Cracking a skill-specific interview, like one for Materials Science and Properties, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Materials Science and Properties Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both crucial measures of a material’s ability to withstand tensile forces (pulling forces), but they represent different points on the material’s stress-strain curve. Tensile strength represents the maximum stress a material can withstand before it fractures or breaks. Think of it as the ultimate breaking point. Yield strength, on the other hand, indicates the stress at which the material begins to deform permanently. It’s the point where the material starts to yield or stretch plastically, meaning the deformation is irreversible.

Imagine pulling on a piece of taffy. The yield strength is reached when the taffy starts to stretch noticeably and doesn’t snap back to its original shape when you let go. The tensile strength is when it finally breaks. Materials with high tensile strength are strong and resistant to breaking, while those with high yield strength are resistant to permanent deformation.

In engineering design, understanding both tensile and yield strength is vital for selecting materials appropriate for different applications. A bridge, for instance, requires a material with both high tensile and yield strengths to withstand significant loads without breaking or permanently deforming.

Q 2. Describe the various types of crystal structures.

Crystalline materials are characterized by the ordered arrangement of atoms, ions, or molecules. Several common crystal structures exist, categorized primarily by the unit cell – the smallest repeating unit that defines the entire crystal lattice. Key types include:

- Body-Centered Cubic (BCC): Atoms are located at the corners and the center of a cube. Examples include iron (at lower temperatures), chromium, and tungsten. BCC structures often exhibit good strength and ductility.

- Face-Centered Cubic (FCC): Atoms are located at the corners and the center of each face of a cube. Examples include aluminum, copper, nickel, and gold. FCC structures are known for their ductility and malleability.

- Hexagonal Close-Packed (HCP): Atoms are arranged in a hexagonal close-packed arrangement. Examples include titanium, magnesium, and zinc. HCP structures generally show good strength but lower ductility compared to FCC.

- Simple Cubic (SC): While less common due to low packing efficiency, it features atoms only at the corners of a cube. It serves as a fundamental structure for understanding more complex arrangements.

The type of crystal structure significantly influences a material’s properties. For example, the slip systems (planes along which atoms can easily move) within these structures directly affect a material’s ductility and strength.

Q 3. What are the factors affecting the corrosion resistance of a material?

Corrosion resistance, the ability of a material to withstand deterioration caused by its environment, is affected by several factors:

- Material Composition: Noble metals like gold and platinum are highly corrosion-resistant due to their inherent stability. The presence of alloying elements can also significantly affect corrosion resistance. Stainless steel, for example, owes its corrosion resistance to chromium, which forms a passive oxide layer.

- Environment: The surrounding environment plays a crucial role. Highly acidic or alkaline environments are more corrosive than neutral ones. The presence of oxygen, moisture, and other chemicals accelerates corrosion. Salt water is particularly corrosive.

- Temperature: Higher temperatures generally increase the rate of corrosion reactions.

- Surface Finish: Rough surfaces provide more area for corrosion to initiate, making them less resistant than smooth surfaces.

- Stress: Stress concentration areas are more susceptible to corrosion (stress corrosion cracking).

Understanding these factors is crucial for selecting appropriate materials for specific applications. For instance, marine applications demand materials with exceptional corrosion resistance to withstand the harsh saltwater environment.

Q 4. How does grain size influence the mechanical properties of a material?

Grain size, the average size of the individual crystals (grains) in a polycrystalline material, profoundly impacts its mechanical properties. Smaller grains generally lead to:

- Increased Strength: Smaller grains present more grain boundaries, which act as barriers to dislocation movement (dislocations are defects in the crystal lattice that contribute to plastic deformation). More grain boundaries mean more resistance to deformation, resulting in higher strength.

- Increased Hardness: Similar to strength, smaller grains hinder dislocation movement, leading to increased hardness.

- Improved Ductility (sometimes): While generally increasing strength, a reduction in grain size can sometimes improve ductility in certain materials within a specific range of grain sizes. However, excessively small grain sizes can lead to decreased ductility.

- Improved Toughness: Finer-grained materials often exhibit greater toughness due to the increased resistance to crack propagation.

Techniques like controlled cooling during solidification or cold working are used to manipulate grain size and achieve desired mechanical properties. For example, the strength of steel can be significantly improved through processes that reduce grain size.

Q 5. Explain the concept of stress-strain curve and its significance.

A stress-strain curve graphically represents the relationship between stress (force per unit area) and strain (deformation) applied to a material. It’s a fundamental tool for characterizing material behavior under tensile loading. The curve typically displays several key regions:

- Elastic Region: The material deforms elastically, meaning it returns to its original shape upon removal of the load. The slope of this region represents Young’s modulus (a measure of stiffness).

- Yield Point: The point at which plastic deformation begins. Beyond this point, the material will not return to its original shape.

- Plastic Region: The material undergoes permanent deformation. This region shows strain hardening (work hardening), where the material becomes stronger with increasing deformation.

- Ultimate Tensile Strength: The maximum stress the material can withstand before failure.

- Fracture Point: The point at which the material breaks.

The stress-strain curve’s significance lies in its ability to provide crucial information about a material’s mechanical properties, including its yield strength, tensile strength, ductility, and modulus of elasticity. Engineers use this data for material selection and design optimization.

Q 6. Describe different types of non-destructive testing methods for materials.

Non-destructive testing (NDT) methods allow for the evaluation of a material’s properties without causing damage. Several common techniques include:

- Visual Inspection: A simple but effective method for detecting surface cracks, corrosion, or other defects.

- Liquid Penetrant Testing: A dye penetrant is applied to the surface to reveal surface-breaking flaws.

- Magnetic Particle Inspection: Used to detect surface and near-surface flaws in ferromagnetic materials. Magnetic particles are attracted to discontinuities.

- Ultrasonic Testing: High-frequency sound waves are used to detect internal flaws. The technique is based on the reflection of sound waves from discontinuities.

- Radiographic Testing (X-ray or Gamma-ray): Penetrating radiation is used to create an image of the internal structure, revealing internal flaws.

- Eddy Current Testing: Uses electromagnetic induction to detect surface and subsurface flaws in conductive materials.

NDT methods are critical in ensuring the integrity of structures and components in various industries, including aerospace, automotive, and construction.

Q 7. What are the common methods used for materials characterization?

Materials characterization involves determining the physical, chemical, and structural properties of a material. Common methods include:

- Microscopy (Optical, SEM, TEM): Visualizing the material’s microstructure at different magnifications. Optical microscopy examines surface features, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) reveal fine details of the structure.

- X-ray Diffraction (XRD): Determining the crystal structure and phase composition.

- Mechanical Testing (Tensile, Compression, Hardness): Measuring mechanical properties like strength, ductility, and hardness.

- Thermal Analysis (Differential Scanning Calorimetry, Thermogravimetric Analysis): Investigating thermal transitions and decomposition behavior.

- Spectroscopy (UV-Vis, FTIR, Raman): Analyzing the chemical composition and bonding.

- Chemical Analysis (e.g., Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES)): Determining elemental composition.

The choice of characterization technique depends on the specific properties of interest and the nature of the material being studied. For example, XRD is ideal for determining crystal structure, while tensile testing provides information about strength and ductility.

Q 8. Explain the principles behind X-ray diffraction (XRD).

X-ray diffraction (XRD) is a powerful technique used to determine the crystal structure of a material. It relies on the principle of constructive interference of X-rays scattered by the atoms in a crystalline lattice. Imagine throwing pebbles into a still pond – the ripples interfere with each other. Similarly, X-rays, which are electromagnetic waves, scatter from the atoms in a crystal. When the path difference between scattered waves is an integer multiple of the wavelength, constructive interference occurs, producing a strong diffracted beam. This occurs at specific angles, which are unique to the crystal structure and spacing of atoms.

The Bragg’s Law, nλ = 2d sinθ, governs this phenomenon. Here, n is an integer (order of reflection), λ is the wavelength of the X-rays, d is the interplanar spacing (distance between parallel planes of atoms), and θ is the angle of incidence (and reflection). By measuring the angles (θ) at which these strong diffracted beams occur, we can calculate the d-spacings and ultimately determine the crystal structure of the material. XRD is extensively used in materials science to identify phases, determine crystallite size, measure strain, and analyze preferred orientation.

For example, XRD can distinguish between quartz (SiO2) and cristobalite (another form of SiO2) because they have different crystal structures, resulting in different diffraction patterns. This is crucial in geological applications, ceramic manufacturing, and many other fields.

Q 9. Describe different types of polymers and their properties.

Polymers are large molecules composed of repeating structural units called monomers. They’re categorized based on various properties and structures. Some key types include:

- Thermoplastics: These polymers soften when heated and harden when cooled, allowing for repeated molding. Examples include polyethylene (used in plastic bags), polypropylene (used in containers), and polystyrene (used in packaging).

- Thermosets: These polymers undergo irreversible chemical changes upon heating, forming a rigid, cross-linked structure. They don’t melt upon reheating and are typically stronger and more resistant to heat than thermoplastics. Examples include epoxy resins (used as adhesives) and vulcanized rubber (used in tires).

- Elastomers: These are flexible polymers with high elasticity, meaning they can stretch significantly and return to their original shape. Rubber is a classic example, found in many applications from tires to seals.

The properties of polymers vary widely depending on their chemical composition, molecular weight, and degree of crystallinity. For example, high-density polyethylene (HDPE) is stronger and more rigid than low-density polyethylene (LDPE) due to its higher degree of crystallinity and longer polymer chains.

Q 10. What are composites and their advantages?

Composites are materials made from two or more constituent materials with significantly different properties. These materials are combined to create a new material with enhanced properties. A classic example is reinforced concrete: concrete (a brittle material) is reinforced with steel rods (a ductile material) to increase its tensile strength.

The advantages of composites are numerous:

- High strength-to-weight ratio: Composites often exhibit superior strength and stiffness compared to their individual components, especially when considering weight.

- Tailored properties: The properties of a composite can be finely tuned by adjusting the type and amount of constituent materials, making them highly versatile.

- Corrosion resistance: Certain composites exhibit exceptional resistance to corrosion and degradation.

- Design flexibility: Composites can be molded into complex shapes, allowing for innovative designs.

Examples of composites include fiberglass (glass fibers in a polymer matrix), carbon fiber reinforced polymer (CFRP) used in aerospace applications, and wood (cellulose fibers in a lignin matrix).

Q 11. How do you select materials for a specific application?

Material selection is a crucial step in engineering design. It involves a systematic approach considering several factors:

- Required properties: What mechanical, thermal, electrical, or chemical properties are needed for the application? For example, a material for a high-temperature application needs excellent thermal stability.

- Environmental conditions: Will the material be exposed to corrosive environments, high temperatures, or extreme pressures? This influences the choice of material greatly.

- Cost: The cost of the material and its processing should be considered. Some high-performance materials might be too expensive for certain applications.

- Manufacturing process: The material must be compatible with the chosen manufacturing process. For example, a material that’s difficult to machine might not be suitable for a complex part.

- Availability and sustainability: The availability of the material and its environmental impact must be considered. Sustainable and recyclable materials are becoming increasingly important.

A systematic approach, often using material selection charts or software, helps narrow down the options. For instance, choosing a material for a bicycle frame involves balancing strength, weight, and cost, with considerations for fatigue resistance and impact resistance. Steel, aluminum, and carbon fiber composites are all viable options, each with its own set of trade-offs.

Q 12. Explain the concept of fatigue failure in materials.

Fatigue failure is the progressive and localized structural damage that occurs when a material is subjected to cyclic loading (repeated stresses). Imagine repeatedly bending a paperclip – eventually, it will break, even if the applied stress in each cycle is far below the material’s ultimate tensile strength. This is fatigue.

The process begins with the initiation of micro-cracks at stress concentration points (e.g., surface imperfections, notches). These cracks propagate gradually with each loading cycle until they reach a critical size, leading to sudden failure. Fatigue failure is often catastrophic and unpredictable because the cracks propagate below the yield strength of the material.

Factors influencing fatigue life include the magnitude of the applied stress, the number of cycles, the material’s properties (e.g., yield strength, ductility), surface finish, and environmental factors. Fatigue testing is critical in engineering to determine the fatigue strength and life of components, ensuring their reliability and preventing unexpected failures in applications like aircraft wings, bridges, and medical implants.

Q 13. Describe the different types of heat treatments for metals.

Heat treatments are processes that involve carefully controlling the temperature and time to alter the microstructure and mechanical properties of metals. Common types include:

- Annealing: This process involves heating the metal to a specific temperature, holding it for a period, and then slowly cooling it. It relieves internal stresses, softens the metal, and improves ductility. Different types of annealing exist, such as stress-relief annealing and recrystallization annealing.

- Quenching: This involves rapidly cooling a heated metal, usually in water or oil. It’s used to increase hardness and strength by transforming the microstructure. The cooling rate is crucial in determining the final microstructure.

- Tempering: This process follows quenching and involves reheating the quenched metal to a lower temperature and then cooling it slowly. It reduces the brittleness associated with quenching while maintaining a significant increase in hardness.

- Normalizing: Similar to annealing, but the cooling rate is faster, resulting in a finer grain size and improved mechanical properties.

These heat treatments are widely used to tailor the properties of metals for specific applications. For example, steel used in tools and cutting instruments undergoes quenching and tempering to achieve high hardness and toughness. The type and parameters of heat treatment are carefully chosen based on the desired properties and the metal’s composition.

Q 14. Explain the difference between ductile and brittle fracture.

Ductile and brittle fracture are two distinct modes of failure in materials under stress. Ductile fracture is characterized by significant plastic deformation before fracture, exhibiting noticeable necking and yielding. Think of pulling taffy – it stretches and necks down before breaking. Brittle fracture, on the other hand, occurs suddenly and without much plastic deformation. Imagine snapping a dry twig – it breaks instantly without much bending.

Key differences:

- Ductile fracture: Shows considerable plastic deformation, slow crack propagation, and warning signs before failure. The fracture surface is typically rough and fibrous.

- Brittle fracture: Shows minimal plastic deformation, rapid crack propagation, and often catastrophic failure with little warning. The fracture surface is usually smooth and crystalline.

The type of fracture depends on factors like material properties (ductility, toughness), temperature, loading rate, and the presence of flaws or cracks. Ductile materials are preferred in many applications where warning signs before failure are critical for safety, while brittle materials may be acceptable in applications where failure is less critical, or where high strength is paramount despite the lack of ductility.

Q 15. What are the common methods for joining materials?

Joining materials is crucial in manufacturing and construction, creating stronger, more complex structures from individual components. Common methods broadly fall into two categories: those involving melting and those that don’t.

- Fusion Bonding: This involves melting the materials to be joined, allowing them to intermix and solidify together. Examples include welding (using heat and pressure, often with a filler material), brazing (using a lower-melting-point filler metal), and soldering (similar to brazing but with even lower melting point filler metals). The choice depends on the materials’ melting points and desired joint strength. For instance, welding steel beams in a skyscraper requires high-temperature techniques, while soldering electronic components uses much lower temperatures.

- Solid-State Joining: These techniques join materials without melting them. Examples include adhesive bonding (using polymers or epoxies), mechanical fastening (riveting, bolting, screwing), and diffusion bonding (applying heat and pressure to allow atomic diffusion across the interface). Consider the use of adhesives in automotive manufacturing for joining different plastic parts, or the riveting of aircraft aluminum panels for strength and lightweight construction.

The optimal method depends heavily on the materials being joined, the required strength of the joint, the cost constraints, and the application’s environmental conditions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of phase diagrams.

Phase diagrams are graphical representations showing the equilibrium relationships between different phases (solid, liquid, gas) of a material system as a function of temperature, pressure, and composition. Think of it as a map guiding you through the material’s possible states. They are essential for understanding material behavior and processing.

For instance, a binary phase diagram (for a two-component system) shows how the phases change with varying temperature and composition. Key features include: liquidus (the temperature at which the last solid melts), solidus (the temperature at which the last liquid solidifies), and different phase regions (solid solution, eutectic, etc.). Understanding the phase diagram helps predict the microstructure and therefore the properties of the material after processing. For example, a steelmaker uses the iron-carbon phase diagram to control the cooling rate during steel production to achieve a specific microstructure (e.g., martensite for hardness, pearlite for strength).

These diagrams are vital in materials selection and processing. They allow us to predict the resulting microstructure and, consequently, the material properties under different conditions.

Q 17. Describe different types of ceramics and their applications.

Ceramics are inorganic, non-metallic materials formed by heating non-metallic minerals to high temperatures. Their properties depend heavily on their composition and processing.

- Oxides: These are the most common type, including alumina (Al2O3) used in high-strength applications and zirconia (ZrO2) in thermal barrier coatings. Alumina is known for its high hardness and is used in cutting tools, while zirconia’s high temperature stability makes it ideal for engine components.

- Carbides: These are compounds of carbon and another element, such as tungsten carbide (WC), which is exceptionally hard and used in cutting tools and drill bits. Its hardness stems from the strong covalent bonds between tungsten and carbon atoms.

- Nitrides: These are compounds of nitrogen and another element. Silicon nitride (Si3N4) is a high-strength, high-temperature material used in engine components and cutting tools, known for its excellent thermal shock resistance.

- Silicates: These are compounds containing silicon and oxygen, forming the basis of many glasses and ceramics, including common glass and porcelain, used in diverse applications from windows and insulators to tableware.

The application of each type depends on its unique properties: strength, hardness, thermal shock resistance, electrical insulation, etc. Careful selection based on the phase diagram and microstructure analysis is critical in ensuring optimal performance.

Q 18. What are the challenges in using nanomaterials?

Nanomaterials, with at least one dimension less than 100 nanometers, offer unique properties due to their high surface area to volume ratio. However, several challenges exist in their application:

- Synthesis and Characterization: Controlled synthesis of nanomaterials with precise size and shape is difficult, and characterization requires sophisticated techniques like electron microscopy and X-ray diffraction.

- Aggregation and Stability: Nanoparticles tend to agglomerate due to strong van der Waals forces, affecting their properties and requiring stabilizing agents.

- Toxicity and Environmental Impact: The potential toxicity of some nanomaterials to humans and the environment is a major concern. Proper handling and disposal protocols are necessary. For instance, some carbon nanotubes have shown potential toxicity in certain biological systems.

- Scalability and Cost: Producing nanomaterials in large quantities cost-effectively remains a challenge, hindering their widespread adoption.

- Mechanical and Electrical Properties: While often enhanced, the mechanical and electrical properties are sometimes unpredictable and difficult to control consistently.

Overcoming these challenges is critical for harnessing the full potential of nanomaterials in various sectors, such as medicine, electronics, and energy.

Q 19. Explain the concept of diffusion in materials.

Diffusion is the net movement of atoms or molecules from a region of higher concentration to a region of lower concentration. In materials science, it’s a fundamental process impacting many properties and phenomena, particularly at elevated temperatures.

The driving force is the concentration gradient. Think of it like dropping a sugar cube into a cup of water – the sugar molecules spread out until evenly distributed. The rate of diffusion depends on temperature (higher temperatures lead to faster diffusion), the type of material (crystalline structures have different diffusion pathways than amorphous ones), and the diffusing species (smaller atoms diffuse faster).

Examples include the annealing of metals (heat treatment to reduce stresses and improve ductility), the doping of semiconductors (introducing impurities to control electrical conductivity), and the formation of solid solutions.

Understanding diffusion is vital for controlling various material processes, such as heat treatments, sintering, and surface modifications.

Q 20. How does temperature affect the mechanical properties of materials?

Temperature significantly affects the mechanical properties of materials. Generally, increasing the temperature leads to decreased strength and hardness but increased ductility.

At low temperatures, atomic vibrations are minimal, and the material is strong and brittle. As temperature increases, atomic vibrations become more pronounced, leading to increased dislocation motion (which is responsible for plastic deformation). This results in reduced strength and increased ductility. At even higher temperatures, creep (slow deformation under sustained stress) can occur, resulting in permanent deformation even under low stress. Also, some materials exhibit phase transformations at specific temperatures, leading to significant changes in their properties. For example, steel’s microstructure changes significantly around 727°C (A1), which significantly influences its properties.

This understanding is crucial in designing and selecting materials for high-temperature applications such as jet engines, where creep resistance is paramount.

Q 21. Describe the different types of bonding in materials.

Materials are held together by different types of bonding, each influencing their properties significantly.

- Ionic Bonding: This involves the transfer of electrons from one atom to another, resulting in oppositely charged ions that are electrostatically attracted. Sodium chloride (NaCl) is a classic example; the sodium atom loses an electron to become a positive ion, and the chlorine atom gains an electron to become a negative ion, forming a strong ionic bond.

- Covalent Bonding: This involves the sharing of electrons between atoms. This type of bond is very strong and common in ceramics, such as silicon carbide (SiC). Diamond is another excellent example, showing exceptional hardness due to its strong covalent network structure.

- Metallic Bonding: This involves the delocalization of electrons in a ‘sea’ of electrons surrounding a lattice of positively charged metal ions. This type of bonding accounts for the high electrical and thermal conductivity of metals. Copper, for example, is an excellent conductor because its electrons are easily mobile.

- Van der Waals Bonding: This is a weaker type of bonding resulting from temporary fluctuations in electron distribution around atoms or molecules. It plays a role in holding together polymer chains and contributes to the properties of some soft materials.

- Hydrogen Bonding: A special type of dipole-dipole attraction involving a hydrogen atom bonded to a highly electronegative atom (like oxygen or nitrogen).

Understanding these bonding types is essential for predicting and controlling material properties. For example, the strong covalent bonds in diamond lead to its exceptional hardness, while the weak van der Waals bonds in polymers lead to their flexibility.

Q 22. What are smart materials and their applications?

Smart materials, also known as intelligent materials or responsive materials, are substances that exhibit a significant change in their properties in response to small changes in their environment. This change can be triggered by various stimuli, including temperature, light, pressure, electric or magnetic fields, or pH levels. Think of them as materials with a built-in ‘sensing’ and ‘actuating’ capability.

- Shape Memory Alloys (SMAs): These alloys, like Nitinol (Nickel-Titanium), can ‘remember’ their original shape and return to it after deformation when subjected to a specific temperature. Applications include medical stents (expanding within arteries) and actuators in robotics.

- Piezoelectric Materials: These materials generate an electric charge in response to applied mechanical stress, and vice versa. They are used in sensors, actuators, and energy harvesting devices. For example, they’re found in inkjet printers and some microphones.

- Electrochromic Materials: These materials change their optical properties (e.g., color or transparency) when an electric field is applied. Applications include ‘smart windows’ that automatically adjust light transmission based on sunlight intensity.

- Magnetostrictive Materials: These materials change their shape or dimensions when exposed to a magnetic field. Used in sensors, actuators, and ultrasonic transducers.

Smart materials are revolutionizing various industries by enabling the creation of adaptive and responsive systems. Their applications range from aerospace and automotive to biomedical engineering and consumer electronics, continuously pushing the boundaries of innovation.

Q 23. Explain the concept of creep in materials.

Creep is the time-dependent plastic deformation of a material under a constant load or stress at elevated temperatures. Imagine a metal beam supporting a heavy weight; over time, at high enough temperature, the beam will slowly deform and sag even though the weight remains constant. This is creep.

The process is driven by thermally activated diffusion of atoms within the material’s crystal structure. This allows dislocations (crystal defects) to move and rearrange, leading to permanent deformation. The rate of creep is highly dependent on temperature, applied stress, and the material’s microstructure. Higher temperatures and stresses accelerate creep, while a finer grain size generally enhances creep resistance.

Creep is a critical factor in the design of high-temperature components like turbine blades in jet engines or pressure vessels in power plants. Accurate prediction of creep behavior is vital to ensure the long-term structural integrity of these components.

Q 24. Describe different types of failure mechanisms in materials.

Material failure mechanisms describe the processes leading to the loss of a material’s ability to function. Many mechanisms can act individually or in combination. Here are some key types:

- Ductile Fracture: Characterized by significant plastic deformation before fracture. The fracture surface shows a cup-and-cone appearance. It’s often associated with void nucleation, growth, and coalescence.

- Brittle Fracture: Occurs suddenly with little or no plastic deformation. The fracture surface is typically flat and relatively smooth. It’s often initiated by flaws or cracks.

- Fatigue Failure: Results from repeated cyclical loading, even below the material’s yield strength. Microscopic cracks initiate and propagate, eventually leading to fracture. Fatigue failure is a major cause of failure in many engineering applications.

- Creep Rupture: Occurs at elevated temperatures under sustained loading due to the time-dependent creep deformation. The material gradually weakens and eventually fractures.

- Corrosion: Degradation of materials due to chemical or electrochemical reactions with their environment. Corrosion can significantly weaken a material, making it susceptible to other failure mechanisms.

Understanding these failure mechanisms is crucial for designing safe and reliable structures and components. Engineers need to carefully consider the operating conditions, material properties, and potential failure modes to prevent catastrophic failures.

Q 25. How do you interpret a fracture surface?

Interpreting a fracture surface is a crucial aspect of failure analysis. It provides valuable insights into the cause and mechanism of failure. A detailed examination can reveal information about the type of fracture (ductile or brittle), the direction of crack propagation, and the presence of any initiating flaws.

The process involves visual inspection using a stereo microscope, often supplemented by other techniques such as scanning electron microscopy (SEM) for higher magnification and detailed surface analysis. Key features to observe include:

- Fracture Surface Topography: Ductile fractures exhibit dimples (indicating void coalescence), while brittle fractures are usually flat and feature cleavage facets.

- Crack Propagation Direction: The direction of crack propagation can reveal the loading conditions and the presence of stress concentrations.

- Evidence of Fatigue: Fatigue failures typically exhibit characteristic striations (fine lines) or beach marks on the fracture surface, indicating the progressive growth of cracks under cyclic loading.

- Inclusion or Defect Analysis: The presence of inclusions or defects can serve as crack initiation sites. SEM analysis can identify these and their role in the fracture.

By carefully analyzing these features, a skilled materials scientist or engineer can reconstruct the failure sequence and identify the root cause, aiding in the prevention of similar incidents.

Q 26. What is the significance of material selection in product design?

Material selection is paramount in product design; the choice of material directly impacts the product’s performance, durability, cost, and environmental impact. A poorly chosen material can lead to functional failure, premature wear, or excessive costs.

The selection process typically involves considering several factors:

- Mechanical Properties: Strength, stiffness, hardness, ductility, toughness, fatigue strength, and creep resistance are critical, depending on the intended application.

- Physical Properties: Density, thermal conductivity, electrical conductivity, magnetic properties, and optical properties influence the product’s functionality and behavior.

- Chemical Properties: Corrosion resistance, reactivity, and biocompatibility are essential for materials exposed to aggressive environments or in biomedical applications.

- Manufacturing Considerations: The ease and cost of manufacturing and processing the selected material must also be taken into account.

- Cost and Availability: The cost of the material and its availability need to be balanced against performance requirements.

- Environmental Impact: The material’s life cycle assessment (LCA), considering its environmental impact throughout its production, use, and disposal, is increasingly important.

Tools like Ashby charts can be utilized to aid in material selection by visualizing the trade-offs between different material properties. The overall goal is to select the optimal material that meets all design requirements while minimizing costs and environmental impact.

Q 27. Explain the concept of viscoelasticity.

Viscoelasticity describes the behavior of materials that exhibit both viscous (fluid-like) and elastic (solid-like) properties. Imagine silly putty: you can stretch it like an elastic solid, but it also flows slowly like a viscous liquid. This dual behavior is viscoelasticity.

Viscoelastic materials deform under stress, but the deformation is not instantaneous; there is a time-dependent component. When the stress is removed, the material partially recovers its original shape, but some residual deformation remains. This behavior is characterized by its dependence on both stress and time.

The concept is described using constitutive models, such as the Maxwell model (spring and dashpot in series) or the Kelvin-Voigt model (spring and dashpot in parallel). These models provide a mathematical framework for predicting the material’s response to various loading conditions. Viscoelasticity is crucial in applications involving polymers, rubbers, and biological tissues where time-dependent deformation is significant.

Examples include shock absorbers in vehicles, which use viscoelastic materials to dampen vibrations, and certain biomedical implants designed to mimic the viscoelastic properties of human tissues.

Q 28. Describe the role of defects in influencing material properties.

Defects in materials, deviations from the perfect crystal lattice structure, significantly influence their properties. These defects can range from point defects (vacancies, interstitial atoms, substitutional atoms) to line defects (dislocations) and planar defects (grain boundaries, stacking faults).

The impact of defects can be substantial:

- Strength and Hardness: Dislocations impede the movement of other dislocations, increasing the material’s strength and hardness. Grain boundaries also hinder dislocation movement.

- Ductility: Excessive dislocation density can lead to reduced ductility (the ability to deform plastically) by impeding dislocation motion.

- Electrical Conductivity: Point defects can act as scattering centers for electrons, reducing the electrical conductivity of metals. In semiconductors, carefully controlled doping (introducing specific impurities) creates defects that modify electrical properties.

- Thermal Conductivity: Defects scatter phonons (lattice vibrations) which carry heat, thus affecting thermal conductivity.

- Corrosion Resistance: Grain boundaries can act as preferential sites for corrosion initiation.

Defect engineering, the controlled introduction or modification of defects, is a powerful tool in materials science for tailoring material properties to meet specific application needs. For example, controlled doping of semiconductors is essential for creating transistors and other electronic devices.

Key Topics to Learn for Materials Science and Properties Interview

- Crystal Structures and Defects: Understanding crystallographic structures (BCC, FCC, HCP), point defects (vacancies, interstitials), line defects (dislocations), and their impact on material properties. Consider practical examples like strengthening mechanisms in metals.

- Mechanical Properties: Mastering concepts like stress, strain, elasticity, plasticity, yield strength, tensile strength, ductility, hardness, and fracture toughness. Think about how these properties relate to material selection for specific engineering applications (e.g., choosing a material for a high-strength component vs. a flexible one).

- Phase Diagrams and Transformations: Learn to interpret phase diagrams (e.g., iron-carbon diagram), understand phase transformations (e.g., solidification, eutectic reactions), and their influence on microstructure and properties. Consider the implications for heat treatments and alloy design.

- Diffusion and Mass Transport: Grasp the principles of diffusion (Fick’s laws), its mechanisms, and its importance in processes like sintering, doping, and corrosion. Think about examples in semiconductor fabrication or ceramic processing.

- Thermodynamics and Kinetics of Materials: Understand the thermodynamic principles governing phase equilibria and the kinetic factors influencing the rate of phase transformations. Consider the application of these concepts to material processing and performance.

- Electronic and Optical Properties: Explore concepts like conductivity, band theory, and dielectric properties. Consider applications in semiconductors, insulators, and optoelectronic devices.

- Material Characterization Techniques: Familiarize yourself with common techniques like XRD, SEM, TEM, and mechanical testing. Understand the information obtained from each technique and its relevance to materials analysis.

- Materials Selection and Design: Practice selecting appropriate materials for specific applications based on their properties and performance requirements. This involves understanding trade-offs and limitations.

Next Steps

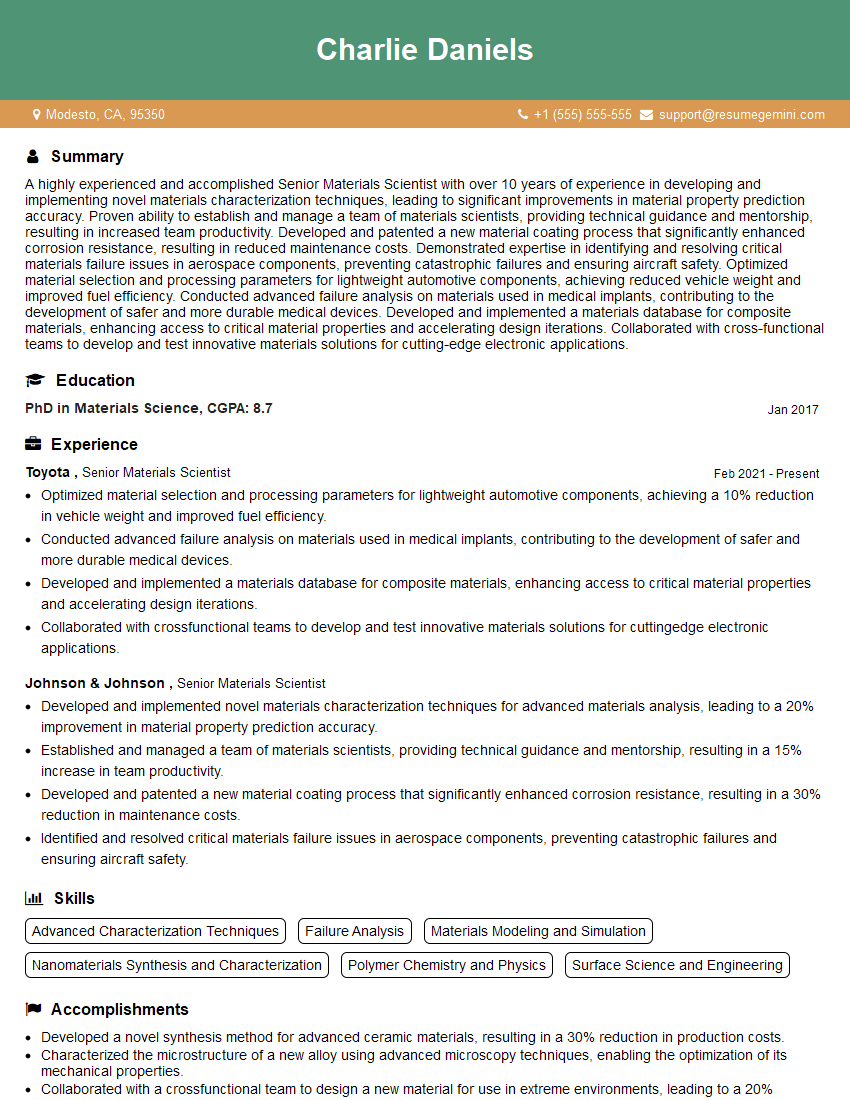

Mastering Materials Science and Properties is crucial for a successful and rewarding career in various engineering fields. A strong understanding of these concepts opens doors to exciting opportunities in research, development, and manufacturing. To maximize your job prospects, it’s vital to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to Materials Science and Properties are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO