Record all findings, noting any issues identified. Report any major problems and do not operate the forklift until they are resolved.

Imagine it like a pre-flight check for an airplane – a careful inspection ensures a safe journey. Skipping this step is reckless and potentially dangerous.

Q 6. What are the limitations of a particular type of crane?

Let’s consider the limitations of a tower crane as an example. While incredibly powerful, they have several limitations:

- Limited Reach and Height: A tower crane’s reach and height are fixed, determined by its design and assembly. It cannot lift loads outside this designated area.

- Swing Radius Restrictions: The crane’s swing radius is also restricted, meaning there are areas it cannot reach safely due to potential collisions with structures or obstructions.

- Wind Sensitivity: Tower cranes are particularly sensitive to strong winds, which can significantly reduce their lifting capacity or even make operation unsafe. Wind speed limits are strictly enforced.

- Ground Conditions: The stability of the crane is significantly influenced by ground conditions. Uneven or unstable ground can compromise its stability and lifting capacity.

- Accessibility: The assembly, disassembly, and maintenance of tower cranes are complex, requiring specialized equipment and expertise. This can limit their accessibility to certain sites.

- Load Capacity Variations: The load capacity of a tower crane varies depending on the radius and height of the lift. Capacity is reduced significantly as reach increases.

Understanding these limitations is crucial for safe and effective operation. Improper planning or disregarding these limitations can lead to serious accidents.

Q 7. How do you calculate the safe working load of a hoist?

Calculating the safe working load (SWL) of a hoist is critical for preventing accidents. The SWL is the maximum load the hoist can safely lift under normal operating conditions. It’s usually specified by the manufacturer and clearly marked on the hoist itself. The calculation isn’t simply about the hoist’s mechanical strength; it considers various safety factors:

The SWL is not directly calculated but rather obtained from the manufacturer’s specifications. These specifications take into account various factors, including:

- Material Strength: The tensile strength of the hoist’s components (cables, chains, gears).

- Safety Factors: These factors (typically between 5 and 10, depending on regulations) are added to account for unexpected stresses, wear, and other variables.

- Environmental Conditions: Factors like temperature and humidity can affect material strength.

- Dynamic Loads: The hoist’s capacity is typically reduced for dynamic loads (accelerating or decelerating loads) compared to static loads.

Example: If a manufacturer specifies a hoist’s SWL as 1000 kg, this means it should never be used to lift more than 1000 kg, even under ideal conditions. Always err on the side of caution and ensure the actual load weight is significantly less than the SWL to account for variations and uncertainties.

Q 8. Explain the different types of slings and their appropriate uses.

Slings are the crucial link between the load and the lifting equipment. Choosing the right sling for the job is paramount for safety and efficiency. Several types exist, each with specific strengths and limitations.

- Polyester Slings: These are strong, lightweight, and relatively inexpensive. They offer good resistance to abrasion and are suitable for general lifting applications. However, they can be susceptible to damage from sharp edges and excessive heat.

- Nylon Slings: Similar to polyester in many aspects, nylon slings are known for their excellent shock absorption, making them ideal for lifting fragile or delicate loads. They’re also more resistant to stretching than polyester.

- Chain Slings: Extremely durable and strong, chain slings are preferred for heavy lifting and applications involving harsh environments or sharp edges. Their metallic nature makes them easily inspected for damage, crucial for safety. However, they can be heavier and more cumbersome than fabric slings.

- Wire Rope Slings: These are incredibly strong and suitable for extremely heavy loads. They are often used in demanding industrial settings. However, they require careful inspection for wear and damage, and their stiffness can make precise positioning of the load more difficult.

- Round Slings: Often made of synthetic materials like polyester or nylon, these slings offer a versatile solution for many applications. Their round shape allows them to conform to irregularly shaped loads, improving stability.

Appropriate Uses: The choice of sling depends heavily on the load’s weight, shape, material, and the environment. For example, a delicate piece of machinery might require a nylon sling for its shock absorption properties, while a heavy steel beam would demand the strength of a chain or wire rope sling.

Q 9. Describe the procedures for rigging a heavy load.

Rigging a heavy load is a complex process that requires meticulous planning and execution. Improper rigging can lead to catastrophic accidents. A well-defined procedure ensures safety and efficiency.

- Planning and Assessment: This includes determining the load’s weight, center of gravity, dimensions, and any unique characteristics. The environment, including the ground conditions, available lifting equipment, and any obstacles, must also be considered.

- Equipment Selection: Choosing the right crane, slings, shackles, and other rigging components is crucial. The chosen equipment’s load capacity must significantly exceed the weight of the load, allowing for a substantial safety margin.

- Rigging Assembly: Assemble the rigging components, ensuring all connections are secure and free from damage. Use appropriate safety devices, such as shackles and thimbles, to prevent slippage or failure.

- Load Attachment: Carefully attach the slings to the load, ensuring the load is balanced and evenly distributed. The slings should be positioned to prevent excessive stress on any single point.

- Lift and Placement: The load should be lifted slowly and smoothly. Communication between the crane operator and ground crew is essential to ensure safe movement and placement.

- Inspection: A thorough inspection of all rigging components is essential after each lift, checking for signs of damage or wear.

Example: Imagine lifting a large transformer. The planning stage would involve determining the transformer’s weight, finding the center of gravity, selecting a suitable crane with enough capacity, and choosing multiple, heavy-duty chain slings to evenly distribute the weight.

Q 10. What are the common causes of load handling accidents?

Load handling accidents stem from a multitude of factors, often stemming from a combination of human error and equipment failure. Some common causes include:

- Improper Rigging: Incorrect sling angles, inadequate load distribution, and faulty attachments are frequent culprits.

- Equipment Malfunction: Faulty cranes, damaged slings, or worn-out shackles can lead to catastrophic failures.

- Inadequate Training: Lack of proper training for crane operators and riggers significantly increases the risk of accidents.

- Negligence and Poor Communication: Lack of attention to detail, rushing the process, and poor communication among the crew are all major risk factors.

- Unforeseen Circumstances: Unexpected environmental conditions, such as strong winds or unstable ground, can compromise safety.

- Overloading: Exceeding the safe working load limits of any piece of equipment is a primary cause of accidents.

Example: A crane collapsing because it was overloaded, or a sling breaking due to improper hitching resulting in a dropped load.

Q 11. How do you identify and mitigate potential hazards in a load handling operation?

Hazard identification and mitigation are critical to safe load handling. A systematic approach is necessary:

- Pre-lift Inspection: Thoroughly inspect all equipment—crane, slings, shackles, and attachments—before each lift for any signs of damage or wear. This includes checking for proper lubrication, ensuring bolts are tight, and visually assessing the condition of all components.

- Environmental Assessment: Evaluate the surrounding area for potential hazards, such as overhead obstructions, unstable ground, and weather conditions. Consider the presence of people or other equipment that could be impacted by the operation.

- Risk Assessment: Identify potential hazards and assess the likelihood and severity of each risk. A formal risk assessment matrix can be very helpful.

- Mitigation Strategies: Develop and implement control measures to minimize or eliminate identified hazards. This could involve using additional safety devices, implementing stricter work procedures, or modifying the lifting plan.

- Emergency Planning: Establish clear emergency procedures, including communication protocols and evacuation plans, should an accident occur.

- Supervision: Ensure competent supervision throughout the entire lifting operation.

Example: If an area has strong winds, the lifting operation might be postponed or modified using stronger rigging or wind-protection measures.

Q 12. What is the importance of load charts and how are they used?

Load charts are essential documents that provide critical information regarding the safe working loads (SWL) for various lifting equipment and configurations. They are crucial for ensuring safe operations.

Importance: Load charts provide the maximum load that a piece of equipment can safely handle under specific conditions (e.g., sling angle, type of sling, etc.). Using load charts helps prevent overloading, a leading cause of accidents.

How They Are Used: Before any lift, the rigger must consult the load chart to determine the safe working load for the chosen equipment and configuration. The load’s weight should be significantly lower than the SWL to ensure a safety margin. Load charts often include diagrams illustrating appropriate sling angles and configurations.

Example: A load chart for a specific type of sling might show that the SWL is 10,000 lbs at a 60-degree sling angle but reduces to 5,000 lbs at a 90-degree angle. The rigger must carefully consider the sling angle and ensure it does not exceed the listed SWL to avoid a catastrophic failure.

Q 13. Explain the concept of center of gravity and its relevance to load handling.

The center of gravity (CG) is the point where the weight of an object is considered to be concentrated. Understanding the CG is critical for safe load handling.

Relevance to Load Handling: Knowing the CG’s location is essential to ensure stable and safe lifting. If the CG is not properly aligned, the load may become unbalanced and cause the load to swing, tilt, or even topple over, potentially causing damage or injury.

Practical Application: When lifting, the CG should be kept as close to the vertical axis of the crane hook as possible. If the load is unstable, additional bracing or support may be necessary. In unevenly shaped loads, the CG can be found by a mathematical calculation based on the distribution of the weight of the item.

Example: Lifting a long, heavy steel beam. The CG is at the center point. If a sling is attached to only one end, the beam will tilt during the lift. To prevent this, slings must be attached to points closer to the beam’s center to balance the weight.

Q 14. Describe different types of lifting accessories and their applications.

Lifting accessories play a vital role in load handling by enhancing safety and efficiency. Various types of lifting accessories cater to specific needs.

- Shackles: These are U-shaped metal connectors used to connect slings to hooks or other rigging components. They come in various sizes and strengths, allowing for different load capacities.

- Swivels: Swivels prevent twisting and kinking of slings during the lift, especially beneficial when the load is rotated. They ensure uniform load distribution.

- Bridles: Sets of slings used to distribute the load more evenly across multiple points, especially valuable for irregularly shaped loads.

- Beam Clamps: Used to grip and lift steel beams without the need for slings. They must be chosen carefully based on the beam dimensions and weight.

- Spreader Beams: Used to spread the load across multiple slings, allowing for larger and more oddly shaped objects to be lifted.

- Eye Bolts: Heavy-duty bolts with a loop at one end, providing a secure attachment point for lifting.

Applications: The application depends on the load’s shape, weight, and handling requirements. For instance, shackles and swivels are frequently used in conjunction with slings, while beam clamps are specific to steel beams. A spreader beam is frequently required to lift a large container.

Q 15. How do you handle unstable or unusual loads?

Handling unstable or unusual loads requires a methodical approach prioritizing safety. First, a thorough assessment is crucial. This involves identifying the load’s center of gravity, its weight distribution, and any potential hazards like sharp edges or fragile components. We then select the appropriate equipment – this might involve specialized slings, rigging hardware, or even custom-designed load handling solutions. For example, a load with an uneven weight distribution might require multiple attachment points to ensure even weight distribution on the lifting device. For unusually shaped objects, we might need to use custom cradles or specialized lifting beams. Throughout the entire process, securement is paramount – using appropriate straps, chains, or nets to prevent shifting or accidental drops. Finally, extra personnel may be required for spotting during lifting and movement to quickly address any instability issues.

Imagine lifting a very long, thin beam. It’s inherently unstable. We wouldn’t simply attach a single sling in the middle. Instead, we’d use multiple slings strategically placed along its length to distribute the weight and prevent swaying. This is all about risk mitigation and proactive safety measures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the emergency procedures in case of a load handling incident?

Emergency procedures for load handling incidents are vital. Our response hinges on rapid and organized action, starting with immediate isolation of the affected area to prevent further incidents or injuries. The first step is to secure the load, ensuring it doesn’t move or collapse further. This usually involves using additional securing devices or stabilizing the load with available resources. Then, we alert emergency services and the relevant authorities, providing detailed information about the incident, including the type of equipment involved, the nature of the load, and the extent of any injuries. A post-incident investigation is mandatory, to determine the root cause of the failure and implement corrective actions to prevent recurrence. This might include retraining, equipment inspections, or process changes.

For instance, if a crane hook fails, we immediately cut power to the crane, evacuate personnel, and then call for specialized equipment to remove the load safely. Detailed documentation of the incident and a thorough investigation will follow, helping prevent future failures.

Q 17. How do you select the appropriate load handling equipment for a specific task?

Selecting the right load handling equipment is a critical decision involving several factors. First, we assess the load’s weight, dimensions, and characteristics (fragile, hazardous, etc.). Then we consider the environment – indoor versus outdoor, space constraints, and ground conditions. The task itself dictates the type of equipment needed: forklifts for pallets, overhead cranes for heavy objects, or specialized equipment for unusual loads. Safety factors are paramount; we always select equipment with a safety rating exceeding the load’s weight. Finally, regulatory compliance is crucial; ensuring the equipment meets all relevant safety standards and is properly certified.

Let’s say we need to move a heavy transformer. We wouldn’t use a forklift. Instead, we’d likely use a heavy-duty crane with specialized slings capable of safely handling the transformer’s weight and unique shape, following strict safety protocols.

Q 18. Explain the importance of regular maintenance for load handling equipment.

Regular maintenance is paramount for load handling equipment. It minimizes the risk of failures, improves equipment lifespan, and enhances operational efficiency. This involves scheduled inspections, preventative maintenance tasks, and prompt repairs. We follow manufacturer’s recommendations for inspection frequencies and adhere to strict safety protocols during maintenance. Regular lubrication, checks for wear and tear, and functional tests help ensure everything is functioning optimally. Documentation is crucial, keeping meticulous records of all inspections and maintenance performed. This proactive approach prevents costly downtime and significantly reduces the risk of accidents.

Neglecting maintenance is akin to driving a car without regular oil changes. Eventually, you’ll experience catastrophic failure, and that’s much more dangerous and costly when dealing with heavy machinery.

Q 19. What are the signs of equipment malfunction and how do you respond?

Recognizing equipment malfunction is vital. Signs can range from subtle issues – unusual noises, vibrations, or fluid leaks – to more obvious ones like broken parts or malfunctioning controls. Any deviation from normal operation should be investigated immediately. For example, a forklift that doesn’t respond correctly to steering inputs or a crane exhibiting unusual swaying should be immediately taken out of service. Our response includes immediate shutdown of the equipment, reporting the issue, and preventing further use until a qualified technician has assessed and repaired the problem. Detailed records of the malfunction and corrective actions are maintained.

Think of a car’s check engine light. Ignoring it could lead to a major breakdown. The same principle applies to load handling equipment; immediate action prevents bigger issues.

Q 20. How do you ensure the stability of the load during transportation?

Ensuring load stability during transport involves meticulous planning and execution. First, the load must be correctly secured using appropriate straps, chains, or other fastening devices. The securing method depends on the load’s nature and the mode of transport. Weight distribution is crucial; we aim for even weight distribution to prevent shifting during transit. For example, unevenly distributed weight on a truck could cause instability and accidents. The transportation vehicle must also be suitable for the load’s weight and dimensions. Appropriate speed limits and careful maneuvering are necessary to avoid sudden movements or impacts that could compromise stability.

Imagine transporting a large glass panel. It requires special care and attention. We’d use protective padding, secure straps, and a vehicle with suspension capable of handling fragile cargo. We would also drive slowly and carefully.

Q 21. Describe your experience with different types of load handling software.

I have experience with several load handling software packages, including those focused on crane management, rigging calculations, and inventory tracking. These programs are indispensable for optimizing operations, minimizing risks, and ensuring regulatory compliance. Crane management software provides real-time monitoring of crane operations, ensuring safe working loads are not exceeded. Rigging calculation software helps determine the correct sling angles and ensures that the lifting equipment is appropriately sized for the task. Inventory tracking software assists in managing equipment maintenance schedules, ensuring that all equipment is properly inspected and maintained.

For example, I’ve used a system that integrates with our crane’s sensors to provide real-time feedback on load weight and crane status. This allows for proactive intervention and prevents accidents related to overloading or equipment malfunction.

Q 22. How do you communicate effectively with other workers during a load handling operation?

Effective communication is paramount in load handling. Think of it like a well-orchestrated symphony – everyone needs to be on the same page to avoid a disastrous ‘crash’. I utilize a multi-pronged approach. Firstly, I always confirm the load details with the signaler using clear, concise language. This includes weight, dimensions, center of gravity, and any special handling requirements. Secondly, I employ hand signals, which are universally understood and reduce the risk of miscommunication amidst noise or distance. Where radio communication is available, I use it to confirm actions and provide updates on the lift progress. Finally, post-lift, I always conduct a quick debrief with the team to identify areas for improvement and to ensure everyone is safe and understands the procedures.

For example, during a recent project involving a large transformer, we used a combination of hand signals to guide the crane and radio communication to update the team on the weight distribution and lifting progress. This meticulous communication ensured a smooth and safe lift.

Q 23. What are the different types of load securing methods?

Load securing is crucial to prevent shifting or damage during transport. It’s like using seatbelts in a car – critical for safety. Several methods exist, categorized by the type of load and transport.

- Chaining and Wire Roping: Used for securing heavy and bulky items; requires proper tensioning and attachment points.

- Strapping: Strong, flexible straps (steel or nylon) provide excellent security for various loads, especially palletized goods. Proper tensioning is key to prevent slippage.

- Wedging: Used to prevent movement within a confined space, often supplementing other methods. It’s like filling gaps to prevent shifting.

- Dunnage: Materials like wood blocks, padding, or air bags are employed to fill gaps and distribute the load’s weight evenly, preventing movement and damage.

- Netting: Provides containment for smaller items, often used with other securing methods.

Choosing the right method depends on the load’s characteristics, transport method, and environmental factors. For instance, delicate equipment might require more padding and soft straps, while heavy steel beams would necessitate robust chains and secure attachment points.

Q 24. How do you manage different types of load configurations?

Managing diverse load configurations necessitates a systematic approach. I begin by carefully assessing the load’s dimensions, weight distribution, and center of gravity. This informs the choice of lifting equipment and securing methods. For example, an unevenly distributed load might require additional dunnage or careful sling placement to ensure stability.

I also consider the load’s fragility; delicate items require specialized handling and protection. Oversized loads often require specialized transport arrangements, such as outrigger supports for the crane or escorts during transportation. Understanding the structural integrity of the load is crucial – a damaged or unstable load poses significant risks. I always document my assessment and the chosen handling plan, including safety measures, to maintain accountability and ensure a consistent approach.

Q 25. Explain your experience with different types of crane systems.

My experience encompasses a variety of crane systems, including:

- Overhead Cranes: I’m proficient in operating various types, from simple jib cranes to advanced gantry cranes, understanding their load limits and operational safety procedures.

- Mobile Cranes: I’ve worked with various models, including hydraulic truck-mounted cranes and crawler cranes, considering factors like ground conditions and stability when planning lifts.

- Tower Cranes: I understand their setup, dismantling, and safe operating procedures, especially regarding load capacity and reach limitations.

My experience also includes working with different control systems, from simple manual levers to advanced computer-controlled systems. Each system requires a distinct understanding of its limitations and capabilities.

Q 26. What are your strategies for preventing equipment damage?

Preventing equipment damage is a priority. It’s like preventative maintenance on your car; regular checks minimize larger problems down the road. My strategies include:

- Regular Inspections: I always inspect equipment before each use, checking for wear and tear, loose parts, and any signs of damage.

- Proper Operation: Adhering to manufacturer’s guidelines and operating within the equipment’s rated capacity is essential. Overloading or mishandling are major causes of damage.

- Environmental Protection: Protecting equipment from harsh weather conditions and corrosive substances is crucial. Proper storage and maintenance are key.

- Lubrication and Maintenance: Regular lubrication and scheduled maintenance minimize wear and tear and extend equipment lifespan.

For instance, I recently noticed a slight crack in a crane hook during a pre-operation check. This early detection prevented a potential accident and costly repairs.

Q 27. Describe your experience with load testing procedures.

Load testing is a crucial process to verify equipment’s structural integrity and operational limits. It’s like stress-testing a bridge before opening it to traffic. I have extensive experience in conducting and documenting load tests according to industry standards.

The process usually involves incrementally increasing the load until the equipment reaches its rated capacity or a predetermined limit. Detailed observations and measurements of deflection, strain, and other parameters are recorded and analyzed to ensure the equipment meets safety standards. These tests are typically done with certified load cells and under the supervision of qualified personnel. Detailed records are maintained for future reference and compliance audits.

Q 28. How do you comply with OSHA regulations for load handling?

OSHA compliance is non-negotiable. I ensure compliance through a multi-faceted approach:

- Training and Certification: I maintain current certifications in load handling and crane operation, complying with OSHA’s requirements for training and qualifications.

- Safe Operating Procedures: I meticulously follow established safety procedures, including pre-lift planning, load securing, and communication protocols.

- Regular Inspections: The routine inspection of equipment and work areas ensures compliance with OSHA’s standards for workplace safety.

- Incident Reporting: Any incidents or near misses are promptly reported and investigated to identify root causes and prevent future occurrences.

- Personal Protective Equipment (PPE): I always wear and ensure my team uses appropriate PPE, such as hard hats, safety glasses, and high-visibility clothing.

Compliance is not just about following rules; it’s about creating a safe and responsible work environment for everyone.

Key Topics to Learn for Load Handling Equipment Interview

- Types of Load Handling Equipment: Understand the differences and applications of cranes (tower, overhead, mobile), forklifts, conveyors, hoists, and other relevant equipment. Consider their strengths and limitations in various operational settings.

- Safety Regulations and Procedures: Master relevant safety standards (OSHA, etc.), load capacity calculations, inspection procedures, and emergency protocols. Be prepared to discuss practical experience ensuring safe operation.

- Maintenance and Troubleshooting: Familiarize yourself with routine maintenance tasks, common malfunctions, and troubleshooting techniques for different equipment types. Highlight your ability to diagnose problems and implement effective solutions.

- Operational Efficiency and Optimization: Demonstrate understanding of optimizing load handling processes for speed, safety, and cost-effectiveness. Discuss strategies for improving workflow and minimizing downtime.

- Material Handling Principles: Showcase your knowledge of center of gravity, load stability, load distribution, and appropriate rigging techniques. Be ready to explain how these principles impact safe and efficient operations.

- Technological Advancements: Discuss your awareness of modern technologies used in load handling, such as automated guided vehicles (AGVs), robotics, and advanced control systems. Show your willingness to adapt to new technologies.

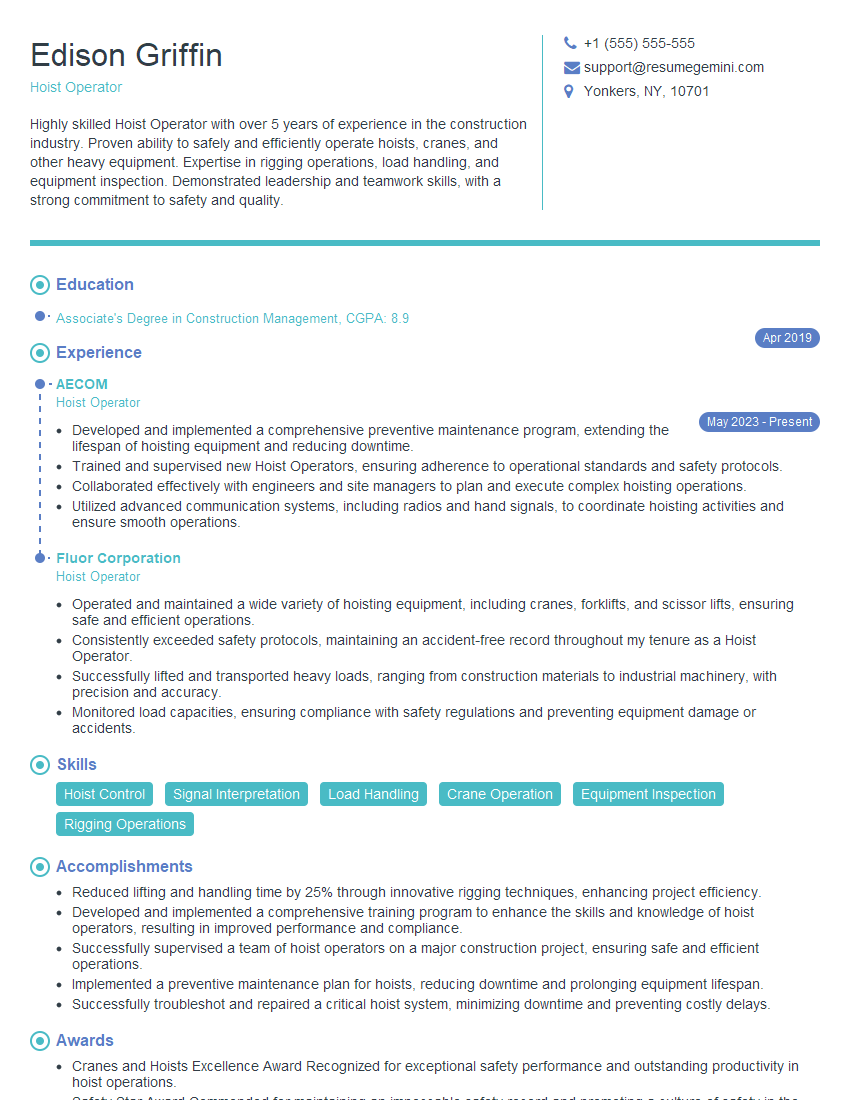

Next Steps

Mastering Load Handling Equipment opens doors to exciting career opportunities in diverse industries, offering excellent growth potential and competitive salaries. To maximize your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource for building professional, impactful resumes that get noticed. Leverage their expertise to craft a compelling resume that highlights your qualifications. Examples of resumes tailored to Load Handling Equipment are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO