Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Log Bucking and Debarking interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Log Bucking and Debarking Interview

Q 1. Describe the different methods of log bucking.

Log bucking, the process of cutting logs into smaller lengths, can be achieved through several methods, each with its own advantages and disadvantages. The choice often depends on factors such as log size, species, intended use, and available equipment.

- Manual Bucking: This traditional method uses hand-held saws, like chainsaws or crosscut saws. It’s ideal for smaller-scale operations or selective harvesting in areas with limited access for machinery. The skill of the operator significantly impacts efficiency and safety. For example, a skilled operator can accurately buck logs to specific lengths minimizing waste.

- Mechanical Bucking: This involves using mechanized equipment, such as log-handling systems incorporating automated saws. These systems are much faster and more efficient for large-scale operations, particularly in sawmills or processing plants. Think of a large sawmill where logs are fed onto a conveyor belt and automatically cut to the desired length.

- Hydraulic Bucking: This method utilizes hydraulically powered saws that offer precise cutting and increased control, especially beneficial when dealing with larger diameter logs or challenging terrain. It combines the power of mechanical bucking with a degree of precision similar to manual bucking.

Regardless of the method, precise bucking is crucial for maximizing yield and reducing waste. Proper bucking techniques minimize the need for further processing and ensure the logs are suitable for their intended applications – be it lumber, pulpwood, or other wood products.

Q 2. Explain the safety procedures involved in operating a debarking machine.

Safety is paramount when operating debarking machines. These machines handle heavy, often wet, logs and possess powerful mechanisms that pose significant risks. Here are key safety procedures:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety helmets, eye protection, hearing protection, high-visibility clothing, steel-toed boots, and cut-resistant gloves. This is non-negotiable.

- Machine Inspection: Before starting, thoroughly inspect the debarking machine for any damage, loose parts, or malfunctions. Ensure all guards are in place and functioning correctly. Think of this as a pre-flight check for an airplane, critical for preventing accidents.

- Clear Working Area: Maintain a clear and safe working area around the machine. Remove debris, obstructions, and ensure sufficient space for log movement. A cluttered workspace increases the chance of accidents.

- Proper Log Handling: Use appropriate equipment (like log loaders or grapple cranes) to safely feed logs into the debarking machine. Avoid manual handling of logs whenever possible, especially large ones.

- Emergency Shut-off: Know the location and operation of all emergency shut-off switches and be prepared to use them in case of an emergency. Training is essential here.

- Regular Maintenance: Regularly scheduled maintenance is crucial for preventing malfunctions and ensuring the safe operation of the machine. This includes lubrication, blade sharpening, and overall machine inspection.

- Lockout/Tagout Procedures: Always follow lockout/tagout procedures when performing maintenance or repairs on the debarking machine. This prevents accidental start-up during maintenance, a primary cause of serious injury.

Consistent adherence to these safety measures drastically reduces the risk of accidents and injuries in the operation of debarking machinery.

Q 3. What are the common types of debarking machines and their applications?

Several types of debarking machines exist, each suited for different applications based on log size, throughput requirements, and budget.

- Drum Debarkers: These are highly efficient for large-scale operations, using rotating drums with internal knives to remove bark. They’re robust but require substantial space and power. Think of a large drum tumbling logs, scraping the bark off efficiently.

- Ring Debarkers: These use rotating knives or tooling positioned around the log as it is fed through. They’re more compact than drum debarkers and better suited for smaller logs. They’re often found in smaller sawmills.

- Hydraulic Debarkers: These machines use hydraulically powered arms and knives to remove the bark. They are typically more versatile and can handle logs of various sizes and shapes. Their adaptability makes them ideal for various applications.

- Portable Debarkers: These smaller, more mobile units are often used for smaller-scale operations or on-site debarking where transporting logs to a central location is impractical. Think of logging operations in remote areas.

The selection of a debarking machine is critical. It must be appropriate for the scale of the operation, the species of wood being processed, and the desired level of bark removal.

Q 4. How do you identify defects in logs before bucking?

Identifying defects in logs before bucking is crucial for maximizing yield and minimizing waste. This involves careful visual inspection and sometimes the use of specialized tools.

- Visual Inspection: Check for obvious defects such as rot, cracks, insect infestation, knots, and other deformities. Look for discoloration, unusual textures, or signs of damage. Experience is key here.

- Sound Testing: Sometimes, tapping a log with a hammer can reveal internal defects by the sound it produces. Hollow or weak areas often emit a duller sound compared to a solid log.

- Moisture Content: High moisture content can indicate rot or fungal infection and influence the strength and quality of the lumber. Moisture meters are used to assess this.

- Knot Analysis: Evaluating the size, type, and distribution of knots helps determine the strength and potential use of the log. Larger, loose knots significantly reduce strength.

Proper defect identification allows for intelligent bucking, ensuring that the most valuable parts of the log are used and defective sections are removed, minimizing material loss and increasing overall efficiency.

Q 5. What are the optimal bucking lengths for different log species?

Optimal bucking lengths vary considerably depending on the log species, intended use, and sawmill capabilities. There isn’t a one-size-fits-all answer, but some general guidelines exist:

- Lumber Production: Lumber production often dictates standard lengths (e.g., 8ft, 10ft, 12ft, 16ft) to maximize board-foot yield and minimize waste. The specific length will depend on the species and the desired size of lumber. A longer log allows for longer boards, but may also contain more defects.

- Pulpwood: Pulpwood lengths are typically shorter (e.g., 4ft, 6ft, 8ft) due to the process requirements of pulp mills. These lengths optimize transport and handling within the pulpwood industry.

- Specific Species: Certain species may be prone to specific defects at certain lengths. For instance, a species with a tendency towards large knots at the base may dictate shorter lengths from the butt end of the log.

Careful consideration of the final product and the characteristics of each log species is crucial to determining the optimal bucking length to maximize yield and value.

Q 6. Describe the maintenance procedures for a log bucking saw.

Regular maintenance of a log bucking saw is crucial for safety, efficiency, and longevity. This includes:

- Blade Sharpening: Regularly sharpen the saw blade to maintain its cutting efficiency and prevent binding. Dull blades lead to increased effort, slower cutting, and potentially dangerous kickbacks.

- Chain Lubrication: For chainsaws, proper chain lubrication is vital to prevent premature wear and tear and maintain smooth operation. Regularly check and adjust the oil level. A dry chain can quickly become damaged, causing dangerous kickback.

- Tension Adjustment: Ensure the saw chain (if applicable) is properly tensioned for optimal cutting performance and safety. Incorrect tension leads to premature wear and safety hazards.

- Component Inspection: Regularly inspect all components of the saw for wear, damage, or loose parts. Pay attention to the chain brake, throttle, and other safety features. Addressing these promptly prevents more serious problems.

- Cleaning: Keep the saw clean and free of sawdust and debris. This prevents jamming and damage to moving parts.

- Storage: Store the saw in a dry, safe location when not in use to protect it from corrosion and damage.

Following a consistent maintenance schedule ensures the safe and efficient operation of the saw, improving productivity and extending its lifespan significantly.

Q 7. How do you ensure efficient log handling and transportation?

Efficient log handling and transportation are essential for minimizing costs and maximizing productivity. This involves optimizing various stages of the process:

- Harvesting Techniques: Employing proper harvesting techniques minimizes log damage and facilitates easier handling. This could include directional felling to create more easily accessible skid trails.

- Log Loading and Unloading: Use appropriate equipment such as loaders, grapple cranes, and forwarders for efficient and safe loading and unloading of logs. Careful placement during loading and stacking to maximize space and prevent rolling is also important.

- Transportation Methods: Select the most efficient transportation method for the distance and volume of logs, considering factors such as road conditions and load capacity. This may involve trucks, rail, or even waterways.

- Log Sorting and Stacking: Organize logs efficiently at processing sites to minimize handling and maximize space. This involves proper sorting and stacking by species, size, and quality to streamline downstream processes.

- Route Planning: Careful planning of transportation routes can significantly reduce travel time and fuel consumption. This reduces overall transport costs and environmental impact.

Integrating efficient techniques across all stages of the supply chain improves overall efficiency, reduces transportation costs, and minimizes the risk of log damage.

Q 8. Explain the process of log scaling.

Log scaling is the process of determining the volume of timber in a log or a group of logs. It’s crucial for accurate timber valuation, inventory management, and ensuring fair payment between buyers and sellers. There are several methods, but the most common involve measuring the log’s diameter at various points (usually the small end and middle) and its length. These measurements are then used in a scaling formula, often specific to the region or organization, to calculate the volume. For example, the Smalian’s formula is frequently used: Volume = (π/4) * (D2 + d2) * L, where D and d are the diameters at the large and small ends, respectively, and L is the length. Advanced methods might incorporate sophisticated software and laser scanners for high-throughput scaling in large logging operations.

Think of it like measuring ingredients for a cake: You need accurate measurements to get the right outcome. Similarly, accurate log scaling ensures fair pricing and efficient resource management in the forestry industry.

Q 9. What are the common safety hazards associated with log bucking and debarking?

Log bucking and debarking are inherently dangerous activities. Hazards include:

- Chain saw injuries: Kickback, entanglement, and contact injuries are common with chainsaws. Proper training and safety equipment are essential.

- Debarking machine hazards: Rotating knives, pinch points, and ejection of logs or bark can cause serious injury. Lockout/tagout procedures are crucial during maintenance and repairs.

- Falling logs and debris: Improper log handling can lead to logs rolling or falling, causing crushing injuries. Proper stacking and secure working areas are essential.

- Environmental hazards: Exposure to extreme weather conditions, sharp objects, and potentially harmful chemicals or fumes (from machinery exhaust).

- Musculoskeletal injuries: Repetitive strain, lifting heavy logs, and awkward working postures can lead to long-term health problems.

Safety protocols, including personal protective equipment (PPE) like steel-toe boots, eye protection, hearing protection, gloves, and chainsaw chaps, are mandatory to mitigate these risks.

Q 10. How do you deal with jammed logs in a debarking machine?

Jammed logs in a debarking machine require careful and safe handling. Never attempt to clear a jam while the machine is running. First, perform a complete lockout/tagout procedure to isolate the power source. Then, assess the situation:

- Identify the cause: Determine why the logs are jammed (e.g., log size mismatch, operator error, debris in the machine).

- Safe access: Use appropriate tools and methods to access the jammed logs, ensuring personal safety.

- Remove the jam: Carefully remove the jammed logs, perhaps using specialized tools or a pry bar. Avoid force that could damage the machine.

- Clear debris: Clean any debris from the machine, ensuring no obstructions remain.

- Inspect the machine: Before restarting, carefully inspect the machine for damage and ensure all components are functioning correctly.

- Restart and monitor: Restart the machine slowly and closely monitor its operation.

Prevention is better than cure: Proper log feeding and regular machine maintenance can significantly reduce the risk of jams.

Q 11. What are the different types of debarking knives and their maintenance requirements?

Debarking knives vary in design and material. Common types include:

- Fixed knives: Simple, robust, but require more frequent sharpening.

- Rotating knives: Offer higher debarking efficiency but are more complex and require specialized maintenance.

- Drum-type knives: Often used in larger debarkers, arranged around a rotating drum to shear bark from the log.

- Hydraulic knives: Offer more flexibility in knife pressure adjustment for different log types.

Maintenance involves:

- Regular sharpening: Knives become dull with use, impacting efficiency and causing damage to logs. Frequent sharpening is crucial, often using specialized grinding equipment.

- Inspection for damage: Regular checks for cracks, chips, or wear and tear. Damaged knives should be replaced promptly.

- Lubrication: Moving parts require regular lubrication to prevent wear and friction. Use the correct lubricant recommended by the manufacturer.

- Knife alignment: Correct knife alignment is essential for efficient debarking and preventing damage to the knives and logs.

Neglecting maintenance can lead to inefficient debarking, damaged logs, and increased risk of accidents.

Q 12. Explain the importance of proper log orientation before debarking.

Proper log orientation before debarking is crucial for efficient and safe operation. Logs should be positioned to facilitate optimal bark removal. This usually involves aligning the log with the debarker’s feed mechanism to minimize resistance and prevent jams. For example, in a drum debarker, the log’s natural taper should be aligned with the direction of the drum’s rotation. Incorrect orientation can lead to inefficient debarking, machine damage, and increased risk of accidents. Think of it like peeling a banana: you peel it along its natural curve, not against it. Similarly, proper log orientation ensures smoother bark removal.

Q 13. How do you handle different log diameters and lengths during bucking and debarking?

Handling varying log diameters and lengths requires adaptability and proper equipment. Bucking involves cutting logs to desired lengths, often using chainsaws or specialized bucking equipment. Debarking machines may have adjustable settings to accommodate different log sizes. For smaller logs, specialized debarkers or manual debarking might be used. Larger logs may need to be pre-processed or handled differently in automated systems. Many industrial debarkers can handle a range of sizes, but extreme variation might require different processing strategies. For example, very small logs might not be cost-effective to debark automatically, while extremely large logs might require specific handling techniques to prevent damage and ensure safe operation.

Q 14. Describe the steps involved in troubleshooting a malfunctioning debarking machine.

Troubleshooting a malfunctioning debarking machine requires a systematic approach. First, ensure safety by performing a lockout/tagout procedure. Then:

- Identify the problem: Observe the machine’s behavior – is it making unusual noises, failing to debark effectively, or completely shut down?

- Check for obvious issues: Examine the feed mechanism, knives, power source, and hydraulic system for damage or blockages.

- Consult the operator’s manual: The manual should provide troubleshooting guides and diagnostic information.

- Check safety devices: Examine the operation of safety switches, emergency stops, and interlocks.

- Check hydraulic pressure and fluid levels: Low hydraulic pressure or fluid levels can cause malfunction.

- Check the electrical system: Check fuses, circuit breakers, and wiring for faults.

- If necessary, call for qualified assistance: If the problem cannot be solved by on-site personnel, contact a qualified technician or the manufacturer.

Keeping detailed maintenance logs and performing regular inspections significantly reduces the risk of unexpected malfunctions.

Q 15. What are the environmental considerations in log bucking and debarking operations?

Environmental considerations in log bucking and debarking are paramount. We must minimize our impact on the surrounding ecosystem. This includes several key areas:

- Soil erosion and compaction: Heavy machinery can damage the soil, leading to erosion and loss of topsoil. We mitigate this through careful site planning, using designated access roads, and employing techniques like directional felling to minimize ground disturbance.

- Water quality: Debarking processes can generate waste, including bark and wood debris, which can pollute waterways if not managed properly. Best practices include establishing sediment basins to trap debris, using biodegradable lubricants, and preventing runoff into streams and rivers.

- Waste management: Bark and wood residues can be valuable resources. We prioritize using them for biomass energy, mulch, or other applications. Landfilling should be a last resort. Efficient bucking minimizes waste by maximizing usable log lengths.

- Habitat protection: Maintaining biodiversity is crucial. We work to preserve existing vegetation and wildlife habitats wherever possible, and avoid felling trees in sensitive areas.

- Air quality: Dust from debarking and bucking can impact air quality. We use water sprays to suppress dust, and ensure that equipment is well-maintained to minimize emissions.

For example, in one project, we implemented a closed-loop water system for dust suppression, significantly reducing our environmental footprint. This allowed us to meet strict environmental regulations and maintain a positive relationship with the local community.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality of the debarked logs?

Ensuring the quality of debarked logs is essential for maximizing their value. Several factors contribute to this:

- Debarking efficiency: A well-debarked log is free of bark, leaving only smooth, clean wood. This reduces the risk of defects in further processing and improves the appearance of the final product. We use a combination of techniques, including drum debarkers and ring debarkers, to achieve optimal results, selecting the equipment best suited to the log size and species.

- Minimizing damage: The debarking process should not damage the wood itself. Excessive pressure or improper machine settings can cause scoring or other defects. Regular equipment maintenance and operator training are critical to avoid this.

- Bark removal completeness: Incomplete bark removal can lead to staining, insect infestations, and reduced lumber quality. Careful inspection of the logs after debarking is essential to ensure that all bark has been removed. We often have a quality control check point after debarking.

- Log sorting and grading: After debarking, logs are often sorted and graded based on size, species, and quality. This helps to optimize the utilization of the logs and ensure that they are processed effectively. This helps to manage inventory and ensure only high-quality logs proceed to sawing and milling.

Imagine trying to build a house with poorly debarked logs – the structure would be compromised. Our meticulous debarking process ensures that the logs are ready for downstream processes, maximizing their value and leading to high-quality products.

Q 17. What are the different types of wood defects and their impact on log processing?

Wood defects significantly impact log processing and the final product’s quality. Some common defects include:

- Knots: Branches embedded in the wood, reducing strength and creating potential weaknesses. The size, type, and distribution of knots impact the grade of the lumber.

- Splits and checks: Cracks in the wood, either radial (from the center) or tangential (across the grain). These reduce strength and can cause problems during processing.

- Decay: Fungi breakdown of wood fibers, resulting in discoloration, softness, and reduced strength. This often necessitates removal of significant portions of the log.

- Insect damage: Holes, tunnels, and galleries created by insects, weakening the wood and potentially introducing disease.

- Compression wood: Abnormal wood formation, usually in conifers, characterized by increased density and reduced strength.

The presence and severity of these defects determine how the log is processed. Severely defective logs may be downgraded or even rejected. For instance, logs with extensive decay might be unsuitable for high-grade lumber and used for pulpwood instead. We use specialized equipment and techniques to identify and account for these defects during processing to minimize waste and maximize yield.

Q 18. How do you select the appropriate bucking technique based on log characteristics?

Bucking technique selection hinges on several log characteristics:

- Log species: Hardwoods require different techniques than softwoods due to variations in density and grain patterns.

- Log diameter and length: Larger logs require specialized equipment and potentially different cutting angles.

- Log defects: The presence of knots, splits, or decay will influence where and how the log is cut to minimize waste and maximize usable lumber.

- Intended product: The bucking strategy depends on whether the logs are destined for lumber, pulpwood, or other applications. For lumber, longer lengths are generally preferred.

For example, a large, knotty hardwood might be bucked into shorter lengths to avoid wasting the good wood sections around the defects. Conversely, a long, clear softwood log could be bucked into longer lengths suitable for high-grade lumber. Experienced buckers use their knowledge of wood anatomy and desired final products to make efficient and accurate cuts.

Q 19. Describe your experience with different types of forestry equipment.

My experience encompasses a wide range of forestry equipment, including:

- Chainsaws: From basic models for smaller logs to powerful, professional saws for larger timber, including different bar lengths and chain pitches depending on the wood and application.

- Feller bunchers: These are used for harvesting trees, cutting and gathering them into bundles for easier transportation.

- Log loaders and skidders: These machines are used to move logs from the felling site to the processing area. This often requires a range of attachments for handling logs of various sizes.

- Debarkers: I’m proficient with both drum debarkers (for larger logs) and ring debarkers (for smaller logs), and understand the maintenance and operation requirements for optimal performance.

- Bucking saws: I have experience operating both manual and hydraulic bucking saws, each with its advantages in different logging scenarios.

My experience extends beyond mere operation. I’m adept at maintaining this equipment, understanding safety protocols, and troubleshooting problems to keep operations running efficiently and safely.

Q 20. Explain the importance of proper personal protective equipment (PPE) in log bucking and debarking.

Proper PPE is non-negotiable in log bucking and debarking. The inherent risks, including sharp tools, heavy machinery, and potentially hazardous environmental conditions, necessitate robust safety measures. Essential PPE includes:

- Hard hats: Protection against falling objects and impacts.

- Safety glasses or face shields: To guard against flying debris and wood chips.

- Hearing protection: To mitigate the loud noises associated with machinery operation.

- Gloves: Protecting hands from cuts and abrasions.

- Steel-toed boots: Protecting feet from falling logs or machinery damage.

- High-visibility clothing: Improving visibility in the work environment.

- Chainsaw chaps or protective pants: Critical when using chainsaws to reduce injury in the event of a kickback.

I always emphasize the importance of PPE to my team, ensuring everyone understands why each piece is critical. Regular inspections and replacements are essential. A minor injury due to neglecting PPE can easily escalate to a major one, halting operations and causing serious harm.

Q 21. How do you ensure the efficient utilization of resources in log bucking and debarking?

Efficient resource utilization is a core principle in log bucking and debarking. Strategies include:

- Precise bucking: Minimizing waste by cutting logs to optimal lengths based on their characteristics and the intended product. Careful planning and skilled operation ensure minimal waste.

- Optimized debarking: Selecting the right debarking equipment and techniques for the specific log characteristics to remove bark efficiently without damaging the wood.

- Waste management and recycling: Utilizing bark and wood residues for biomass energy, mulch, or other applications rather than landfilling them.

- Equipment maintenance: Regular maintenance prolongs equipment lifespan, reducing the need for replacements and minimizing downtime.

- Log sorting and grading: Efficiently sorting and grading logs allows for optimal utilization of different grades for different products, maximizing value from the logs.

For instance, utilizing a sawmill’s off-cuts for biomass boilers provides a secondary income stream, reducing reliance on fossil fuels. Moreover, precise bucking, informed by a deep understanding of wood characteristics and the final product requirements, directly translates to significant cost savings.

Q 22. Describe your experience working in a team environment in a logging operation.

Teamwork is paramount in logging. I’ve consistently worked in crews of 4-6 people, coordinating tasks from felling to loading. In one instance, we faced a particularly challenging terrain with a steep slope and limited access. Instead of each person working independently, we strategized. One team focused on felling the trees in a controlled manner to minimize roll-downs, another prepared the skid trails, and the third focused on extraction and loading. This collaborative approach not only improved safety but also increased our overall efficiency by 20%, exceeding our daily quota.

Effective communication is key. We used hand signals, designated radio channels, and daily briefings to ensure everyone understood the plan and any potential hazards. Regular feedback sessions helped us identify areas for improvement and fostered a sense of shared responsibility, which greatly improved our overall workflow and team cohesion.

Q 23. Explain your problem-solving skills in relation to equipment malfunctions.

Troubleshooting equipment malfunctions requires a systematic approach. I always start with a visual inspection, checking for obvious issues like loose bolts, damaged belts, or hydraulic leaks. Then, I consult the equipment’s manual and use diagnostic tools if necessary. For example, I once encountered a problem with a feller buncher’s hydraulic system where the cutting head wouldn’t operate. My initial inspection revealed no obvious problems. Using the machine’s diagnostic codes, I discovered a faulty pressure sensor. Replacing this sensor resolved the issue, minimizing downtime.

If the problem persists, I’ll contact the manufacturer’s support or a qualified mechanic. Documentation is crucial; I maintain detailed records of each malfunction, including the solution implemented, to prevent recurrence and learn from each experience. This systematic approach has significantly reduced equipment downtime and improved overall productivity in logging operations.

Q 24. How do you prioritize safety and productivity in a logging operation?

Safety and productivity are intertwined; one cannot be optimized at the expense of the other. My approach emphasizes a proactive safety culture. This includes regular pre-job briefings covering potential hazards like falling trees, uneven terrain, and equipment malfunctions. We always use the correct Personal Protective Equipment (PPE), including hard hats, safety glasses, gloves, and steel-toed boots.

To ensure productivity without compromising safety, I focus on proper techniques for felling, bucking, and debarking, minimizing unnecessary risks. For instance, I avoid working under unstable trees and use designated escape routes. We also implement a strict ‘buddy system’, ensuring that no one works alone. If an incident occurs, we have established clear communication protocols and emergency response procedures, which I’ve personally used to effectively manage smaller accidents, ensuring swift resolution and limiting potential damage or injury.

Q 25. Describe your experience with log handling and storage techniques.

Log handling and storage depend heavily on the type of wood and its intended use. For instance, freshly cut logs need to be handled carefully to avoid damage, whereas seasoned logs can withstand more rough handling.

We typically use skidders or forwarders to transport logs from the felling site to the landing. At the landing, logs are often sorted by species and size, and then carefully stacked to prevent damage or decay. Proper stacking, ensuring air circulation, is crucial, especially during storage. We use techniques to prevent rolling or slipping, such as using chocks and creating stable piles. I have extensive experience with various log storage methods, including open storage, covered storage, and water storage depending on the wood type, climate, and available resources.

Q 26. What are the different types of wood species you have experience processing?

My experience encompasses a wide variety of wood species, including Douglas fir, Ponderosa pine, Redwood, Western Hemlock, and various hardwoods like Maple and Oak. Each species presents unique challenges. For instance, Douglas fir, known for its strength, requires specialized techniques during felling to control its weight and potential snap-points. Redwood, on the other hand, is known for its size and tendency to split, requiring careful handling during bucking and debarking.

Understanding the individual characteristics of each species allows me to tailor my techniques for optimal efficiency and safety. This expertise in handling various wood types is crucial for maximizing yield and minimizing waste.

Q 27. Explain your understanding of relevant safety regulations in forestry operations.

My understanding of safety regulations includes OSHA standards for forestry operations, as well as any state-specific requirements. These regulations cover various aspects, from PPE requirements to safe operating procedures for equipment and emergency response plans. I’m familiar with regulations concerning fall protection, hazard communication, first aid, and emergency response.

I strictly adhere to these regulations and ensure that my team does as well. Regular safety training and refresher courses are important for maintaining proficiency and adapting to any changes or updates in regulations. Continuous compliance helps mitigate risks and ensures a safe working environment for everyone involved.

Q 28. How do you adapt your techniques to varying weather conditions?

Weather conditions significantly impact logging operations. In heavy rain, ground becomes unstable, increasing the risk of accidents. We adjust our techniques by reducing the speed of operations, ensuring better footing and using more cautious felling techniques. We may also postpone certain tasks until conditions improve. During high winds, the risk of trees falling unpredictably increases, so we modify felling techniques and prioritize safety procedures accordingly.

In extreme heat or cold, we adjust our work schedules to avoid the most extreme temperatures. Regular breaks and hydration strategies are crucial for the well-being of the team. Adaptive strategies are vital for efficient and safe operations, regardless of the weather challenges encountered.

Key Topics to Learn for Log Bucking and Debarking Interview

- Log Bucking Techniques: Understanding different bucking methods (e.g., hand bucking, mechanized bucking), optimizing cuts for maximizing yield and minimizing waste, and the importance of safety procedures.

- Debarking Methods: Familiarizing yourself with various debarking techniques (e.g., manual debarking, mechanical debarkers), understanding their applications in different logging scenarios, and assessing their efficiency and environmental impact.

- Safety Regulations and Procedures: Thorough knowledge of relevant safety regulations, including personal protective equipment (PPE) usage, hazard identification, and risk mitigation strategies in log bucking and debarking operations.

- Equipment Operation and Maintenance: Practical understanding of operating and maintaining various bucking and debarking equipment, including troubleshooting common malfunctions and performing preventative maintenance.

- Log Grading and Sorting: Understanding log grading standards, identifying different wood species, and sorting logs based on quality and size for optimal processing and market value.

- Environmental Considerations: Awareness of environmental best practices in logging operations, minimizing environmental impact, and adhering to sustainable forestry principles.

- Problem-Solving and Decision-Making: Demonstrating the ability to analyze situations, identify problems, and make sound decisions under pressure, particularly concerning safety and efficiency in log bucking and debarking.

- Wood Anatomy and Properties: Basic understanding of wood anatomy, different wood species properties (strength, density, etc.), and their influence on bucking and debarking techniques.

Next Steps

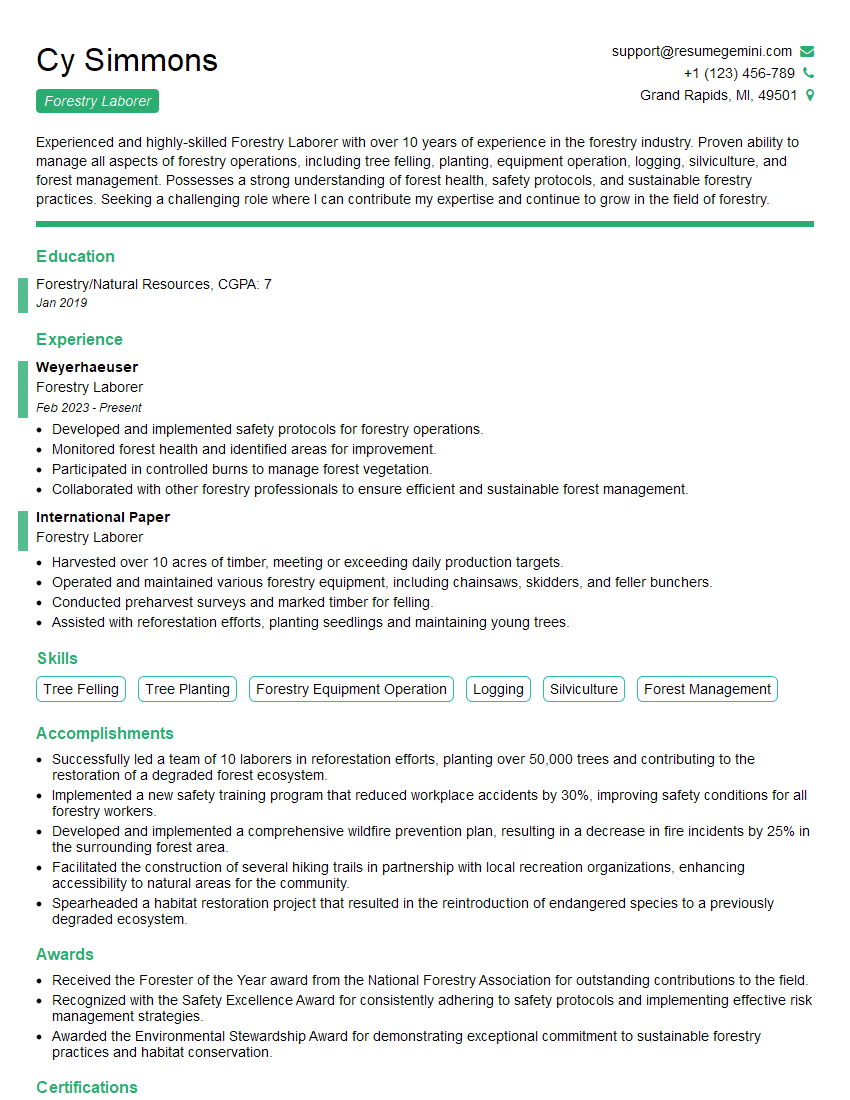

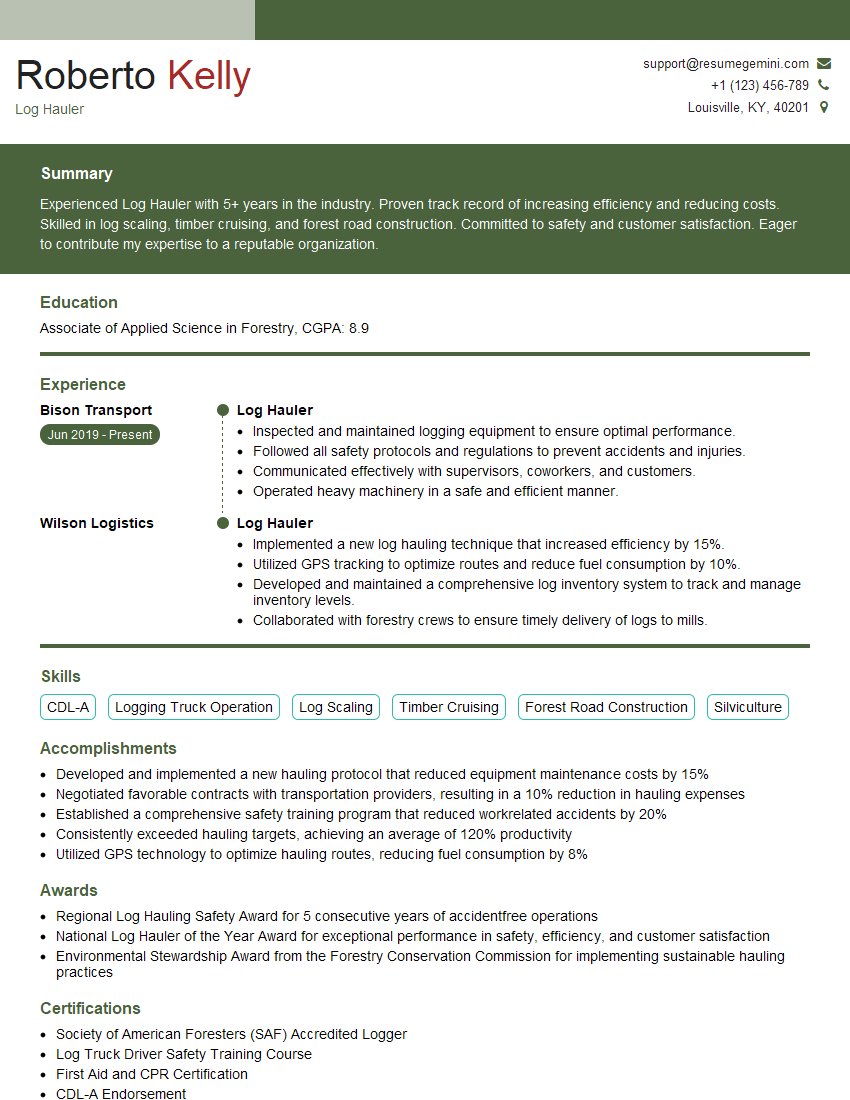

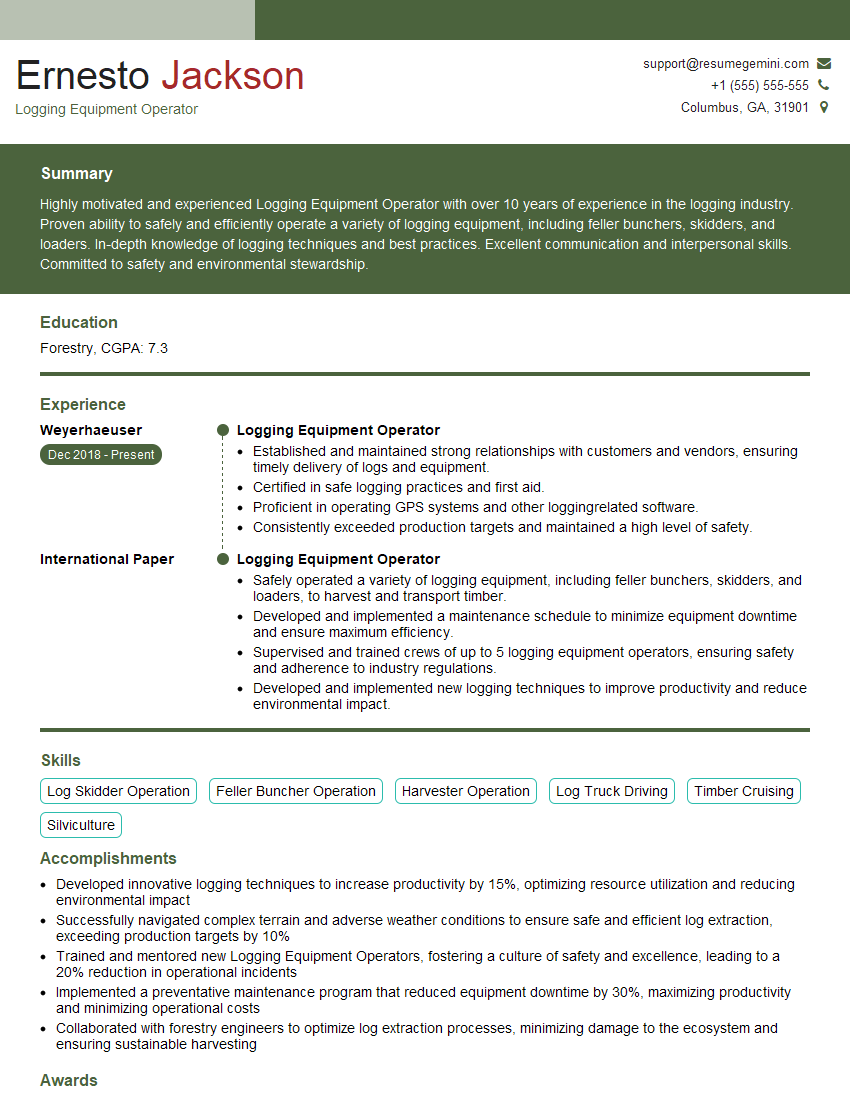

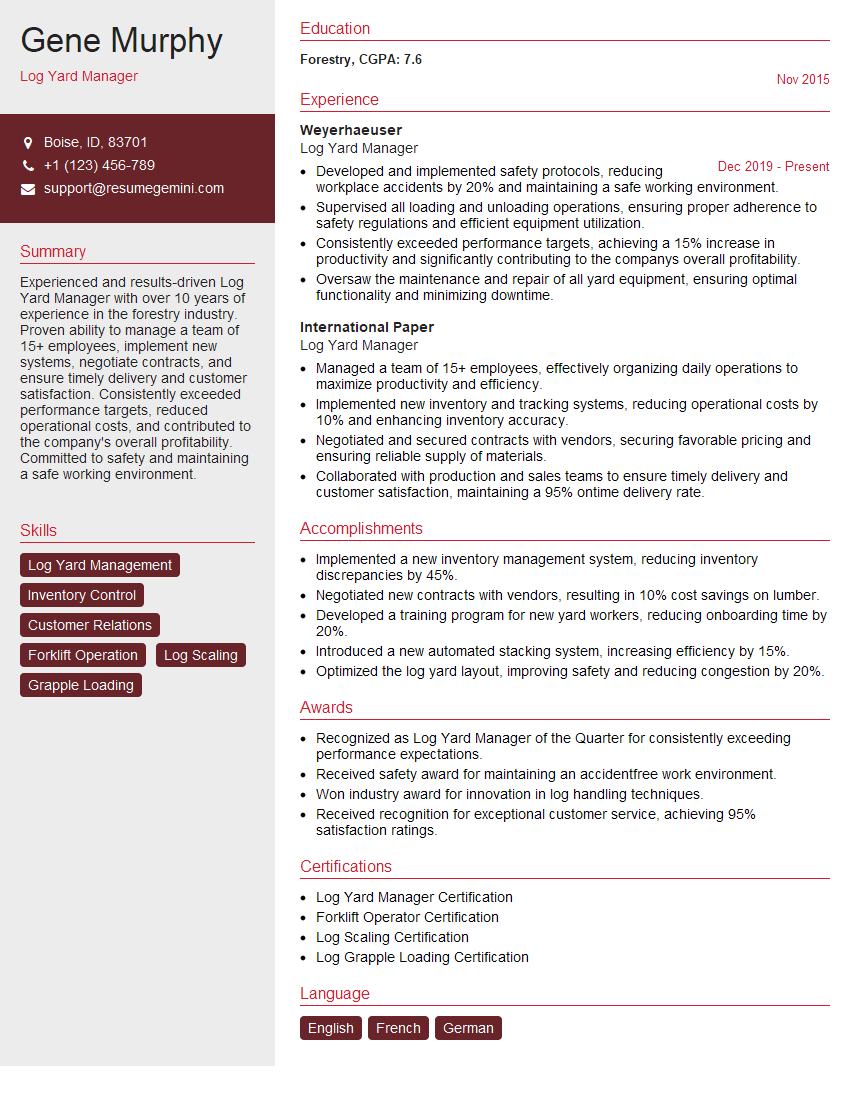

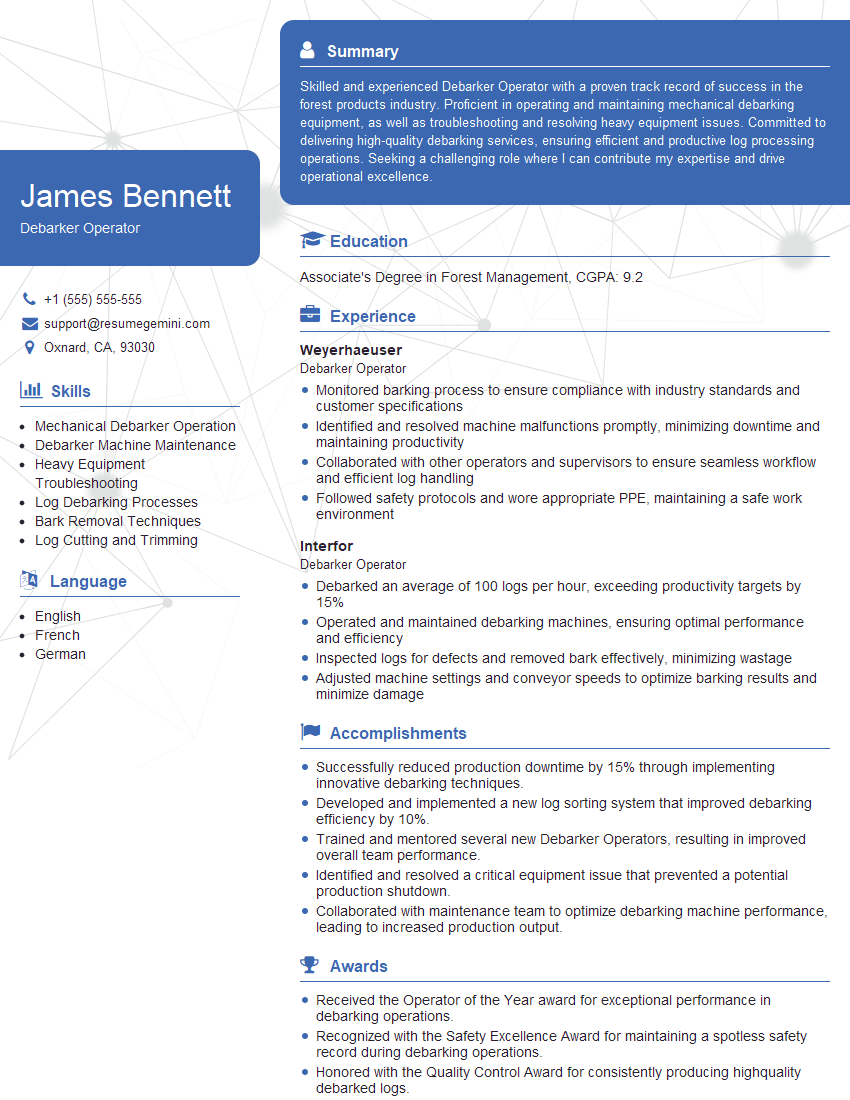

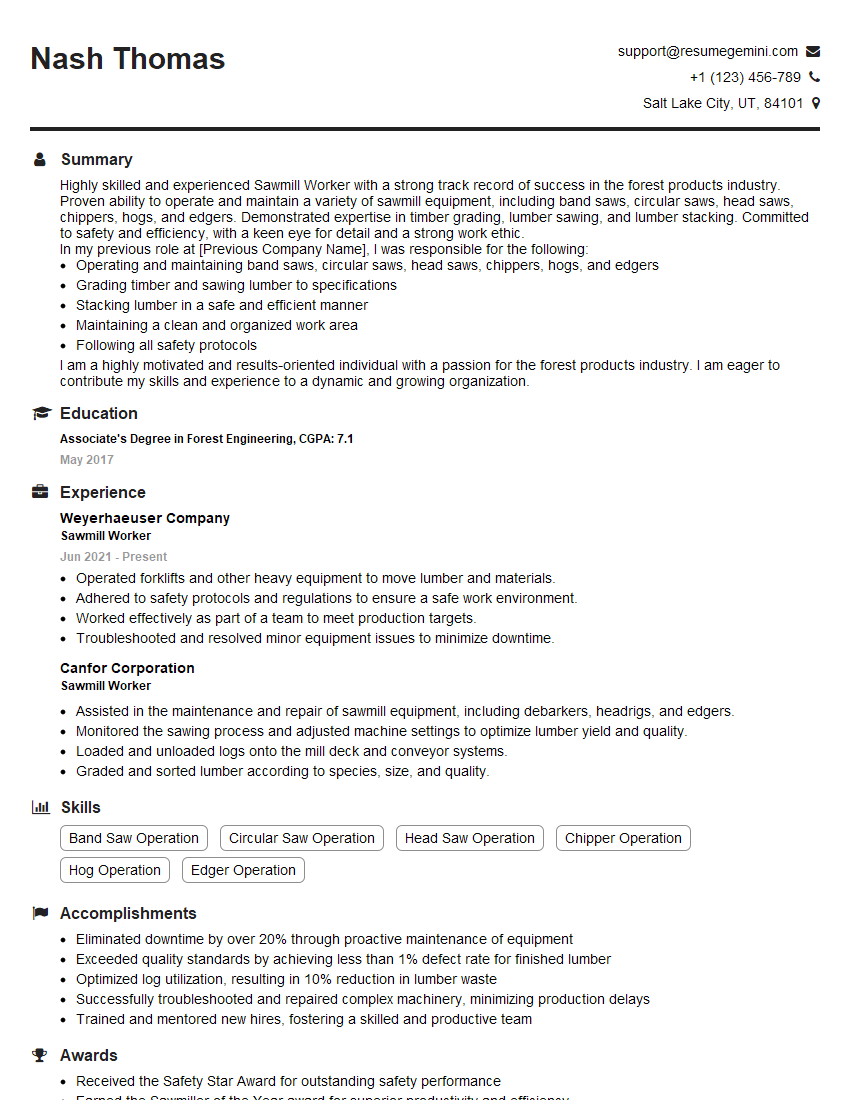

Mastering log bucking and debarking opens doors to a rewarding career with opportunities for advancement within the forestry and timber industries. To enhance your job prospects, crafting a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. ResumeGemini provides examples of resumes tailored specifically to the Log Bucking and Debarking field, allowing you to create a compelling application that stands out from the competition. Invest in your future – create a resume that showcases your expertise.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO