Cracking a skill-specific interview, like one for Mold Smoothing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Mold Smoothing Interview

Q 1. Describe your experience with various mold smoothing techniques.

My experience encompasses a wide range of mold smoothing techniques, tailored to the specific type of mold damage and substrate material. This includes techniques for smoothing minor imperfections, repairing significant damage from water damage and mold growth, and preparing surfaces for painting or other finishes. For minor imperfections, I often utilize fine-grit sanding and specialized mold-resistant primers. For more extensive damage, I employ techniques involving the application of multiple coats of joint compound or skim coat, carefully feathering the edges for a seamless finish. I’m also proficient in using specialized patching compounds for deep gouges or holes, ensuring a structurally sound and aesthetically pleasing repair. For instance, I once worked on a historic building where we had to carefully smooth out areas affected by decades of water damage, using a combination of skim coating and careful sanding to match the existing texture.

I also have extensive experience working with various mold remediation methods such as scraping, brushing and HEPA vacuuming before smoothing begins to ensure the area is safe and clean.

Q 2. What safety precautions do you take when smoothing mold-affected surfaces?

Safety is paramount in mold smoothing. Before I even begin, I always conduct a thorough assessment of the affected area to determine the extent of the mold growth and potential hazards. This includes wearing appropriate personal protective equipment (PPE), which typically consists of a N95 respirator to prevent inhalation of mold spores, safety glasses to protect my eyes from dust and debris, gloves to prevent skin contact with potentially harmful materials, and protective clothing to cover my skin.

I meticulously contain the work area using plastic sheeting and tape to prevent the spread of mold spores during the smoothing process. All debris and dust are carefully collected and disposed of in sealed bags according to EPA guidelines. After completing the job, I thoroughly clean the area using HEPA vacuuming, ensuring all dust and debris are removed. Furthermore, I always maintain proper ventilation throughout the project, and if necessary I’ll utilize air scrubbers to remove any airborne mold spores.

Q 3. Explain the importance of proper surface preparation before smoothing.

Proper surface preparation is crucial for successful mold smoothing. A poorly prepared surface will lead to an uneven finish, potential peeling or cracking of the smoothing compound, and compromised longevity of the repair. This preparation involves several key steps: Firstly, the affected area must be thoroughly cleaned to remove any loose material, mold growth, dust or debris. This often involves scraping away loose mold with a putty knife, followed by brushing and vacuuming using a HEPA filter vacuum.

Secondly, the surface must be completely dried before applying any smoothing compound. Moisture will hinder the adhesion of the compound, resulting in an uneven finish or failure of the repair. Thirdly, any damaged or compromised sections of the substrate needs to be repaired or replaced before smoothing, ensuring a solid base for the smoothing compound. Think of it like building a house: you wouldn’t start building walls on an unstable foundation! Ignoring this step will inevitably lead to problems down the line.

Q 4. How do you determine the appropriate smoothing compound for different substrates?

Selecting the appropriate smoothing compound depends entirely on the substrate. For drywall, a standard joint compound is usually sufficient for minor imperfections. For larger holes or extensive damage, a stronger patching compound might be necessary. Wood substrates may require wood filler, ensuring compatibility and proper adhesion. For more delicate surfaces like plaster, a specialized lightweight compound might be needed to avoid cracking. The key is to choose a compound that is compatible with the existing substrate and appropriate for the size and type of damage to ensure a long-lasting and aesthetically pleasing repair. I always consult the manufacturer’s recommendations to ensure correct application and curing time for each compound.

Q 5. What are the common challenges encountered during mold smoothing?

Common challenges during mold smoothing include dealing with extensive damage, ensuring proper adhesion on porous surfaces, achieving a smooth, even finish, and matching the existing texture. Sometimes, the mold damage is so extensive that multiple coats of smoothing compound are required, increasing the risk of cracking or unevenness. Porous surfaces like wood or some types of plaster can absorb moisture from the compound, hindering adhesion and leading to uneven drying. Matching the existing texture, especially on older surfaces, can be particularly challenging, requiring patience and careful attention to detail. In these cases, careful sanding and the appropriate application techniques are crucial. Lastly, if the underlying mold remediation is incomplete, new mold growth will continue and the smoothing will fail.

Q 6. How do you ensure the smooth, even application of smoothing compounds?

Achieving a smooth, even application requires a methodical approach. I start by applying thin, even coats of the smoothing compound, ensuring complete coverage without overloading the surface. I use a variety of tools, including putty knives, trowels, and smoothing blades, depending on the scale and type of repair. Each coat is allowed to dry completely before applying the next, avoiding the temptation to rush the process. I carefully feather the edges of each coat to create a seamless transition with the surrounding surface. Sanding between coats is often necessary to achieve a perfectly smooth surface. The final sanding is performed using progressively finer grits of sandpaper until the desired smoothness is achieved.

Q 7. Describe your experience with different types of smoothing compounds (e.g., skim coat, joint compound).

I have extensive experience with various smoothing compounds. Skim coat compounds are excellent for creating a smooth, level surface over larger areas. They offer good adhesion and excellent filling properties, making them suitable for repairing significant damage. Joint compound, on the other hand, is ideal for filling smaller imperfections and joints in drywall. It dries quickly and is easy to sand, making it a versatile choice for many projects. I also use specialty compounds designed for specific substrates or to address particular issues, such as crack-resistant compounds for areas prone to movement or compounds designed for use over porous materials to increase adhesion. The selection of the right compound is always based on the substrate, extent of damage, and desired final finish. The key to success lies in understanding the properties of each compound and choosing the one best suited for the task at hand.

Q 8. How do you handle mold-affected areas with complex shapes or contours?

Handling mold in areas with complex shapes requires a meticulous approach. We can’t just slap on a solution; we need precision. Think of it like sculpting – you wouldn’t use a sledgehammer on a delicate figurine! Instead, we use specialized tools and techniques adapted to the specific contours. For example, on intricately carved moldings, we might employ smaller, hand-held smoothing tools or even specialized brushes to apply the remediation product. In areas with deep crevices or recesses, we may utilize low-pressure sprayers to ensure even penetration. The key is patience and attention to detail to ensure complete coverage and prevent leaving any untreated areas. We might also employ specialized sealant application techniques to get into those hard-to-reach spaces effectively.

For instance, on a heavily ornate ceiling, we’d start by carefully cleaning the area and then use a combination of a low-pressure sprayer and a brush to treat the intricate details. We’d follow this with a final inspection using a strong light source to ensure no areas were missed.

Q 9. What are the signs of improper mold smoothing?

Signs of improper mold smoothing are often subtle but can have significant consequences. One major indicator is the reappearance of mold within a short period – say, a few weeks or months. This suggests incomplete treatment or the use of inadequate materials. Other signs include visible patches of discoloration, indicating uneven application or insufficient penetration of the smoothing compound. A musty odor lingering after treatment, despite thorough cleaning, also suggests that mold may not have been fully addressed. Finally, a sticky or tacky residue left on the surface can signify an improperly cured smoothing agent, potentially leaving behind a breeding ground for future mold growth. It’s like painting a wall – if you miss spots or don’t use the right primer, the paint will peel.

Q 10. How do you ensure proper ventilation during the smoothing process?

Proper ventilation is paramount during mold smoothing to remove moisture and spores, preventing further mold growth and protecting the workers’ health. We use a combination of techniques. Firstly, we ensure the work area is well-contained, often using plastic sheeting to create a barrier. Powerful exhaust fans are strategically placed to draw out contaminated air, and fresh air is introduced through properly sealed air inlets. This creates a controlled air flow, preventing the spread of spores to other areas. Air quality is monitored using specialized equipment to ensure effectiveness. Think of it as creating a controlled environment, similar to a clean room in a manufacturing facility, but with the primary focus on safely removing contaminated air.

We often start by setting up powerful fans that draw air outwards from the affected space, thus creating negative pressure. This method prevents the contamination from migrating into other parts of the structure. We always follow safety protocols and use respiratory protective equipment during this process.

Q 11. Explain your understanding of mold remediation protocols and regulations.

My understanding of mold remediation protocols and regulations is comprehensive. I’m familiar with industry best practices, including those outlined by organizations like the EPA and IICRC. These protocols emphasize safety first, requiring the use of personal protective equipment (PPE), proper containment procedures to prevent cross-contamination, and rigorous cleaning and disposal methods for contaminated materials. Regulations vary by location, and I’m adept at navigating these differences, ensuring compliance with all relevant local, state, and federal requirements. Failure to comply can lead to serious health risks and legal repercussions, so adherence to these regulations is paramount. For example, in certain jurisdictions, we are required to submit detailed reports documenting the remediation process and the disposal methods for contaminated waste materials. Documentation is critical to ensure traceability and accountability in any mold remediation project.

Q 12. How do you dispose of contaminated materials after smoothing?

Disposal of contaminated materials after smoothing is crucial and follows strict protocols to prevent further mold spread. All materials are carefully double-bagged in heavy-duty, leak-proof bags clearly labeled with biohazard warnings. This is then sealed with appropriate tape and promptly transported to a licensed hazardous waste disposal facility. The chosen facility must be compliant with all applicable environmental regulations. We maintain detailed records of all waste disposal, including the facility name, date of disposal, and the quantity of materials disposed of. This documentation provides a complete audit trail, ensuring accountability and compliance with environmental regulations. The entire process is similar to the disposal of medical waste, with a strong emphasis on safety and environmental responsibility.

Q 13. What are the differences between mold removal and mold smoothing?

Mold removal and mold smoothing are distinct processes. Mold removal involves the complete eradication of mold and affected materials. Think of it like removing a rotten apple from a basket – you get rid of the entire apple. It’s typically used for extensive mold infestations requiring complete demolition and replacement of affected materials. In contrast, mold smoothing focuses on treating the affected area without removing the underlying material. It’s like treating a small bruise on an apple – you treat the bruise but keep the apple. Mold smoothing is more suitable for smaller infestations or superficial mold growth on surfaces such as walls or ceilings. The choice between the two depends on the extent and severity of the mold infestation, the type of material affected and budget.

Q 14. Describe your experience with using specialized tools for mold smoothing.

My experience with specialized tools is extensive. I’m proficient in using various types of sprayers, ensuring even application of remediation products, including low-pressure sprayers for delicate surfaces and higher-pressure options for larger areas. I’m also skilled in the use of specialized brushes and scraping tools for detailed work and the removal of surface mold. Furthermore, I’m experienced in utilizing HEPA vacuum systems to capture and remove spores during the cleaning process, minimizing the risk of re-contamination. The use of these specialized tools is critical to ensure efficient and effective mold smoothing, while minimizing environmental impact and protecting the workers’ safety. For instance, I recently used a specialized HEPA vacuum with a specialized brush attachment for a job involving mold on ornate plasterwork, enabling me to thoroughly clean the surface without causing damage to the intricate details. The right tool for the job is crucial for a successful project.

Q 15. How do you ensure the longevity and durability of your mold smoothing work?

Ensuring the longevity and durability of mold smoothing relies on a multi-pronged approach that begins even before the smoothing process itself. It’s not just about the surface; it’s about creating a stable and resistant subsurface.

- Proper Mold Remediation: Before any smoothing takes place, complete and thorough mold remediation is absolutely crucial. This means identifying the source of the mold, removing all visible mold, and using appropriate antimicrobial treatments to prevent regrowth. Skipping this step is like painting over rust – the problem will reappear.

- Substrate Preparation: Once the mold is eradicated and the area is completely dry, the substrate (the surface beneath the smoothing compound) needs to be prepared. This often involves cleaning, repairing any damaged drywall, and ensuring a sound base for the smoothing compound. Think of it as building a strong foundation for a house – a weak foundation leads to future problems.

- High-Quality Materials: Using high-quality mold-resistant drywall compound is essential. I typically use compounds specifically formulated for damp or moisture-prone areas. Cheap compounds are more likely to crack or degrade over time.

- Proper Application Techniques: This includes applying thin coats, allowing adequate drying time between coats, and using appropriate tools for a smooth, even finish. Rushing the process can lead to cracking and peeling later on.

- Protective Coatings (When Necessary): In high-moisture areas, a sealant or mold-resistant primer can provide an extra layer of protection. This is particularly useful in bathrooms or kitchens.

For example, on a recent project in a bathroom with significant mold damage behind the shower, we meticulously removed the damaged drywall, treated the underlying studs with an antimicrobial solution, repaired the water damage, and then applied several thin coats of a high-quality mold-resistant drywall compound, followed by a sealant. The result? A smooth, durable finish that’s held up perfectly for over a year.

Career Expert Tips:

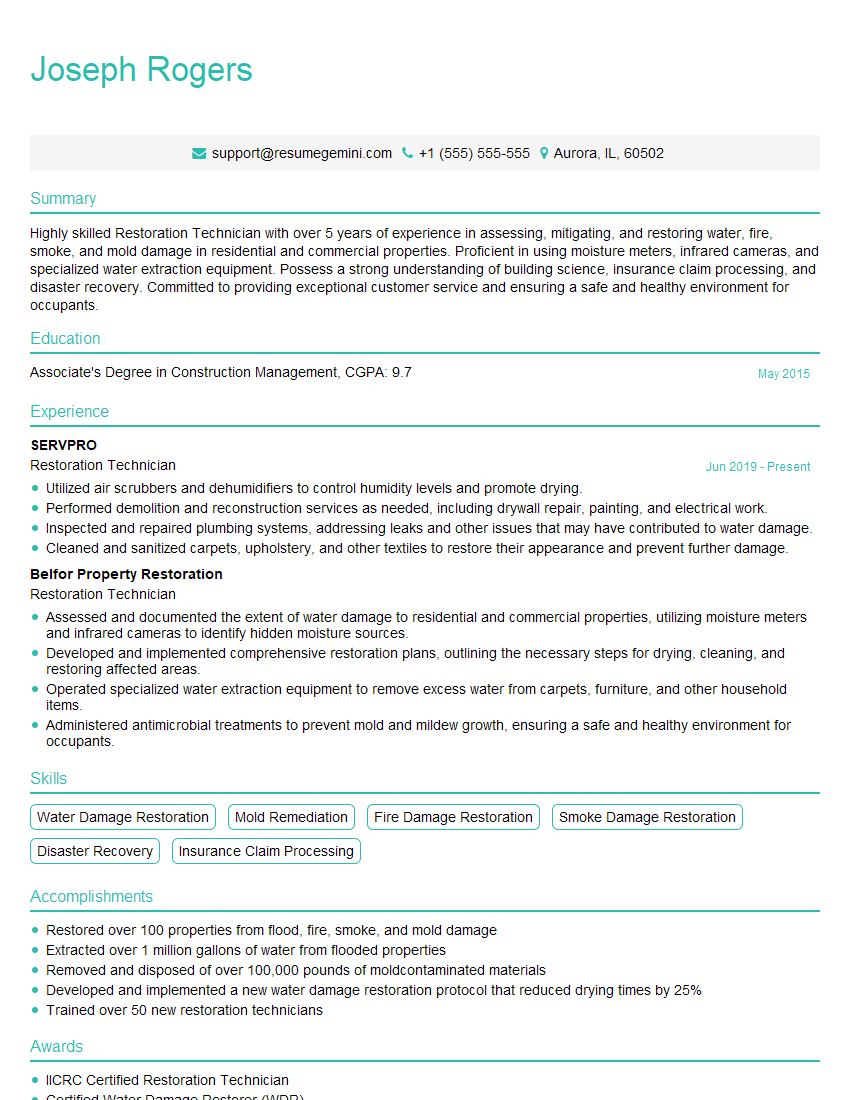

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine the extent of mold damage before beginning smoothing?

Determining the extent of mold damage is a critical first step that requires a careful and systematic approach. It’s not just about what’s visible on the surface.

- Visual Inspection: I start with a thorough visual inspection, looking for visible mold growth, discoloration, and signs of water damage. This gives a general idea of the affected area.

- Moisture Meter Testing: I then use a moisture meter to assess the moisture content of the drywall and underlying structures. Elevated moisture levels can indicate hidden mold growth.

- Testing for Mold (if necessary): In cases of significant damage or uncertainty, I often take samples and send them to a professional laboratory for mold testing. This provides definitive confirmation of the type and extent of mold contamination.

- Exploration Behind Wall Cavities and other Hidden Spaces: Sometimes mold damage extends beyond what’s visible. I use tools to access areas like wall cavities, checking for the source of the damage and its full extent.

Once the full extent of the damage is determined, I can create an accurate plan of action to repair and smooth the affected areas effectively and prevent future problems. Failing to properly assess the damage can lead to incomplete repairs and future recurrence of mold growth.

Q 17. What is your experience with different types of drywall repair techniques?

My experience with drywall repair techniques is extensive, encompassing various methods depending on the severity and type of damage. I’m proficient in the following:

- Patching Small Holes and Cracks: This involves using appropriate compound, applying thin coats, sanding smooth, and priming/painting.

- Replacing Damaged Sections: Larger areas of damage often require cutting out the affected section and replacing it with new drywall. This includes cutting, measuring, installing, taping, and mudding.

- Repairing Water-Damaged Drywall: This is more complex and may involve removing and replacing saturated drywall, treating underlying structures for mold, and ensuring proper drying before applying new drywall.

- Dealing with Mold-Damaged Drywall: This requires adhering to strict safety protocols, proper mold remediation, and using mold-resistant compounds.

For example, I’ve worked on projects ranging from patching minor nail holes to completely reconstructing sections of walls affected by severe water damage and mold. My approach is always tailored to the specific nature of the problem for the best possible outcome.

Q 18. Describe your process for inspecting your work after smoothing.

Inspecting my work after smoothing is crucial to ensure a high-quality finish and prevent future problems. My inspection process is thorough and multi-faceted:

- Visual Inspection under Different Lighting: I carefully examine the smoothed areas under various lighting conditions to detect any imperfections, inconsistencies, or texture issues.

- Texture and Smoothness Assessment: I run my hand across the surface to feel for any bumps, dips, or uneven areas.

- Checking for Cracks or Gaps: I closely inspect the edges of the repaired areas for any cracks or gaps where the compound has not adhered properly.

- Moisture Check: If there was any water damage involved, I’ll use a moisture meter to make sure the area is completely dry.

This comprehensive inspection ensures the highest quality of work and allows for any necessary touch-ups or corrections before painting or further finishing. It’s like a final quality control check before presenting a finished product to the client.

Q 19. How do you address inconsistencies or imperfections during smoothing?

Addressing inconsistencies or imperfections during smoothing is a normal part of the process. It’s about having the skills and patience to correct these issues. My approach depends on the nature of the imperfection.

- Minor Imperfections: Small inconsistencies are often addressed through careful sanding and the application of thin coats of additional compound. This is the most common method for resolving minor imperfections.

- Larger Imperfections: More significant flaws might require more extensive repairs. This could involve removing a section of compound, re-applying it, and then sanding and smoothing the area.

- Cracks and Gaps: Cracks and gaps usually indicate a problem with the underlying substrate or insufficient drying time. These need to be addressed by finding and fixing the root cause before any smoothing can be done.

For instance, if a small crack appears after drying, I wouldn’t just skim over it; I’d carefully remove the cracked area, apply a new layer, and re-sand, ensuring a smooth and flawless finish. This detailed attention shows my commitment to quality.

Q 20. How do you manage your time effectively during a mold smoothing project?

Effective time management during a mold smoothing project is key. My approach is based on meticulous planning and execution.

- Detailed Project Planning: Before starting, I create a detailed plan, outlining each step, material requirements, and estimated timeframes for each task. This plan acts as a roadmap for completing the project efficiently.

- Prioritization of Tasks: I prioritize tasks based on their importance and dependencies. For example, mold remediation must be completed before smoothing can begin.

- Efficient Work Methods: I use efficient work methods to minimize wasted time. This includes using the right tools for the job, pre-measuring materials, and preparing the workspace properly.

- Realistic Time Estimates: I’m realistic about how long each task will take. Overly optimistic estimates often lead to delays.

- Communication with Client: Open and honest communication with the client throughout the project ensures expectations are aligned and avoids unnecessary delays or changes.

This system ensures I deliver high-quality work within a reasonable timeframe. It’s like having a well-organized toolbox – everything is in its place and ready for use, minimizing wasted effort and time.

Q 21. How do you prioritize tasks when working on multiple areas of mold damage?

Prioritizing tasks when dealing with multiple areas of mold damage involves a combination of factors. Safety and containment are always paramount.

- Safety First: Areas with the most extensive or hazardous mold contamination need to be addressed first. This involves proper containment and personal protective equipment to ensure a safe working environment.

- Containment: Containment of affected areas is crucial to prevent further mold spread during the repair process.

- Severity of Damage: Areas with the most severe damage take precedence. This ensures the most urgent issues are addressed promptly.

- Accessibility: Areas that are easier to access are often tackled first to maintain momentum and efficiency.

- Client Priorities: I also consider the client’s priorities, such as highly visible areas or those affecting critical functions of the space.

My approach is to create a prioritized list that balances safety, the severity of damage, and logistical considerations. It’s a carefully balanced approach to ensure the most effective and efficient use of time and resources while maintaining safety.

Q 22. How do you communicate effectively with clients and colleagues regarding mold smoothing?

Effective communication is paramount in mold smoothing. With clients, I begin by actively listening to their concerns, explaining the process clearly in layman’s terms, and providing realistic timelines and cost estimates. I use visual aids like photos and diagrams to illustrate the extent of the problem and the proposed solution. I always ensure they understand the safety precautions involved. With colleagues, clear and concise communication is key for efficient teamwork. This includes pre-job briefings to outline tasks, safety protocols, and potential challenges, as well as regular updates during the project. For example, if I encounter an unexpected issue, I immediately communicate this to the team and client, outlining potential solutions and their implications. Open communication fosters trust and ensures everyone is on the same page.

Q 23. Describe your experience with working in confined spaces or difficult-to-access areas.

I have extensive experience working in confined spaces and difficult-to-access areas, such as crawl spaces, attics, and areas behind walls. Safety is my top priority. I always use appropriate safety harnesses, respirators, and confined space entry procedures as mandated by OSHA regulations. For instance, during a project in a cramped attic, I employed a portable HEPA vacuum system with a long hose to efficiently remove mold-contaminated debris while minimizing my exposure. In cases involving particularly difficult-to-reach areas, I utilize specialized tools like extendable sanding poles and HEPA filtration systems designed for maximum reach and efficiency. Detailed planning and risk assessment are critical before entering these spaces; this usually involves pre-job site inspections and creating a detailed plan outlining the safest procedures.

Q 24. How do you handle unexpected issues or problems during a smoothing project?

Unexpected issues are common in mold smoothing. My approach is systematic: First, I assess the situation thoroughly, identifying the root cause of the problem. Then, I develop a contingency plan, considering the impact on the project timeline and budget. For instance, if I discover hidden mold damage during demolition, I immediately communicate this to the client, explaining the additional work required and adjusting the plan accordingly. Effective problem-solving involves careful documentation—I meticulously photograph and document all unexpected findings, which assists with accurate reporting and future project planning. Communication and problem-solving go hand-in-hand; keeping all parties informed every step of the way minimizes unexpected issues and allows for cooperative solutions.

Q 25. What are your skills in using personal protective equipment (PPE)?

My skills in using personal protective equipment (PPE) are comprehensive and adhere to all relevant safety standards. This includes respirators (N95 or higher, depending on the mold type), gloves (nitrile or neoprene), coveralls, eye protection, and appropriate footwear. I am trained in the proper donning and doffing procedures to minimize contamination risk. Regular maintenance and inspection of PPE are crucial; I ensure that all equipment is in good working order and replace any damaged items immediately. I understand the limitations of each piece of PPE and its specific use case. For example, I wouldn’t use a standard dust mask for dealing with toxic mold; a powered air-purifying respirator (PAPR) would be more appropriate. Safety is non-negotiable; proper PPE use is a cornerstone of my work.

Q 26. Explain your understanding of different types of mold and their remediation requirements.

I have a thorough understanding of different mold types and their remediation requirements. Stachybotrys chartarum (black mold) requires more stringent protocols than other less toxic molds, such as Cladosporium. The remediation process depends on the extent of the infestation, the type of mold, and the building materials involved. For example, surface mold can often be addressed by cleaning and applying a biocide, while extensive mold growth necessitates complete removal of contaminated materials. I always conduct thorough testing to identify the species of mold present before recommending a course of action. This ensures I can employ the most effective and appropriate remediation techniques. My knowledge extends to understanding the environmental factors that contribute to mold growth, such as humidity and moisture problems, which helps to prevent future infestations.

Q 27. How do you ensure that your work meets industry standards and regulations?

I meticulously ensure my work meets all industry standards and regulations, including those set by OSHA and the EPA. This includes following proper containment procedures, using certified equipment, and adhering to specific protocols for mold remediation. I maintain detailed records of all work performed, including before and after photos, material samples, and test results. This documentation is crucial for demonstrating compliance and ensuring accountability. I regularly update my knowledge on industry best practices and regulations through professional development courses and certifications. Continuous improvement is critical for providing high-quality service and maintaining a high level of safety. Furthermore, I am always mindful of local building codes and regulations, ensuring that any repairs or replacements I undertake are compliant and meet the highest quality standards.

Key Topics to Learn for Mold Smoothing Interview

- Understanding Mold Growth and Types: Learn to identify different mold species and their impact on surfaces, understanding the factors contributing to mold growth (moisture, temperature, substrate).

- Surface Preparation Techniques: Master the various methods for preparing surfaces before smoothing, including cleaning, priming, and addressing existing damage. This includes understanding the appropriate safety measures.

- Smoothing Techniques and Materials: Explore different smoothing techniques, from hand application to using specialized equipment. Become familiar with the properties and applications of various smoothing compounds and their suitability for different mold types and substrates.

- Quality Control and Inspection: Understand the importance of thorough inspection before, during, and after the smoothing process. Learn to identify potential issues and implement corrective measures.

- Health and Safety Regulations: Familiarize yourself with relevant health and safety regulations concerning mold remediation and the handling of chemicals used in smoothing. This includes proper PPE and waste disposal procedures.

- Troubleshooting Common Issues: Be prepared to discuss common problems encountered during mold smoothing, such as uneven surfaces, cracking, or incomplete coverage, and the solutions to address them.

- Industry Best Practices: Research and understand industry best practices and standards for mold smoothing, ensuring you are up-to-date on the latest techniques and regulations.

Next Steps

Mastering mold smoothing techniques opens doors to exciting career opportunities in the construction, restoration, and environmental remediation industries. A strong understanding of these techniques showcases your expertise and commitment to high-quality workmanship. To significantly increase your chances of landing your dream role, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to the Mold Smoothing field are available to help you craft a compelling application that showcases your unique qualifications. Invest time in crafting a strong resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO