Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Loader Operation Supervision interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Loader Operation Supervision Interview

Q 1. Describe your experience supervising loader operators.

My experience supervising loader operators spans over 10 years, encompassing various projects ranging from large-scale construction sites to smaller-scale industrial operations. I’ve overseen teams of up to 15 operators simultaneously, coordinating their efforts to meet project deadlines and maintain optimal efficiency. This has involved everything from daily task assignments and performance monitoring to addressing operator concerns and providing on-the-job training. For instance, on a recent highway construction project, I successfully implemented a new loading technique that reduced cycle times by 15%, leading to significant cost savings and project completion ahead of schedule. This involved close collaboration with the operators, providing clear instructions, and fostering a culture of continuous improvement.

Q 2. What safety protocols do you enforce when supervising loader operations?

Safety is paramount in loader operations. My enforced protocols include mandatory pre-operation inspections of equipment, ensuring operators are wearing appropriate personal protective equipment (PPE), such as safety helmets, high-visibility vests, and safety boots. Strict adherence to speed limits within the worksite, designated loading zones, and communication protocols – hand signals, two-way radios – are crucial. Blind spot awareness training is mandatory, along with regular refresher courses on safe operating procedures. I also implement a robust system for reporting near-misses and accidents, analyzing the root cause and taking corrective actions to prevent future occurrences. For example, we implemented a ‘buddy system’ where operators work in pairs, constantly monitoring each other’s actions, significantly reducing the chances of accidents.

Q 3. How do you ensure efficient material handling using loaders?

Efficient material handling involves optimizing loader utilization, minimizing idle time, and ensuring smooth material flow. This begins with careful planning of loading and unloading points, efficient route planning to minimize travel time, and ensuring that sufficient stockpiles are available to avoid delays. I continuously monitor the loader’s productivity through data logging systems and adjust schedules based on real-time needs. For example, during peak hours, I might assign operators to specific tasks based on their skills and experience to maximize output. We also regularly review and refine our loading techniques, incorporating best practices to improve efficiency and reduce fuel consumption. This might involve experimenting with different bucket sizes or loading strategies to find the optimal balance between speed and safety.

Q 4. Explain your experience with different types of loaders (wheel, track, etc.).

My experience encompasses a variety of loaders, including wheel loaders, track loaders (skid steers), and telescopic handlers. Wheel loaders are ideal for large-scale earthmoving and material handling over long distances due to their mobility and high capacity. Track loaders excel in confined spaces and rough terrain thanks to their superior traction. Telescopic handlers offer versatility for lifting and placing materials at heights, often used in construction and warehousing. Understanding the strengths and limitations of each type is crucial for assigning the right machine for each task. For instance, on a recent project involving trench work, using a track loader ensured stability and maneuverability in a constrained area. Conversely, for moving large volumes of material across a wide construction site, a wheel loader was the most efficient choice.

Q 5. How do you handle equipment malfunctions or breakdowns during operations?

Equipment malfunctions or breakdowns are addressed swiftly and systematically. Our protocol involves immediate operator shutdown of the machine, ensuring operator safety. A detailed assessment of the problem is conducted, and if beyond the operator’s skill set, a qualified mechanic is called in. We maintain a comprehensive maintenance schedule to prevent unexpected breakdowns, and our operators are trained to perform basic troubleshooting. We also have contingency plans in place, such as backup loaders or alternative strategies, to minimize disruption to project schedules. For example, a recent hydraulic failure on a wheel loader was quickly resolved by a swift on-site repair, limiting downtime to less than two hours thanks to our proactive maintenance program and readily available spare parts.

Q 6. What are the key performance indicators (KPIs) you track for loader operations?

Key Performance Indicators (KPIs) I track include: Tons per hour (measures material handling efficiency), Fuel consumption per ton (monitors operational cost-effectiveness), Machine uptime (tracks operational availability), Number of safety incidents (assesses safety performance), and Cycle time (measures the time taken to complete a single loading cycle). These KPIs are monitored daily, and any significant deviations are investigated to identify the root cause and implement corrective actions. Data is analyzed using specialized software to generate reports that are used for performance reviews, cost control, and continuous improvement initiatives. For instance, consistently low tons per hour could indicate a need for operator retraining, while high fuel consumption might suggest the need for equipment maintenance or a different operating strategy.

Q 7. How do you manage loader operator schedules and rotations?

Loader operator schedules are created based on project requirements, considering factors like workload, operator experience, and availability. Rotations are established to ensure fair workload distribution and prevent fatigue, promoting safety and productivity. We utilize a computerized scheduling system which considers individual operator preferences and skill sets, assigning tasks to match operator proficiency. Regular breaks are incorporated into the schedule to avoid operator burnout. We also ensure adequate staffing to cover unexpected absences or equipment breakdowns, minimizing disruptions to operations. For instance, a three-shift rotating system is implemented for larger projects to ensure continuous operation.

Q 8. Describe your approach to training new loader operators.

My approach to training new loader operators is multifaceted and focuses on building a strong foundation of both theoretical knowledge and practical skills. It begins with classroom instruction covering safety regulations, machine operation, pre-operational checks, and load capacity calculations. We use visual aids, diagrams, and interactive simulations to enhance understanding.

Following classroom training, hands-on training in a controlled environment is crucial. Operators start with basic maneuvers, gradually progressing to more complex tasks under the close supervision of an experienced trainer. We utilize a progressive training system, where operators must demonstrate proficiency at each stage before moving on. For example, they’ll master basic controls before attempting loading and unloading in various terrains. Regular assessments and feedback throughout the training process ensure they understand the material and are developing safe and efficient operating techniques.

Post-training, ongoing mentorship and observation continue. We emphasize continuous improvement through regular performance reviews and opportunities for further skill development. This combination of classroom learning, hands-on practice, and continuous feedback helps develop skilled and safe loader operators.

Q 9. How do you ensure compliance with all relevant safety regulations?

Ensuring compliance with safety regulations is paramount. This begins with thorough knowledge of all applicable OSHA (or relevant local) regulations concerning heavy machinery operation, including pre-operation inspections, personal protective equipment (PPE) requirements, and safe operating procedures. We conduct regular safety briefings and refresher training to reinforce key safety concepts.

Our safety program emphasizes preventative measures. Pre-shift inspections of the loaders are mandatory, and operators are trained to identify and report any potential hazards immediately. We maintain detailed records of all inspections, repairs, and training activities. We also conduct regular site inspections to ensure the work environment remains safe and compliant. In addition to routine checks, we conduct random safety audits to proactively identify and correct any potential safety violations. Non-compliance is addressed swiftly and decisively with corrective actions and additional training to prevent recurrence.

Q 10. What is your experience with loader maintenance scheduling and oversight?

My experience with loader maintenance scheduling and oversight involves implementing and managing a preventative maintenance program based on manufacturer recommendations and operational hours. This typically includes scheduled lubrication, fluid changes, component inspections, and timely replacement of worn parts. I utilize computerized maintenance management systems (CMMS) to track maintenance schedules, record completed work, and generate reports for analysis.

Beyond scheduled maintenance, I oversee the prompt repair of any malfunctions or damage to the loaders. This involves working closely with mechanics, ensuring repairs are completed correctly and efficiently to minimize downtime. Data analysis from the CMMS helps identify trends and potential problems, enabling proactive interventions to reduce unexpected breakdowns and extend the lifespan of the equipment. For instance, if we notice a recurring issue with a specific component, we can investigate the root cause and potentially adjust our maintenance schedule or operator training to prevent future occurrences.

Q 11. Explain your experience with load capacity calculations and limitations.

Accurate load capacity calculations are essential to safe and efficient operation. I have extensive experience in determining the safe operating load limits of different loaders based on their specifications, considering factors like the material being handled, the terrain, and environmental conditions. This includes understanding the difference between rated capacity (manufacturer’s maximum) and operational capacity (a more conservative estimate factoring in real-world limitations).

Overloading is a major safety hazard. I train operators to visually inspect loads to ensure they are within the safe operating limits. We utilize load charts and weight estimation tools to assist in this process. In situations where the load weight is uncertain, we use scales or other weighing equipment to ensure accurate measurement. Exceeding load capacity is strictly prohibited, and operators are trained to refuse any load they believe is unsafe.

Q 12. How do you assess and mitigate risks associated with loader operations?

Risk assessment is an ongoing process. We use a systematic approach, regularly identifying potential hazards in loader operations. This includes analyzing the work environment, identifying potential points of failure in the equipment, and evaluating operator actions. We use Job Safety Analysis (JSA) and other risk assessment methods to systematically evaluate tasks and control risks.

Mitigation strategies are implemented based on the identified risks. Examples include establishing clear traffic routes, implementing safe work procedures, providing appropriate PPE, and ensuring adequate training. Regular safety meetings and toolbox talks are used to discuss identified risks and ensure workers are aware of control measures. We also use near-miss reporting to analyze events that could have led to accidents, enabling improvements to our safety procedures.

Q 13. Describe your proficiency in using loader operation software or tracking systems.

I am proficient in using various loader operation software and tracking systems. This includes telematics systems that monitor loader performance, location, and operating hours. These systems provide valuable data for maintenance scheduling, fuel consumption tracking, and identifying potential operational issues. Some systems also allow for real-time monitoring of loader operations, enabling immediate intervention if necessary.

Experience with these systems allows for improved efficiency and reduced downtime. Data analysis from the tracking systems allows us to optimize workflows, identify areas for improvement in operator training, and ensure loaders are utilized effectively. For example, we can analyze fuel consumption data to identify inefficient operating practices and implement strategies for fuel optimization. The data collected helps us make data-driven decisions to enhance safety and productivity.

Q 14. How do you manage operator fatigue and ensure adequate rest periods?

Operator fatigue is a significant safety concern. We address this by adhering to strict work schedules that comply with regulations and incorporate mandatory rest breaks throughout the workday. We also monitor operator performance for signs of fatigue, such as decreased attention or slower reaction times.

Our safety procedures emphasize the importance of reporting fatigue. Operators are trained to communicate their fatigue levels to supervisors, enabling adjustments to work schedules or assignments as needed. We avoid scheduling long shifts and provide adequate facilities for rest and recuperation. Regular health and wellness programs that encourage a healthy lifestyle outside of work contribute to overall operator well-being and reduces fatigue.

Q 15. What is your experience with different loading techniques and methodologies?

My experience encompasses a wide range of loading techniques, from the basic bucket loading for excavation and stockpiling to more specialized methods like clamshell bucket operations for bulk materials and the use of specialized attachments like forks or grapple buckets for handling various materials. I’m proficient in different methodologies including pre-planning load routes to optimize efficiency, implementing safety procedures based on material type and terrain, and adjusting techniques based on the loader’s capacity and the specific project requirements.

For example, when loading trucks with aggregates, I’d optimize the loading process by positioning the loader strategically to minimize travel time and prevent spillage. Conversely, in a confined space like a building site, I would utilize more precise loading techniques with smaller bucket sizes to ensure safety and prevent damage. The choice of loading technique always depends on several factors including material characteristics, available space, and the overall project objectives.

- Bucket Loading: Standard method for various materials.

- Clamshell Bucket Loading: Efficient for bulk materials like sand and gravel.

- Fork and Grapple Bucket Loading: Handles palletized or irregularly shaped materials.

Career Expert Tips:

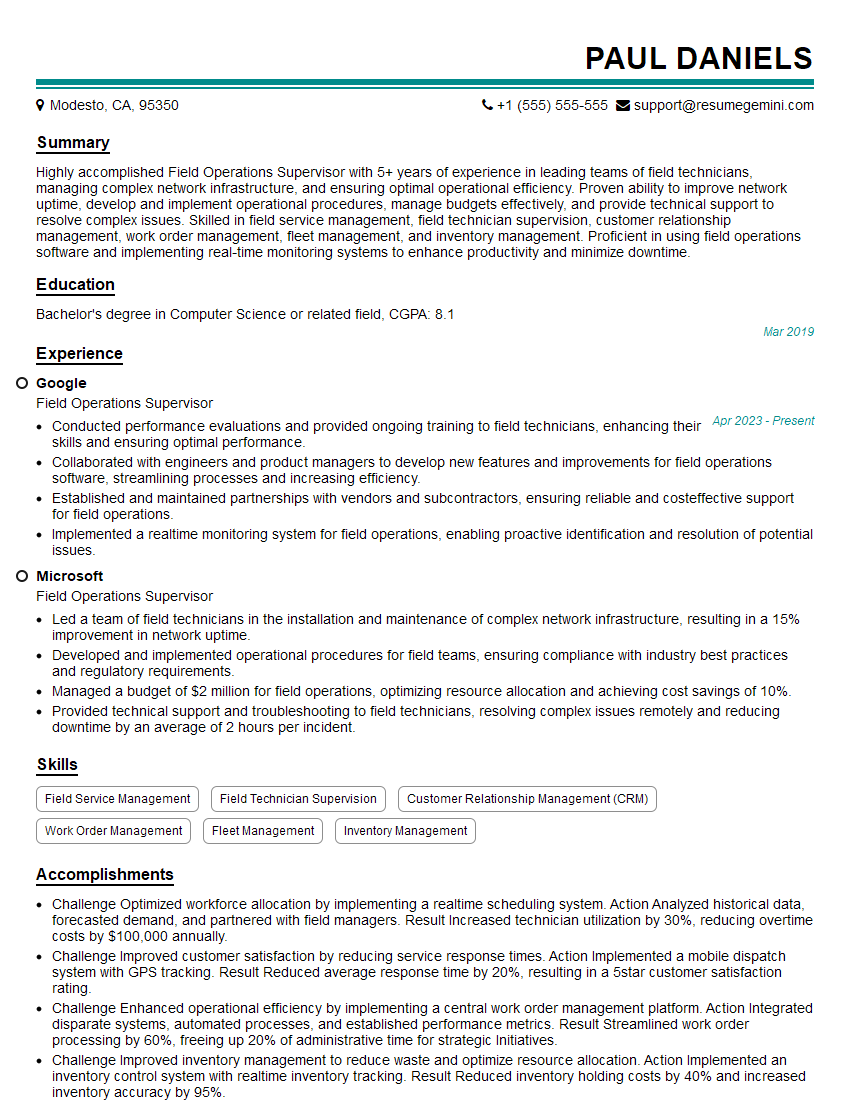

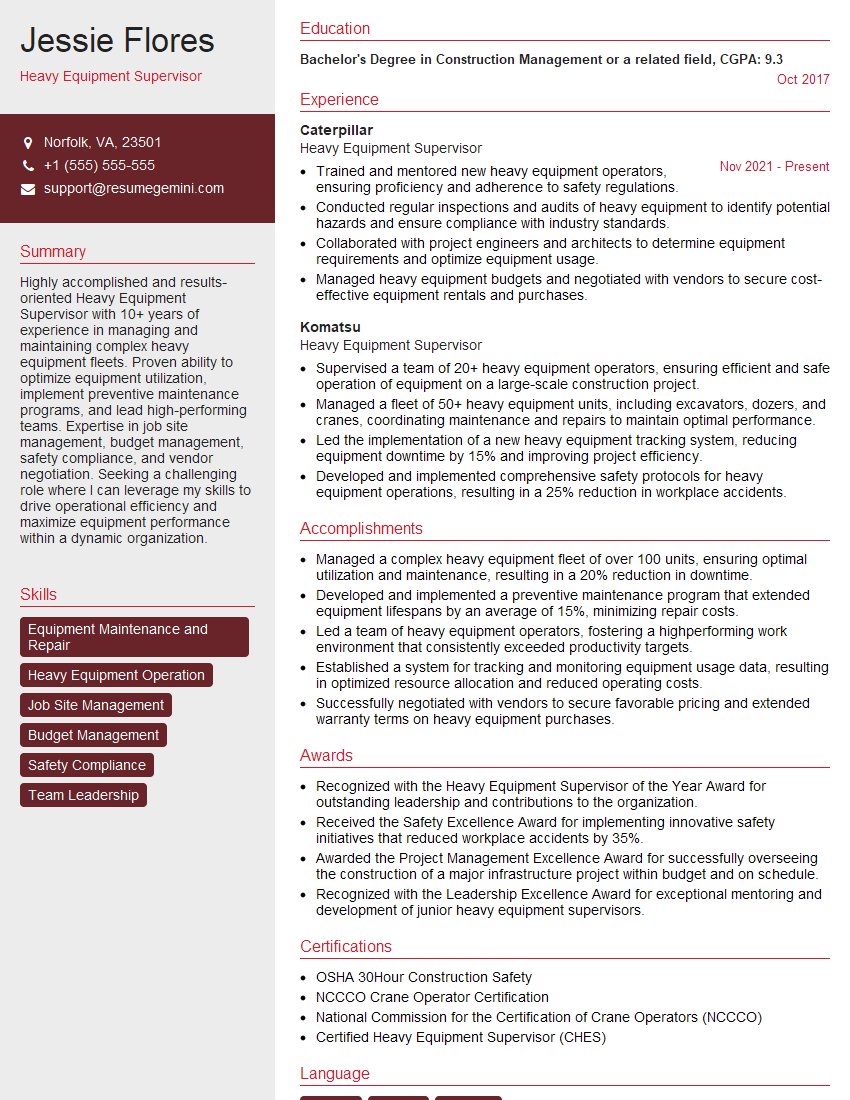

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you resolve conflicts or disagreements among loader operators?

Resolving conflicts among loader operators requires a calm and diplomatic approach, focusing on clear communication and a collaborative problem-solving strategy. I would start by listening attentively to each operator’s perspective, identifying the root cause of the disagreement. Often, conflicts stem from misunderstandings regarding loading procedures, safety protocols, or scheduling.

Once the issues are clearly understood, I facilitate a discussion, ensuring each operator feels heard. We’d then collaboratively devise solutions, emphasizing safety and efficiency. If the conflict involves safety violations, I’d enforce the appropriate disciplinary actions outlined in the company’s safety manual. The goal is to ensure a safe and productive work environment where operators feel valued and respected.

For instance, if two operators disagree on the optimal loading sequence for a specific project, I’d facilitate a review of the project schedule and site layout, collaboratively finding a solution that balances both operators’ needs and overall project efficiency.

Q 17. Describe a time you successfully improved loader operation efficiency.

During a large-scale earthmoving project, we faced significant delays due to inefficient material handling. Observing the operation, I noticed that operators were frequently idling while waiting for trucks. To address this, I implemented a system using a simple whiteboard to track truck availability and the loader’s progress. This allowed for better synchronization between the two operations, eliminating idle time for both the loaders and the trucks.

Furthermore, I introduced a standardized loading procedure, clearly defining loading zones and communication protocols. This improved safety and significantly reduced the overall cycle time. We also analyzed the loader’s loading patterns and adjusted the bucket size to optimize the load per cycle. The result was a 15% increase in productivity and a noticeable reduction in operational costs, all while improving safety. This demonstrated that simple changes in organization and planning can greatly enhance efficiency.

Q 18. How do you handle challenging terrain or weather conditions during loader operations?

Handling challenging terrain and weather requires adapting operation strategies to ensure both safety and efficiency. For challenging terrain, I’d adjust the loader’s speed and ensure the appropriate traction is available by adjusting tire pressure or selecting a suitable tire configuration. I’d also meticulously plan load routes, avoiding steep slopes or unstable ground, and prioritize safe working loads for the given conditions.

In adverse weather, such as heavy rain or snow, visibility and traction become crucial factors. Safety procedures would be emphasized, including reduced speed limits and increased operator awareness of slippery surfaces. Appropriate visibility aids, like extra lights, might be utilized. In extreme conditions, operations might be temporarily suspended to ensure worker safety. For example, in snowy conditions, we may need to use chains on the tires and ensure the ground is cleared to a degree for safe operation.

Q 19. What is your experience with pre-operational inspections of loaders?

Pre-operational inspections are crucial for safety and efficient operation. My inspections are thorough and follow a standardized checklist covering all critical components, including fluid levels (hydraulic oil, engine oil, coolant), tire pressure, brake function, lights, and structural integrity of the loader’s frame and attachments. I also check for any signs of leaks, damage, or unusual wear and tear.

Documentation of these inspections is meticulously maintained, recording any issues discovered. If any problems are identified, they are immediately reported to maintenance personnel, preventing potential breakdowns and ensuring that the equipment operates safely. This proactive approach minimizes downtime and maximizes operational reliability. A simple, well-maintained checklist is key for consistent and thorough inspections.

Q 20. How do you communicate effectively with other site personnel regarding loader operations?

Effective communication with other site personnel is vital for smooth operations. I prioritize clear and concise communication, using two-way radios, hand signals, or visual aids to coordinate loader movements with other equipment and personnel. Before commencing any operation, I confirm the loading schedule and designated areas with other team members, clarifying any potential conflicts.

For instance, I would use hand signals to guide the truck drivers when loading materials, ensuring that the material is correctly positioned within the truck to maximize payload and minimize spillage. Clear communication helps prevent accidents and ensures the smooth flow of materials across the site.

Q 21. Describe your experience with reporting and documentation for loader operations.

Reporting and documentation for loader operations include daily logs recording operational hours, materials handled, any maintenance issues, and any incidents or near misses. These logs contribute to equipment maintenance scheduling and risk assessment. I also maintain records of operator performance, including productivity metrics and safety compliance. This data is crucial for optimizing operational efficiency and identifying areas for improvement.

For instance, regular analysis of the daily logs might reveal patterns of inefficiency or potential maintenance problems. This data-driven approach helps improve planning and decision-making, leading to better resource allocation and overall productivity. Using digital tools and spreadsheets aids this process significantly, increasing the efficiency and accuracy of record-keeping.

Q 22. How do you manage fuel consumption and optimize efficiency in loader usage?

Managing fuel consumption and optimizing loader efficiency is crucial for both cost reduction and environmental responsibility. It’s a multifaceted approach involving operator training, machine maintenance, and strategic planning.

- Operator Training: I emphasize training operators on techniques like smooth acceleration and deceleration, minimizing idling time, and matching engine speed to the load. For example, I’d teach them to avoid ‘gunning’ the engine – unnecessarily revving the engine to increase power – which drastically increases fuel burn without proportionally increasing efficiency.

- Preventative Maintenance: Regular maintenance is paramount. Ensuring proper tire pressure, engine tune-ups, and timely filter changes all contribute significantly to fuel economy. A poorly maintained machine will consume far more fuel than a well-maintained one.

- Load Optimization: Planning is key. Overloading a loader strains the engine, forcing it to work harder and consume more fuel. Careful load planning, matching loader capacity to the task, prevents unnecessary fuel waste.

- Technology Utilization: Modern loaders often incorporate fuel monitoring systems and telematics. Analyzing this data helps identify areas for improvement. For instance, if we notice consistently high fuel consumption during a particular task, we can adjust the operational procedures or assess if a different machine is better suited for the job.

In one project, we implemented a fuel efficiency program incorporating all these elements. We saw a 15% reduction in fuel consumption within six months, demonstrating the tangible benefits of a comprehensive strategy.

Q 23. How familiar are you with various types of attachments used with loaders?

My experience encompasses a wide range of loader attachments. Understanding their specific applications and limitations is vital for safe and efficient operation.

- Buckets: I’m proficient with various bucket types, including general-purpose buckets, light-material buckets, and heavy-duty rock buckets, each designed for different materials and conditions. The selection of the right bucket significantly impacts efficiency and reduces wear and tear.

- Forks: I’m experienced in using forks for pallet handling, material stacking, and transportation. Proper technique is essential to prevent damage to both the load and the machine.

- Specialty Attachments: I’m familiar with attachments like grapples for handling logs or scrap metal, snow blades for winter operations, and augers for various tasks. Safety training for each attachment is critical before allowing operators to use them.

- Quick Couplers: I have hands-on experience with quick coupler systems, which allow for rapid changing of attachments. This speeds up operations and improves overall productivity.

Understanding the strengths and limitations of each attachment allows me to select the right tool for the job, maximizing efficiency and minimizing downtime. For instance, using a general-purpose bucket for rock removal would be inefficient and potentially damaging to the bucket and loader.

Q 24. Explain your experience with load planning and optimization.

Load planning and optimization are crucial aspects of my role. It involves assessing the job site, determining the best loading sequence, and optimizing the number of passes required. This translates into enhanced productivity and reduced wear and tear on equipment.

- Site Assessment: Before starting any operation, I carefully survey the site to identify potential obstacles, assess material distribution, and determine the most efficient loading paths.

- Sequence Planning: I develop loading sequences that minimize travel time and maximize load capacity. This might involve strategically positioning the loader to minimize travel distance or loading materials from multiple sources simultaneously.

- Material Handling Analysis: I analyze the type and characteristics of materials being moved to determine the most appropriate loading techniques and equipment. For example, loose materials require a different approach than palletized goods.

- Data Analysis: When possible, I leverage technology to analyze loading patterns and identify areas for improvement. Data from GPS trackers and machine monitoring systems provides valuable insights.

In a recent project, we implemented a new load-planning strategy, resulting in a 20% increase in productivity by reducing unproductive travel time and optimizing loading cycles.

Q 25. How do you ensure the safe storage and handling of materials being loaded?

Safe storage and handling of materials are paramount for preventing accidents and ensuring operational efficiency. My approach emphasizes several key areas.

- Proper Material Storage: I ensure materials are stored in designated areas, stable and secured to prevent collapse or shifting. This includes using appropriate supports, bundling materials as needed, and creating clear walkways.

- Safe Loading Practices: I train operators on safe loading techniques, including proper weight distribution, avoiding overloading, and maintaining awareness of surroundings. Regular inspections of the loader and its attachments help to prevent accidents.

- Signage and Barriers: Clear signage and barriers demarcate loading zones and restricted areas, preventing unauthorized access and maintaining a safe working environment.

- Emergency Procedures: I develop and regularly review emergency procedures to ensure a swift and organized response in case of accidents. This includes communication protocols and evacuation plans.

By consistently implementing these measures, we create a safe work environment that minimizes the risk of accidents and maximizes operational efficiency. A well-organized site minimizes the chances of delays and damage.

Q 26. What is your experience with preventative maintenance for loaders?

Preventative maintenance is fundamental to ensuring the longevity and efficiency of loaders. My experience includes developing and overseeing a comprehensive preventative maintenance program (PMP).

- Scheduled Inspections: I establish a rigorous schedule for routine inspections, covering all critical components, including hydraulic systems, engines, transmissions, and attachments. Checklists ensure thoroughness.

- Lubrication and Fluid Changes: Regular lubrication and timely fluid changes are crucial. I ensure these are performed according to the manufacturer’s recommendations.

- Component Replacement: I oversee the timely replacement of worn or damaged components to prevent major breakdowns. This includes proactively replacing parts nearing the end of their lifespan.

- Record Keeping: Meticulous record-keeping is essential. We maintain detailed logs of all maintenance activities, enabling us to track performance, identify potential problems early, and optimize maintenance schedules.

Our PMP has resulted in a significant reduction in unexpected downtime and improved overall machine lifespan. Predictive maintenance, based on data analysis, helps us move beyond simple scheduled maintenance to anticipate potential issues before they become critical.

Q 27. Describe your process for monitoring operator performance and providing feedback.

Monitoring operator performance and providing feedback is a crucial part of enhancing safety and efficiency. My approach is a combination of observation, data analysis, and constructive feedback.

- Direct Observation: I regularly observe operators in action, assessing their technique, adherence to safety protocols, and overall efficiency. This includes observing their handling of materials, machine operation, and adherence to site rules.

- Data Analysis: I analyze data from machine telematics systems, assessing fuel consumption, cycle times, and other key performance indicators (KPIs). This provides objective insights into operator performance.

- Performance Feedback: I provide regular feedback to operators, focusing on both positive reinforcement and constructive criticism. Feedback sessions are tailored to each operator’s strengths and weaknesses, ensuring a positive and productive learning environment.

- Training and Development: I identify training needs based on observations and data analysis. This might involve refresher training on safety protocols or advanced training on specific techniques.

By providing consistent, constructive feedback, we improve operator skills, enhance safety, and boost operational efficiency. Creating an environment where operators feel supported and valued is essential for achieving the best results.

Q 28. How do you ensure compliance with environmental regulations during loader operations?

Compliance with environmental regulations is non-negotiable. My approach involves understanding and implementing procedures that minimize environmental impact.

- Fuel Management: Minimizing fuel consumption is directly related to reducing emissions. Our fuel efficiency program, as previously discussed, contributes significantly to environmental compliance.

- Dust Control: I implement measures to control dust generation, including regular watering of haul roads and the use of dust suppressants where appropriate. This reduces airborne particulate matter and protects both workers and the environment.

- Spill Prevention and Response: I establish procedures for preventing and responding to fuel and material spills, including proper containment and cleanup procedures. This minimizes contamination of soil and water resources.

- Waste Management: I ensure the proper disposal of waste materials according to regulations. This might involve recycling, repurposing, or utilizing licensed disposal facilities.

- Regular Audits and Reporting: Regular audits ensure ongoing compliance. We maintain detailed records of our environmental practices and prepare reports to demonstrate adherence to all relevant regulations.

Environmental stewardship is integral to our operations. By consistently implementing these measures, we minimize our environmental footprint and ensure compliance with all relevant regulations.

Key Topics to Learn for Loader Operation Supervision Interview

- Safety Procedures and Regulations: Understanding and implementing OSHA regulations, site-specific safety protocols, and conducting regular safety inspections.

- Loader Operation Proficiency: Demonstrating knowledge of various loader types, their functionalities, maintenance requirements, and safe operating procedures. Practical application includes describing experience troubleshooting mechanical issues and performing preventative maintenance.

- Crew Management and Supervision: Understanding effective team leadership, delegation of tasks, conflict resolution, and fostering a safe and productive work environment. This includes outlining strategies for motivating and training team members.

- Production Planning and Optimization: Knowledge of efficient loading techniques, material handling strategies, and optimizing workflows to maximize productivity and minimize downtime. This could involve explaining experience with scheduling and resource allocation.

- Logistics and Material Handling: Understanding the flow of materials, inventory management, and the efficient movement of goods within the operational context. This includes experience with load planning and tracking.

- Equipment Maintenance and Troubleshooting: Proficiency in identifying and resolving mechanical issues, performing preventative maintenance, and managing equipment repairs. This involves outlining practical experience diagnosing problems and implementing solutions.

- Communication and Reporting: Effectively communicating with team members, supervisors, and other stakeholders, accurately documenting work progress, and providing clear and concise reports.

Next Steps

Mastering Loader Operation Supervision opens doors to significant career advancement, offering increased responsibility, higher earning potential, and opportunities for specialized training. To maximize your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. We provide examples of resumes tailored to Loader Operation Supervision to help you craft the perfect application. Invest time in crafting a strong resume – it’s your first impression and a critical step in landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO