Are you ready to stand out in your next interview? Understanding and preparing for Machining and Grinding Techniques interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Machining and Grinding Techniques Interview

Q 1. Explain the difference between subtractive and additive manufacturing.

Subtractive and additive manufacturing represent fundamentally different approaches to creating parts. Subtractive manufacturing, encompassing techniques like machining and grinding, starts with a larger block of material and removes material to achieve the desired shape. Think of a sculptor chipping away at a block of marble – material is subtracted to reveal the final form. Additive manufacturing, also known as 3D printing, builds up a part layer by layer from a raw material, adding material until the desired shape is complete. Imagine a 3D printer constructing a plastic object, adding plastic filament layer upon layer.

The key difference lies in the material removal versus material addition process. Subtractive methods are generally better for high-precision parts and complex geometries where tight tolerances are crucial, while additive methods excel in rapid prototyping, creating complex internal structures, and producing customized parts on demand. The choice depends heavily on the part’s design, required precision, material properties, and production volume.

Q 2. Describe various types of grinding wheels and their applications.

Grinding wheels are classified based on their bonding material, abrasive grain type, and grain size. The bonding material holds the abrasive grains together and influences the wheel’s life and performance. Common bonding materials include vitrified (ceramic), resinoid (synthetic resin), and silicate (silicate bond).

- Vitrified wheels are durable, resistant to heat, and suitable for high-speed grinding. They are ideal for precision grinding operations.

- Resinoid wheels offer flexibility and are often used for grinding softer materials or intricate shapes.

- Silicate wheels are less common but are good for grinding softer metals.

Abrasive grains determine the wheel’s cutting ability. Common abrasives include aluminum oxide (Al2O3) for steel and cast iron, and silicon carbide (SiC) for non-ferrous metals, ceramics, and stone. Grain size affects the surface finish; finer grains create smoother surfaces while coarser grains are better for faster stock removal. For example, a vitrified aluminum oxide wheel with a fine grain size would be used for finishing a precision steel part, while a resinoid silicon carbide wheel with a coarse grain size would be better suited for rough grinding a ceramic component.

Q 3. What are the different types of CNC machining processes?

CNC machining encompasses a variety of processes, all controlled by a computer numerical control system. Some common types include:

- Milling: Uses a rotating cutter to remove material from a workpiece. This can create various shapes, from simple flats to complex 3D contours.

- Turning: A rotating workpiece is machined by a cutting tool that moves linearly, creating cylindrical shapes, threads, and other features.

- Drilling: Creates holes in the workpiece using a rotating drill bit.

- Boring: Enlarges an existing hole to a precise diameter.

- Reaming: Improves the accuracy and surface finish of a hole.

- Tapping: Creates internal threads.

The selection of a specific CNC machining process depends on the part geometry, material properties, and desired tolerances. For instance, milling is best for creating complex shapes, turning is ideal for cylindrical parts, and drilling is used for creating holes.

Q 4. How do you select the appropriate cutting tool for a specific material?

Selecting the right cutting tool is crucial for efficient machining and optimal surface finish. The choice depends on several factors:

- Material of the workpiece: Different materials require different tool materials and geometries. Harder materials necessitate harder cutting tools. For example, carbide tools are commonly used for steels, while high-speed steel (HSS) tools might be suitable for softer materials like aluminum.

- Machining operation: Different operations (milling, turning, drilling) require different tool designs. A milling cutter is vastly different from a turning tool.

- Desired surface finish: Sharper tools generally provide better surface finishes.

- Cutting speed and feed rate: These parameters must be matched to the tool material and workpiece material to prevent tool breakage or poor surface finish.

For example, when machining hardened steel, a carbide insert with a specific geometry designed for interrupted cuts would be selected to handle the high forces and prevent chipping. For machining aluminum, a high-speed steel tool with a larger rake angle might be chosen for efficient material removal and to avoid built-up edge formation.

Q 5. Explain the concept of cutting speed, feed rate, and depth of cut.

Cutting speed (V), feed rate (f), and depth of cut (d) are fundamental parameters in machining that significantly influence the machining process’s efficiency and quality.

- Cutting speed (V): The surface speed of the cutting tool as it moves across the workpiece (measured in feet per minute or meters per minute). A higher cutting speed generally leads to faster material removal but also increases tool wear and heat generation. It’s crucial to find the optimal speed for the material and tool used.

- Feed rate (f): The rate at which the cutting tool advances into the workpiece (measured in inches per revolution or millimeters per revolution). A higher feed rate increases material removal rate but may lead to increased tool wear and poor surface finish.

- Depth of cut (d): The amount of material removed in a single pass (measured in inches or millimeters). A deeper depth of cut increases material removal but may also result in excessive forces on the machine and tool, possibly leading to tool breakage or chatter.

The relationship between these parameters is critical. An improper combination can lead to inefficient machining, poor surface finish, or even tool failure. Manufacturers often use empirical data or computer simulations to optimize these parameters for specific machining operations.

Q 6. How do you calculate machining time?

Calculating machining time involves considering the length of each cutting pass, the number of passes required, and the machine’s feed rate and cutting speed. It’s best calculated by breaking down the machining process into individual operations.

Example: Assume we’re milling a rectangular block. Let’s say the length of the cut is 10 inches, the feed rate is 10 inches per minute, and we need 5 passes. The total cutting time for this operation would be (10 inches/10 inches/minute) * 5 passes = 5 minutes.

However, this is a simplified example. Real-world machining time calculations often include additional factors like:

- Setup time: Time required to set up the workpiece and tools.

- Non-cutting time: Time spent on tool changes, workpiece positioning, and other auxiliary operations.

- Approach and retract time: Time the tool takes to approach and retract from the workpiece.

For complex parts, Computer-Aided Manufacturing (CAM) software is used to automate the calculation of machining times, taking all relevant factors into account.

Q 7. Describe different types of grinding machines (e.g., surface, cylindrical).

Grinding machines are designed to remove small amounts of material from workpieces to achieve high precision and surface finish. Several types exist, each suited for specific applications:

- Surface grinding: Uses a rotating wheel to grind flat surfaces. This is widely used for producing precision flat components and for surface finishing.

- Cylindrical grinding: Used to grind cylindrical workpieces like shafts and rollers. This can involve external or internal grinding.

- Centerless grinding: Grinds cylindrical parts without using a center. It’s efficient for high-volume production of cylindrical parts with consistent dimensions.

- Internal grinding: Grinds the inside diameter of cylindrical parts or holes.

- Creep feed grinding: A specialized technique involving extremely slow feed rates and high downfeed rates to remove large amounts of material, often used for difficult-to-machine materials.

The choice of grinding machine depends on the workpiece geometry, required precision, and production volume. For instance, surface grinding is ideal for creating flat surfaces, cylindrical grinding is used for cylindrical components, and internal grinding is necessary for machining inner diameters.

Q 8. What are the common causes of grinding wheel wear?

Grinding wheel wear is a natural consequence of the abrasive process, but excessive wear can significantly impact part quality and machining efficiency. Several factors contribute to this:

- Abrasive Grain Wear: The abrasive grains on the wheel dull and fracture due to repeated impacts with the workpiece. This is the primary cause of wear and is influenced by factors like the type of abrasive, bond strength, and workpiece material hardness.

- Bond Degradation: The bond holding the abrasive grains together can wear away, causing grains to be lost and leading to wheel glazing (a smooth, non-cutting surface). This is often accelerated by high temperatures or improper coolant application.

- Attrition: The abrasive grains can wear down by rubbing against each other, particularly in grinding operations where the wheel is under heavy load.

- Thermal Cracking: High temperatures generated during grinding can cause thermal stresses that lead to cracks in the wheel, weakening it and accelerating wear. This is more prevalent with harder workpieces or aggressive grinding parameters.

- Loading: The wheel can become loaded with workpiece material, reducing its cutting ability and increasing wear. This is often visible as a buildup of material on the wheel face.

Understanding these causes is crucial for selecting the appropriate grinding wheel, optimizing grinding parameters, and implementing effective wheel dressing techniques to maintain optimal performance and extend wheel life.

Q 9. How do you measure surface roughness after grinding?

Surface roughness after grinding is measured using a profilometer, which uses a stylus to trace the surface profile and measure the deviations from a mean line. The result is expressed as Ra (average roughness) or Rz (ten-point height), usually in micrometers (µm) or microinches (µin). Ra represents the average deviation of the profile from the mean line, while Rz represents the difference between the highest and lowest points within a sampling length.

Other methods, like optical profilometry or confocal microscopy, provide non-contact surface roughness measurements and are becoming increasingly popular. The selection of a measurement technique depends on the desired accuracy, surface characteristics, and the available equipment.

Imagine trying to measure the roughness of a freshly painted wall versus a piece of sandpaper. The profilometer is like a highly sensitive fingertip feeling the texture, providing quantitative data about the bumps and valleys of the surface.

Q 10. Explain the importance of coolant in machining and grinding operations.

Coolant plays a vital role in both machining and grinding operations by performing several crucial functions:

- Cooling: It reduces the heat generated during cutting, preventing workpiece and tool damage from thermal softening or burning. This is especially critical in grinding, where high temperatures are generated.

- Lubrication: Coolant reduces friction between the tool and workpiece, improving surface finish and extending tool life. It forms a lubricating film that minimizes wear and tear.

- Chip Removal: Coolant helps to flush away chips and debris, preventing them from accumulating and interfering with the cutting process. This is essential for maintaining consistent cutting performance and preventing damage to the workpiece or machine.

- Corrosion Prevention: Some coolants offer corrosion protection, preventing rust and oxidation on the workpiece, tools, and machine components.

The type of coolant (e.g., water-soluble oil, synthetic coolants) selected depends on the material being machined and the specific application requirements. Insufficient coolant can lead to poor surface finish, tool wear, and even fires.

Q 11. How do you troubleshoot common machining errors (e.g., chatter, tool breakage)?

Troubleshooting machining errors requires a systematic approach. Let’s consider chatter and tool breakage:

Chatter: This is characterized by high-frequency vibrations during cutting, resulting in a poor surface finish and potential tool damage. Troubleshooting involves:

- Reduce cutting speed and feed rate: Lowering these parameters can often reduce or eliminate chatter.

- Increase cutting depth: A deeper cut can sometimes provide better stability.

- Improve clamping rigidity: Ensure that the workpiece and tool are securely clamped to minimize vibrations.

- Optimize tool geometry: Using a different tool insert or geometry can improve stability.

- Check machine condition: Worn bearings, spindle problems, or loose parts in the machine itself can contribute to chatter.

Tool Breakage: This can be due to various factors, including:

- Incorrect tool selection: Using a tool that’s not appropriate for the material or cutting parameters.

- Excessive cutting forces: This often happens when pushing the limits of the machine or tool.

- Tool wear: Worn or damaged tools are more prone to breakage.

- Improper clamping: If a tool is not securely clamped, it can break under stress.

- Workpiece defects: Cracks or other defects in the workpiece can lead to unpredictable forces and tool breakage.

In both cases, careful observation of the machining process, systematic investigation, and diligent record-keeping are crucial for pinpointing the root cause and implementing effective solutions.

Q 12. What safety precautions are necessary when operating machining and grinding equipment?

Safety is paramount when operating machining and grinding equipment. Key precautions include:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses or goggles, hearing protection, and machine-specific safety equipment (e.g., face shields for grinding, cut-resistant gloves).

- Machine Guards: Ensure that all machine guards are in place and functioning correctly before operation. Never operate a machine with missing or damaged guards.

- Lockout/Tagout Procedures: Follow proper lockout/tagout procedures before performing any maintenance or repair work on the machine. This prevents accidental startup.

- Proper Tool Handling: Handle tools carefully to prevent dropping or accidental injuries. Inspect tools for damage before use.

- Safe Work Practices: Maintain a clean and organized workspace. Keep hands, hair, and loose clothing away from moving parts. Be aware of your surroundings and avoid distractions.

- Emergency Shutdown Procedures: Know the location and operation of emergency stop buttons and other safety mechanisms.

- Training and Certification: Ensure that all operators are properly trained and certified on the machines they operate.

Ignoring safety precautions can lead to serious injury or even death. A culture of safety is crucial in any machining environment.

Q 13. Explain the concept of tolerance and its importance in machining.

Tolerance in machining refers to the permissible variation in the dimensions or geometry of a manufactured part. It’s defined as the acceptable range of deviation from a specified nominal value. Tolerances are crucial because they:

- Ensure Functionality: Tolerances ensure that parts will fit together correctly and function as intended. Imagine a car engine – if the parts aren’t manufactured to the correct tolerances, the engine won’t work.

- Control Costs: Tight tolerances increase manufacturing costs, while overly loose tolerances can result in poor quality and functionality. Finding the optimal balance is key.

- Define Quality Standards: Tolerances serve as a measure of the quality and precision of a manufacturing process.

Tolerances are expressed on engineering drawings using various notations (e.g., ±0.01 mm, ISO 286 standard). The level of tolerance required depends on the application and the criticality of the part’s function.

For example, a tolerance of ±0.1 mm might be acceptable for a low-precision part, while a tolerance of ±0.001 mm might be necessary for a highly precise component in aerospace engineering.

Q 14. How do you interpret engineering drawings?

Interpreting engineering drawings requires a systematic approach and understanding of various symbols, conventions, and notations. Key elements to focus on include:

- Views: Drawings often use multiple views (front, top, side) to show the part’s three-dimensional shape. Understanding orthographic projection is fundamental.

- Dimensions: Dimensions specify the sizes of the part’s features, including length, width, height, and diameter. Tolerances are usually specified with the dimensions.

- Material Specification: The drawing indicates the material the part is made from (e.g., steel, aluminum, plastic). This is essential for selecting appropriate machining processes.

- Surface Finish: Symbols and specifications denote the required surface roughness or texture. This influences the choice of machining process and parameters.

- Tolerances: As explained earlier, these specify the permissible variations in dimensions.

- Notes and Specifications: Any special instructions, requirements, or additional information is typically given in notes or a parts list.

- Section Views and Details: Often, complex parts require section views or detailed views to clearly show internal features.

Familiarity with standard drafting practices and relevant symbols is essential. Practice and experience are key to developing proficiency in interpreting engineering drawings effectively and accurately. Think of it like reading a map – you need to understand the symbols and conventions to navigate it successfully.

Q 15. Describe the process of setting up a CNC machine.

Setting up a CNC machine is a meticulous process requiring precision and safety. It involves several key steps, starting with verifying the machine’s physical condition and ensuring its environment is suitable. This includes checking for any obstructions, loose parts, or damage. Next, we carefully load the CNC program, ensuring it’s the correct one for the job. This often involves checking the program’s parameters against the workpiece specifications and the tooling.

Then comes the tool setup. This is critical for accuracy. Each cutting tool is precisely positioned in its designated holder, ensuring it’s properly clamped and aligned. We use tool setting procedures, like edge finders or touch probes, to accurately determine the tool’s position relative to the machine’s coordinate system. This eliminates errors stemming from incorrect tool length offsets.

Following tool setup, workpiece fixturing is crucial. The workpiece needs to be securely held in place, preventing movement during machining. This often involves using specialized vises, clamps, or chucks. Incorrect fixturing can lead to inaccurate cuts and potentially damage the machine. Finally, a test run (often at a reduced speed and depth of cut) is conducted to verify the program’s accuracy, toolpaths, and workpiece security before proceeding with the full production run. This ensures early identification of potential issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of grinding fluids and their purposes?

Grinding fluids, also known as coolants, are essential in grinding operations. They serve several critical purposes: lubrication, cooling, and cleaning. Different types cater to various needs.

- Water-based fluids: These are commonly used and offer good cooling and lubricity. They’re relatively inexpensive and environmentally friendly, but can be prone to bacterial growth if not managed properly. They can also lead to rust formation on certain materials.

- Oil-based fluids: These offer superior lubrication, particularly for difficult-to-machine materials. They provide better protection against rust but are less effective at cooling and can be more expensive and environmentally less desirable.

- Synthetic fluids: These offer a balance between the properties of water and oil-based fluids, often providing excellent lubricity, cooling, and corrosion protection. They are typically more expensive but offer improved performance in many applications.

- Semi-synthetic fluids: A blend of synthetic and oil-based coolants providing enhanced properties tailored to specific needs.

The choice of grinding fluid depends on factors like the material being ground, the grinding process parameters (speed, feed, depth of cut), and environmental concerns. For instance, a water-based fluid might suffice for grinding mild steel, but a synthetic fluid may be necessary for grinding hardened tool steels.

Q 17. How do you perform a pre-operation inspection of a CNC machine?

A pre-operation inspection of a CNC machine is critical for safety and accuracy. It involves a systematic check of several key aspects:

- Visual Inspection: Examine the machine for any obvious damage, loose parts, or signs of wear. Check coolant lines, electrical connections, and safety guards.

- Functional Tests: Check the machine’s movement axes, ensuring they move smoothly and accurately. Test the spindle’s speed and rotation. Verify the proper functioning of the coolant system.

- Tooling Check: Inspect cutting tools for wear or damage. Ensure that they are properly secured in their holders.

- Workpiece Inspection: Ensure that the workpiece is free of defects that could affect the machining process. Double-check dimensions and verify the material type.

- Program Verification: Review the CNC program to ensure it’s correct and suitable for the workpiece and tooling. Simulate the program on the machine, whenever possible, to preview the toolpaths.

- Safety Checks: Ensure that all safety interlocks and guards are functioning correctly. Verify emergency stop mechanisms and appropriate safety protocols are in place.

A thorough pre-operation inspection minimizes the risk of accidents and ensures high-quality machining, reducing the likelihood of scrap.

Q 18. What are the different types of measuring instruments used in machining?

Machining relies on precise measurements. We use a variety of instruments, each suited for specific tasks:

- Vernier Calipers: Accurate for measuring linear dimensions and depths.

- Micrometers: Provide even higher precision for measuring smaller dimensions.

- Dial Indicators: Used to check surface flatness, parallelism, and runout.

- Height Gauges: Measure heights and distances precisely.

- Coordinate Measuring Machines (CMMs): Highly accurate for complex three-dimensional measurements.

- Optical Comparators: Compare the workpiece with a master template for detecting minor deviations.

- Digital Indicators: Provide direct digital readout of measured values.

The choice of measuring instrument depends on the required accuracy, the complexity of the part, and the specific measurement needed. For example, a vernier caliper might suffice for checking overall dimensions, while a CMM is necessary for complex geometries requiring high accuracy.

Q 19. How do you maintain and clean machining and grinding equipment?

Maintaining and cleaning machining and grinding equipment is crucial for extending its lifespan, ensuring accuracy, and promoting safety. Regular cleaning removes chips and debris, preventing damage and improving performance. This includes:

- Regular Cleaning: Remove chips and debris from the machine bed, ways, and other components after each operation. Use appropriate cleaning solvents and brushes.

- Coolant System Maintenance: Regularly flush the coolant system to remove contaminants. Change the coolant as needed, adhering to recommended intervals.

- Lubrication: Lubricate moving parts as per the manufacturer’s recommendations. Use the correct type and quantity of lubricant.

- Inspection and Adjustment: Regularly inspect belts, pulleys, and other moving components for wear. Adjust them as needed.

- Periodic Maintenance: Conduct more thorough periodic maintenance, potentially involving professional technicians, to address more complex tasks such as adjusting machine settings, replacing worn components, or calibration.

Proper maintenance extends the machine’s life, prevents downtime, and ensures consistently accurate work.

Q 20. Explain the concept of workholding in machining.

Workholding in machining refers to the method used to secure the workpiece during the machining process. It’s critical for ensuring accuracy, safety, and efficient material removal. Poor workholding can lead to inaccurate dimensions, surface imperfections, and even damage to the workpiece or the machine.

The ideal workholding method depends on several factors including workpiece geometry, material properties, and the type of machining operation. Common methods include:

- Vises: Versatile and commonly used for holding workpieces securely.

- Clamps: Offer greater flexibility for holding complex shapes.

- Chucks: Used for rotating workpieces, particularly in lathe operations.

- Magnetic Chucks: Ideal for holding ferromagnetic materials.

For example, a simple vise might be suitable for milling a flat piece of metal, while a more sophisticated fixture may be required to hold a complex component during a multi-axis milling operation. Selecting the appropriate workholding method is vital for success.

Q 21. Describe different types of cutting fluids and their properties.

Cutting fluids, also known as coolants or lubricants, are crucial in machining to improve the efficiency and quality of the cutting process. They perform multiple functions: cooling, lubricating, and chip removal. Different types exist, each with specific properties:

- Water-based fluids: These are inexpensive, readily available, and offer good cooling. However, they may not provide sufficient lubrication for some materials or operations.

- Oil-based fluids: Provide excellent lubrication, particularly for difficult-to-machine materials. However, they’re less effective at cooling and can create environmental concerns.

- Synthetic fluids: Offer a balance of cooling and lubrication, often with enhanced properties such as rust inhibition and reduced environmental impact. They are more expensive.

- Emulsions: These are mixtures of oil and water, combining the advantages of both types. The concentration of oil and water can be adjusted to suit specific needs.

The properties of a cutting fluid directly impact the machining process. For example, inadequate cooling can lead to excessive heat buildup, resulting in tool wear, workpiece distortion, and poor surface finish. Insufficient lubrication can cause increased friction, leading to tool breakage and reduced tool life. Choosing the correct cutting fluid is vital for optimal results and efficiency, considering the materials involved, the machining process, and the overall cost-effectiveness.

Q 22. What is the purpose of a fixture in machining?

A fixture in machining is a workholding device that securely positions and supports a workpiece during the machining process. Think of it as a vise, but often much more sophisticated. Its primary purpose is to ensure accurate and repeatable machining operations, preventing workpiece movement that could lead to inaccurate dimensions or damage to the workpiece or the cutting tool. Without a properly designed fixture, even the most precise machine tool can produce inaccurate parts.

Fixtures can range from simple clamps and vises to complex multi-axis systems with integrated sensors for precise workpiece location. The complexity of the fixture is directly related to the complexity of the part and the tolerances required. For example, a simple block might only need a simple vise, whereas a complex aerospace component might require a highly specialized fixture with numerous clamping points and alignment features.

A well-designed fixture ensures consistent part quality by minimizing variations caused by improper workpiece positioning. It also improves operator safety by securely holding the part during potentially hazardous operations.

Q 23. How do you identify and correct common grinding defects?

Identifying and correcting grinding defects requires a systematic approach. The first step is careful observation of the workpiece to identify the type of defect. Common grinding defects include chatter marks (wavy surface), burns (discolored, heat-affected zones), glazing (smooth, shiny surface with reduced hardness), and surface cracks.

- Chatter marks are usually caused by excessive vibration, which can be due to improper machine setup, worn machine components, or insufficient clamping pressure on the workpiece. Correction involves improving machine rigidity, balancing the grinding wheel, ensuring proper workpiece clamping and optimal cutting parameters.

- Burns occur due to excessive heat generation, often caused by too high a feed rate, too low a depth of cut or a dull grinding wheel. Reducing these parameters is the first step. Using a coolant is crucial for heat dissipation.

- Glazing is caused by a wheel that is not cutting efficiently often from being too fine. Dressing the grinding wheel to expose fresh abrasive grit and using a more aggressive grinding wheel will remedy this.

- Surface cracks are a sign of excessive stress on the workpiece during grinding. Reducing the grinding force, using a coolant, or modifying the grinding process to use multiple passes are strategies for crack prevention.

Microscopic examination may be necessary to pinpoint the cause in more complex cases. It’s a combination of understanding the grinding process, knowing your machinery, and implementing appropriate corrective measures based on observation and analysis.

Q 24. Explain different methods for measuring roundness and cylindricity.

Roundness and cylindricity are crucial parameters for many machined parts. Several methods are used to measure these geometric characteristics:

- Dial indicators: A simple and widely used method for roundness measurement. The workpiece is rotated, and a dial indicator measures the radial variation. This provides a good approximation, but accuracy is limited by the resolution of the dial indicator and the precision of the setup.

- Coordinate Measuring Machines (CMMs): CMMs are highly accurate machines that use probes to measure various points on the workpiece surface. The data gathered can be used to generate a roundness profile. CMMs offer much greater accuracy and can also measure cylindricity, incorporating length measurements.

- Laser scanning systems: Non-contact measurements provide high speed and accuracy in roundness and cylindricity assessment. The laser scans the surface, generating a detailed 3D model from which roundness and cylindricity deviation can be extracted.

- Roundness testers: These specialized instruments are specifically designed for accurate and precise roundness measurements. They offer various features like advanced data analysis and reporting functionalities.

The choice of method depends on the required accuracy, the complexity of the part, and the available resources. For very high precision work, CMMs or laser scanning systems are often preferred, while dial indicators are suitable for simpler parts or quick checks.

Q 25. What is the significance of surface finish in machining?

Surface finish is a critical aspect of machined parts. It refers to the texture or roughness of the surface and significantly impacts several properties of the component:

- Functional performance: Surface finish affects things like friction, wear resistance, fatigue strength, and sealing capabilities. A smoother surface generally reduces friction and wear.

- Aesthetics: For visible components, surface finish is paramount for its contribution to the overall appearance and quality.

- Corrosion resistance: Rough surfaces can trap contaminants and promote corrosion. A smoother surface provides better corrosion resistance.

- Manufacturing costs: Achieving a very fine surface finish usually requires additional machining operations, thus increasing production costs.

The desired surface finish depends on the application. For example, a bearing surface requires an extremely smooth finish for low friction, while a structural component might only need a relatively rough finish for sufficient strength.

Surface finish is usually specified using parameters like Ra (average roughness), Rz (ten-point height), and other roughness parameters. These values are determined through surface profilometry.

Q 26. How do you determine the optimal grinding parameters for a specific application?

Determining optimal grinding parameters is crucial for efficient and high-quality grinding. These parameters are interconnected and must be carefully chosen to achieve desired results:

- Wheel speed: Influences the cutting action and heat generation. Too high a speed can lead to burning, while too low a speed can result in slow grinding and poor surface finish.

- Work speed: The speed at which the workpiece moves relative to the grinding wheel. This affects the material removal rate and surface finish.

- Depth of cut: The amount of material removed in each pass. Deeper cuts result in higher material removal rates but also generate more heat and stress on the workpiece.

- Feed rate: The speed at which the workpiece advances along the grinding wheel. This influences the material removal rate and surface finish.

- Coolant selection and flow rate: Crucial for heat dissipation and to ensure adequate lubrication of the grinding zone.

- Wheel type and grade: The choice of grinding wheel significantly impacts the grinding efficiency and surface quality. The wheel’s hardness and grain size must be matched to the workpiece material.

The optimal parameters are often determined through experimentation and are often specific to the material being ground, the desired surface finish and tolerances, and the grinding machine itself. Software tools and empirical data from previous grinding operations are also very useful in optimizing these parameters. Often a series of test runs is required to refine the parameters.

Q 27. Describe your experience with different types of CNC programming software.

Throughout my career, I’ve had extensive experience with several CNC programming software packages. My proficiency includes:

- Mastercam: I’m highly proficient in using Mastercam for creating complex 2D and 3D machining programs. I have experience with various milling, turning, and grinding strategies, including high-speed machining and 5-axis programming.

- NX CAM: I have worked extensively with NX CAM for various machining applications. Its advanced features for simulation and optimization have been instrumental in enhancing efficiency and accuracy in my work.

- Fusion 360: Fusion 360’s integrated design and CAM capabilities provide a streamlined workflow. I have used it for smaller projects and rapid prototyping, taking advantage of its intuitive interface and cloud-based collaboration features.

My experience extends to post-processor customization and the generation of G-code for various CNC machine controllers. I am comfortable working with different control systems and adapting my programming skills to the specific requirements of each machine. I am also adept at using CAM software to analyze toolpaths and optimize cutting parameters for enhanced productivity and reduced cycle times.

Q 28. How would you handle a situation where a machine malfunctions during production?

Machine malfunctions during production are a serious matter. My approach involves a systematic process:

- Safety First: The immediate priority is to ensure the safety of myself and other personnel. This involves immediately shutting down the machine and clearing the area.

- Assessment: The next step is to identify the nature of the malfunction. This might involve checking error messages on the machine control, visually inspecting the machine, or consulting machine manuals and documentation.

- Troubleshooting: Based on the assessment, I will try to identify the root cause of the problem. This may involve checking for loose connections, worn parts, or other mechanical issues.

- Repair or Maintenance: If I can safely and effectively repair the problem myself, I will do so. If the problem is beyond my immediate capability, I will contact maintenance personnel or the machine supplier for assistance. A detailed report of the malfunction and the corrective actions taken will be documented.

- Preventive Measures: Once the problem is resolved, I will take steps to prevent similar incidents in the future. This might involve better machine maintenance procedures or operator training.

- Documentation and Reporting: A thorough report on the malfunction and the corrective actions must be made and filed for future reference and analysis. This allows improvements in machine maintenance protocols and operator training.

My experience and training equip me to handle many common machining malfunctions, but I understand the importance of seeking expert help when necessary.

Key Topics to Learn for Machining and Grinding Techniques Interview

- Fundamentals of Machining Processes: Understanding various machining operations like turning, milling, drilling, and their applications in different industries. Consider the theoretical principles behind material removal rates and cutting forces.

- Grinding Techniques and Applications: Explore different grinding methods (surface, cylindrical, centerless), abrasive selection, and the importance of wheel speed and feed rates. Understand the applications of grinding for precision finishing and surface quality improvement.

- Tooling and Tool Geometry: Learn about different types of cutting tools (single-point, multi-point), their geometry, and how it affects machining performance. Discuss the selection criteria for tools based on material, operation, and desired finish.

- CNC Machining and Programming: Familiarize yourself with CNC machine operation, G-code programming, and setup procedures. Understand the importance of proper programming for accuracy and efficiency.

- Measurement and Quality Control: Master the use of various measuring instruments (calipers, micrometers, CMM) to ensure dimensional accuracy and surface finish. Understand quality control procedures and statistical process control (SPC) concepts.

- Material Selection and Properties: Gain a strong understanding of the properties of different machinable materials (metals, plastics, composites) and how these properties affect machining processes. Understand the implications of material selection on tooling and process parameters.

- Troubleshooting and Problem-Solving: Develop skills in diagnosing and resolving common machining and grinding issues, such as tool wear, surface defects, and dimensional inaccuracies. Practice applying your theoretical knowledge to practical scenarios.

- Safety Procedures and Practices: Demonstrate a thorough understanding of safety regulations and procedures related to machining and grinding equipment. This is crucial for any role in this field.

Next Steps

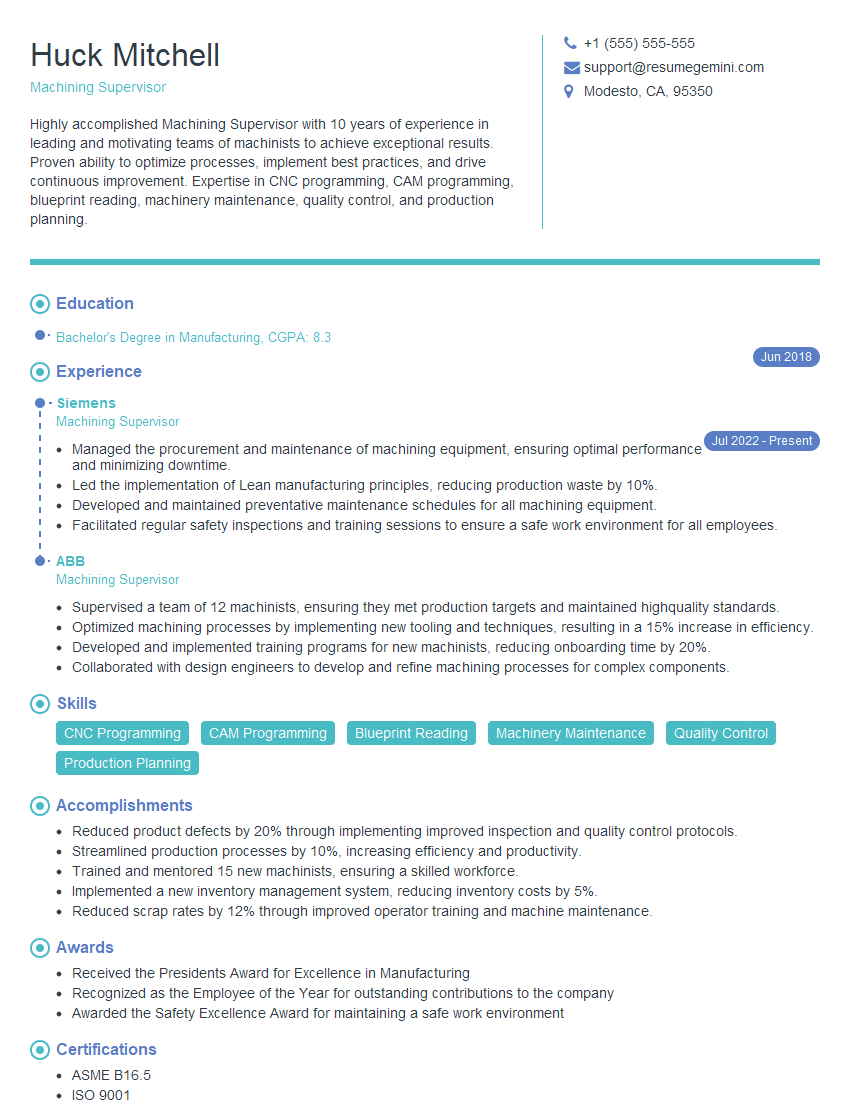

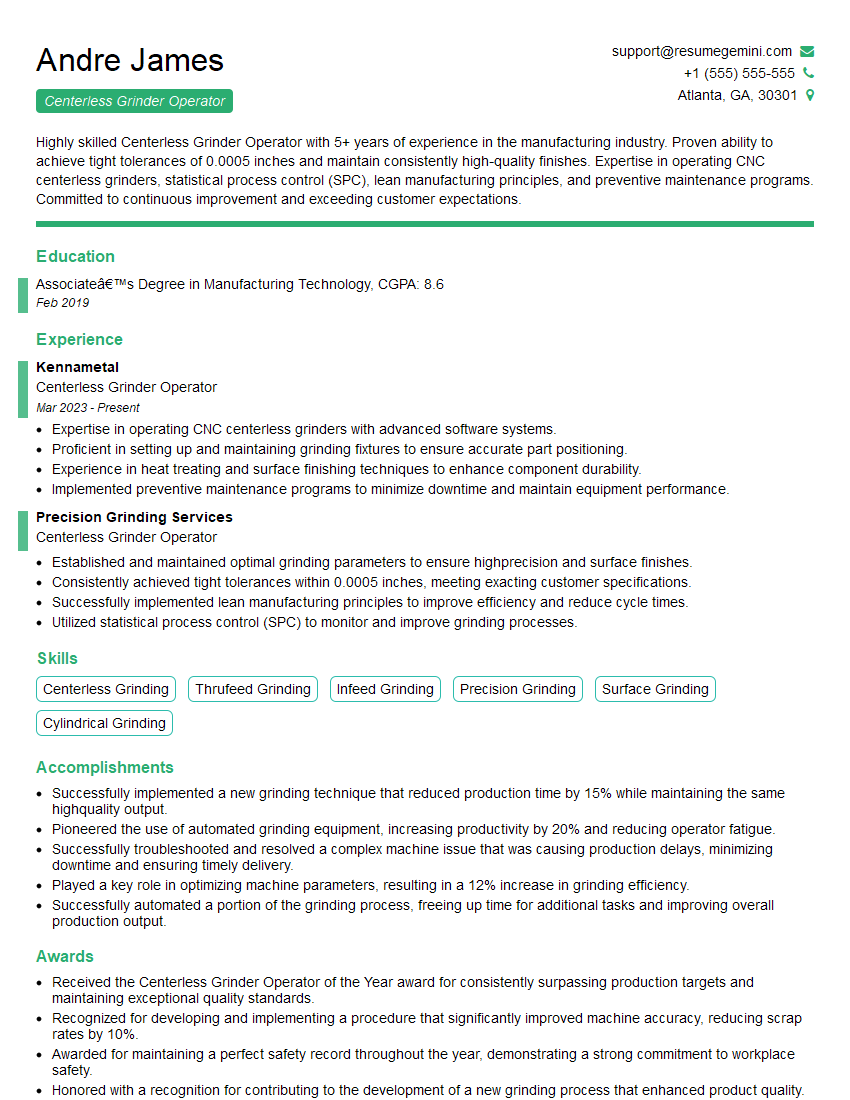

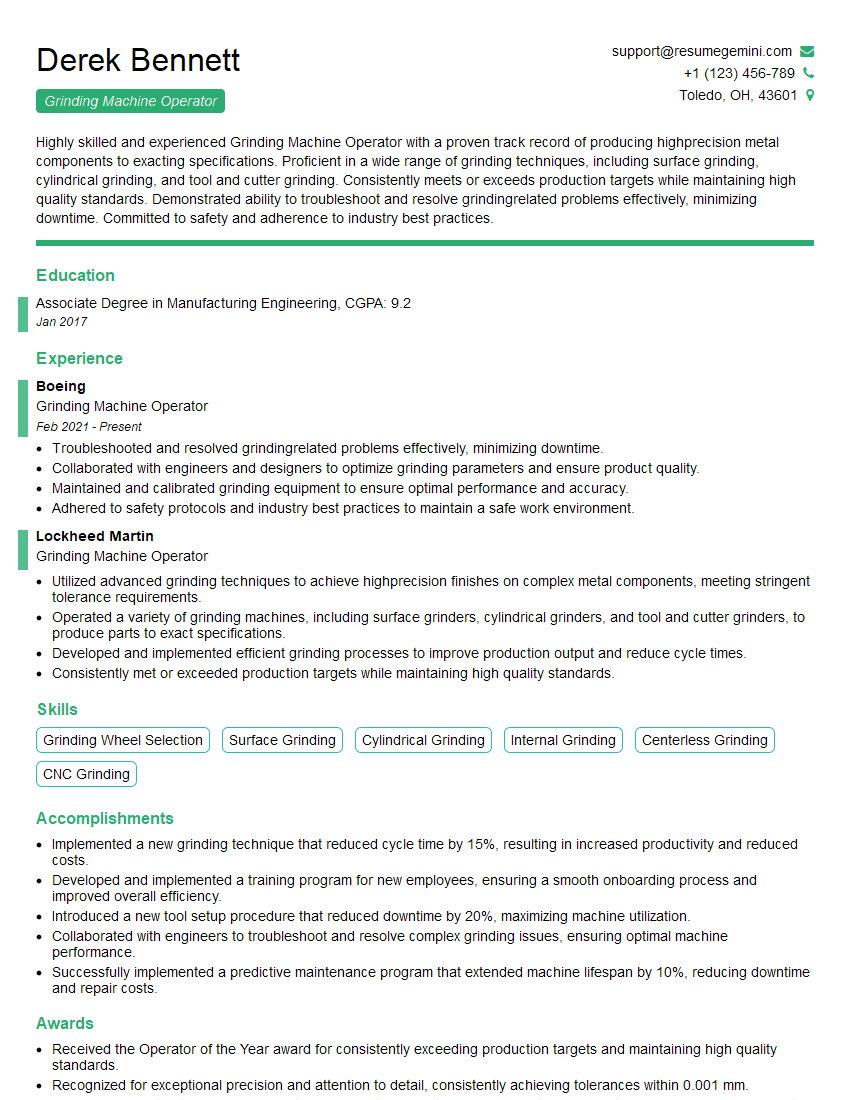

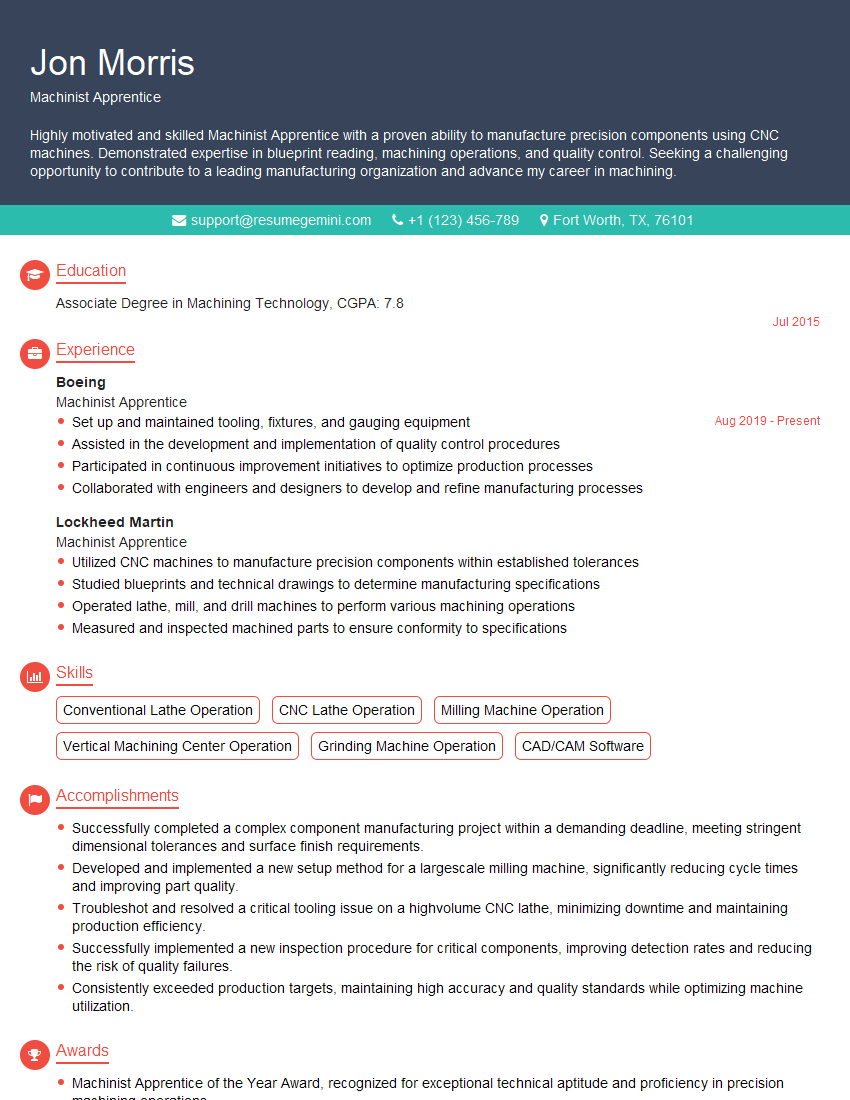

Mastering Machining and Grinding Techniques opens doors to exciting and rewarding career opportunities in manufacturing, aerospace, automotive, and many other high-growth industries. To stand out from the competition, a well-crafted resume is essential. An ATS-friendly resume increases your chances of getting your application noticed by recruiters and hiring managers. ResumeGemini is a trusted resource that can help you build a professional and effective resume. They provide examples of resumes tailored to Machining and Grinding Techniques, so you can create a document that showcases your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO