The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Maintain Work Area interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Maintain Work Area Interview

Q 1. Describe your experience maintaining a clean and organized workspace.

Maintaining a clean and organized workspace isn’t just about aesthetics; it’s crucial for safety, efficiency, and productivity. My approach is based on a proactive, systematic method, combining regular cleaning with preventative measures to avoid clutter build-up. This involves a daily routine of tidying up after each task, ensuring tools are returned to their designated places, and removing any unnecessary items. Weekly, I conduct a more thorough cleaning, focusing on hard-to-reach areas and sanitizing frequently touched surfaces. Think of it like a gardener tending to a garden; consistent, smaller efforts prevent larger, more time-consuming cleanups later. In one instance, I worked in a lab where meticulous organization prevented cross-contamination and improved workflow significantly. We had designated areas for different chemicals, clearly labeled containers, and a strict ‘clean-as-you-go’ policy.

Q 2. What cleaning products and equipment are you familiar with?

My familiarity with cleaning products and equipment spans a wide range, depending on the specific environment and task. For general cleaning, I’m proficient with all-purpose cleaners, disinfectants (like bleach solutions – always diluted properly!), glass cleaners, and floor cleaners. For specialized tasks, I’ve used industrial-strength degreasers, solvents (with appropriate safety precautions), and specialized cleaning agents for specific materials. Equipment-wise, I’m experienced with mops, brooms, vacuum cleaners, pressure washers (for outdoor areas), and various cleaning tools like scrub brushes, sponges, and microfiber cloths. I’m also comfortable using industrial cleaning equipment like floor buffers and carpet extractors when necessary. Safety is paramount; I always refer to the safety data sheets (SDS) for any chemical I use to understand proper handling procedures and personal protective equipment (PPE) requirements.

Q 3. How do you prioritize cleaning tasks in a busy environment?

Prioritizing cleaning tasks in a busy setting requires a structured approach. I utilize a combination of urgency and importance to create a prioritized list. High-priority tasks are those that directly impact safety or operational efficiency, like spills, biohazards, or blocked walkways. Medium-priority tasks are those that impact workplace aesthetics or general hygiene, such as dusting or vacuuming. Low-priority tasks are often scheduled during periods of lower activity. This method, essentially a form of time management, allows me to address critical issues immediately while ensuring the overall cleanliness of the environment is maintained. For example, addressing a chemical spill takes precedence over dusting shelves. A simple color-coded system, or a task management app can help visually organize and track progress.

Q 4. Explain your process for handling hazardous waste.

Handling hazardous waste demands strict adherence to safety regulations and established protocols. My process involves:

- Identification: Correctly identifying the type of hazardous waste (e.g., chemical, biological, sharps).

- Segregation: Separating different types of hazardous waste into designated containers.

- Storage: Storing waste in appropriately labeled containers in designated areas, adhering to temperature and containment requirements.

- Documentation: Maintaining detailed records of waste generation, storage, and disposal.

- Disposal: Coordinating with licensed waste disposal companies to ensure proper and safe removal of hazardous materials according to all applicable regulations.

Q 5. How do you ensure workplace safety while performing maintenance tasks?

Workplace safety is my top priority. I consistently follow safety procedures, using appropriate PPE (gloves, safety glasses, respirators when necessary), and following all established safety protocols. Before starting any maintenance task, I inspect the work area for potential hazards, like electrical wiring, slippery surfaces, or obstructed walkways. I’ll employ safety barriers or warning signs when needed. Regular equipment maintenance, including inspections for wear and tear, is also critical to prevent accidents. For example, ensuring ladders are stable and free from defects is essential for safe work at height. Furthermore, I always report any unsafe conditions or accidents immediately to the appropriate personnel.

Q 6. Describe your experience with preventative maintenance.

Preventative maintenance is crucial in minimizing downtime and extending the lifespan of equipment. My experience involves regular inspections of equipment, identifying potential issues before they become major problems. This includes tasks like lubricating moving parts, tightening loose screws, cleaning filters, and replacing worn-out components. I keep detailed logs of all maintenance activities, including dates, procedures performed, and any parts replaced. Regularly scheduling preventative maintenance helps avoid unexpected breakdowns and reduces the need for costly repairs. In my previous role, we instituted a preventative maintenance program for our industrial machinery, reducing downtime by 20% within six months.

Q 7. How do you identify and report maintenance issues?

Identifying and reporting maintenance issues follows a clear procedure. When I observe a problem, I thoroughly document the issue – including location, nature of the problem, potential impact, and any safety concerns. I use a formal reporting system, usually a computerized maintenance management system (CMMS), to log the issue. This system allows tracking, prioritizing, and assigning the repair to the appropriate personnel. For urgent issues, I’ll notify the relevant supervisor immediately. Clear and concise reporting is crucial for efficient problem-solving and preventing escalation. For instance, a dripping faucet might seem minor, but left unattended, it can lead to significant water damage.

Q 8. What are your methods for dealing with spills and accidents?

My approach to spills and accidents prioritizes safety and efficiency. First, I assess the situation – identifying the type of spill (chemical, food, etc.) and its volume. This dictates the appropriate response. For example, a small water spill might only require absorbent towels, while a chemical spill necessitates a specialized kit and potentially evacuation procedures (depending on the severity and the workplace’s safety protocols).

I always use personal protective equipment (PPE) like gloves, eye protection, and appropriate clothing depending on the substance. My next steps include containing the spill to prevent further spread using absorbent materials or containment booms. Then, I carefully clean the area, following the instructions on any safety data sheets (SDS) for chemicals involved. Finally, I properly dispose of the contaminated materials according to safety regulations and document the incident. A detailed report is crucial for future preventative measures and safety analysis.

For instance, during my time at a large office complex, we had a significant coffee spill. By immediately implementing the spill control protocol, we prevented it from spreading to nearby workstations, minimizing disruption. Thorough cleaning and prompt documentation ensured a swift return to normalcy.

Q 9. How do you manage your time effectively when performing multiple cleaning tasks?

Effective time management during multiple cleaning tasks involves prioritization and organization. I start by creating a checklist or schedule, prioritizing tasks based on urgency and impact. This might involve tackling high-traffic areas first or focusing on tasks that require longer preparation time. I break down large tasks into smaller, manageable steps to prevent feeling overwhelmed.

Using a timer to allocate specific times for each task enhances efficiency. For example, I might allot 15 minutes for vacuuming a particular area and then move onto another task. Regular breaks are crucial for maintaining focus and preventing fatigue. Additionally, I always strive to complete tasks logically, using a systematic approach that avoids wasted movement. Think of it like a choreographed dance; each step is planned, smooth, and efficient.

During my previous role, managing a large retail space, this method reduced cleaning time by 15% while maintaining the same high standard of cleanliness. The optimized workflow enabled me to cover more ground and complete all cleaning tasks in a timely manner.

Q 10. What are your strategies for maintaining a hygienic work environment?

Maintaining a hygienic work environment involves a multifaceted approach. It begins with regular cleaning and disinfection of all surfaces, including floors, countertops, restrooms, and equipment. This includes using appropriate cleaning agents based on the type of surface and the level of soiling. I’m always careful to follow the manufacturer’s instructions for both safety and effectiveness.

Beyond routine cleaning, I emphasize proper waste management. This entails regular emptying of trash cans, recycling materials appropriately, and disposing of hazardous waste according to regulations. Another key element is good ventilation to mitigate the spread of airborne contaminants. Finally, I encourage consistent hand hygiene among the staff, providing hand sanitizer dispensers in key locations and reinforcing the importance of regular hand washing.

In one instance, I implemented a color-coded cleaning system to prevent cross-contamination in a food preparation area. This simple visual cue was incredibly effective at improving hygiene practices.

Q 11. Explain your experience with different types of cleaning equipment (e.g., vacuum cleaners, floor buffers).

I have extensive experience with a wide range of cleaning equipment, including vacuum cleaners (upright, canister, and backpack styles), floor buffers (both high-speed and low-speed), carpet extractors, and various cleaning solutions. I understand the strengths and weaknesses of each piece of equipment and choose the most appropriate one for each task. For instance, I use a high-speed buffer for polishing hard floors, but a low-speed buffer for delicate surfaces to prevent damage. Similarly, I select vacuum cleaners based on floor type and the level of dirt and debris.

I know how to maintain and troubleshoot common issues. Regular maintenance such as changing vacuum cleaner bags, cleaning filter systems, and inspecting the functionality of the equipment is essential for efficient and safe operation. I am also skilled in safely using and disposing of cleaning solutions following proper safety guidelines.

During my work in a large hospital setting, my proficiency with specialized cleaning equipment for infection control significantly improved our hygiene ratings and reduced the risk of cross-contamination.

Q 12. Describe your experience with inventory management of cleaning supplies.

Inventory management of cleaning supplies is crucial for efficient operations. I use a combination of methods including regular stock checks, keeping detailed inventory records, and using a first-in, first-out (FIFO) system to minimize waste. This involves tracking the quantity and type of each cleaning supply, noting usage patterns, and identifying potential shortages. This data informs purchasing decisions to avoid stockouts or unnecessary overstocking.

I maintain a spreadsheet or digital inventory system that allows for quick and easy monitoring and reporting. It is important to check expiration dates to prevent the use of outdated cleaning supplies, especially those with chemical compositions that could become less effective or even hazardous over time. By utilizing this system, I have successfully reduced waste and minimized costs by efficiently managing our cleaning supply inventory.

In a previous role, I implemented a streamlined inventory system, resulting in a 10% reduction in cleaning supply costs due to reduced waste and more effective purchasing decisions.

Q 13. How do you adapt your cleaning methods to different surfaces and materials?

Adapting cleaning methods to different surfaces and materials is critical for preventing damage and achieving optimal results. I understand the properties of various surfaces – such as wood, tile, marble, carpet, and upholstery – and select cleaning agents and techniques accordingly. For example, I use different mops and cleaning solutions for hardwood floors versus tile floors. I also adjust cleaning techniques depending on the type of soil present (e.g., grease, dirt, stains).

I am always mindful of the potential damage certain cleaning chemicals can have on various surfaces, and never use abrasive cleaners or harsh chemicals that can harm sensitive materials. This requires a strong knowledge of materials and their reaction to various cleaning agents. Before using any new cleaning agent, especially on more delicate surfaces, I always test it on an inconspicuous area first.

In a hotel setting, my ability to adapt cleaning methods to preserve the quality and appearance of various surfaces was essential in maintaining the hotel’s high standard of cleanliness and avoiding costly repairs.

Q 14. How do you ensure the proper disposal of cleaning supplies?

Proper disposal of cleaning supplies is paramount for environmental protection and worker safety. I strictly adhere to all relevant regulations and guidelines, segregating waste according to its type (hazardous or non-hazardous). Hazardous waste, such as chemical cleaners and solvents, requires special handling and disposal through designated channels, often involving specialized contractors. I always consult the safety data sheet (SDS) for specific disposal instructions for each cleaning product.

Non-hazardous waste, such as empty spray bottles and paper towels, is disposed of through standard waste management procedures. It’s crucial to ensure that all containers are properly labeled to avoid confusion and accidents. Regular training on proper waste handling protocols ensures that we maintain a safe and environmentally responsible workplace.

In a previous role, our strict adherence to proper disposal procedures not only ensured a clean and safe work environment but also averted potential fines and environmental damage.

Q 15. How do you communicate effectively with colleagues and supervisors regarding maintenance needs?

Effective communication is paramount in maintenance. I believe in proactive and transparent communication. For routine maintenance needs, I use a combination of methods: daily checklists shared with my supervisor, regular briefings highlighting potential issues or upcoming projects, and a dedicated communication log for tracking progress and any unresolved issues. For urgent needs, I immediately notify my supervisor, outlining the problem, its potential impact, and any immediate actions I’ve taken.

For example, if a critical piece of equipment malfunctions, I’d immediately inform my supervisor, explaining the problem and any safety concerns. Then, depending on my authorization level, I might initiate repairs or request a qualified technician. After the issue is resolved, I’d follow up with a detailed report documenting the problem, solution, and any preventative measures to avoid recurrence.

- Proactive reporting: Anticipating potential issues and reporting them before they escalate.

- Clear and concise communication: Using precise language and avoiding technical jargon unless the recipient understands it.

- Active listening: Paying close attention to feedback and addressing concerns.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using safety data sheets (SDS).

Safety Data Sheets (SDS) are crucial for safe handling of chemicals and materials. My experience involves regularly consulting SDS before handling any new product or cleaning agent. I meticulously review information on hazards, protective measures, first aid procedures, and disposal methods. I ensure that all relevant SDS information is accessible to my team and that we are all properly trained on their use. I also check the SDS for any updates or revisions to ensure we are always using the most current information.

For instance, if I need to use a new floor cleaner, I’ll first consult its SDS. This allows me to understand its potential risks (like skin irritation or flammability), select appropriate Personal Protective Equipment (PPE) like gloves and eye protection, and determine the correct disposal method.

Q 17. How do you troubleshoot minor equipment malfunctions?

Troubleshooting minor equipment malfunctions is a regular part of my work. My approach is systematic and follows a simple process:

- Safety First: Always disconnect power or isolate the equipment before attempting any repair.

- Identify the Problem: Carefully observe the malfunctioning equipment to pinpoint the exact issue.

- Check Obvious Causes: Look for simple issues like unplugged cords, tripped breakers, or jammed mechanisms.

- Consult Manuals: Reference the equipment’s operational manual or online resources for troubleshooting guides or diagrams.

- Perform Basic Repairs: If the cause is identified and the repair is within my skillset, I’ll perform the necessary repairs, always prioritizing safety.

- Escalate if Necessary: If the problem persists or is beyond my expertise, I’ll immediately report it to a qualified technician or supervisor.

For example, if a printer jams, I’d first turn it off, then carefully examine the paper path to remove the jam. If I’m unable to resolve it, I’d consult the printer manual or contact IT support.

Q 18. What are your strategies for dealing with difficult stains or messes?

Dealing with difficult stains and messes requires a methodical approach. I always start by identifying the type of stain or mess to choose the appropriate cleaning agent and method. I prioritize safety by using appropriate PPE and ensuring good ventilation. My strategies involve testing any cleaning agent in an inconspicuous area first to avoid damage.

- Categorization: Identifying the stain type (e.g., grease, blood, ink) guides the choice of cleaning solution.

- Testing: Prevents damage to the surface by trying a cleaning method in an inconspicuous area.

- Sequential cleaning: Employing a graduated approach, starting with less aggressive methods before moving to stronger ones.

- Proper disposal: Handling waste products according to safety regulations and minimizing environmental impact.

For example, for a stubborn grease stain, I might start with a mild dish soap solution, then progress to a degreasing agent if necessary, always following the manufacturer’s instructions and safety precautions.

Q 19. How do you ensure compliance with relevant health and safety regulations?

Compliance with health and safety regulations is non-negotiable. My approach involves several key steps:

- Regular Training: I actively participate in all required health and safety training to stay updated on best practices and regulations.

- Adherence to Procedures: I diligently follow established safety protocols and procedures, including the use of PPE and correct handling of chemicals.

- Hazard Identification and Risk Assessment: I actively identify potential hazards in my work area and report them promptly.

- Record Keeping: I maintain accurate records of all safety-related incidents, inspections, and training.

- Compliance Reporting: I contribute to reporting on compliance with all relevant legislation.

For example, I would always use appropriate safety glasses when using cleaning chemicals, and I would immediately report any near misses or accidents to my supervisor.

Q 20. How do you handle complaints regarding cleanliness?

Handling complaints regarding cleanliness involves a professional and empathetic approach. My process includes:

- Acknowledge and Listen: I actively listen to the complaint, showing empathy and understanding.

- Investigate Thoroughly: I thoroughly investigate the complaint, identifying the root cause of the problem.

- Take Immediate Action: I take immediate action to address the problem, ensuring a prompt resolution.

- Follow Up: I follow up with the complainant to confirm that the issue is resolved to their satisfaction.

- Preventative Measures: I review my cleaning procedures to identify areas for improvement to prevent similar complaints in the future.

For example, if someone complains about a dirty restroom, I would immediately clean it, check if there are any underlying issues (e.g., malfunctioning plumbing), and possibly adjust my cleaning schedule to address the problem effectively.

Q 21. Describe your experience with pest control.

My experience with pest control involves working closely with licensed pest control professionals. My role focuses on preventative measures and reporting any pest sightings immediately. This includes keeping the work area clean and free of debris, properly storing food and waste, and regularly inspecting for signs of infestation. I am also responsible for ensuring that any pest control treatments are carried out safely and effectively, adhering to all safety regulations and guidelines.

For example, I would immediately report any sighting of rodents or insects to my supervisor, who would then arrange for a professional pest control service to deal with the problem.

Q 22. How do you monitor and maintain the cleanliness of restrooms?

Maintaining restroom cleanliness involves a multi-faceted approach focusing on prevention and regular cleaning. It’s not just about cleaning; it’s about creating and maintaining a hygienic environment.

- Regular Cleaning Schedule: I establish a detailed cleaning schedule, typically including daily, weekly, and monthly tasks. Daily tasks might involve wiping down surfaces, refilling soap and paper dispensers, and emptying trash receptacles. Weekly tasks could include deeper cleaning of toilets, floors, and sinks. Monthly tasks would encompass more thorough cleaning and sanitization, including disinfection of high-touch areas.

- Stocking Supplies: Maintaining adequate supplies of soap, paper towels, toilet paper, and hand sanitizer is crucial. I regularly check stock levels and ensure timely replenishment to avoid shortages.

- Proactive Maintenance: I proactively identify and address minor issues like leaky faucets or clogged drains before they become major problems. This prevents larger, more disruptive repairs and minimizes the risk of unsanitary conditions.

- Monitoring and Inspection: Regular inspections are vital to ensure the cleaning schedule is effective. I check for cleanliness, functionality of fixtures, and any signs of damage or vandalism. This allows for immediate corrective action.

- Employee Training: If I manage a team, thorough training on proper cleaning techniques, use of cleaning chemicals, and safety procedures is essential. This ensures consistency and prevents cross-contamination.

For example, in my previous role, we implemented a color-coded cleaning system to differentiate cleaning tasks and ensure complete coverage. This system, along with regular inspections, significantly improved restroom hygiene and reduced the frequency of complaints.

Q 23. Explain your experience with maintaining outdoor areas (e.g., landscaping, snow removal).

My experience with outdoor maintenance encompasses a range of tasks, from routine upkeep to addressing seasonal challenges. I understand the importance of both aesthetic appeal and functional maintenance.

- Landscaping: This includes mowing lawns, trimming hedges, weeding flower beds, and planting seasonal flowers. I’m familiar with proper lawn care techniques, including fertilization and pest control. I prioritize using environmentally friendly practices whenever possible.

- Snow Removal: I have experience operating snow blowers and shovels for clearing walkways and parking lots, ensuring safe passage for pedestrians and vehicles. This includes planning for snow removal during storms and knowing when to salt or sand icy surfaces.

- General Upkeep: This involves tasks such as repairing fences, cleaning gutters, and inspecting outdoor lighting to ensure functionality and safety. I’m adept at identifying potential hazards and taking preventive measures.

- Equipment Maintenance: I understand the importance of properly maintaining landscaping equipment, including regular cleaning, sharpening blades, and scheduling necessary repairs to prevent breakdowns and extend the lifespan of equipment.

For instance, at my previous workplace, I developed a detailed seasonal maintenance plan that included specific tasks for each season. This systematic approach minimized disruption and ensured the outdoor areas were consistently well-maintained and safe.

Q 24. How do you deal with unexpected maintenance issues?

Unexpected maintenance issues require a calm, efficient response. My approach prioritizes safety, damage control, and timely resolution.

- Assessment: The first step is a quick assessment of the situation to determine the nature and extent of the problem. This might involve identifying the source of the problem, assessing the potential hazards, and determining the urgency of the repair.

- Safety First: Safety is paramount. If the issue presents a safety risk, I’ll take immediate steps to secure the area and prevent access until the problem is resolved. This might involve putting up caution tape or temporarily shutting down a section of the building.

- Troubleshooting: I’ll attempt to troubleshoot the problem myself if possible. This often involves consulting manuals, diagrams, or online resources. My experience allows me to quickly identify common issues and implement solutions.

- Seeking Assistance: If I cannot resolve the issue independently, I’ll promptly contact the appropriate individuals or contractors for assistance. This involves clearly explaining the situation, providing any relevant information, and following up to ensure the problem is addressed.

- Documentation: I always meticulously document the issue, the steps taken to resolve it, and the outcome. This creates a record for future reference and helps prevent similar issues from occurring.

For example, I once encountered a sudden power outage during a critical event. I immediately assessed the situation, secured the area, contacted the building management, and worked with them to implement a temporary lighting solution. We successfully minimized disruption and ensured the event continued without major incident.

Q 25. What are your strategies for preventing workplace accidents related to maintenance?

Preventing workplace accidents related to maintenance requires a proactive approach focused on safety training, risk assessment, and the implementation of safety protocols.

- Safety Training: Regular safety training for all maintenance staff is essential. This includes training on the proper use of tools and equipment, safe handling of chemicals, and emergency procedures.

- Risk Assessment: Regular risk assessments identify potential hazards in the workplace. This includes identifying potential slip, trip, and fall hazards, electrical hazards, and chemical hazards. Once identified, appropriate control measures are implemented.

- Personal Protective Equipment (PPE): Ensuring that all maintenance personnel use appropriate PPE, such as safety glasses, gloves, and protective footwear, is crucial. The type of PPE will vary depending on the task being performed.

- Regular Inspections: Regular inspections of equipment and work areas are vital. This ensures that equipment is properly maintained, and that the work environment is safe and free from hazards.

- Lockout/Tagout Procedures: Implementing strict lockout/tagout procedures when working on equipment ensures that the equipment is de-energized and cannot be accidentally turned on during maintenance.

For example, I implemented a system of daily safety checks before each work shift, ensuring that all equipment was in good working order and that the work area was free from hazards. This significantly reduced the number of minor accidents in my previous role.

Q 26. Describe your experience with maintaining equipment logs and records.

Maintaining accurate and up-to-date equipment logs and records is critical for effective maintenance management. This allows for efficient tracking of repairs, maintenance schedules, and overall equipment lifespan.

- Centralized System: I prefer using a centralized system, either a digital database or a well-organized physical filing system, to store all equipment records. This system should be easily accessible to authorized personnel.

- Detailed Information: Each equipment record should include detailed information, such as the equipment’s make, model, serial number, purchase date, and maintenance history. Any repairs or replacements should also be meticulously documented.

- Scheduled Maintenance: The system should track scheduled maintenance tasks, including inspection dates, service dates, and the completion of tasks. This helps prevent equipment failure and ensures compliance with regulatory requirements.

- Inventory Management: The system should also include information about spare parts and supplies, allowing for efficient inventory management and timely ordering of necessary parts.

- Regular Updates: Regular updates of the system are essential. All maintenance activities should be recorded promptly and accurately.

In a previous role, I implemented a digital equipment log using a spreadsheet program. This system was highly effective in tracking equipment maintenance and helped us anticipate and prevent costly repairs. We were also able to generate reports easily, providing valuable data for budget planning and resource allocation.

Q 27. How do you ensure the efficient use of cleaning supplies and minimize waste?

Efficient use of cleaning supplies and waste minimization are crucial for both environmental responsibility and cost-effectiveness.

- Proper Dilution: Always follow the manufacturer’s instructions for diluting cleaning solutions. Over-dilution is ineffective, while over-concentration can be wasteful and potentially harmful.

- Appropriate Cleaning Tools: Use cleaning tools appropriate for the task. Using the right tools minimizes the amount of cleaning solution needed and reduces the risk of damage to surfaces.

- Reusable Supplies: Using reusable microfiber cloths and mops instead of disposable wipes significantly reduces waste. Proper cleaning and sanitization of reusable items are critical.

- Inventory Management: Maintain an inventory of cleaning supplies to prevent overstocking and waste. Regularly check stock levels to avoid purchasing more than necessary.

- Recycling and Disposal: Follow proper procedures for recycling and disposing of cleaning supplies and waste materials. This minimizes environmental impact and promotes sustainability.

For instance, in my previous position, I implemented a system to track cleaning supply usage. This allowed us to identify areas where we could reduce consumption without compromising cleanliness. We were able to cut cleaning supply costs by 15% by optimizing our purchasing and usage.

Q 28. Describe a time you had to deal with a challenging cleaning or maintenance problem.

One challenging cleaning problem involved a significant grease buildup in the kitchen exhaust hood of a restaurant. The grease had accumulated over time, creating a serious fire hazard.

The challenge wasn’t just the sheer amount of grease but also the need to complete the cleaning without disrupting restaurant operations.

- Safety First: The first step was to disconnect the exhaust system and ensure the area was properly ventilated to reduce the risk of fire and exposure to hazardous fumes.

- Degreasing: I used a combination of commercial degreasers and high-pressure washing equipment to remove the grease. This process required multiple applications and thorough rinsing.

- Safety Precautions: Throughout the process, I adhered strictly to safety protocols, wearing appropriate PPE, and following all manufacturer’s instructions for the degreasing agents.

- Time Management: To minimize disruption, I scheduled the cleaning during off-peak hours, working efficiently to complete the task before the restaurant reopened.

- Post-Cleaning Inspection: After the cleaning, I thoroughly inspected the exhaust hood to ensure all grease was removed, preventing future hazards.

Successfully resolving this issue required careful planning, attention to detail, and the appropriate application of cleaning techniques and equipment. It underscored the importance of both proactive maintenance and having a strategy for dealing with unexpected, substantial maintenance needs. The restaurant manager was extremely pleased with the outcome and the minimal disruption to their business.

Key Topics to Learn for Maintain Work Area Interview

- Work Area Organization and Efficiency: Understanding principles of 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) and their practical application in maintaining a clean and organized work area. This includes optimizing workflow and minimizing waste.

- Safety Procedures and Regulations: Demonstrating knowledge of relevant safety protocols, hazard identification, and risk mitigation strategies within the work area. This includes understanding and adhering to company-specific safety guidelines.

- Equipment Maintenance and Troubleshooting: Familiarity with routine maintenance tasks for common tools and equipment within the work area. This includes basic troubleshooting skills and the ability to identify and report malfunctions effectively.

- Inventory Management and Control: Understanding the importance of accurate inventory tracking, managing stock levels, and identifying potential shortages or discrepancies. This includes using inventory management systems effectively.

- Waste Management and Disposal: Knowledge of proper waste disposal procedures, including segregation of materials and adherence to environmental regulations. This includes understanding the importance of recycling and minimizing environmental impact.

- Communication and Collaboration: Highlighting the importance of clear communication with colleagues and supervisors regarding work area issues, safety concerns, and maintenance requirements. This includes active participation in team discussions and problem-solving.

- Problem-Solving and Decision-Making: Demonstrating the ability to identify and solve problems related to work area maintenance, including prioritizing tasks and making informed decisions based on available information.

Next Steps

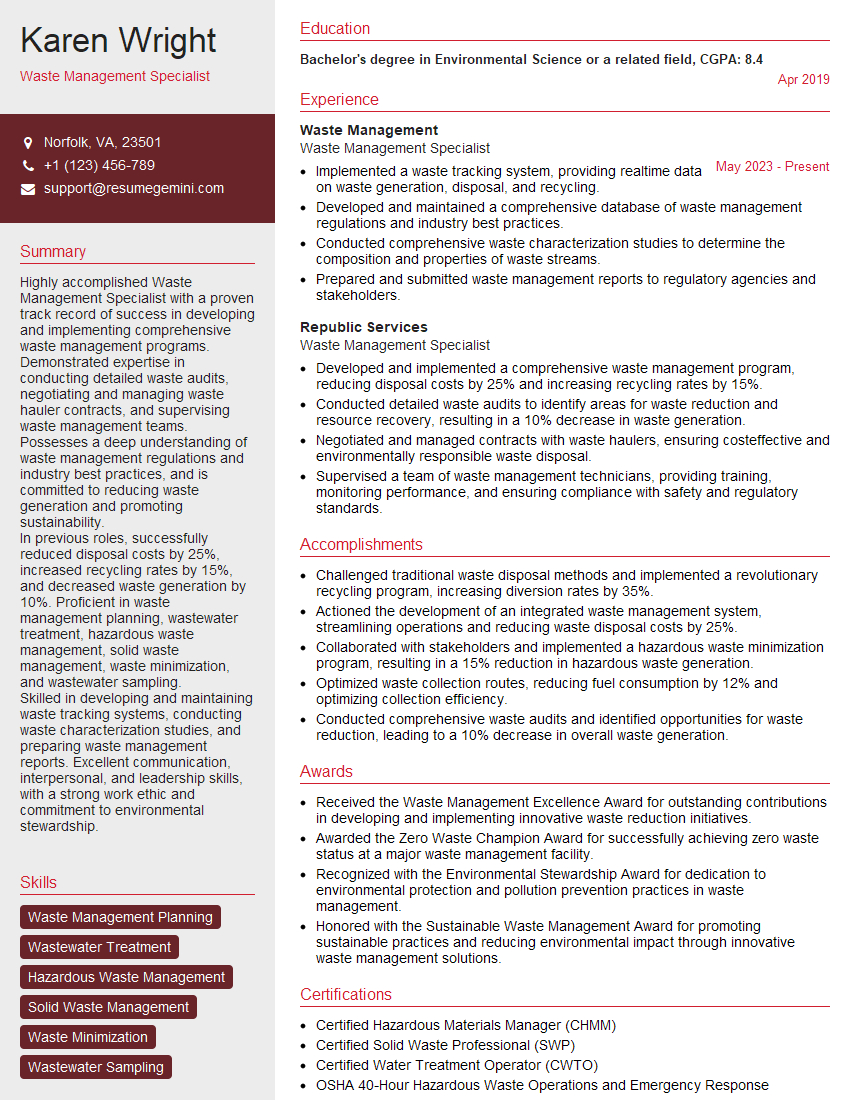

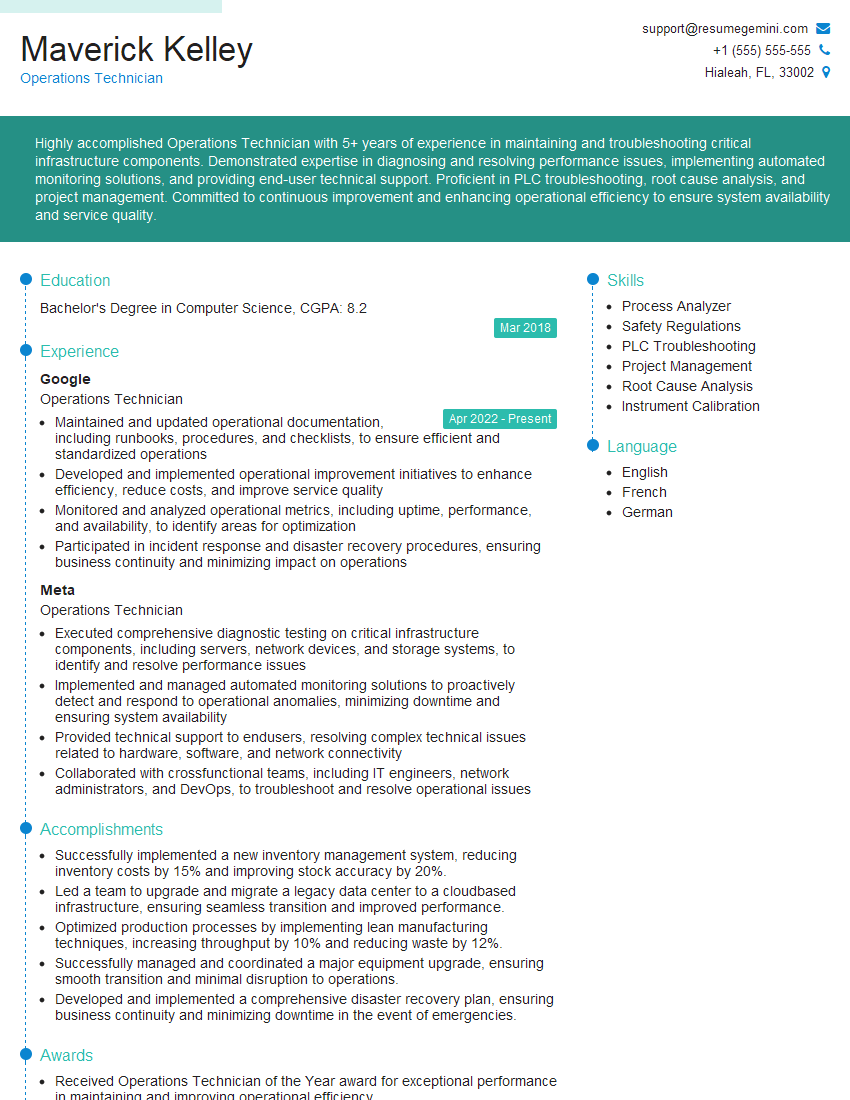

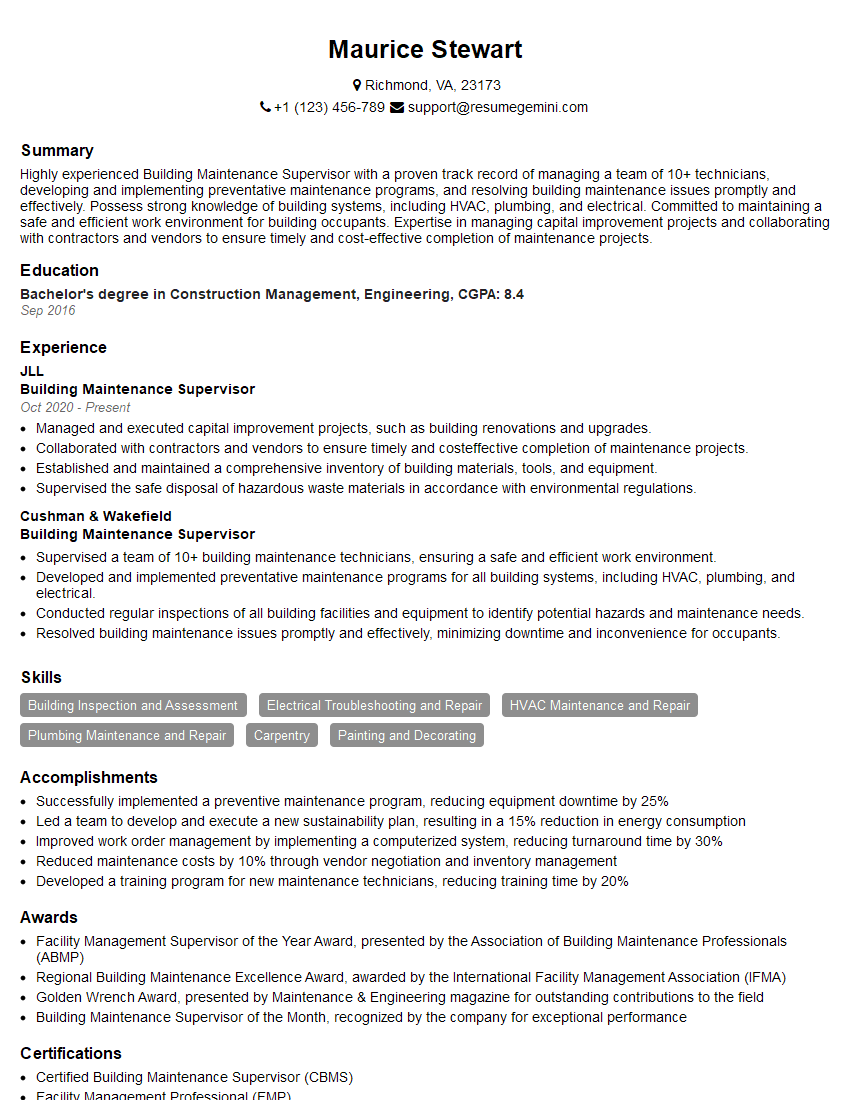

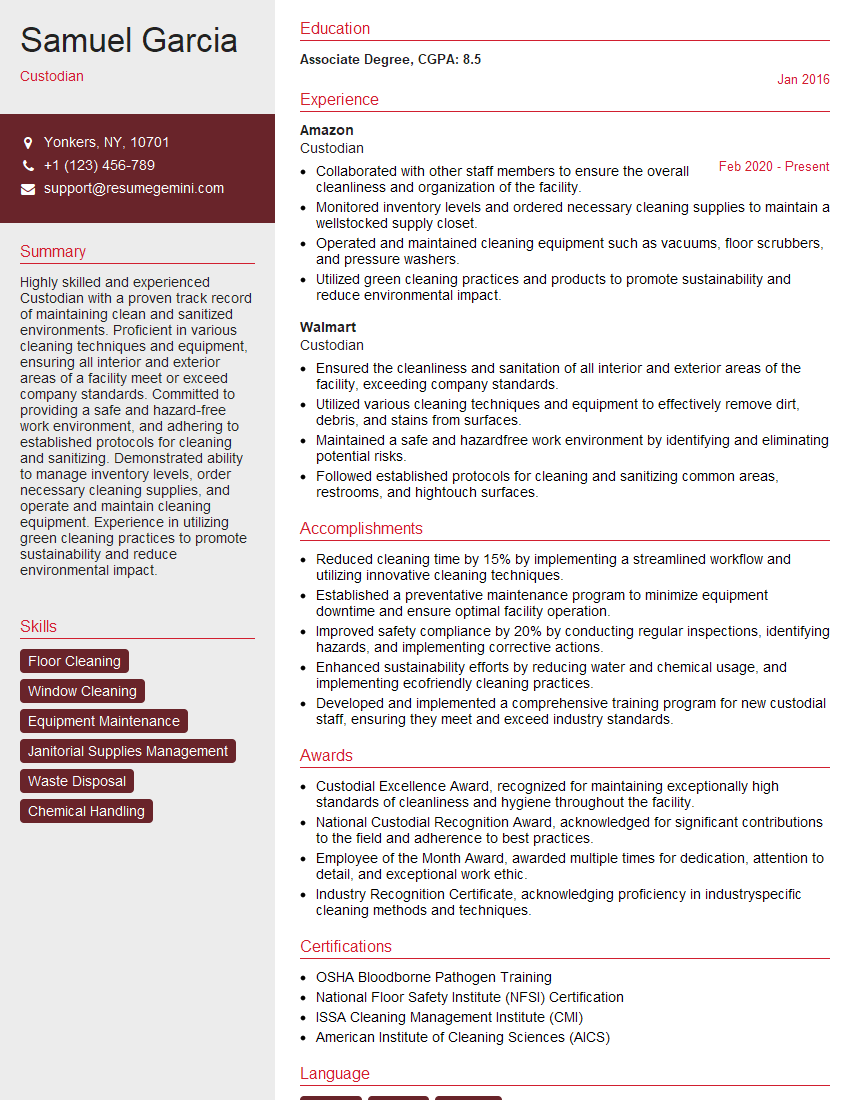

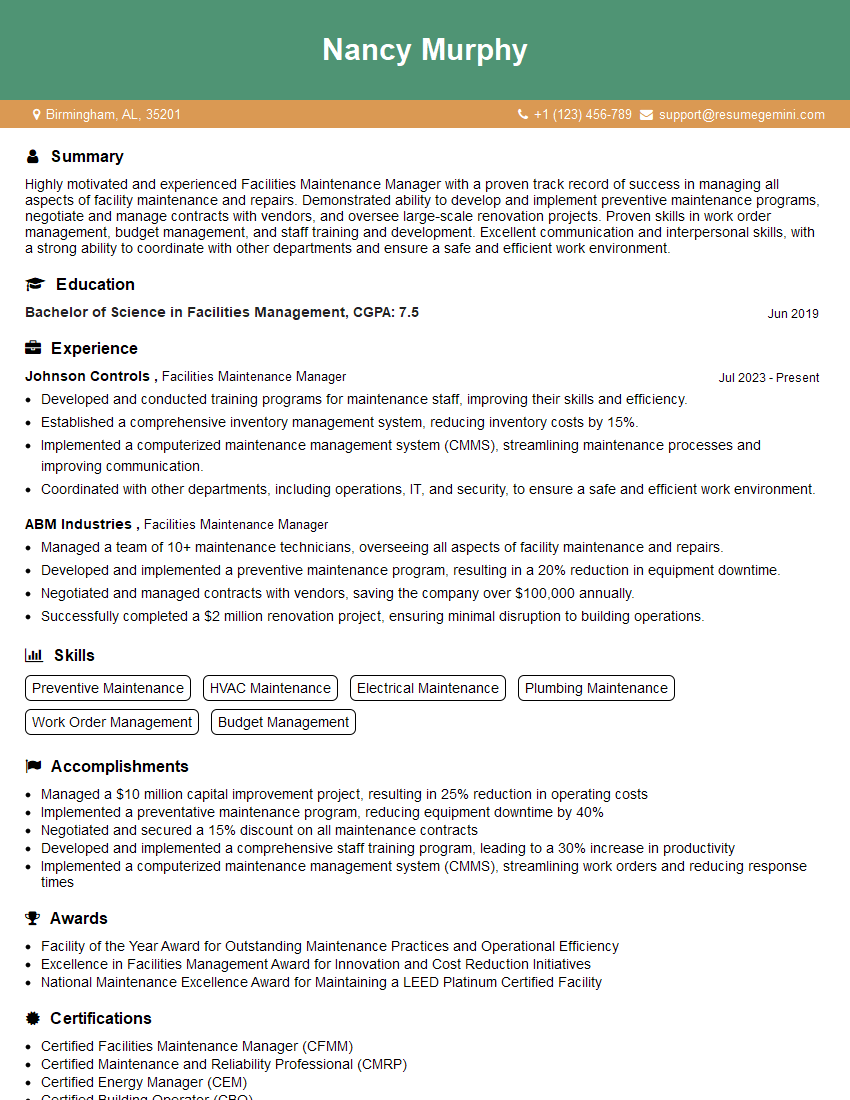

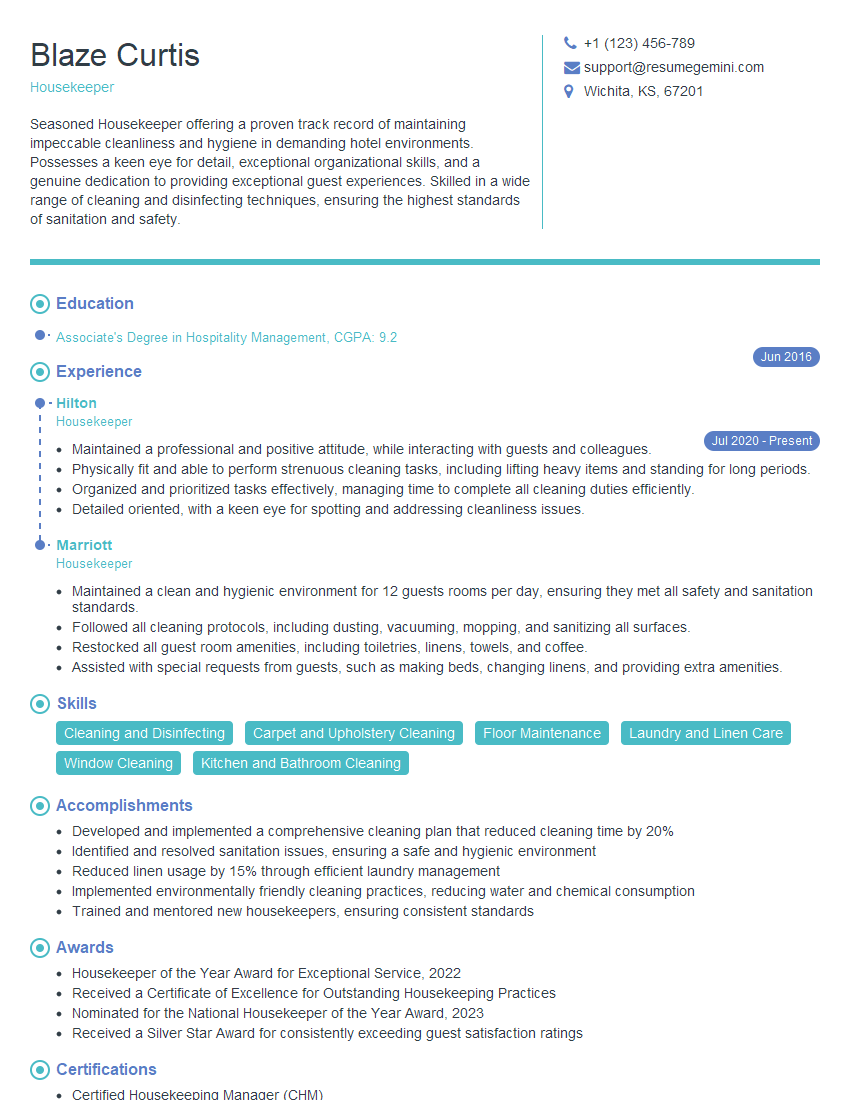

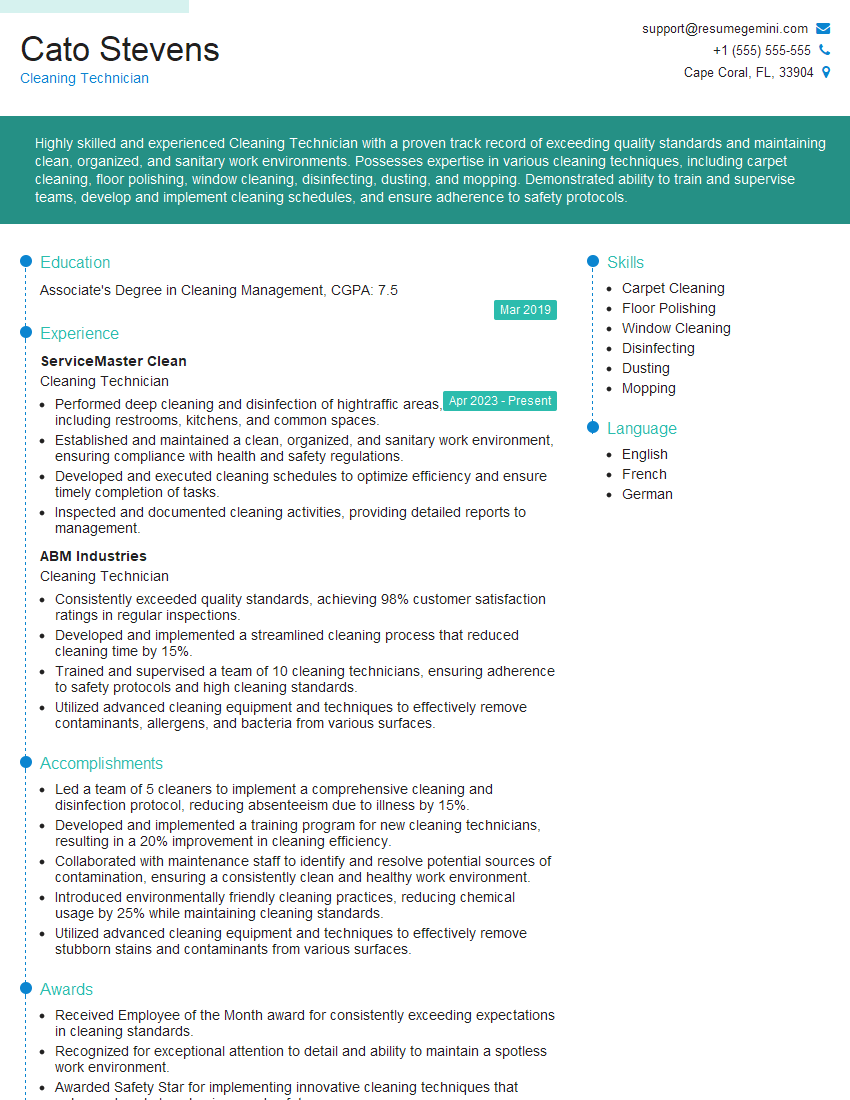

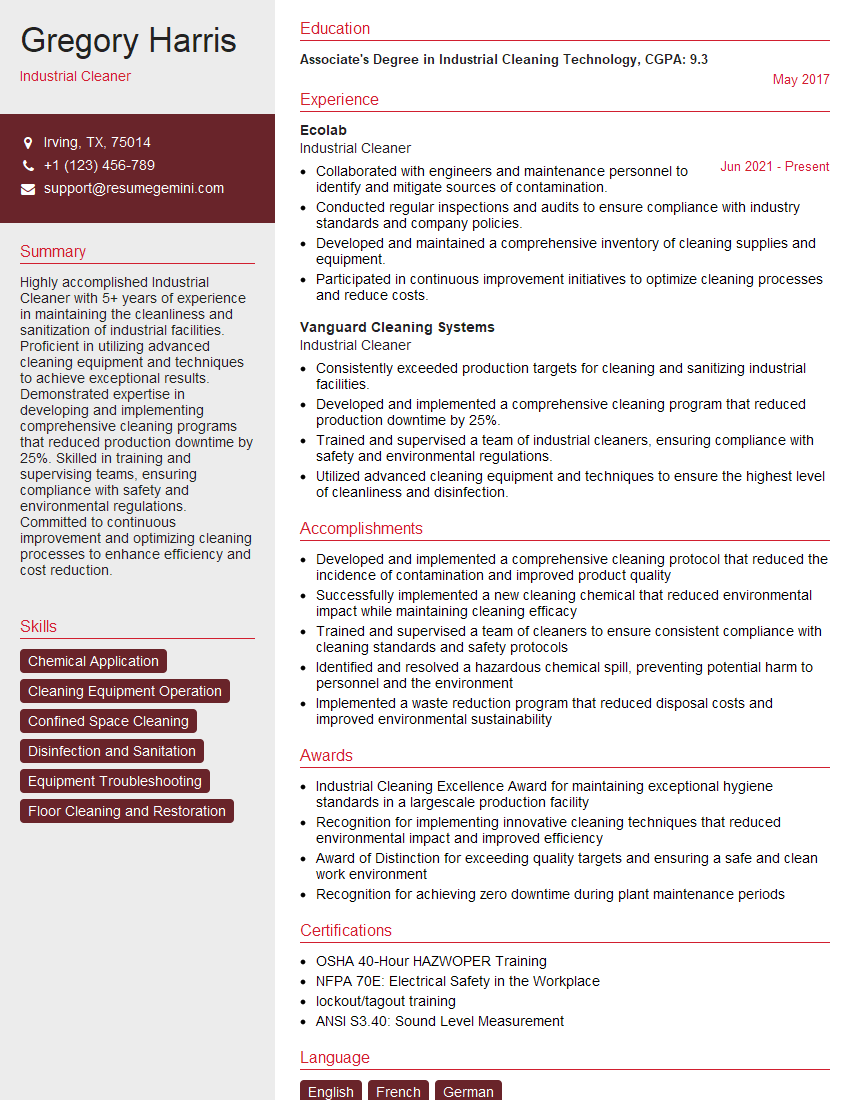

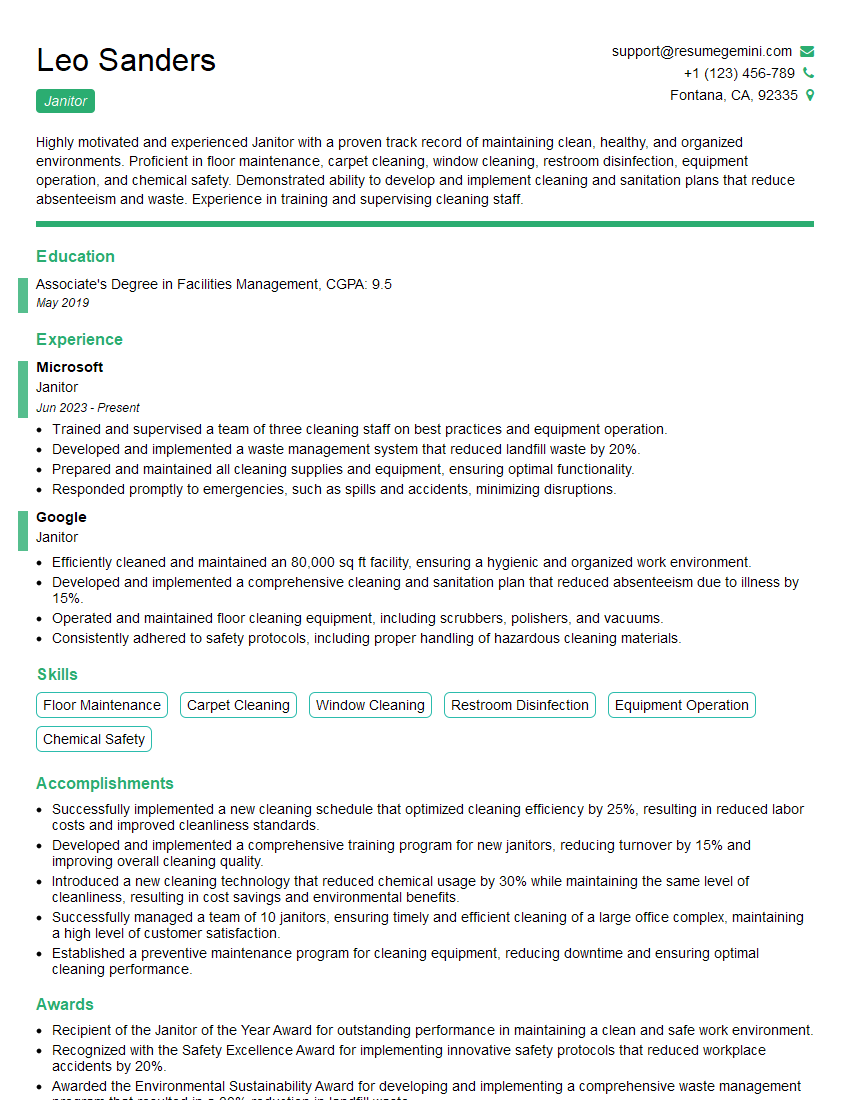

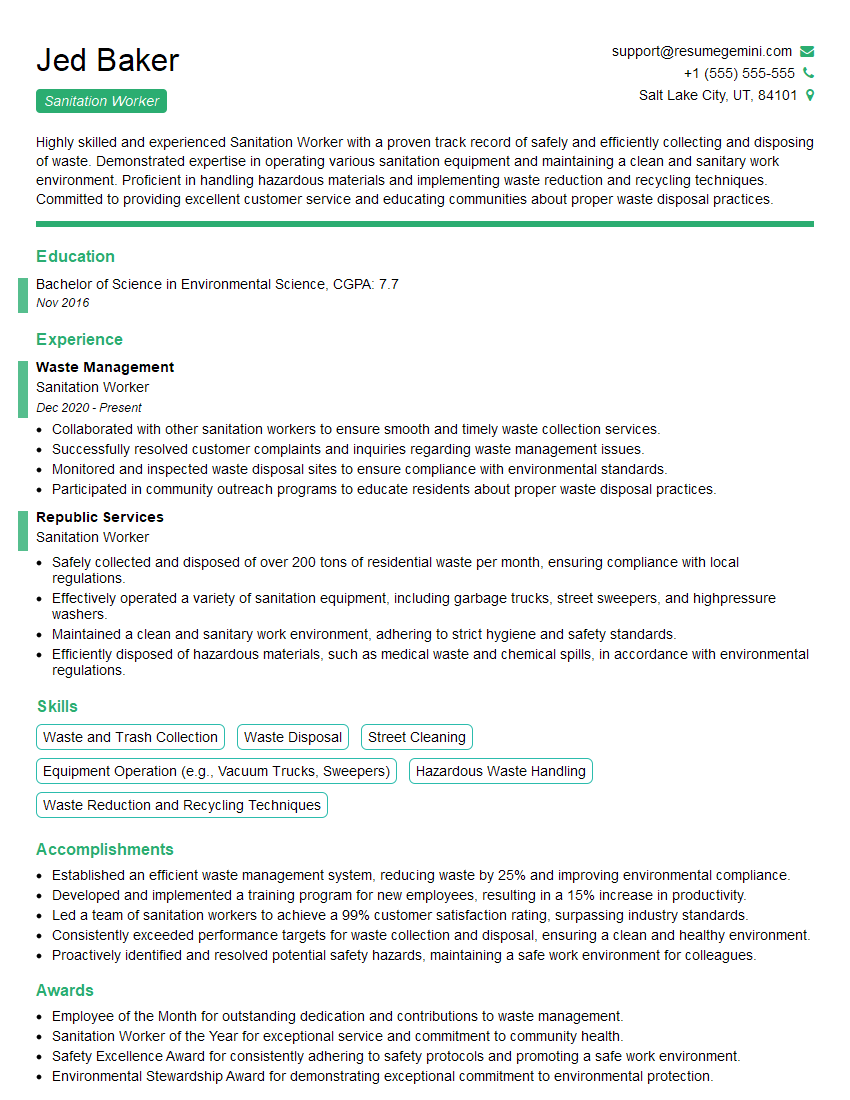

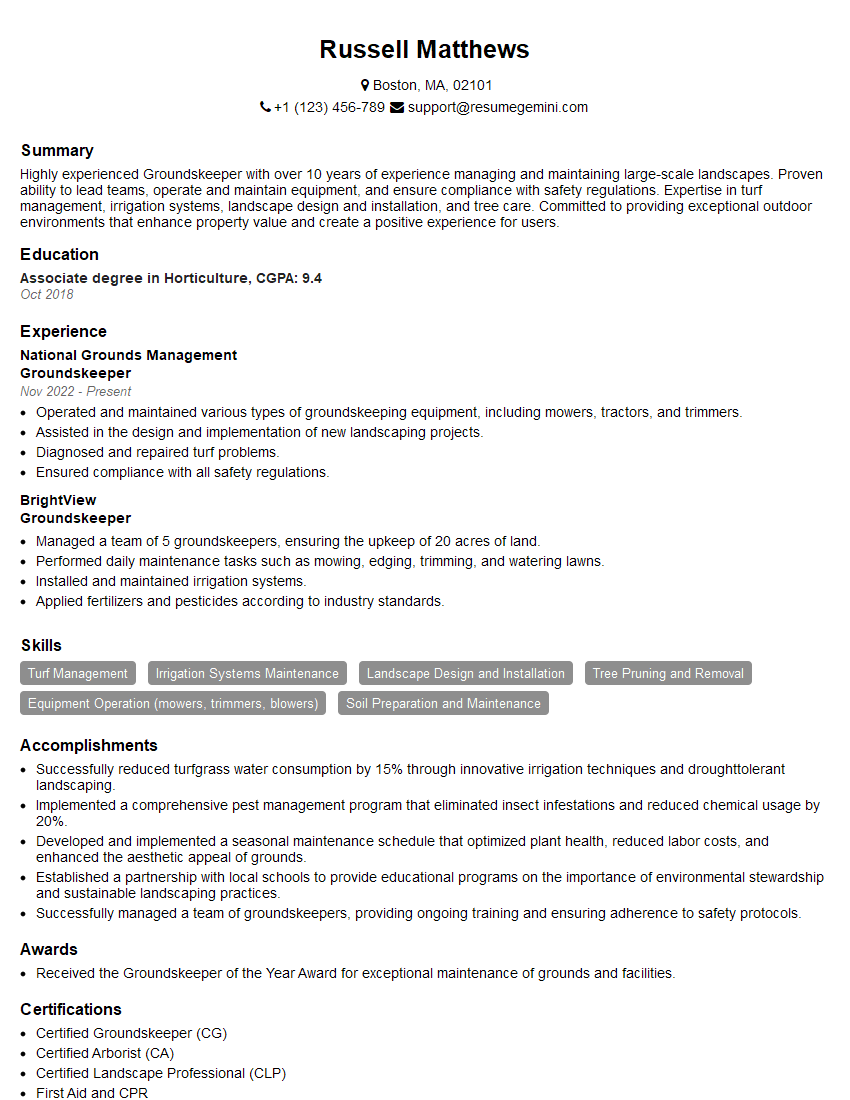

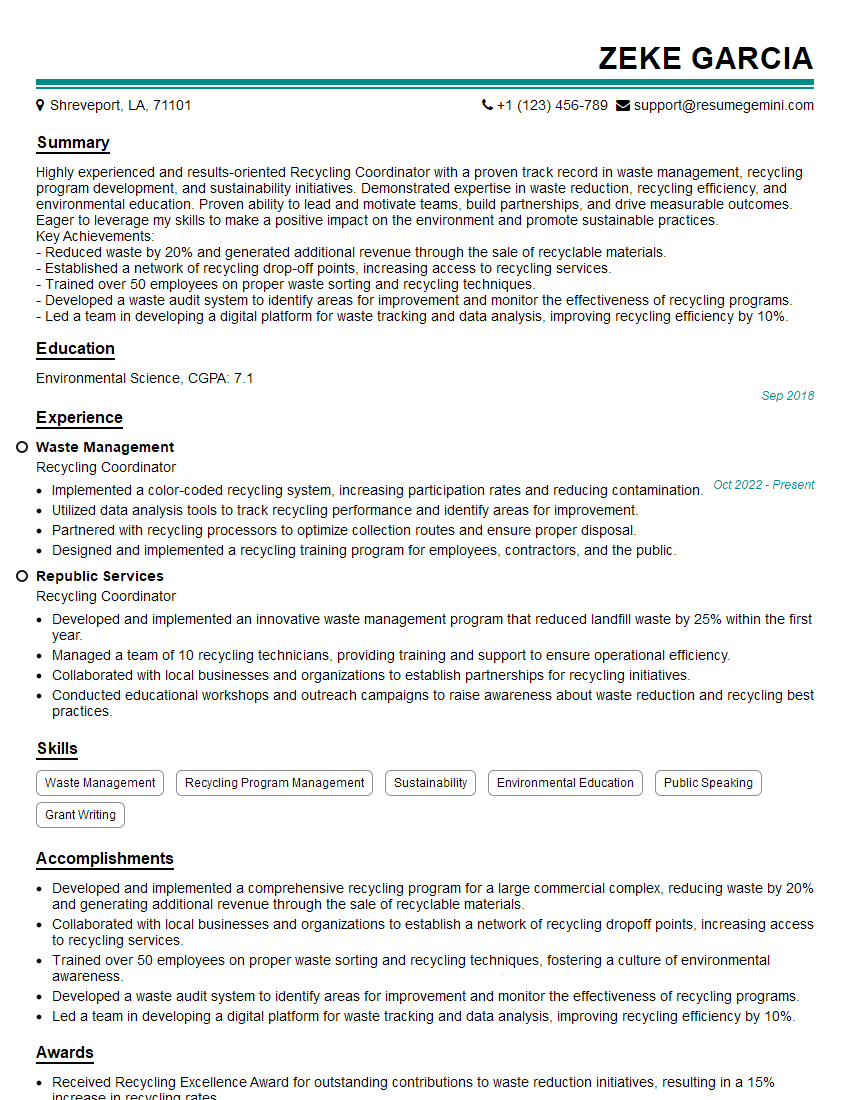

Mastering Maintain Work Area principles is crucial for career advancement, demonstrating your commitment to efficiency, safety, and a productive work environment. Employers highly value candidates who possess these skills. To significantly improve your job prospects, it’s essential to create an ATS-friendly resume that highlights your relevant abilities. We strongly recommend using ResumeGemini to build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Maintain Work Area are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO