Preparation is the key to success in any interview. In this post, we’ll explore crucial Minor Repair interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Minor Repair Interview

Q 1. Describe your experience diagnosing minor equipment malfunctions.

Diagnosing minor equipment malfunctions involves a systematic approach combining observation, testing, and troubleshooting. I begin by carefully inspecting the equipment, noting any visible signs of damage or unusual activity – a flickering light, unusual noise, or a specific error code displayed. Then, I’ll perform basic tests to confirm the malfunction. This might involve checking power connections, testing individual components with a multimeter (if safe and appropriate), or running diagnostic routines built into the equipment itself. For example, if a computer is running slowly, I’d first check resource usage (CPU, RAM, disk), then investigate potential software conflicts or malware. My experience allows me to quickly pinpoint the probable cause and narrow down the scope of the problem before proceeding to repairs.

Q 2. What are your preferred methods for identifying the root cause of a minor repair issue?

My preferred methods for identifying the root cause involve a blend of deductive reasoning and systematic elimination. I start by gathering information – observing symptoms, reviewing maintenance logs, and talking to the user if possible. Then, I create a hypothesis about the likely cause. I test this hypothesis through a series of targeted checks. If the hypothesis is incorrect, I move onto another potential cause. This process is often iterative, with each test leading to refined hypotheses. For instance, if a printer isn’t printing, I’d first check the paper, then the ink/toner, then the connections, and finally the printer drivers. Visual inspection often reveals loose wires, damaged components, or incorrect settings that are easily rectified. If not, using a systematic diagnostic chart or flowchart can help to guide the troubleshooting process.

Q 3. Explain your process for prioritizing multiple minor repair tasks.

Prioritizing minor repair tasks involves a combination of urgency, impact, and resource allocation. I use a triage system, classifying tasks based on severity and potential disruption. Tasks causing immediate safety hazards or critical operational downtime get top priority. For example, a faulty fire alarm would take precedence over a flickering light. Next, I’d prioritize tasks with the largest impact on productivity or user experience. I then consider the resources required – time, tools, and parts – to schedule repairs efficiently. I often use a task management system to track progress, deadlines, and resource usage, ensuring I address the most pressing issues first while maintaining a balanced workload.

Q 4. What safety precautions do you consistently follow during minor repairs?

Safety is paramount. Before starting any repair, I ensure the equipment is disconnected from the power source. I always use appropriate personal protective equipment (PPE), such as safety glasses, gloves, and anti-static wrist straps when handling electronic components. I’m meticulous about handling tools correctly and ensuring a safe workspace, free of obstructions and trip hazards. I follow all relevant safety regulations and manufacturer’s guidelines. If I encounter any unexpected hazards or uncertainties during the repair, I immediately stop the work and seek guidance or assistance from a supervisor or more experienced colleague. Prevention of electrical shock is always at the forefront of my mind. I regularly inspect my tools for damage and keep them in good repair.

Q 5. How do you document your minor repair work effectively?

Effective documentation is crucial. For each minor repair, I create a detailed record that includes the date, time, equipment identification, problem description, troubleshooting steps, parts used, repair solution, and testing results. I use clear and concise language, avoiding technical jargon unless absolutely necessary. I utilize a standardized reporting format (e.g., a checklist or template) to ensure consistency and completeness. Photographs and diagrams can be invaluable additions, especially for complex repairs or unique problem resolution. All documentation is stored in a secure and accessible location, allowing for easy retrieval and future reference. A clear and complete record is beneficial for tracking repairs, identifying trends, and facilitating efficient maintenance planning.

Q 6. Describe a time you had to improvise a solution for a minor repair.

During a recent repair of a broken office chair, the supplier of the replacement part was backlogged. The chair was crucial for the employee. I couldn’t simply wait. Using my knowledge of materials, I improvised a temporary fix using strong adhesive and a sturdy piece of wood to reinforce the broken armrest. This wasn’t a permanent solution, but it allowed the employee to use the chair safely and comfortably until the proper replacement part arrived. The key was understanding the structural requirements of the chair and finding a readily available material that could provide adequate temporary support. This demonstrates my resourcefulness and ability to find creative solutions in challenging situations.

Q 7. What types of minor repairs are you most proficient in?

My expertise spans a range of minor repairs, including those on office equipment (printers, computers, copiers), basic electrical repairs (wiring, lighting fixtures), and furniture repairs (chairs, desks). I’m proficient in troubleshooting network connectivity issues, replacing worn-out parts (e.g., printer cartridges, mouse sensors), and fixing simple mechanical problems. My experience also includes software troubleshooting, such as resolving application errors or restoring system settings. I’m comfortable working with various tools and materials commonly used in minor repair tasks. My skills are constantly evolving through continuous learning and on-the-job experience.

Q 8. How do you stay up-to-date with the latest techniques and tools for minor repair?

Staying current in the rapidly evolving field of minor repair requires a multi-pronged approach. It’s not just about knowing how to fix things, but also understanding the latest materials and techniques. I actively participate in online forums dedicated to repair techniques, often engaging in discussions with other professionals and sharing knowledge. This allows me to learn about new tools and methods from diverse experiences. I also subscribe to relevant industry magazines and journals which provide in-depth articles and case studies on innovative repair solutions. Finally, I dedicate time to online courses and webinars offered by tool manufacturers and industry experts. These platforms often provide practical tutorials and demonstrations of the latest tools and methods, allowing for hands-on learning and improving my skill set.

For example, recently I learned about a new adhesive specifically designed for repairing delicate electronics through an online forum. This adhesive is significantly faster drying and more precise than previous options, directly improving my repair efficiency and outcome.

Q 9. What is your experience with using diagnostic tools for minor repairs?

Diagnostic tools are essential for efficient and accurate minor repairs. My experience encompasses a wide range of tools, from simple multimeters for electrical checks to more sophisticated diagnostic software used in repairing modern electronics. I’m proficient in using multimeters to identify voltage, current, and resistance issues in circuits, often isolating faulty components quickly. For more complex systems, I’m experienced with using manufacturer-specific diagnostic software and hardware interfaces. This software enables me to read error codes, perform system tests, and sometimes even remotely diagnose problems. For mechanical repairs, I utilize tools like calipers and dial indicators to ensure precise measurements and adjustments.

For instance, in repairing a faulty laptop, I used a multimeter to pinpoint a short circuit in the power supply, leading to a quick and effective repair. In another case, I used diagnostic software to identify a specific failing hard drive sector on a desktop computer before the failure caused data loss.

Q 10. Describe your experience with common hand tools used in minor repair work.

A solid foundation in minor repair relies heavily on the effective use of hand tools. My experience spans a broad spectrum, from basic tools like screwdrivers and pliers to more specialized instruments. I’m highly proficient with various types of screwdrivers (Phillips, flathead, Torx), ensuring I always have the right tool for the specific screw type. I regularly use pliers for gripping, bending, and cutting wires, and I’m adept at using different types of pliers for varying tasks (needle-nose, slip-joint, lineman’s). Beyond these, I’m experienced with wrenches, sockets, hammers, chisels, and saws, adapting my tool selection to the particular repair job.

For example, while repairing a broken chair, my knowledge of different types of wood and the appropriate chisels to use ensured a clean and precise repair without causing further damage. In another instance, the proper use of adjustable wrenches allowed me to tighten a loose fitting on a faucet, preventing further water leakage.

Q 11. How do you manage your time effectively when handling multiple minor repair requests?

Managing multiple minor repair requests efficiently requires a structured approach. I utilize a prioritized task list, arranging requests based on urgency and complexity. This ensures that time-sensitive repairs are tackled first. I also employ time-blocking techniques, allocating specific time slots for each task, promoting focus and reducing interruptions. Additionally, I regularly review my progress, adjusting the schedule as needed to account for unforeseen delays or complications. This allows me to maintain a steady workflow and deliver repairs in a timely manner.

For example, a simple system using a Kanban board or even a whiteboard can effectively visualize the workflow, showing the progress of different repairs and allowing for quick readjustment. This keeps me organized and allows me to accurately estimate time commitments to clients.

Q 12. How do you handle unexpected complications during a minor repair job?

Unexpected complications are inevitable in minor repair work. My approach involves systematically identifying the problem. The first step is a thorough reassessment of the situation, often involving a detailed examination of the affected area. Then, I consult various resources such as manuals, online forums, and colleagues, leveraging collective knowledge to find potential solutions. I then develop a plan of action, considering various approaches to tackle the complication while prioritizing safety and the long-term functionality of the repair. If the issue is beyond my expertise, I will not hesitate to refer the item to a specialist or advise the client accordingly.

For instance, while repairing a vintage clock, I discovered a damaged gear. I consulted online resources and specialized clock repair manuals to find a suitable replacement part. Once I obtained the correct replacement, I carefully repaired the clock, ensuring its continued functionality.

Q 13. Explain your process for ordering and managing repair parts.

Ordering and managing repair parts is a crucial aspect of efficient repair work. I maintain a well-organized inventory system, cataloging commonly used parts for quick access. For less common parts, I utilize a reliable network of suppliers, prioritizing those with proven track records of timely delivery and quality products. When ordering parts, I meticulously record part numbers, quantities, and supplier information to ensure accurate tracking and prevent future delays. I also maintain a log of part usage, allowing me to anticipate future needs and maintain optimal stock levels. This proactive management ensures minimal downtime during repairs.

For example, using a spreadsheet or a dedicated inventory management software enables me to keep track of parts, their location, and their usage history, providing valuable data for efficient purchasing decisions.

Q 14. How do you ensure the quality of your minor repair work?

Quality assurance is paramount in my approach to minor repairs. I start by meticulously inspecting the repair area before commencing work, creating a baseline for comparison after the repair. During the repair process, I adhere to best practices and use appropriate tools and materials to ensure a clean and precise outcome. Finally, I conduct thorough testing post-repair to confirm proper functionality and identify any potential issues. This testing may involve functional checks, stress testing, and performance evaluation, depending on the nature of the repair. This three-step process ensures high-quality repairs and a level of reliability my clients can trust.

For instance, after repairing a broken electrical appliance, I perform multiple power-on cycles and safety checks to confirm that the appliance is working correctly and safely, ensuring there are no lingering issues.

Q 15. Describe a time you had to troubleshoot a problem that wasn’t readily apparent.

One time, I was troubleshooting a malfunctioning door lock. The problem wasn’t a simple broken key or jammed mechanism; the door wouldn’t latch properly, even with a new key. Initially, I suspected a problem with the locking mechanism itself. However, after careful inspection, I discovered the issue was a slightly misaligned strike plate – the metal plate on the door frame where the bolt engages. The misalignment was so slight it was almost invisible to the naked eye.

My troubleshooting process involved systematically eliminating possibilities. First, I checked the obvious: the key, the cylinder, and the visible parts of the mechanism. Then, I carefully examined the door frame and the strike plate, using a level to check for alignment. I found a tiny offset.

The solution was simple once I identified the root cause: I carefully adjusted the strike plate using a screwdriver and re-secured it. The door locked perfectly afterward. This experience highlighted the importance of meticulous observation and methodical troubleshooting, even when the problem isn’t immediately apparent.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with different types of materials used in minor repairs?

My experience encompasses a wide range of materials commonly used in minor repairs. I’m proficient in working with wood, including various types like hardwoods and softwoods, using techniques such as sanding, staining, and applying finishes. I’m also experienced with different metals, including steel, aluminum, and brass, familiar with techniques such as soldering, brazing, and using fasteners. I’m comfortable with plastics, understanding their different properties and how to repair cracks or breaks using adhesives or fillers. Finally, I’m skilled in handling various fabrics and materials used in upholstery repairs.

For example, I once repaired a wobbly table leg using wood glue and wood dowels to reinforce the joint. In another instance, I repaired a broken plastic part using epoxy resin, ensuring a strong and lasting repair. Understanding the properties of different materials and selecting the right repair technique is crucial for achieving a successful and lasting fix.

Q 17. How do you maintain a clean and organized workspace while performing minor repairs?

Maintaining a clean and organized workspace is paramount for efficiency and safety. My approach involves a few key steps. First, I always start with a clean and clear work surface. Before beginning any repair, I remove unnecessary items and arrange my tools logically. I typically use tool organizers or trays to keep smaller parts and fasteners separated and easily accessible.

During the repair process, I regularly clean up debris, such as sawdust, metal shavings, or excess adhesive. I use appropriate containers for disposal of waste materials. When the repair is complete, I carefully clean my tools and return them to their designated places. This meticulous approach prevents accidents, allows me to focus on the task at hand, and ensures a professional finish.

Q 18. Describe your experience with working from blueprints, diagrams, or schematics.

I have extensive experience interpreting and working from blueprints, diagrams, and schematics. Understanding these documents is essential for accurately performing repairs, especially on complex items. I’m proficient in reading both 2D and 3D representations, interpreting dimensions, identifying components, and understanding assembly procedures.

For example, I recently repaired a damaged antique clock using a detailed schematic. The schematic showed the intricate arrangement of gears and other internal components. This allowed me to accurately disassemble the clock, identify the damaged parts, and reassemble it correctly. My ability to read and interpret technical drawings ensures accuracy and efficiency in complex repair projects.

Q 19. What is your understanding of relevant safety regulations related to minor repairs?

Safety is my top priority. My understanding of safety regulations related to minor repairs encompasses several key areas. This includes the proper use of personal protective equipment (PPE), such as safety glasses, gloves, and respirators, depending on the materials and tools being used. I always follow the manufacturer’s instructions for any tools or equipment involved in the repair. I’m also aware of and adhere to guidelines concerning the handling and disposal of hazardous materials, including adhesives, solvents, and cleaning agents.

Furthermore, I’m familiar with workplace safety protocols, such as maintaining a clean and organized workspace to prevent tripping hazards, and using proper lifting techniques to prevent injuries. Understanding and adhering to these safety regulations is essential for preventing accidents and ensuring a safe working environment.

Q 20. How familiar are you with basic electrical principles related to minor repairs?

I have a solid understanding of basic electrical principles relevant to minor repairs. This includes knowledge of voltage, current, and resistance (Ohm’s Law), and how they relate to electrical circuits. I understand the importance of working with electricity safely, including using appropriate safety precautions such as disconnecting power before starting any electrical repair. I’m familiar with common electrical components such as switches, outlets, and wiring, and can troubleshoot simple electrical problems.

For instance, I’ve successfully repaired faulty light fixtures by replacing damaged wiring or switches. I always prioritize safety and disconnect the power source before working with any electrical components. My knowledge of electrical principles allows me to perform minor electrical repairs safely and effectively.

Q 21. How do you assess the severity of a minor repair issue before beginning work?

Assessing the severity of a minor repair issue involves a systematic approach. First, I carefully examine the damage to understand its extent. I look for visible cracks, breaks, or other signs of damage. Then, I test the functionality of the item to see if it’s fully operational or if there are any performance issues. For instance, if it’s a chair, I might check if a leg is wobbly or if the seat is unstable. This initial assessment helps determine if the repair is something I can handle or if it requires specialized tools or expertise.

If the damage appears extensive, I might recommend seeking professional help. However, for minor issues, I can often provide an effective and cost-efficient repair solution. For example, a small crack in a plastic item might only require adhesive, while a more significant crack might require more extensive repair techniques or even replacement.

Q 22. Describe your experience with preventative maintenance to avoid minor repairs.

Preventative maintenance is the key to minimizing minor repairs and extending the lifespan of equipment and structures. It involves regularly inspecting items for wear and tear and addressing potential problems before they become major issues. Think of it like regular check-ups at the doctor – much better to catch something small before it becomes a serious problem.

- Regular Cleaning: For example, regularly cleaning gutters prevents water damage to the house’s foundation and siding, avoiding costly repairs down the line.

- Lubrication: Keeping moving parts, like hinges and door tracks, lubricated prevents squeaks and sticking, avoiding the need for adjustments or replacements.

- Tightening Fasteners: Periodically checking and tightening loose screws on furniture or appliances prevents wobbling and potential damage.

- Inspections: Visual inspections for cracks, loose wiring, or other signs of wear and tear allow for early intervention, preventing escalation to larger problems.

In my experience, implementing a preventative maintenance schedule, even a simple one, drastically reduces the frequency and severity of minor repairs needed.

Q 23. What is your experience with customer interaction regarding minor repair issues?

Customer interaction is paramount in minor repair work. It’s about building trust and ensuring the customer feels heard and understood. I always start by actively listening to the customer describe the problem, asking clarifying questions to fully grasp the situation. Then, I clearly explain the repair process, the estimated time, and the associated costs before starting any work. Transparency is key to avoiding misunderstandings and building a positive relationship.

For example, I once had a customer who was distraught about a small crack in their favorite ceramic vase. Instead of simply fixing it, I took the time to explain the repair process, showing them the materials and techniques I would use. This reassurance eased their concerns significantly, and the end result was not only a repaired vase, but also a satisfied customer who felt valued.

Q 24. How do you handle situations where a minor repair escalates into a larger issue?

Sometimes a minor repair can unexpectedly escalate. My approach is to first thoroughly assess the situation. If I discover the problem is beyond a simple fix (e.g., a seemingly minor water leak turns out to be a plumbing issue requiring professional expertise), I immediately halt the work and inform the customer.

It’s crucial to be honest and upfront about limitations. I explain why the problem is beyond my capabilities and recommend qualified professionals who can handle the larger issue. I then assist in contacting those professionals, if the customer wishes, providing any relevant information gathered during my initial assessment. Maintaining open communication throughout this process is key to maintaining customer trust and preventing further damage.

Q 25. What is your experience with different types of adhesives and sealants used in minor repairs?

My experience encompasses a wide range of adhesives and sealants, each with its strengths and weaknesses depending on the material and application. For example:

- Epoxy: Excellent for strong bonds on various materials like wood, metal, and ceramics. It’s crucial to follow the manufacturer’s instructions precisely regarding mixing ratios and curing time.

- Acrylic Adhesives: Great for fast-setting bonds, especially on porous materials like wood and fabrics. They’re generally less robust than epoxies but suitable for many minor repairs.

- Silicone Sealants: Ideal for creating watertight seals in bathrooms or kitchens. Different silicone formulations exist (e.g., paintable, high-temperature), so selecting the correct type is crucial.

- Cyanoacrylate (Super Glue): Fast-bonding, but less forgiving and prone to brittle bonds. It’s essential to use sparingly and with precision.

I always consider the type of materials being joined, the required strength of the bond, and the environmental conditions (temperature, humidity) when selecting an adhesive or sealant.

Q 26. Describe your experience with power tools related to minor repair work.

Proficiency with power tools is essential for efficient and precise minor repairs. My experience includes the safe and effective use of:

- Drills: Used for creating pilot holes, installing screws, and various other tasks. Safety measures like wearing safety glasses and ensuring proper bit selection are paramount.

- Sander (orbital, belt): For smoothing surfaces, removing old paint or varnish, and creating a uniform finish. Different grit levels are selected based on the desired outcome.

- Jigsaw/Reciprocating Saw: For cutting various materials precisely and efficiently, but careful attention is needed to avoid injury.

Regular maintenance of these tools, including cleaning and lubrication, is critical for both safety and ensuring accurate performance. I always prioritize safety, following all manufacturer guidelines and wearing appropriate personal protective equipment (PPE).

Q 27. How do you determine when a minor repair is beyond your capabilities?

Recognizing the limits of my skills is crucial for avoiding botched repairs or causing further damage. Several factors guide my judgment:

- Complexity of the problem: If the repair requires specialized knowledge, tools, or techniques beyond my expertise, I will not attempt it.

- Safety concerns: If a repair involves potential risks, such as working with electricity or gas lines, I’ll immediately refer the issue to a qualified professional.

- Structural integrity: If the repair concerns critical structural elements, a professional structural engineer’s assessment is necessary.

Ultimately, prioritizing safety and avoiding potential damage overrides any pressure to tackle a repair that is outside my skillset.

Q 28. How do you ensure the longevity of your minor repair work?

The longevity of a minor repair depends on several key aspects:

- Proper Material Selection: Choosing high-quality materials, appropriate for the intended use and environmental conditions, is critical. For instance, using exterior-grade paint for outdoor repairs enhances durability.

- Precise Execution: Careful preparation, proper technique, and attention to detail during the repair process greatly improve the longevity of the repair.

- Protective Coatings: Applying appropriate sealants or coatings after repair protects the area from the elements or further damage.

- Post-Repair Monitoring: Regularly inspecting the repair to address any potential issues early prevents further problems.

Taking these steps significantly increases the lifespan of the repair, ultimately saving time and money in the long run.

Key Topics to Learn for Minor Repair Interview

- Understanding Repair Processes: Learn the fundamental steps involved in diagnosing and fixing minor issues, including assessing damage, selecting appropriate tools and materials, and executing repairs efficiently.

- Material Knowledge: Demonstrate familiarity with common materials used in minor repairs (e.g., adhesives, fasteners, paints) and their appropriate applications. Understanding material limitations and best practices is crucial.

- Tool Proficiency: Showcase your knowledge of various hand tools and power tools commonly used in minor repair tasks. Explain how to safely and effectively use these tools for different materials and applications.

- Troubleshooting and Problem Solving: Practice identifying and resolving common issues encountered during minor repairs. Be prepared to discuss your approach to diagnosing problems and selecting the best solutions.

- Safety Procedures: Highlight your understanding of safety regulations and best practices related to minor repairs. This includes proper handling of tools and materials, use of personal protective equipment (PPE), and safe work habits.

- Repair Documentation and Reporting: Demonstrate your ability to clearly and concisely document repair procedures, findings, and outcomes. This includes creating accurate reports and maintaining organized records.

- Cost Estimation and Budgeting: Show your understanding of estimating the costs associated with minor repairs, including materials, labor, and potential unforeseen expenses. Understanding budgetary constraints is often key.

Next Steps

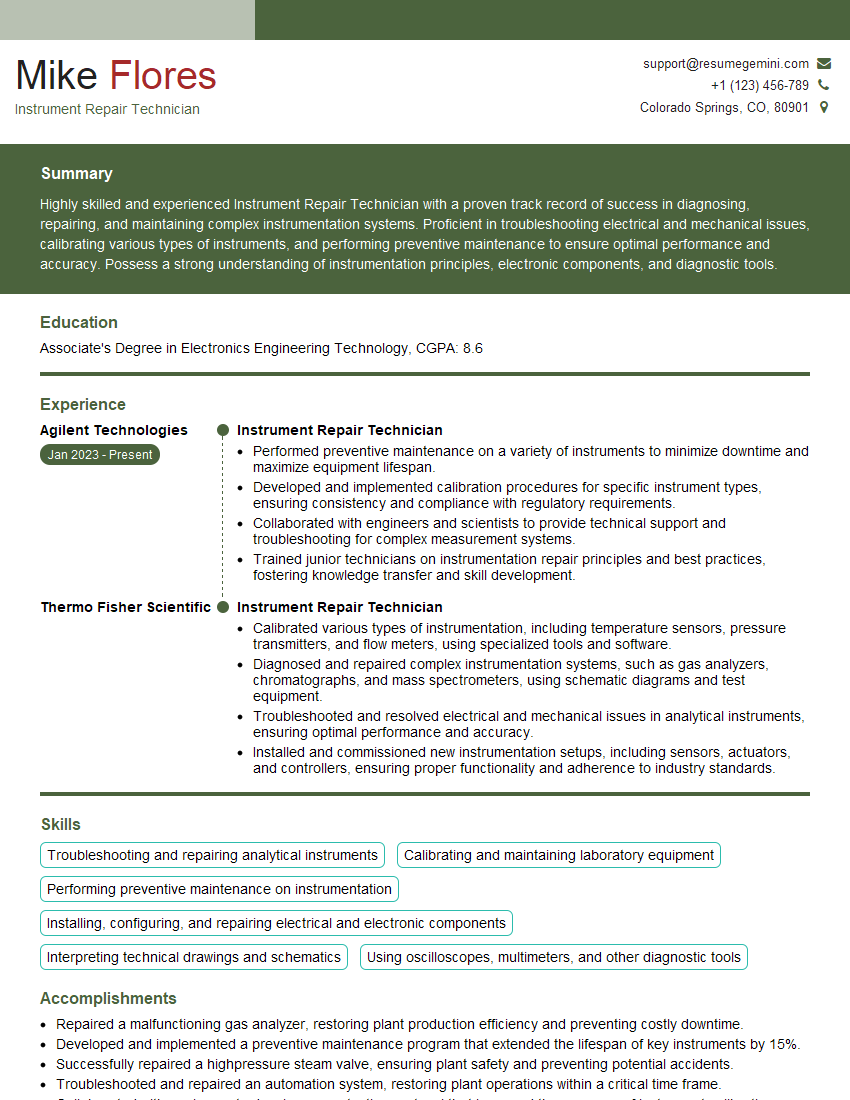

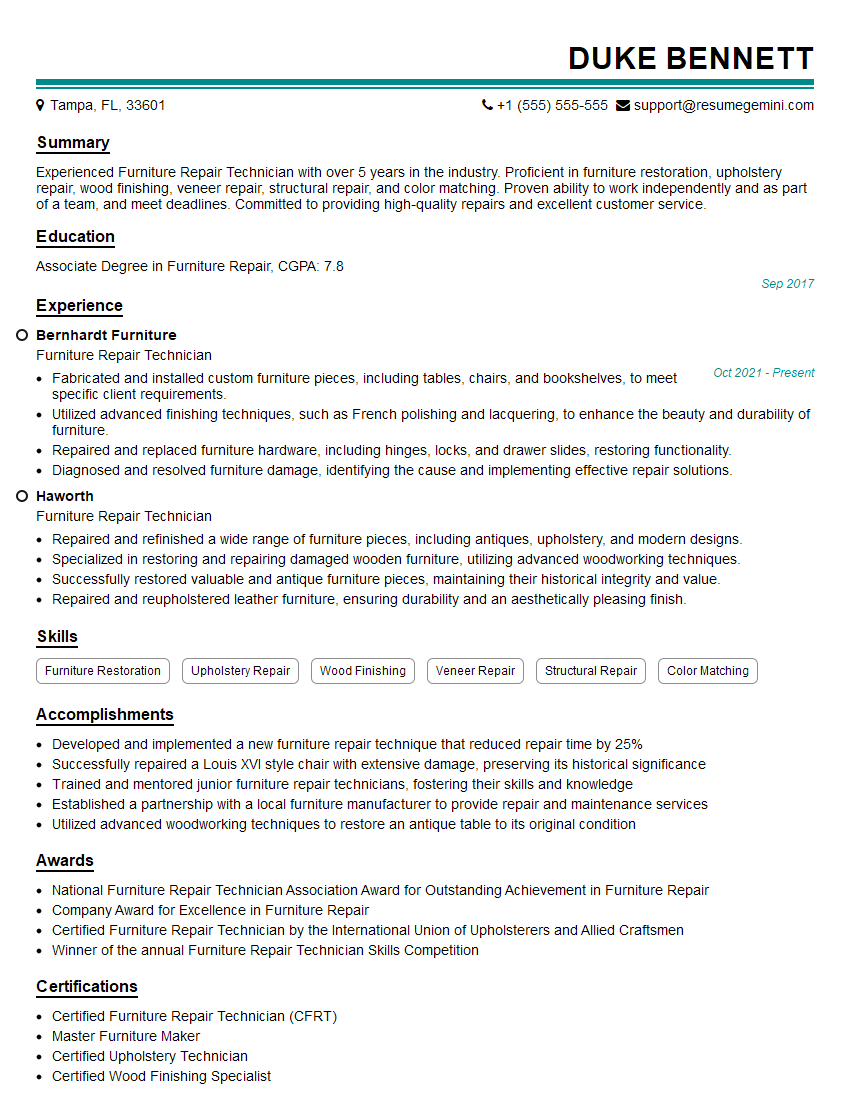

Mastering minor repair skills opens doors to diverse career opportunities and enhances your value in any role requiring practical problem-solving and technical aptitude. To maximize your job prospects, focus on creating a professional, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a compelling resume that showcases your abilities in the best possible light. Examples of resumes tailored to Minor Repair are available to help guide you in this process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO