Unlock your full potential by mastering the most common Millwork and Carpentry interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Millwork and Carpentry Interview

Q 1. What types of wood are best suited for exterior applications?

Choosing the right wood for exterior applications is crucial for longevity and aesthetic appeal. The best woods possess natural resistance to rot, decay, and insect infestation. They should also be durable enough to withstand harsh weather conditions like rain, sun, and temperature fluctuations.

- Cedar: Known for its natural resistance to rot and insects, cedar is a popular choice for siding, decking, and fences. Its beautiful reddish hue adds warmth to any exterior.

- Redwood: Similar to cedar in its durability and natural resistance, redwood is prized for its rich color and ability to withstand harsh climates. It’s often used in high-end exterior projects.

- Ipe: A very dense and durable hardwood from South America, Ipe is exceptionally resistant to rot, insects, and wear. It’s incredibly strong and long-lasting, making it ideal for decking and other high-traffic areas. However, it’s also more expensive than other options.

- Pressure-Treated Lumber: While not a naturally resistant wood, pressure-treated lumber undergoes a process that imbues it with preservatives, making it suitable for ground contact and exterior use. This is a cost-effective option for applications where natural resistance isn’t paramount.

When selecting wood for exterior use, always consider the specific climate and the project’s requirements. Consulting with a lumber supplier to choose the appropriate grade and species is highly recommended.

Q 2. Explain the process of installing crown molding.

Installing crown molding is a detail-oriented process that requires precision and patience. It’s the finishing touch that elevates a room’s aesthetic. The process involves several key steps:

- Preparation: This involves cleaning the walls and ceiling to ensure a clean surface for adhesion. Any imperfections should be addressed before installation.

- Measurement and Cutting: Accurate measurement is critical. Measure the length of each wall section requiring molding, accounting for inside and outside corners. Use a miter saw to cut the molding at precise angles (typically 45 degrees for inside and outside corners).

- Securing the Molding: Crown molding is typically secured using construction adhesive and finishing nails. Apply adhesive to the back of the molding and then carefully press it against the wall and ceiling. Use small finishing nails to further secure the molding and hold it in place until the adhesive sets. Countersink the nails and fill the holes with wood filler.

- Caulking: After the adhesive sets, use paintable caulk to fill any gaps between the molding and the walls/ceiling. This ensures a seamless and professional finish.

- Sanding and Finishing: Once the caulk is dry, lightly sand the entire molding to smooth out any imperfections. Finally, prime and paint the molding to match the room’s décor.

Remember to always wear safety glasses and a dust mask when working with power tools and wood dust.

Q 3. Describe your experience with different joinery techniques.

My experience encompasses a wide range of joinery techniques, each chosen based on the project’s requirements and the desired aesthetic. Some of my most frequently used techniques include:

- Miter Joints: These angled cuts are perfect for creating clean corners in crown molding, picture frames, and other decorative millwork. Precise cuts are essential for a perfect fit.

- Butt Joints: Simple and straightforward, butt joints involve joining the ends of two pieces of wood at a 90-degree angle. They’re often reinforced with dowels, biscuits, or screws for added strength.

- Dovetail Joints: A classic and strong joinery method, dovetail joints are renowned for their strength and beauty. The interlocking ‘tails’ and ‘pins’ create a robust and visually appealing connection, ideal for fine furniture and cabinetry.

- Mortise and Tenon Joints: This technique involves creating a hole (mortise) in one piece of wood and a protruding piece (tenon) on another, fitting them together for a strong and durable joint. It’s frequently used in furniture making and structural carpentry.

- Finger Joints: Similar to dovetail joints, finger joints use interlocking ‘fingers’ for strength. They are often used for joining boards edge-to-edge to create wider panels or for box construction.

I adapt my joinery techniques based on the wood species, project scale, and the desired level of strength and aesthetics. Choosing the right technique is crucial for a project’s success.

Q 4. How do you ensure accurate measurements for custom millwork projects?

Accuracy in measurements is paramount in custom millwork. Inaccurate measurements lead to costly rework and project delays. I use a multi-pronged approach to ensure precision:

- Detailed Shop Drawings: I begin with meticulously prepared shop drawings that include precise dimensions and annotations. These drawings serve as the blueprint for the project.

- Multiple Measurements: I never rely on a single measurement. I take multiple measurements at different points and cross-check them for consistency. Any discrepancies are thoroughly investigated.

- Laser Measurement Tools: I utilize laser measuring tools for accurate and quick measurements, especially in challenging locations or for large-scale projects. These tools offer greater precision than traditional measuring tapes.

- Template Creation: For complex shapes or repetitive elements, I create templates from sturdy material like plywood or hardboard. This ensures consistent and accurate cutting of multiple pieces.

- On-site Verification: Before fabrication begins, I always verify measurements on-site. This allows for adjustments and helps prevent surprises during installation.

By combining these methods, I minimize errors and ensure a perfect fit in every project.

Q 5. What safety precautions do you prioritize when using power tools?

Safety is my top priority when working with power tools. It’s not just about me; it’s about protecting everyone on the job site. My safety precautions include:

- Personal Protective Equipment (PPE): I consistently use safety glasses, hearing protection, and a dust mask to protect against eye injuries, hearing loss, and respiratory problems. Appropriate gloves are also worn when handling materials.

- Tool Maintenance: I regularly inspect and maintain my power tools to ensure they are in optimal working condition. Sharp blades and properly adjusted guards are essential for safe operation.

- Proper Tool Use: I always follow the manufacturer’s instructions for each power tool. I never rush, and I take my time to ensure proper technique.

- Work Area Safety: I maintain a clean and organized work area, free of clutter and tripping hazards. Cords are neatly managed to prevent entanglement.

- Lockout/Tagout Procedures: When working on equipment that requires maintenance or repair, I follow lockout/tagout procedures to ensure the equipment is safely de-energized.

I believe that a safe work environment is a productive work environment. Safety is not an option but a necessity.

Q 6. Explain your experience with cabinet installation, including hinge and drawer slide installation.

Cabinet installation is a significant part of my expertise. It involves precision, attention to detail, and a thorough understanding of cabinet construction. The process includes:

- Wall Preparation: Ensuring the walls are plumb and level is crucial for proper cabinet alignment. Any necessary adjustments are made before installation begins.

- Cabinet Placement: Cabinets are carefully positioned and secured to the wall using appropriate fasteners. Leveling and alignment are continuously checked throughout the process.

- Hinge Installation: I use various hinge types depending on the cabinet design and customer preferences. Precise placement of hinges is critical for proper door alignment and function. I typically use self-closing hinges for convenience and smooth operation.

- Drawer Slide Installation: Drawer slides are installed ensuring smooth and easy drawer operation. The type of slide used (undermount, side-mount, etc.) depends on the cabinet design. Proper adjustment is critical for ensuring the drawers open and close smoothly without binding.

- Finishing Touches: Once the cabinets are installed, I check all doors and drawers for proper alignment and operation. Any necessary adjustments are made, and final cleaning is performed.

My experience includes working with a variety of cabinet materials, styles, and hardware, enabling me to adapt to different project requirements and client preferences. I’ve installed hundreds of cabinets over my career, ranging from simple kitchen cabinets to complex custom designs.

Q 7. How do you handle discrepancies between shop drawings and on-site conditions?

Discrepancies between shop drawings and on-site conditions are not uncommon in construction. Addressing these discrepancies efficiently and effectively is crucial for project success. My approach involves:

- Careful On-site Assessment: The first step is a thorough on-site assessment to identify the exact nature and extent of the discrepancies. This may involve re-measuring, verifying existing structures, and checking for any unexpected obstacles.

- Documentation: I meticulously document all discrepancies, including photographs and detailed notes. This documentation provides a clear record for decision-making and future reference.

- Communication: I immediately communicate the discrepancies to the client and relevant stakeholders. This open communication ensures that everyone is informed and involved in finding a solution. Collaboration is key.

- Problem-Solving: Depending on the nature of the discrepancy, I develop solutions that minimize rework and maintain the project’s integrity. This may involve adjusting the design, making minor modifications, or ordering additional materials.

- Revised Drawings: For significant changes, I create revised shop drawings reflecting the on-site conditions and the adopted solutions. This ensures that everyone works from the same updated plan.

My goal is always to find a solution that preserves the project’s quality and meets the client’s expectations, even when faced with unexpected challenges. Experience has taught me that flexibility and problem-solving skills are invaluable in such situations.

Q 8. Describe your experience with different wood finishes and their applications.

Wood finishes are crucial for protecting and enhancing the beauty of millwork. My experience encompasses a wide range, from simple stains to complex, multi-layered finishes. The choice depends heavily on the wood species, the desired aesthetic, and the intended environment.

- Stains: These penetrate the wood, enhancing its natural grain and color. Oil-based stains are durable and offer deep penetration, while water-based stains are easier to clean up and offer less odor. I’ve used oil-based stains extensively on oak and cherry, achieving rich, warm tones. Water-based stains are often my preference for softer woods like pine, where their gentler penetration prevents blotchiness.

- Varnishes: These are clear coatings that protect the wood from moisture and abrasion. They offer varying degrees of gloss, from high-gloss to matte. I often select polyurethane varnishes for their durability and UV resistance, ideal for high-traffic areas. For a more traditional look, I’ve utilized shellac varnish on antique restorations.

- Lacquers: These fast-drying finishes offer excellent durability and a smooth, hard surface. They are particularly well-suited for fine millwork requiring a high-gloss finish, such as custom cabinetry. I’ve used lacquer successfully on projects demanding a flawless, mirror-like surface.

- Paints: While sometimes overlooked as a ‘finish,’ paint offers exceptional protection and a vast array of color options. I’ve utilized high-quality paints on various projects, including priming to prevent bleed-through on knotty pine and employing specialized paint for moisture-prone areas.

Selecting the right finish involves considering factors such as the wood’s porosity, the desired level of protection, and the overall design aesthetic. For instance, a rustic, reclaimed wood piece might benefit from a simple oil finish that allows the natural character of the wood to shine through, while a modern, sleek cabinet would be better suited to a high-gloss lacquer.

Q 9. How do you manage a project timeline and budget effectively?

Effective project management is critical for success in millwork. I use a combination of strategies to ensure projects are completed on time and within budget. It begins with meticulous planning.

- Detailed Planning: This includes a thorough review of the plans, detailed material lists, and realistic scheduling based on the complexity of the project and potential challenges. I break down large projects into smaller, manageable tasks.

- Regular Monitoring: I track progress consistently, comparing actual work to the schedule. This allows for early identification of potential delays and allows me to adjust the plan accordingly. Daily logs and weekly progress reports are key to this process.

- Cost Control: Accurate cost estimations are crucial, factoring in material costs, labor, and potential unforeseen expenses. Regular review of spending against the budget is vital. I often utilize project management software to track costs and expenses.

- Communication: Open and frequent communication with clients, subcontractors, and suppliers is crucial. This ensures everyone is on the same page and allows for efficient problem-solving. Regular meetings and progress updates prevent misunderstandings.

For example, on a recent large-scale commercial project involving intricate custom moldings, I used a Gantt chart to visualize the project timeline and assigned specific deadlines to each task. Through constant monitoring, we identified a potential supply chain delay, allowing us to proactively source alternative materials, thus avoiding a project delay. Effective communication with the client kept them informed of the situation and prevented any concerns.

Q 10. What are the common issues encountered during millwork installation and how do you resolve them?

Millwork installation presents unique challenges. Common issues include dimensional inaccuracies, unforeseen structural problems, and difficulties with hardware integration.

- Dimensional Inaccuracies: Slight discrepancies in measurements can create significant problems. I address this through careful double-checking of plans and on-site measurements. Minor adjustments are often made on-site, and any major discrepancies are communicated immediately to the client and design team.

- Structural Problems: Uneven walls or ceilings can complicate installation. I overcome this by employing shims and other adjustments as needed to ensure a smooth, flush finish. In severe cases, I consult with structural engineers to address underlying issues.

- Hardware Issues: Problems with hinges, drawer slides, or other hardware are common. I prevent these by specifying high-quality hardware and carefully checking the functionality of each piece before installation. If problems arise, I troubleshoot the issue, often replacing faulty components.

- Finish Issues: Damage during installation is a concern. Careful handling, proper protective measures, and meticulous attention to detail during installation minimize such problems.

For instance, on a recent custom bookcase installation, I discovered a slight bowing in the wall during measurements. Instead of forcing the installation, I used shims to compensate for the irregularity, ensuring a perfect fit and preventing future issues. This proactive approach prevented potential cracks and ensured the longevity of the installation.

Q 11. What software programs are you proficient in for design and/or estimating?

Proficiency in design and estimating software is essential for efficient millwork projects. My skills include:

- SketchUp: I use SketchUp extensively for 3D modeling and visualization. It allows me to create detailed models that clients can easily understand, enhancing communication and reducing the risk of misunderstandings. I can also generate accurate measurements and cut lists directly from the model.

- AutoCAD: AutoCAD is invaluable for creating detailed shop drawings and working with architectural plans. Its precision is crucial for accurate fabrication and installation.

- Cabinet Vision (or similar): This type of software allows for precise design and manufacturing of cabinetry. It automates many aspects of the process, helping to create efficient material lists and reducing waste. Furthermore, it aids in creating accurate cost estimates.

- Microsoft Excel: I use Excel for creating spreadsheets to track material costs, labor hours, and project budgets, maintaining precise financial records and aiding in financial forecasting.

For example, on a recent kitchen renovation project, I used SketchUp to create a 3D model that allowed the client to visualize the finished kitchen before the fabrication started. This ensured the design met their needs and prevented costly changes later in the process. The accurate measurements and cut lists generated by SketchUp helped to minimize material waste and reduced overall costs.

Q 12. Explain your understanding of building codes related to millwork and carpentry.

Understanding building codes is paramount for ensuring the safety and legality of millwork installations. I am familiar with the International Building Code (IBC) and relevant local codes, paying close attention to requirements concerning:

- Fire Safety: This includes requirements for fire-resistant materials, smoke detectors, and fire suppression systems, often involving the choice of specific materials and their fire ratings.

- Accessibility: I’m knowledgeable about ADA (Americans with Disabilities Act) guidelines, specifically regarding grab bars, accessible countertops, and other elements relevant to millwork designs.

- Structural Integrity: Millwork must be installed to withstand expected loads and stresses. I ensure that my installations meet the structural requirements outlined in the relevant codes and are properly anchored and braced.

- Energy Efficiency: Codes often address energy efficiency, such as requirements for insulation and airtightness in window and door frames.

I always review the relevant codes before starting any project and ensure that the designs and materials meet all applicable regulations. For example, in a recent project involving a stair railing, I ensured that the baluster spacing met code requirements for child safety, utilizing precise measurements and accurate calculations to verify compliance. This proactive approach avoids potential risks and ensures compliance.

Q 13. How do you interpret architectural drawings and blueprints?

Interpreting architectural drawings and blueprints is a fundamental skill. I approach this systematically:

- Overall Review: I start with a thorough review of the entire set of drawings to understand the project’s scope, noting key dimensions, details, and specifications. This includes carefully reviewing the legend and noting any unusual notations.

- Detailed Examination: I then focus on the specific drawings related to my work, carefully examining details such as dimensions, materials, and construction methods. I use a scale ruler to translate the drawing’s scale to actual measurements.

- Identification of Key Information: I carefully identify key information such as locations of electrical outlets, plumbing fixtures, and other elements that impact millwork placement and installation. This is crucial to avoid conflicts during installation.

- Cross-Referencing: I cross-reference different drawings to ensure consistency and identify potential conflicts. This careful checking prevents errors and rework.

For example, on a recent project involving custom built-in shelving, I carefully reviewed the architectural drawings to identify the exact dimensions of the alcove, the location of electrical outlets, and the height of the ceiling. This information was crucial in designing the shelving units to fit perfectly and avoid interfering with other building systems. My careful interpretation ensured a seamless integration of the shelving units within the existing space.

Q 14. Describe your experience with working with different types of hardware.

Experience with diverse hardware is essential for successful millwork projects. My experience ranges from simple hinges and knobs to complex drawer slides and specialized locking mechanisms.

- Hinges: I work with a variety of hinges, including butt hinges, concealed hinges, and specialty hinges for specific applications. Understanding different hinge types and their appropriate uses is critical for proper door and cabinet operation. I select hinges based on factors such as weight capacity, desired aesthetic, and application requirements.

- Drawer Slides: I have extensive experience with various drawer slide types, from simple side-mount slides to advanced undermount slides with features like soft-close mechanisms. The selection depends on the drawer size, weight, and desired level of functionality.

- Latches and Locks: I’m familiar with numerous latches and locking mechanisms for cabinets, doors, and other millwork components. I choose these based on security needs, aesthetic preferences, and accessibility requirements.

- Specialty Hardware: This includes decorative hardware, such as knobs, pulls, and handles, as well as specialized hardware for unique applications, such as sliding barn doors or custom lift systems.

On a recent project involving a custom media cabinet, I selected high-quality, soft-close drawer slides for smooth and quiet operation. I also incorporated concealed hinges to enhance the clean, modern aesthetic. Selecting the correct hardware is crucial for both functionality and the overall aesthetic success of the project.

Q 15. What is your experience with using hand tools vs. power tools?

My experience with hand tools and power tools is extensive and balanced. I view them not as mutually exclusive, but as complementary skill sets. Hand tools, like chisels, hand planes, and saws, offer unparalleled precision and control, especially in intricate detailing or when working in tight spaces. For instance, I rely heavily on hand tools for creating custom moldings or fitting intricate joinery where power tools might be too aggressive. Power tools, such as routers, planers, and table saws, are indispensable for efficiency and speed on larger projects, such as constructing framing or cutting large sheets of plywood. I skillfully adapt my tool selection to the specific requirements of each project, prioritizing the tool that best delivers both accuracy and efficiency.

For example, when creating a custom curved staircase, I would use a hand plane to refine the curve after the rough cut is made with a power saw, ensuring a perfect, smooth finish that a power tool alone might struggle to achieve. Conversely, when building the supporting structure for that same staircase, I’d leverage the speed and power of a chop saw and cordless drill for rapid and precise cuts and fastening.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the quality and precision of your work?

Maintaining quality and precision in my millwork is a holistic process, starting with careful planning and material selection. I meticulously review plans, paying attention to every detail, ensuring I understand the design intent fully. I use high-quality materials and check them for flaws before starting work. Precision is achieved through a combination of precise measuring techniques, utilizing measuring tools like calipers and digital levels to confirm accuracy at each stage. I double and triple-check my measurements, performing test fits frequently throughout the process, especially when working with intricate joinery. Furthermore, I regularly maintain and calibrate my tools, keeping them sharp and in optimal working order. This preventative maintenance is crucial in preventing errors and ensuring consistent results.

For example, when fitting a complex inlay, I might use a combination of marking gauges and precision chisels, making many small adjustments to ensure a perfect fit. Any deviations are corrected immediately using hand tools for the ultimate level of fine-tuning.

Q 17. How do you communicate effectively with clients and other tradespeople?

Effective communication is the cornerstone of successful projects. With clients, I emphasize active listening and clear, concise explanations. I use visual aids like sketches and samples to ensure a shared understanding of the design and materials. I actively solicit feedback and address any concerns promptly, maintaining open communication throughout the project. With other tradespeople, I follow the same principle: clear and respectful communication, coordinating schedules and work sequences to avoid conflicts and ensure a smooth workflow. I meticulously document all aspects of my work and provide accurate information, preventing misunderstandings and streamlining the collaboration process. For example, I will always confirm dimensions and specifications with other trades before starting work that interfaces with their own.

Q 18. Describe a time you had to troubleshoot a problem on a millwork project.

On a recent project involving a custom library, we encountered a problem with the veneer. A section of the cherry veneer developed significant cracking after the initial application. We discovered that the substrate wasn’t properly prepared; insufficient moisture control during the veneer application resulted in the wood expanding and contracting differently.

My solution involved a step-by-step process: First, we carefully removed the cracked veneer. Next, we properly prepared the substrate, ensuring it was completely dry and stable. We then applied a thin coat of appropriate adhesive and carefully applied a new piece of veneer, ensuring consistent pressure to prevent future cracking. Finally, we applied a final coat of finish. Through methodical troubleshooting, clear communication, and careful execution, we resolved the issue without significant delay or compromise to the project’s quality.

Q 19. What is your experience with different types of wood veneers?

My experience with wood veneers is broad, encompassing various types like oak, maple, cherry, walnut, and exotic species such as mahogany and zebrawood. I understand the properties of each type, its grain pattern, and how these characteristics influence the final aesthetic and the techniques required for proper application. I am familiar with different veneer grades, from high-grade, flawless veneers to those with slight imperfections, and I select the appropriate grade based on project requirements and budget. I’m also experienced with different veneer application techniques, including contact cement, iron-on, and edge banding.

For instance, a high-end project might call for a flawless, perfectly matched veneer, while a more rustic piece might benefit from a veneer with natural variations. Understanding these differences is essential to selecting the right veneer for each project and ensuring a successful outcome.

Q 20. How familiar are you with sustainable woodworking practices?

Sustainable woodworking practices are integral to my work. I prioritize the use of sustainably sourced lumber, certified by organizations like the Forest Stewardship Council (FSC). I minimize waste by carefully planning cuts and using offcuts for smaller projects or as material for future projects. I utilize dust collection systems to reduce airborne particles and properly dispose of leftover materials, ensuring responsible waste management. Furthermore, I employ water-based finishes that are low in VOCs (volatile organic compounds) to reduce my environmental impact. I am always researching and adapting my practices to incorporate new technologies and strategies for reducing environmental impact.

Q 21. Explain your experience with laminate and solid surface countertop installation.

I have extensive experience installing both laminate and solid surface countertops. Laminate installation requires precise cutting and careful application of adhesive to ensure a seamless and durable finish. I’m adept at using various tools, including jigsaws, routers, and laminate trimmers, for achieving clean cuts and precise edging. Solid surface countertops require a different approach, needing precise measurement and fabrication techniques to achieve smooth, seamless joins. This often involves utilizing specialized tools and techniques to create accurate curves and integrated sinks. Both types of installation demand careful attention to detail to prevent chipping, cracking, and ensure a professional, high-quality finish. I am proficient in creating templates, cutting materials to precise dimensions, and using the right adhesives and sealants to ensure longevity.

For instance, when installing a solid surface countertop with an integrated sink, I meticulously create a template to ensure an accurate and watertight fit. In laminate installations, I pay close attention to the edges and corners, using various tools and techniques to achieve a clean, polished look. Safety is always a priority in any installation process.

Q 22. What are your preferred methods for cutting and shaping wood?

My approach to cutting and shaping wood depends heavily on the specific project and the desired outcome. For precise cuts, I rely heavily on my table saw, ensuring accurate measurements and using the appropriate blade for the wood type. For intricate curves and shaping, a bandsaw offers unparalleled flexibility. I frequently use a router for detailed work, employing various bits to create rabbets, dados, and decorative profiles. Hand tools, like chisels and hand planes, still play a crucial role, particularly for fine-tuning and achieving a superior finish, especially in restoration projects where preserving the integrity of antique pieces is paramount.

For example, when crafting a complex crown molding profile, I’d initially rough-cut the shape on the bandsaw, then refine it using the router with specialized profile bits. Finally, I’d use hand planes and chisels to achieve the final smooth, precise finish. Similarly, when working with hardwoods like cherry or walnut, hand tools allow for greater control and prevent tear-out.

Q 23. Describe your experience with working with different types of wood stains.

My experience with wood stains is extensive, encompassing a wide range of products, from oil-based to water-based, and various finishes like penetrating stains, gel stains, and lacquers. Understanding the properties of each stain is crucial. Oil-based stains offer deep penetration and rich color but require longer drying times and proper ventilation. Water-based stains are quicker drying, easier cleanup, and environmentally friendly, but their penetration might be less profound. Gel stains are excellent for covering imperfections and creating a uniform color, ideal for furniture restoration. I also consider the wood’s grain and porosity when choosing a stain; a dense hardwood like mahogany might require a different approach than a porous wood like pine.

For instance, on a project involving antique oak furniture, I would carefully select a penetrating oil-based stain to enhance the wood’s natural beauty without obscuring the grain. Conversely, for new pine cabinets, a gel stain would help achieve a consistent color and cover any minor imperfections in the wood.

Q 24. How do you deal with challenging or complex millwork designs?

Tackling complex millwork designs necessitates a systematic approach. It begins with a thorough understanding of the design – meticulously studying blueprints, sketches, or 3D models. I break down the project into manageable segments, focusing on individual components and their assembly. Careful planning is key; I create detailed cutting lists and assembly diagrams to ensure accuracy and minimize waste. I frequently use digital modeling software to visualize and refine the design before proceeding with the actual construction, anticipating and resolving potential challenges proactively.

For example, a curved staircase presents numerous challenges. I would initially create a digital model to determine the precise angles and curves. Then, I would fabricate the individual components – stringers, treads, and risers – meticulously, paying close attention to the joinery. Finally, the assembly process would be carried out step-by-step, ensuring each piece fits perfectly.

Q 25. What are your strengths and weaknesses as a millworker/carpenter?

My strengths lie in my precision, attention to detail, and problem-solving abilities. I’m adept at reading blueprints and translating designs into tangible results. My experience encompasses a wide array of woodworking techniques and materials, making me adaptable to various project demands. I also pride myself on my commitment to quality and my ability to consistently produce high-quality work. However, my weakness could be considered my perfectionism, sometimes leading to longer project completion times than initially planned. I’m actively working on improving my time management skills to mitigate this.

Q 26. How do you handle working under pressure and meeting tight deadlines?

Working under pressure and meeting deadlines is a crucial aspect of this profession. My approach focuses on meticulous planning and efficient execution. Prioritizing tasks, allocating sufficient time for each stage of the project, and maintaining open communication with clients to manage expectations are critical. I avoid rushing, as it often leads to errors. Instead, I focus on staying organized and employing effective time management strategies, like breaking down large projects into smaller, manageable tasks. I also remain flexible and adapt to unforeseen circumstances, which is often necessary in this field.

Q 27. Describe your experience with custom door and window installation.

I possess significant experience in custom door and window installation. This involves not only the precise fitting of the units but also ensuring proper sealing and weatherproofing. Understanding the nuances of different frame types, such as wood, vinyl, or clad, is critical, as each requires a unique installation method. I’m skilled in preparing the rough openings, ensuring accurate dimensions and squareness, and addressing any necessary adjustments to achieve a perfect fit. Finally, the finishing touches – caulking, painting, and hardware installation – contribute to the overall aesthetics and functionality of the doors and windows.

For example, installing a historically accurate, handcrafted wood window requires a deep understanding of traditional joinery and careful attention to detail. The process begins with a precise measurement of the opening, followed by the careful preparation of the frame and the meticulous installation to ensure a perfect fit and minimal air leakage.

Q 28. What is your experience with installing and finishing hardwood flooring?

My hardwood flooring experience covers all aspects – from initial site preparation and subfloor assessment to installation and finishing. This includes selecting the appropriate flooring based on the client’s needs and the environment’s conditions. I’m proficient in various installation methods, such as nail-down, glue-down, and floating floors, tailoring my approach to the specific type of hardwood and the subfloor’s characteristics. The finishing process, including sanding, staining, and sealing, is just as critical in achieving a long-lasting, beautiful floor. Proper moisture control and acclimation of the wood are crucial for preventing issues like shrinking or expansion.

A recent project involved installing wide-plank oak flooring in a historic home. This required careful planning to account for the age of the house and ensure the subfloor was adequately prepared to support the flooring. The finishing process included meticulous sanding and multiple coats of a durable, high-quality sealant.

Key Topics to Learn for Your Millwork and Carpentry Interview

- Wood Selection and Properties: Understanding different wood types (hardwoods, softwoods), their grain patterns, strengths, weaknesses, and suitability for various projects. Practical application: Choosing the right wood for a specific job based on its properties and budget.

- Joinery Techniques: Mastering various joinery methods (e.g., mortise and tenon, dovetail, dado, rabbet) and their appropriate applications. Practical application: Explaining the advantages and disadvantages of different joints for specific furniture pieces or structures.

- Measuring and Layout: Accurate and efficient measuring techniques, including using measuring tools and blueprints. Practical application: Demonstrating proficiency in transferring measurements from drawings to materials and ensuring precision.

- Tool Knowledge and Safety: Familiarity with hand tools (chisels, saws, planes) and power tools (routers, table saws, planers), including their safe and proper operation and maintenance. Practical application: Describing safety protocols for specific tools and explaining how to prevent accidents.

- Finishing Techniques: Knowledge of various finishing methods (staining, painting, varnishing, lacquering) and their impact on the final product. Practical application: Explaining how to achieve a specific finish based on the project requirements and wood type.

- Blueprint Reading and Interpretation: Understanding architectural drawings, millwork details, and specifications. Practical application: Accurately interpreting blueprints to determine material needs and construction procedures.

- Problem-Solving and Troubleshooting: Identifying and resolving issues that may arise during the construction process, such as material defects or design flaws. Practical application: Describing a challenging project and how you overcame obstacles to achieve a successful outcome.

- Estimating and Costing: Calculating material costs, labor hours, and overall project budget. Practical application: Providing a realistic cost estimate for a given project and justifying your calculations.

- Building Codes and Regulations: Understanding relevant building codes and safety regulations related to millwork and carpentry. Practical application: Explaining how to ensure compliance with building codes in a specific project.

Next Steps

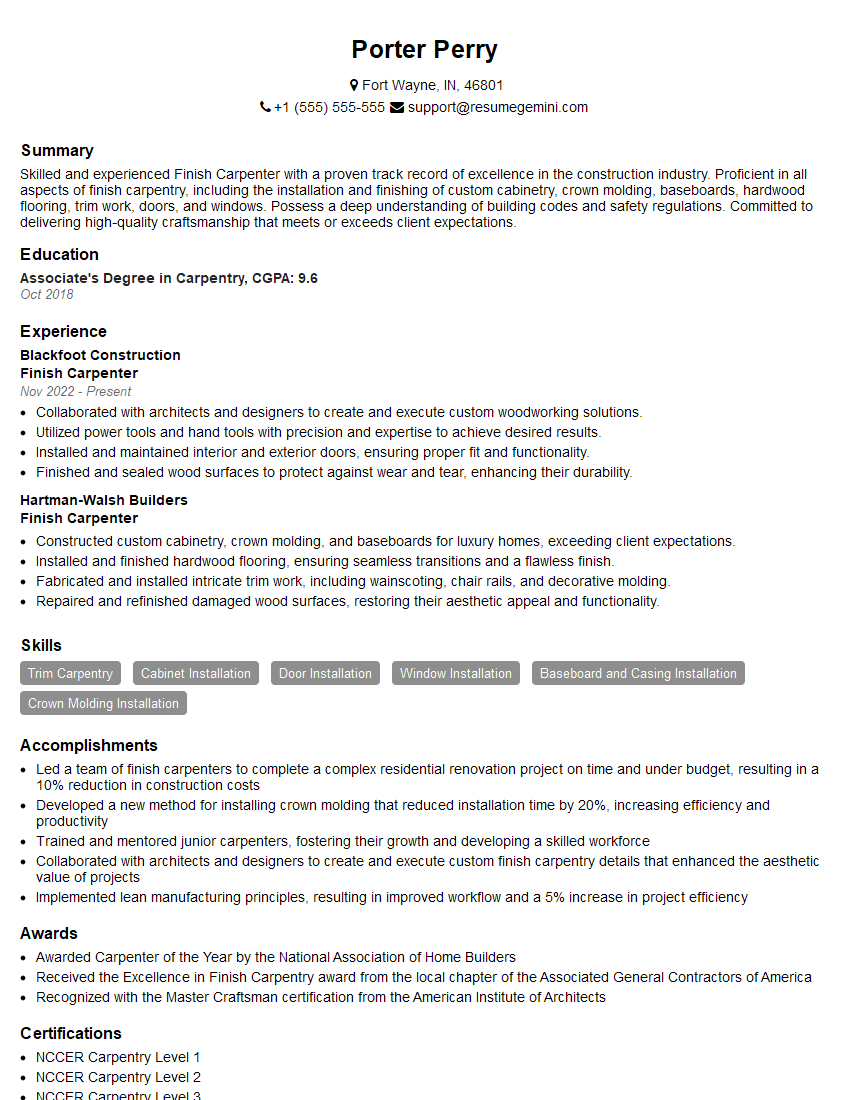

Mastering Millwork and Carpentry skills opens doors to a rewarding and diverse career, offering opportunities for growth and specialization. To significantly boost your job prospects, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that gets noticed. We provide examples of resumes tailored to the Millwork and Carpentry industry to help you get started. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO