Cracking a skill-specific interview, like one for Mechatronics and Automation, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Mechatronics and Automation Interview

Q 1. Explain the fundamental principles of mechatronics.

Mechatronics is the synergistic integration of mechanical engineering, electrical engineering, computer engineering, and control engineering. It’s not simply combining these disciplines; it’s about designing systems where each component works in harmony to achieve a specific function, often with a high degree of automation. Think of it like a well-orchestrated symphony – each instrument (mechanical, electrical, computer) plays its part to create a beautiful, unified whole.

Fundamentally, mechatronics involves:

- Sensing: Acquiring information about the system’s state through sensors (e.g., temperature, position, pressure).

- Processing: Using a microcontroller or computer to analyze sensor data and make decisions.

- Actuation: Implementing control actions using actuators (e.g., motors, valves, pumps) to manipulate the system.

- Control: Employing control algorithms (like PID controllers) to regulate the system’s behavior and achieve desired performance.

For example, an anti-lock braking system (ABS) in a car is a perfect mechatronics system. Sensors detect wheel speed, a computer processes this data, and actuators (hydraulic brakes) are controlled to prevent wheel lockup during braking.

Q 2. Describe different types of sensors used in automation systems and their applications.

Automation systems rely heavily on sensors to gather information about the environment and the system’s state. Different types of sensors are used depending on the specific application.

- Proximity Sensors: Detect the presence or absence of an object without physical contact. Inductive, capacitive, and ultrasonic proximity sensors are commonly used in robotics and automated assembly lines.

- Temperature Sensors: Measure temperature, crucial for process control and safety. Thermocouples, RTDs (Resistance Temperature Detectors), and thermistors are examples.

- Pressure Sensors: Detect pressure variations, used in hydraulic and pneumatic systems, as well as in environmental monitoring.

- Optical Sensors: Detect light intensity or changes in light patterns. Photodiodes, phototransistors, and image sensors are used in machine vision systems and barcode scanners.

- Position Sensors: Measure the position or displacement of an object. Potentiometers, encoders, and linear variable differential transformers (LVDTs) are common examples.

In a factory automation setting, for example, proximity sensors might detect the presence of a part on a conveyor belt, triggering a robotic arm to pick it up. Temperature sensors would ensure the system doesn’t overheat, while pressure sensors could monitor the air pressure in a pneumatic system.

Q 3. What are the advantages and disadvantages of using PLC’s in automation?

Programmable Logic Controllers (PLCs) are the workhorses of industrial automation. They offer several advantages:

- Reliability: PLCs are designed for harsh industrial environments and are highly reliable.

- Flexibility: They can be easily reprogrammed to control different processes.

- Modularity: They can be expanded with input/output modules to accommodate varying numbers of sensors and actuators.

- Cost-effective: While the initial investment might seem high, the long-term cost-effectiveness outweighs the initial cost.

However, there are some disadvantages:

- Programming Complexity: Programming PLCs can be complex, requiring specialized knowledge and training.

- Vendor Dependence: Different PLC manufacturers often use proprietary programming languages, creating vendor lock-in.

- Scalability Challenges: Scaling up a PLC-based system can sometimes be challenging and costly.

In essence, the decision of whether to use PLCs depends on the specific application and its requirements. For large-scale, complex automation tasks, PLCs offer significant advantages, but smaller applications might benefit from simpler solutions.

Q 4. Explain the function of a PID controller and its tuning methods.

A Proportional-Integral-Derivative (PID) controller is a widely used feedback control algorithm used to regulate a process variable (like temperature or speed) to a desired setpoint. It uses three terms to achieve this:

- Proportional (P): The output is proportional to the error (difference between setpoint and actual value). A larger error results in a larger corrective action.

- Integral (I): The output is proportional to the integral of the error over time. This term addresses persistent errors, eliminating steady-state error.

- Derivative (D): The output is proportional to the rate of change of the error. This term anticipates future errors and helps to dampen oscillations.

Output = Kp * error + Ki * integral(error) + Kd * derivative(error)

PID tuning involves adjusting the proportional gain (Kp), integral gain (Ki), and derivative gain (Kd) to achieve optimal performance. Methods for tuning include:

- Trial and Error: Manually adjusting the gains until satisfactory performance is achieved. This is time-consuming but simple.

- Ziegler-Nichols Method: A systematic approach that involves finding the ultimate gain and ultimate period of oscillation and then calculating the gains.

- Auto-tuning: Many modern controllers have auto-tuning features that automatically adjust the gains.

Proper PID tuning is crucial for achieving stability, minimizing overshoot, and reducing settling time. Incorrect tuning can lead to instability, oscillations, or poor performance.

Q 5. Describe different types of actuators used in mechatronics and their applications.

Actuators are the muscles of a mechatronic system, converting energy into motion or force. Different types exist, each suited for specific applications:

- Electric Motors: DC motors, AC motors (induction, synchronous, stepper), and servo motors are widely used. They offer precise control, high efficiency, and easy integration with electronic control systems. Servo motors are particularly valuable for applications requiring precise positioning and speed control.

- Hydraulic Actuators: Use pressurized fluids to generate force. They are capable of producing very high forces and are suitable for heavy-duty applications. Examples include hydraulic cylinders and rotary actuators.

- Pneumatic Actuators: Use compressed air to generate motion. They are relatively inexpensive, safe (compared to hydraulics), and well-suited for lighter applications. Examples include pneumatic cylinders and rotary actuators.

- Piezoelectric Actuators: Use piezoelectric materials that change shape when an electric field is applied. They offer extremely precise and rapid movements, ideal for micropositioning applications.

For example, a robotic arm might use electric servo motors for precise joint movements, a large industrial press might employ a hydraulic actuator for its powerful operation, and a simple automated valve might use a pneumatic actuator for its operation.

Q 6. What are the different types of robotic arms and their applications?

Robotic arms are versatile manipulators used in various industries. Different types exist based on their structure and degrees of freedom:

- Cartesian Robots (Gantry Robots): Move along three linear axes (X, Y, Z). They are simple, accurate, and suitable for pick-and-place operations in a defined workspace.

- Cylindrical Robots: Have one rotary joint and two linear joints. Their workspace is cylindrical.

- Spherical Robots (Polar Robots): Have two rotary joints and one linear joint. Their workspace is spherical.

- Articulated Robots (Revolute Robots): Have multiple rotary joints, resembling a human arm. They offer high flexibility and dexterity, allowing them to reach various positions and orientations.

- SCARA Robots (Selective Compliance Assembly Robot Arm): Have two parallel rotary joints and one vertical linear joint. They are well-suited for assembly tasks requiring high speed and accuracy in a planar workspace.

Applications vary significantly: Cartesian robots are common in CNC machining, cylindrical robots are found in welding applications, articulated robots are widely used in industrial automation and assembly, SCARA robots are ideal for electronic assembly, and spherical robots are sometimes used in painting or spraying applications.

Q 7. Explain the concept of closed-loop control systems.

A closed-loop control system, also known as a feedback control system, uses feedback from the system’s output to adjust its input and maintain the desired output. This contrasts with an open-loop system where the output is not monitored and corrected. Imagine driving a car: in open-loop control, you set the steering wheel at a certain angle and hope for the best, regardless of where the car actually goes. In closed-loop control, you continuously monitor your position using visual feedback and adjust the steering to stay on course.

A closed-loop system typically includes:

- Setpoint: The desired value of the controlled variable.

- Controller: Processes the error signal and generates a control signal.

- Actuator: Applies the control signal to the process.

- Process: The system being controlled.

- Sensor: Measures the actual value of the controlled variable.

- Error Signal: The difference between the setpoint and the actual value.

The feedback loop allows the system to adapt to changes and disturbances, maintaining stability and achieving the desired performance. Many everyday systems use closed-loop control, from thermostats regulating room temperature to cruise control in vehicles maintaining a constant speed.

Q 8. Describe your experience with different programming languages used in automation (e.g., Ladder Logic, C++, Python).

My experience with programming languages in automation spans several domains. Ladder Logic (LD) is my bread and butter for Programmable Logic Controllers (PLCs), particularly with Allen-Bradley and Siemens systems. I’ve used LD extensively for designing and implementing control logic for conveyor systems, robotic arms, and packaging machines. For more complex algorithms and data manipulation, I’m proficient in C++, leveraging its power for real-time control applications and embedded systems development. For example, I developed a C++ application for a high-speed vision system used in quality control, interfacing directly with the camera hardware and processing image data to identify defects. Finally, Python’s versatility proves invaluable for scripting, data analysis, and creating user interfaces for automation systems. I’ve used Python to develop custom HMI (Human-Machine Interface) applications and automate repetitive tasks involved in data logging and report generation.

- Ladder Logic (LD): Used for PLC programming; excels in logic-based control.

- C++: Excellent for real-time applications, embedded systems, and complex algorithms.

- Python: Ideal for scripting, data analysis, and HMI development.

Q 9. How do you troubleshoot a malfunctioning automation system?

Troubleshooting a malfunctioning automation system requires a systematic approach. My strategy typically involves these steps:

- Safety First: Secure the system and ensure personnel safety before proceeding.

- Gather Information: Collect data regarding the failure – error messages, logs, witness accounts, etc. Understanding the circumstances surrounding the malfunction is crucial.

- Isolate the Problem: Use diagnostic tools (e.g., PLC programming software, network analyzers) to pinpoint the source of the issue. A methodical approach, checking inputs, outputs, and communication links sequentially, helps to narrow down the possibilities.

- Verify Signals: Inspect sensor readings, actuator states, and communication signals to identify discrepancies or inconsistencies from expected values.

- Test Hypotheses: Based on the gathered evidence, formulate hypotheses about the cause and test them systematically. This may involve replacing suspect components or temporarily bypassing sections of the system.

- Document Findings: Meticulous documentation of the troubleshooting process, including the steps taken, findings, and resolutions, is essential for future reference and preventing recurrence.

- Implement Corrective Actions: Once the root cause is identified and verified, implement the necessary repairs or code changes.

- System Verification: After implementing the fix, thoroughly test the system to ensure its proper functionality and stability.

For instance, in one project involving a robotic welding cell, I systematically checked sensor signals, PLC program logic, and communication links between the robot controller and the PLC to isolate a malfunction causing inaccurate welding positions. I eventually discovered a faulty sensor causing erroneous feedback, ultimately leading to the resolution of the issue.

Q 10. Explain your experience with SCADA systems.

I have extensive experience with SCADA (Supervisory Control and Data Acquisition) systems, primarily using Ignition and Wonderware InTouch. SCADA systems are crucial for monitoring and controlling industrial processes. My experience includes designing and implementing SCADA systems for various applications, from water treatment plants to manufacturing facilities. This involves configuring data acquisition from PLCs and other field devices, designing intuitive operator interfaces, creating alarm management systems, and generating reports. I am familiar with various aspects of SCADA system design, including database management, network configuration, and cybersecurity. In one project, I implemented a SCADA system for a large-scale manufacturing plant that improved process visibility, reduced downtime, and enhanced overall operational efficiency. The implementation involved integrating multiple PLCs, sensors, and actuators, and developing a user-friendly HMI for operators to monitor and control the entire production line. A key element was the implementation of a robust alarm management system to ensure timely response to any process deviations.

Q 11. Describe your experience with different types of industrial communication protocols (e.g., Profibus, Ethernet/IP).

My experience encompasses a variety of industrial communication protocols. I’m highly proficient in Profibus, a common fieldbus widely used in factory automation for connecting PLCs, sensors, and actuators. I’ve used it extensively in projects involving complex machine control systems. My understanding extends to Ethernet/IP, a robust industrial Ethernet protocol that offers high bandwidth and advanced features. I have leveraged Ethernet/IP for integrating robotic systems, vision systems, and other high-speed data acquisition devices into larger automation networks. Other protocols I’ve worked with include Modbus TCP/RTU, Profinet, and EtherCAT. The choice of protocol often depends on factors like the application requirements, network topology, and available hardware. Understanding the intricacies and limitations of each protocol is crucial for designing efficient and reliable industrial communication networks.

Q 12. How do you ensure the safety of automation systems?

Ensuring the safety of automation systems is paramount. My approach is multifaceted and integrates safety considerations throughout the entire system lifecycle, from design and implementation to operation and maintenance. This includes:

- Risk Assessment: Conducting thorough risk assessments to identify potential hazards and evaluate their likelihood and severity.

- Safety Instrumented Systems (SIS): Designing and implementing SIS to mitigate critical risks, employing redundant and independent safety mechanisms.

- Emergency Stop Systems: Implementing robust emergency stop circuits and procedures to ensure immediate shutdown in hazardous situations.

- Lockout/Tagout Procedures: Establishing and enforcing stringent lockout/tagout procedures to prevent accidental activation during maintenance or repair activities.

- Safety Standards Compliance: Adhering to relevant safety standards (e.g., IEC 61508, ISO 13849) to ensure the system meets regulatory requirements.

- Regular Inspections and Maintenance: Implementing a preventative maintenance schedule to detect and rectify potential safety issues promptly.

- Operator Training: Providing comprehensive training to operators on safe operating procedures and emergency responses.

For example, in a project involving high-pressure hydraulic systems, I integrated pressure sensors and emergency shut-off valves within a safety instrumented system to ensure the immediate shutdown of the system in case of a pressure surge. This demonstrates my commitment to designing safe and reliable automation solutions.

Q 13. What is your experience with motion control systems?

My experience with motion control systems is extensive, covering various aspects from servo and stepper motor control to advanced robotics. I’ve worked with different types of motion controllers, including those based on PLCs, dedicated motion controllers, and PC-based systems. My expertise involves the design, implementation, and tuning of motion control algorithms. I’ve used these systems in projects involving robotic arms, pick-and-place machines, and precision assembly lines. For example, I designed and implemented a motion control system for a robotic arm used in a high-precision assembly application that required accurate positioning and smooth movement with minimal vibrations. This involved selecting appropriate motors and drives, designing the control algorithms, and fine-tuning the system to achieve the desired performance parameters.

Q 14. Explain the concept of feedback control and its importance in automation.

Feedback control is a fundamental concept in automation, where the output of a system is continuously monitored and used to adjust the system’s input to maintain a desired setpoint. Think of a thermostat: it measures the room temperature (output), compares it to the desired temperature (setpoint), and adjusts the heating/cooling system (input) accordingly. This closed-loop system ensures accuracy and stability. Without feedback control, systems would be prone to significant errors and drift from the desired setpoint. It is essential in automation because it enables precise control of processes, improves responsiveness, and enhances stability. In many applications, feedback control is critical to achieving the required accuracy and performance. Examples in automation include:

- Temperature control in industrial ovens or reactors.

- Position control in robotic arms or CNC machines.

- Speed control in conveyor belts or motor drives.

- Process control in chemical plants or refineries.

The choice of control algorithm (PID, for example) depends on the specific application and the characteristics of the system being controlled. Effective feedback control requires careful selection of sensors, actuators, and control algorithms, along with proper tuning to ensure optimal performance and stability.

Q 15. Describe your experience with robotic vision systems.

Robotic vision systems are the eyes of robots, enabling them to ‘see’ and interact with their environment. My experience encompasses the entire lifecycle, from system design and integration to calibration and troubleshooting. This includes selecting appropriate cameras (e.g., monochrome for high-precision tasks, color for object recognition), choosing suitable lighting techniques (structured light, backlighting), and implementing image processing algorithms for tasks such as object detection, recognition, and measurement.

For instance, in a previous project involving automated part sorting, I integrated a vision system using a high-resolution monochrome camera and structured lighting to accurately identify and classify different components on a conveyor belt. The system used a combination of edge detection and template matching algorithms to achieve high accuracy and speed. We were able to improve throughput by 30% compared to the previous manual system. Another project involved using a 3D vision system with a laser scanner to inspect complex geometries for defects – a task impossible to achieve reliably with a 2D system alone.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you design a reliable and maintainable automation system?

Designing a reliable and maintainable automation system is paramount. It hinges on a modular design philosophy, adhering to standardized protocols, and incorporating thorough documentation. Modularity allows for easier troubleshooting and replacement of individual components without impacting the entire system. Standardized communication protocols (like Profibus or Ethernet/IP) simplify integration and reduce compatibility issues. Comprehensive documentation, including schematics, software code, and maintenance logs, is crucial for future troubleshooting and upgrades.

Consider a manufacturing line: Designing it with modular robotic cells allows for flexibility in production changes and easier maintenance. If a specific cell malfunctions, it can be isolated and repaired without shutting down the entire line. Using standardized PLC programming further enhances maintainability. Imagine troubleshooting a system where the entire code is a single monolithic block – a nightmare! In contrast, modular, well-documented code promotes ease of understanding and maintenance. Regular preventative maintenance is also essential for preventing downtime and extending equipment life.

Q 17. What are the different types of machine vision systems and their applications?

Machine vision systems are broadly categorized based on their sensing technology and application. Common types include:

- 2D Vision Systems: These systems use cameras to capture 2D images. Applications include object detection, barcode reading, and quality inspection in flat surfaces. Examples include verifying the correct labeling on packages or detecting defects on printed circuit boards.

- 3D Vision Systems: These utilize techniques like stereo vision, structured light, or time-of-flight to create 3D models of scenes. Applications include robotic bin picking, 3D surface inspection, and precise measurement of complex objects. For instance, a 3D vision system is essential for a robot to pick parts from a bin with varying orientations.

- Thermal Vision Systems: These systems detect infrared radiation, useful for applications requiring temperature measurement or detection of hot spots. Applications range from quality control in manufacturing to predictive maintenance by detecting overheating components.

The choice of system depends entirely on the application requirements. Factors such as accuracy needs, speed requirements, and the complexity of the scene determine the optimal system.

Q 18. Explain your experience with simulation software for automation systems.

Simulation software plays a critical role in the design and validation of automation systems. My experience includes using software packages like RobotStudio (ABB), Delmia (Dassault Systèmes), and Siemens PLCSIM. These tools allow us to model the physical system, program and test robotic movements, and predict system behavior before physical implementation. This significantly reduces development time, costs, and the risk of errors during commissioning.

For example, in a recent project involving a complex palletizing system, we utilized RobotStudio to simulate the robot’s movements, optimize the pallet layout, and identify potential collisions before deploying the system on the factory floor. This virtual prototyping identified and resolved several potential issues, saving significant time and resources. The simulation also allowed us to train operators on the system before its installation.

Q 19. Describe your experience with different types of industrial robots (e.g., articulated, SCARA, delta).

I have extensive experience with various industrial robot types, each suited to specific tasks:

- Articulated Robots: These are the most common type, with multiple rotary joints offering high dexterity and a large workspace. Ideal for complex assembly tasks, material handling, and welding.

- SCARA Robots: Selective Compliance Assembly Robot Arm. These are characterized by two parallel joints offering high speed and accuracy in vertical planes. Excellent for pick-and-place operations and assembly in planar applications.

- Delta Robots: These robots have three arms connected to a central platform, known for extremely high speed and precision in a limited workspace. Perfect for high-speed pick-and-place applications, such as packaging and food processing.

The selection of the robot type depends heavily on the application. Factors like payload capacity, speed requirements, reach, and degrees of freedom influence the decision. For instance, a delta robot might be best for fast candy-sorting operations whereas an articulated robot might be needed for welding a complex car chassis.

Q 20. How do you ensure the quality of automated processes?

Ensuring the quality of automated processes requires a multi-pronged approach. This involves incorporating quality control checks at various stages of the process, using statistical process control (SPC) techniques, and implementing robust error handling mechanisms.

For example, we might include in-process vision inspections to verify the quality of parts during assembly. After a particular step, a quality check might verify the tightness of a bolt or the presence of a component. Data from these checks are tracked and analyzed using SPC to identify trends and potential issues before they become major problems. A well-designed system incorporates robust error handling mechanisms, such as sensors detecting out-of-tolerance conditions and initiating corrective actions or alerts. This ensures that defects are quickly identified and addressed, thus preventing them from propagating throughout the entire production process.

Q 21. What are the key considerations for designing a human-robot collaborative workspace?

Designing a safe and productive human-robot collaborative (HRC) workspace requires careful consideration of several factors. Safety is paramount, requiring risk assessment and the implementation of safety features like light curtains, emergency stop buttons, and speed and force limiting.

Ergonomics plays a vital role. The workspace should be designed to be comfortable and intuitive for human operators, minimizing physical strain and promoting efficiency. Clear visual cues, such as robot status indicators, are crucial for maintaining situational awareness. The robot’s programming should consider human movement patterns and avoid potentially hazardous interactions. For example, collaborative robots (cobots) often have built-in safety features to stop operation if an unexpected contact occurs. Finally, thorough training for human operators is indispensable to ensure safe and productive collaboration.

Q 22. Explain your experience with data acquisition and analysis in automation systems.

Data acquisition and analysis are crucial in automation for monitoring system performance, identifying issues, and optimizing processes. My experience encompasses designing and implementing data acquisition systems using various sensors, analog-to-digital converters (ADCs), and data loggers. I’ve worked with both hardware and software aspects, integrating sensors like pressure transducers, temperature sensors, and flow meters into PLC-controlled systems. The data is then channeled to a supervisory control and data acquisition (SCADA) system or a dedicated database for storage and analysis.

For analysis, I utilize statistical methods, signal processing techniques, and data visualization tools to identify trends, anomalies, and potential problems. For instance, I once used time-series analysis to detect a subtle vibration pattern in a robotic arm that indicated impending bearing failure, allowing for preventative maintenance and avoiding costly downtime. I am proficient in using software like MATLAB and Python for data processing and visualization, creating custom scripts to automate data analysis workflows and generate comprehensive reports.

Q 23. Describe your experience with different types of programmable logic controllers (PLCs).

My experience spans various PLC platforms, including Allen-Bradley (Rockwell Automation), Siemens (SIMATIC), and Schneider Electric (Modicon). Each platform has its strengths and weaknesses, and selecting the right one depends on the specific application requirements. For example, Allen-Bradley PLCs are known for their robust architecture and extensive library of pre-built functions, making them suitable for complex industrial automation applications. Siemens PLCs are renowned for their advanced communication capabilities and scalability, ideal for large-scale systems. Schneider Electric PLCs offer a good balance of features and cost-effectiveness.

My expertise extends beyond just selecting the hardware. I’m proficient in programming PLCs using ladder logic, structured text, and function block diagrams. I’ve worked on projects involving complex control algorithms, motion control, and data communication protocols. I can effectively troubleshoot and debug PLC programs, identify and resolve faults, and implement improvements to optimize system performance. For example, I recently optimized a PLC program for a packaging line, reducing cycle time by 15% through careful code restructuring and the application of more efficient algorithms.

Q 24. How do you handle unexpected events or errors in an automated system?

Handling unexpected events and errors is paramount in automation. My approach involves a multi-layered strategy that includes preventative measures, robust error detection, and efficient recovery mechanisms. This starts with meticulous system design and thorough testing during the development phase. I employ techniques like redundancy (using backup systems), fail-safes (mechanisms that ensure safety in case of failure), and self-diagnostic features (allowing the system to identify its own problems).

During operation, the system continuously monitors various parameters. If an error occurs, the PLC’s programmed logic triggers an alarm, logs the error, and initiates a predefined recovery procedure. This could range from simply shutting down a specific part of the system to initiating a complete shutdown to prevent further damage. Prioritization is key – safety always comes first. For example, in a robotic welding cell, an emergency stop mechanism is crucial to prevent accidents if an unexpected situation arises. Post-error analysis is equally crucial, allowing for a root cause investigation and improvements to prevent recurrence. This process involves reviewing logs, diagnosing the issue, and implementing necessary corrections to the system design, code, or hardware.

Q 25. Explain your experience with industrial networking and communication.

Industrial networking and communication are vital for integrating various components within an automation system and exchanging data between them. My experience encompasses various communication protocols, including Profibus, Profinet, Ethernet/IP, Modbus, and others. I understand the strengths and limitations of each protocol and can select the appropriate one based on factors like speed, reliability, distance, and cost.

I’ve worked on projects involving both wired and wireless communication networks. For example, I designed a wireless sensor network for remote monitoring of environmental parameters in a manufacturing facility, utilizing Zigbee for its low power consumption and suitability for short-range communication. I have also integrated PLCs, robots, SCADA systems, and other devices into a unified network using Ethernet-based protocols, leveraging their high bandwidth and robust error detection capabilities. Furthermore, I’m familiar with network security best practices in industrial environments, including implementing firewalls and intrusion detection systems to safeguard the system from cyber threats. The security aspect is particularly important in contemporary industrial settings.

Q 26. Describe your experience with various automation system architectures.

I’ve worked with a variety of automation system architectures, from simple, stand-alone systems to complex, distributed control systems. These architectures range from centralized architectures, where a single PLC controls all aspects of the system, to decentralized architectures, where multiple PLCs work collaboratively to manage different parts of the process. Each architecture has its own advantages and disadvantages. Centralized systems are simpler to design and manage but can be prone to single points of failure. Decentralized systems are more fault-tolerant and scalable but are more complex to design and maintain.

My experience also includes working with hierarchical architectures, where multiple levels of control exist. For example, a high-level supervisory system might coordinate the actions of several lower-level PLCs. I’ve also worked with client-server architectures, where a server provides data and control commands to clients like operator interfaces or remote monitoring systems. Choosing the right architecture requires careful consideration of factors such as system complexity, scalability requirements, fault tolerance, and maintainability. For each project, I tailor the architecture to the specific needs and constraints of the application.

Q 27. What is your understanding of Industry 4.0 and its impact on automation?

Industry 4.0 represents a paradigm shift in manufacturing, driven by advancements in digital technologies like the Internet of Things (IoT), cloud computing, big data analytics, and artificial intelligence (AI). Its impact on automation is profound, leading to greater efficiency, flexibility, and connectivity. Smart factories leverage these technologies to optimize processes, improve productivity, and enhance product quality.

My understanding of Industry 4.0 focuses on the integration of cyber-physical systems, where physical processes are monitored and controlled by digital systems, enabling real-time data analysis and autonomous decision-making. This includes incorporating predictive maintenance techniques based on data analytics, using AI-powered robots for increased flexibility and adaptability in manufacturing, and implementing digital twins for virtual simulations and process optimization. I see Industry 4.0 as an evolution, not a revolution, building upon existing automation technologies and incorporating new capabilities to address the challenges of a rapidly changing industrial landscape. It demands expertise in both traditional automation and newer digital technologies, a combination I am well-equipped to handle.

Q 28. Explain your experience with implementing and maintaining industrial robots.

Implementing and maintaining industrial robots requires a multidisciplinary approach combining mechanical, electrical, and software engineering expertise. My experience involves working with various types of robots, including articulated robots, SCARA robots, and collaborative robots (cobots). The implementation process starts with careful planning and system design, including selecting the appropriate robot model based on application requirements, defining the work envelope, and designing the necessary tooling and fixtures.

Programming industrial robots typically involves using robot-specific programming languages, such as RAPID (ABB), KRL (KUKA), or proprietary software packages. I’m proficient in these programming languages and can create complex robot programs for tasks like welding, painting, assembly, and material handling. Maintaining industrial robots involves regular inspections, preventative maintenance, and troubleshooting. This includes checking mechanical components, electrical systems, and software programs. I’ve performed various maintenance tasks, ranging from replacing worn-out parts to calibrating sensors and performing software updates. Safety is always paramount, and all maintenance procedures are performed following strict safety protocols to prevent accidents.

Key Topics to Learn for Your Mechatronics and Automation Interview

- Control Systems: Understand fundamental concepts like feedback control, PID controllers, and state-space representation. Be prepared to discuss practical applications in robotics, industrial automation, and process control.

- Robotics and Automation: Familiarize yourself with different robot types (e.g., SCARA, articulated), kinematics, dynamics, and path planning. Consider examples of automation in manufacturing, logistics, and other industries.

- Sensors and Actuators: Gain a solid understanding of various sensor technologies (e.g., proximity sensors, encoders, vision systems) and actuator types (e.g., pneumatic, hydraulic, electric). Be ready to explain their integration within mechatronic systems.

- Microcontrollers and Embedded Systems: Demonstrate knowledge of programming microcontrollers (e.g., Arduino, Raspberry Pi) and designing embedded systems. Discuss real-world applications in automated machinery and control systems.

- Mechanical Design and Engineering: Review fundamental mechanical engineering principles relevant to mechatronic systems, including CAD design, material selection, and stress analysis. Be prepared to discuss design considerations for robustness and efficiency.

- Troubleshooting and Problem-Solving: Practice diagnosing and resolving common issues in mechatronic systems. Develop your ability to systematically approach problems and apply your knowledge to find effective solutions.

- PLC Programming (Programmable Logic Controllers): Understand ladder logic diagrams and the programming of PLCs for industrial automation. Be ready to discuss different PLC architectures and their applications.

Next Steps

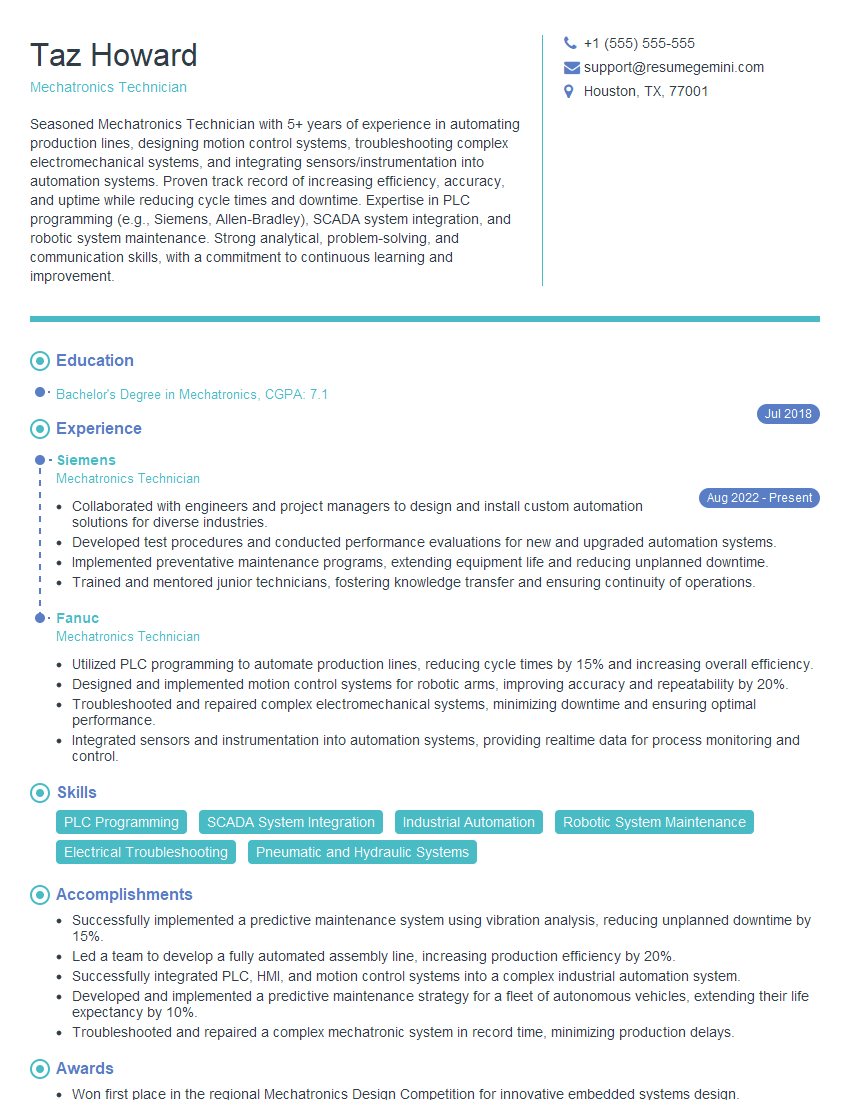

Mastering Mechatronics and Automation opens doors to exciting and rewarding careers in a rapidly evolving technological landscape. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that showcases your skills and experience effectively. Examples of resumes tailored to Mechatronics and Automation are available to help guide you through the process. Invest time in crafting a strong resume—it’s your first impression on potential employers!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO