The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Loading/Unloading Procedures interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Loading/Unloading Procedures Interview

Q 1. Describe your experience with different loading/unloading techniques.

My experience encompasses a wide range of loading and unloading techniques, tailored to the specific cargo and environment. I’ve worked with everything from manual handling of smaller, lighter goods to operating sophisticated machinery for heavy or bulk materials. This includes:

- Forklift Operation: Extensive experience operating various forklift models, including reach trucks, counterbalance trucks, and order pickers, ensuring safe and efficient pallet handling in warehouses and loading docks. For example, I’ve optimized pallet stacking strategies to maximize space utilization and minimize loading times.

- Crane Operation: Skilled in operating both mobile and overhead cranes for loading and unloading heavy equipment, containers, and oversized cargo. Safety protocols, load securing techniques and weight limits are always strictly adhered to. One project involved carefully positioning a large generator onto a barge for transport.

- Conveyor Belt Systems: Proficient in using and maintaining conveyor systems, ensuring smooth flow of goods throughout the process. This includes troubleshooting jams and making minor repairs to keep the system running efficiently. I once resolved a significant bottleneck in a food processing facility by identifying and clearing a blockage on a conveyor.

- Manual Handling: I’m also adept at manual loading and unloading techniques, ensuring proper lifting techniques to prevent injuries and employing appropriate equipment (hand trucks, dollies) for heavier items. I frequently train new team members on safe manual handling procedures.

My approach always emphasizes safety, efficiency, and the specific characteristics of the cargo to be handled.

Q 2. How do you ensure the safety of personnel and equipment during loading/unloading?

Safety is paramount in loading and unloading operations. My approach is multi-faceted:

- Pre-shift Inspections: Before any work begins, I meticulously inspect equipment (forklifts, cranes, etc.) for any mechanical faults or safety hazards. This proactive measure prevents accidents.

- Proper PPE: Ensuring everyone on the team wears appropriate personal protective equipment (PPE), including safety boots, high-visibility vests, gloves, and hard hats, is non-negotiable.

- Safe Lifting Techniques: I provide regular training and actively enforce correct lifting techniques to prevent musculoskeletal injuries, particularly when manual handling is involved. We use lifting aids whenever feasible.

- Traffic Management: Establishing and maintaining clear communication and designated walkways prevents collisions between personnel and equipment, especially in busy environments. We utilize traffic control measures such as cones and designated lanes.

- Load Securing: Correct load securing is critical. This involves using appropriate straps, chains, and other restraints to prevent shifting or falling during transit. Proper load weight distribution also reduces strain on equipment and improves handling safety.

- Emergency Procedures: Everyone on the team is thoroughly briefed on emergency procedures and knows the location of safety equipment, including fire extinguishers and first-aid kits.

My commitment to safety isn’t just about following rules; it’s about fostering a safety-first culture where everyone feels empowered to identify and report hazards.

Q 3. Explain your process for verifying the accuracy of incoming and outgoing shipments.

Accurate verification is crucial for inventory control and customer satisfaction. My process involves:

- Pre-loading Verification: Before loading, I carefully check the incoming shipment against the accompanying documentation (packing slips, invoices, purchase orders). I visually inspect items for any visible damage. Discrepancies are immediately noted and reported.

- Quantity Checks: I count items and verify that the quantities match the paperwork. For bulk shipments, I may use weight measurements to confirm quantities. I’ve developed proficiency in efficient counting techniques for large quantities of goods.

- Condition Checks: I examine items for any damage (dents, scratches, tears) and note these on the documentation. This process is critical for insurance claims and preventing issues later on. Photos are taken for documentation when necessary.

- Post-unloading Verification: After unloading, I perform another check to ensure everything is accounted for. This second verification helps identify any potential losses or damages that may have occurred during transit.

- Barcode/RFID Scanning: Where applicable, barcode or RFID scanning is used to efficiently and accurately track items. This technology minimizes human error and streamlines the verification process.

This multi-stage verification process ensures accuracy and minimizes errors, leading to smoother operations and stronger client relationships.

Q 4. How do you handle damaged goods during the loading/unloading process?

Handling damaged goods requires a methodical approach:

- Documentation: I meticulously document the damage, including taking photos, noting the quantity of damaged items, and describing the nature of the damage. This documentation is crucial for insurance claims.

- Segregation: Damaged goods are immediately segregated from undamaged items to prevent further damage and contamination. Clear labeling is essential to identify them.

- Reporting: I promptly report the damage to the relevant parties (e.g., supervisors, clients, shipping companies) and follow their instructions on how to proceed.

- Return/Disposal: Depending on the nature and extent of the damage, the damaged goods may be returned to the supplier, repaired, or disposed of according to company policy and environmental regulations.

- Root Cause Analysis: Where possible, I help investigate the cause of the damage to prevent recurrence. This might involve reviewing handling procedures or providing feedback to the shipping company.

My goal is to minimize losses, handle the situation efficiently, and learn from the experience to prevent similar occurrences in the future.

Q 5. What are your strategies for efficient loading/unloading operations?

Efficient loading/unloading strategies are built on planning and execution:

- Optimized Layout: Understanding the layout of the loading area, storage locations, and transportation vehicles is critical for efficient workflow. This may involve mapping out optimal routes.

- Proper Sequencing: Prioritizing items based on delivery schedules or urgency optimizes loading efficiency. Similar items should be grouped together for easier handling.

- Load Planning Software: Utilizing load planning software can significantly optimize space utilization in trucks and containers, reducing the number of trips required.

- Cross-training: Training team members in multiple loading/unloading techniques enables flexibility and adaptability in responding to changing demands.

- Regular Equipment Maintenance: Ensuring equipment is in optimal working condition minimizes downtime and maximizes efficiency.

- Teamwork & Communication: Effective teamwork and clear communication among team members are vital for a smooth and efficient process. A well-coordinated team can make all the difference.

By implementing these strategies, we can significantly reduce loading and unloading times, resulting in cost savings and improved productivity.

Q 6. How do you prioritize tasks during peak loading/unloading periods?

During peak periods, effective prioritization is key:

- Time-Sensitive Shipments: High-priority shipments with tight deadlines are given precedence. This might involve using dedicated loading bays or allocating extra resources to these specific orders.

- Order Fulfillment: Orders awaiting shipment are prioritized based on the delivery schedules and customer requirements. This helps meet customer expectations and maintains business relationships.

- Inventory Management: Prioritizing the unloading of incoming shipments ensures sufficient stock for upcoming orders and minimizes storage issues.

- Resource Allocation: During peak times, I’d work with supervisors to strategically allocate personnel and equipment to the highest-priority tasks. This ensures efficiency and reduces bottlenecks.

- Communication: Open communication with drivers and warehouse staff helps ensure smooth workflows and reduces delays.

A combination of careful planning and flexible adaptation allows for smooth operations even under significant pressure.

Q 7. What types of equipment have you operated for loading/unloading?

Throughout my career, I’ve operated a variety of equipment for loading and unloading:

- Forklifts: Various types, including sit-down counterbalance forklifts, reach trucks, and order pickers, with capacities ranging from 3,000 lbs to 10,000 lbs.

- Cranes: Mobile cranes and overhead cranes, both for lifting and placing heavy materials and equipment.

- Conveyors: Various types of conveyor belts and systems used for moving goods efficiently, including roller conveyors, belt conveyors, and powered conveyors.

- Hand Trucks and Pallet Jacks: I’m proficient in using a variety of manual handling equipment for moving smaller items and pallets.

- Strapping Machines: Experience using strapping machines to secure goods onto pallets or for shipping.

My experience extends to using specialized equipment as required for specific projects and types of cargo. The specific equipment used is always chosen based on the task and the safety considerations involved.

Q 8. Describe your experience with inventory management related to loading/unloading.

Inventory management is crucial for efficient loading and unloading. My experience involves meticulously tracking inventory levels before, during, and after each operation. This includes using inventory management systems (IMS) to update stock levels in real-time, reconciling discrepancies, and forecasting future needs based on loading/unloading schedules. For example, I’ve used systems like SAP and Oracle to manage inventory across multiple warehouses, ensuring that we had the correct number of pallets ready for dispatch and sufficient space to receive incoming shipments. I also developed and implemented a system of barcoding and RFID tagging to improve accuracy and speed up the inventory process, reducing the time spent on manual counts and minimizing errors.

In one instance, we anticipated a surge in demand for a particular product. By analyzing historical data and sales forecasts within the IMS, I proactively ensured that enough of this item was available for loading, preventing potential stockouts and delays. This proactive approach saved the company significant revenue and reputational damage.

Q 9. How do you maintain a clean and organized loading/unloading area?

Maintaining a clean and organized loading/unloading area is paramount for safety and efficiency. My approach involves a multi-pronged strategy focusing on preventative measures and regular maintenance. This includes clearly marked designated areas for different types of goods, regular sweeping and debris removal, proper storage of equipment, and clear pathways for both personnel and equipment. We utilize visual management tools like color-coded zones and signage to promote organization and prevent confusion. Regular inspections are conducted to identify and address potential hazards, like spills or obstructions.

For example, we implemented a ‘5S’ methodology (Sort, Set in Order, Shine, Standardize, Sustain) in our loading dock, significantly improving organization and reducing the risk of accidents. This involved clearly designating areas for different types of goods, creating a system for storing pallets and equipment, and establishing a cleaning schedule.

Q 10. Explain your understanding of warehouse safety regulations.

Warehouse safety regulations are critical to my work. My understanding encompasses OSHA (Occupational Safety and Health Administration) standards, along with company-specific policies. This includes, but is not limited to, proper forklift operation and training, the use of personal protective equipment (PPE) like safety shoes, high-visibility vests, and gloves, and the adherence to load-bearing capacity limits for both equipment and structures. I am well-versed in hazard communication, emergency procedures, and reporting requirements. Regular safety training and drills are vital to ensuring a safe work environment.

For instance, I’ve overseen the implementation of a comprehensive safety training program, covering topics ranging from forklift operation to fire safety. This resulted in a significant reduction in workplace accidents. I am also familiar with the regulations concerning hazardous materials handling and storage.

Q 11. How do you handle discrepancies between shipping documents and actual inventory?

Discrepancies between shipping documents and actual inventory are addressed systematically. I first verify the accuracy of both documents, including the packing slips, bills of lading, and inventory management system records. If discrepancies are found, a thorough investigation is carried out. This might involve recounting inventory, checking for damaged goods, and carefully reviewing all documentation. The investigation aims to pinpoint the source of the error—whether it’s a data entry mistake, a packing error, or theft. Once the cause is determined, corrective actions are taken, and a detailed report is filed. Communication with both the receiving and shipping parties is crucial to resolve the discrepancy and prevent future occurrences.

For example, I once discovered a significant shortage in a shipment. By meticulously comparing the packing list, the inventory count, and the delivery receipt, we discovered a pallet had been mistakenly sent to a different warehouse. Tracking it down and returning it ensured timely delivery to the correct location.

Q 12. Describe your experience with different types of packaging and how it impacts loading/unloading.

Experience with various packaging types, from pallets and crates to individual boxes and shrink-wrapped items, significantly impacts loading and unloading procedures. Understanding the material strength, dimensions, and weight of packaging is essential for selecting the appropriate equipment and handling techniques. For instance, fragile items require extra cushioning and careful handling. Heavy items require proper stacking and securement to prevent damage and collapse. The size and shape of packaging impact space utilization within the vehicle or warehouse.

I’ve worked with various packaging materials, including corrugated cardboard, wooden pallets, and specialized containers for hazardous materials. My experience allows me to optimize loading strategies to maximize space utilization and ensure safe transportation. For example, I learned to efficiently load irregular-shaped items by strategically arranging them to fill gaps and minimize wasted space. This not only saves space but also improves stability during transit.

Q 13. How do you prevent product damage during loading/unloading?

Preventing product damage during loading and unloading requires a proactive and meticulous approach. This starts with proper planning, selecting appropriate handling equipment, and training personnel on correct techniques. Using protective materials like bubble wrap, dunnage, and corner boards is essential. Careful stacking is crucial, with heavier items placed on the bottom and fragile items protected from compression. The use of load-securing techniques is fundamental to preventing shifting and damage during transit.

I’ve implemented a system for using anti-slip mats on loading docks and within trucks to prevent items from sliding. Careful monitoring of load weights and ensuring they don’t exceed vehicle limits prevents equipment damage and potential accidents. Training workers on proper lifting techniques and the use of mechanical aids prevents injuries and product damage caused by mishandling.

Q 14. What is your experience with load securing techniques?

Load securing techniques are vital to prevent cargo shifting during transit, leading to accidents and damage. My experience includes using various techniques, such as straps, chains, and netting, to secure loads on pallets and within vehicles. I am familiar with different securing methods appropriate for various types of cargo and transportation modes. Understanding load distribution and center of gravity is crucial for effective securing. This knowledge includes understanding regulations and best practices related to load securing to meet legal requirements and minimize risks.

For example, I’ve trained teams in the proper use of ratchet straps to effectively secure palletized goods, and I’ve designed customized load-securing plans for oversized or irregularly shaped items, incorporating techniques such as blocking and bracing.

Q 15. How do you communicate effectively with drivers and other team members during loading/unloading?

Effective communication is the cornerstone of efficient loading and unloading operations. I believe in clear, concise, and respectful communication at all times. This involves using a combination of verbal and non-verbal cues. For instance, before starting, I’ll conduct a brief pre-load meeting with the driver, clarifying the number of pallets, the delivery address, and any special handling instructions. This is often facilitated by a shared digital manifest or delivery note.

- Clear instructions: I use simple language and avoid jargon. For example, instead of saying ‘secure the load with ratchet straps,’ I might say, ‘make sure the load is tightly fastened with these straps, ensuring nothing can shift during transit.’

- Active listening: I pay close attention to the driver’s concerns or questions, ensuring they fully understand the process and feel comfortable. For example, if a driver expresses concern about access to the loading dock, we’ll collaboratively find a solution, such as using a different loading bay or adjusting the unloading sequence.

- Visual aids: When necessary, I’ll use visual aids like maps or diagrams to illustrate the loading sequence or location of specific items. This is particularly useful when dealing with large or complex orders.

- Teamwork: Within my team, I encourage open communication and collaboration. We regularly use hand signals for safety and efficiency, especially in busy environments. We communicate potential issues immediately and work together to solve them. For instance, if a pallet is damaged, we’ll communicate this immediately to minimize disruption and prevent accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience using a warehouse management system (WMS).

I’ve extensive experience using various Warehouse Management Systems (WMS), including Manhattan Associates and Blue Yonder. These systems are integral to streamlining the loading/unloading process. My experience encompasses all aspects, from order fulfillment and picking to loading optimization and real-time tracking. I’m proficient in using the system’s features to generate picking lists, allocate dock doors, manage inventory, and track shipment statuses.

For example, using a WMS, I can access real-time inventory information to optimize the loading sequence, ensuring that frequently needed items are easily accessible. The system can automatically generate loading manifests, reducing manual errors and saving time. Furthermore, I use the WMS to monitor the progress of the loading process, identify bottlenecks, and adjust the schedule as necessary. I can also generate reports on key metrics like loading time, order accuracy, and on-time delivery performance, which helps to identify areas for improvement and track our overall performance.

Example: Using the WMS's 'Dock Scheduling' feature, I can assign specific dock doors to particular trucks based on their arrival time and the type of goods being unloaded, maximizing efficiency and minimizing congestion.Q 17. What are your strategies for managing time constraints during loading/unloading?

Managing time constraints effectively during loading and unloading relies on a multi-pronged approach. It’s like conducting an orchestra – each section needs to be in sync for a harmonious outcome. My strategies include:

- Pre-planning: Careful pre-planning is crucial. This involves reviewing the order details, confirming the availability of equipment and personnel, and anticipating potential delays. I often create a detailed loading plan, assigning specific tasks and responsibilities to team members.

- Efficient processes: I streamline the loading process by optimizing the layout of the warehouse, ensuring clear pathways and easy access to loading docks. Implementing lean principles helps to eliminate waste and improve overall efficiency.

- Prioritization: When faced with multiple orders, I prioritize based on delivery deadlines and urgency. This might involve using a first-in, first-out (FIFO) system or prioritizing orders with specific time-sensitive requirements.

- Technology integration: Leveraging a WMS allows for real-time tracking and monitoring of the loading process, enabling proactive adjustments and preventing delays.

- Communication: Open and constant communication with the drivers, warehouse staff, and other stakeholders allows for early detection and resolution of potential problems, minimizing delays.

For instance, if an unexpected delay arises like a damaged pallet, I immediately communicate this to the driver and inform the shipping department to adjust delivery expectations. I also coordinate with my team to resolve the issue as efficiently as possible, perhaps by using a replacement pallet or adjusting the loading sequence. Problem solving under pressure is key.

Q 18. How do you adapt your loading/unloading techniques for different product types?

Adapting loading/unloading techniques for different product types is fundamental to safety and efficiency. It’s not a ‘one-size-fits-all’ approach. Consider the following:

- Fragile items: These require extra care, using proper padding, bracing, and secure stacking to prevent damage. We might use specialized equipment like air-ride suspension trucks to minimize shock and vibration during transit.

- Heavy items: These require the use of appropriate lifting equipment, such as forklifts and pallet jacks, and skilled personnel to ensure safe handling. Proper weight distribution on pallets is also critical.

- Temperature-sensitive items: These require temperature-controlled storage and transport. We ensure that refrigerated trucks are used and that the temperature is monitored throughout the loading and unloading process.

- Liquid products: These necessitate the use of appropriate containers, ensuring proper sealing and handling to prevent spills or leakage.

- Bulk items: This may necessitate specialized equipment, such as conveyors or bulk handling systems. Proper securing of the load is essential to prevent shifting and damage.

For example, when handling fragile ceramics, we use air-cushion packaging and carefully brace the pallets to prevent shifting during transit. This requires a different approach than handling heavy machinery, where securing the load with chains and using heavy-duty straps are vital.

Q 19. How do you ensure the correct loading sequence for optimal space utilization?

Optimal space utilization during loading is crucial for efficiency and cost savings. The correct loading sequence minimizes wasted space and reduces the number of trips required. My approach involves:

- Weight distribution: Heavier items should be loaded at the bottom and distributed evenly to maintain balance and stability.

- Dimensions: I consider the dimensions of items and the truck’s interior to maximize space utilization. Larger items are often placed first, acting as a base for smaller items.

- Delivery sequence: Items destined for the same location are grouped together to facilitate quicker unloading at the delivery point. This reduces the need for internal sorting at the destination.

- WMS integration: The WMS often provides optimized loading plans based on the order details and the available space, taking into account item weight, dimensions, and delivery destination.

- Visual aids: Using diagrams and loading plans helps to visualize the loading sequence and ensure that items are placed correctly.

For example, when loading a truck with various sized boxes for multiple destinations, I’ll first arrange larger boxes to create a stable foundation, filling in gaps with smaller packages. Boxes going to the same delivery point are grouped together for faster unloading.

Q 20. What is your experience with hazardous material handling during loading/unloading?

Handling hazardous materials requires strict adherence to safety regulations and procedures. My experience includes working with various hazardous materials, such as chemicals, flammable liquids, and corrosive substances. I am thoroughly familiar with relevant safety data sheets (SDS) and understand the associated risks.

- Proper labeling and documentation: I ensure that all hazardous materials are correctly labeled and accompanied by the necessary documentation, including SDS sheets and shipping papers.

- Specialized equipment: I use appropriate equipment, such as specialized containers, spill kits, and personal protective equipment (PPE), to ensure safe handling.

- Training and certification: I have received relevant training and hold certifications for handling hazardous materials, ensuring compliance with all safety regulations.

- Segregation and containment: I follow strict segregation rules, keeping incompatible materials apart to prevent reactions or accidents. Spills are immediately contained and cleaned up using appropriate procedures.

- Emergency procedures: I’m familiar with emergency procedures in case of accidents or spills. We have established clear communication channels and emergency response protocols.

For example, when loading corrosive chemicals, I ensure that the containers are in good condition and properly sealed, wearing protective gloves and eye protection while handling them. The containers are placed in designated areas and secured to prevent movement.

Q 21. How do you address delays or unexpected issues during the loading/unloading process?

Addressing delays or unexpected issues requires a proactive and systematic approach. It’s about adapting quickly and effectively to maintain operational efficiency. My strategy involves:

- Identifying the root cause: The first step is to quickly identify the cause of the delay. Is it equipment malfunction, a lack of personnel, or an unexpected issue with the shipment?

- Problem solving: Once the root cause is identified, I work with my team to develop a solution. This might involve finding alternative equipment, re-allocating personnel, or adjusting the loading sequence.

- Communication: I communicate the delay and the implemented solution to all relevant parties, including the driver, warehouse management, and the client.

- Documentation: I document the delay, the cause, and the actions taken to address it. This helps to identify patterns and improve future performance.

- Continuous improvement: After the issue is resolved, I review the situation to identify potential improvements to the process. This could involve modifying loading procedures, acquiring new equipment, or enhancing training.

For example, if a forklift breaks down mid-loading, I will immediately contact maintenance and re-allocate personnel to continue the loading process using manual pallet jacks. I will also inform the client and adjust the expected delivery time accordingly.

Q 22. Describe your experience with different types of loading docks and their functionalities.

My experience encompasses a wide range of loading docks, each designed for specific needs and functionalities. I’ve worked with everything from basic, ground-level docks to sophisticated, hydraulically-powered systems.

- Ground-level docks: These are the simplest, requiring manual loading and unloading. They’re cost-effective but can be less efficient for high-volume operations. I’ve used these frequently for smaller deliveries and shipments where efficiency isn’t paramount.

- Ramp docks: These utilize ramps for easier access to trucks, often involving forklifts or pallet jacks. I’ve found them particularly useful for handling palletized goods and reducing manual labor, improving both speed and safety.

- Leveling docks (or dock levelers): These bridge the gap between the dock and the truck bed, ensuring safe and efficient loading/unloading regardless of truck height variations. They significantly reduce the risk of injury and improve overall productivity; this is my preferred type of dock due to its enhanced safety and efficiency.

- Cross-dock facilities: These advanced systems involve direct transfer of goods from one truck to another, bypassing storage. I’ve managed operations in such facilities where minimizing handling time is crucial. This necessitates precise coordination and efficient workflow management.

Understanding the limitations and capabilities of each dock type is vital. For instance, a ground-level dock might be suitable for a small retail store, while a cross-dock is necessary for a large distribution center. Selecting the right dock is crucial for operational efficiency and safety.

Q 23. What are your strategies for dealing with challenging weather conditions during loading/unloading?

Challenging weather conditions demand proactive strategies to ensure safety and prevent delays. My approach involves a multi-pronged strategy:

- Safety First: Prioritize employee safety. In heavy rain or snow, ensure visibility with appropriate lighting and high-visibility clothing. Provide non-slip mats to prevent falls.

- Weather-Appropriate Equipment: Use weather-resistant packaging materials to protect goods from rain, snow, and wind. Employ covered loading docks or tarps when necessary. Forklifts and other equipment may require specific maintenance and checks under adverse weather conditions.

- Adjusted Work Schedules: Severe weather might necessitate adjusted schedules or temporary work stoppages. This involves communicating with all stakeholders to manage expectations and prevent delays.

- Contingency Planning: Have backup plans in place, such as alternative loading locations or temporary storage solutions, should conditions deteriorate significantly.

For example, during a heavy snowstorm, we once used a covered loading bay and had extra personnel assist with snow removal to keep the access roads clear. This proactive approach ensured minimal disruption to our operations.

Q 24. How do you contribute to a team environment during loading/unloading operations?

Teamwork is the cornerstone of efficient loading/unloading operations. My contribution focuses on:

- Clear Communication: I ensure everyone understands their roles, responsibilities, and the overall plan. This includes daily briefings, clear instructions, and open communication channels.

- Coordination and Support: I coordinate efforts between different team members, making sure the workflow is smooth and efficient. I actively assist colleagues when needed, fostering a sense of mutual support.

- Positive Attitude: Maintaining a positive and collaborative atmosphere is essential. I encourage team spirit, celebrate successes, and address concerns promptly.

- Safety Awareness: I actively promote safety practices and encourage team members to report any hazards or unsafe conditions immediately.

In one instance, a team member struggled with a heavy pallet. By quickly assisting, not only did we resolve the situation but also reinforced the collaborative spirit of our team.

Q 25. Explain your understanding of weight distribution and its importance during loading.

Weight distribution is paramount to prevent vehicle overload, damage to goods, and potential accidents. It’s about evenly distributing the weight across the vehicle’s load-bearing capacity.

Understanding the vehicle’s weight limits (Gross Vehicle Weight Rating – GVWR) and axle weight limits is crucial. Improper weight distribution can lead to:

- Vehicle instability: Uneven weight can make the vehicle difficult to handle, increasing the risk of rollovers or accidents.

- Damage to goods: Concentrated weight can crush or damage goods, especially fragile items.

- Legal issues: Overloading can result in hefty fines and legal penalties.

Effective weight distribution involves strategically placing heavier items lower and towards the center of gravity. I use load charts and weight scales, meticulously recording the weight of each item and its location to optimize distribution. For example, stacking heavy boxes at the bottom of a pallet, and ensuring heavier pallets are placed towards the vehicle’s center, prevents instability and ensures that weight is distributed safely and evenly.

Q 26. How do you maintain records of loading/unloading activities?

Maintaining accurate records is crucial for accountability, inventory management, and tracing purposes. My approach involves a combination of manual and digital methods:

- Bill of Lading (BOL): This is a crucial document tracking the shipment. I meticulously verify the information against the goods being loaded/unloaded. Every discrepancy is noted and addressed immediately.

- Delivery Receipts: These acknowledge the receipt of goods by the recipient. Signatures and timestamps are crucial components of record-keeping.

- Digital Inventory Systems: I’m proficient in using inventory management software (e.g., WMS – Warehouse Management System) to record every loading/unloading activity, including timestamps, items loaded/unloaded, and any related notes or exceptions.

- Spreadsheets and Databases: I maintain detailed spreadsheets or databases to supplement digital systems, recording relevant data such as truck number, driver information, and any challenges encountered.

A robust record-keeping system ensures traceability in case of discrepancies or damages, enabling swift problem resolution.

Q 27. Describe your experience using scanners and other technologies for loading/unloading.

I am experienced in using various technologies to streamline loading/unloading procedures:

- Barcode and RFID Scanners: These technologies enable rapid identification and tracking of items, minimizing manual data entry and improving accuracy. I use them to verify items against the BOL and update inventory systems in real-time.

- Warehouse Management Systems (WMS): WMS integrates with scanners and provides real-time visibility of inventory, guiding the loading/unloading process and optimizing workflow.

- Telematics Systems: These track vehicle location, driving behavior, and other data, enhancing logistics and overall operational efficiency. This has been particularly useful in improving our delivery times.

- Dock Management Systems: These integrated systems can manage dock scheduling, track door assignments, and provide real-time updates on loading/unloading progress.

For instance, using RFID scanners allowed us to significantly reduce the time spent verifying items, improving overall efficiency by approximately 15%.

Q 28. What are your strategies for continuous improvement in loading/unloading efficiency?

Continuous improvement is essential for optimal efficiency. My strategies include:

- Data Analysis: I regularly analyze data from various sources (WMS, spreadsheets, etc.) to identify bottlenecks and areas for improvement. This could involve analyzing loading times, identifying frequent errors, or assessing worker productivity.

- Process Optimization: Based on data analysis, I propose and implement process improvements, such as optimizing the layout of the loading dock, adjusting work schedules, or re-evaluating procedures.

- Employee Feedback: I actively solicit feedback from loading/unloading personnel to understand their challenges and perspectives. Their on-the-ground experience often unveils unexpected opportunities for improvement.

- Technology Adoption: Staying abreast of new technologies and evaluating their potential for enhancing efficiency is crucial. This could involve exploring new scanning technologies, implementing advanced WMS features, or adopting automation solutions.

- Benchmarking: Comparing our performance against industry best practices helps identify further avenues for optimization.

By continuously refining our processes and leveraging technology, we can achieve consistently higher levels of efficiency and safety in loading/unloading operations.

Key Topics to Learn for Loading/Unloading Procedures Interview

- Safety Regulations and Procedures: Understanding and adhering to OSHA regulations, company-specific safety protocols, and the use of personal protective equipment (PPE).

- Equipment Operation and Maintenance: Safe and efficient operation of forklifts, pallet jacks, conveyor systems, and other relevant equipment; basic maintenance checks and reporting malfunctions.

- Load Planning and Optimization: Efficiently planning load placement to maximize space utilization, prevent damage, and ensure stability during transport. This includes understanding weight distribution and balance.

- Inventory Management and Tracking: Accurate counting, scanning, and documentation of loaded and unloaded goods; understanding inventory control systems and procedures.

- Handling Different Cargo Types: Safe handling techniques for various goods, including fragile items, hazardous materials, and oversized loads; recognizing and addressing potential risks associated with each.

- Documentation and Record Keeping: Maintaining accurate records of loading and unloading activities, including bills of lading, shipping manifests, and damage reports.

- Problem-Solving and Troubleshooting: Identifying and resolving issues that may arise during the loading/unloading process, such as damaged goods, equipment malfunctions, or logistical challenges.

- Communication and Teamwork: Effective communication with colleagues, supervisors, and drivers; working collaboratively within a team environment to ensure efficient operations.

Next Steps

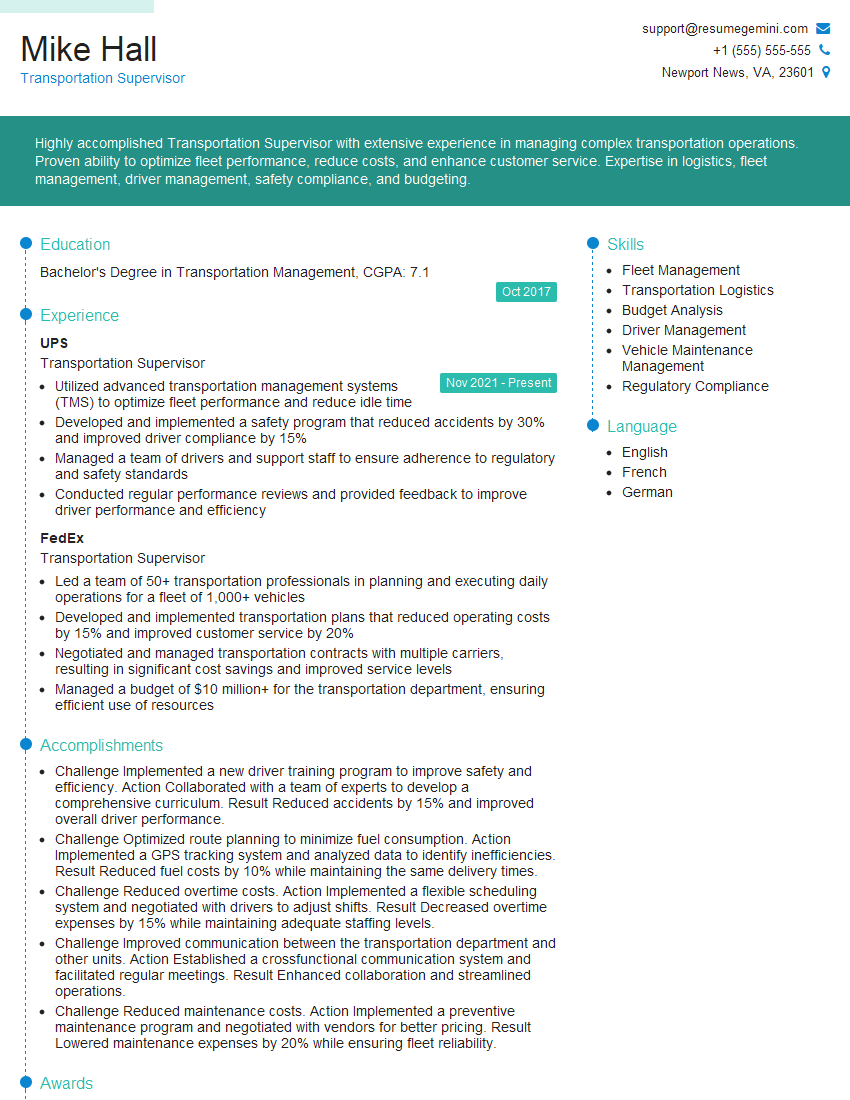

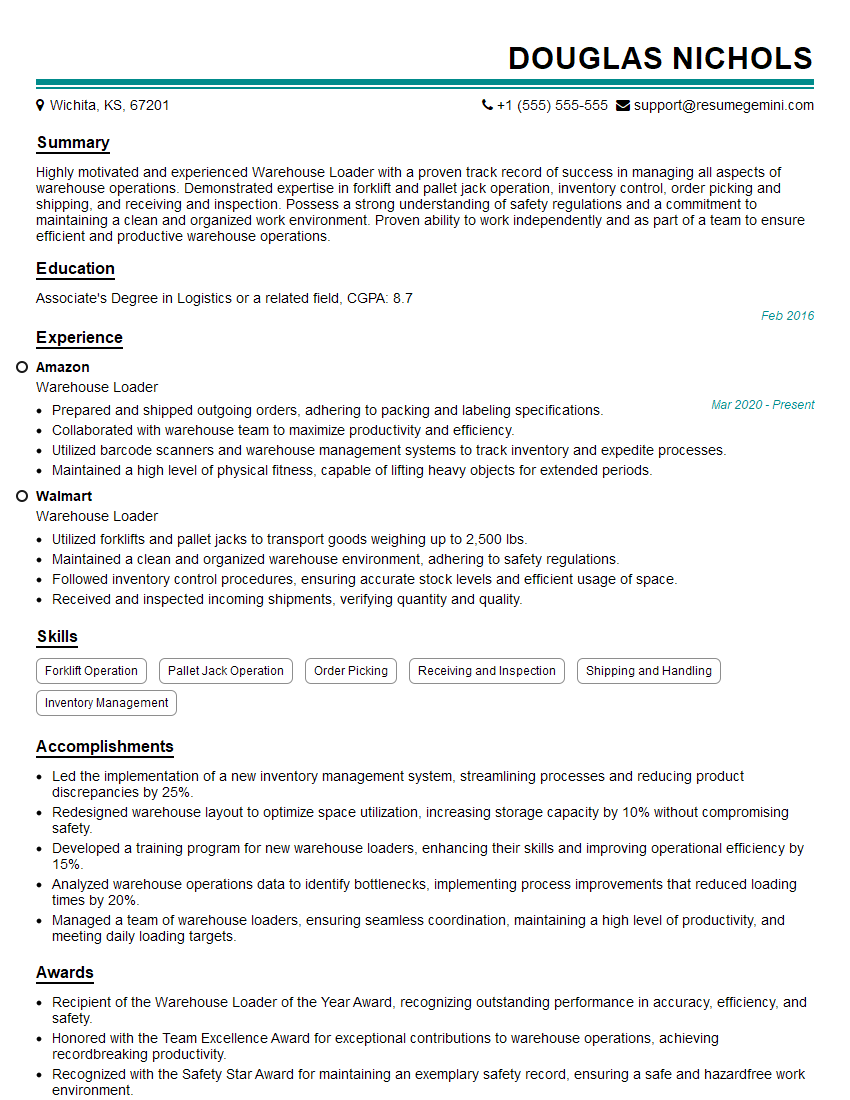

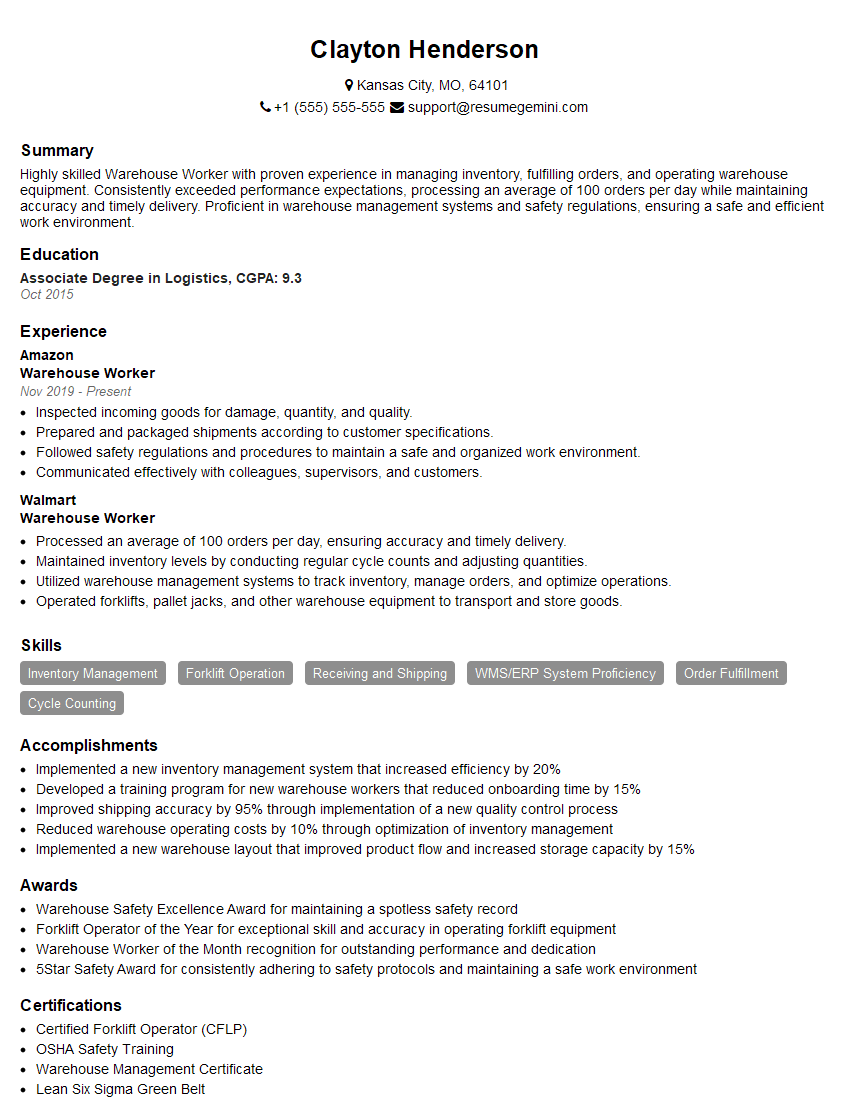

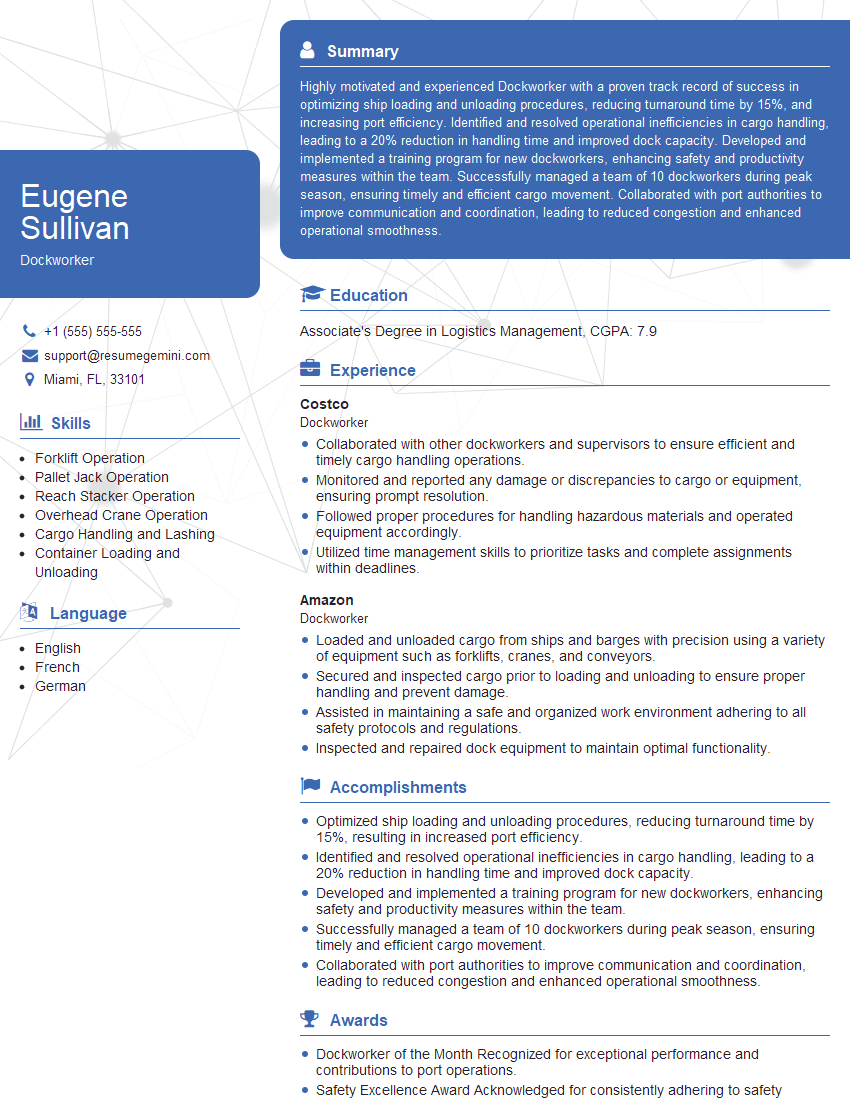

Mastering loading and unloading procedures is crucial for career advancement in logistics, warehousing, and transportation. These skills demonstrate your commitment to safety, efficiency, and accuracy – qualities highly valued by employers. To significantly boost your job prospects, create a compelling, ATS-friendly resume that showcases your abilities. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your qualifications effectively. Examples of resumes tailored to Loading/Unloading Procedures are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO