Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Log Cutting and Harvesting Techniques interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Log Cutting and Harvesting Techniques Interview

Q 1. Describe the different felling techniques used in log harvesting.

Felling techniques are crucial for safe and efficient log harvesting. The choice depends on factors like tree size, species, terrain, and surrounding obstacles. Here are some common methods:

- Humboldt felling: This technique involves making an undercut on the side the tree is to fall, followed by a felling cut on the opposite side. It’s ideal for larger trees and allows for more control over the direction of the fall. Think of it like carefully guiding a giant domino.

- Open-face felling: This is a simpler method where the felling cut is made directly opposite the direction of the fall. It’s faster but requires a good understanding of tree lean and requires more precision. It’s like chopping down a small, less resistant sapling.

- Directional felling: This involves strategic notch placement and felling cuts to guide the tree in a specific direction, often using wedges or felling levers to ensure a controlled fall, even with challenging leans or obstacles. This is the most skill demanding and is applied where precision is paramount.

- Notching and Bucking: This involves a series of cuts that section the tree into logs of manageable sizes at the base of the tree prior to felling.

Choosing the right technique is paramount for safety and efficiency. Incorrect felling can lead to dangerous tree movement, equipment damage, and injuries.

Q 2. Explain the safety procedures involved in operating a chainsaw.

Chainsaw safety is non-negotiable. It starts with proper training and the consistent application of safety protocols. Here’s a breakdown:

- Personal Protective Equipment (PPE): This includes chainsaw chaps (protective leg coverings), safety helmet with face shield or goggles, gloves, and sturdy footwear with steel toes. Think of PPE as your armor.

- Pre-operational checks: Always inspect the chainsaw for damage, ensure the chain is properly tensioned and lubricated, and check the fuel and bar oil levels before starting. A quick check can prevent a major accident.

- Proper felling techniques: Choose the right felling technique based on the tree’s characteristics and the surrounding environment. Incorrect felling is the leading cause of accidents.

- Awareness of surroundings: Always be aware of your surroundings, including the location of other workers, obstacles, and the potential fall path of the tree. Maintain a safe distance from the felling zone for yourself and others.

- Refueling Safety: Only refuel the chainsaw in a well-ventilated area, with the engine turned off and cooled down. Never refuel a hot chainsaw, as the fumes are flammable.

- Emergency Procedures: Always have a first-aid kit nearby and know emergency contact numbers. Have a plan for emergencies, such as a tree falling unexpectedly.

Safety isn’t just a procedure; it’s a mindset. Consistent vigilance is key to avoiding accidents.

Q 3. What are the common types of logging equipment and their applications?

Logging equipment varies greatly depending on the scale and type of operation. Here are some common types:

- Chainsaws: The fundamental tool for felling trees and bucking (cutting into logs). Different sizes and power outputs exist to match various tree sizes and harvesting conditions.

- Felling heads/Processors: These are attachments for excavators or other machines that automatically fell trees, limb them, and cut them into logs, significantly increasing efficiency and safety. They’re like automated chainsaw crews.

- Skidders: These are powerful machines used to drag felled logs from the felling site to a landing area. They are often tracked vehicles designed for challenging terrain.

- Forwarders: Forwarders are similar to skidders but lift and carry logs rather than dragging them. They are more efficient on steeper slopes and uneven terrain.

- Harvesters: These are highly sophisticated machines combining felling, limbing, and bucking into a single operation. They significantly improve efficiency but require specialized training and have a high initial investment.

- Loaders: Loaders are typically used at the landing to load logs onto trucks for transport. They range from small skid steer loaders to large wheeled loaders, depending on the scale of operation.

The choice of equipment is critical for optimizing productivity, safety, and cost-effectiveness. Terrain, tree size, and logging volume all play major roles in determining the most efficient combination of equipment.

Q 4. How do you assess tree risk before felling?

Assessing tree risk before felling is crucial for safety. It’s a multi-faceted assessment combining visual inspection and consideration of several factors:

- Tree lean: Observe the direction and degree of lean. Significant lean can drastically alter the fall path.

- Deadwood and decay: Check for signs of decay, broken branches, or rot that could weaken the tree. A seemingly healthy tree might have hidden weaknesses.

- Crown condition: Examine the crown for dead branches, broken tops, or unusual growth patterns. These indicate potential instability.

- Soil conditions: Assess the soil type and moisture content. Loose or wet soil can increase the risk of root failure.

- Obstacles: Identify any obstacles in the potential fall path, including other trees, rocks, or equipment.

- Wind conditions: Wind can significantly affect the fall path and increase the risk of accidents. Strong winds will often mean delaying felling until the weather improves.

A thorough risk assessment is an investment in safety. Ignoring potential hazards can result in serious accidents.

Q 5. Explain the process of skidding logs from the felling site.

Skidding logs involves transporting felled logs from the felling site to a designated landing area. This often involves specialized equipment and careful planning:

- Pre-skidding preparation: Logs are often bunched or chained together to facilitate easier skidding.

- Skidder selection: The appropriate skidder type is selected based on factors like terrain, log size, and distance to the landing.

- Skid trail preparation: Skid trails might need preparation, such as clearing obstacles or improving the trail surface.

- Skidding operation: The skidder grabs or chains the logs and pulls them along the skid trail to the landing. The operator needs excellent spatial awareness to avoid damaging equipment or the surrounding environment.

- Log unloading: Logs are unloaded at the landing area, typically using a loader or other appropriate equipment. This requires precise maneuvering of both the skidder and the unloading device to avoid hazards or damage.

Skidding efficiency is critical for overall logging productivity. Proper planning and use of suitable equipment can significantly reduce the time and effort involved.

Q 6. What are the different methods for measuring log volume?

Accurate log volume measurement is essential for calculating timber yield and determining the value of harvested wood. Several methods exist:

- Doyle Log Rule: A widely used rule, particularly in North America, that estimates volume based on log diameter and length. It’s a relatively simple method but can underestimate volume, especially for larger logs.

- Scribner Log Rule: Another common rule, often preferred for larger logs than the Doyle rule. It’s more accurate than the Doyle rule for many species and log sizes but still offers only an estimate.

- International 1/4-inch Log Rule: This rule is designed to be more accurate than other rules and is widely used for a variety of species and log sizes. It provides a closer approximation to actual volume than simpler rules.

- Smalian’s Formula: A more precise method using cross-sectional areas at both ends of the log, combined with the log length, to calculate volume. It requires more measurements than simple log rules.

- Volume Tables: These tables provide pre-calculated volumes for specific species based on diameter and length. They are handy for rapid estimations but require using a table specific to your species of tree.

- 3D Scanning: Modern techniques like 3D scanning enable highly accurate volume measurement. It’s a more technologically advanced but very accurate method.

The best method depends on the required accuracy and available resources. For simple estimations, log rules are adequate. For high-precision work, 3D scanning may be more appropriate.

Q 7. Describe your experience with various harvesting systems (e.g., clear-cut, selection cutting).

My experience encompasses various harvesting systems, each with its own advantages and drawbacks:

- Clear-cutting: I’ve been involved in clear-cut operations, where all trees within a designated area are harvested. This is efficient for large-scale operations but can have significant environmental impacts if not properly managed. I’ve seen projects where reforestation efforts were integrated to mitigate negative environmental effects.

- Selection cutting: I have extensive experience with selection cutting, where individual trees or small groups of trees are harvested, leaving the majority of the forest intact. This is more sustainable and minimizes environmental impact but is less efficient and often more labor-intensive. I was involved in a project that used selection cutting in a wildlife preserve, carefully selecting trees to maintain habitat and biodiversity.

- Shelterwood cutting: This method involves removing mature trees in stages, leaving some trees to provide shelter and seed for regeneration. It’s a sustainable approach that requires careful planning and a deep understanding of forest dynamics.

- Seed-tree cutting: A variation of shelterwood, leaving only a few seed trees to regenerate the stand. This is a more aggressive method, used only in certain conditions where the goal is to rapidly repopulate a stand with a specific species.

Each system requires careful consideration of environmental impacts, economic factors, and forest regeneration. My experience allows me to select and adapt the most appropriate system for a given situation, considering all the relevant factors and aiming for ecologically responsible and profitable harvesting.

Q 8. How do you ensure the safety of your crew during harvesting operations?

Crew safety is paramount in logging. It’s not just a matter of compliance; it’s a fundamental aspect of our operation’s success and ethical responsibility. We implement a multi-layered approach encompassing pre-harvest planning, ongoing training, and strict adherence to safety protocols.

- Pre-harvest planning: This involves detailed site assessments to identify potential hazards like unstable terrain, deadfall, and proximity to power lines. We create detailed operational plans outlining safe work practices and emergency procedures, specific to each site’s unique challenges. For example, if we’re working near a riverbank, we’ll establish designated safe zones and implement strict faller’s limits.

- Training and competency: All crew members receive regular, comprehensive safety training, including certifications in first aid, chainsaw operation, and hazard recognition. We emphasize practical, hands-on training, and refresher courses are mandatory. Proficiency assessments ensure everyone understands and can apply the safety guidelines. We also conduct regular toolbox talks to address specific job site risks and best practices.

- Daily safety checks and communication: Before each shift, we conduct equipment checks and pre-job briefings to ensure everyone is aware of the day’s tasks and potential hazards. Open communication is crucial; we encourage our crew to report any safety concerns immediately, without fear of reprisal. We use daily safety reports to track incidents and identify areas for improvement.

- Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE is non-negotiable. This includes hard hats, safety glasses, hearing protection, chainsaw chaps, steel-toed boots, and high-visibility clothing. Regular inspections of PPE ensure its functionality and proper fit.

We consider safety not just a cost of doing business but an investment in our workforce and our company’s future. A safe work environment leads to increased productivity, reduced accidents, and fosters a positive work culture.

Q 9. What are the environmental considerations in log harvesting?

Environmental considerations are integral to responsible logging. We aim to minimize our impact on the ecosystem through careful planning and execution. This includes adhering to strict regulations and implementing best management practices.

- Selective harvesting: We prioritize selective cutting techniques, focusing on removing specific trees while leaving the forest’s overall structure intact. This preserves biodiversity, minimizes soil erosion, and reduces the overall impact on the environment.

- Erosion and sediment control: We implement measures to prevent soil erosion and sedimentation of waterways. This includes creating buffer zones along streams and rivers, utilizing proper skidding techniques, and avoiding logging in sensitive areas. We often construct water bars and sediment basins to further minimize erosion.

- Reforestation: We actively participate in reforestation efforts, planting seedlings to replace harvested trees. This ensures long-term forest sustainability and helps restore the ecosystem.

- Wildlife habitat considerations: We carefully plan operations to avoid disrupting wildlife habitats and migration routes. We consult with wildlife biologists to identify sensitive areas and minimize disturbances to animal populations.

- Waste management: We carefully manage logging debris, striving to minimize waste and utilize it for other purposes whenever possible, such as creating biomass for energy generation.

Environmental stewardship is not just a responsibility; it is vital for the long-term health of our forests and the communities that depend on them. We strive to operate in a way that leaves the forest better than we found it.

Q 10. How do you maintain logging equipment to ensure optimal performance and safety?

Maintaining logging equipment is critical for both performance and safety. Regular maintenance prevents costly breakdowns, reduces downtime, and ensures the equipment operates as efficiently and safely as intended.

- Preventive maintenance schedule: We follow a strict preventive maintenance schedule for all equipment, including chainsaws, skidders, feller bunchers, and loaders. This involves regular inspections, lubrication, and component replacements as per manufacturer’s recommendations. We meticulously record all maintenance activities for traceability and to predict potential issues before they arise.

- Operator training: Our operators receive comprehensive training on proper equipment operation, maintenance, and safety procedures. They are taught to perform daily checks before operating machinery and to report any issues immediately.

- Repair and replacement: We promptly repair or replace any faulty components. We use only high-quality parts to ensure equipment reliability and longevity. We collaborate with certified mechanics to conduct complex repairs.

- Cleanliness and storage: We maintain a clean and organized equipment yard to ensure easy access to machinery and prevent damage or theft. Equipment is properly stored when not in use, protecting it from the elements and extending its lifespan.

By implementing this comprehensive maintenance program, we can extend the operational life of our equipment, reduce repair costs, and ensure the safety of our crew.

Q 11. Explain your understanding of different log grades and their applications.

Log grades classify logs based on their quality and intended use. This impacts price and how it is processed. Different grades reflect different characteristics such as size, straightness, knot density, and the presence of defects.

- High-grade logs: These logs are typically straight, large-diameter, and free from defects. They’re used for high-value products like structural lumber, veneer, and plywood for furniture or construction.

- Medium-grade logs: These logs have fewer imperfections but may be smaller in diameter or have some knots. They are suitable for dimensional lumber, pallets, and less demanding applications.

- Low-grade logs: These logs contain significant defects like large knots, rot, or crook. They’re often used for pulpwood, biomass fuel, or lower-grade lumber products.

Understanding log grades is crucial for effective forest management and efficient resource allocation. It enables us to maximize the value of harvested timber by matching each log to its most appropriate use. For example, we might choose to use high-grade logs for veneer production and lower-grade logs for pulp and paper production.

Q 12. Describe your experience with using GPS and GIS in logging operations.

GPS and GIS technology have revolutionized logging operations, improving efficiency and precision. We utilize these tools for various purposes:

- Pre-harvest planning: GIS allows us to create detailed maps of the logging area, identifying road networks, streams, and other features. We use this information to optimize harvest layouts, minimizing environmental impact and maximizing efficiency.

- Road construction and planning: GPS assists in planning and constructing efficient logging roads, reducing damage to the forest and minimizing transportation costs. GPS-guided machinery ensures accurate road alignment and minimizes soil disturbance.

- Harvesting operations: GPS-equipped equipment enables precise felling and skidding, ensuring efficient use of timber and reduced waste. Real-time tracking capabilities allow us to monitor the progress of logging operations and make adjustments as needed.

- Data collection and analysis: GIS is used to collect and analyze data related to timber volume, tree species, and forest health. This data is crucial for making informed decisions regarding forest management and planning future operations.

Integrating GPS and GIS into our operations has improved our precision, reduced environmental impact, and optimized our overall efficiency. For instance, precise GPS guidance helps reduce the amount of trees felled outside our designated harvest areas and reduces road damage by accurately plotting the routes for machines.

Q 13. How do you manage log transportation and storage effectively?

Efficient log transportation and storage are crucial for minimizing costs and maintaining timber quality. We employ various strategies to optimize these processes.

- Efficient road networks: Well-planned logging roads are essential for efficient transportation. We design roads to minimize distance and ensure they can handle the weight of loaded trucks.

- Proper loading and securing: Logs are carefully loaded and secured on trucks to prevent damage during transport. Proper loading techniques ensure stability and safety during transport.

- Designated landing areas: Logs are transported to designated landing areas where they are temporarily stored before transport to mills or processing facilities. These areas are designed to minimize soil compaction and environmental impact.

- Storage strategies: Logs are stored in a manner that protects them from the elements and minimizes degradation. This may involve stacking logs properly, using covers to protect from rain and sun, or utilizing specialized storage facilities.

Careful planning and execution of these processes are critical to preserving timber quality and minimizing transportation costs. For example, by utilizing efficient road networks and proper loading techniques, we can reduce fuel consumption and minimize the risk of log damage.

Q 14. What are the key factors to consider when planning a logging operation?

Planning a logging operation requires careful consideration of numerous factors to ensure efficiency, safety, and environmental responsibility.

- Site assessment: A thorough site assessment is the first step. This involves identifying terrain features, tree species and their distribution, presence of waterways and sensitive areas, and any potential hazards.

- Harvesting method selection: The choice of harvesting method depends on factors such as terrain, tree size, and environmental considerations. Different methods, such as clear-cutting, selective harvesting, and shelterwood cutting, have varying impacts on the forest ecosystem.

- Environmental considerations: Minimizing environmental impact is paramount. This includes planning to avoid sensitive areas, implementing erosion and sediment control measures, and adhering to relevant regulations.

- Log transportation planning: The planning phase involves designing efficient road networks and identifying suitable landing areas. This minimizes transportation costs and protects forest resources.

- Resource allocation: This involves determining the optimal number of workers, equipment, and logistical resources needed to complete the operation efficiently and safely.

- Safety protocols: Safety is a top priority. Detailed safety plans must be in place, including pre-job briefings, PPE provision, emergency procedures, and ongoing training.

- Legal and regulatory compliance: Operations must adhere to all relevant laws and regulations, including forest management plans, environmental permits, and worker safety standards.

A well-planned logging operation ensures a profitable and sustainable approach to forest management. A successful plan balances economic viability with environmental responsibility and worker safety.

Q 15. Describe your experience with different types of saws and their maintenance.

My experience encompasses a wide range of saws, from hand saws for precise cuts in delicate situations to powerful mechanized saws like chainsaws and feller bunchers for large-scale operations. Hand saws, such as crosscut saws and bucksaws, require regular sharpening to maintain efficiency and prevent damage to the saw teeth. I’m proficient in using both single-man and two-man crosscut saws. Chainsaws, on the other hand, demand meticulous maintenance, including regular chain sharpening and lubrication, bar cleaning, and air filter replacement. Ignoring this leads to decreased cutting performance, increased risk of kickback (a dangerous situation where the saw recoils violently), and ultimately, saw damage. I also have experience with feller bunchers, which are highly mechanized and require routine checks of hydraulic systems, blade sharpness, and overall structural integrity. Maintenance logs are meticulously kept for all equipment to ensure safety and optimal performance.

For example, during a recent harvest, a chainsaw’s chain became dull, resulting in slower cutting and increased effort. Immediate sharpening restored its efficiency, preventing fatigue and potential accidents. Similarly, a routine check on a feller buncher revealed a minor hydraulic leak. Addressing it promptly prevented a major system failure which could have halted the operation and caused significant downtime.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and address potential hazards in a logging site?

Hazard identification at a logging site is paramount. It’s a multi-step process starting with a thorough site assessment before any work begins. This includes identifying potential hazards such as unstable terrain, dead or hanging trees (snags), proximity to power lines, and the presence of wildlife. I utilize hazard mapping techniques to visually represent these risks, ensuring everyone is aware. Regular safety briefings are conducted before each shift, emphasizing safe operating procedures, personal protective equipment (PPE) use, and emergency response protocols. Communication is key; we maintain constant radio contact to quickly address any emerging dangers.

For instance, spotting a potential snag requires immediate action. We would either fell it using controlled techniques or carefully clear the area to eliminate the risk of it falling unpredictably. Similarly, working near power lines requires establishing a safe working distance and employing spotters to monitor operations.

Q 17. What are the regulatory requirements for log harvesting in your region?

Regulatory requirements for log harvesting in my region are stringent and vary depending on the type of forest and the land ownership. Key regulations include obtaining necessary permits and licenses before commencing operations, adhering to strict environmental protection laws related to soil erosion, water quality, and endangered species protection, and meeting safety standards mandated by OSHA (Occupational Safety and Health Administration) and other relevant authorities. These regulations often include detailed plans for post-harvest site restoration. Detailed record-keeping is essential, documenting all aspects of the harvesting operation, including the number of trees felled, the volume of timber harvested, and any environmental impacts. Non-compliance can lead to significant penalties.

For example, in areas with sensitive ecosystems, special permits might be required to minimize environmental disturbance. Similarly, detailed plans for reforestation must be submitted and approved before harvesting is allowed in designated areas. Regular inspections by regulatory bodies are common to ensure compliance.

Q 18. Explain your understanding of sustainable forestry practices.

Sustainable forestry is crucial for the long-term health of our forests and the environment. My understanding of sustainable practices involves selectively harvesting mature trees, minimizing damage to remaining trees and the surrounding ecosystem, and ensuring forest regeneration. This includes techniques like pre-commercial thinning to promote healthy tree growth and reduce competition. We employ reduced-impact logging (RIL) techniques to minimize soil compaction and damage to watercourses. Reforestation and afforestation efforts are crucial elements, ensuring the replenishment of harvested timber. Sustainable practices also encompass biodiversity conservation and the protection of wildlife habitats.

A real-world example is using directional felling to minimize tree damage to residual stands. This involves carefully planning the felling direction to avoid damaging healthy trees. Another example involves creating buffer zones around streams and other water bodies to prevent soil erosion and pollution.

Q 19. How do you handle unexpected problems or emergencies during harvesting?

Handling unexpected problems requires a calm and methodical approach. Our team is trained to respond to various emergencies, including equipment malfunctions, injuries, and weather-related incidents. We have well-defined emergency response plans with designated roles and responsibilities. Immediate actions are prioritized: securing the scene, providing first aid if necessary, and contacting emergency services. A post-incident review is conducted to analyze what happened and to identify ways to prevent similar incidents in the future. Clear communication and teamwork are essential during emergency situations.

For instance, if a chainsaw malfunctions, the operator immediately stops work, reports the problem, and the backup saw is used while the faulty one is repaired or replaced. If an injury occurs, first aid is provided and then the injured person is transported to medical care.

Q 20. Describe your experience working with different types of terrain.

My experience includes working in diverse terrains, from steep slopes and rocky areas to flatlands and swampy conditions. Terrain significantly influences harvesting techniques and equipment choices. Steep slopes pose significant challenges; safety measures, such as using specialized equipment and employing winch systems, are essential to prevent accidents. In rocky areas, careful planning is required to avoid damaging equipment and ensure safe operation. Working in swampy conditions necessitates using specialized equipment and techniques to avoid getting stuck and damaging the environment. Each terrain requires specific risk assessments and adjusted safety protocols.

For example, harvesting on steep slopes might involve using cable logging systems to transport logs safely downhill. In swampy areas, we might employ lighter equipment and carefully plan the routes to minimize ground disturbance.

Q 21. How do you ensure the quality of logs harvested?

Ensuring log quality starts with careful selection of trees to be harvested, prioritizing those that meet specific size, species, and quality criteria. Careful felling techniques minimize damage to the logs, avoiding splitting or breakage. Proper handling and transportation also contribute to high-quality logs; avoiding unnecessary dragging and dropping reduces defects. Regular monitoring of logs from felling to delivery ensures that the quality is maintained throughout the process. This involves inspecting logs for defects and ensuring proper stacking and storage to prevent damage.

For example, the correct felling angle is crucial to avoid splitting, and minimizing the distance the log is dragged reduces the risk of bark damage. Careful stacking avoids damage and decay.

Q 22. Explain your experience with pre-harvest planning.

Pre-harvest planning is crucial for efficient and safe logging operations. It involves a detailed assessment of the logging area to determine the best approach for felling, extracting, and transporting timber. This planning minimizes environmental impact and maximizes productivity.

My experience includes utilizing various tools and techniques. For example, I’ve used LiDAR data and GIS mapping to create detailed 3D models of the forest, allowing us to identify optimal harvesting routes, minimize damage to residual trees, and plan for efficient skidder and forwarder movements. I also consider factors such as soil type, slope, and the presence of waterways to determine suitable harvesting methods and prevent erosion. We also perform careful tree marking, designating which trees will be harvested and which will remain to ensure sustainable forest management. A comprehensive pre-harvest plan will incorporate details on safety protocols, emergency procedures, and environmental mitigation strategies.

In one particular project, detailed pre-harvest planning allowed us to reduce harvesting time by 15% and significantly reduce soil disturbance compared to previous projects where less planning had been done.

Q 23. How do you communicate effectively with other members of the logging crew?

Effective communication is paramount in a logging crew. It’s not just about giving instructions; it’s about ensuring everyone understands their role and the potential hazards involved. We use a combination of methods to ensure clear and concise communication.

- Pre-shift briefings: We start each day with a briefing outlining the tasks, safety procedures, and potential hazards specific to that day’s work. I emphasize the importance of observing hand signals and maintaining radio contact.

- Clear and concise instructions: I make sure my instructions are straightforward, avoiding jargon and using visual aids when necessary. For instance, I’ll demonstrate the proper felling technique rather than simply describing it.

- Open communication channels: We maintain open communication channels, encouraging crew members to raise concerns or ask questions without hesitation. This creates a safer and more productive work environment.

- Regular feedback: We regularly provide and receive feedback to ensure everyone is on the same page and any issues are addressed promptly. For example, I’ll ask the feller about ground conditions before they begin felling.

Think of it like a well-oiled machine: each part has its role, and communication is the grease that keeps everything moving smoothly and safely.

Q 24. What are the advantages and disadvantages of different harvesting methods?

Several harvesting methods exist, each with advantages and disadvantages.

- Clearcutting: This involves removing all trees in a designated area. It’s efficient and cost-effective for large-scale operations, but it can have significant environmental impacts, such as soil erosion and habitat loss. Suitable for fast-growing species and even-aged stands.

- Shelterwood Cutting: This method involves removing trees in stages, leaving some mature trees to provide shade and seed for regeneration. It’s less disruptive to the environment than clearcutting but less efficient in terms of immediate timber yield. Good for preserving biodiversity.

- Selection Cutting: This involves removing only selected trees, leaving the rest to continue growing. It’s the least disruptive method, promoting sustainable forest management, but it’s less efficient and may not be suitable for all species or stand structures. Suitable for uneven-aged stands, maintaining forest biodiversity.

- Seed-Tree Cutting: Leaving a few seed trees to regenerate the area. This method is suitable for areas where natural regeneration is desired and species are well suited to regeneration this way.

The choice of method depends on various factors, including the species of trees, the terrain, environmental regulations, and economic considerations. A well-informed decision requires careful consideration of all these factors.

Q 25. How do you ensure compliance with safety regulations and environmental standards?

Safety and environmental compliance are non-negotiable aspects of logging. I adhere to all applicable regulations and standards meticulously.

- Pre-harvest inspections: Before any operation begins, I conduct thorough site inspections to identify potential hazards. This includes assessing the terrain, identifying unstable trees, and checking equipment for safety issues.

- Safety training: I ensure that all crew members receive comprehensive safety training before beginning work, and we conduct regular refresher courses. This covers everything from safe felling techniques to emergency procedures.

- Personal protective equipment (PPE): We use appropriate PPE at all times, including hard hats, safety glasses, hearing protection, and high-visibility clothing. Regular equipment checks are a standard part of our process.

- Environmental monitoring: We monitor environmental impacts throughout the operation, ensuring compliance with regulations regarding soil erosion, water quality, and wildlife protection. This often involves documenting the process with photos and reports.

- Waste management: We manage waste appropriately, minimizing debris and reducing environmental impact through careful planning and removal.

We maintain detailed records of all safety procedures and environmental compliance efforts, including incident reports and environmental monitoring data. This ensures accountability and facilitates continuous improvement.

Q 26. Describe your experience with different log handling techniques.

Log handling techniques are critical for efficient and safe transport. My experience encompasses various methods, each suited to specific circumstances.

- Skidding: This involves dragging logs from the felling site to a landing using skidders or tractors. The choice of equipment depends on terrain and log size. Careful planning is crucial to avoid damage to the environment.

- Forwarding: This involves using specialized machines that load, transport, and unload logs efficiently. This method is often favored on steeper slopes and less accessible areas. Forwarders are generally more efficient than skidders on difficult terrain.

- Loading and Unloading: We use various techniques, including loaders, cranes, and grapple skidders, to load logs onto trucks for transport. Safety is paramount during these operations to prevent accidents.

- Pre-bunching: This involves grouping logs together before forwarding or skidding, increasing efficiency and reducing the number of trips needed.

The selection of the appropriate technique depends on the terrain, the size and volume of logs, and the accessibility of the site. For instance, in mountainous terrain, forwarding is preferred, while in flatter areas skidding might be more efficient. We prioritize methods that minimize damage to the forest floor and surrounding environment.

Q 27. How do you use technology to improve efficiency and safety in logging operations?

Technology plays a significant role in improving efficiency and safety in logging. I’ve utilized several technological advancements in my work.

- GPS and GIS: We use GPS to track equipment and personnel, improving efficiency and safety. GIS mapping enables detailed pre-harvest planning, optimizing routes, and minimizing environmental impact.

- LiDAR: LiDAR technology provides high-resolution 3D models of the forest, aiding in detailed planning and reducing potential hazards.

- Remote sensing: We can use satellite imagery and aerial photography to monitor forest conditions, identify areas for harvesting, and plan efficient operations.

- Harvesting simulators: These software programs simulate harvesting operations, allowing us to test different scenarios and optimize efficiency before the actual work begins.

- Smart harvesting equipment: Many machines are now equipped with sensors and automated systems, improving precision, efficiency, and safety.

By incorporating these technologies, we can significantly enhance productivity, reduce costs, improve safety, and minimize the environmental impact of logging operations.

Q 28. What are your career aspirations within the log cutting and harvesting industry?

My career aspirations are focused on continued growth and leadership within the log cutting and harvesting industry. I aim to further develop my expertise in sustainable forestry practices, incorporating advanced technologies to maximize efficiency and minimize environmental impact.

I’m particularly interested in exploring opportunities in forest management and consulting, using my knowledge to help companies implement responsible and profitable logging practices. I want to contribute to the advancement of the industry by sharing my knowledge and helping others adopt safer, more environmentally sound techniques. Ultimately, I envision a future where logging is a sustainable practice, balancing economic needs with environmental responsibility.

Key Topics to Learn for Log Cutting and Harvesting Techniques Interview

- Safety Regulations and Procedures: Understanding and adhering to all relevant safety regulations, including personal protective equipment (PPE) use and hazard identification. Practical application: Demonstrate knowledge of safe felling techniques and emergency procedures.

- Felling Techniques: Mastering various felling techniques based on tree size, species, and terrain. Practical application: Explain the differences between felling techniques like directional felling and notch cuts, and when to use each.

- Log Processing and Bucking: Efficiently processing felled trees into logs of specified lengths and quality. Practical application: Describe different bucking techniques and their impact on log value and waste reduction.

- Harvesting Equipment Operation and Maintenance: Safe and proficient operation of chainsaws, skidders, and other harvesting machinery. Practical application: Explain routine maintenance procedures and troubleshooting common equipment malfunctions.

- Timber Harvesting Planning and Management: Understanding sustainable harvesting practices, including forest inventory, road construction, and environmental impact assessment. Practical application: Discuss the importance of pre-harvest planning and its impact on efficiency and environmental responsibility.

- Environmental Considerations: Minimizing environmental impact during harvesting operations, including soil erosion control and wildlife habitat protection. Practical application: Explain strategies for reducing the environmental footprint of logging operations.

- Log Scaling and Measurement: Accurate measurement of log volume and grade. Practical application: Describe different scaling methods and their accuracy.

Next Steps

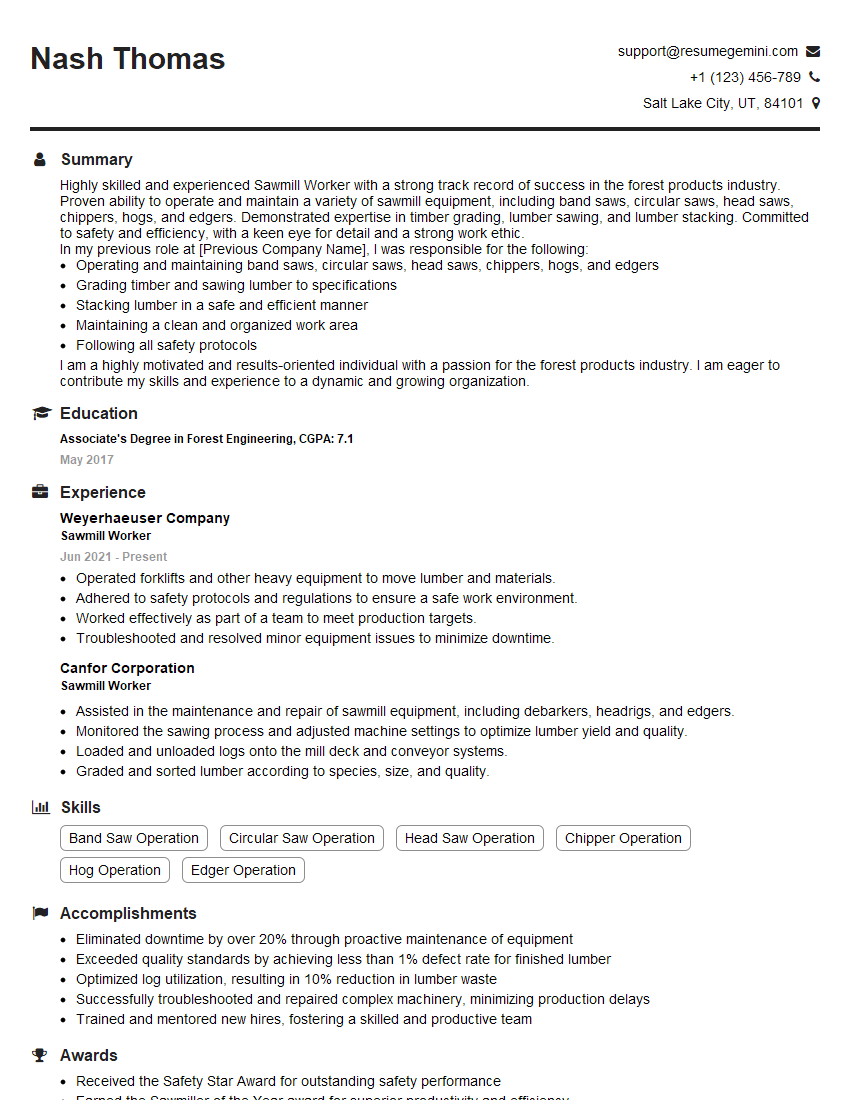

Mastering Log Cutting and Harvesting Techniques is crucial for career advancement in the forestry and timber industries, opening doors to higher-paying positions and increased responsibility. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential to ensure your application gets noticed by potential employers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to help you craft a compelling narrative that showcases your skills and experience. Examples of resumes tailored to Log Cutting and Harvesting Techniques are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO