Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Melt Furnace Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Melt Furnace Operation Interview

Q 1. Explain the different types of melt furnaces and their applications.

Melt furnaces are crucial in various industries for melting metals and other materials. The type of furnace used depends heavily on the material being processed and the desired outcome. Here are some common types:

- Electric Arc Furnaces (EAFs): These use electric arcs to generate intense heat, making them ideal for melting scrap metal, particularly steel. Think of it like a giant, super-powered welding arc, melting down tons of material. They’re very energy-efficient for scrap recycling.

- Induction Furnaces: These utilize electromagnetic induction to heat the material. A coil generates a rapidly changing magnetic field that induces eddy currents within the metal, causing it to heat up. These are known for their precise temperature control and are often used in the production of high-quality alloys, where precise melting points are crucial.

- Coreless Induction Furnaces: A variation of induction furnaces, these offer better stirring of the molten metal, leading to improved homogeneity. They’re particularly useful in applications where consistent alloy composition is critical.

- Reverberatory Furnaces: These furnaces use radiant heat from a separate combustion chamber to melt the material. They’re simpler in design than some other types but offer less precise temperature control. They might be used for melting non-ferrous metals.

The choice of furnace depends on factors such as the material’s melting point, the required purity, production scale, and energy costs. For instance, EAFs excel in steel recycling due to their ability to handle large quantities of scrap, while induction furnaces are preferred when precise temperature control is paramount.

Q 2. Describe the process of charging a melt furnace.

Charging a melt furnace is a carefully orchestrated process, crucial for efficient and safe operation. The specific procedure varies depending on the furnace type and the material being processed. Generally, it involves these steps:

- Preparation: Ensure the furnace is preheated to the appropriate temperature. Inspect the furnace lining for any damage. Prepare the charging materials: This often involves weighing and pre-processing raw materials (like scrap metal) to ensure consistent quality and size to avoid issues during charging.

- Charging: Materials are typically added using a charging system, which could be a crane, a charging bucket, or a conveyor system. The method depends on the size and type of the furnace. The aim is to distribute the charge evenly to promote uniform heating and avoid localized overheating. It’s important to avoid sudden large additions that could cause thermal shock.

- Monitoring: Throughout the charging process, monitor the furnace temperature and pressure. Sensors alert operators to any irregularities.

- Melting: Once the charge is complete, the furnace is adjusted to melt the materials thoroughly. This requires careful control of the heating elements to avoid issues like slag formation.

Imagine it like baking a cake: You wouldn’t just throw all the ingredients in at once – you’d carefully add them in stages to ensure even baking. The same principle applies to charging a melt furnace to avoid issues and maximize the quality of the molten material.

Q 3. How do you monitor and control the temperature within a melt furnace?

Precise temperature control is critical in melt furnace operation, impacting both product quality and the furnace’s lifespan. This is achieved through a combination of sensors, controllers, and automated systems. Temperature is measured using various sensors such as thermocouples (measuring the temperature difference between two junctions) and optical pyrometers (measuring temperature based on emitted light). This data is fed into a control system that adjusts the power input to maintain the desired temperature. For example, in an electric arc furnace, the arc power is modulated to control the heat input. In induction furnaces, the frequency and power of the induced current is adjusted. Modern furnaces often employ advanced control systems using sophisticated algorithms to ensure optimal temperature profiles throughout the melting process.

Imagine a thermostat in your home; it constantly monitors the temperature and adjusts the heating or cooling accordingly. Melt furnace temperature control is similar, but on a much larger and more complex scale. Real-time monitoring and data logging systems provide historical data for analysis, helping optimize energy use and improve process control.

Q 4. What safety precautions are essential when operating a melt furnace?

Safety is paramount in melt furnace operation. The high temperatures, molten metal, and potential for hazardous fumes necessitate stringent safety measures. Key precautions include:

- Personal Protective Equipment (PPE): This includes heat-resistant clothing, safety glasses, hearing protection, and respirators to protect against fumes and dust.

- Emergency Shutdowns: The furnace must have readily accessible emergency shutdown mechanisms to quickly halt operations in case of an emergency. Regular testing of these systems is critical.

- Lockout/Tagout Procedures: These procedures ensure that the furnace is safely isolated before maintenance or repairs to prevent accidental activation.

- Fume Extraction: Effective fume extraction systems are essential to remove harmful gases and particulate matter produced during melting. These help maintain a safe working environment.

- Training and Procedures: Operators must receive thorough training on safe operating procedures and emergency response protocols. This includes routine inspections and maintenance checklists.

- Fire Suppression Systems: Adequate fire suppression systems, including fire extinguishers and sprinkler systems, are crucial in case of fire.

Working with molten metal is inherently dangerous; even a minor mistake can have catastrophic consequences. Following safety protocols religiously is not just a good practice; it’s essential for the well-being of the operators and the integrity of the facility.

Q 5. Explain the role of refractory materials in melt furnace operation.

Refractory materials are the lifeblood of a melt furnace, forming the protective lining that withstands the extreme temperatures and harsh chemical environments. These materials, typically bricks or monolithic castings, are designed to resist thermal shock, corrosion, and erosion. Common refractory materials include various types of alumina, magnesia, silica, and zircon.

The choice of refractory depends on the material being melted and the operating temperature. For example, furnaces melting steel often use magnesia-based refractories known for their high melting point and resistance to basic slags. Proper selection, installation, and maintenance of the refractory lining are crucial for extending furnace life and preventing costly downtime. Regular inspections help identify wear and tear, enabling timely repairs before complete lining failure occurs. Imagine the refractory lining as a fortress, shielding the furnace shell from the intense heat and chemical reactions within.

Q 6. How do you identify and address common melt furnace malfunctions?

Troubleshooting melt furnace malfunctions requires a systematic approach. Common issues include:

- Temperature fluctuations: These could result from sensor malfunction, faulty control systems, or issues with the power supply. Troubleshooting involves checking sensor readings, calibrating the control system, and investigating power supply stability.

- Refractory damage: This can lead to heat loss and furnace failure. Regular inspections and prompt repair are essential. The cause of damage (e.g., thermal shock, chemical attack) needs to be identified to prevent recurrence.

- Electrode problems (in arc furnaces): Electrode wear or breakage affects the arc stability and temperature control. Routine monitoring and timely electrode replacement are vital.

- Slag accumulation: Excessive slag accumulation can hinder the melting process and cause operational issues. Regular slag tapping is required.

A structured diagnostic approach involves analyzing operational data, inspecting the furnace, and conducting tests to pinpoint the root cause. It’s often a process of elimination, systematically checking different components and systems to identify the source of the problem.

Q 7. Describe the process of tapping a melt furnace.

Tapping a melt furnace is the process of carefully draining the molten metal from the furnace. This is a critical operation requiring precision and safety. The process generally involves:

- Preparation: Ensure the receiving vessel (e.g., a ladle) is properly positioned and ready to receive the molten metal. The tapping spout or hole is carefully cleaned to ensure a smooth flow.

- Tapping: The taphole is opened, typically using a controlled process to regulate the flow rate. This might involve drilling a small hole or opening a pre-prepared taphole using specialized tools. The speed of the tapping process can be controlled to ensure a safe and even flow.

- Monitoring: Continuous monitoring of the flow rate and temperature is essential. Operators need to be vigilant for any irregularities or potential hazards.

- Closure: Once the desired amount of molten metal is tapped, the taphole is securely closed. The process must be quick and efficient to minimize heat loss and prevent safety hazards.

Imagine carefully pouring a pot of boiling water: You wouldn’t rush it, and you’d be cautious to avoid spills. Tapping a melt furnace involves similar considerations, only on a much grander, more challenging scale, with extremely high temperatures and large quantities of molten metal involved. It’s a highly specialized procedure demanding a high level of skill and experience.

Q 8. What are the key quality control measures for melt furnace operations?

Quality control in melt furnace operations is paramount for producing consistent, high-quality metal. It’s a multifaceted process involving rigorous monitoring and control at every stage, from raw material input to final product analysis.

Chemical Composition Control: Regular chemical analysis of the molten metal using techniques like Optical Emission Spectroscopy (OES) ensures the final product meets the specified composition. Deviations trigger adjustments to the melting process.

Temperature Monitoring and Control: Precise temperature control is crucial. Using thermocouples and sophisticated control systems helps maintain the optimal temperature range for the specific metal and prevents overheating or underheating, which can lead to defects. Think of it like baking a cake – you need the right temperature to achieve the desired outcome.

Inclusion Control: Monitoring for inclusions (foreign particles in the molten metal) is essential. These can significantly impact the final product’s properties. Techniques like fluxing and filtration are employed to minimize inclusions.

Documentation and Traceability: Detailed records of every stage of the melting process, including raw materials used, temperature profiles, and chemical analysis results, are crucial for traceability and quality assurance. This allows us to identify and correct any issues quickly and efficiently.

Q 9. How do you ensure the consistent chemical composition of the molten metal?

Ensuring consistent chemical composition requires a multi-pronged approach. It starts with carefully selecting and analyzing the raw materials to ensure they meet the specified chemical requirements. Imagine building with LEGOs – you wouldn’t expect a castle if you use the wrong blocks. The same principle applies here.

Precise Weighing and Charging: Accurate weighing and charging of raw materials into the furnace are crucial. This ensures the correct proportions of different alloying elements are added.

Real-time Monitoring and Adjustment: Real-time monitoring of the melt’s chemical composition using OES allows for immediate adjustments to be made if any deviations from the target composition are detected. We may need to add more of a particular element or remove impurities.

Degassing and Refining Techniques: Techniques like vacuum degassing or inert gas purging are employed to remove undesirable elements, like hydrogen or nitrogen, from the molten metal, further improving its chemical consistency and properties. Think of it like cleaning impurities out of a solution before using it.

Q 10. Explain the importance of maintaining proper furnace atmosphere.

Maintaining a proper furnace atmosphere is vital for preventing oxidation and contamination of the molten metal. The atmosphere should be controlled to minimize interaction with the molten metal and ensure the desired chemical composition is achieved.

Oxidation Control: An oxidizing atmosphere can lead to the formation of oxides on the surface of the molten metal, resulting in defects and altering the chemical composition. Inert gases, like argon or nitrogen, are often used to create a protective atmosphere.

Contamination Prevention: A controlled atmosphere minimizes the risk of contamination from external sources. This is critical for maintaining the purity and quality of the molten metal.

Reaction Control: In some cases, a specific atmosphere might be necessary to control certain chemical reactions during the melting process. For instance, a slightly reducing atmosphere might be preferred to reduce the formation of certain oxides.

Q 11. How do you handle emergency situations such as furnace leaks or power outages?

Emergency situations require a swift and coordinated response. Our safety protocols are meticulously designed to ensure the safety of personnel and the equipment.

Furnace Leaks: In case of a furnace leak, we immediately shut down the furnace, isolate the area, and evacuate personnel. Leak repair is then conducted following stringent safety procedures.

Power Outages: Power outages can cause the melt to cool rapidly. We have emergency power backup systems to prevent this and maintain a safe operating temperature until power is restored. If that fails, we’d initiate controlled cooling procedures to prevent thermal shock.

Fire: In the case of a fire, we have well-rehearsed emergency response plans which include the use of fire extinguishers and a call to emergency services. We also make sure all personnel are trained in fire safety procedures.

Emergency Shutdown Procedures: All operators are regularly trained in emergency shutdown procedures to ensure a consistent response in a variety of critical situations.

Q 12. Describe your experience with different types of molten metals.

Throughout my career, I have worked extensively with various molten metals, including aluminum alloys, steel (various grades like stainless steel, carbon steel), copper alloys (brass, bronze), and nickel-based superalloys. Each metal has unique properties and requires specific melting and processing techniques. For example, aluminum alloys require careful control of the temperature and atmosphere to prevent oxidation, while steel requires specific deoxidation practices to achieve desired mechanical properties.

My experience working with these different metals has given me a thorough understanding of the nuances of each material and how to optimize the melting process to achieve optimal results. This includes understanding different melting points, thermal conductivities, and susceptibility to various contaminants.

Q 13. What are the common causes of refractory wear and tear in a melt furnace?

Refractory wear and tear in a melt furnace is a common problem that can significantly impact furnace lifespan and operational efficiency. Several factors contribute to this degradation.

Chemical Attack: The molten metal and slags can chemically react with the refractory lining, causing erosion and dissolution. This is particularly pronounced with highly reactive metals or slags.

Thermal Shock: Rapid temperature changes during furnace heating and cooling cycles can cause thermal shock, leading to cracking and spalling of the refractory. Think of repeatedly heating and cooling a glass – it eventually cracks.

Abrasion: The movement of molten metal and slags within the furnace can cause abrasive wear on the refractory lining, especially in areas with high flow rates.

Mechanical Damage: Improper charging practices or accidental impacts can cause mechanical damage to the refractory lining.

Poor Refractory Quality: The quality of the refractory materials itself greatly influences its lifespan. Using high-quality refractories with good chemical and thermal resistance is essential.

Q 14. How do you perform routine maintenance on a melt furnace?

Routine maintenance is crucial for preventing major issues and ensuring the melt furnace operates efficiently and safely. It’s a proactive approach rather than reactive. It involves regular inspections, cleaning, and repairs to extend the life of the equipment.

Visual Inspections: Regular visual inspections of the furnace lining and other components help detect any signs of wear, damage, or leaks early on.

Temperature Monitoring: Closely monitoring furnace temperatures helps identify potential issues before they become serious problems. This ensures the furnace operates within safe parameters and prevents thermal shock.

Cleaning and Repair: Regular cleaning of the furnace helps remove accumulated slag and other materials that can contribute to refractory wear and tear. Minor repairs should be carried out promptly to prevent them from escalating.

Refractory Replacement: Planned refractory replacement is essential to prevent catastrophic failure. The frequency of replacement depends on the type of furnace, the molten metal processed, and the operating conditions.

Documentation: Maintaining detailed records of all maintenance activities is crucial for tracking the furnace’s health and identifying recurring issues.

Q 15. Describe your experience with automated control systems in melt furnace operation.

My experience with automated control systems in melt furnace operation spans over a decade, encompassing various platforms from basic Programmable Logic Controllers (PLCs) to sophisticated Distributed Control Systems (DCS). I’m proficient in configuring and troubleshooting these systems, ensuring optimal furnace performance and safety. For instance, in my previous role, we implemented a new DCS system that integrated real-time data acquisition, advanced process control algorithms, and predictive maintenance capabilities. This upgrade significantly reduced energy consumption by optimizing melt rates and minimizing thermal losses, while also improving product quality consistency. I’m also experienced with SCADA systems for monitoring and control, allowing for remote oversight and efficient problem solving.

Specifically, I’ve worked extensively with systems that automate parameters like temperature, gas flow, and melt level. These systems help maintain consistent product quality, minimize material waste, and reduce the risk of human error. One project involved integrating a vision system into the melt furnace control to improve the detection and removal of contaminants in the molten metal, a process previously reliant on manual inspection. This automation dramatically increased efficiency and improved product purity.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret and analyze data from melt furnace monitoring systems?

Interpreting data from melt furnace monitoring systems requires a holistic approach, combining technical understanding with practical experience. We look at multiple data streams simultaneously – temperature profiles, gas analysis, power consumption, and melt level readings – to gain a comprehensive picture of the furnace’s state. Anomalies, such as unexpected temperature spikes or fluctuations in gas composition, are immediately flagged for investigation.

For example, a sudden drop in temperature might indicate a problem with the burner system, while consistent high power consumption could point to inefficient insulation or a problem with the refractory lining. We use statistical process control (SPC) charts to track key parameters over time, helping us identify trends and predict potential issues before they escalate. This proactive approach allows for preventative maintenance, minimizing downtime and production losses. We also leverage data analytics to optimize operational parameters, maximizing yield and minimizing scrap.

Furthermore, we use the data to identify opportunities for improvement in the overall process. For instance, analyzing historical data on energy consumption can help pinpoint inefficiencies that can be addressed through process optimization or equipment upgrades. A trend analysis of temperature profiles might show that minor adjustments to the heating profile can lead to significant energy savings.

Q 17. Explain your understanding of energy efficiency in melt furnace operations.

Energy efficiency is paramount in melt furnace operation, both economically and environmentally. It’s about minimizing energy consumption while maintaining optimal performance. This involves a multi-faceted approach.

- Optimized heating profiles: Carefully designed heating curves minimize energy waste by ensuring the melt reaches the desired temperature efficiently.

- Insulation improvements: Regular inspection and maintenance of furnace insulation is crucial to prevent heat loss. New, advanced insulation materials can significantly improve efficiency.

- Burner optimization: Proper burner adjustment and maintenance ensure complete combustion, minimizing fuel consumption and emissions.

- Recuperation systems: These systems recapture waste heat from the exhaust gases and reuse it for preheating the incoming air or materials, significantly boosting energy efficiency.

- Advanced control systems: Sophisticated control systems allow for precise control over parameters like temperature and gas flow, minimizing energy waste through precise control.

In one instance, by implementing a more efficient heating profile and upgrading the insulation, we achieved a 15% reduction in energy consumption without compromising production rates. This demonstrates the significant impact of a focused approach to energy efficiency in melt furnace operation.

Q 18. What are the environmental considerations related to melt furnace emissions?

Environmental considerations related to melt furnace emissions are of utmost importance. Emissions include greenhouse gases (CO2, NOx, SOx), particulate matter (PM), and potentially hazardous heavy metals depending on the materials being processed. Minimizing these emissions is crucial for environmental compliance and responsible manufacturing.

Strategies for mitigating environmental impact include implementing advanced emission control technologies such as:

- Selective Catalytic Reduction (SCR): Reduces NOx emissions.

- Electrostatic precipitators (ESP): Controls particulate matter emissions.

- Bag filters: Also controls particulate matter emissions.

- Flue gas desulfurization (FGD): Reduces SOx emissions.

Regular monitoring of emissions is essential using continuous emission monitoring systems (CEMS). This data is used to optimize furnace operation and ensure compliance with environmental regulations. Proper waste management practices for slag and other byproducts are also critical to minimize environmental impact. Furthermore, responsible sourcing of raw materials is crucial in reducing the environmental footprint of the entire manufacturing process.

Q 19. How do you ensure the safety of yourself and your colleagues during melt furnace operations?

Safety is the top priority in melt furnace operations. This involves a combination of engineering controls, administrative controls, and personal protective equipment (PPE). Engineering controls encompass features such as interlocks, emergency shut-off systems, and robust safety systems within the furnace control system itself. Administrative controls involve establishing and adhering to strict safety protocols, including regular safety training, lockout/tagout procedures, and thorough risk assessments before any maintenance or repairs. PPE includes specialized clothing, heat-resistant gloves, eye protection, and respiratory equipment to protect against heat, fumes, and potential splashes of molten material.

Regular safety inspections and audits are conducted to ensure the proper functioning of safety systems and compliance with safety protocols. Incident investigations are performed to identify root causes of accidents or near misses and to implement preventive measures. Open communication and team-based safety initiatives encourage reporting of potential hazards and continuous improvement of safety practices. A culture of safety is instilled, making safety a shared responsibility of every member of the team.

Q 20. Describe your experience with troubleshooting electrical problems in a melt furnace.

Troubleshooting electrical problems in a melt furnace requires a systematic approach, combining electrical engineering knowledge with an understanding of the furnace’s operational characteristics. The process starts with a thorough assessment of the problem, including identifying symptoms and gathering relevant data. This might involve checking voltage levels, current draw, and examining circuit breakers and other electrical components.

Safety is paramount during troubleshooting, requiring adherence to lockout/tagout procedures and the use of appropriate safety equipment. Troubleshooting may involve tracing faulty wiring, identifying damaged components (e.g., transformers, relays, or sensors), and replacing or repairing faulty elements. In several instances, I’ve used specialized testing equipment like multimeters, insulation testers, and thermal cameras to pinpoint the source of electrical faults within the complex wiring of the furnace system. My experience extends to interpreting electrical schematics and understanding the interplay of various components within the control system.

For example, a sudden power outage in a section of the furnace led to an investigation involving a thermal camera to detect overheated connections in a cable harness, ultimately preventing a major shutdown and potential fire hazard. It’s crucial to have a solid understanding of electrical safety codes and standards to ensure both safe and effective troubleshooting.

Q 21. Explain your experience with different types of furnace linings and their maintenance.

I have extensive experience with various furnace linings, including monolithic refractories, modular refractories, and castable refractories. The choice of lining depends on factors like the type of metal being melted, the operating temperature, and the desired lifespan. Monolithic linings, for instance, offer excellent thermal shock resistance and can be tailored to the specific needs of the furnace. Modular refractories are pre-fabricated and easily replaced, reducing downtime during maintenance. Castable refractories offer good flexibility and are often used for repairs.

Maintenance of furnace linings is crucial for both safety and operational efficiency. Regular inspections are performed to detect signs of wear, erosion, or damage. This includes visual inspection, temperature monitoring, and potentially ultrasonic testing to assess the integrity of the lining. Timely repairs are crucial to prevent premature failure and catastrophic events. This involves removing damaged sections of the lining and replacing them with new refractory material, ensuring proper curing and drying to maximize its lifespan. Proper lining maintenance minimizes energy losses through heat leaks, ensuring optimal energy efficiency and reduced operating costs.

One specific example was troubleshooting excessive wear in a particular area of a monolithic lining. Through careful analysis of the operating parameters, we identified a slight imbalance in the melt flow that was causing the localized wear. By adjusting the melt flow, we greatly extended the lifespan of the lining and prevented costly shutdowns.

Q 22. How do you manage and dispose of waste materials from melt furnace operations?

Waste management in melt furnace operations is crucial for environmental compliance and operational efficiency. It involves a multi-step process focusing on segregation, treatment, and responsible disposal.

- Segregation: We meticulously separate waste streams. This includes separating slag (the byproduct of the melting process), dust from the furnace’s exhaust system, and any spilled or unusable metal. Proper labeling and storage are vital to prevent accidental mixing.

- Treatment: Slag often undergoes further processing. This might involve crushing for easier handling, or sometimes, specialized chemical treatments to recover valuable metals. Dust is typically collected using baghouses or electrostatic precipitators and may require further treatment depending on its composition.

- Disposal: Treated slag is often sent to designated landfills, adhering strictly to environmental regulations. Hazardous waste, like certain chemicals used in fluxing, is handled by licensed hazardous waste disposal companies. Recyclable materials, like scrap metal, are always prioritized for reuse in the process.

For example, in a previous role, we implemented a new slag handling system that reduced our landfill waste by 15% through optimized slag granulation and improved metal recovery. This not only saved on disposal costs but also minimized our environmental footprint.

Q 23. Describe your experience with quality control testing of molten metal.

Quality control in molten metal is paramount. It ensures the final product meets the required specifications and avoids costly defects. My experience involves several key aspects:

- Temperature Monitoring: Precise temperature control is crucial for achieving the desired alloy composition and properties. We use thermocouples and advanced sensors for continuous monitoring and data logging.

- Chemical Analysis: Regular sampling of the molten metal is essential. Spectrometers provide rapid analysis of the elemental composition, ensuring it adheres to the specified chemical composition. Discrepancies trigger immediate corrective actions.

- Visual Inspection: While less quantitative, visual inspection of the molten metal for impurities (like inclusions) is still valuable. An experienced operator can often identify potential problems before they lead to defects in the final product.

- Mechanical Testing (Post-Processing): After casting, samples undergo mechanical testing (tensile strength, hardness, etc.) to verify that the finished product meets the required performance characteristics.

In one instance, I identified a systematic error in our spectrometer calibration leading to consistent underestimation of a key alloying element. By correcting the calibration, we improved product consistency and reduced rejection rates dramatically.

Q 24. How do you ensure the efficient use of energy and resources in melt furnace operations?

Efficient energy and resource use is a key focus in modern melt furnace operation. It’s not just about cost savings but also about environmental responsibility. Here’s how we approach it:

- Furnace Optimization: We regularly review and optimize furnace parameters (temperature profiles, melting cycles) to minimize energy consumption while maintaining production targets. Advanced control systems, such as programmable logic controllers (PLCs), are vital here.

- Insulation & Refractory Maintenance: Proper insulation and regular maintenance of refractory materials (the lining of the furnace) are critical to reducing heat loss. We implement preventative maintenance schedules to detect and address deterioration early.

- Waste Heat Recovery: Considerable heat is lost during the melting process. Strategies like using waste heat for preheating the charge materials or generating steam for other operations can significantly improve overall efficiency.

- Material Selection: Choosing the right charge materials (scrap metal, raw materials) and optimizing their preparation (size, cleanliness) can reduce energy consumption during the melting process.

For instance, by implementing a more efficient preheating system, we were able to reduce our energy consumption by 8% in one of our facilities without affecting production capacity.

Q 25. What is your experience with different types of melt furnace fuels?

My experience encompasses several types of melt furnace fuels, each with its own advantages and disadvantages:

- Natural Gas: Clean burning, relatively low cost, and readily available, natural gas is a common choice. However, its price can fluctuate, and its availability may be a concern in some regions.

- Electricity: Electric induction furnaces offer excellent control over temperature and atmosphere, leading to high-quality metal production. They are clean but can be significantly more expensive to operate than fuel-fired furnaces.

- Fuel Oil: A viable alternative, especially in regions with limited access to natural gas. However, fuel oil is generally less efficient and produces more emissions than natural gas.

- Propane: Offers advantages similar to natural gas, but its higher cost and transportation challenges can be limiting factors.

The choice of fuel is driven by factors like cost, environmental regulations, availability, and the specific requirements of the melting process. I’ve had firsthand experience switching from fuel oil to natural gas in one plant, resulting in both cost savings and environmental improvements.

Q 26. How do you optimize the melt process to minimize defects?

Minimizing defects in the melt process is a continuous improvement effort. It requires a systematic approach that integrates several key areas:

- Careful Charge Preparation: Thorough cleaning and sorting of scrap metal, ensuring the correct proportion of alloying elements, and controlling the moisture content are crucial first steps. Contamination from impurities can lead to numerous defects.

- Precise Temperature Control: Maintaining the correct temperature throughout the melting process is essential. Deviations can result in porosity, cracking, or inconsistent mechanical properties.

- Optimized Melting Cycles: The duration and ramping rate of the melting cycle significantly impact the final product. Careful optimization minimizes the risk of oxidation, overheating, or uneven alloying.

- Fluxing Practices: Selecting the appropriate fluxing agents (chemicals added to remove impurities) and controlling their addition is crucial for the quality of the molten metal.

- Pouring Techniques: The pouring technique must ensure smooth and controlled flow to avoid gas entrapment and formation of defects in the final casting.

For example, I once identified a recurring issue with porosity in aluminum castings. By carefully analyzing the melting cycle and adjusting the fluxing procedure, we were able to eliminate the problem, resulting in a significant reduction in scrap and improved yield.

Q 27. Explain your experience with data analysis and process improvement in melt furnace operations.

Data analysis and process improvement are fundamental to optimizing melt furnace operations. We utilize various techniques to gain insights and drive improvements:

- Statistical Process Control (SPC): Implementing SPC charts allows us to monitor key process variables and detect variations early. This ensures timely intervention before they lead to significant quality issues.

- Data Logging & Trend Analysis: Continuous data logging of furnace parameters (temperature, power, etc.) provides valuable insights into operational trends. Identifying patterns and anomalies helps in optimizing processes and preventative maintenance scheduling.

- Root Cause Analysis: When defects or operational problems occur, we employ techniques like the ‘5 Whys’ or fishbone diagrams to systematically identify the underlying causes. This helps in implementing effective corrective actions and preventing recurrence.

- Process Simulation: Software simulations can be used to model different scenarios and predict the impact of process changes before implementing them in the real world. This minimizes risks and optimizes the chances of successful improvements.

In a previous role, by analyzing furnace data using SPC, we identified a correlation between fluctuations in gas pressure and inconsistencies in the melt temperature. Adjusting the gas pressure regulation system resulted in a measurable reduction in scrap and improved energy efficiency.

Q 28. Describe your understanding of the different types of metal alloys and their properties.

Understanding different metal alloys and their properties is essential for successful melt furnace operations. The choice of alloy depends heavily on the desired application and its performance requirements. Here are some examples:

- Steel Alloys: These are iron-carbon alloys with varying amounts of other elements (e.g., chromium, nickel, manganese). Their properties range from high strength (e.g., high-carbon steel) to corrosion resistance (e.g., stainless steel).

- Aluminum Alloys: Known for their lightweight and corrosion resistance, these alloys find extensive use in aerospace and automotive industries. Different alloying elements (e.g., magnesium, silicon) alter their mechanical properties and formability.

- Copper Alloys (Brass & Bronze): Brass (copper-zinc) and bronze (copper-tin) are widely used due to their excellent machinability, corrosion resistance, and aesthetic appeal. Their specific properties are adjusted by varying the composition.

- Nickel Alloys: These alloys exhibit exceptional high-temperature strength and corrosion resistance, making them suitable for demanding applications like gas turbines and chemical processing.

My experience involves working with numerous alloys, including stainless steel, aluminum alloys (especially 6061 and 7075), and various brass compositions. A deep understanding of each alloy’s melting point, solidification behavior, and susceptibility to defects is crucial for successful and efficient furnace operations.

Key Topics to Learn for Melt Furnace Operation Interview

- Furnace Design and Components: Understanding the various types of melt furnaces (e.g., electric arc, induction), their components (e.g., electrodes, refractory linings, cooling systems), and their operating principles.

- Melting Processes and Techniques: Mastering the intricacies of the melting process, including charge preparation, melting parameters (temperature, power, time), and alloying techniques. Practical application includes understanding how to adjust parameters based on material properties and desired outcomes.

- Safety Procedures and Regulations: Thorough knowledge of all safety protocols, including personal protective equipment (PPE), emergency procedures, and adherence to relevant industry regulations (OSHA, etc.).

- Quality Control and Analysis: Familiarity with quality control methods used to ensure the consistent production of high-quality molten metal, including sampling, chemical analysis, and temperature monitoring. This includes understanding how to troubleshoot deviations from specifications.

- Troubleshooting and Maintenance: Developing problem-solving skills to identify and address common issues like electrode wear, refractory damage, and power fluctuations. Understanding preventative maintenance schedules and procedures is crucial.

- Energy Efficiency and Optimization: Understanding strategies to maximize energy efficiency in melt furnace operations, minimizing waste and optimizing production parameters for cost-effectiveness.

- Environmental Considerations: Knowledge of environmental regulations and best practices related to emissions control and waste management in melt furnace operations.

Next Steps

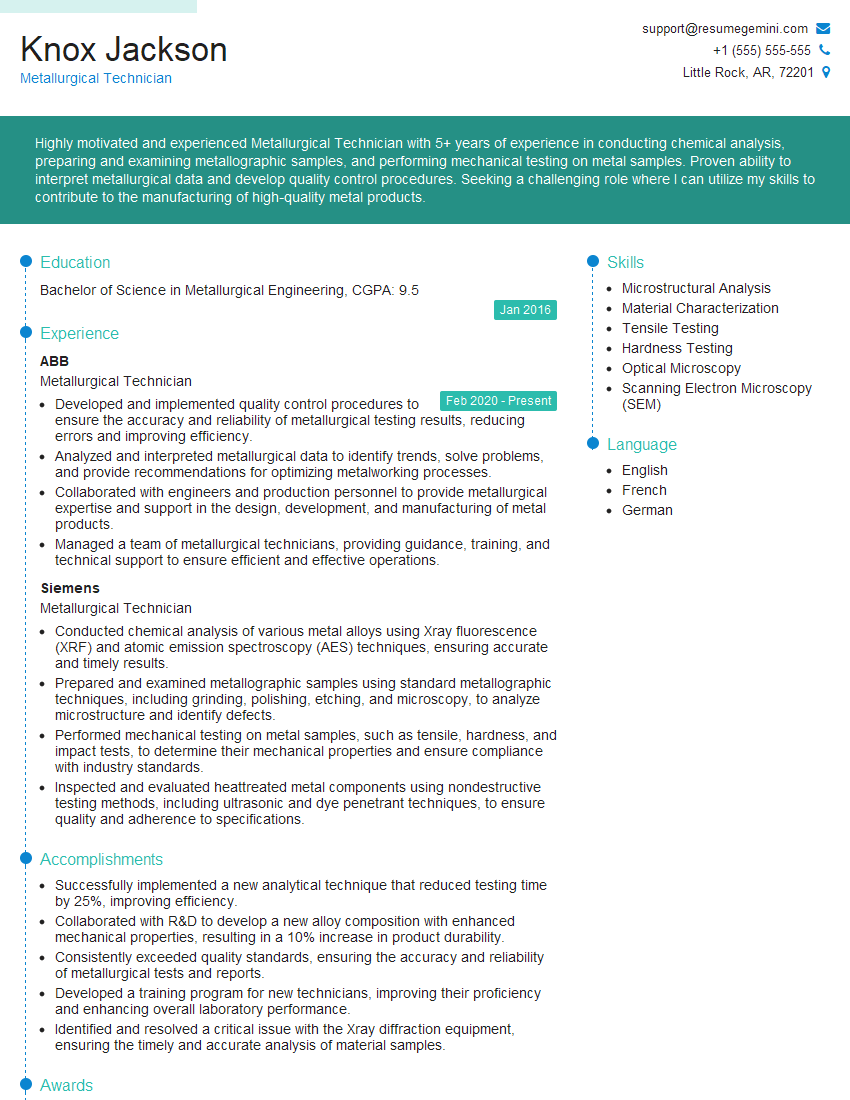

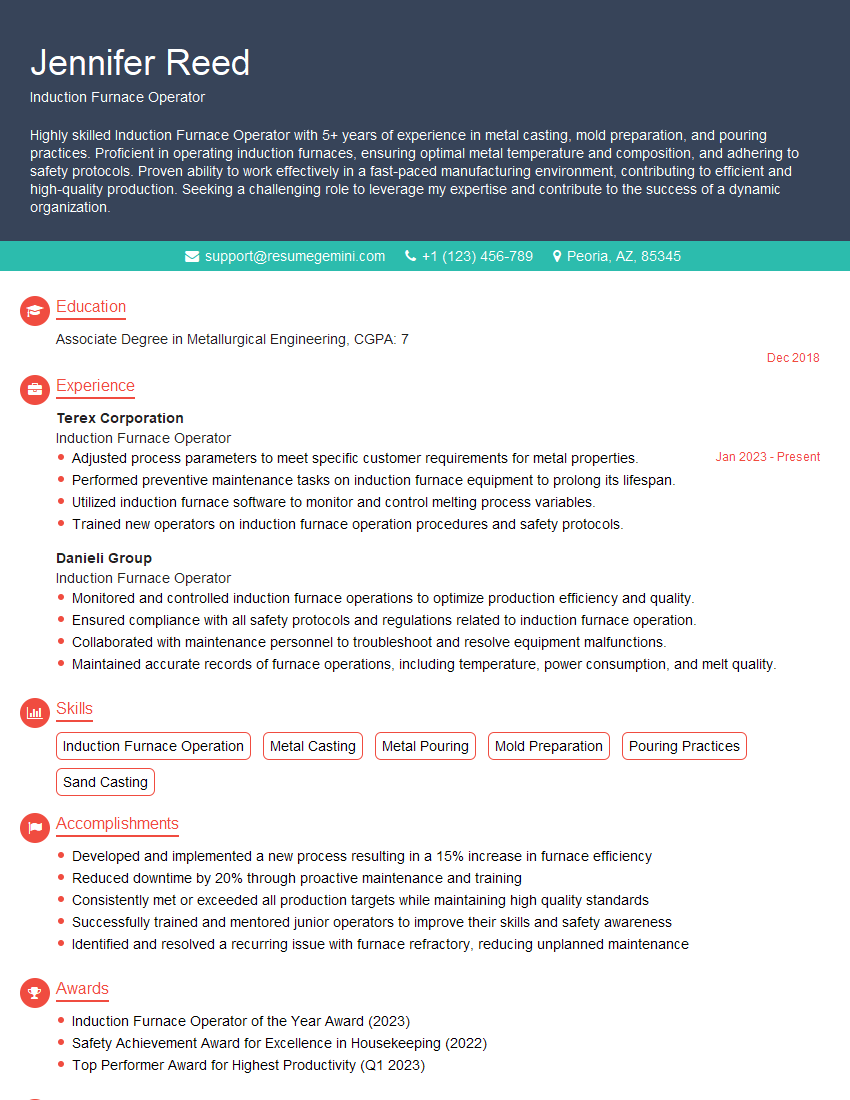

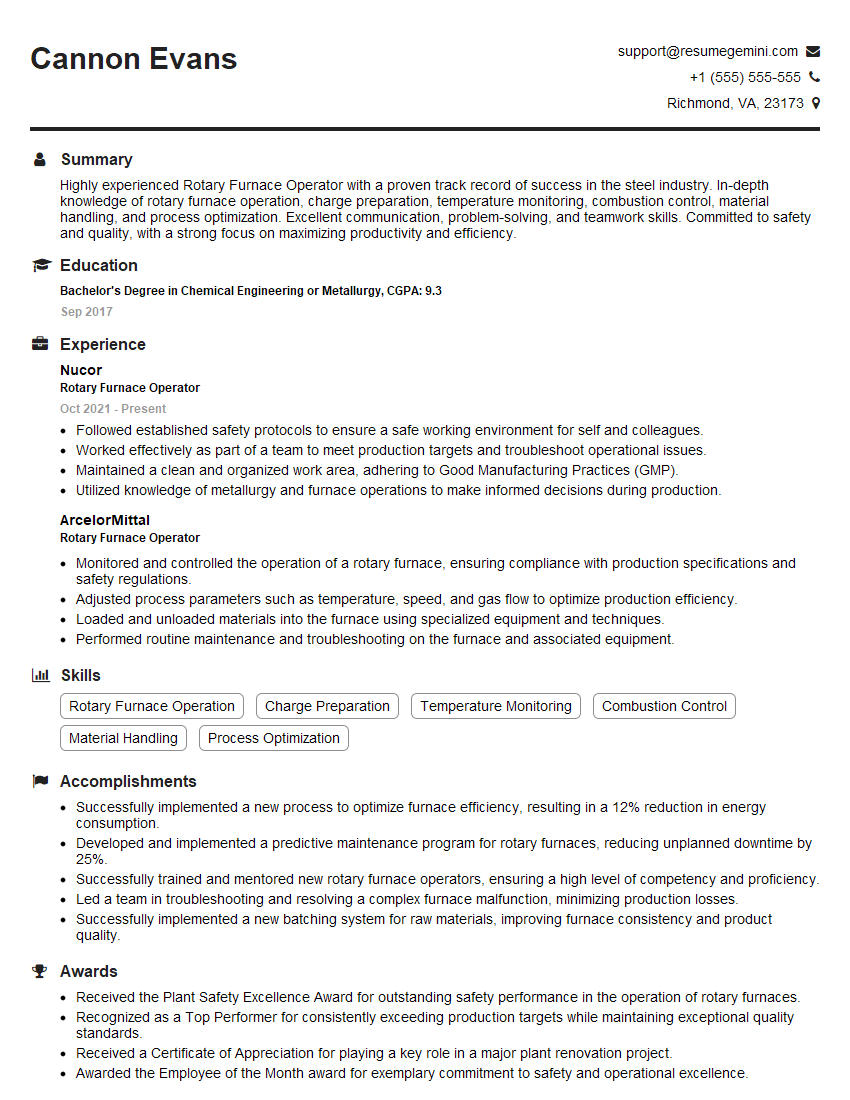

Mastering Melt Furnace Operation opens doors to rewarding careers with excellent growth potential in manufacturing and metallurgical industries. To stand out from the competition, it’s crucial to present your skills effectively. An ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. To create a compelling and effective resume, consider using ResumeGemini, a trusted resource for building professional resumes. ResumeGemini provides examples of resumes tailored to Melt Furnace Operation, helping you showcase your expertise and land your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO