Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Log Bucking and Scaling interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Log Bucking and Scaling Interview

Q 1. Describe the different methods used for log bucking.

Log bucking, the process of cutting felled trees into logs of specific lengths, employs several methods, each chosen based on factors like tree size, terrain, and intended use.

- Hand Bucking: This traditional method uses a handsaw or chainsaw to cut the tree into logs. It’s labor-intensive but offers precision in log length and minimizes waste. Imagine a logger carefully measuring and cutting a large redwood into manageable sections for transport.

- Mechanical Bucking: This method utilizes specialized equipment like feller bunchers or harvesters that cut and process the tree in a single operation. These machines greatly increase efficiency, particularly in large-scale logging operations. Think of a large forestry operation in the Pacific Northwest, where these machines are essential for rapid and efficient processing.

- Bucking with a Skidder: Some operations use skidders equipped with bucking saws. This integrates the bucking process into the log-hauling operation, improving workflow and reducing turnaround time. This is common in smaller operations where a single machine handles both transport and processing.

The choice of method is a balancing act between labor cost, efficiency, precision, and environmental impact. A large-scale operation might prioritize mechanical bucking for speed, while a small-scale operation might favor hand bucking for greater control.

Q 2. Explain the importance of accurate log scaling.

Accurate log scaling is crucial for several reasons. It’s the foundation for fair and accurate payment to loggers, ensuring they receive just compensation for their work. For the buyer, accurate scaling prevents overpayment and allows for precise cost estimation in downstream processes.

Accurate scaling also contributes to sustainable forest management. By precisely measuring the volume of timber harvested, regulatory bodies can monitor logging activity, ensure compliance with environmental regulations, and prevent overexploitation of forest resources. Imagine the consequences if logging companies weren’t held accountable to accurate measurements – potential for over-harvesting, impacting ecological balance.

Finally, accurate scaling facilitates efficient inventory management and planning. Knowing the exact volume of available timber helps businesses make informed decisions about resource allocation, production planning, and pricing strategies.

Q 3. What are the common tools and equipment used in log bucking and scaling?

The tools and equipment used in log bucking and scaling vary based on the scale and method.

- Log Bucking: Handsaws, chainsaws (various sizes and power sources), feller bunchers, harvesters, skidders with bucking attachments.

- Log Scaling: Scaling sticks (various types and sizes), diameter tapes, electronic scalers (e.g., laser scanners), calipers, measuring tapes, and sometimes even drones for larger-scale inventories.

Safety equipment, such as safety glasses, hearing protection, and appropriate clothing, is essential for all operations. Choosing the right tool for the job is paramount, ensuring efficiency and safety.

Q 4. How do you calculate the volume of a log using different scaling methods?

Several methods exist for calculating log volume. The most common are:

- Smalian’s Formula: This is a widely used method that approximates the volume of a log by treating it as a frustum of a cone. The formula is:

Volume = (π/12) * L * (D² + d² + D*d)where L is the log length, D is the diameter at the large end, and d is the diameter at the small end. This method accounts for the tapered shape of logs. - Huber’s Formula: This simpler method uses the average diameter:

Volume = (π/4) * L * ( (D+d)/2 )². While less precise than Smalian’s formula, it’s faster for field estimations. - Newton’s Formula: This method provides a more precise calculation. It takes into account the shape of a curved log and employs calculus to calculate the volume based on sectional measurements.

- Electronic Scalers: Modern electronic scalers utilize laser or ultrasonic technology to measure the log’s diameter and length, automatically calculating volume based on pre-programmed formulas. This is a faster and more accurate method, reducing human error.

The choice of method depends on the required accuracy and available tools. Smalian’s formula offers a good balance between accuracy and ease of use in most scenarios, while electronic scalers are preferred for efficiency and accuracy in large-scale operations.

Q 5. What are the different log grades and their implications?

Log grades classify logs based on characteristics impacting their value and end use. These characteristics include species, diameter, length, quality (knots, rot, splits), and straightness. Different grades command different prices.

- High-Grade Logs: These have minimal defects, ideal dimensions, and are suited for high-value products like lumber for construction or fine furniture. They might be clear of knots or have very small, tight knots. Think premium lumber used in high-end construction.

- Medium-Grade Logs: These logs have some defects but are still usable for construction or other applications. They might have some knots or smaller imperfections.

- Low-Grade Logs: These logs have significant defects like large knots, rot, or severe damage. They are often used for pulpwood, biomass, or less demanding applications.

Understanding log grades is essential for pricing, efficient resource allocation, and meeting the demands of different markets. A lumber mill, for example, needs different grades for different products. High-grade logs might be used for flooring, while lower-grade logs might be pulped for paper.

Q 6. How do you identify different tree species and their characteristics?

Identifying tree species requires careful observation of several characteristics.

- Bark: Bark texture (smooth, rough, furrowed), color, and pattern are key identifiers. For example, the bark of a pine is generally scaly, while that of a birch is papery.

- Leaves and Needles: Leaf shape, arrangement, and size are distinctive features. Pine needles grow in bundles, while oak leaves are lobed.

- Branches and Growth Habits: Branch patterns, height, and overall growth habit help differentiate species. Some trees have a conical shape, others a more rounded shape.

- Wood Characteristics: While not always readily visible in the field, color, grain patterns, and density are crucial for species identification. These are usually checked in processed lumber.

Field guides, experience, and even apps can assist in tree species identification. For professionals, accurate identification is crucial to ensure proper grading and resource management.

Q 7. Explain the process of using a log scaling stick or electronic scaler.

Log scaling sticks and electronic scalers provide different approaches to volume measurement.

- Log Scaling Stick: This is a traditional tool with pre-calculated scales based on log diameter and length. The scaler finds the diameter of the log at both ends using a diameter tape, then aligns the measurements on the stick to obtain the log’s volume. It’s a manual, relatively quick method requiring some practice and skill in reading the scales accurately. Imagine an experienced scaler expertly working a stick on a large, felled tree.

- Electronic Scaler: Modern electronic scalers use either laser or ultrasonic technology. The device is aimed at the log, measurements are taken, and the volume is calculated and displayed automatically, often with information on log diameter and length. These provide faster and more accurate results, particularly for large-scale operations. This reduces human error and provides immediate data for inventory and sales.

Both methods require careful measurement for accuracy. However, electronic scalers offer a significant advantage in efficiency and data management, though they may have a higher initial investment cost compared to the simple scaling stick.

Q 8. Describe safety procedures for log bucking and scaling operations.

Safety is paramount in log bucking and scaling. It’s not just about following rules; it’s about anticipating hazards and proactively mitigating risks. We begin with a thorough pre-job safety briefing, covering specific site hazards like uneven terrain, unstable logs, and potential equipment malfunctions. Personal Protective Equipment (PPE) is mandatory, including safety helmets, high-visibility clothing, steel-toed boots, gloves, and eye protection. Before any cutting, we assess the log’s position and surrounding area, ensuring a safe working zone free from obstructions and potential hazards. We use wedges to prevent logs from pinching the saw and always employ a spotter when working with heavy or unstable logs. Furthermore, regular equipment maintenance is critical; a malfunctioning chainsaw is a significant safety risk. We also adhere strictly to faller’s safety zones, ensuring that no one is in the path of potential falling debris during bucking. Finally, emergency procedures and communication protocols are established and practiced to ensure a swift response in case of an incident.

For example, on a recent job site with a steep incline, we established a designated anchor point for our equipment and worked methodically from the top down to minimize risk of uncontrolled movement. This involved securing logs with chains to prevent them from rolling down the hill.

Q 9. How do you handle difficult terrain or challenging log positions?

Challenging terrain and log positions demand creative problem-solving and a careful risk assessment. Difficult terrain might require the use of specialized equipment like skidders or winches to move logs into more accessible locations. For instance, on a site with heavily wooded, swampy areas, we used a tracked skidder to access and maneuver the logs. This allowed us to work safely without putting ourselves or the equipment at undue risk. If a log is in an awkward position, we might employ various techniques like using levers, wedges, or even rigging systems to reposition it. The focus is always on safety – we’ll never attempt a maneuver that puts us or others at risk. We may choose to employ a different technique or even postpone the task until the proper equipment is available. Thorough planning and assessment before any action is essential. This includes considering factors like soil stability, potential for logs to shift during manipulation, and access routes for safe movement.

Q 10. What are the common causes of measurement errors in log scaling?

Measurement errors in log scaling can stem from various sources. Inaccurate measuring tools, such as damaged or improperly calibrated tapes, are a common culprit. Human error, including misreading the tape, improper log handling (leading to inaccurate diameter measurements), and failing to account for defects in the log, also contribute to errors. Environmental factors like uneven ground can affect the accuracy of measurements. Finally, inconsistent application of scaling rules and failure to account for taper (the gradual decrease in diameter towards the top of the log) can introduce significant errors into the scaling process.

For example, a small error in measuring the diameter of a log, especially a large one, can result in a substantial difference in the calculated volume.

Q 11. How do you ensure the accuracy and precision of your measurements?

Accuracy and precision are crucial for fair compensation in log sales. We begin with regular calibration of all measuring instruments, following manufacturer recommendations and using certified standards. We employ proper measuring techniques, ensuring that the tape is taut and measurements are taken at right angles to the log axis. We also take multiple measurements to account for taper and irregularities. To minimize human error, we carefully record measurements and use double-checking methods. We also incorporate proper log handling techniques to avoid skewing diameter readings, ensuring the log is properly supported and positioned for accurate measurement. We use digital calipers to supplement our tape measures for greater precision, particularly in measuring smaller diameter logs. Adherence to industry standards and scaling rules is essential to maintain consistency and accuracy.

Q 12. Describe your experience with different types of logging equipment.

My experience encompasses a wide range of logging equipment. I’m proficient in using various chainsaws, from smaller models for selective felling and bucking to larger, more powerful saws for processing larger logs. I’m familiar with both manual and mechanized scaling tools, including various types of measuring tapes, calipers, and even electronic scaling devices. I have experience operating skidders and loaders, understanding their use in log handling and transportation. I am also familiar with log harvesting equipment such as feller bunchers and harvesters. This broad experience gives me a comprehensive understanding of the entire logging process, enhancing my efficiency and ability to adapt to diverse job site conditions.

Q 13. Explain the importance of adhering to industry standards and regulations.

Adhering to industry standards and regulations is vital for safety, legal compliance, and ensuring fair business practices. Standards like those set by organizations like the Society of American Foresters (SAF) provide guidelines for safe practices and accurate scaling techniques. Regulations concerning worker safety, environmental protection, and timber harvesting practices must be followed diligently. These standards and regulations are not mere suggestions; they are crucial to protecting workers, minimizing environmental impact, and maintaining the integrity of the industry. Non-compliance can lead to serious consequences, including fines, legal repercussions, and reputational damage. Therefore, we place the utmost importance on understanding and strictly adhering to all relevant standards and regulations.

Q 14. How do you manage your time effectively during log bucking and scaling?

Effective time management in log bucking and scaling is essential for productivity. This starts with careful pre-job planning – organizing the work sequence to minimize unnecessary movements. Prioritization of tasks, focusing on high-value logs first, increases efficiency. Utilizing appropriate equipment and techniques for each task reduces handling time. I also break down large tasks into smaller, manageable units to avoid feeling overwhelmed and maintaining focus. Regular communication with the team, particularly on potential delays or changing site conditions, helps maintain efficiency. Consistent application of work methods and procedures speeds up processing. Finally, we actively monitor our progress, adjusting our approach if necessary to stay on schedule.

For example, if we encounter a difficult log early in the morning, we might quickly assess other logs to see if it’s more efficient to deal with that problem log later after finishing tasks with more predictable timeframes.

Q 15. Describe your experience working as part of a team in a logging operation.

Teamwork is fundamental in log bucking and scaling. In my previous role at Redwood Logging, we operated as a highly coordinated unit. My responsibilities included scaling logs using a tape measure and tallying the volume, while working closely with the feller bunchers, skidder operators, and truck drivers. We relied on clear communication – hand signals, radio communication, and daily briefings – to ensure smooth operations and avoid accidents. For instance, if a log was particularly large or awkwardly positioned, I would radio the skidder operator to adjust their approach, ensuring both safety and efficiency. This collaborative environment fostered a sense of shared responsibility and mutual respect, leading to a significantly higher output with minimal downtime. We constantly shared insights and best practices, and I actively participated in problem-solving sessions to optimize workflows.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle conflicts or disagreements within your team?

Disagreements are inevitable in any team setting. My approach prioritizes open communication and respectful dialogue. I believe in active listening to understand different perspectives before offering my own. If a conflict arises, I try to identify the root cause – is it a misunderstanding, a difference in opinion, or something else? For instance, if a disagreement occurs about the grading of a log, I’d refer to the established grading guidelines and present the facts objectively. If the disagreement persists, we escalate it to our supervisor for mediation. The key is to focus on finding a solution that works for everyone, while maintaining professionalism and respect. The goal is not to ‘win’ the argument, but to arrive at the best outcome for the operation.

Q 17. What are your strengths and weaknesses in relation to log bucking and scaling?

My strengths lie in my accuracy and speed in both bucking and scaling logs. Years of experience have honed my ability to quickly assess log volume and accurately record measurements. I am proficient in using various scaling tools, from traditional tapes to electronic measuring devices. I am also adept at identifying different species of wood and assessing their quality. However, like any skill, there’s always room for improvement. One area I’m actively working on is enhancing my knowledge of emerging technologies in log handling and measurement. While I am comfortable with traditional methods, I recognize the potential benefits of integrating new tools and techniques to further improve efficiency and accuracy.

Q 18. How do you maintain the accuracy of your records and data?

Maintaining accurate records is crucial for ensuring fair payment and efficient inventory management. I use a combination of methods. Firstly, I meticulously record all measurements in a durable, weather-resistant logbook, cross-referencing it with digital records whenever possible. This cross-referencing acts as a double-check. Secondly, I regularly review my records for any inconsistencies. If discrepancies are found, I immediately investigate the cause. Thirdly, I always double-check my calculations before submitting any reports. In case of any uncertainty regarding measurements, I consult with senior colleagues for verification. Finally, I am conscientious about maintaining my equipment (measuring tapes, calculators, etc.), ensuring it’s calibrated and in good working condition for consistent accuracy.

Q 19. Describe your problem-solving skills in relation to unexpected challenges on the job.

Unexpected challenges are commonplace in log bucking and scaling. For example, I once encountered a log jam that significantly delayed operations. My first step was to assess the situation: identify the cause of the jam, evaluate potential hazards, and determine the safest and most efficient solution. I then collaborated with the skidder operator and feller buncher operator to develop a plan to clear the jam without causing further damage or injury. We used a combination of manual techniques and machinery to carefully dislodge the logs. My problem-solving approach relies on a structured process: assess, plan, act, and review. This systematic approach helps me remain calm under pressure and find effective solutions, even in challenging situations. It’s about adapting to the circumstances and leveraging teamwork.

Q 20. Explain your experience with log sorting and grading.

Log sorting and grading involves categorizing logs based on species, size, quality, and intended use. My experience encompasses sorting logs according to different grading rules, including those defined by specific lumber mills or export markets. I can identify defects like knots, rot, or splits that impact the grade and value of a log. I’m familiar with various grading systems and understand the implications of different grades on pricing and end-use. For example, high-grade logs with minimal defects are generally destined for higher-value products like furniture, while lower grades might be suitable for pulpwood or less demanding applications. This knowledge helps me efficiently sort logs to optimize their value and minimize waste. I also utilize technological tools such as automated scanning systems where available to improve speed and accuracy.

Q 21. How do you ensure the safety of yourself and others during log handling?

Safety is paramount in log handling. I always adhere to strict safety protocols, including wearing appropriate personal protective equipment (PPE) such as safety boots, hard hats, high-visibility clothing, and safety glasses. Before starting any task, I inspect my equipment and the work area to identify and mitigate any potential hazards. I also maintain awareness of my surroundings and communicate effectively with my team members to avoid accidents. I’m trained in safe log-handling techniques, including proper lifting and moving procedures, and am familiar with emergency procedures and protocols. Regular safety briefings and training keep me informed about best practices and potential risks. Proactive safety measures are not just a matter of compliance; they’re a way to ensure everyone goes home safe at the end of the day.

Q 22. What are the environmental considerations during log harvesting?

Environmental considerations in log harvesting are paramount to sustainable forestry. They encompass a wide range of factors, aiming to minimize the impact on ecosystems and biodiversity.

- Soil Erosion and Compaction: Harvesting techniques must minimize soil disturbance. This might involve using directional felling to reduce the impact on the ground, and avoiding harvesting during wet periods. Proper road construction and maintenance are crucial to prevent erosion.

- Water Quality: Protecting water sources is essential. Sedimentation from roads and skid trails can pollute streams and rivers. Best practices include buffer strips along waterways and careful management of logging debris.

- Wildlife Habitat: Log harvesting can disrupt wildlife habitats. Strategies such as selective logging, leaving behind snags (dead trees) for habitat, and maintaining corridors of undisturbed forest can mitigate these effects. Careful planning around breeding seasons is also critical.

- Air Quality: Burning slash (logging debris) can release pollutants into the air. Sustainable forestry promotes alternative methods of slash disposal, such as chipping or leaving it on the forest floor to decompose naturally.

- Biodiversity Conservation: Protecting endangered species and maintaining biodiversity requires careful consideration of forest structure and composition during harvesting. Maintaining a range of tree ages and sizes helps support diverse plant and animal communities.

For instance, in a recent project, we implemented a riparian buffer zone of 50 meters around a stream to prevent sedimentation and protect aquatic life. This required careful planning of logging roads and harvesting operations.

Q 23. How familiar are you with different types of logging contracts?

My familiarity with logging contracts is extensive. They vary significantly depending on the specific needs of landowners, logging companies, and the type of forest being harvested. Common types include:

- Lumber Contracts: These contracts specify the species, volume, and quality of timber to be harvested, often with a fixed price per unit. Detailed specifications on scaling and bucking are usually included.

- Stumpage Contracts: The landowner retains ownership of the timber until it is cut. The logging company pays a per-unit price for the right to harvest, taking on the risk of market fluctuations. This requires careful negotiation and precise scaling to ensure fair payment.

- Timber Sales Contracts: Similar to stumpage contracts, but the sale is handled by a government agency or other intermediary. These often involve competitive bidding and stringent environmental regulations.

- Custom Harvesting Contracts: The landowner hires a logging company to perform all aspects of harvesting, including felling, bucking, skidding, and hauling. This usually involves a detailed specification of work and payment schedule.

I’ve worked with each type, and my experience allows me to understand and negotiate the terms effectively, ensuring both environmental protection and economic viability for all parties involved.

Q 24. Explain your understanding of sustainable forestry practices.

Sustainable forestry practices prioritize the long-term health and productivity of forests while meeting current needs. This involves a holistic approach that balances ecological, economic, and social considerations.

- Selective Logging: Instead of clear-cutting, only mature or less desirable trees are harvested, preserving the overall forest structure and biodiversity.

- Reduced-Impact Logging (RIL): Techniques that minimize damage to the forest floor and remaining trees, including careful planning of skid trails and using low-impact equipment.

- Reforestation and Afforestation: Planting new trees after harvesting to ensure continued forest cover and productivity. This includes selecting appropriate species for the site conditions.

- Forest Monitoring and Certification: Regular assessment of forest health and adherence to sustainable practices through certification programs such as the Forest Stewardship Council (FSC).

- Community Involvement: Engaging local communities in forest management decisions, ensuring equitable benefits and promoting responsible forestry practices.

For example, in one project, we implemented RIL techniques, reducing soil compaction and minimizing damage to young trees. This resulted in a healthier forest and improved regeneration after harvest.

Q 25. Describe your experience with data analysis related to log scaling and bucking.

My experience with data analysis in log scaling and bucking is extensive. I use data to optimize harvesting operations, ensuring accurate volume calculations, and maximizing profitability.

- Volume Estimation: I utilize various scaling methods, including Smalian’s formula and Huber’s formula, along with software that integrates data from tree diameter measurements and length to calculate volumes accurately. This minimizes errors and ensures fair payment.

- Bucking Optimization: I analyze data to determine optimal bucking patterns to maximize the yield of high-value lumber. This might involve using software to simulate different bucking strategies, considering factors like knot size and wood quality.

- Productivity Analysis: I track data on harvesting rates, equipment utilization, and crew performance to identify bottlenecks and areas for improvement. This data-driven approach ensures efficient operations and cost reduction.

- Quality Control: Data on log defects and grade helps in identifying areas where improvements in harvesting or processing can be made. This ensures higher quality products and reduces waste.

For example, by analyzing bucking data from a previous harvest, we identified a pattern of over-bucking certain species, leading to unnecessary waste. By adjusting the bucking guidelines, we reduced waste by 15% in the next harvest.

Q 26. How do you use technology to improve efficiency in your work?

Technology significantly improves efficiency in log bucking and scaling. I routinely use various tools to enhance my work.

- Laser Scanners: These provide precise measurements of log dimensions, eliminating the need for manual taping and reducing errors. The data is directly integrated into volume calculation software.

- GPS and GIS: These technologies allow for precise mapping of forest stands, logging roads, and harvesting operations. This optimizes harvesting routes, minimizing damage and improving efficiency.

- Remote Sensing: Satellite and aerial imagery provides valuable data on forest cover, tree species composition, and biomass, assisting in pre-harvest planning and sustainable management.

- Data Management Software: Specialized software facilitates efficient data collection, analysis, and reporting, streamlining the entire process from scaling to accounting.

In a recent project, using laser scanners reduced the time required for log scaling by approximately 40%, leading to significant cost savings and improved efficiency.

Q 27. How do you stay updated with the latest advancements in log bucking and scaling techniques?

Staying updated in this dynamic field is crucial. I employ several strategies to maintain my expertise:

- Professional Organizations: Active membership in organizations like the Society of American Foresters (SAF) provides access to publications, conferences, and networking opportunities, keeping me abreast of the latest techniques and research.

- Industry Publications and Journals: I regularly read trade journals and scientific publications dedicated to forestry, logging, and wood science, staying informed on new technologies and best practices.

- Conferences and Workshops: Attendance at industry conferences and workshops allows for hands-on learning and exposure to new equipment and techniques. It also facilitates valuable networking with other professionals.

- Online Courses and Webinars: Numerous online resources offer continuing education opportunities, allowing me to update my skills and knowledge in specific areas.

For example, I recently completed a webinar on advanced scaling techniques using drones, learning a method that could significantly improve the accuracy and speed of our scaling operations.

Q 28. Describe a time you had to make a critical decision related to safety during log handling.

During a large-scale harvesting operation, we encountered a situation where a partially felled tree was precariously balanced, posing a significant risk to the crew. The initial plan was to use a grapple to pull it down, but I assessed the situation and judged this too risky due to the unstable position and nearby equipment.

Instead, I made the critical decision to halt operations immediately and call in a specialized rigging crew experienced in dealing with dangerous tree falls. This decision, while delaying the project temporarily, prioritized the safety of my crew over the project timeline. The specialized crew used advanced techniques to safely fell the tree without incident.

This experience reinforced the importance of prioritizing safety, even if it means altering plans or incurring additional costs. The safety of my team is always my paramount concern.

Key Topics to Learn for Log Bucking and Scaling Interview

- Log Bucking Techniques: Understanding different bucking methods (e.g., hand bucking, mechanized bucking), optimizing cuts for various log sizes and species, and the impact of bucking on log value and mill processing.

- Scaling Practices: Mastering accurate log scaling methods (e.g., Scribner, Doyle, International 1/4-inch), understanding scaling rules and regulations, and utilizing scaling tools effectively.

- Safety Procedures: Thorough knowledge of safety protocols for log bucking and scaling, including personal protective equipment (PPE) use, hazard identification, and risk mitigation strategies.

- Log Grading and Quality Assessment: Ability to assess log quality based on factors like species, defects, and dimensions, understanding the impact on value and marketability.

- Timber Measurement and Volume Calculation: Proficiency in calculating log volume using different formulas and understanding the implications of accurate measurement for financial settlements.

- Environmental Considerations: Awareness of sustainable forestry practices, minimizing waste, and the environmental impact of log bucking and scaling operations.

- Equipment Operation and Maintenance (if applicable): Familiarization with the operation and maintenance of relevant equipment such as chainsaws, scaling tools, and mechanized bucking systems. Understanding preventative maintenance and troubleshooting procedures.

- Problem-Solving and Decision-Making: Ability to analyze situations, identify problems, and make effective decisions in the field, adapting to varying log characteristics and environmental conditions.

Next Steps

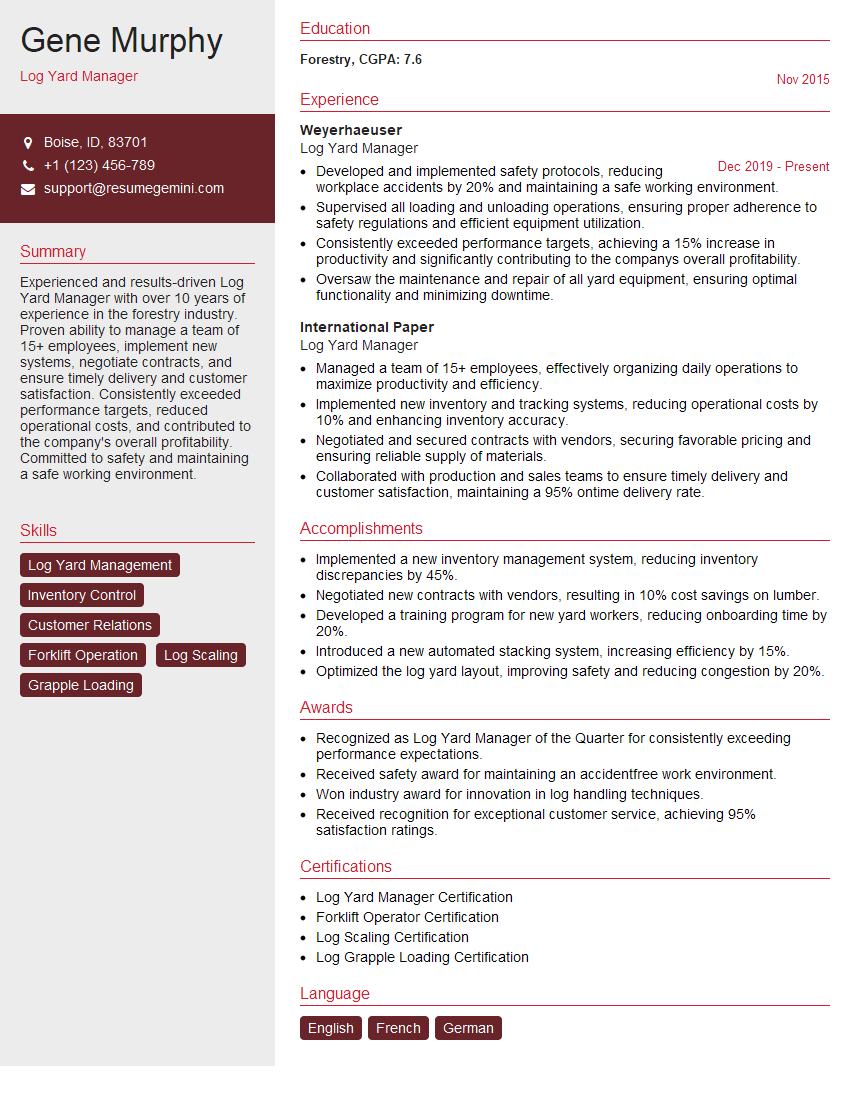

Mastering Log Bucking and Scaling opens doors to rewarding careers in the forestry and timber industries, offering opportunities for advancement and specialized roles. A strong resume is crucial for highlighting your skills and experience to potential employers. Creating an ATS-friendly resume significantly improves your chances of getting noticed by recruiters. To enhance your resume and maximize your job prospects, we highly recommend using ResumeGemini, a trusted resource for building professional resumes. Examples of resumes tailored to Log Bucking and Scaling are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO