Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Log Splitting interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Log Splitting Interview

Q 1. What safety precautions do you take when operating a log splitter?

Safety is paramount when operating a log splitter. Think of it like driving a car – you wouldn’t drive without a seatbelt, and you shouldn’t operate a log splitter without the proper precautions.

- Personal Protective Equipment (PPE): Always wear safety glasses or a face shield to protect your eyes from flying debris. Hearing protection is also crucial, as log splitters can be quite loud. Sturdy work gloves are essential to prevent cuts and blisters. Consider steel-toed boots for added foot protection.

- Clear Workspace: Ensure the area around the log splitter is free of obstructions and bystanders. A cluttered workspace increases the risk of accidents. Keep children and pets well away from the operating machine.

- Proper Technique: Never force a log into the splitter. If it’s too large or wedged, don’t risk injury by trying to force it. Use a smaller log splitter or consider breaking the log down before feeding it into the machine.

- Machine Maintenance: Regularly inspect the log splitter for damage or wear. Make sure all safety features are functioning correctly before each use. A well-maintained machine is a safe machine.

- Emergency Shutdown: Familiarize yourself with the emergency stop mechanism and know how to use it quickly in case of an emergency. Don’t ever reach into the splitting area while the machine is running.

For instance, I once saw someone get a splinter in their eye because they weren’t wearing safety glasses. It’s a small detail that can have a significant impact.

Q 2. Describe the different types of log splitters you are familiar with.

Log splitters come in a variety of types, each suited to different needs and log sizes.

- Hydraulic Log Splitters: These are the most common type, using a hydraulic ram to split logs. They are generally powerful and efficient, ranging from small, portable models to large, stationary units capable of handling extremely large logs. Think of them as the workhorses of the log-splitting world.

- Gas-Powered Log Splitters: These use a gas engine to power the hydraulic pump. They offer portability and are ideal for use in areas without access to electricity.

- Electric Log Splitters: These are powered by electricity and are usually more affordable and quieter than gas-powered models. However, they often lack the power of their gas counterparts and their range is limited by the cord length.

- Manual Log Splitters: These rely solely on human power, usually using a wedge and mallet. They’re ideal for small-scale splitting and are excellent for building hand-eye coordination and physical strength.

The choice depends on factors like budget, power requirements, and the volume of logs to be split. For a large-scale operation, a hydraulic splitter is preferred, while a smaller homeowner might choose an electric or even manual splitter depending on their needs.

Q 3. How do you assess the condition of a log before splitting it?

Before splitting a log, a thorough assessment is crucial to prevent damage to the equipment and ensure a safe splitting process.

- Knots and Cracks: Carefully check for knots, cracks, or any signs of decay. Knots can deflect the splitting force, potentially damaging the splitter or causing it to bind. Cracks can cause the log to split unexpectedly, possibly resulting in injury.

- Size and Shape: Assess the size and shape of the log. Oversized logs can overwhelm smaller splitters. Logs with unusual shapes might require pre-splitting or a different approach.

- Moisture Content: Green (freshly cut) wood is significantly harder to split than seasoned (dried) wood. The moisture content significantly impacts the splitting process. Green wood often requires more force and can strain the equipment.

- Hidden Metal: Be mindful of nails, screws, or other hidden metallic objects embedded within the wood. These can damage the splitting blade or cause injuries.

I remember one time a nail shattered the splitting wedge because it hadn’t been detected before splitting. A simple visual inspection saved a costly repair.

Q 4. What are the common causes of log splitter malfunctions?

Log splitter malfunctions can stem from various causes, often linked to operator error or lack of maintenance.

- Hydraulic Fluid Leaks: Leaks in the hydraulic system lead to reduced power or complete failure. Regular inspection and maintenance are essential.

- Engine Problems (Gas Models): Issues like clogged air filters, faulty spark plugs, or low fuel can lead to engine failure. Routine maintenance prevents these issues.

- Electrical Issues (Electric Models): Faulty wiring, blown fuses, or motor problems can cause electric splitters to malfunction.

- Worn Components: Over time, components like wedges, rams, and hydraulic hoses wear out. Regular inspection and replacement of worn parts are necessary to prevent failures.

- Log Jams: Oversized or improperly positioned logs can cause the splitting mechanism to jam.

Many problems can be prevented with regular maintenance and proper operating procedures. For example, regularly changing the hydraulic fluid in a hydraulic splitter extends its life and reduces the likelihood of leaks.

Q 5. How do you troubleshoot a jammed log splitter?

Troubleshooting a jammed log splitter requires a careful and methodical approach, prioritizing safety.

- Turn off the Machine: The first and most crucial step is to completely turn off the log splitter and disconnect the power source (if applicable).

- Assess the Jam: Carefully examine the cause of the jam. Is the log wedged against the ram, the wedge, or another part of the machine?

- Remove the Log: Use caution when removing the jammed log. Never attempt to force it. If possible, use a pry bar or another tool to carefully lever the log free. In some instances, you might need to disassemble the log into smaller sections.

- Inspect for Damage: After removing the log, thoroughly inspect the splitter for any damage caused by the jam.

- Restart and Test: Once the jam is cleared and any damage is addressed, restart the splitter and test its operation.

If you’re unsure about resolving the jam yourself, it’s always best to seek assistance from a qualified technician. A badly managed jam can lead to much more significant repairs.

Q 6. Explain the proper technique for using a maul or axe to split logs.

Splitting logs with a maul or axe requires skill, precision, and a strong understanding of wood grain. Improper technique can result in injury or damage to the tool.

- Stance and Grip: Maintain a balanced stance, feet shoulder-width apart. Grip the maul or axe firmly but not too tightly.

- Identifying the Grain: Carefully assess the wood grain to identify the most efficient splitting point. Look for natural cracks or splits to guide your strike.

- Swing and Impact: Use a smooth, controlled swing, bringing the maul or axe down squarely onto the chosen point. Let the weight of the tool do the work; don’t rely on brute force.

- Follow Through: Allow the tool to follow through completely after impact.

- Safety Precautions: Always wear appropriate safety gear, including safety glasses and sturdy work gloves. Ensure sufficient space around you to prevent injury.

Practicing on smaller logs is crucial to develop proper technique. Think of each swing as a precise movement, not a power contest.

Q 7. How do you handle different wood species when splitting logs?

Different wood species present varying challenges when splitting logs. Some woods are naturally easier to split than others.

- Hardwoods: Hardwoods like oak and hickory are considerably denser and tougher to split than softwoods. They often require more force and may need pre-splitting.

- Softwoods: Softwoods such as pine and fir are generally easier to split due to their lower density.

- Green vs. Seasoned Wood: Green wood, high in moisture, is significantly more challenging to split than seasoned wood. Seasoned wood is less resistant to splitting.

- Knots and Grain: Knots significantly impact the splitting process, often leading to deflection or the need for multiple strikes. Understanding the wood grain aids in choosing the optimal splitting point.

For example, splitting green oak might require a significantly more powerful splitter or multiple passes compared to splitting dry pine. Adjusting technique and power depending on the wood is key to efficient log splitting.

Q 8. What is the best way to prepare logs for efficient splitting?

Proper log preparation is crucial for efficient and safe splitting. Think of it like preparing a good meal – the better the prep, the easier the cooking (splitting!). It all starts with selecting the right wood. Seasoned hardwood is significantly easier to split than green wood, which is wet and resistant.

- Seasoning: Allow logs to dry for at least six months, preferably a year or more. This reduces moisture content, making them more brittle and easier to cleave.

- Size and Shape: Avoid splitting extremely large logs unless you have a powerful splitter. Consider pre-cutting oversized logs into more manageable sections using a chainsaw. Similarly, curved or oddly shaped logs can be challenging; try to cut them into more straight sections for better splitting results.

- Clearing Debris: Remove any dirt, rocks, or metal objects from the wood. These can damage your tools and cause injury.

For example, I once spent hours wrestling with a green oak log, only to make minimal progress. The next day, after cutting it into smaller pieces, it split like butter using the same maul. Proper preparation is key!

Q 9. Describe your experience with different types of wedges.

My experience encompasses various wedge types, each suited for different applications. The choice often depends on the wood type, log size, and the splitting tool used.

- Traditional Wedges: These are the classic, often steel, wedges driven into the wood using a sledgehammer or maul. They’re versatile but require considerable force. Different shapes exist (e.g., the classic tapered wedge, splitting wedges with broader faces for less penetration but more splitting power). I favor hardened steel for durability.

- Hydraulic Wedges/Splitters: These are power tools that offer significantly increased force, making them ideal for large or tough logs. The wedge design is usually a tapered blade. I often use one for larger commercial jobs.

- Flying Wedges: These are designed to be thrown into a log to cause a splitting action, usually used in conjunction with a maul or axe. They’re not as efficient for larger logs, but perfect for smaller, quicker splits.

A recent job involved a stubborn, knotty maple log. A traditional wedge simply wouldn’t budge, but my hydraulic wedge split it cleanly with minimal effort. The right tool for the right job is paramount.

Q 10. How do you maintain a log splitter to ensure optimal performance?

Maintaining a log splitter is essential for its longevity and safety. Regular maintenance prevents unexpected breakdowns and ensures optimal performance. It’s similar to caring for a well-loved car.

- Blade/Wedge Sharpening: Regularly inspect and sharpen or replace the blade, depending on its type. A dull blade requires more force, increases the risk of injury, and can damage the wood. For hydraulic splitters, blade replacement is important when showing significant wear.

- Hydraulic Fluid Check (for hydraulic splitters): Check and top off hydraulic fluid levels as needed. Low fluid levels can affect performance and damage the pump.

- Lubrication: Keep all moving parts properly lubricated to reduce friction and wear. This is crucial for preventing premature wear and tear.

- Safety Checks: Before each use, visually inspect the entire machine for any damage, loose parts, or leaks. This is a vital safety measure.

Ignoring maintenance leads to costly repairs, downtime, and potential hazards. I always prioritize regular maintenance to keep my tools in top condition.

Q 11. What are the signs of a worn-out log splitter blade or wedge?

Recognizing signs of a worn-out blade or wedge is crucial for safety and efficiency. A worn blade can lead to inefficient splitting and increase the risk of injury.

- Chipping or Cracking: Cracks or significant chipping on the blade or wedge indicate substantial wear and potential failure. Replace immediately.

- Blunting: A dull blade requires considerably more force, leading to fatigue and a higher chance of mishaps. The splitting action becomes less efficient and more effort is required.

- Mushrooming: If the end of the wedge starts to mushroom (spread out), it’s lost its effectiveness and is probably no longer safe to use.

I once used a significantly blunted wedge, and it slipped during a split, causing a near miss. Now I religiously inspect my blades and wedges before every use, and promptly replace any exhibiting these signs.

Q 12. How do you handle large or knotty logs?

Handling large or knotty logs demands a strategic approach. Force is not always the best solution, careful planning is key.

- Strategic Cuts: For large logs, use a chainsaw to create smaller, more manageable sections. Follow the grain of the wood to make clean cuts that follow its natural weakness.

- Targeting Knots: Knots are points of stress within the wood and can make splitting difficult. Use wedges to split the log around the knot or strategically place the initial cut to avoid it.

- Multiple Wedges: Employ multiple wedges, either simultaneously or in succession to split large pieces.

- Leverage: Use leverage to your advantage. Position your wedge or splitting tool to exploit natural cracks or weaknesses in the wood.

I once tackled a massive oak log with numerous knots. Instead of brute force, I used a combination of chainsaw cuts, multiple wedges, and leverage, splitting it safely and efficiently into smaller, usable pieces. A strategic approach saved me time, effort, and prevented injuries.

Q 13. What are the potential hazards associated with log splitting?

Log splitting, while rewarding, comes with potential hazards. Ignoring these hazards can lead to serious injuries.

- Flying Debris: Splintering wood can fly at high speeds, causing eye injuries or cuts. Protective eyewear is crucial.

- Back Injuries: Repeatedly swinging a maul or axe can strain your back, leading to long-term problems. Maintaining proper posture and technique is essential.

- Hand and Foot Injuries: Striking fingers or toes with the maul or axe is easily possible. Wear appropriate footwear and use caution.

- Equipment Malfunction: Hydraulic splitters can malfunction. Regular maintenance and safety checks are paramount.

Many people underestimate the power involved in splitting wood. I’ve witnessed firsthand the dangers of ignoring safety precautions; a friend suffered a nasty eye injury because he lacked appropriate eye protection.

Q 14. How do you ensure the safety of yourself and others while splitting logs?

Safety is paramount during log splitting. A few simple yet effective strategies can greatly reduce the risk of injury.

- Protective Gear: Always wear appropriate safety gear, including safety glasses, gloves, sturdy work boots, and hearing protection (particularly with power splitters).

- Work Area: Choose a clear, stable work area free of obstacles that could cause tripping. Keep children and pets away from the working area.

- Proper Technique: Master the proper technique for swinging a maul or axe to reduce strain and prevent injury. Avoid using excessive force; let the weight and momentum of the tool do the work.

- Regular Maintenance: Ensure all your equipment is in good working order and regularly maintained.

- Never rush the process: Work at a steady pace that allows for safe and controlled splitting.

I always emphasize safety to my team, emphasizing that every precaution taken is an investment in their well-being. A safe jobsite is a productive jobsite.

Q 15. What is your experience with different log splitter power sources (gas, electric, hydraulic)?

My experience encompasses all three major log splitter power sources: gas, electric, and hydraulic. Each has its strengths and weaknesses.

- Gas-powered splitters offer unmatched portability and power, ideal for remote locations or large-scale jobs where access to electricity is limited. However, they require regular maintenance, including fuel and oil changes, and produce exhaust fumes.

- Electric splitters are quieter, cleaner, and easier to maintain than gas-powered models. They are best suited for smaller jobs and areas with readily available power. Their power output is generally lower than gas-powered options.

- Hydraulic splitters are the workhorses of the log splitting world, offering a combination of power and efficiency. They use hydraulic pressure to drive the splitting ram, resulting in smooth, powerful splitting action. They can be either gas or electric-powered, combining the benefits of both.

For example, I’ve used a gas-powered splitter to clear a large pile of fallen timber after a storm, and an electric splitter for smaller projects around the home. The hydraulic splitter is my go-to for professional jobs requiring consistent, high-power splitting.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the appropriate size of log splitter for a specific job?

Determining the right log splitter size depends on several factors: the size and type of wood, the volume of logs to be split, and the desired splitting speed. Consider these key aspects:

- Tonnage: This refers to the splitting force, measured in tons. Larger tonnage equates to greater splitting power, allowing you to handle larger and harder logs. For example, a 20-ton splitter will handle most residential needs, but larger operations might require 30 tons or more.

- Ram speed and length: Faster ram speeds improve efficiency, but slower speeds can be preferable when splitting particularly tough or knotty logs. The ram length determines the maximum log length you can split.

- Vertical vs. Horizontal: Vertical splitters are generally more compact but may require more maneuvering. Horizontal splitters are often preferred for larger logs.

For instance, for a small residential property with mostly smaller logs, a 15-ton electric or gas splitter might suffice. However, a commercial operation processing large hardwood logs would need a considerably larger, 30-ton or higher, hydraulic splitter.

Q 17. Describe your experience with different log splitting techniques.

My log splitting experience involves various techniques, tailoring my approach to the specific circumstances:

- Traditional wedge splitting: This involves using mauls or sledgehammers to drive wedges into the wood. It’s a labor-intensive but effective method for smaller logs and irregular shapes. I’ve found it useful for particularly stubborn knots or difficult grain patterns.

- Machine splitting (using log splitters): This is the most efficient method for large volumes of logs. The choice of log splitter (hydraulic, electric, or gas) depends on the scale and location of the job, as previously discussed.

- Combination methods: Sometimes, a combination of methods is needed. I might pre-crack a large log with a wedge before feeding it into a log splitter, reducing stress on the machine and improving efficiency.

For example, I recently had a job where a significant portion of the logs were extremely large and knotty. I pre-split these with a wedge and sledgehammer before using the hydraulic splitter to complete the task. This prevented damage to the splitter and made the overall process safer and more efficient.

Q 18. How do you handle unexpected problems or equipment failures during log splitting?

Handling unexpected problems requires a systematic approach. Safety always comes first.

- Identify the problem: Is it a jammed log, a hydraulic leak, a blown fuse, or something else?

- Assess the risk: Is the situation safe to proceed with? If not, shut down the equipment and seek assistance if needed.

- Troubleshooting: Based on the problem, I’d follow the appropriate troubleshooting steps, consulting the equipment manual if necessary. Common issues include clearing jammed logs, checking hydraulic fluid levels, or replacing fuses.

- Seek professional help if needed: If I cannot resolve the issue, I’d contact a qualified technician for repair or replacement parts.

For example, I once had a hydraulic line burst on a gas-powered splitter. I immediately shut down the machine, secured the area, and contacted a repair service. Safety is paramount; attempting a repair without proper knowledge could lead to serious injury.

Q 19. What is your understanding of OSHA regulations related to log splitting?

My understanding of OSHA regulations concerning log splitting is crucial for ensuring workplace safety. Key aspects include:

- Personal Protective Equipment (PPE): This is non-negotiable. I always wear safety glasses, hearing protection, sturdy work gloves, and steel-toed boots when operating log splitters or using hand tools.

- Machine guarding: Log splitters must be properly maintained and guarded to prevent accidental contact with moving parts. Regular inspections are vital.

- Safe operating procedures: This includes never operating the equipment while intoxicated, ensuring proper clearance around the machine, and never reaching into the splitting area while it’s operating.

- Emergency response planning: Knowing how to handle various emergencies, such as a jammed log or equipment malfunction, is critical.

Ignoring these regulations can lead to serious injuries or even fatalities. Compliance with OSHA standards is not merely a legal requirement but a fundamental aspect of responsible operation.

Q 20. What is your experience working with different types of wood?

Experience with various wood types significantly impacts log splitting techniques and equipment selection.

- Hardwoods (Oak, Hickory, Maple): These are dense and require more power to split. A higher-tonnage splitter is necessary, and pre-splitting or using wedges might be required.

- Softwoods (Pine, Fir, Spruce): These are generally easier to split, requiring less power. However, knotty softwoods can still present challenges.

- Green vs. seasoned wood: Green wood (recently cut) contains more moisture and is more difficult to split than seasoned (dried) wood. Green wood can also damage equipment if forced through a splitter.

For example, splitting seasoned oak requires significantly more power than splitting seasoned pine. Understanding these differences allows for appropriate equipment selection and efficient operation.

Q 21. How do you prioritize safety and efficiency when splitting logs?

Prioritizing both safety and efficiency is crucial. They are not mutually exclusive but rather interdependent.

- Risk assessment: Before starting any log splitting task, I assess the risks involved, including the type of wood, the condition of the equipment, and the environment.

- Proper technique: Using the correct technique for each log and piece of equipment minimizes the risk of injury and maximizes efficiency.

- Regular maintenance: Keeping equipment in good working order reduces the risk of malfunctions and ensures optimal performance.

- Clear workspace: Ensuring a clear and organized workspace minimizes tripping hazards and improves overall efficiency.

For example, using wedges to pre-split large or knotty logs reduces the strain on the log splitter and makes the entire process safer and more efficient. Maintaining a clear workspace prevents accidents and streamlines the process, making it faster and less prone to mistakes.

Q 22. How do you stack and store split logs to prevent damage or deterioration?

Proper stacking and storage of split logs is crucial for preventing rot, insect infestation, and splitting further. Think of it like building a log castle, but with an eye towards airflow and protection from the elements.

- Air Circulation: Logs should be stacked off the ground, ideally on pallets or a layer of gravel, to allow for air circulation. This prevents moisture buildup, a major contributor to decay. Imagine the difference between a damp sponge and one that’s allowed to air dry.

- Covered Storage: A simple tarp or a more permanent structure (like a woodshed) provides protection from rain and snow. Think of it as providing a raincoat to your precious firewood.

- Orientation: Stack logs with the split faces facing outward. This allows for better drying and reduces the risk of the wood getting trapped against another log and retaining moisture.

- Spacing: Don’t pack the logs too tightly. Leave gaps between the rows to enable air to flow freely, just like you’d arrange your groceries to prevent squashing.

- Type of wood: Some woods are more susceptible to moisture damage than others. Softer woods need more careful stacking and possibly quicker use.

Following these guidelines ensures your firewood remains dry, clean, and ready to burn for a long time.

Q 23. What is your understanding of wood anatomy and its impact on splitting?

Understanding wood anatomy is key to efficient log splitting. The grain, density, and presence of knots significantly affect how easily a log splits. Think of it like trying to break a piece of candy – some are brittle and break easily, others are tougher and require more force.

- Grain: The direction of the wood grain greatly impacts splitting. Logs split more easily along the grain than against it. Imagine trying to break a piece of wood along its length versus across its width – which is easier?

- Density: Denser woods like oak require more force to split than softer woods like pine. This is like the difference between splitting a rock and splitting a piece of foam.

- Knots: Knots are where branches grew from the tree. They represent points of weakness and often cause splitting to deviate or stop, making them the bane of any wood splitter. These can make for uneven splits and sometimes even cause the maul to get stuck.

- Heartwood vs. Sapwood: Heartwood is the older, darker, and denser wood at the center of a log; sapwood is the younger, lighter, outer layer. Heartwood is generally harder to split than sapwood.

By observing the wood’s structure, you can anticipate splitting challenges and adjust your technique accordingly.

Q 24. What are the environmental considerations related to log splitting?

Environmental considerations in log splitting are primarily related to waste reduction and sustainable practices. It’s about minimizing our impact on the natural world.

- Waste Reduction: Proper splitting reduces waste by maximizing the usable wood for firewood. Minimizing the amount of unusable wood left behind lessens the impact on the surrounding environment. Efficient splitting means less waste.

- Sustainable Sourcing: Ensuring the wood comes from responsibly managed forests is vital for preserving natural resources. This includes sourcing logs from sustainable forestry operations.

- Air Quality: Burning wood produces emissions, so proper drying and splitting help reduce the smoke created from incompletely burned wood. Better drying reduces harmful emissions.

- Noise Pollution: Log splitting can be noisy, especially with mechanized splitters. Consider using quieter equipment and adhering to noise regulations.

By keeping these environmental factors in mind, we can ensure that our log-splitting practices are both efficient and responsible.

Q 25. How do you adapt your techniques for different weather conditions?

Weather significantly affects log splitting. Think of how different it is to work with wet clay versus dry clay.

- Cold Weather: Cold temperatures can make wood more brittle and easier to split. However, frozen wood can be dangerous to split. It’s important to thaw it slightly before splitting.

- Hot Weather: Hot, dry weather can make wood harder to split as it can become dry and less likely to break in a clean split.

- Wet Weather: Wet wood is significantly more difficult to split and can dull tools quickly. It’s usually best to avoid splitting logs when it’s raining or snowing. However, if necessary, you may need to take extra precautions to prevent tool damage.

Adapting my technique involves choosing the right tools and using caution in various conditions. Safety first, always.

Q 26. Describe your experience working in a team environment during log splitting tasks.

Teamwork in log splitting is all about efficiency and safety. It’s like a well-oiled machine where each member plays their role effectively.

- Task Allocation: We usually divide tasks based on strength and skill. Those with more experience might handle the more challenging logs, whilst others can focus on stacking and organization.

- Communication: Clear communication is vital. Calling out potential hazards or coordinating actions ensures smooth workflow and avoids accidents.

- Safety: We always maintain a safe distance when splitting logs, especially if using a maul. We prioritize our safety over speed.

- Mutual Support: If someone is struggling, the team helps out. A helping hand is always appreciated, making the entire process smoother and more enjoyable.

Working as a team dramatically increases efficiency and makes the often physically demanding job easier and safer.

Q 27. What are your strategies for managing a large volume of logs to be split?

Managing a large volume of logs requires a systematic approach. It’s like planning a large-scale construction project.

- Sorting: I begin by sorting logs by size and species. This allows me to optimize splitting efficiency. Smaller logs are easier to handle and faster to split.

- Staging: Logs are staged in designated areas to ensure a smooth flow of work. This prevents congestion and unnecessary movement.

- Prioritization: I prioritize logs based on urgency and type, ensuring that logs needed immediately are processed first.

- Equipment: Using appropriate equipment, such as a mechanical splitter for larger logs, is crucial for efficient processing of large volumes.

A structured approach is vital for effectively tackling large volumes of logs while maintaining efficiency and safety.

Q 28. How do you plan and organize your work to efficiently split logs?

Efficient log splitting requires careful planning and organization. It’s about working smarter, not harder.

- Assessment: I begin by assessing the volume and size of logs, considering the available tools and manpower.

- Work Area Setup: A well-organized work area is crucial. This includes clear access to logs, a safe splitting area, and designated spaces for split and unsplit wood.

- Tool Maintenance: Ensuring that all equipment, including axes, mauls, and wedges are sharp and in good working order maximizes efficiency and minimizes the risk of injury.

- Process Optimization: I constantly evaluate my technique and seek improvements for increased efficiency. This might include experimenting with different splitting techniques or adjusting my work area layout.

A well-planned and organized approach not only increases efficiency but also reduces the risk of accidents, making the job safer and less strenuous.

Key Topics to Learn for Log Splitting Interview

- Log Selection and Assessment: Understanding wood grain, identifying knots and weaknesses, and choosing the appropriate splitting technique based on log characteristics.

- Safety Procedures and Equipment Handling: Safe use of mauls, wedges, splitting axes, and other tools; proper body mechanics to prevent injury; understanding and implementing safe work practices in various environments.

- Splitting Techniques: Mastering different splitting methods (e.g., vertical, horizontal, using wedges), adapting techniques based on log size and type, and recognizing when to use specialized tools.

- Maintenance and Care of Tools: Sharpening and maintaining axes and mauls, proper storage techniques, recognizing signs of tool damage and performing necessary repairs or replacements.

- Log Handling and Stacking: Efficiently moving and stacking split wood, minimizing strain and maximizing storage space, understanding different stacking methods for optimal drying.

- Environmental Considerations: Understanding the impact of log splitting on the environment, responsible wood sourcing and disposal of waste materials.

- Troubleshooting and Problem Solving: Identifying and resolving common issues encountered during log splitting, such as stubborn knots or difficult-to-split wood; adapting techniques to overcome challenges.

Next Steps

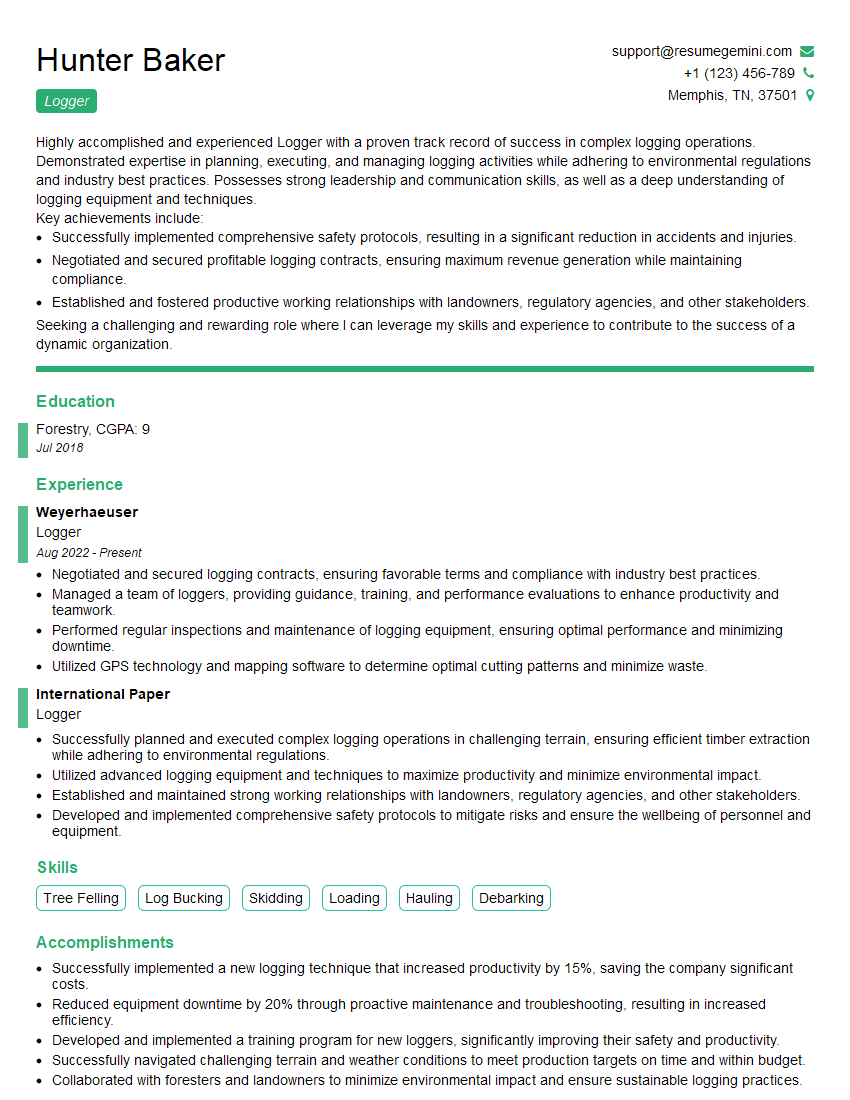

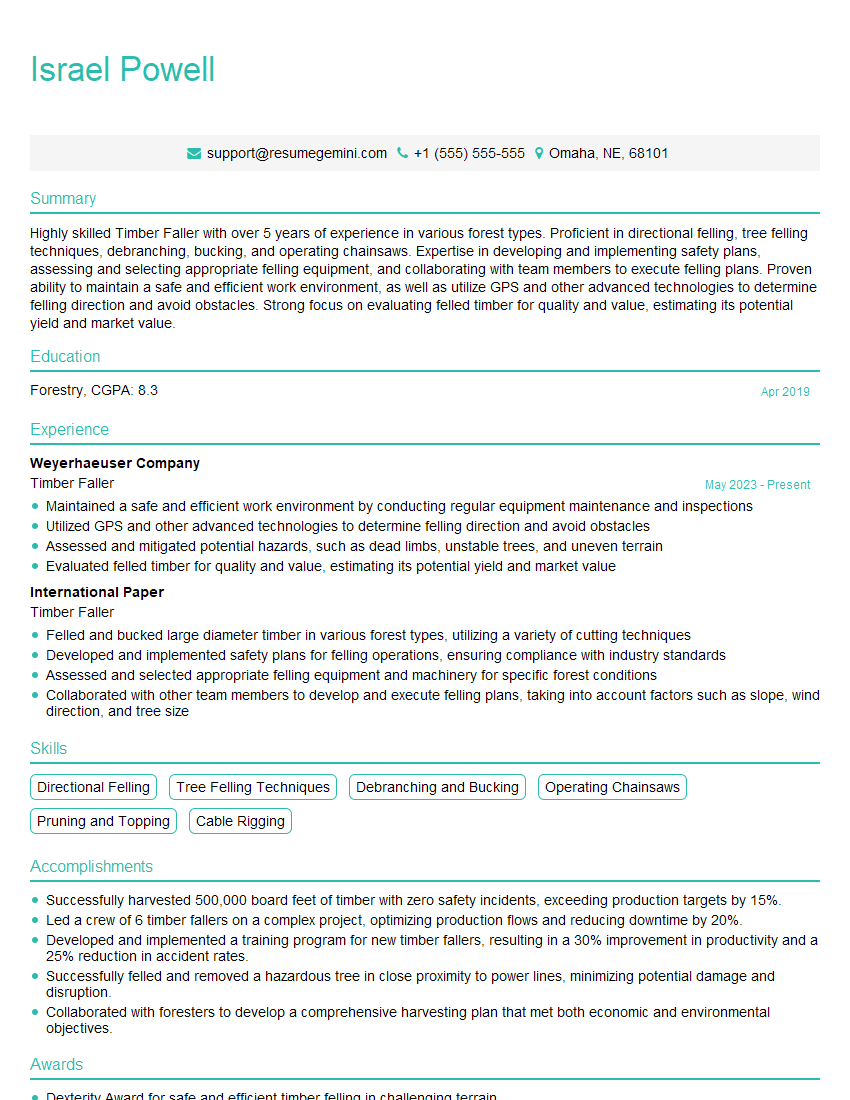

Mastering log splitting techniques demonstrates valuable skills applicable across various industries—from problem-solving and physical dexterity to attention to detail and safety awareness. These skills make you a highly desirable candidate for roles requiring practical abilities and a commitment to safety. To maximize your job prospects, it’s crucial to have an ATS-friendly resume that highlights your expertise. Use ResumeGemini to build a professional and impactful resume that showcases your skills effectively. ResumeGemini provides examples of resumes tailored to the log splitting field to guide you through the process. This will significantly improve your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO