Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Maintaining Workplace Safety interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Maintaining Workplace Safety Interview

Q 1. Describe your experience conducting workplace safety audits.

Conducting workplace safety audits involves a systematic evaluation of a workplace to identify hazards and assess the effectiveness of safety measures. It’s like giving your workplace a thorough health check-up. My approach is thorough and multi-faceted. First, I review existing safety documentation – policies, procedures, training records, incident reports. Then, I conduct on-site observations, using checklists and focusing on high-risk areas like machinery, chemical handling, and electrical systems. I interview employees at all levels to get their perspectives on safety concerns and practices. Finally, I analyze my findings, identifying gaps and areas for improvement, and prepare a detailed report with recommendations. For example, during an audit at a manufacturing plant, I discovered a lack of proper lockout/tagout procedures on heavy machinery, a significant safety hazard. My report detailed this deficiency and recommended a comprehensive training program and a strict adherence protocol to rectify the issue. In another instance, at a construction site, I noticed inadequate fall protection measures. This resulted in recommendations for immediate implementation of appropriate guardrails and harness systems, along with refresher training for the workers.

Q 2. Explain your understanding of OSHA regulations.

My understanding of OSHA (Occupational Safety and Health Administration) regulations is extensive. OSHA sets national standards for workplace safety and health, aiming to prevent workplace injuries, illnesses, and deaths. I’m familiar with a wide range of OSHA standards, including those concerning hazard communication (HAZCOM), personal protective equipment (PPE), machine guarding, fall protection, confined space entry, lockout/tagout, and emergency action plans. I understand that compliance with these regulations is crucial and that non-compliance can lead to serious penalties, including fines and legal action. My knowledge extends beyond just the regulations themselves; I understand the underlying principles of risk assessment and hazard control that underpin OSHA’s guidelines. For example, I know the specifics of OSHA’s Hazard Communication Standard (29 CFR 1910.1200) which mandates the creation and implementation of Safety Data Sheets (SDS) and the training of workers on hazardous chemicals present in the workplace. Similarly, I’m deeply familiar with OSHA’s General Duty Clause, which requires employers to provide a workplace free from recognized hazards.

Q 3. How do you identify and assess workplace hazards?

Identifying and assessing workplace hazards is a proactive and continuous process, not a one-time event. Think of it like being a detective, investigating potential threats before they cause harm. My process involves several steps: First, conducting a thorough walkthrough of the facility, observing work processes, and identifying potential hazards. This includes looking for physical hazards like tripping hazards, unguarded machinery, and poor lighting; chemical hazards like exposure to hazardous substances; biological hazards such as bacteria or viruses; ergonomic hazards like repetitive strain injuries; and psychosocial hazards like stress and harassment. Next, I use a variety of tools such as checklists, job safety analyses (JSAs), and hazard and operability studies (HAZOPs) to systematically evaluate the severity and likelihood of each identified hazard. A Job Safety Analysis (JSA) breaks down a job into steps, identifies potential hazards at each step, and outlines precautions to mitigate those hazards. For instance, if we analyze a task such as lifting heavy boxes, a JSA would specify correct lifting techniques, the use of proper equipment, and limits to the weight lifted to prevent back injuries. Following the identification and assessment, I prioritize hazards based on their risk level, using a risk matrix that considers both the likelihood and severity of potential harm. This prioritization guides the development of effective control measures.

Q 4. What methods do you use to develop and implement safety training programs?

Developing and implementing effective safety training programs is crucial for a safe and productive workplace. I approach this by first identifying the specific training needs of the workforce based on the identified hazards and job roles. Then, I design training modules that are engaging, practical, and relevant. I use a variety of methods, including classroom instruction, hands-on training, simulations, and online modules. I ensure the training is tailored to different learning styles and language proficiency levels. For example, I might use interactive computer-based training for younger employees while utilizing more hands-on demonstrations for older employees who may learn better through practical application. I incorporate real-life case studies and examples of incidents to make the training relatable and impactful. Post-training assessments ensure understanding and competency. Further, I believe in providing regular refreshers and updates to keep the employees current on best practices and new safety regulations. For instance, if there’s a change in the company’s handling of hazardous chemicals, a supplemental training session must be implemented and documented.

Q 5. How do you investigate workplace accidents and near misses?

Investigating workplace accidents and near misses is crucial for identifying root causes and preventing future incidents. My approach is thorough and systematic, following a standardized investigation process. I start by securing the scene, if necessary, and documenting the event with photos, videos, and witness statements. I interview individuals involved, including the injured worker(s), witnesses, and supervisors. I review relevant documents like incident reports, safety records, and equipment maintenance logs. I then reconstruct the events leading up to the accident, utilizing root cause analysis techniques such as the “5 Whys” method or fault tree analysis to identify underlying causes, not just superficial explanations. For example, if a worker fell from a ladder, a superficial explanation might be “the worker fell.” However, through the 5 Whys method, we might uncover that the worker fell because the ladder was not secured properly, because the proper safety equipment was not provided, because the supervisor didn’t enforce the safety rules, because the safety training was insufficient, and finally because the company didn’t prioritize employee safety. This detailed analysis allows for a more effective development of preventative measures. Following the investigation, I prepare a detailed report with recommendations for corrective actions and preventative measures to prevent similar occurrences in the future. The insights gained are invaluable for improving safety procedures and training.

Q 6. Describe your experience with developing and implementing safety policies and procedures.

Developing and implementing safety policies and procedures is fundamental to a strong safety culture. My experience includes collaborating with stakeholders from various departments to draft comprehensive, easy-to-understand documents. I ensure policies align with all applicable regulations (like OSHA) and industry best practices. The policies cover all aspects of workplace safety, including hazard identification, risk assessment, emergency procedures, personal protective equipment usage, training requirements, and reporting procedures. For instance, a policy regarding lockout/tagout procedures would detail the step-by-step process for safely isolating equipment before maintenance, identifying authorized personnel, and ensuring appropriate tagging and labeling. I utilize clear and concise language, avoiding technical jargon whenever possible. Following policy development, I ensure effective communication and distribution to all employees, along with mandatory training and acknowledgment of understanding. Regular review and updates of these policies are crucial to maintain their effectiveness and to address evolving hazards or regulatory changes. For example, if a new piece of machinery is introduced, the relevant safety policies and procedures would be updated to address this new equipment and its associated hazards.

Q 7. How do you ensure compliance with safety regulations?

Ensuring compliance with safety regulations requires a multifaceted strategy. First, a thorough understanding of all applicable regulations is paramount. Second, a robust safety management system needs to be implemented. This includes regular safety inspections and audits, maintaining accurate records, implementing corrective actions based on audit findings, and training employees on safety procedures and regulations. Third, conducting regular employee training is critical. Employees need to understand their roles in maintaining a safe workplace and the consequences of non-compliance. Fourth, proactive hazard identification and risk assessment are crucial, leading to the implementation of preventative measures. Beyond these, effective communication and open dialogue between management and employees are essential to foster a strong safety culture. For instance, regular safety meetings allow for discussions about ongoing safety issues, feedback on policies, and reinforcement of safe practices. Finally, a system of tracking, monitoring, and reporting is essential to track compliance, identify trends, and measure the effectiveness of safety initiatives. Non-compliance can result in penalties, legal issues, and even worker injuries or fatalities, making compliance not only an ethical imperative but also a business necessity.

Q 8. How do you communicate safety information to employees?

Communicating safety information effectively requires a multi-pronged approach, ensuring information reaches every employee in a way they understand and remember. I leverage various methods to ensure maximum impact.

Regular Safety Meetings: These are crucial for addressing specific hazards, reviewing incident reports, and providing updates on safety procedures. I always encourage two-way communication, allowing employees to voice concerns and suggestions.

Training Programs: Comprehensive, hands-on training is key. This includes both initial onboarding sessions and refresher courses, using a combination of classroom lectures, videos, and practical demonstrations tailored to the specific job roles and risks involved. For example, for operating heavy machinery, hands-on training with qualified instructors is essential.

Visual Aids: Posters, signs, and safety checklists in multiple languages are vital, especially in diverse work environments. Pictures often speak louder than words, making complex information accessible to all.

Digital Communication: Utilizing emails, intranet portals, and even short safety-focused videos improves reach and allows for easy updates and reminders. For example, a short video demonstrating the correct use of PPE is far more engaging than a lengthy memo.

Feedback Mechanisms: Implementing suggestion boxes, anonymous reporting systems, and regular safety surveys ensures open communication and allows employees to report hazards or concerns without fear of reprisal.

Q 9. What are some effective strategies for promoting a safety culture?

Building a strong safety culture isn’t just about rules; it’s about embedding safety into the very fabric of the workplace. It requires consistent effort and visible leadership commitment.

Leadership Commitment: Leaders must visibly champion safety, actively participating in safety initiatives and holding themselves and their teams accountable. Their active involvement sets the tone from the top.

Employee Involvement: Safety committees composed of employees from different levels are invaluable for brainstorming, identifying hazards, and suggesting improvements. This demonstrates that safety is a shared responsibility.

Recognition and Rewards: Acknowledging and rewarding safe work practices, both individually and team-wide, reinforces positive behavior and encourages continued safe performance. A simple ‘thank you’ or a small reward can go a long way.

Open Communication: Creating a culture where employees feel comfortable reporting near misses and hazards without fear of punishment is paramount. Near misses are invaluable learning opportunities.

Continuous Improvement: Regularly reviewing safety performance, analyzing incident data, and implementing corrective actions demonstrates a commitment to ongoing improvement. This cyclical approach is critical.

Q 10. How do you manage workplace risks?

Managing workplace risks involves a systematic process, often following a risk assessment methodology. This generally involves a cycle of identifying hazards, assessing risks, implementing control measures, monitoring, and reviewing.

Hazard Identification: This involves systematically identifying potential sources of harm in the workplace, such as unsafe equipment, hazardous materials, or ergonomic issues. This often involves walk-throughs, job hazard analyses, and consultations with employees.

Risk Assessment: This involves evaluating the likelihood and severity of each identified hazard, determining the level of risk. Tools like risk matrices can help quantify this.

Control Measures: Based on the risk assessment, appropriate control measures are implemented to reduce or eliminate the risk. These can range from engineering controls (e.g., machine guarding) to administrative controls (e.g., safety procedures) and PPE.

Monitoring and Review: Regularly monitoring the effectiveness of control measures and reviewing the risk assessment process ensures ongoing effectiveness and adaptation to changing conditions.

For example, if we identify a risk of slips and falls near a wet floor, the control measures might include signage, non-slip mats, and training on safe walking practices.

Q 11. Explain your experience with incident reporting and investigation.

I have extensive experience in incident reporting and investigation, following established protocols to ensure thorough analysis and prevention of future occurrences. My approach emphasizes factual accuracy and identifying root causes, not placing blame.

Incident Reporting: I ensure a clear and concise reporting system, making it easy for employees to report incidents, near misses, and hazards. This often involves online reporting systems and immediate follow-up to ascertain details.

Investigation: Investigations are conducted promptly and impartially, gathering evidence, interviewing witnesses, and analyzing contributing factors. I use techniques such as fault tree analysis to identify root causes.

Corrective Actions: Based on the investigation findings, I recommend and implement corrective actions to prevent recurrence. These actions are documented and monitored for effectiveness.

Reporting and Analysis: Regular reports on incident trends and patterns are crucial for identifying areas needing improvement and informing ongoing safety initiatives.

For instance, in an incident involving a worker’s injury due to a malfunctioning machine, the investigation would not only determine how the injury occurred but also identify the root cause of the machine failure – whether it was due to lack of maintenance, inadequate training, or a design flaw – to prevent future incidents.

Q 12. How do you handle conflicts related to safety issues?

Conflicts related to safety issues need to be addressed promptly and fairly, ensuring that all parties feel heard and that safety remains the paramount concern. My approach prioritizes collaboration and finding mutually acceptable solutions.

Open Communication: Creating a safe space for individuals to express concerns without fear of reprisal is crucial. Active listening is key to understanding differing perspectives.

Mediation: If a conflict arises, I often act as a mediator, facilitating discussions between parties to identify common ground and find solutions. This collaborative approach focuses on solutions rather than assigning blame.

Fairness and Impartiality: It’s vital to remain impartial, ensuring that decisions are based on factual evidence and safety protocols, not personal bias.

Documentation: Maintaining clear and concise records of conflicts, the resolution process, and outcomes is essential for transparency and accountability.

For example, if two employees disagree about a particular safety procedure, a facilitated discussion can clarify the procedure, address concerns, and reach a consensus on the best approach.

Q 13. What is your experience with personal protective equipment (PPE)?

My experience with personal protective equipment (PPE) encompasses selection, fitting, training, maintenance, and ensuring compliance with relevant regulations. It’s critical to ensure the right PPE is used for each specific hazard.

Selection: PPE selection is based on a thorough risk assessment, ensuring that the chosen equipment adequately protects against identified hazards. This includes considering factors like comfort, fit, and compatibility with other equipment.

Training: Employees must receive proper training on how to correctly use, wear, and maintain their PPE. This includes understanding limitations and knowing when to replace damaged equipment.

Fitting: Proper fitting is crucial to ensure the effectiveness of PPE. This often requires individualized fitting and adjustment.

Maintenance: Regular inspections and maintenance of PPE are necessary to ensure its continued effectiveness. Damaged or worn-out equipment must be replaced immediately.

Compliance: Ensuring compliance with all relevant regulations and standards is paramount. This includes regular audits and updates to maintain compliance with evolving standards.

Q 14. How do you ensure the proper use and maintenance of safety equipment?

Ensuring the proper use and maintenance of safety equipment is crucial for preventing accidents and maintaining a safe working environment. My approach involves a multi-layered strategy focusing on training, inspection, and record-keeping.

Regular Inspections: Safety equipment undergoes routine inspections to identify any damage, wear, or malfunctions. This involves visual inspections and, where necessary, functional tests.

Preventive Maintenance: A scheduled maintenance program is crucial to address potential issues before they become hazards. This might involve lubrication, cleaning, or calibration of equipment.

Training and Competency: Employees responsible for using and maintaining the equipment receive appropriate training to ensure safe and effective operation. Competency checks and certifications are vital.

Record-Keeping: Detailed records of inspections, maintenance, and repairs are maintained to track the equipment’s history and ensure compliance. This provides valuable data for future risk assessments.

Employee Reporting: A system for employees to report any defects or issues with safety equipment is crucial for prompt attention and repair.

For instance, a regular inspection of fire extinguishers would involve checking pressure gauges, nozzle functionality, and overall condition. Any issues would be documented, and the extinguisher would be serviced or replaced as needed.

Q 15. How familiar are you with emergency response procedures?

Emergency response procedures are the cornerstone of any effective workplace safety program. My familiarity extends beyond simply knowing the steps; I understand the importance of proactive planning, regular drills, and post-incident analysis. I’m proficient in various emergency response plans, including fire safety, evacuation protocols, medical emergencies, and hazardous material spills. For instance, in my previous role at a manufacturing plant, I led the development and implementation of a new emergency response plan that reduced evacuation time by 15% and improved overall preparedness. This involved not only creating detailed procedures but also conducting regular training simulations and updating the plan based on lessons learned from drills and near-miss incidents. Crucially, I ensure everyone understands their roles and responsibilities, from identifying hazards to activating emergency services.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with ergonomics and workplace design.

Ergonomics and workplace design are crucial for preventing musculoskeletal injuries and promoting employee well-being. My experience involves assessing workstations, recommending adjustments to furniture and equipment, and educating employees on proper posture and lifting techniques. For example, in a previous role at an office setting, I conducted a comprehensive ergonomic assessment, identifying several risk factors like improper chair height and monitor positioning. This led to implementing changes such as providing adjustable chairs, monitor arms, and keyboard trays, which resulted in a significant reduction in reported musculoskeletal complaints. I also designed training programs focusing on safe lifting techniques and promoting regular stretching breaks. Beyond individual workstations, I consider the overall layout of the workplace, ensuring sufficient space, clear pathways, and proper lighting to minimize hazards and enhance productivity.

Q 17. How do you measure the effectiveness of safety programs?

Measuring the effectiveness of safety programs requires a multi-faceted approach that goes beyond simply tracking accident rates. Key performance indicators (KPIs) include incident rates (lost-time incidents, recordable incidents), near-miss reporting rates, training participation rates, safety observation scores, and employee satisfaction surveys. For instance, we can track the reduction in lost-time incidents over time, analyzing trends to identify areas for improvement. Near-miss reporting is especially critical, as it allows for proactive intervention before an actual incident occurs. Analyzing trends in near-miss reports can highlight systemic issues. Employee satisfaction surveys provide valuable qualitative data on perceptions of safety culture and effectiveness of implemented programs. A robust safety program will demonstrate improvements in all these areas, showing a positive impact on both safety performance and employee morale.

Q 18. What are your strategies for improving safety performance?

Improving safety performance relies on a proactive, multi-pronged strategy. It starts with a strong safety culture – a commitment from leadership and employees alike. Key strategies include:

- Regular safety training: Ensuring employees receive ongoing training on relevant hazards and safety procedures.

- Hazard identification and risk assessment: Proactively identifying potential hazards and implementing control measures. This involves thorough workplace inspections and using methods like Job Safety Analysis (JSA) to understand potential risks.

- Incident investigation and root cause analysis: Thoroughly investigating incidents to determine root causes and implement corrective actions to prevent recurrence.

- Safety committees and employee involvement: Establishing safety committees to involve employees in identifying hazards and developing solutions. This fosters ownership and enhances buy-in.

- Reward and recognition programs: Recognizing and rewarding employees for safe behavior and contributions to safety improvement.

- Leading indicators tracking: Monitoring leading indicators, such as safety observations and near-miss reporting, to identify potential problems before they become incidents.

Q 19. How do you handle employee resistance to safety procedures?

Handling employee resistance to safety procedures requires a thoughtful and empathetic approach. It’s vital to understand the reasons behind the resistance. This could stem from discomfort with new procedures, lack of understanding, concerns about productivity, or even a perception that safety rules are inconvenient. My approach involves:

- Open communication and education: Clearly explaining the rationale behind the procedures, emphasizing the benefits of compliance, and addressing specific concerns.

- Involving employees in the process: Seeking input from employees on safety procedures, making them feel involved in the decision-making process.

- Providing positive reinforcement: Recognizing and rewarding employees for complying with safety procedures.

- Addressing concerns and providing support: Addressing individual concerns and providing the necessary support or training to help employees comply.

- Consistent enforcement: Fairly and consistently enforcing safety rules, ensuring that all employees are held accountable.

Q 20. Describe your experience with safety inspections and monitoring.

Safety inspections and monitoring are critical for identifying hazards and ensuring compliance with safety regulations. My experience includes conducting both routine and targeted inspections, using checklists and observation techniques to identify potential hazards. I use various methods including, but not limited to, walk-through inspections, detailed equipment inspections, and environmental monitoring. For example, a routine inspection might involve checking for tripping hazards, proper use of personal protective equipment (PPE), and the condition of machinery. Targeted inspections might focus on specific areas or equipment identified as high-risk. Following inspections, I generate detailed reports outlining findings, recommended corrective actions, and timelines for completion. Regular monitoring ensures that corrective actions are implemented and that the workplace remains safe. Furthermore, I utilize data from inspections and safety incidents to identify trends, allowing for proactive intervention and improvement of the safety program.

Q 21. What are your knowledge of different types of workplace hazards (physical, chemical, biological)?

Workplace hazards encompass a broad range of threats to employee health and safety. My knowledge encompasses:

- Physical hazards: These include ergonomic hazards (repetitive strain injuries, poor posture), slips, trips, and falls, noise, vibration, radiation, and extreme temperatures. For example, a poorly designed workstation can lead to musculoskeletal disorders, while inadequate lighting can increase the risk of falls.

- Chemical hazards: These include exposure to hazardous substances such as solvents, acids, and gases. Proper ventilation, personal protective equipment (PPE), and safe handling procedures are crucial to mitigate these risks. Understanding Safety Data Sheets (SDS) is critical in managing chemical hazards.

- Biological hazards: These involve exposure to biological agents such as bacteria, viruses, and fungi. This could include risks in healthcare settings, laboratories, or industries handling biological materials. Proper hygiene, sanitation, and appropriate PPE are vital for controlling biological hazards.

Q 22. What is your experience with lockout/tagout procedures?

Lockout/Tagout (LOTO) procedures are critical for preventing the unexpected energization or startup of machinery and equipment during maintenance or repair. My experience encompasses implementing, training, and auditing LOTO programs across various industrial settings. I’ve worked with everything from simple single-point LOTO on smaller equipment to complex, multi-person LOTO procedures for large-scale machinery and process lines. This includes the creation and enforcement of written procedures, the selection and application of appropriate lockout devices, and conducting regular inspections to ensure compliance.

For example, in a previous role at a manufacturing plant, I was responsible for developing a new LOTO procedure for a high-speed press. This involved a thorough risk assessment, defining clear steps for isolating energy sources (electrical, hydraulic, pneumatic), selecting appropriate lock and tag devices, and implementing a comprehensive training program for all technicians. The result was a significant reduction in near-miss incidents and a marked improvement in overall workplace safety.

Beyond execution, I also have experience in troubleshooting LOTO challenges. This includes identifying and resolving issues with inadequate energy isolation, non-compliant devices, and inconsistent procedural adherence. This often requires creative solutions, like designing custom lockout devices or adapting procedures to accommodate specific equipment configurations. The key is always to ensure complete energy isolation and unambiguous communication to prevent accidents.

Q 23. How familiar are you with confined space entry procedures?

Confined space entry procedures are vital for protecting workers from hazards associated with limited access, poor ventilation, and the potential for oxygen deficiency, toxic gases, or engulfment. My experience includes developing and overseeing confined space entry permits, providing training on atmospheric monitoring, rescue procedures, and emergency response. I’ve worked extensively with various confined space types, such as tanks, vessels, trenches, and underground utilities.

I’m familiar with all aspects of confined space entry, from pre-entry assessments – including atmospheric testing for oxygen levels, flammable gases, and toxic substances – to the selection and use of appropriate personal protective equipment (PPE) like respirators and harnesses. Furthermore, I’m experienced in creating and implementing rescue plans that detail emergency procedures and the use of rescue equipment such as harnesses, tripods, and retrieval systems. A specific example involves a project where I designed a permit-required confined space entry program for a wastewater treatment facility, ensuring full compliance with OSHA regulations and a dramatic reduction in worker exposure to hazardous atmospheres.

A critical part of confined space safety is continuous monitoring and documentation. This means meticulously recording atmospheric readings, entry and exit times, and any unusual observations. Thorough documentation allows for improved risk assessment and the identification of potential problems before they lead to accidents.

Q 24. What is your experience with hazard communication programs?

Hazard communication programs are essential for informing employees about potential workplace hazards. My experience involves designing and managing comprehensive hazard communication programs compliant with OSHA’s Hazard Communication Standard (HCS). This includes the creation and maintenance of Safety Data Sheets (SDS), the implementation of proper labeling procedures, and the delivery of training on chemical handling and hazard recognition.

I’ve been involved in developing and distributing SDSs that are clear, concise, and readily accessible to workers. I’ve also worked to ensure that all chemical containers are clearly labeled with appropriate hazard warnings and pictograms, in compliance with GHS (Globally Harmonized System) standards. Training is a vital component – providing workers with the knowledge to understand SDSs and to use chemicals safely is paramount. I use a combination of hands-on demonstrations, interactive sessions, and written materials to effectively communicate the information.

A notable success was improving the hazard communication program at a chemical processing facility. By streamlining the SDS management system and providing more engaging training, we were able to improve employee understanding of chemical hazards and reduce incidents related to chemical mishandling. This involved not just updating the documentation, but also improving the training materials and delivery method, using visual aids and real-world examples to make the information more memorable and accessible.

Q 25. Describe your experience with developing safety budgets and resource allocation.

Developing safety budgets and allocating resources requires a strategic approach that balances immediate needs with long-term goals. My experience involves creating detailed safety budgets that encompass personal protective equipment (PPE), safety training, emergency response systems, and facility modifications. This includes justifying expenditures to senior management and securing funding for necessary safety initiatives.

I begin by conducting a thorough risk assessment to identify the most critical safety hazards and prioritize resource allocation accordingly. For example, if a risk assessment identifies a high risk of falls, a significant portion of the budget will be allocated to fall protection equipment and training. Similarly, if there’s a potential for fire hazards, resources are dedicated to fire suppression systems and fire safety training.

Resource allocation is more than just numbers. It’s about prioritizing proactive measures over reactive ones. Investing in preventative measures, such as safety training and equipment upgrades, reduces the likelihood of accidents and saves costs in the long run. I always use data-driven decision-making. By tracking incident rates and safety performance indicators, I can demonstrate the return on investment for various safety measures, helping justify budget requests and optimizing the allocation of resources.

Q 26. How do you stay current with changes in safety regulations and best practices?

Staying current with changes in safety regulations and best practices is crucial for maintaining a safe workplace. I utilize a multi-pronged approach to ensure my knowledge remains up-to-date. This includes actively participating in professional organizations such as the American Society of Safety Professionals (ASSP), attending industry conferences and workshops, and subscribing to relevant industry publications and online resources. I also actively track changes in OSHA regulations and other relevant safety standards.

Regular professional development is vital. This could involve pursuing certifications like a Certified Safety Professional (CSP) or attending specialized training courses focusing on new technologies or emerging safety challenges. Staying abreast of new technologies is crucial – innovations in PPE, safety equipment, and hazard detection methods continuously improve workplace safety.

Networking is equally important. Attending conferences and engaging with other safety professionals allows for the exchange of best practices and the learning of valuable lessons from different industries and experiences. This combined approach ensures that I remain informed about the latest developments in workplace safety, allowing me to adapt and implement best practices in my work.

Q 27. Explain your understanding of risk assessment methodologies.

Risk assessment methodologies are the foundation of effective safety management. My understanding encompasses a variety of approaches, from simple qualitative assessments to more sophisticated quantitative methods. These methodologies all aim to identify potential hazards, analyze their likelihood and severity, and develop effective control measures.

I frequently use methods such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis). HAZOP is a systematic approach that involves reviewing process flow diagrams to identify potential deviations and hazards. FMEA analyzes potential failures in a system or process, evaluating their potential impact and likelihood. These methods help identify potential hazards, their consequences, and the measures needed to mitigate them.

The output of a risk assessment isn’t just a report; it’s a roadmap for implementing control measures. This could involve implementing engineering controls (e.g., guarding machinery), administrative controls (e.g., implementing work permits), and personal protective equipment (PPE). It’s a continuous cycle – regularly reviewing and updating the risk assessment is vital to account for changes in the workplace or new information. The goal is to continuously reduce risks and improve workplace safety.

Q 28. How do you handle situations where safety procedures are not being followed?

When safety procedures aren’t being followed, a multi-step approach is necessary, prioritizing both immediate correction and preventing future occurrences. My approach begins with immediate observation and intervention, addressing the unsafe behavior directly and politely but firmly. This might involve a simple reminder of the correct procedure or a more direct intervention if the situation warrants it.

Following the immediate correction, I investigate the root cause of the non-compliance. Was it a lack of training, inadequate equipment, unclear procedures, or something else? Understanding the underlying cause is critical to developing effective corrective actions. This often involves interviewing the individual, reviewing related documentation, and potentially involving other stakeholders. This ensures a full picture of the situation.

Once the root cause is identified, appropriate corrective actions are implemented. This might include additional training, improved procedural clarity, updating equipment, or implementing additional safety measures. Following this, I document the incident, the root cause analysis, and the corrective actions taken. This serves as a record for future reference and helps prevent similar incidents from occurring again. In cases of repeated or serious violations, disciplinary actions may be necessary, always in line with company policy.

Key Topics to Learn for Maintaining Workplace Safety Interview

- Hazard Identification and Risk Assessment: Understanding methods like Job Safety Analysis (JSA) and HAZOP to proactively identify potential hazards and assess their risks.

- Practical Application: Developing and implementing control measures (e.g., engineering controls, administrative controls, PPE) to mitigate identified risks in various workplace scenarios (e.g., construction, manufacturing, office environments).

- Emergency Response Planning and Procedures: Knowledge of emergency response protocols, including evacuation plans, first aid procedures, and reporting mechanisms. Practical experience with drills and simulations is valuable.

- Safety Regulations and Compliance: Familiarity with relevant OSHA (or equivalent) standards and regulations, and the ability to explain how these regulations are applied in a practical setting. Demonstrate understanding of record-keeping and reporting requirements.

- Safety Training and Communication: Understanding the importance of effective safety training programs for employees, and different communication strategies to engage workers and promote a strong safety culture. This includes methods for delivering safety information and addressing employee concerns.

- Incident Investigation and Reporting: Understanding root cause analysis techniques to investigate workplace incidents, identify contributing factors, and implement corrective actions to prevent recurrence. Knowing how to properly document and report incidents.

- Personal Protective Equipment (PPE): Knowledge of various types of PPE, their proper selection, use, and limitations, as well as understanding relevant regulations and standards related to PPE.

- Ergonomics and Musculoskeletal Disorders (MSDs): Understanding ergonomic principles and their application to reduce the risk of MSDs. This includes workstation setup, lifting techniques, and the importance of employee training in these areas.

- Problem-Solving Approaches: Demonstrating the ability to analyze safety-related problems, propose solutions, and evaluate their effectiveness. This may include scenarios involving conflicting priorities or limited resources.

Next Steps

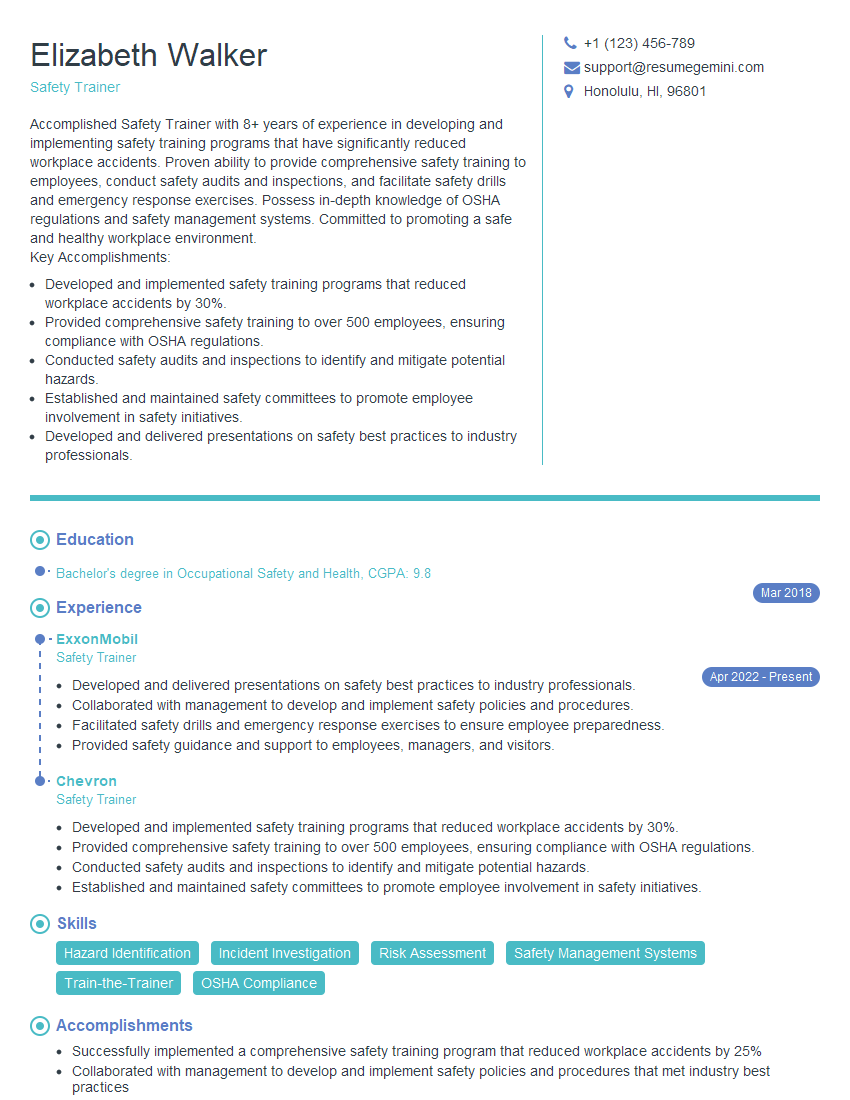

Mastering Maintaining Workplace Safety significantly enhances your career prospects, opening doors to leadership roles and higher earning potential. A strong safety record is highly valued by employers. To maximize your job search success, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the specific requirements of Maintaining Workplace Safety positions. Examples of resumes tailored to this field are provided to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO